Pressure NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4151 of 4801

ST-48

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

RACK SLIDING FORCE

Power Steering Oil PumpINFOID:0000000009461285

Power Steering FluidINFOID:0000000009461286

P215/60R16 P215/55R17 - P245/45R18

Rack stroke in neutral position (L) 72.5 mm (2.9in) 70.0 mm (2.8in)

Average 330 N (33.7 kg, 74.2 lb)

Relief oil pressure

9,700 - 10,300 kPa (98.9 - 105.1 kg/cm2, 1406.5 - 1493.5 psi)

Fluid type E-PSF

Fluid capacity 1.1 (1-1/8 US qt, 1 lmp qt)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4154 of 4801

PRECAUTIONSSTC-3

< PRECAUTION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951730

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Service Notice and Precautions for Hydrau lic Pump Electric Power Steering System

INFOID:0000000009460340

• Check each tire for proper air pressure and size. Refer to WT-60, "Tire".

• Verify that the steering system components are G enuine NISSAN parts and have been installed properly.

• Check the steering column for loose mounting bolts.

• Check the steering gear assembly for loose mounting bolts. Check the inner sockets and outer sockets for

damage or wear. Inspect the boots and seals for leakage of power steering fluid.

• Verify proper wheel alignment. Refer to FSU-7, "Inspection and Adjustment"

.

• Check for any damage, wear, or modification to the suspension and body that would result in increased

weight or an improper wheelarch height. Refer to FSU-26, "Wheelarch Height (Unladen*

1)".

• Check for proper battery voltage.

• Verify that all power steering pump assembly connections are clean and fully seated.

• Verify that only Genuine NISSAN E-PSF is used. Use of any power steering fluid other than Genuine NIS-

SAN E-PSF will prevent the power st eering system from proper operation.

• An audible high pitch noise may be heard from the engine compartment when the steering wheel is oper-

ated, particularly at low speeds such as a parking lot maneuver. This condition is not a malfunction, rather

normal system operation. Steering at low speeds or parking lot maneuvers demands higher hydraulic assis-

tance, resulting in larger power st eering pump load and increased system noise.

• The power steering pump is electrically controlled by the power steering control module.

• Before connecting or disconnecting the power steeri ng control module harness connectors, turn ignition

switch “OFF” and disconnect battery ground cable. Batter y voltage is applied to power steering control mod-

ule even if ignition switch is turned “OFF”.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4156 of 4801

COMPONENT PARTSSTC-5

< SYSTEM DESCRIPTION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

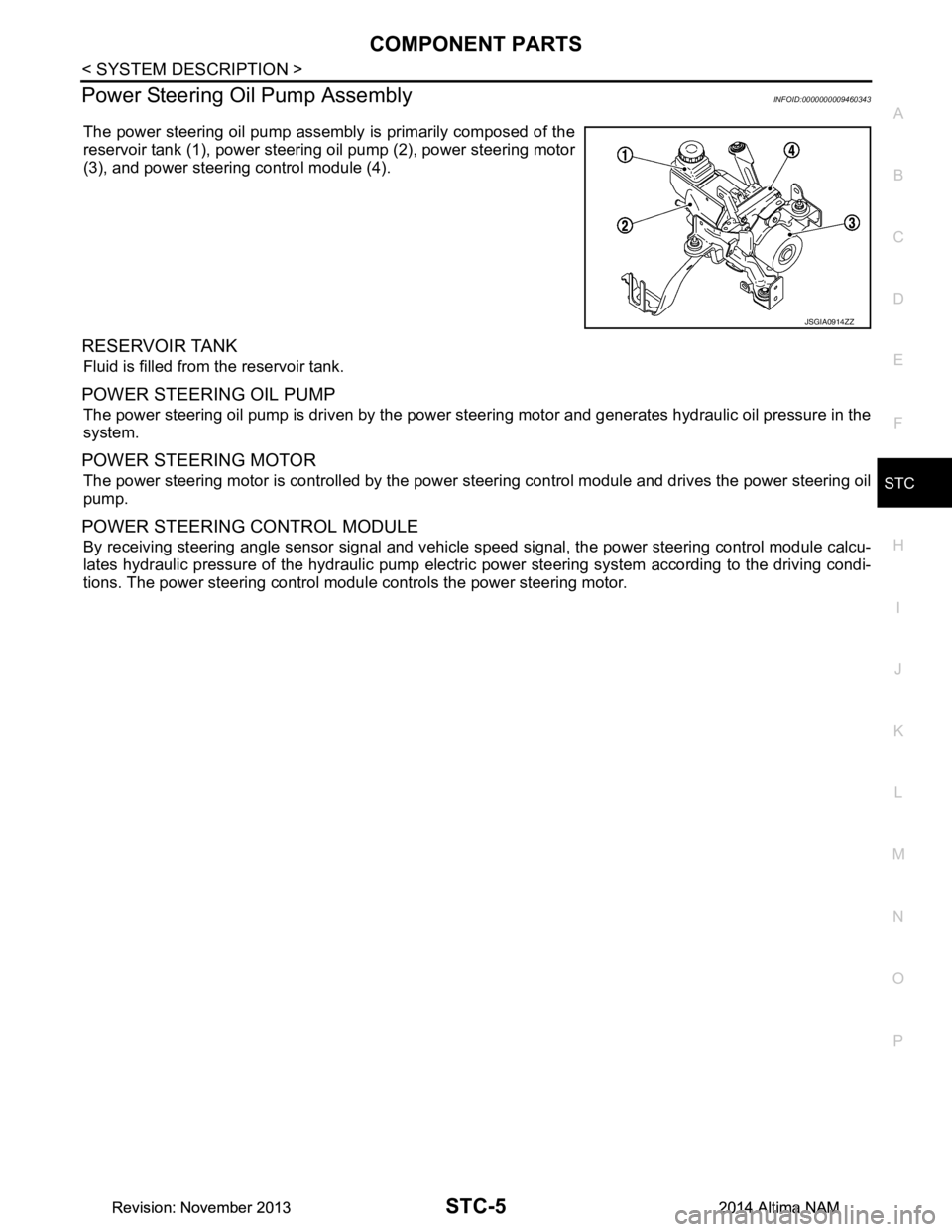

Power Steering Oil Pump AssemblyINFOID:0000000009460343

The power steering oil pump assembly is primarily composed of the

reservoir tank (1), power steering oil pump (2), power steering motor

(3), and power steering control module (4).

RESERVOIR TANK

Fluid is filled from the reservoir tank.

POWER STEERING OIL PUMP

The power steering oil pump is driven by the power steer ing motor and generates hydraulic oil pressure in the

system.

POWER STEERING MOTOR

The power steering motor is controll ed by the power steering control module and drives the power steering oil

pump.

POWER STEERING CONTROL MODULE

By receiving steering angle sensor signal and vehicle speed signal, the power steering control module calcu-

lates hydraulic pressure of the hydraulic pump electric power steering system according to the driving condi-

tions. The power steering control modul e controls the power steering motor.

JSGIA0914ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4157 of 4801

STC-6

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

HYDRAULIC PUMP ELECTRIC POWER STEERING SYSTEM

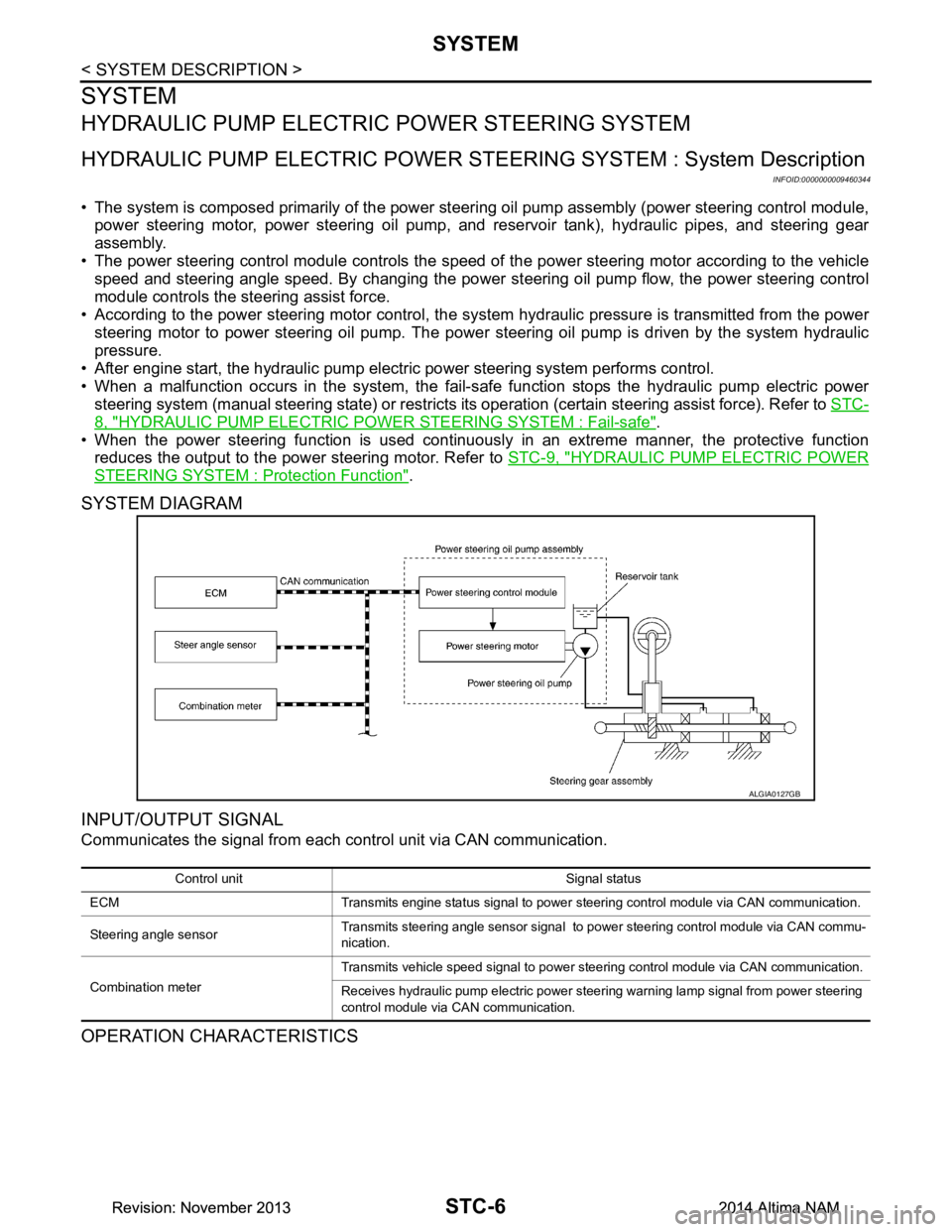

HYDRAULIC PUMP ELECTRIC POWER ST EERING SYSTEM : System Description

INFOID:0000000009460344

• The system is composed primarily of the power steeri ng oil pump assembly (power steering control module,

power steering motor, power steering oil pump, and reservoir tank), hydraulic pipes, and steering gear

assembly.

• The power steering control module controls the speed of the power steering motor according to the vehicle

speed and steering angle speed. By changing the power st eering oil pump flow, the power steering control

module controls the steering assist force.

• According to the power steering motor control, the sy stem hydraulic pressure is transmitted from the power

steering motor to power steering oil pump. The power steering oil pump is driven by the system hydraulic

pressure.

• After engine start, the hydraulic pump electric power steering system performs control.

• When a malfunction occurs in the system, the fail-safe function stops the hydraulic pump electric power

steering system (manual steering state) or restricts it s operation (certain steering assist force). Refer to STC-

8, "HYDRAULIC PUMP ELECTRIC POWER STEERING SYSTEM : Fail-safe".

• When the power steering function is used continuously in an extreme manner, the protective function

reduces the output to the power steering motor. Refer to STC-9, "HYDRAULIC PUMP ELECTRIC POWER

STEERING SYSTEM : Protection Function".

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL

Communicates the signal from each control unit via CAN communication.

OPERATION CHARACTERISTICS

ALGIA0127GB

Control unit Signal status

ECM Transmits engine status signal to power steering control module via CAN communication.

Steering angle sensor Transmits steering angle sensor signal to power steering control module via CAN commu-

nication.

Combination meter Transmits vehicle speed signal to power steering control module via CAN communication.

Receives hydraulic pump electric power steering warning lamp signal from power steering

control module via CAN communication.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4158 of 4801

SYSTEMSTC-7

< SYSTEM DESCRIPTION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

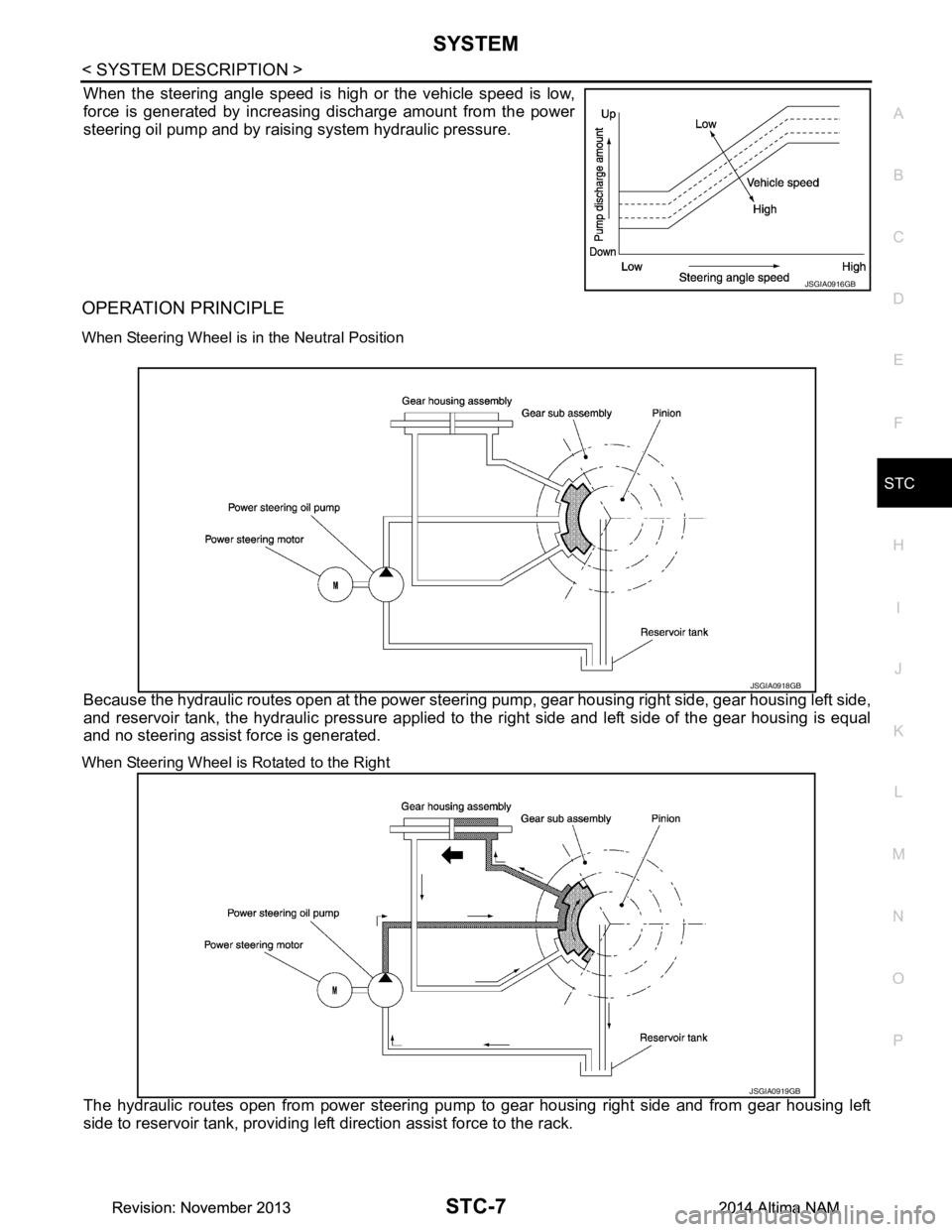

When the steering angle speed is high or the vehicle speed is low,

force is generated by increasing discharge amount from the power

steering oil pump and by raising system hydraulic pressure.

OPERATION PRINCIPLE

When Steering Wheel is in the Neutral Position

Because the hydraulic routes open at the power steeri ng pump, gear housing right side, gear housing left side,

and reservoir tank, the hydraulic pressure applied to the right side and left side of the gear housing is equal

and no steering assist force is generated.

When Steering Wheel is Rotated to the Right

The hydraulic routes open from power steering pump to gear housing right side and from gear housing left

side to reservoir tank, providing left direction assist force to the rack.

JSGIA0916GB

JSGIA0918GB

JSGIA0919GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4208 of 4801

STR-18

< DTC/CIRCUIT DIAGNOSIS >

B TERMINAL CIRCUIT

DTC/CIRCUIT DIAGNOSIS

B TERMINAL CIRCUIT

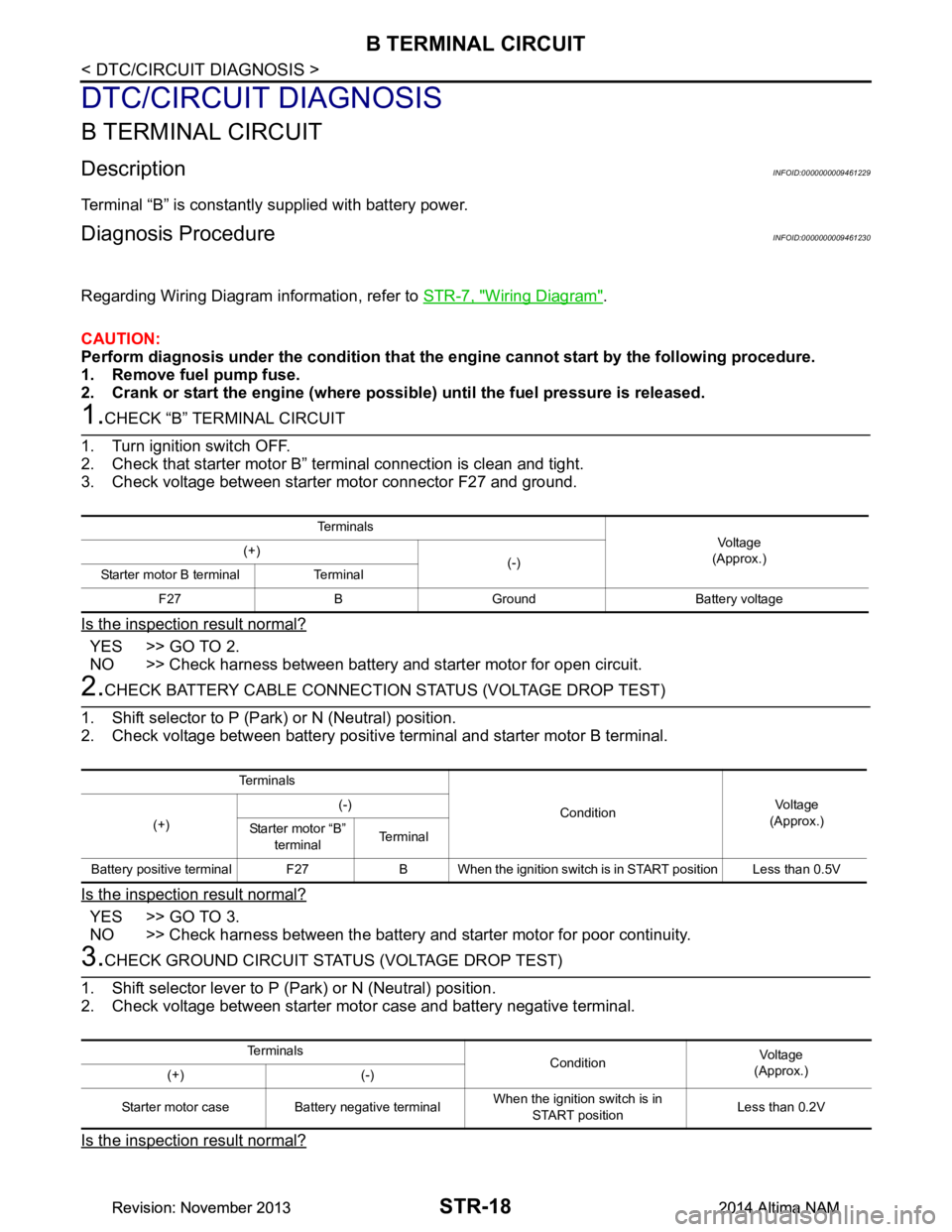

DescriptionINFOID:0000000009461229

Terminal “B” is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000009461230

Regarding Wiring Diagram information, refer to STR-7, "Wiring Diagram".

CAUTION:

Perform diagnosis under the condi tion that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Check that starter motor B” terminal connection is clean and tight.

3. Check voltage between starter motor connector F27 and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

1. Shift selector to P (Park) or N (Neutral) position.

2. Check voltage between battery positive terminal and starter motor B terminal.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check harness between the battery and starter motor for poor continuity.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

1. Shift selector lever to P (Park) or N (Neutral) position.

2. Check voltage between starter motor case and battery negative terminal.

Is the inspection result normal?

Te r m i n a l s

Voltage

(Approx.)

(+)

(-)

Starter motor B terminal Terminal

F27 B Ground Battery voltage

Te r m i n a l s

ConditionVoltage

(Approx.)

(+) (-)

Starter motor “B” terminal Te r m i n a l

Battery positive terminal F27 B When the ignition switch is in START position Less than 0.5V

Te r m i n a l s ConditionVoltage

(Approx.)

(+) (-)

Starter motor case Battery negative terminal When the ignition switch is in

START position Less than 0.2V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4210 of 4801

STR-20

< DTC/CIRCUIT DIAGNOSIS >

S CONNECTOR CIRCUIT

S CONNECTOR CIRCUIT

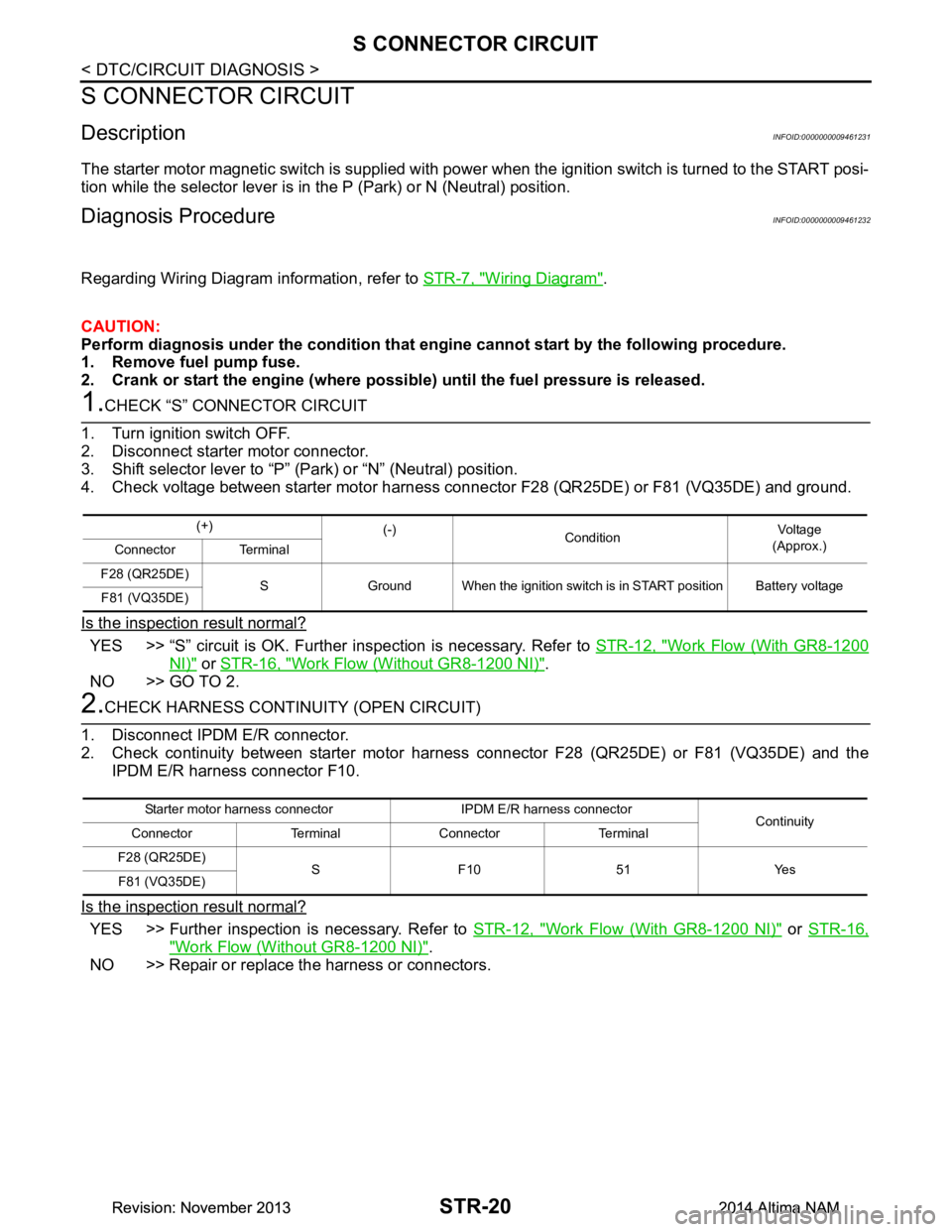

DescriptionINFOID:0000000009461231

The starter motor magnetic switch is supplied with power when the ignition switch is turned to the START posi-

tion while the selector lever is in the P (Park) or N (Neutral) position.

Diagnosis ProcedureINFOID:0000000009461232

Regarding Wiring Diagram information, refer to STR-7, "Wiring Diagram".

CAUTION:

Perform diagnosis under the condi tion that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Shift selector lever to “P” (Park) or “N” (Neutral) position.

4. Check voltage between starter motor harness con nector F28 (QR25DE) or F81 (VQ35DE) and ground.

Is the inspection result normal?

YES >> “S” circuit is OK. Further inspection is necessary. Refer to STR-12, "Work Flow (With GR8-1200

NI)" or STR-16, "Work Flow (Without GR8-1200 NI)".

NO >> GO TO 2.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector.

2. Check continuity between starter motor harness connector F28 (QR25DE) or F81 (VQ35DE) and the

IPDM E/R harness connector F10.

Is the inspection result normal?

YES >> Further inspection is necessary. Refer to STR-12, "Work Flow (With GR8-1200 NI)" or STR-16,

"Work Flow (Without GR8-1200 NI)".

NO >> Repair or replace the harness or connectors.

(+) (-)

Condition Voltage

(Approx.)

Connector Terminal

F28 (QR25DE) S Ground When the ignition switch is in START position Battery voltage

F81 (VQ35DE)

Starter motor harness connector IPDM E/R harness connector Continuity

Connector Terminal Connector Terminal

F28 (QR25DE) S F10 51 Yes

F81 (VQ35DE)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4216 of 4801

TM-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION TM

A

B

TM

N

O P

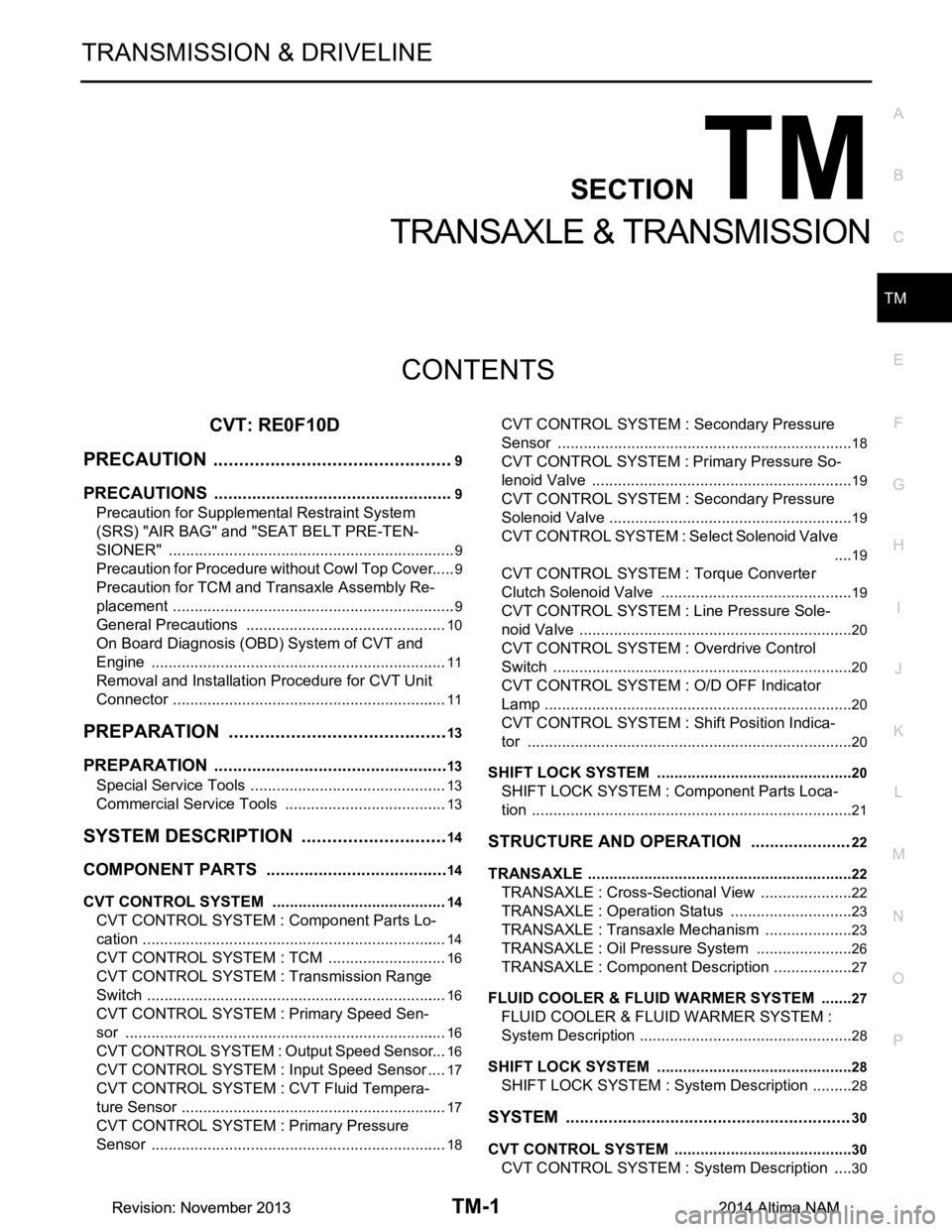

CONTENTS

TRANSAXLE & TRANSMISSION

CVT: RE0F10D

PRECAUTION ................ ...............................

9

PRECAUTIONS .............................................. .....9

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

9

Precaution for Procedure without Cowl Top Cover ......9

Precaution for TCM and Transaxle Assembly Re-

placement ............................................................ ......

9

General Precautions ...............................................10

On Board Diagnosis (OBD) System of CVT and

Engine ................................................................. ....

11

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ....

11

PREPARATION ...........................................13

PREPARATION .............................................. ....13

Special Service Tools .......................................... ....13

Commercial Service Tools ......................................13

SYSTEM DESCRIPTION .............................14

COMPONENT PARTS ................................... ....14

CVT CONTROL SYSTEM .........................................14

CVT CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ....

14

CVT CONTROL SYSTEM : TCM ............................16

CVT CONTROL SYSTEM : Transmission Range

Switch .................................................................. ....

16

CVT CONTROL SYSTEM : Primary Speed Sen-

sor ....................................................................... ....

16

CVT CONTROL SYSTEM : Output Speed Sensor ....16

CVT CONTROL SYSTEM : In put Speed Sensor ....17

CVT CONTROL SYSTEM : CVT Fluid Tempera-

ture Sensor .......................................................... ....

17

CVT CONTROL SYSTEM : Primary Pressure

Sensor ................................................................. ....

18

CVT CONTROL SYSTEM : Secondary Pressure

Sensor ................................................................. ....

18

CVT CONTROL SYSTEM : Primary Pressure So-

lenoid Valve ......................................................... ....

19

CVT CONTROL SYSTEM : Secondary Pressure

Solenoid Valve ..................................................... ....

19

CVT CONTROL SYSTEM : Select Solenoid Valve

....

19

CVT CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ....

19

CVT CONTROL SYSTEM : Line Pressure Sole-

noid Valve ............................................................ ....

20

CVT CONTROL SYSTEM : Overdrive Control

Switch .................................................................. ....

20

CVT CONTROL SYSTEM : O/D OFF Indicator

Lamp .................................................................... ....

20

CVT CONTROL SYSTEM : Shift Position Indica-

tor ........................................................................ ....

20

SHIFT LOCK SYSTEM ..............................................20

SHIFT LOCK SYSTEM : Component Parts Loca-

tion ....................................................................... ....

21

STRUCTURE AND OPERATION .....................22

TRANSAXLE .......................................................... ....22

TRANSAXLE : Cross-Sectional View ......................22

TRANSAXLE : Operation Stat us .............................23

TRANSAXLE : Transaxle Me chanism .....................23

TRANSAXLE : Oil Pressure System .......................26

TRANSAXLE : Component De scription ...................27

FLUID COOLER & FLUID WARMER SYSTEM .... ....27

FLUID COOLER & FLUID WARMER SYSTEM :

System Description .............................................. ....

28

SHIFT LOCK SYSTEM ..............................................28

SHIFT LOCK SYSTEM : Syst em Description ..........28

SYSTEM ...................... ......................................30

CVT CONTROL SYSTEM ..... .....................................30

CVT CONTROL SYSTEM : S ystem Description .....30

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4217 of 4801

TM-2

CVT CONTROL SYSTEM : Fail-safe .................. ...31

CVT CONTROL SYSTEM : Protection Control ... ...34

LINE PRESSURE CONTROL ................................ ...35

LINE PRESSURE CONTROL : System Descrip-

tion ....................................................................... ...

35

SHIFT CONTROL ................................................... ...35

SHIFT CONTROL : System Description .................36

SELECT CONTROL ............................................... ...37

SELECT CONTROL : System Description .............38

LOCK-UP CONTROL ............................................. ...38

LOCK-UP CONTROL : System Description ...........38

ON BOARD DIAGNOSTIC (OBD) SYSTEM .....40

Description ........................................................... ...40

Function of OBD .....................................................40

DIAGNOSIS SYSTEM (TCM) ............................41

DIAGNOSIS DESCRIPTION .................................. ...41

DIAGNOSIS DESCRIPTION : 1 Trip Detection Di-

agnosis and 2 Trip Detection Diagnosis .............. ...

41

DIAGNOSIS DESCRIPTION : DTC and DTC of

1st Trip ................................................................. ...

41

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ...

41

DIAGNOSIS DESCRIPTION : Counter System .....41

CONSULT Function ................................................43

ECU DIAGNOSIS INFORMATION ..............49

TCM ................................................................. ...49

Reference Value .................................................. ...49

Fail-safe ..................................................................56

Protection Control ...................................................59

DTC Inspection Priority Chart .................................59

DTC Index ..............................................................60

WIRING DIAGRAM .....................................62

CVT CONTROL SYSTEM ............................... ...62

Wiring diagram .................................................... ...62

CVT SHIFT LOCK SYSTEM ........................... ...73

Wiring diagram .................................................... ...73

BASIC INSPECTION ...................................77

DIAGNOSIS AND REPAIR WORK FLOW ..... ...77

Flowchart of Trouble Diagnosis ........................... ...77

Question sheet .......................................................78

ADDITIONAL SERVICE WHEN REPLACING

TCM ................................................................. ...

80

Description ........................................................... ...80

Work Procedure ......................................................80

ADDITIONAL SERVICE WHEN REPLACING

TRANSAXLE ASSEMBLY ............................. ...

81

Description ........................................................... ...81

Work Procedure ................................................... ...81

CVT FLUID ........................................................83

Replacement ........................................................ ...83

Adjustment ..............................................................84

STALL TEST .....................................................86

Work Procedure ................................................... ...86

CVT POSITION ..................................................87

Inspection ............................................................. ...87

Adjustment ..............................................................87

DTC/CIRCUIT DIAGNOSIS ........................88

U0073 COMMUNICATION BUS A OFF ......... ...88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

U0100 LOST COMMUNICATION (ECM A) .......89

DTC Logic ............................................................ ...89

Diagnosis Procedure ...............................................89

U0140 LOST COMMUNICATION (BCM) ..........90

DTC Logic ............................................................ ...90

Diagnosis Procedure ...............................................90

U0141 LOST COMMUNICATION (BCM A) ......91

DTC Logic ............................................................ ...91

Diagnosis Procedure ...............................................91

U0155 LOST COMMUNICATION (IPC) ............92

DTC Logic ............................................................ ...92

Diagnosis Procedure ...............................................92

U0300 CAN COMMUNICATION DATA ............93

DTC Logic ............................................................ ...93

Diagnosis Procedure ...............................................93

U1000 CAN COMM CIRCUIT ............................94

Description ........................................................... ...94

DTC Logic ...............................................................94

Diagnosis Procedure ...............................................94

U1117 LOST COMMUNICATION (ABS) ...........95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

P062F EEPROM ................................................96

Description ........................................................... ...96

DTC Logic ...............................................................96

Diagnosis Procedure ...............................................96

P0705 TRANSMISSION RANGE SENSOR A ...97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

Component Inspection ..........................................101

P0706 TRANSMISSION RANGE SENSOR A ..103

DTC Logic ............................................................ .103

Diagnosis Procedure .............................................103

Component Inspection ..........................................105

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4218 of 4801

TM-3

CEF

G H

I

J

K L

M A

B

TM

N

O P

P0711 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A .......................................... ..

106

DTC Logic ........................................................... ..106

Diagnosis Procedure .............................................107

P0712 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A .......................................... ..

110

DTC Logic ........................................................... ..110

Diagnosis Procedure .............................................110

Component Inspection ..........................................110

P0713 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A .......................................... ..

112

DTC Logic ........................................................... ..112

Diagnosis Procedure .............................................112

Component Inspection ..........................................113

P0715 INPUT SPEED SENSOR A ...................114

DTC Logic ........................................................... ..114

Diagnosis Procedure .............................................115

P0717 INPUT SPEED SENSOR A ...................117

DTC Logic ........................................................... ..117

Diagnosis Procedure .............................................118

P0740 TORQUE CONVERTER ........................120

DTC Logic ........................................................... ..120

Diagnosis Procedure .............................................121

P0743 TORQUE CONVERTER ........................122

DTC Logic ........................................................... ..122

Diagnosis Procedure .............................................123

P0744 TORQUE CONVERTER ........................124

DTC Logic ........................................................... ..124

Diagnosis Procedure .............................................125

P0746 PRESSURE CONTROL SOLENOID A ..126

DTC Logic ........................................................... ..126

Diagnosis Procedure .............................................127

P0776 PRESSURE CONTROL SOLENOID B ..128

DTC Logic ........................................................... ..128

Diagnosis Procedure .............................................129

P0778 PRESSURE CONTROL SOLENOID B ..130

DTC Logic ........................................................... ..130

Diagnosis Procedure .............................................130

P0779 PRESSURE CONTROL SOLENOID B ..132

DTC Logic ........................................................... ..132

Diagnosis Procedure .............................................132

P0841 TRANSMISSION FLUID PRESSURE

SEN/SW A ...................................................... ..

134

DTC Logic ........................................................... ..134

Diagnosis Procedure .............................................134

P0847 TRANSMISSION FLUID PRESSURE

SEN/SW B ...................................................... ..

135

DTC Logic ........................................................... ..135

Diagnosis Procedure ........................................... ..135

P0848 TRANSMISSION FLUID PRESSURE

SEN/SW B .......................................................

137

DTC Logic ............................................................ ..137

Diagnosis Procedure .............................................137

P084C TRANSMISSION FLUID PRESSURE

SEN/SW H .......................................................

139

DTC Logic ............................................................ ..139

Diagnosis Procedure .............................................139

P084D TRANSMISSION FLUID PRESSURE

SEN/SW H .......................................................

141

DTC Logic ............................................................ ..141

Diagnosis Procedure .............................................141

P0863 TCM COMMUNICATION .....................143

DTC Logic ..............................................................143

Diagnosis Procedure .............................................143

P0890 TCM ......................................................144

DTC Logic ..............................................................144

Diagnosis Procedure .............................................144

P0962 PRESSURE CONTROL SOLENOID A .145

DTC Logic ............................................................ ..145

Diagnosis Procedure .............................................145

P0963 PRESSURE CONTROL SOLENOID A .147

DTC Logic ............................................................ ..147

Diagnosis Procedure .............................................147

P0965 PRESSURE CONTROL SOLENOID B .149

DTC Logic ............................................................ ..149

Diagnosis Procedure .............................................150

P0966 PRESSURE CONTROL SOLENOID B .151

DTC Logic ............................................................ ..151

Diagnosis Procedure .............................................151

P0967 PRESSURE CONTROL SOLENOID B .153

DTC Logic ............................................................ ..153

Diagnosis Procedure .............................................153

P2765 INPUT SPEED SENSOR B ..................155

DTC Logic ..............................................................155

Diagnosis Procedure .............................................156

P2813 SELECT SOLENOID ...........................158

DTC Logic ..............................................................158

Diagnosis Procedure .............................................159

P2814 SELECT SOLENOID ...........................160

DTC Logic ..............................................................160

Diagnosis Procedure .............................................160

P2815 SELECT SOLENOID ...........................162

DTC Logic ..............................................................162

Diagnosis Procedure .............................................162

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM