fuse NISSAN TEANA 2014 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 913 of 4801

REMOTE KEYLESS ENTRY RECEIVERDLK-145

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

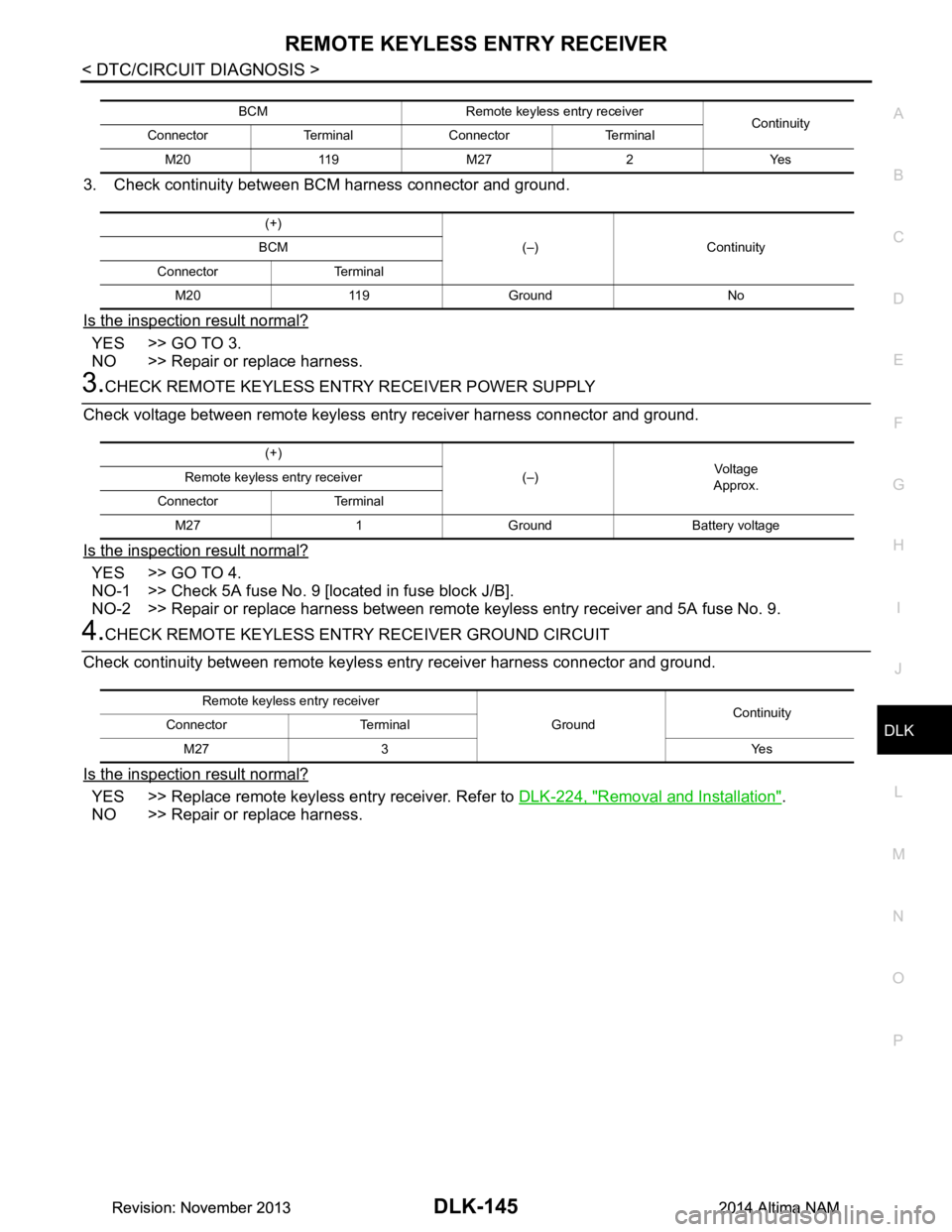

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK REMOTE KEYLESS ENTRY RECEIVER POWER SUPPLY

Check voltage between remote keyless entry receiver harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO-1 >> Check 5A fuse No. 9 [located in fuse block J/B].

NO-2 >> Repair or replace harness between remote keyless entry receiver and 5A fuse No. 9.

4.CHECK REMOTE KEYLESS ENTR Y RECEIVER GROUND CIRCUIT

Check continuity between remote keyles s entry receiver harness connector and ground.

Is the inspection result normal?

YES >> Replace remote keyless entry receiver. Refer to DLK-224, "Removal and Installation".

NO >> Repair or replace harness.

BCM Remote keyless entry receiver Continuity

Connector Terminal Connector Terminal

M20 119 M27 2 Yes

(+) (–) Continuity

BCM

Connector Terminal M20 119 Ground No

(+) (–)Vo l ta g e

Approx.

Remote keyless entry receiver

Connector Terminal M27 1 Ground Battery voltage

Remote keyless entry receiver GroundContinuity

Connector Terminal

M27 3 Yes

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 918 of 4801

DLK-150

< DTC/CIRCUIT DIAGNOSIS >

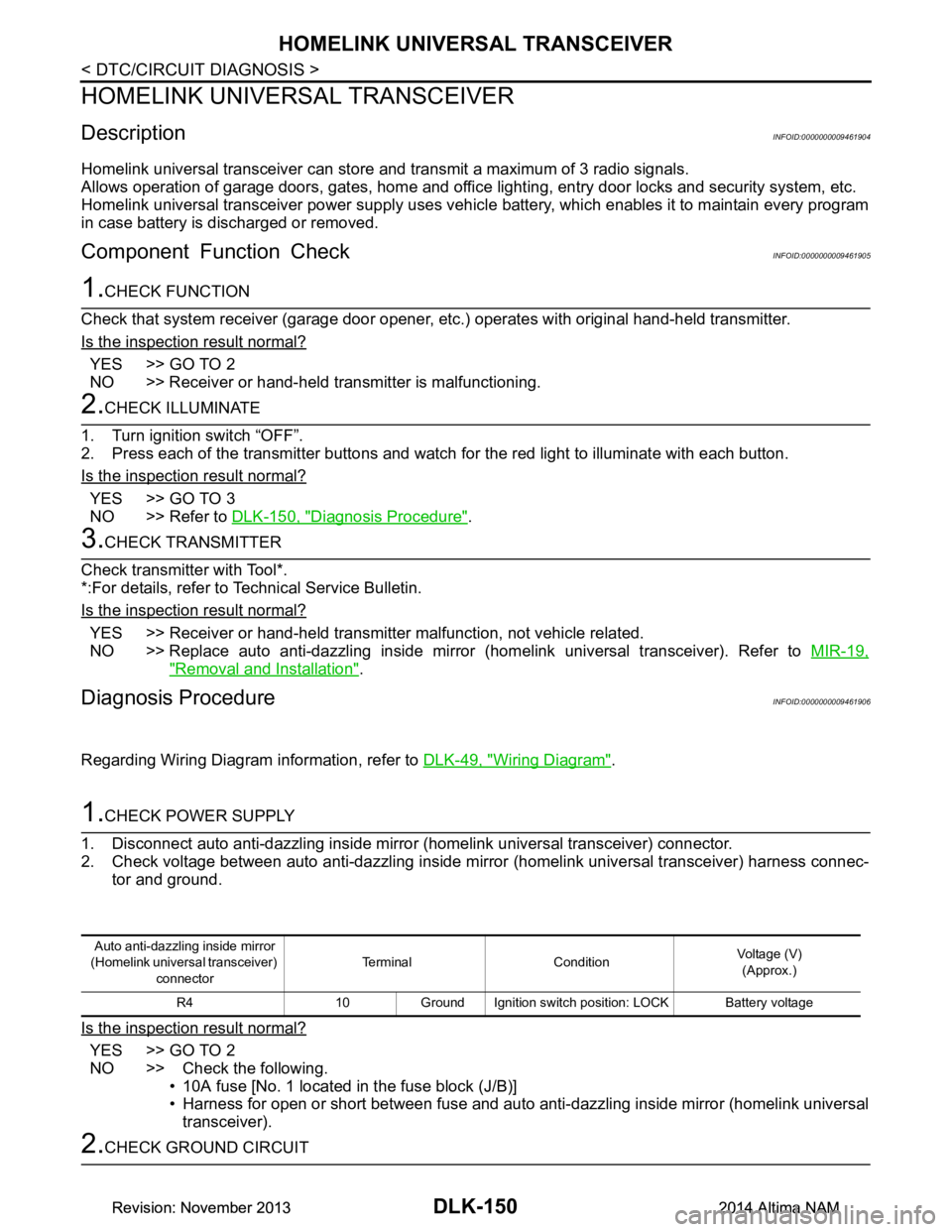

HOMELINK UNIVERSAL TRANSCEIVER

HOMELINK UNIVERSAL TRANSCEIVER

DescriptionINFOID:0000000009461904

Homelink universal transceiver can store and transmit a maximum of 3 radio signals.

Allows operation of garage doors, gates, home and office lighting, entry door locks and security system, etc.

Homelink universal transceiver power supply uses vehicl e battery, which enables it to maintain every program

in case battery is discharged or removed.

Component Function CheckINFOID:0000000009461905

1.CHECK FUNCTION

Check that system receiver (garage door opener, et c.) operates with original hand-held transmitter.

Is the inspection result normal?

YES >> GO TO 2

NO >> Receiver or hand-held transmitter is malfunctioning.

2.CHECK ILLUMINATE

1. Turn ignition switch “OFF”.

2. Press each of the transmitter buttons and watch for the red light to illuminate with each button.

Is the inspection result normal?

YES >> GO TO 3

NO >> Refer to DLK-150, "Diagnosis Procedure"

.

3.CHECK TRANSMITTER

Check transmitter with Tool*.

*:For details, refer to Technical Service Bulletin.

Is the inspection result normal?

YES >> Receiver or hand-held transmitter malfunction, not vehicle related.

NO >> Replace auto anti-dazzling inside mirror (homelink universal transceiver). Refer to MIR-19,

"Removal and Installation".

Diagnosis ProcedureINFOID:0000000009461906

Regarding Wiring Diagram information, refer to DLK-49, "Wiring Diagram".

1.CHECK POWER SUPPLY

1. Disconnect auto anti-dazzling inside mirror (homelink universal transceiver) connector.

2. Check voltage between auto anti-dazzling inside mirror (homelink universal transceiver) harness connec-

tor and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check the following. • 10A fuse [No. 1 located in the fuse block (J/B)]

• Harness for open or short between fuse and auto anti-dazzling inside mirror (homelink universal

transceiver).

2.CHECK GROUND CIRCUIT

Auto anti-dazzling inside mirror

(Homelink universal transceiver) connector Terminal Condition

Voltage (V)

(Approx.)

R4 10 Ground Ignition switch position: LOCK Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1032 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-32

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Air Fuel Ratio (A/F) Sensor 1

INFOID:0000000009462072

The sensor element of the A/F sensor 1 is composed an electrode

layer, which transports ion NISSAN TEANA 2014 Workshop Manual

EC-32

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Air Fuel Ratio (A/F) Sensor 1

INFOID:0000000009462072

The sensor element of the A/F sensor 1 is composed an electrode

layer, which transports ion](/img/5/57390/w960_57390-1031.png)

EC-32

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Air Fuel Ratio (A/F) Sensor 1

INFOID:0000000009462072

The sensor element of the A/F sensor 1 is composed an electrode

layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the lean and rich range. Together with its

control electronics, the sensor outputs a cl ear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusi on layer at the sensor cell. An electrode layer is

applied voltage, and this current relati ve oxygen density in lean. Also this current relative hydrocarbon density

in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In additi on, a heater is integrated in the

sensor to ensure the required operating temperature of approxi-

mately 760 °C (1,400 °F).

A/F SENSOR 1 HEATER

A/F sensor 1 heater is integrated in the sensor.

The ECM performs ON/OFF duty control of the A/F sensor 1 heater corresponding to the engine operating

condition to keep the temperature of A/F s ensor 1 element within the specified range.

Heated Oxygen Sensor 2INFOID:0000000009462073

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1 V in richer conditions to 0 V in leaner con-

ditions.

Under normal conditions the heated ox ygen sensor 2 is not used for

engine control operation.

HEATED OXYGEN SENSOR 2 HEATER

Heated oxygen sensor 2 heater is integrated in the sensor.

The ECM performs ON/OFF control of the heated oxy gen sensor 2 heater corresponding to the engine speed,

amount of intake air and engine coolant temperature.

JPBIA4038GB

JPBIA5446GB

SEF327R

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1182 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-182

< BASIC INSPECTION >[QR25DE]

FUEL PRESSURE

FUEL PRESSURE

Work ProcedureINFOID:0000000009462142

FUEL PRESSURE RELEASE

1.FUEL PRESSURE RELEASE

With CONSULT

1. Turn ignition switch ON.

2. Perfor NISSAN TEANA 2014 Workshop Manual

EC-182

< BASIC INSPECTION >[QR25DE]

FUEL PRESSURE

FUEL PRESSURE

Work ProcedureINFOID:0000000009462142

FUEL PRESSURE RELEASE

1.FUEL PRESSURE RELEASE

With CONSULT

1. Turn ignition switch ON.

2. Perfor](/img/5/57390/w960_57390-1181.png)

EC-182

< BASIC INSPECTION >[QR25DE]

FUEL PRESSURE

FUEL PRESSURE

Work ProcedureINFOID:0000000009462142

FUEL PRESSURE RELEASE

1.FUEL PRESSURE RELEASE

With CONSULT

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEA SE” in “WORK SUPPORT” mode of “ENGINE” using CONSULT.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

Without CONSULT

1. Remove fuel pump fuse located in IPDM E/R. For the fuse number, refer to EC-117, "Wiring Diagram"

. For

the fuse arrangement, refer to PG-72, "Fuse, Connector and Terminal Arrangement"

.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

>> END

FUEL PRESSURE CHECK

CAUTION:

Before disconnecting fuel line, release fuel pr essure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because th is models do not have fuel return system.

• Use Fuel Pressure Gauge Kit [SST: (J-44321)] to check fuel pressure.

1.FUEL PRESSURE CHECK

1. Release fuel pressure to zero.

2. Connect fuel tube adapter [SST:KV10120000] (B) to quick con-

nector.

3. Turn ignition switch ON and check for fuel leakage.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK FUEL HOSES AND FUEL TUBES

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES >> Replace “fuel filter and fuel pump assembly”. Refer to FL-6, "Removal and Installation".

NO >> Repair or replace error-detected parts.

A : Fuel pressure gauge

C : Fuel feed hose

: Vehicle front

At idling : Approximately 350 kPa (3.57 kg/cm2, 51 psi)

ALBIA0811ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1203 of 4801

![NISSAN TEANA 2014 Workshop Manual

POWER SUPPLY AND GROUND CIRCUITEC-203

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462152

1.CHECK FUSE

Check NISSAN TEANA 2014 Workshop Manual

POWER SUPPLY AND GROUND CIRCUITEC-203

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462152

1.CHECK FUSE

Check](/img/5/57390/w960_57390-1202.png)

POWER SUPPLY AND GROUND CIRCUITEC-203

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000009462152

1.CHECK FUSE

Check that the following fuse is not fusing.

Is the fuse fusing?

YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to GI-46, "Circuit Inspection"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace ground connection.

3.CHECK ECM GROUND CIRCUIT

1. Disconnect ECM harness connectors.

2. Check the continuity between ECM harness connector and ground.

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ECM POWER SUPPLY (MAIN)-1

1. Reconnect ECM harness connector.

2. Turn ignition switch ON.

3. Check the voltage between ECM harness connector terminals.

*1: Except for California

*2: For California

Location Fuse No. Capacity

IPDM E/R #38 10 A

#56 10 A

+ −Continuity

ECM

Connector Terminal

F14

*1

F91*2

12

Ground Existed

16

F13

*1

F90*252

E10

*1

E31*2128

ECM Vo l ta g e

Connector +

−

Te r m i n a l

E10

*1

E31*2121 128 Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1320 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-320

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0300, P0301,

P0302, P0303, P0304 MISFIRE

4.CHECK FUNCTION OF FUEL INJECTOR

1. Start engine and let engine idle.

2. Listen to each fuel injector operating s NISSAN TEANA 2014 Workshop Manual

EC-320

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0300, P0301,

P0302, P0303, P0304 MISFIRE

4.CHECK FUNCTION OF FUEL INJECTOR

1. Start engine and let engine idle.

2. Listen to each fuel injector operating s](/img/5/57390/w960_57390-1319.png)

EC-320

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0300, P0301,

P0302, P0303, P0304 MISFIRE

4.CHECK FUNCTION OF FUEL INJECTOR

1. Start engine and let engine idle.

2. Listen to each fuel injector operating sound.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Perform trouble diagnosis for FUEL INJECTOR. Refer

to EC-505, "Diagnosis Procedure"

.

5.CHECK FUNCTION OF IGNITION COIL-1

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

Do not use CONSULT to release fuel pressure, or fuel pressure applies again during the following proce-

dure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoi d the electrical discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50 cm (19.7 in). Be car eful not to get an electrical

shock while checking, becau se the electrical discharge

voltage becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 6.

6.CHECK FUNCTION OF IGNITION COIL-2

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Is the inspection result normal?

Clicking noise should be heard.

PBIB3332E

Spark should be generated.

JMBIA0066GB

Spark should be generated.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1334 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-334

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0420 THREE WAY CATALYST FUNCTION

Diagnosis Procedure

INFOID:0000000009462268

1.CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

Is th NISSAN TEANA 2014 Workshop Manual

EC-334

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0420 THREE WAY CATALYST FUNCTION

Diagnosis Procedure

INFOID:0000000009462268

1.CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

Is th](/img/5/57390/w960_57390-1333.png)

EC-334

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P0420 THREE WAY CATALYST FUNCTION

Diagnosis Procedure

INFOID:0000000009462268

1.CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before the three way catalyst (manifold).

Is exhaust gas leak detected?

YES >> Repair or replace error-detected parts.

NO >> GO TO 3.

3.CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected?

YES >> Repair or replace error-detected parts.

NO >> GO TO 4.

4.CHECK IGNITION TIMING AND IDLE SPEED

Check the following items. Refer to EC-170, "Work Procedure"

.

For specification, refer to EC-541, "Ignition Timing"

For specification, refer to EC-541, "Idle Speed".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Follow the EC-170, "Work Procedure"

.

5.CHECK FUEL INJECTOR

Check the fuel injector. Refer to EC-505, "Component Function Check"

.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Perform EC-505, "Diagnosis Procedure"

.

6.CHECK FUNCTION OF IGNITION COIL-1

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure. NOTE:

Do not use CONSULT to release fuel pressure, or fuel pressure applies again during the following proce-

dure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoi d the electrical discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

PBIB1216E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1420 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-420

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P117A AIR FUEL RATIO

Perform the following procedure in a place with

no combustible objects and good ventilation.

1. Turn ignition switch OFF.

2. Confirm th NISSAN TEANA 2014 Workshop Manual

EC-420

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P117A AIR FUEL RATIO

Perform the following procedure in a place with

no combustible objects and good ventilation.

1. Turn ignition switch OFF.

2. Confirm th](/img/5/57390/w960_57390-1419.png)

EC-420

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P117A AIR FUEL RATIO

Perform the following procedure in a place with

no combustible objects and good ventilation.

1. Turn ignition switch OFF.

2. Confirm that the engine is cooled down and there are no fire hazards near the vehicle.

3. Disconnect all fuel injector harness connectors.

4. Remove fuel tube assembly. Refer to EM-41, "Removal and Installation"

.

Keep fuel hose and all fuel injectors connected to fuel tube.

5. Disconnect all ignition coil harness connectors.

6. Prepare pans or saucers under each fuel injector.

7. Crank engine for approximately 3 seconds.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Replace fuel injector. Refer to EM-41, "Removal and

Installation".

7.CHECK FUNCTION OF IGNITION COIL-1

CAUTION:

Perform the following steps in a well -ventilated area with no combustibles.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse from IPDM E/R to release fuel pressure.

NOTE:

CONSULT must not be used to release fuel pressu re. It develops again during the following steps,

if released by using CONSULT.

3. Start the engine.

4. After an engine stall, crank the engine two or three times to release all the fuel pressure.

5. Turn ignition switch OFF.

6. Disconnect all the harness connectors of ignition coil to prevent electric discharge from occurring in igni-

tion coil.

7. Remove ignition coil assembly and spark plug of cylinder. Refer to EM-40, "Removal and Installation"

.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Allow a 13-17mm (0.52-0.66 in) spacing between spark plug and

grounded metal portion as shown in the figure to fix the ignition

coil with a rope or an equivalent.

11. Crank the engine for approximately 3 seconds to see if sparking occurs between spark plug and the grounded metal portion.

CAUTION:

• The discharge voltage becomes 20 kV or higher. There- fore, always stay away from the spark plug and ignition

coil at least 50 cm (19.7 in) during the inspection.

• Leaving a space of more than 17mm (0.66 in) may damage the ignition coil.

NOTE:

When the gap is less than 13 mm (0.52 in), a the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 10.

8.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-26, "Compression pressure"

.

Is the inspection result normal?

• Fuel should be sprayed evenly for each fuel injector.

• Fuel must not drip from the tip of fuel injector.

PBIA9666J

Spark should be generated.

JMBIA0066GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1496 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-496

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

BRAKE PEDAL POSITION SWITCH

BRAKE PEDAL POSITION SWITCH

Component Function CheckINFOID:0000000009462428

1.CHECK BRAKE PEDAL POSI

TION SWITCH FUNCTION

With CO NISSAN TEANA 2014 Workshop Manual

EC-496

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

BRAKE PEDAL POSITION SWITCH

BRAKE PEDAL POSITION SWITCH

Component Function CheckINFOID:0000000009462428

1.CHECK BRAKE PEDAL POSI

TION SWITCH FUNCTION

With CO](/img/5/57390/w960_57390-1495.png)

EC-496

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

BRAKE PEDAL POSITION SWITCH

BRAKE PEDAL POSITION SWITCH

Component Function CheckINFOID:0000000009462428

1.CHECK BRAKE PEDAL POSI

TION SWITCH FUNCTION

With CONSULT

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “D ATA MONITOR” mode with CONSULT.

3. Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals.

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to EC-496, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009462429

1.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect brake pedal position switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between brake pedal pos ition switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect fuse block (J/B) harness connector.

3. Check the continuity between brake pedal position switch harness connector and fuse block (J/B) harness connector.

Monitor item Condition Indication

BRAKE SW1 Brake pedal Slightly depressed OFF

Fully released ON

ECM Condition Voltage

Connector +–

Te r m i n a l

E10

*1

E31*2116 128 Brake pedal Slightly depressed Approx. 0 V

Fully released Battery voltage

+ -Voltage

Brake pedal position switch

Connector Terminal E51 1 Ground Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1497 of 4801

![NISSAN TEANA 2014 Workshop Manual

BRAKE PEDAL POSITION SWITCHEC-497

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> Perform the trouble diagnosis for power supply circuit.

NISSAN TEANA 2014 Workshop Manual

BRAKE PEDAL POSITION SWITCHEC-497

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> Perform the trouble diagnosis for power supply circuit.](/img/5/57390/w960_57390-1496.png)

BRAKE PEDAL POSITION SWITCHEC-497

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between brake pedal posit ion switch harness connector and ECM harness connec-

tor.

*1: Except for California

*2: For California

4. Also check harness for short to ground and to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK BRAKE PEDAL POSITION SWITCH

Check brake pedal position switch. Refer to EC-497, "Component Inspection (Brake Pedal Position Switch)"

.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-43, "Intermittent Incident".

NO >> Replace brake pedal position switch. Refer to BR-18, "Exploded View"

.

Component Inspection (Brake Pedal Position Switch)INFOID:0000000009462430

1.CHECK BRAKE PEDAL POSITION SWITCH-1

1. Turn ignition switch OFF.

2. Disconnect brake pedal position harness connector.

3. Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH-2

1. Adjust brake pedal position switch installation. Refer to BR-13, "Inspection and Adjustment"

.

2. Check the continuity between brake pedal position switch terminals as per the following conditions.

++

Continuity

Brake pedal position switch Fuse block (J/B)

Connector Terminal Connector Terminal E51 1 E6 1M Existed

++ Continuity

Brake pedal position switch ECM

Connector Terminal Connector Terminal

E51 2 E10

*1

E31*2116 Existed

Brake pedal position switch

Condition Continuity

+ −

Te r m i n a l s

1 2 Brake pedal Fully released Existed

Slightly de-

pressed Not existed

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM