fuse NISSAN TEANA 2014 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2021 of 4801

![NISSAN TEANA 2014 Repair Manual

CAMSHAFT VALVE CLEARANCEEM-23

< PERIODIC MAINTENANCE > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT VALVE CLEARANCE

Camshaft valve clearanceINFOID:0000000009460474

• Perform this inspection a NISSAN TEANA 2014 Repair Manual

CAMSHAFT VALVE CLEARANCEEM-23

< PERIODIC MAINTENANCE > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT VALVE CLEARANCE

Camshaft valve clearanceINFOID:0000000009460474

• Perform this inspection a](/img/5/57390/w960_57390-2020.png)

CAMSHAFT VALVE CLEARANCEEM-23

< PERIODIC MAINTENANCE > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT VALVE CLEARANCE

Camshaft valve clearanceINFOID:0000000009460474

• Perform this inspection as follows after removal, inst

allation, or replacement of the camshaft or any valve-

related parts, or if there are any unusual engine conditions due to changes in valve clearance over time

(starting, idling, and/or noise).

1. Remove the fender protector side cover (RH). Refer to EXT-26, "FENDER PROTECTOR : Removal and

Installation".

2. Remove the rocker cover using power tool. Refer to EM-45, "Removal and Installation"

.

3. Turn crankshaft pulley clockwise when viewed from front to align TDC identification mark (B) with timing indicator (A).

NOTE:

Do not confuse TDC mark (B) with paint marks (C).

4. At this time, check that the both intake and exhaust cam lobes of No. 1 cylinder face outside.

• If they do not face outside, turn crankshaft pulley once more.

5. Measure valve clearances with a feeler gauge at locations marked (X) in the table below.

• No.1 cylinder compression TDC.

ALBIA0840GB

ALBIA0882GB

Cylinder No.1 (A) No.2 (B) No.3 (C) No.4 (D)

Va l v e I N T (E)EXH

(F) INT

(E) EXH

(F) INT

(E) EXH

(F) INT

(E) EXH

(F)

Measure x x x x

: Engine frontALBIA0886GB

Revision: November 20132014 Altima NAM

Page 2040 of 4801

![NISSAN TEANA 2014 Repair Manual

EM-42

< REMOVAL AND INSTALLATION >[QR25DE]

FUEL INJECTOR AND FUEL TUBE

5. Remove quick connector cap (1) from the fuel feed side (B) and

the fuel tube side (A).

6. Disconnect the fuel hose quick conn NISSAN TEANA 2014 Repair Manual

EM-42

< REMOVAL AND INSTALLATION >[QR25DE]

FUEL INJECTOR AND FUEL TUBE

5. Remove quick connector cap (1) from the fuel feed side (B) and

the fuel tube side (A).

6. Disconnect the fuel hose quick conn](/img/5/57390/w960_57390-2039.png)

EM-42

< REMOVAL AND INSTALLATION >[QR25DE]

FUEL INJECTOR AND FUEL TUBE

5. Remove quick connector cap (1) from the fuel feed side (B) and

the fuel tube side (A).

6. Disconnect the fuel hose quick connector at the fuel tube side using Tool (D).

CAUTION:

• Do not pull with lateral force applied. O-ring inside quick connector may be damaged.

• Prepare container and cloth beforehand as fuel will leak out.

• Avoid fire and sparks.

• Be sure to cover openings of disconnected pipes with

plug or plastic bag to avoid fuel leaks and entry of foreign

materials.

• Do not reuse O-ring.

a. With the sleeve (E) side of Tool (D) facing quick connector, install Tool onto fuel tube.

b. Insert Tool into quick connector until sleeve contacts and goes no further (A). Hold the Tool on that posi-

tion.

CAUTION:

Inserting the Tool hard will not disconnect quick connector. Hold Tool where it contacts and goes

no further.

c. Hold the fuel tube in the location (B) and pull the quick connector straight out in direction (C) from the fuel

tube.

7. Disconnect the EVAP canister purge volume control solenoid.

8. Remove the PCV hose from the rocker cover.

9. Disconnect sub-harness for injectors at engine front side, and remove it from bracket.

10. Disconnect the fuel injector harness connectors.

11. Loosen the bolts in the reverse order shown, then remove fuel tube and fuel injectors as an assembly.

12. Remove the fuel injectors from the fuel tube, (if necessary).

a. Release the clip.

b. Pull fuel injector straight out of the fuel tube. CAUTION:

• Be careful not to damage the nozzle.

• Avoid any impact, such as dropping the fuel injector.

• Do not disassemble or adjust the fuel injector.

INSTALLATION

1. Install new O-rings on the fuel injector.

CAUTION:

• Do not reuse O-rings.

• Upper and lower O-rings are different. Be careful not to confuse them.

ALBIA0890GB

Tool number : 16441 6N210 (J-45488)

ALBIA0891GB

AWBIA1261GB

Revision: November 20132014 Altima NAM

Page 2046 of 4801

![NISSAN TEANA 2014 Repair Manual

EM-48

< REMOVAL AND INSTALLATION >[QR25DE]

CAMSHAFT

7. Loosen the valve timing control cover bolts in the reverse order

shown.

a. Remove the valve timing control cover bolts.

8. Remove the valve tim NISSAN TEANA 2014 Repair Manual

EM-48

< REMOVAL AND INSTALLATION >[QR25DE]

CAMSHAFT

7. Loosen the valve timing control cover bolts in the reverse order

shown.

a. Remove the valve timing control cover bolts.

8. Remove the valve tim](/img/5/57390/w960_57390-2045.png)

EM-48

< REMOVAL AND INSTALLATION >[QR25DE]

CAMSHAFT

7. Loosen the valve timing control cover bolts in the reverse order

shown.

a. Remove the valve timing control cover bolts.

8. Remove the valve timing control cover by cutting the liquid gas- ket using Tool (A).

NOTE:

Do not loosen screws (A) on the back of the valve timing control

cover.

9. Set the No.1 cylinder at TDC on its compression stroke using the following procedure:

a. Remove the fender protector side cover RH. Refer to EXT-26,

"FENDER PROTECTOR : Removal and Installation".

b. Rotate crankshaft pulley clockwise, and align mating mark for TDC (B) with timing indicator (A) on front cover, as shown.

NOTE:

Do not confuse TDC (B) with paint mark (C).

ALBIA0839GB

Tool number : KV10111100 (J-37228)

AWBIA1257GB

AWBIA1361ZZ

ALBIA0840GB

Revision: November 20132014 Altima NAM

Page 2164 of 4801

![NISSAN TEANA 2014 Repair Manual

EM-166

< REMOVAL AND INSTALLATION >[VQ35DE]

FUEL INJECTOR AND FUEL TUBE

• Do not reuse O-rings.

• Upper and lower O-rings are different. Be careful not to confuse them.

• Handle O-ring with b NISSAN TEANA 2014 Repair Manual

EM-166

< REMOVAL AND INSTALLATION >[VQ35DE]

FUEL INJECTOR AND FUEL TUBE

• Do not reuse O-rings.

• Upper and lower O-rings are different. Be careful not to confuse them.

• Handle O-ring with b](/img/5/57390/w960_57390-2163.png)

EM-166

< REMOVAL AND INSTALLATION >[VQ35DE]

FUEL INJECTOR AND FUEL TUBE

• Do not reuse O-rings.

• Upper and lower O-rings are different. Be careful not to confuse them.

• Handle O-ring with bare hands. Do not wear gloves.

• Lubricate O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Check that O-ring and its mating pa rt are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring. If O-ring was stretc hed while it was being attached, do not insert it

quickly into fuel tube.

• Insert O-ring straight into fu el injector. Do not twist it.

3. Install fuel injector to fuel tube as follows:

a. Insert clip (3) into clip groove (F) on fuel injector (5).

• Insert clip so that protrusion (E ) of fuel injector matches cutout

(C) of clip.

CAUTION:

• Do not reuse O-rings.

• Do not reuse clip. Replace it with new one.

• Be careful to keep clip from interfering with O-ring. If interference occurs, replace O-ring.

b. Insert fuel injector into fuel tube (1) with clip attached. • Insert it while matching it to the axial center.

• Insert fuel injector so that protrusion (A) of fuel tube matches

cutout (B) of clip.

• Check that fuel tube flange (G) is securely fixed in flange fixing

groove (D) on clip.

c. Check that installation is complete by checking that fuel injector does not rotate or come off.

• Check that protrusions of fuel injectors and fuel tubes are

aligned with cutouts of clips after installation.

4. Install fuel tube and fuel injector assembly to intake manifold. CAUTION:

Be careful not to let tip of injector nozzle come in contact with other parts.

• Tighten bolts in two steps in numerical order as shown.

5. Connect fuel injector harness.

6. Install intake manifold collector. Refer to EM-146, "Removal and Installation"

.

7. Connect quick connector between fuel feed hose and fuel tube connection with the following procedure:

a. Check no foreign substances are deposited in and around fuel tube and quick connector, and no damage on them.Fuel tube side : Black

Nozzle side : Green

(2) : O-ring (black)

(4) : O-ring (green)

JPBIA1959ZZ

: Engine front

1st step : 10.1 N·m (1.0 kg-m, 7 ft-lb)

2nd step : 22.0 N·m (2.2 kg-m, 16 ft-lb)

JPBIA1715ZZ

Revision: November 20132014 Altima NAM

Page 2270 of 4801

EXL-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951582

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

General precautions fo r service operationsINFOID:0000000009463538

• Do not work with wet hands.

• The xenon headlamp system includes a high voltage generating

part. Be sure to disconnect batte ry negative cable (negative termi-

nal) or power fuse before removing, installing, or touching the

xenon headlamp (including lamp bulb).

• Turn the lighting switch OFF before disconnecting and connecting the connector.

• When turning the xenon headlamp on and while it is illuminated, do

not touch the harness, bulb, and socket of the headlamp.

• When checking the headlamp on/off operation, check it on vehicle and with the power connected to the vehicle-side connector.

• Do not touch the headlamp bulb glass surface with bare hands or allow oil or grease to get on it. Do not touch the headl amp bulb just after the headlamp is turned off, because

it is very hot.

• Install the xenon headlamp bulb socket co rrectly. If it is installed improperly, high-voltage leak or corona dis-

charge may occur that can melt the bulb, connector or housing. Do not illuminate the xenon headlamp bulb

out of the headlamp housing. Doing so can cause fire and harm your eyes.

• When the bulb has burned out, wrap it in a thick vinyl bag and discard. Do not break the bulb.

• Leaving the bulb removed from the headlamp housing for a long period of time can deteriorate the perfor- mance of the lens and reflector (dirt, clouding). Al ways prepare a new bulb and have it on hand when replac-

ing the bulb.

• When adjusting the headlamp aiming, turn the aiming adjus tment screw only in the tightening direction. If it

is necessary to loosen the screw, first fully loosen the screw, and then turn it in the tightening direction.

• Do not use organic solvent (paint thinner or gasoline) to clean lamps and to remove old sealant.

PKIA0183E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2274 of 4801

EXL-8

< SYSTEM DESCRIPTION >

COMPONENT PARTS

Component Description

INFOID:0000000009463542

1. BCM (view with combination meter re-

moved) 2. Combination switch

(lighting and turn signal switch) 3. IPDM E/R, (Headlamp high relay,

Headlamp low relay, Tail lamp relay

and Front fog lamp relay (if equipped))

4. Fuse, fusible link and relay box (Stop lamp relay) 5. Combination meter 6. Parking brake switch

7. Stop lamp switch 8. Hazard switch 9. Optical sensor

10. Front door switch LH (RH similar) 11. Rear door switch LH

(RH similar) 12. Daytime light relay

(if equipped)

Part Description

BCM Controls the exterior lighting system.

Combination switch

(Lighting & turn signal switch) Refer to

BCS-8, "COMBINATION SWITCH READIN G SYSTEM : System Description"

.

IPDM E/R Controls the integrated relays and supplies voltage to the load according to the request from the BCM

via CAN communication.

Stop lamp switch Transmits power to the stop lamp relay when the brake pedal is pressed to operate stop lamps.

Combination meter Refer to MWI-9, "METER SYSTEM : System Description"

.

Daytime light relay

(if equipped) Sends power to the daytime lamp when operated by the IPDM E/R.

Stop lamp relay Transmits power to the stop lamps when the brake pedal is pressed.

Front door switch LH/RH Transmits the door open signal to the BCM.

Rear door switch LH/RH

Optical sensor Optical sensor converts the outside brightness (lux) to voltage and transmits the optical sensor signal

to BCM to operate the auto light system.

Parking brake switch Transmits the parking brake switch signal to the combination meter to operate the auto light system.

Hazard switch Inputs the hazard switch signal to BCM.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2355 of 4801

POWER SUPPLY AND GROUND CIRCUITEXL-89

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000009956493

Regarding Wiring Diagram information, refer to BCS-55, "Wiring Diagram".

1. CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse or fusible link blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Disconnect BCM connector M21.

2. Check voltage between BCM connector M21 terminals 131, 139 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M21 terminals 134, 143 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connectors.

IPDM E/R (INTELLIGENT POWER DIST RIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000009956494

Regarding Wiring Diagram information, refer to PCS-21, "Wiring Diagram".

Terminal No. Signal name Fuse and fusible link No.

139 Fusible link battery power I (40A)

131 BCM battery fuse 1 (10A)

BCM GroundVo l ta g e

(Approx.)

Connector Terminal

M21 131

—Batteryvoltage

139

BCM Ground Continuity

Connector Terminal

M21 134

—Yes

143

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2357 of 4801

HEADLAMP (HI) CIRCUITEXL-91

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (HI) CIRCUIT

DescriptionINFOID:0000000009463577

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp high relay based on

inputs from the BCM over the CAN communication li nes. When the headlamp high relay is energized, power

flows through fuses 34 and 35, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp high beam.

Component Function CheckINFOID:0000000009463578

1.CHECK HEADLAMP (HI) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the headlamp switches to the high beam. NOTE:

HI/LO is repeated 1 second each when using the IPDM E/R auto active test.

CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, check t hat the headlamp switches to the high beam.

Is the inspection result normal?

YES >> Headlamp (HI) circuit is normal.

NO >> Refer to EXL-91, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463579

Regarding Wiring Diagram information, refer to EXL-27, "Wiring Diagram - Halogen" or EXL-33, "Wiring Dia-

gram - Xenon".

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE

CONSULT ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp harness connector E213 or E222 in question.

3. Turn the ignition switch ON.

4. Select EXTERNAL LAMP of IP DM E/R active test item.

5. With EXTERNAL LAMP ON, check the voltage between the combination lamp connector and ground.

HI : Headlamp switches to the high beam.

OFF : Headlamp OFF

Unit Location Fuse No. Capacity

Headlamp HI (LH) IPDM E/R 35 10A

Headlamp HI (RH) IPDM E/R 34 10A

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2359 of 4801

HEADLAMP (LO) CIRCUITEXL-93

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (LO) CIRCUIT

HEADLAMP (HALOGEN)

HEADLAMP (HALOGEN) : DescriptionINFOID:0000000009463580

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM over the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 36 and 37, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp low beam.

HEADLAMP (HALOGEN) : Component Function CheckINFOID:0000000009463581

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the headlamp is turned ON.

NOTE:

HI/LO is repeated 1 second each when using the IPDM E/R auto active test.

CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, check that the headlamp is turned ON.

Is the inspection result normal?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-93, "HEADLAMP (HALOGEN) : Diagnosis Procedure"

.

HEADLAMP (HALOGEN) : Diagnosis ProcedureINFOID:0000000009463582

Regarding Wiring Diagram information, refer to EXL-27, "Wiring Diagram - Halogen".

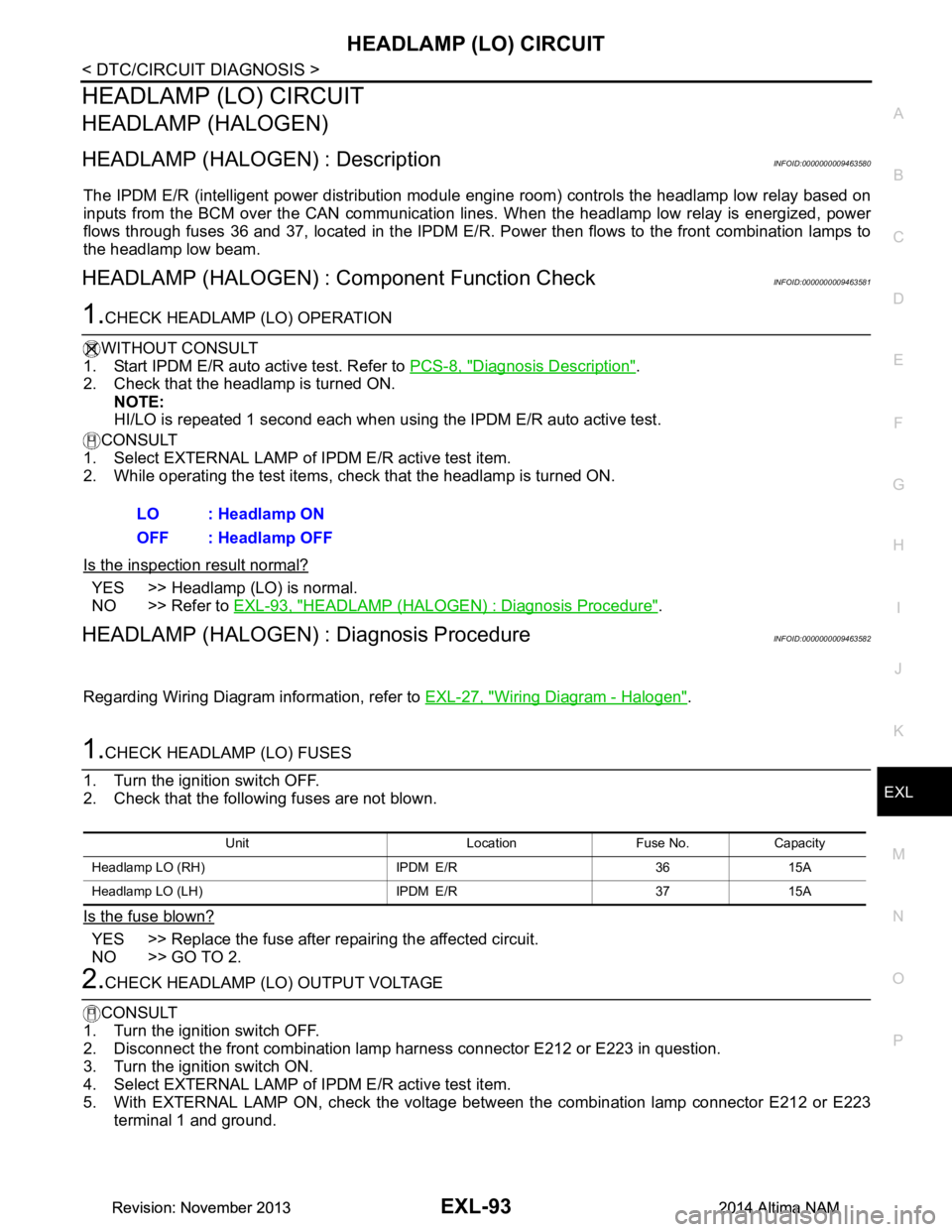

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

CONSULT

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp harness connector E212 or E223 in question.

3. Turn the ignition switch ON.

4. Select EXTERNAL LAMP of IP DM E/R active test item.

5. With EXTERNAL LAMP ON, check the voltage betw een the combination lamp connector E212 or E223

terminal 1 and ground. LO : Headlamp ON

OFF : Headlamp OFF

Unit Location Fuse No. Capacity

Headlamp LO (RH) IPDM E/R 36 15A

Headlamp LO (L H) IPDM E/R 37 15A

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2360 of 4801

EXL-94

< DTC/CIRCUIT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

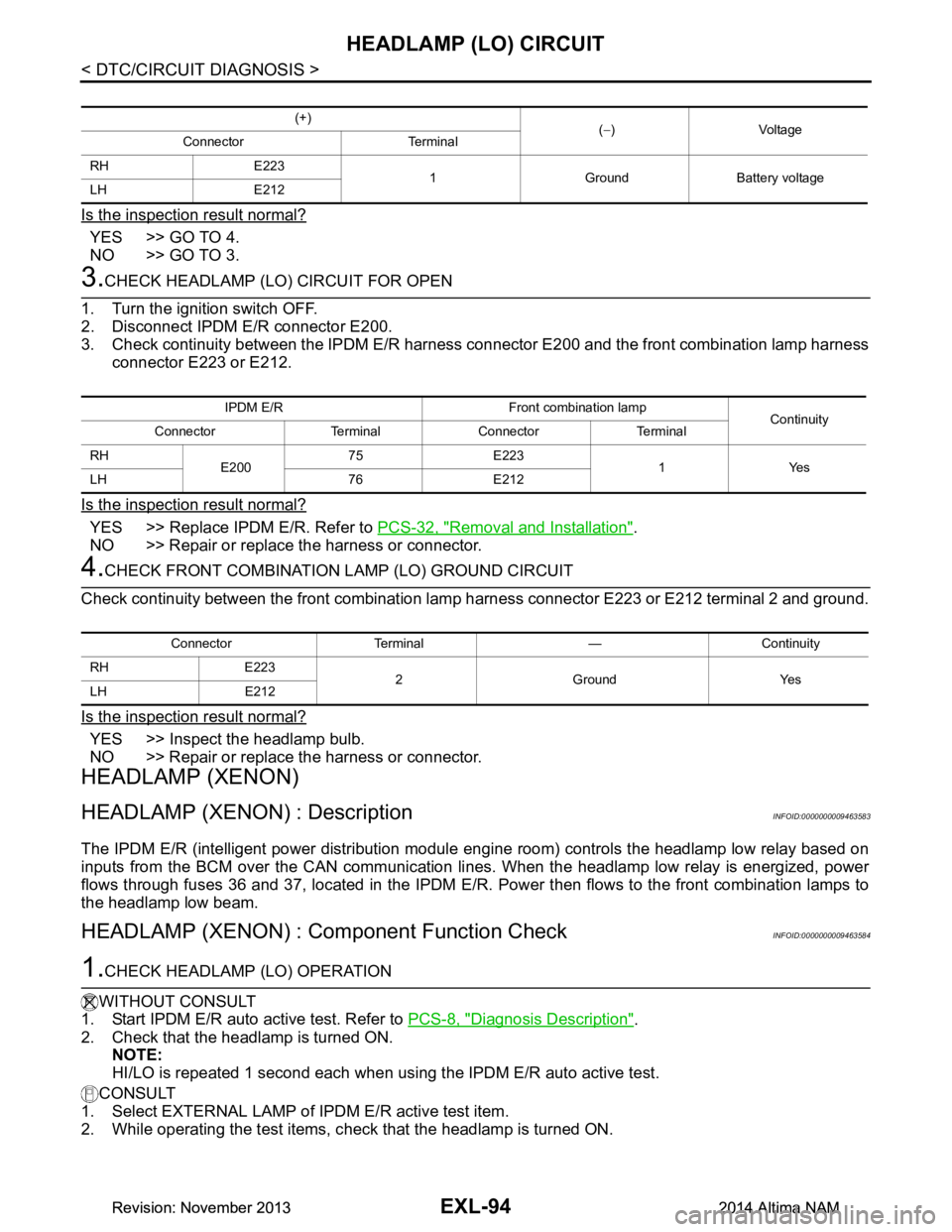

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E200.

3. Check continuity between the IPDM E/R harness c onnector E200 and the front combination lamp harness

connector E223 or E212.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace the harness or connector.

4.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination la mp harness connector E223 or E212 terminal 2 and ground.

Is the inspection result normal?

YES >> Inspect the headlamp bulb.

NO >> Repair or replace the harness or connector.

HEADLAMP (XENON)

HEADLAMP (XENON) : DescriptionINFOID:0000000009463583

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM over the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 36 and 37, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp low beam.

HEADLAMP (XENON) : Component Function CheckINFOID:0000000009463584

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the headlamp is turned ON. NOTE:

HI/LO is repeated 1 second each when usi ng the IPDM E/R auto active test.

CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, c heck that the headlamp is turned ON.

(+)

(− )Voltage

Connector Terminal

RH E223 1 Ground Battery voltage

LH E212

IPDM E/R Front combination lamp Continuity

Connector Terminal Connector Terminal

RH E20075 E223

1Yes

LH 76 E212

Connector Terminal — Continuity

RH E223 2GroundYes

LH E212

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM