engine NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 1 of 4801

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

O

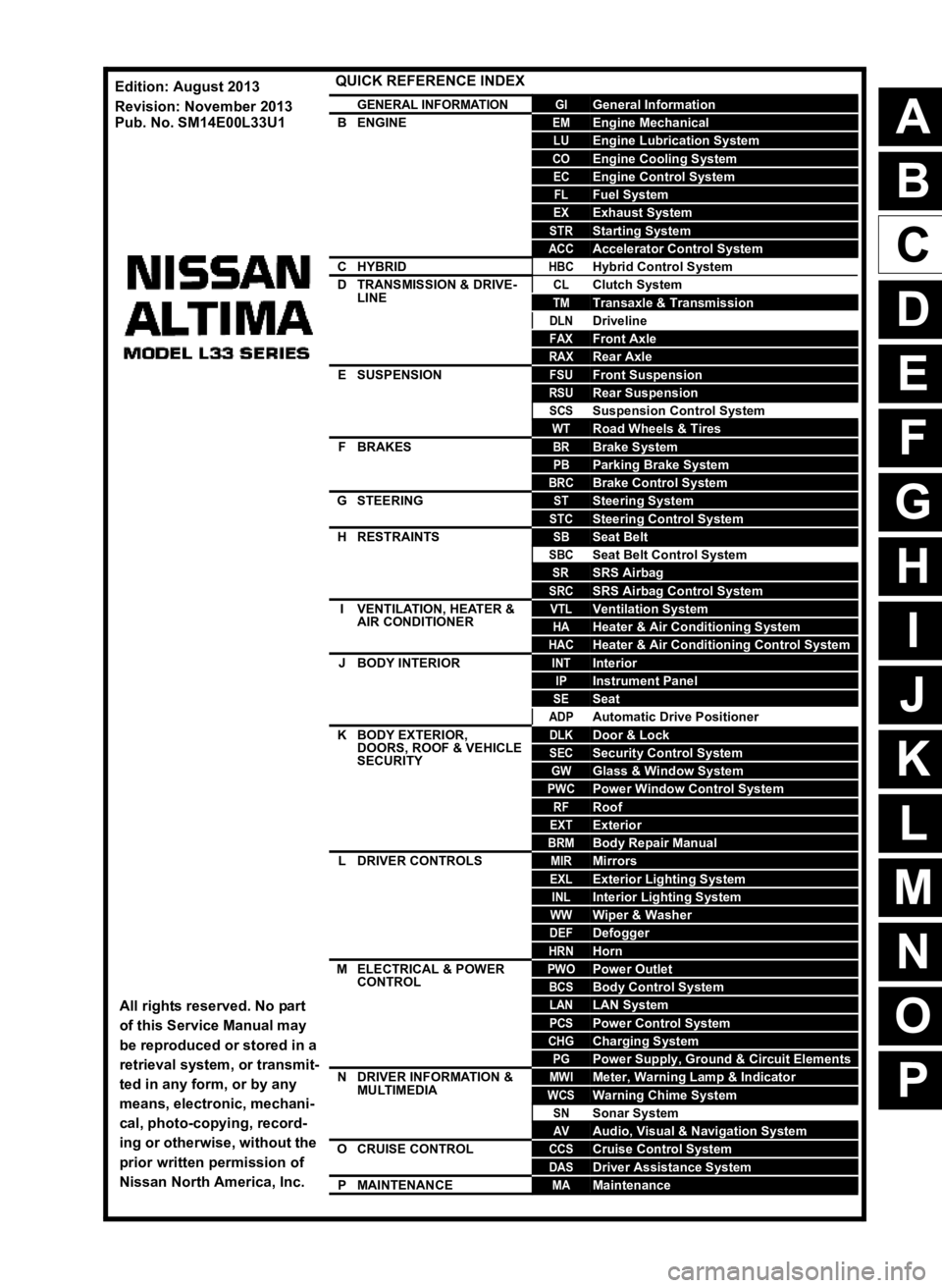

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

DTRANSMISSION & DRIVE-LINECLClutch System

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR, DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

EXTExterior

BRMBody Repair Manual

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROLCCSCruise Control System

DASDriver Assistance System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, photo-copying, record-

ing or otherwise, without the

prior written permission of

Nissan North America, Inc.

Edition: August 2013

Revision: November 2013

Pub. No. SM14E00L33U1

Page 4 of 4801

< SERVICE DATA AND SPECIFICATIONS (SDS) 2014

QUICK REFERENCE CHART: ALTIMA

QUICK REFERENCE CHART: ALTIMA

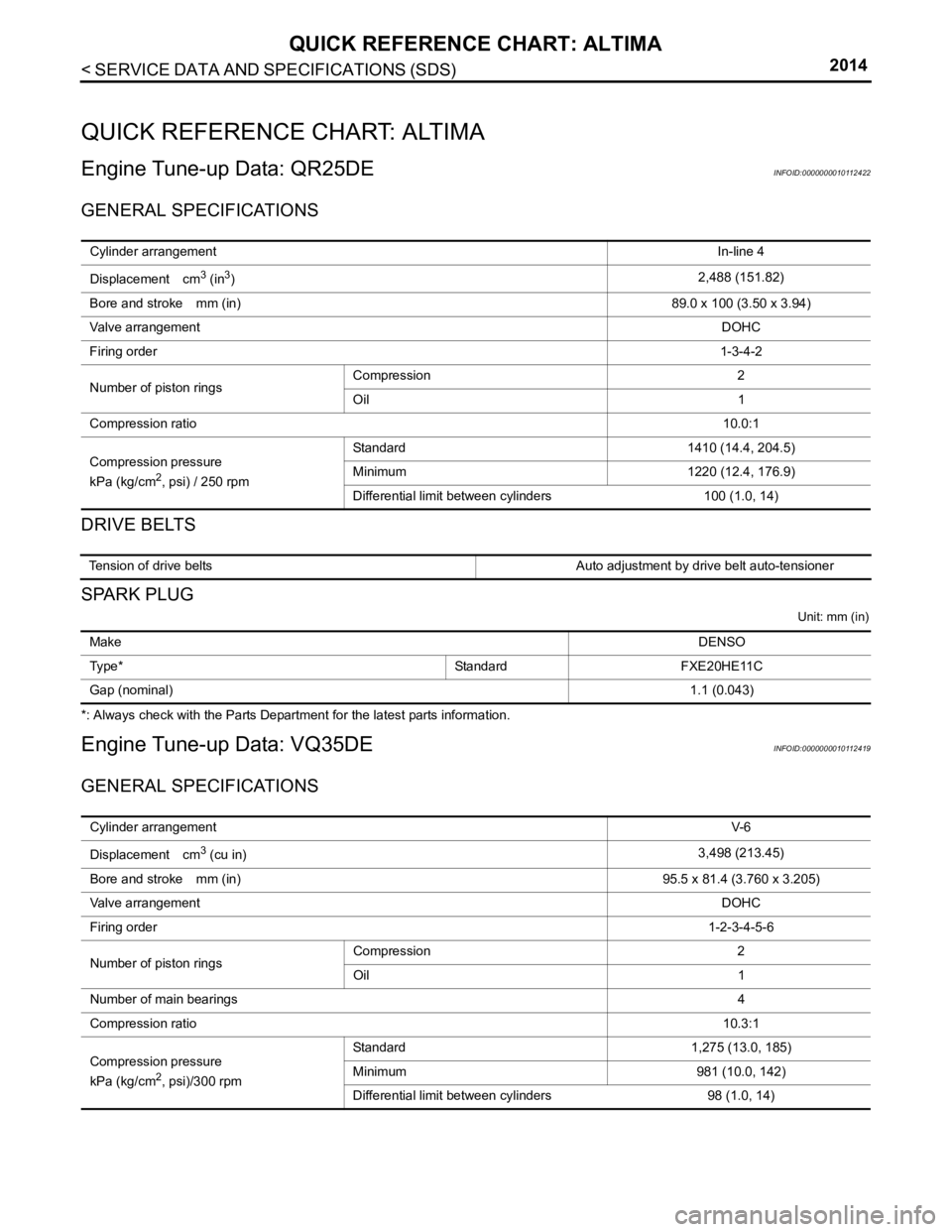

Engine Tune-up Data: QR25DEINFOID:0000000010112422

GENERAL SPECIFICATIONS

DRIVE BELTS

SPARK PLUG

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Engine Tune-up Data: VQ35DEINFOID:0000000010112419

GENERAL SPECIFICATIONS

Cylinder arrangement

In-line 4

Displacement cm

3 (in3) 2,488 (151.82)

Bore and stroke mm (in) 89.0 x 100 (3.50 x 3.94)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression

2

Oil 1

Compression ratio 10.0:1

Compression pressure

kPa (kg/cm

2, psi) / 250 rpm Standard 1410 (14.4, 204.5)

Minimum

1220 (12.4, 176.9)

Differential limit between cylinders 100 (1.0, 14)

Tension of drive belts Auto adjustment by drive belt auto-tensioner

Make DENSO

Type* StandardFXE20HE11C

Gap (nominal) 1.1 (0.043)

Cylinder arrangement V-6

Displacement cm

3 (cu in) 3,498 (213.45)

Bore and stroke mm (in) 95.5 x 81.4 (3.760 x 3.205)

Valve arrangement DOHC

Firing order 1-2-3-4-5-6

Number of piston rings Compression 2

Oil 1

Number of main bearings 4

Compression ratio 10.3:1

Compression pressure

kPa (kg/cm

2, psi)/300 rpm Standard 1,275 (13.0, 185)

Minimum

981 (10.0, 142)

Differential limit between cylinders 98 (1.0, 14)

Page 5 of 4801

QUICK REFERENCE CHART: ALTIMA

2014

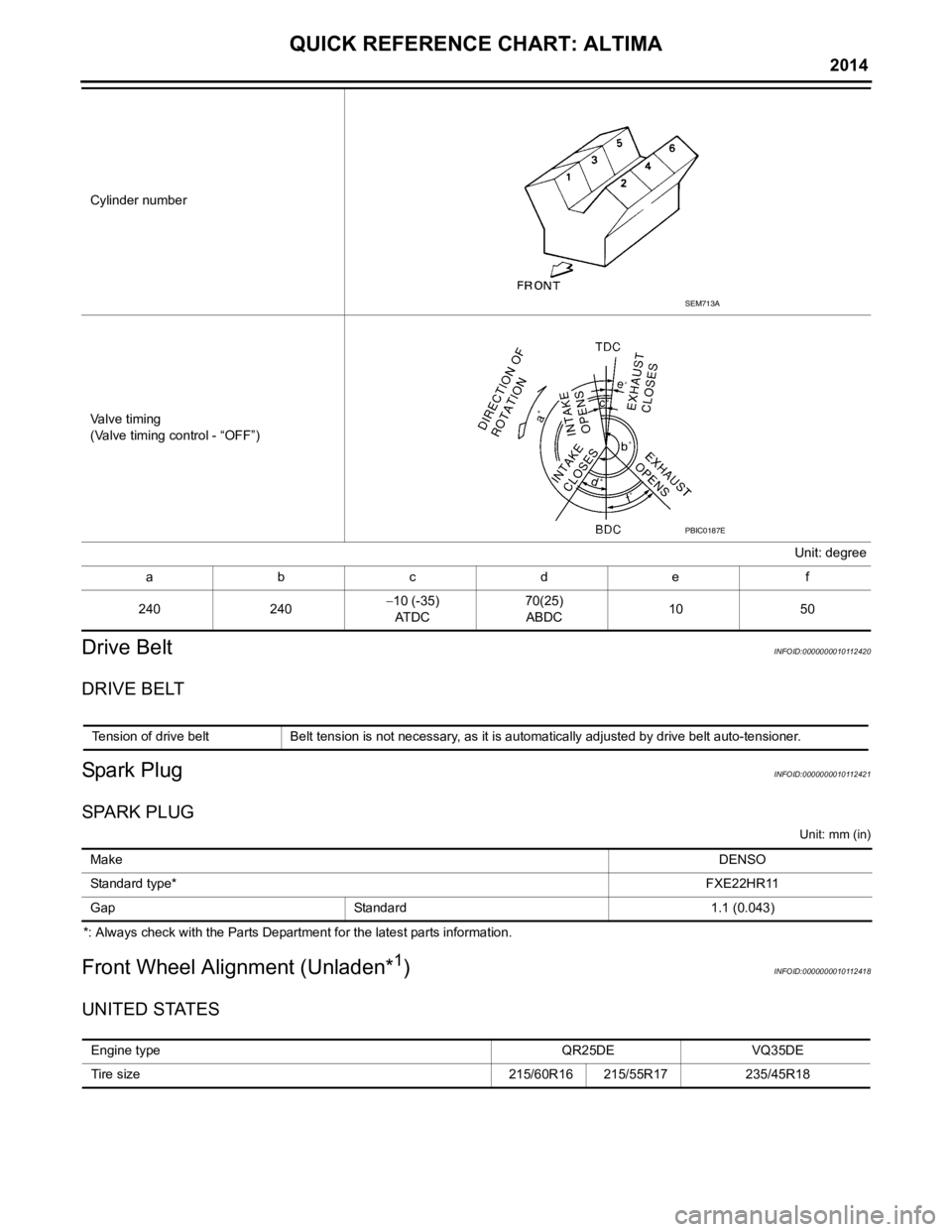

Drive BeltINFOID:0000000010112420

DRIVE BELT

Spark PlugINFOID:0000000010112421

SPARK PLUG

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Front Wheel Alignment (Unladen*1)INFOID:0000000010112418

UNITED STATES

Cylinder number

Valve timing

(Valve timing control - “OFF”)Unit: degree

abcde f

240 240−

10 (-35)

AT D C 70(25)

ABDC 10

50

SEM713A

PBIC0187E

Tension of drive belt Belt tension is not necessary, as it is automatically adjusted by drive belt auto-tensioner.

Make DENSO

Standard type* FXE22HR11

Gap Standard 1.1 (0.043)

Engine type QR25DEVQ35DE

Tire size 215/60R16 215/55R17235/45R18

Page 6 of 4801

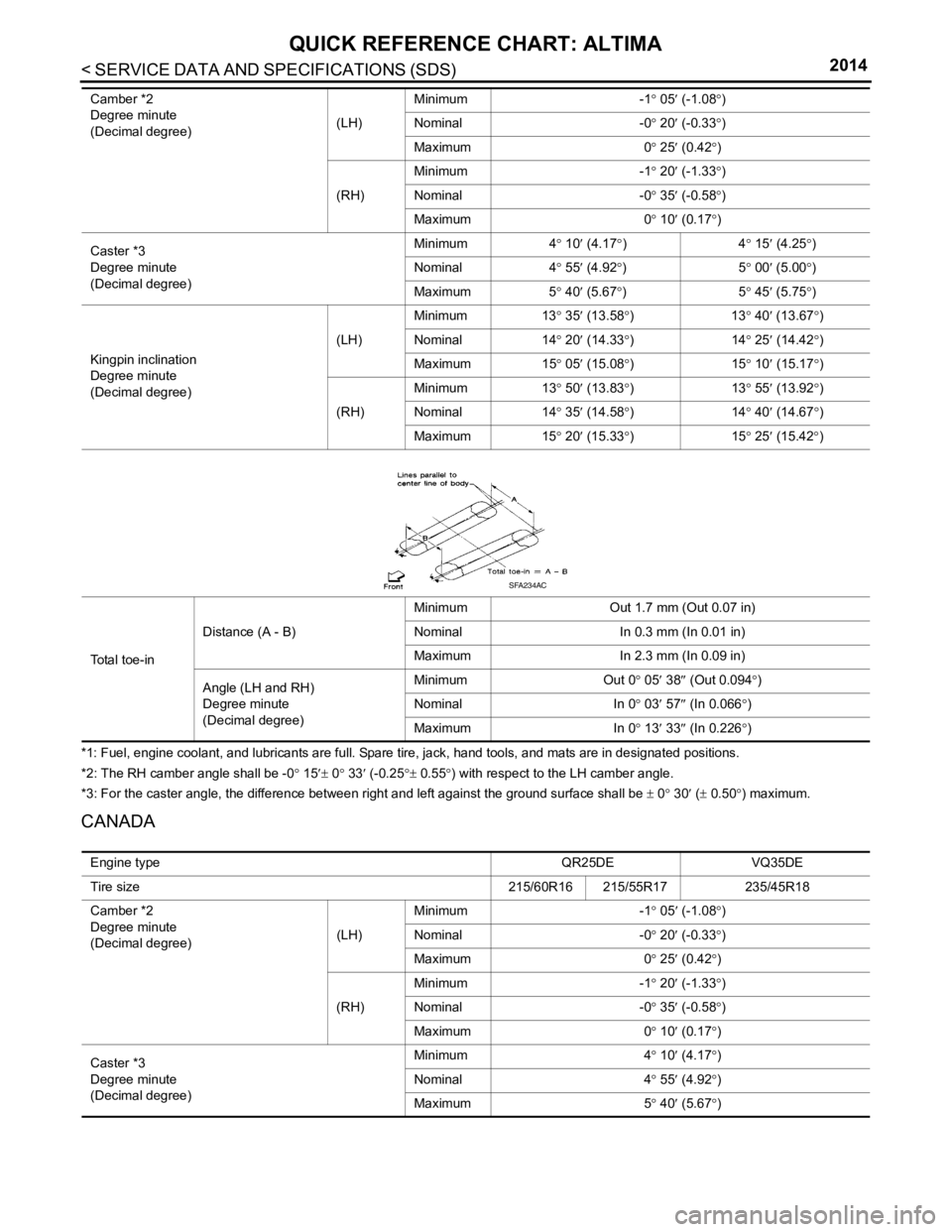

< SERVICE DATA AND SPECIFICATIONS (SDS) 2014

QUICK REFERENCE CHART: ALTIMA

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

*2: The RH camber angle shall be -0

° 15 ′± 0 ° 33 ′ (-0.25 °± 0.55° ) with respect to the LH camber angle.

*3: For the caster angle, the difference between right and left against the ground surface shall be ± 0 ° 30 ′ ( ± 0.50° ) maximum.

CANADA

Camber *2

Degree minute

(Decimal degree) (LH)Minimum

-1° 05 ′ (-1.08 °)

Nominal -0° 20 ′ (-0.33 °)

Maximum 0° 25 ′ (0.42 °)

(RH) Minimum

-1° 20 ′ (-1.33 °)

Nominal -0° 35 ′ (-0.58 °)

Maximum 0° 10 ′ (0.17 °)

Caster *3

Degree minute

(Decimal degree) Minimum

4° 10 ′ (4.17 °)4 ° 15 ′ (4.25 °)

Nominal 4° 55 ′ (4.92 °)5 ° 00 ′ (5.00 °)

Maximum 5° 40 ′ (5.67 °)5 ° 45 ′ (5.75 °)

Kingpin inclination

Degree minute

(Decimal degree) (LH)

Minimum

13° 35 ′ (13.58 °)1 3° 40 ′ (1

3.67 °)

Nominal 14° 20 ′ (14.33 °)1 4° 25 ′ (14.42 °)

Maximum 15° 05 ′ (15.08 °)1 5° 10 ′ (15.17 °)

(RH) Minimum

13° 50 ′ (13.83 °)1 3° 55 ′ (13.92 °)

Nominal 14° 35 ′ (14.58 °)1 4° 40 ′ (14.67 °)

Maximum 15° 20 ′ (15.33 °)1 5° 25 ′ (15.42 °)

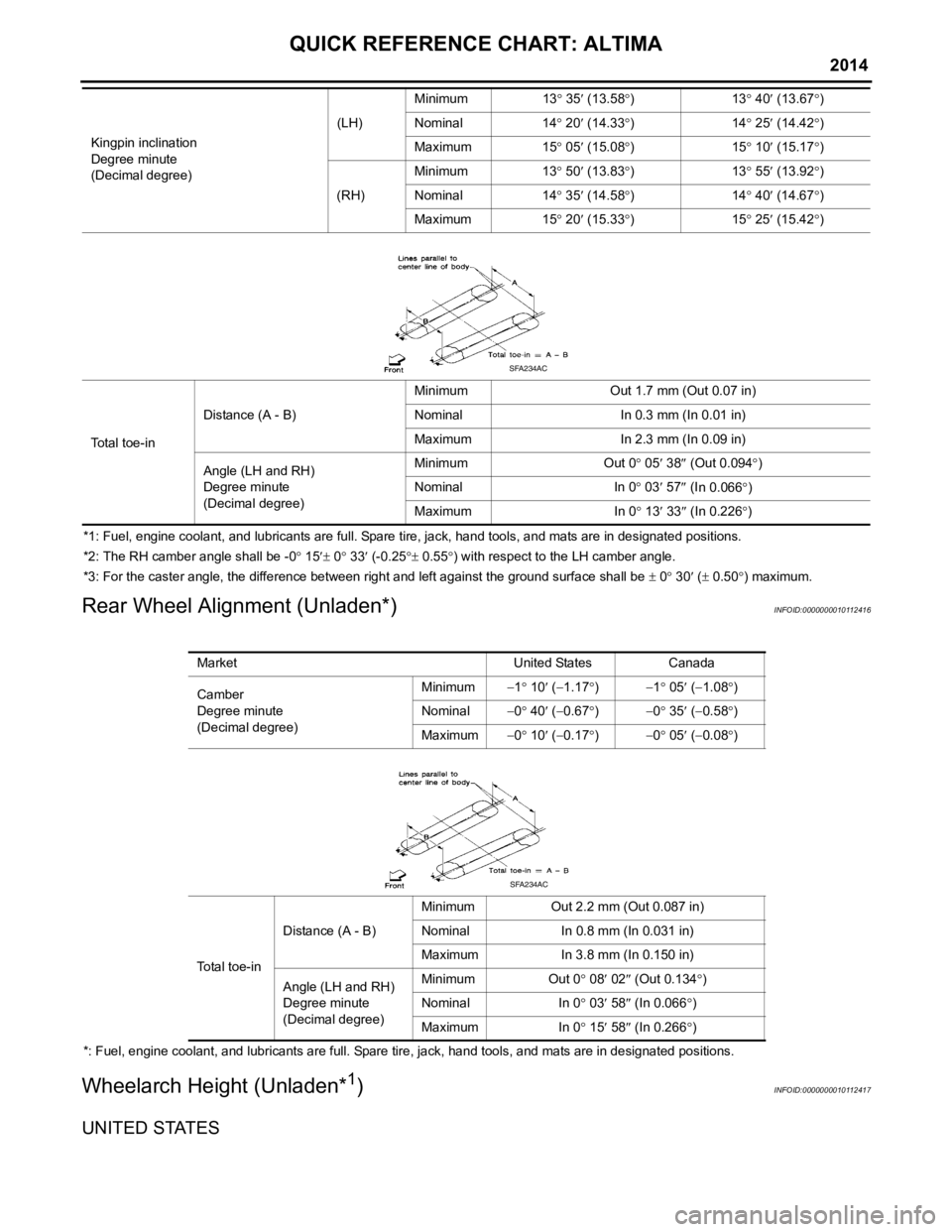

Total toe-in Distance (A - B)

Minimum

Out 1.7 mm (Out 0.07 in)

Nominal In 0.3 mm (In 0.01 in)

Maximum In 2.3 mm (In 0.09 in)

Angle (LH and RH)

Degree minute

(Decimal degree) Minimum

Out 0° 05′ 38 ″ (Out 0.094° )

Nominal In 0° 03 ′ 57 ″ (In 0.066 °)

Maximum In 0° 13′ 33 ″ (In 0.2

26 °)

SFA234AC

Engine type QR25DEVQ35DE

Tire size 215/60R16 215/55R17235/45R18

Camber *2

Degree minute

(Decimal degree) (LH)Minimum

-1° 05 ′ (-1.08 °)

Nominal -0° 20 ′ (-0.33 °)

Maximum 0° 25 ′ (0.42 °)

(RH) Minimum

-1° 20 ′ (-1.33 °)

Nominal -0° 35 ′ (-0.58 °)

Maximum 0° 10 ′ (0.17 °)

Caster *3

Degree minute

(Decimal degree) Minimum

4° 10 ′ (4.17 °)

Nominal 4° 55 ′ (4.92 °)

Maximum 5° 40 ′ (5.67 °)

Page 7 of 4801

QUICK REFERENCE CHART: ALTIMA

2014

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

*2: The RH camber angle shall be -0° 15 ′± 0 ° 33′ (-0.25 °± 0.55 °) with respect to the LH camber angle.

*3: For the caster angle, the difference between right and left against the ground surface shall be ± 0 ° 30 ′ ( ± 0.50 °) maximum.

Rear Wheel Alignment (Unladen*)INFOID:0000000010112416

*: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

Wheelarch Height (Unladen*1)INFOID:0000000010112417

UNITED STATES

Kingpin inclination

Degree minute

(Decimal degree) (LH)

Minimum

13° 35 ′ (13.58 °)1 3° 40 ′ (13.67 °)

Nominal 14° 20 ′ (14.33 °)1 4° 25 ′ (14.42 °)

Maximum 15° 05 ′ (15.08 °)1 5° 10 ′ (15.17 °)

(RH) Minimum

13° 50 ′ (13.83 °)1 3° 55 ′ (13.92 °)

Nominal 14° 35 ′ (14.58 °)1 4° 40 ′ (14.67 °)

Maximum 15° 20 ′ (15.33 °)1 5° 25 ′ (15.42 °)

To t a l t o e - i n Distance (A - B)

Minimum

Out 1.7 mm (Out 0.07 in)

Nominal In 0.3 mm (In 0.01 in)

Maximum In 2.3 mm (In 0.09 in)

Angle (LH and RH)

Degree minute

(Decimal degree) Minimum

Out 0° 05 ′ 38 ″ (Out 0.094 °)

Nominal In 0° 03 ′ 57 ″ (I

n 0.066 °)

Maximum In 0° 13 ′ 33 ″ (In 0.226 °)

SFA234AC

Market United StatesCanada

Camber

Degree minute

(Decimal degree) Minimum

−1° 10 ′ ( −1.17 °) −1 ° 05 ′ ( −1.08° )

Nominal −0° 40 ′ ( −0.67 °) −0 ° 35 ′ ( −0.58° )

Maximum −0° 10 ′ ( −0.17 °) −0 ° 05 ′ ( −0.08° )

Total toe-in Distance (A - B)

Minimum

Out 2.2 mm (Out 0.087 in)

Nominal In 0.8 mm (In 0.031 in)

Maximum In 3.8 mm (In 0.150 in)

Angle (LH and RH)

Degree minute

(Decimal degree) Minimum

Out 0° 08′ 02 ″ (Out 0.134° )

Nominal In 0° 03 ′ 58 ″ (In 0.066 °)

Maximum In 0° 15′ 58 ″ (In 0.266 °)

SFA234AC

Page 8 of 4801

< SERVICE DATA AND SPECIFICATIONS (SDS) 2014

QUICK REFERENCE CHART: ALTIMA

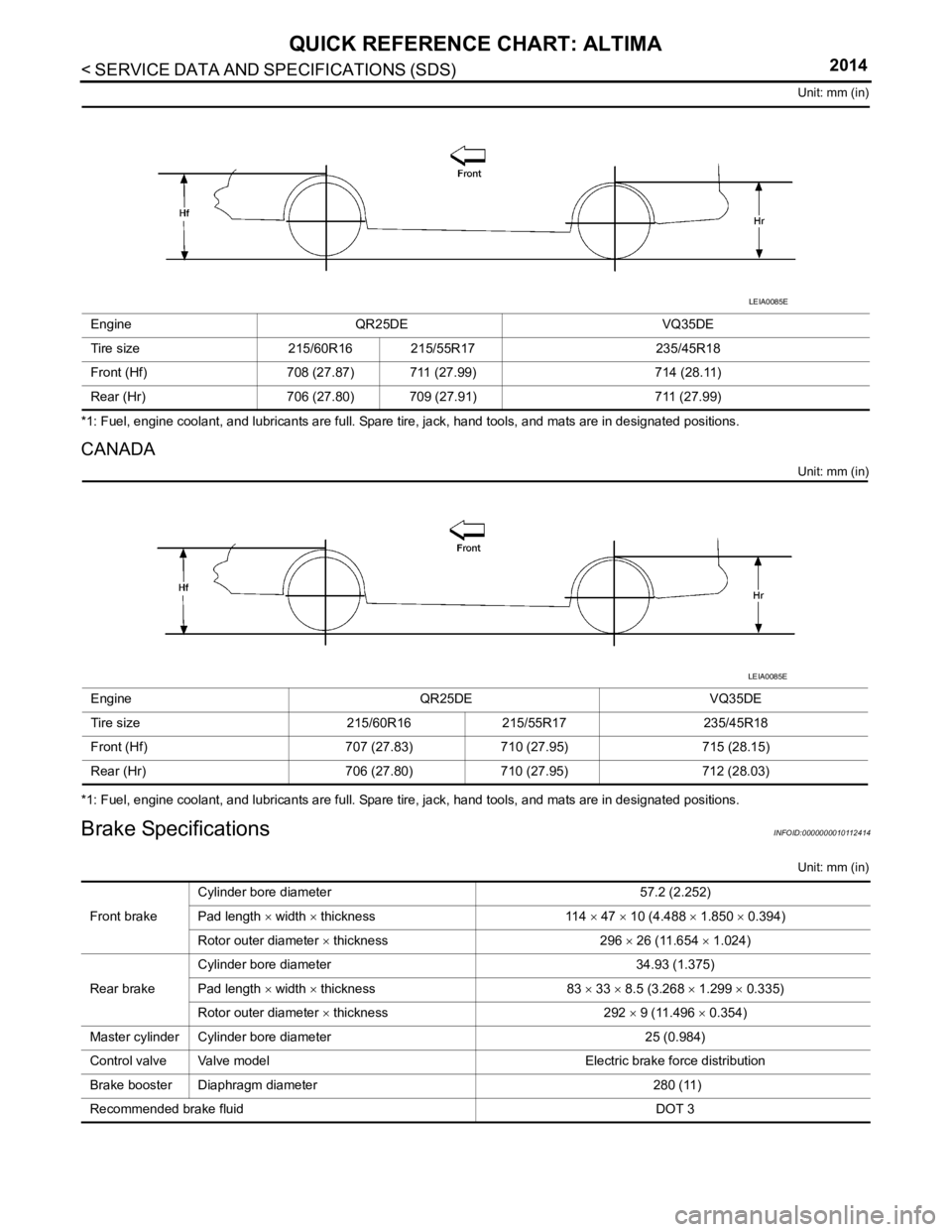

Unit: mm (in)

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

CANADA

Unit: mm (in)

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

Brake SpecificationsINFOID:0000000010112414

Unit: mm (in)

Engine

QR25DE VQ35DE

Tire size 215/60R16 215/55R17 235/45R18

Front (Hf) 708 (27.87) 711 (27.99) 714 (28.11)

Rear (Hr) 706 (27.80) 709 (27.91) 711 (27.99)

LEIA0085E

EngineQR25DEVQ35DE

Tire size 215/60R16215/55R17 235/45R18

Front (Hf) 707 (27.83)710 (27.95) 715 (28.15)

Rear (Hr) 706 (27.80)710 (27.95) 712 (28.03)

LEIA0085E

Front brakeCylinder bore diameter

57.2 (2.252)

Pad length × width × thickness 114 × 47 × 10 (4.488 × 1.850 × 0.394)

Rotor outer diameter × thickness 296 × 26 (11.654 × 1.024)

Rear brake Cylinder bore diameter

34.93 (1.375)

Pad length × width × thickness 83 × 33 × 8.5 (3.268 × 1.299 × 0.335)

Rotor outer diameter × thickness 292 × 9 (11.496 × 0.354)

Master cylinder Cylinder bore diameter 25 (0.984)

Control valve Valve model Electric brake force distribution

Brake booster Diaphragm diameter 280 (11)

Recommended brake fluid DOT 3

Page 10 of 4801

< SERVICE DATA AND SPECIFICATIONS (SDS) 2014

QUICK REFERENCE CHART: ALTIMA

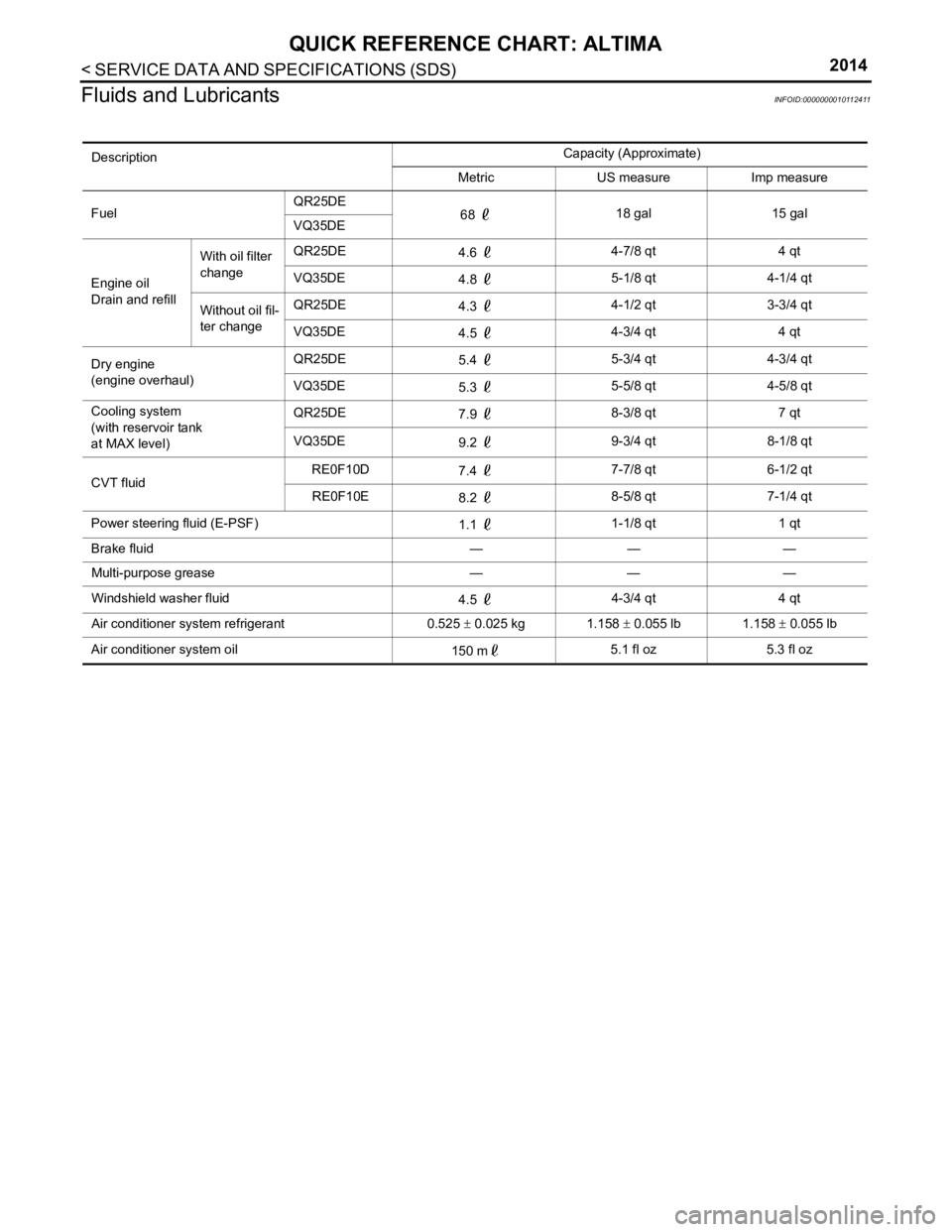

Fluids and Lubricants

INFOID:0000000010112411

Description Capacity (Approximate)

Metric US measure Imp measure

Fuel QR25DE

68 18 gal

15 gal

VQ35DE

Engine oil

Drain and refill With oil filter

change

QR25DE

4.6 4-7/8 qt

4 qt

VQ35DE 4.8 5-1/8 qt

4-1/4 qt

Without oil fil-

ter change QR25DE

4.3 4-1/2 qt

3-3/4 qt

VQ35DE 4.5 4-3/4 qt

4 qt

Dry engine

(engine overhaul) QR25DE

5.4 5-3/4 qt

4-3/4 qt

VQ35DE 5.3 5-5/8 qt

4-5/8 qt

Cooling system

(with reservoir tank

at MAX level) QR25DE

7.9 8-3/8 qt

7 qt

VQ35DE 9.2 9-3/4 qt

8-1/8 qt

CVT fluid RE0F10D

7.4 7-7/8 qt

6-1/2 qt

RE0F10E 8.2 8-5/8 qt

7-1/4 qt

Power steering fluid (E-PSF) 1.1 1-1/8 qt

1 qt

Brake fluid ———

Multi-purpose grease ———

Windshield washer fluid 4.5 4-3/4 qt

4 qt

Air conditioner system refrigerant 0.525 ± 0.025 kg 1.158 ± 0.055 lb 1.158 ± 0.055 lb

Air conditioner system oil 150 m5.1 fl oz

5.3 fl oz

Page 11 of 4801

ACC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION ACC

A

ACC

N

O P

CONTENTS

ACCELERATOR CONTROL SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

REMOVAL AND INSTALLATION ................3

ACCELERATOR CONTROL SYSTEM .......... .....3

Exploded View ..................................................... .....3

Removal and Installation ..........................................3

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..............................................

5

SERVICE DATA AND SPECIFICATIONS

(SDS) ..................................................................

5

Accelerator Control .............................................. .....5

Revision: November 20132014 Altima NAM

Page 12 of 4801

ACC-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951695

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: November 20132014 Altima NAM

Page 18 of 4801

![NISSAN TEANA 2014 Service Manual

BCS

PRECAUTIONSBCS-3

< PRECAUTION > [BCM]

C

D E

F

G H

I

J

K L

B

A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00 NISSAN TEANA 2014 Service Manual

BCS

PRECAUTIONSBCS-3

< PRECAUTION > [BCM]

C

D E

F

G H

I

J

K L

B

A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00](/img/5/57390/w960_57390-17.png)

BCS

PRECAUTIONSBCS-3

< PRECAUTION > [BCM]

C

D E

F

G H

I

J

K L

B

A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951595

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM