ECU NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4152 of 4801

STC-1

STEERING

C

D E

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Service Notice and Precautions for Hydraulic

Pump Electric Power Steering System ............... ......

3

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

Component Description .............................................4

Power Steering Oil Pump Assembly .........................5

SYSTEM ..............................................................6

HYDRAULIC PUMP ELECTRIC POWER STEER-

ING SYSTEM ........ ................................. ......................

6

HYDRAULIC PUMP ELECTRIC POWER

STEERING SYSTEM : System Description ..............

6

HYDRAULIC PUMP ELECTRIC POWER

STEERING SYSTEM : Fail-sa fe ......................... ......

8

HYDRAULIC PUMP ELECTRIC POWER

STEERING SYSTEM : Protec tion Function ..............

9

DIAGNOSIS SYSTEM (POWER STEERING

CONTROL MODULE) .................................... ....

10

CONSULT Function ............................................ ....10

ECU DIAGNOSIS INFORMATION ..............11

POWER STEERING CONTROL MODULE .... ....11

Reference Value ................................................. ....11

Fail-safe ..................................................................12

Protection Function .................................................12

DTC Inspection Priority Chart ............................. ....13

DTC Index ........................................................... ....13

WIRING DIAGRAM ......................................14

HYDRAULIC PUMP ELECTRIC POWER

STEERING SYSTEM .........................................

14

Wiring Diagram .................................................... ....14

BASIC INSPECTION ...................................19

DIAGNOSIS AND REPAIR WORK FLOW .......19

Work Flow ............................................................ ....19

Diagnostic Work Sheet ............................................20

DTC/CIRCUIT DIAGNOSIS .........................22

C1143 STEERING ANGLE SENSOR ...............22

DTC Logic ............................................................ ....22

Diagnosis Procedure ...............................................22

C1601 BATTERY POWER SUPPLY ................23

DTC Logic ................................................................23

Diagnosis Procedure ...............................................23

C1602 NO TUNING SET ...................................26

DTC Logic ................................................................26

Diagnosis Procedure ...............................................26

C1606 EPS MOTOR ..........................................27

DTC Logic ................................................................27

Diagnosis Procedure ...............................................27

C1607, C1608 POWER STEERING CON-

TROL MODULE ................................................

28

DTC Logic ............................................................ ....28

Diagnosis Procedure ...............................................28

C160A HEAT PROTECTION ............................29

DTC Logic ................................................................29

U1000 CAN COMM CIRCUIT ...........................30

Description ...............................................................30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

HYDRAULIC PUMP ELECTRIC POWER

STEERING WARNING LAMP ...........................

31

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4160 of 4801

SYSTEMSTC-9

< SYSTEM DESCRIPTION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

HYDRAULIC PUMP ELECTRIC POWER STEE RING SYSTEM : Protection Function

INFOID:0000000009460346

• When the steering wheel is operated repeatedly or turned all the way for a long period during parking or low

speed driving, the function of the hydraulic pump elec tric power steering system becomes limited to prevent

the system from overheating. Cont inued operation of the steering wheel will cause the hydraulic pump elec-

tric power steering system to stop and the hydraulic pum p electric power steering system warning lamp may

come ON. In this case, the steering wheel operation temporarily becomes hard. This is not a malfunction.

When the engine is turned OFF (ignition switch OFF) and steering operation is stopped for a while, the tem-

perature of the hydraulic pump electric power steer ing system decreases and the steering operation returns

to normal after restarting the engine.

• Then, the hydraulic pump electric power steering syste m warning lamp turns OFF. If the system is OFF

under the protection state, the hydraulic pump electr ic power steering system warning lamp turns ON to

warn that the system is in the manual steering state. (This is not a system malfunction.) In addition, the fol-

lowing DTC remains to distinguish from malfunction.

C1608 Manual steering state

U1000 Normal control

NOTE:

If the cause is in a different ECU, the state changes to fixed steering assist force.

DTC Fail-safe condition

DTC vehicle condition

C160A The system temporarily enters the manual steering state. (This is not a hydraulic pump electric

power steering system malfunction.)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4161 of 4801

STC-10

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (POWER STEERING CONTROL MODULE)

DIAGNOSIS SYSTEM (POWER STEERING CONTROL MODULE)

CONSULT FunctionINFOID:0000000009460347

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentially causing a di scharged battery and a no-start condition.

FUNCTION

CONSULT can display each diagnostic item using the diagnostic test modes shown as per the following.

ECU IDENTIFICATION

Displays the part number stored in the control unit.

SELF-DIAG RESULTS MODE

Refer to STC-13, "DTC Index".

When “CRNT” is displayed on self-diagnosis result.

• The system is presently malfunctioning.

When “PAST” is displayed on self-diagnosis result.• System malfunction in the past is detect ed, but the system is presently normal.

DATA MONITOR MODE

Diagnostic test mode Function

ECU identification The part number stored in the control unit can be read.

Self Diagnostic Results Self-diagnostic results and freeze frame data can be read and erased quickly.

Data monitor Input/Output data in the power steering control module can be read.

Monitor item (Unit) Remarks

BATTERY VOLT (V) Displays the power supply voltage for power steering control module.

STEERING ANGLE (deg) Displays the steering angle based on the steering angle signal transmitted by CAN com-

munications.

STR ANG SPD (deg/s) Displays the steering angle speed based on the steering angle signal transmitted by

CAN communications.

MOTOR CURRENT (A) Displays the cu rrent value consumed by power steering control module.

MTR REV SPD COMM (rpm) Displa ys the power steering motor speed command value.

MTR REV SPD (rpm) Displays the power steering motor speed.

C/U TEMP ( °C or °F) Displays the temperature of the power steering control module.

C/U TEMP A ( °C or °F) Displays the temperature of the power steering control module.

MTR ASSIST (%) Displays the current percentage of the allowable assist ratio power steering motor.

ESTM VHCL SPD (km/h or mph) Displays the vehicle speed calculated by the power steering control module.

WARNING LAMP (On/Off) Hydraulic pump electric power steering system warning lamp control status is displayed.

ENGINE STATUS (STOP/RUN/CRANK) Engine speed is displayed from engine condition signal with CAN communication

VHCL SPD JUDGE (OK/NG) Displays the receiving status of the vehicle speed signal transmitted by CAN communi-

cations.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4162 of 4801

POWER STEERING CONTROL MODULESTC-11

< ECU DIAGNOSIS INFORMATION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

ECU DIAGNOSIS INFORMATION

POWER STEERING CONTROL MODULE

Reference ValueINFOID:0000000009460348

VALUES ON THE DIAGNOSIS TOOL

*1: The value changes according to load of power steering motor.

*2: This is in close agreement with a motor speed command value. Although a quick steering operation may

cause disagreement, this is not a malfunction.

*3: Usually, 100% is displayed. An excessive steer ing operation gradually lowers the percentage. When left

standing, the percentage returns to 100%.

Monitor item Data monitor

Condition Display value

BATTERY VOLT Engine running Battery voltage (V)

STEERING ANGLE The steering wheel is not steered. Approx. 0.0 deg

The steering wheel is steered. Displays steering angle (deg)

STR ANG SPD The steering wheel is not steered. Approx. 0.0 deg/s

The steering wheel is steered. Displays steering angle speed (deg/s)

MOTOR CURRENT Engine running Steering wheel: Not steering (There is

no steering force) MAX approx. 10 A

*1

Steering wheel: Right or left turnDisplays consumption current of pow-

er steering control module (A)

MTR REV SPD COMM Engine running Steering wheel: Not steering (There is

no steering force) Shows an almost constant value

(rpm)

Steering wheel: Right or left turn The value changes as a steering

speed (rpm)

MTR REV SPD Engine running Steering wheel: Not steering (There is

no steering force) Shows an almost constant value

(rpm)

*2

Steering wheel: Right or left turn The value changes as a steering

speed (rpm)*2

C/U TEMP Engine running Displays temperature of inside of

power steering control module ( °C or

° F)

C/U TEMP A Engine running Displays temperature of inside of

power steering control module ( °C or

° F)

MTR ASSIST Engine running 100%

*3

ESTM VHCL SPDVehicle stopped 0.00 km/h or mph

While driving Approximately equal to the indication

on speedometer*4

(inside of ±10%)

WARNING LAMP Hydraulic pump electric power steering warning lamp: ON On

Hydraulic pump electric power steering warning lamp: OFF Off

ENGINE STATUS Engine not running STOP

Engine running RUN

Engine cranking CRANK

VHCL SPD JUDGE Vehicle speed signal can be received via CAN communication OK

Vehicle speed signal cannot be received via CAN communica-

tion NG

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4163 of 4801

STC-12

< ECU DIAGNOSIS INFORMATION >

POWER STEERING CONTROL MODULE

*4: This may not agree with the speedometer indication immediately after the ignition switch is turned ON. This

is not a malfunction.

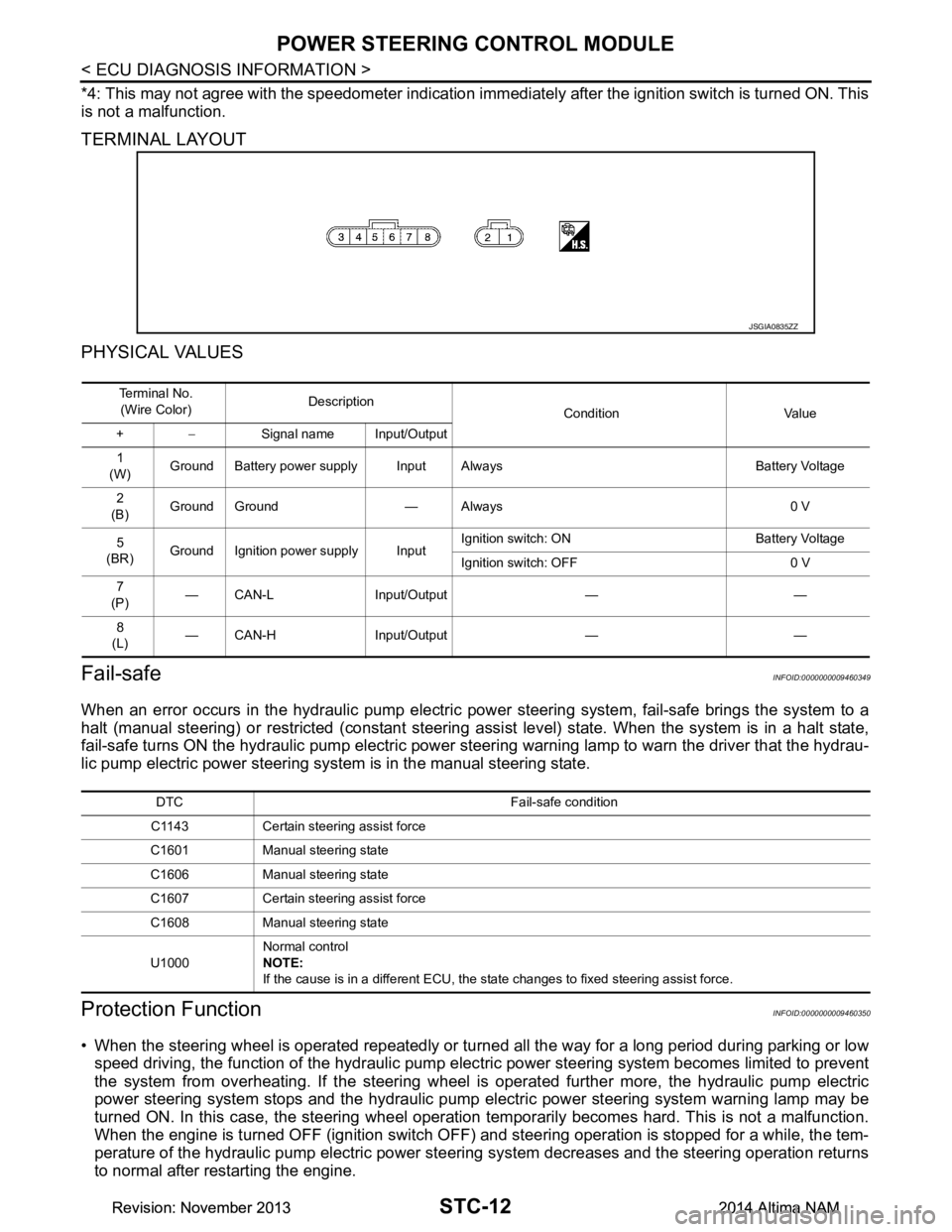

TERMINAL LAYOUT

PHYSICAL VALUES

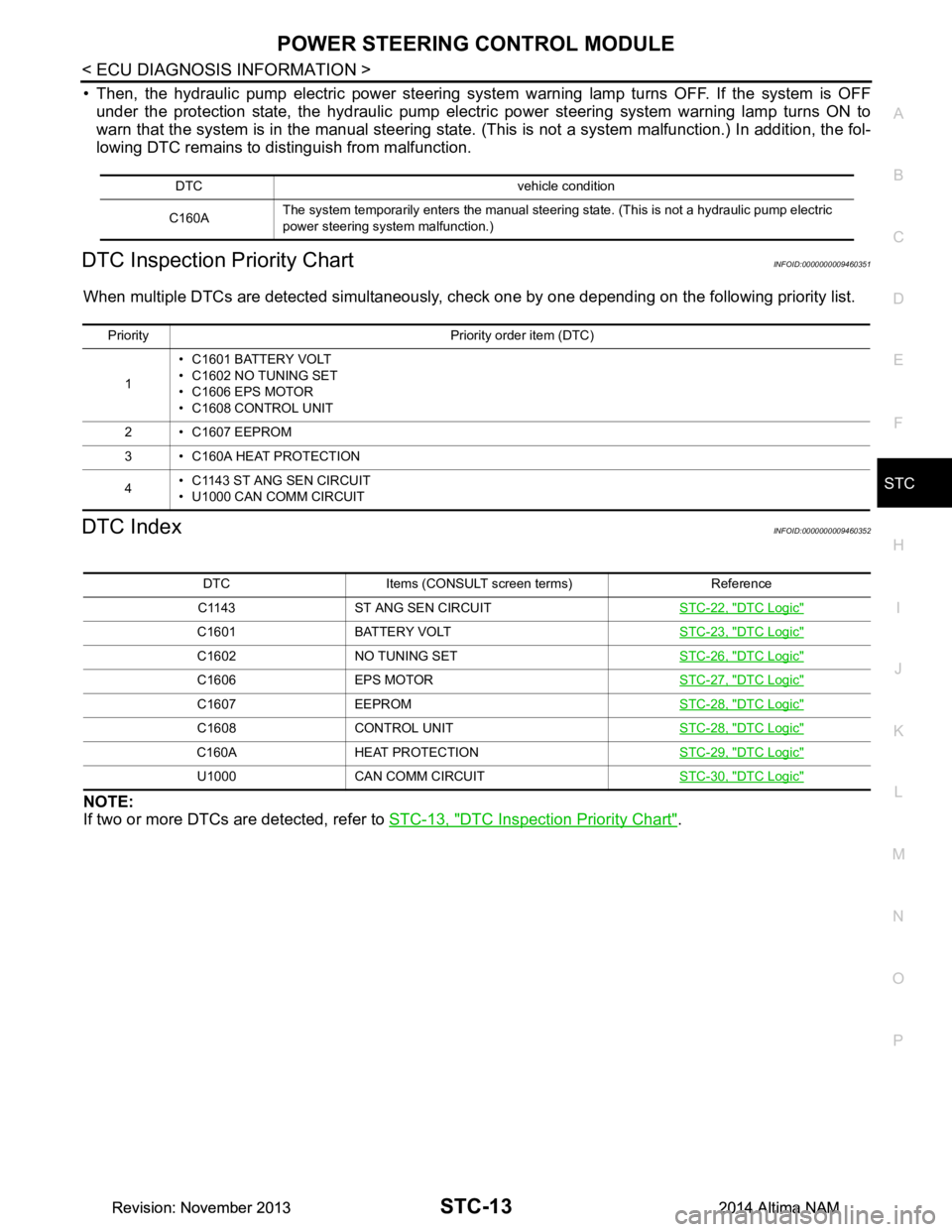

Fail-safeINFOID:0000000009460349

When an error occurs in the hydraulic pump electric pow er steering system, fail-safe brings the system to a

halt (manual steering) or restricted (constant steering assi st level) state. When the system is in a halt state,

fail-safe turns ON the hydraulic pump electric power steer ing warning lamp to warn the driver that the hydrau-

lic pump electric power steering system is in the manual steering state.

Protection FunctionINFOID:0000000009460350

• When the steering wheel is operated repeatedly or turned all the way for a long period during parking or low

speed driving, the function of the hydraulic pump elec tric power steering system becomes limited to prevent

the system from overheating. If the steering wheel is operated further more, the hydraulic pump electric

power steering system stops and the hydraulic pump el ectric power steering system warning lamp may be

turned ON. In this case, the steering wheel operation temporarily becomes hard. This is not a malfunction.

When the engine is turned OFF (ignition switch OFF) and steering operation is stopped for a while, the tem-

perature of the hydraulic pump electric power steeri ng system decreases and the steering operation returns

to normal after restarting the engine.

JSGIA0835ZZ

Te r m i n a l N o .

(Wire Color) Description

Condition Value

+ − Signal name Input/Output

1

(W) Ground Battery power supply Input Always Battery Voltage

2

(B) Ground Ground — Always 0 V

5

(BR) Ground Ignition power supply Input Ignition switch: ON Battery Voltage

Ignition switch: OFF 0 V

7

(P) — CAN-L Input/Output — —

8

(L) — CAN-H Input/Output — —

DTC Fail-safe condition

C1143 Certain steering assist force

C1601 Manual steering state

C1606 Manual steering state

C1607 Certain steering assist force

C1608 Manual steering state

U1000 Normal control

NOTE:

If the cause is in a different ECU, the state changes to fixed steering assist force.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4164 of 4801

POWER STEERING CONTROL MODULESTC-13

< ECU DIAGNOSIS INFORMATION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

• Then, the hydraulic pump electric power steering syste m warning lamp turns OFF. If the system is OFF

under the protection state, the hydraulic pump electr ic power steering system warning lamp turns ON to

warn that the system is in the manual steering state. (This is not a system malfunction.) In addition, the fol-

lowing DTC remains to distinguish from malfunction.

DTC Inspection Priority ChartINFOID:0000000009460351

When multiple DTCs are detected simultaneously, c heck one by one depending on the following priority list.

DTC IndexINFOID:0000000009460352

NOTE:

If two or more DTCs are detected, refer to STC-13, "DTC Inspection Priority Chart"

.

DTC vehicle condition

C160A The system temporarily enters the manual steering state. (This is not a hydraulic pump electric

power steering system malfunction.)

Priority Priority order item (DTC)

1 • C1601 BATTERY VOLT

• C1602 NO TUNING SET

• C1606 EPS MOTOR

• C1608 CONTROL UNIT

2 • C1607 EEPROM

3 • C160A HEAT PROTECTION

4 • C1143 ST ANG SEN CIRCUIT

• U1000 CAN COMM CIRCUIT

DTC Items (CONSULT screen terms) Reference

C1143 ST ANG SEN CIRCUIT STC-22, "DTC Logic"

C1601 BATTERY VOLT STC-23, "DTC Logic"

C1602 NO TUNING SETSTC-26, "DTC Logic"

C1606 EPS MOTORSTC-27, "DTC Logic"

C1607 EEPROMSTC-28, "DTC Logic"

C1608 CONTROL UNITSTC-28, "DTC Logic"

C160A HEAT PROTECTION STC-29, "DTC Logic"

U1000 CAN COMM CIRCUITSTC-30, "DTC Logic"

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4217 of 4801

TM-2

CVT CONTROL SYSTEM : Fail-safe .................. ...31

CVT CONTROL SYSTEM : Protection Control ... ...34

LINE PRESSURE CONTROL ................................ ...35

LINE PRESSURE CONTROL : System Descrip-

tion ....................................................................... ...

35

SHIFT CONTROL ................................................... ...35

SHIFT CONTROL : System Description .................36

SELECT CONTROL ............................................... ...37

SELECT CONTROL : System Description .............38

LOCK-UP CONTROL ............................................. ...38

LOCK-UP CONTROL : System Description ...........38

ON BOARD DIAGNOSTIC (OBD) SYSTEM .....40

Description ........................................................... ...40

Function of OBD .....................................................40

DIAGNOSIS SYSTEM (TCM) ............................41

DIAGNOSIS DESCRIPTION .................................. ...41

DIAGNOSIS DESCRIPTION : 1 Trip Detection Di-

agnosis and 2 Trip Detection Diagnosis .............. ...

41

DIAGNOSIS DESCRIPTION : DTC and DTC of

1st Trip ................................................................. ...

41

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ...

41

DIAGNOSIS DESCRIPTION : Counter System .....41

CONSULT Function ................................................43

ECU DIAGNOSIS INFORMATION ..............49

TCM ................................................................. ...49

Reference Value .................................................. ...49

Fail-safe ..................................................................56

Protection Control ...................................................59

DTC Inspection Priority Chart .................................59

DTC Index ..............................................................60

WIRING DIAGRAM .....................................62

CVT CONTROL SYSTEM ............................... ...62

Wiring diagram .................................................... ...62

CVT SHIFT LOCK SYSTEM ........................... ...73

Wiring diagram .................................................... ...73

BASIC INSPECTION ...................................77

DIAGNOSIS AND REPAIR WORK FLOW ..... ...77

Flowchart of Trouble Diagnosis ........................... ...77

Question sheet .......................................................78

ADDITIONAL SERVICE WHEN REPLACING

TCM ................................................................. ...

80

Description ........................................................... ...80

Work Procedure ......................................................80

ADDITIONAL SERVICE WHEN REPLACING

TRANSAXLE ASSEMBLY ............................. ...

81

Description ........................................................... ...81

Work Procedure ................................................... ...81

CVT FLUID ........................................................83

Replacement ........................................................ ...83

Adjustment ..............................................................84

STALL TEST .....................................................86

Work Procedure ................................................... ...86

CVT POSITION ..................................................87

Inspection ............................................................. ...87

Adjustment ..............................................................87

DTC/CIRCUIT DIAGNOSIS ........................88

U0073 COMMUNICATION BUS A OFF ......... ...88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

U0100 LOST COMMUNICATION (ECM A) .......89

DTC Logic ............................................................ ...89

Diagnosis Procedure ...............................................89

U0140 LOST COMMUNICATION (BCM) ..........90

DTC Logic ............................................................ ...90

Diagnosis Procedure ...............................................90

U0141 LOST COMMUNICATION (BCM A) ......91

DTC Logic ............................................................ ...91

Diagnosis Procedure ...............................................91

U0155 LOST COMMUNICATION (IPC) ............92

DTC Logic ............................................................ ...92

Diagnosis Procedure ...............................................92

U0300 CAN COMMUNICATION DATA ............93

DTC Logic ............................................................ ...93

Diagnosis Procedure ...............................................93

U1000 CAN COMM CIRCUIT ............................94

Description ........................................................... ...94

DTC Logic ...............................................................94

Diagnosis Procedure ...............................................94

U1117 LOST COMMUNICATION (ABS) ...........95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

P062F EEPROM ................................................96

Description ........................................................... ...96

DTC Logic ...............................................................96

Diagnosis Procedure ...............................................96

P0705 TRANSMISSION RANGE SENSOR A ...97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

Component Inspection ..........................................101

P0706 TRANSMISSION RANGE SENSOR A ..103

DTC Logic ............................................................ .103

Diagnosis Procedure .............................................103

Component Inspection ..........................................105

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4220 of 4801

TM-5

CEF

G H

I

J

K L

M A

B

TM

N

O P

General Specification ..........................................

..

212

Shift Characteristics ..............................................212

Stall Speed ............................................................212

Torque Converter ..................................................212

Heater Thermostat ................................................212

CVT: RE0F10E

PRECAUTION ................ ............................

213

PRECAUTIONS .............................................. ..213

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

213

Precaution for Procedure without Cowl Top Cover ..213

Precaution for TCM and Transaxle Assembly Re-

placement ............................................................ ..

213

General Precautions .............................................214

On Board Diagnosis (OBD) System of CVT and

Engine ................................................................. ..

215

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ..

215

PREPARATION .........................................217

PREPARATION .............................................. ..217

Special Service Tools .......................................... ..217

Commercial Service Tools ....................................217

SYSTEM DESCRIPTION ...........................218

COMPONENT PARTS ................................... ..218

CVT CONTROL SYSTEM .......................................218

CVT CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ..

218

CVT CONTROL SYSTEM : TCM ..........................219

CVT CONTROL SYSTEM : Transmission Range

Switch .................................................................. ..

219

CVT CONTROL SYSTEM : Primary Speed Sen-

sor ....................................................................... ..

219

CVT CONTROL SYSTEM : Output Speed Sensor ..220

CVT CONTROL SYSTEM : Input Speed Sensor ..220

CVT CONTROL SYSTEM : CVT Fluid Tempera-

ture Sensor .......................................................... ..

221

CVT CONTROL SYSTEM : Primary Pressure

Sensor ................................................................. ..

221

CVT CONTROL SYSTEM : Secondary Pressure

Sensor ................................................................. ..

222

CVT CONTROL SYSTEM : Primary Pressure So-

lenoid Valve ......................................................... ..

222

CVT CONTROL SYSTEM : Secondary Pressure

Solenoid Valve .................................................... ..

222

CVT CONTROL SYSTEM : Select Solenoid Valve

..

223

CVT CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ..

223

CVT CONTROL SYSTEM : Line Pressure Sole-

noid Valve ........................................................... ..

223

CVT CONTROL SYSTEM : Paddle Shifter ...........223

CVT CONTROL SYSTEM : Shift Position Indica-

tor ........................................................................ ..

223

SHIFT LOCK SYSTEM ............................................223

SHIFT LOCK SYSTEM : Component Parts Loca-

tion ....................................................................... ..

224

STRUCTURE AND OPERATION ...................225

TRANSAXLE .......................................................... ..225

TRANSAXLE : Cross-Sectional View ....................225

TRANSAXLE : Operation Stat us ...........................226

TRANSAXLE : Transaxle Me chanism ...................226

TRANSAXLE : Oil Pressure System .....................228

TRANSAXLE : Component De scription .................229

FLUID COOLER & FLUID WARMER SYSTEM .... ..229

FLUID COOLER & FLUID WARMER SYSTEM :

System Description .............................................. ..

230

SHIFT LOCK SYSTEM ............................................230

SHIFT LOCK SYSTEM : Syst em Description ........230

SYSTEM ...................... ....................................232

CVT CONTROL SYSTEM ..... ...................................232

CVT CONTROL SYSTEM : S ystem Description ...232

CVT CONTROL SYSTEM : Fa il-safe ....................233

CVT CONTROL SYSTEM : Pr otection Control .....236

LINE PRESSURE CONTROL ......................... .........237

LINE PRESSURE CONTROL : System Descrip-

tion ....................................................................... ..

237

SHIFT CONTROL .................................................. ..237

SHIFT CONTROL : System Description ................238

SELECT CONTROL ............................................... ..239

SELECT CONTROL : System Description ............239

LOCK-UP CONTROL ............................................ ..240

LOCK-UP CONTROL : System Description ..........240

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..242

Description .............................................................242

Function of OBD ....................................................242

DIAGNOSIS SYSTEM (TCM) ..........................243

DIAGNOSIS DESCRIPTION .................................. ..243

DIAGNOSIS DESCRIPTION : 1 Trip Detection Di-

agnosis and 2 Trip Detection Diagnosis .............. ..

243

DIAGNOSIS DESCRIPTION : DTC and DTC of

1st Trip ................................................................. ..

243

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ..

243

DIAGNOSIS DESCRIPTION : Counter System ....243

CONSULT Function ............................................. ..245

ECU DIAGNOSIS INFORMATION ............251

TCM .................................................................251

Reference Value .................................................. ..251

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4226 of 4801

![NISSAN TEANA 2014 Service Manual

PRECAUTIONSTM-11

< PRECAUTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

On Board Diagnosis (OBD) System of CVT and EngineINFOID:0000000009463958

The TCM and ECM have an on board diagnostic s NISSAN TEANA 2014 Service Manual

PRECAUTIONSTM-11

< PRECAUTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

On Board Diagnosis (OBD) System of CVT and EngineINFOID:0000000009463958

The TCM and ECM have an on board diagnostic s](/img/5/57390/w960_57390-4225.png)

PRECAUTIONSTM-11

< PRECAUTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

On Board Diagnosis (OBD) System of CVT and EngineINFOID:0000000009463958

The TCM and ECM have an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to

warn the driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and di sconnect the battery cable from the negative terminal

before any repair or inspection work. The open/s hort circuit of related switches, sensors, solenoid

valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Removal and Installation Proc edure for CVT Unit ConnectorINFOID:0000000009463959

REMOVAL

• Rotate bayonet ring (1) counterclockwise. Pull out CVT unit har-

ness connector (2) upward and remove it.

INSTALLATION

1. Align marking (A) on CVT unit harness connector terminal with

marking (B) on bayonet ring. Insert CVT unit harness connector.

2. Rotate bayonet ring clockwise.

3. Rotate bayonet ring clockwise until marking (A) on CVT unit har- ness connector terminal body is aligned with the slit (B) on bayo-

net ring as shown in the figure (correctly fitting condition).

CAUTION:

SCIA6685J

JPDIA0294ZZ

JPDIA0295ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4227 of 4801

![NISSAN TEANA 2014 Service Manual

TM-12

< PRECAUTION >[CVT: RE0F10D]

PRECAUTIONS

• Securely align marking (A) on CVT unit harness connec-

tor terminal body with bayonet ri ng slit (B). Then, be care-

ful not to make a half fit cond NISSAN TEANA 2014 Service Manual

TM-12

< PRECAUTION >[CVT: RE0F10D]

PRECAUTIONS

• Securely align marking (A) on CVT unit harness connec-

tor terminal body with bayonet ri ng slit (B). Then, be care-

ful not to make a half fit cond](/img/5/57390/w960_57390-4226.png)

TM-12

< PRECAUTION >[CVT: RE0F10D]

PRECAUTIONS

• Securely align marking (A) on CVT unit harness connec-

tor terminal body with bayonet ri ng slit (B). Then, be care-

ful not to make a half fit cond ition as shown in the figure.

• Never mistake the slit of bayonet ring for other dent por-

tion.

JPDIA0296ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM