oil level NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 10 of 4801

< SERVICE DATA AND SPECIFICATIONS (SDS) 2014

QUICK REFERENCE CHART: ALTIMA

Fluids and Lubricants

INFOID:0000000010112411

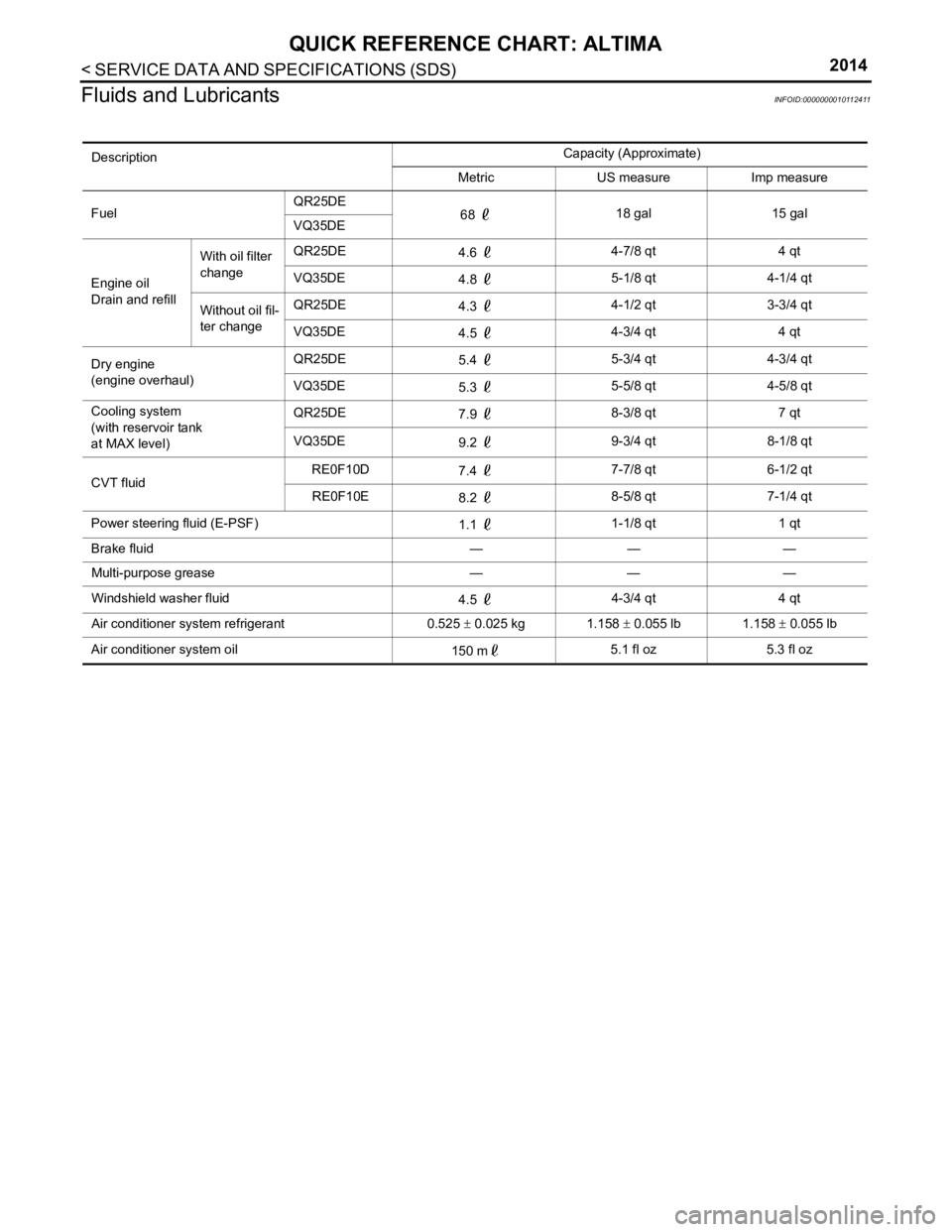

Description Capacity (Approximate)

Metric US measure Imp measure

Fuel QR25DE

68 18 gal

15 gal

VQ35DE

Engine oil

Drain and refill With oil filter

change

QR25DE

4.6 4-7/8 qt

4 qt

VQ35DE 4.8 5-1/8 qt

4-1/4 qt

Without oil fil-

ter change QR25DE

4.3 4-1/2 qt

3-3/4 qt

VQ35DE 4.5 4-3/4 qt

4 qt

Dry engine

(engine overhaul) QR25DE

5.4 5-3/4 qt

4-3/4 qt

VQ35DE 5.3 5-5/8 qt

4-5/8 qt

Cooling system

(with reservoir tank

at MAX level) QR25DE

7.9 8-3/8 qt

7 qt

VQ35DE 9.2 9-3/4 qt

8-1/8 qt

CVT fluid RE0F10D

7.4 7-7/8 qt

6-1/2 qt

RE0F10E 8.2 8-5/8 qt

7-1/4 qt

Power steering fluid (E-PSF) 1.1 1-1/8 qt

1 qt

Brake fluid ———

Multi-purpose grease ———

Windshield washer fluid 4.5 4-3/4 qt

4 qt

Air conditioner system refrigerant 0.525 ± 0.025 kg 1.158 ± 0.055 lb 1.158 ± 0.055 lb

Air conditioner system oil 150 m5.1 fl oz

5.3 fl oz

Page 122 of 4801

BR-26

< REMOVAL AND INSTALLATION >

BRAKE MASTER CYLINDER

BRAKE MASTER CYLINDER

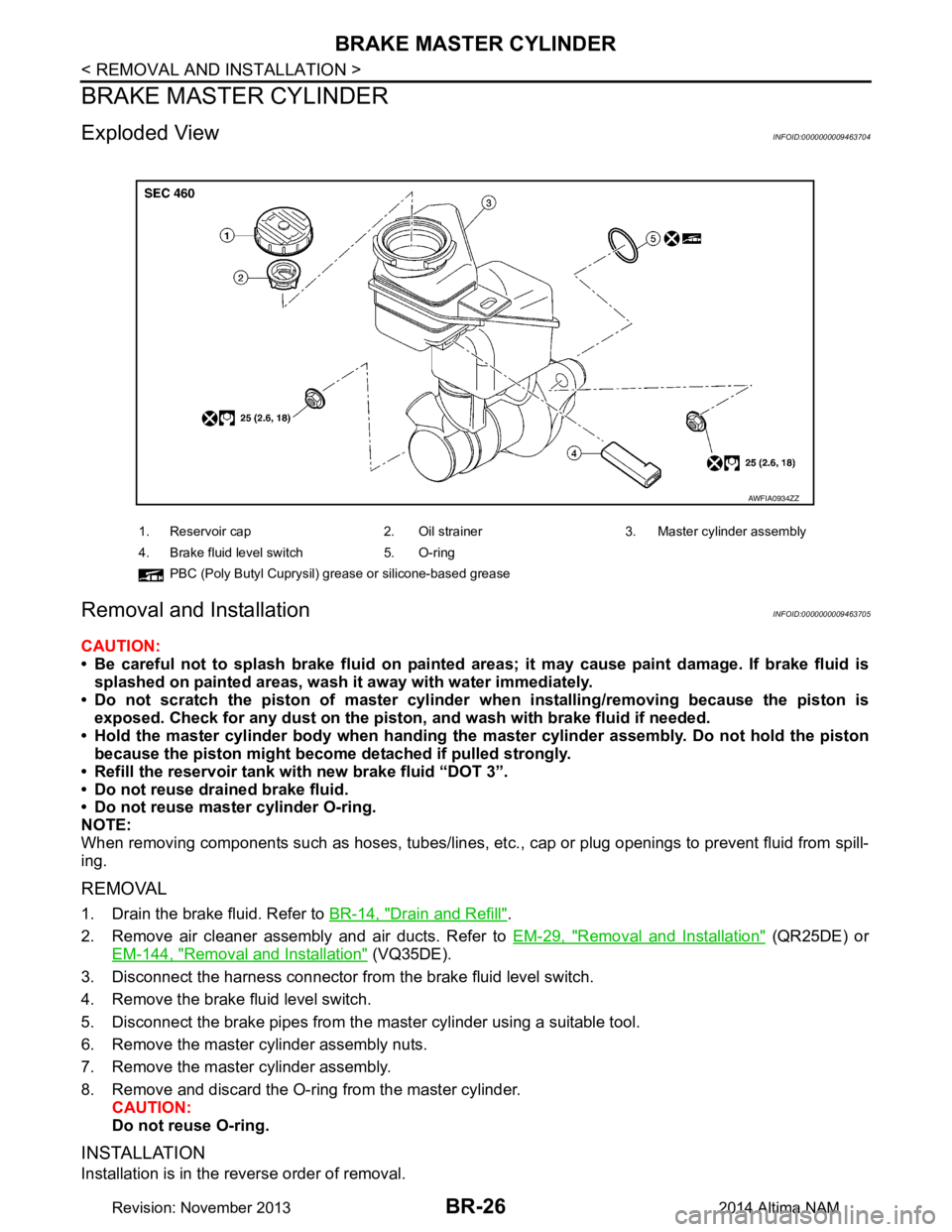

Exploded ViewINFOID:0000000009463704

Removal and InstallationINFOID:0000000009463705

CAUTION:

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Do not scratch the piston of master cylinder when installing/removing because the piston is

exposed. Check for any dust on the piston , and wash with brake fluid if needed.

• Hold the master cylinder body when handing the master cylinder assembly. Do not hold the piston

because the piston might become detached if pulled strongly.

• Refill the reservoir tank wi th new brake fluid “DOT 3”.

• Do not reuse drained brake fluid.

• Do not reuse master cylinder O-ring.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Drain the brake fluid. Refer to BR-14, "Drain and Refill".

2. Remove air cleaner assembly and air ducts. Refer to EM-29, "Removal and Installation"

(QR25DE) or

EM-144, "Removal and Installation"

(VQ35DE).

3. Disconnect the harness connector from the brake fluid level switch.

4. Remove the brake fluid level switch.

5. Disconnect the brake pipes from the master cylinder using a suitable tool.

6. Remove the master cylinder assembly nuts.

7. Remove the master cylinder assembly.

8. Remove and discard the O-ring from the master cylinder. CAUTION:

Do not reuse O-ring.

INSTALLATION

Installation is in the reverse order of removal.

1. Reservoir cap 2. Oil strainer 3. Master cylinder assembly

4. Brake fluid level switch 5. O-ring PBC (Poly Butyl Cuprysil) grease or silicone-based grease

AWFIA0934ZZ

Revision: November 20132014 Altima NAM

Page 427 of 4801

![NISSAN TEANA 2014 Service Manual

WATER PUMPCO-47

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

4. Turn the crankshaft pulley approximately 20

° clockwise so that

the timing chain on the timing chain tension NISSAN TEANA 2014 Service Manual

WATER PUMPCO-47

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

4. Turn the crankshaft pulley approximately 20

° clockwise so that

the timing chain on the timing chain tension](/img/5/57390/w960_57390-426.png)

WATER PUMPCO-47

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

4. Turn the crankshaft pulley approximately 20

° clockwise so that

the timing chain on the timing chain tensioner side is loose.

5. Apply engine oil to the oil feed hole and timing chain tensioner and install the timing chain tensioner.

6. Remove the stopper pin (A).

7. Install valve timing control cover (bank 1) and water pump cover.

a. Before installing, remove all traces of liquid gasket from mating surface of water pump cover and IVT cover using a scraper.

Also remove traces of liquid gasket from the mating surface of the front cover.

b. Apply a continuous bead of liquid gasket to mating surface of IVT cover and water pump cover. Use Gen-

uine RTV Silicone Sealant or equivalent. Refer to GI-21, "Recommended Chemical Products and

Sealants".

CAUTION:

• Installation should be done within 5 minutes afte r applying liquid gasket.

• Do not fill the engine with oil for at least 30 minutes after the co mponents are installed to allow

the sealant to cure.

8. Install water drain plug (A) and copper sealing washer (B). CAUTION:

Do not reuse copper sealing washers.

9. Installation of remaining components is in the reverse order of removal. • After installation, refill coolant and check for leaks. Refer to CO-36, "Changing Engine Coolant"

and CO-

35, "System Inspection".

CAUTION:

Do not spill coolant in en gine compartment. Use a sh op cloth to absorb coolant.

• After starting engine, let idle for three minutes, then rev engine up to 3,000 rpm under no load to purge air from the high-pressure chamber of the chai n tensioner. The engine may produce a rattling noise.

This indicates that air still remains in the chamber and is not a matter of concern.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "FOR USA AND CANADA : Fluids and Lubricants"

.

PBIC0848E

AWBIA0905ZZ

: Front

Water drain plug (A) : Refer to EM-224, "Disas-

sembly and Assembly".

AWBIA1202GB

Revision: November 20132014 Altima NAM

Page 428 of 4801

![NISSAN TEANA 2014 Service Manual

CO-48

< REMOVAL AND INSTALLATION >[VQ35DE]

WATER PUMP

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, NISSAN TEANA 2014 Service Manual

CO-48

< REMOVAL AND INSTALLATION >[VQ35DE]

WATER PUMP

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping,](/img/5/57390/w960_57390-427.png)

CO-48

< REMOVAL AND INSTALLATION >[VQ35DE]

WATER PUMP

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Transmission/

transaxle fluid CVT Models Leakage Level/Leakage Leakage

Other oils and fluids* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gas — Leakage —

Revision: November 20132014 Altima NAM

Page 471 of 4801

![NISSAN TEANA 2014 Service Manual

DAS-38

< BASIC INSPECTION >[ITS CONTROL UNIT]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464665

Always perform the calibration after removing and installing NISSAN TEANA 2014 Service Manual

DAS-38

< BASIC INSPECTION >[ITS CONTROL UNIT]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464665

Always perform the calibration after removing and installing](/img/5/57390/w960_57390-470.png)

DAS-38

< BASIC INSPECTION >[ITS CONTROL UNIT]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464665

Always perform the calibration after removing and installing or replacing the rear view camera.

CAUTION:

• Place the vehicle on level ground wh en the calibration is performed.

• Follow the CONSULT when performing the calib ration. (Rear view camera calibration cannot be

operated without CONSULT).

Work Procedure (Preparation)INFOID:0000000009464666

1.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis of the ITS control unit.

Is any DTC detected?

Except "U1308">> Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to

DAS-20, "DTC Index"

.

"U1308" or no DTC>> GO TO 2.

2.PREPARATION BEFORE REAR VIEW CAMERA CALIBRATION

NOTE:

Select the "AVM" to diagnose the ITS control unit by CONSULT.

1. Perform pre-inspection for diagnosis. Refer to DAS-34, "Inspection Procedure"

.

2. Adjust the tire pressure to the specified pressure value.

3. Maintain no-load in vehicle.

4. Check if coolant and engine oil are filled up to correct level and fuel tank is full.

5. Situate vehicle where the camera is ex posed at an atmosphere temperature between 0 °C (32 °F) and

30 °C (86 °F)

6. Move the shift selector to P (Park) and release the parking brake.

7. Clean the rear view camera.

>> GO TO 3.

3.PREPARATION OF CALIBRATION TARGET MARK

Prepare the calibration target mark according to the following figure:

ALOIA0186ZZ

(1) : Left and right targets

(2) : Center target

(A) : Side of the black or white area = 200 mm (7.87 in)

(B) : Side of the square target = 400 mm (15.75 in)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 540 of 4801

![NISSAN TEANA 2014 Service Manual

DAS

REAR VIEW CAMERA CALIBRATIONDAS-107

< BASIC INSPECTION > [LDW]

C

D E

F

G H

I

J

K L

M B

N P

A

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464741

Always perform the calibration after NISSAN TEANA 2014 Service Manual

DAS

REAR VIEW CAMERA CALIBRATIONDAS-107

< BASIC INSPECTION > [LDW]

C

D E

F

G H

I

J

K L

M B

N P

A

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464741

Always perform the calibration after](/img/5/57390/w960_57390-539.png)

DAS

REAR VIEW CAMERA CALIBRATIONDAS-107

< BASIC INSPECTION > [LDW]

C

D E

F

G H

I

J

K L

M B

N P

A

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464741

Always perform the calibration after removing and installing or replacing the rear view camera.

CAUTION:

• Place the vehicle on level ground when the calibration is performed.

• Follow the CONSULT when performing the calib ration. (Rear view camera calibration cannot be

operated without CONSULT).

Work Procedure (Preparation)INFOID:0000000009464742

1.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis of the ITS control unit.

Is any DTC detected?

Except "U1308">> Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to

DAS-89, "DTC Index"

.

"U1308" or no DTC>>GO TO 2.

2.PREPARATION BEFORE REAR VIEW CAMERA CALIBRATION

NOTE:

Select the "AVM" to diagnose the ITS control unit by CONSULT.

1. Perform pre-inspection for diagnosis. Refer to DAS-103, "Inspection Procedure"

.

2. Adjust the tire pressure to the specified pressure value.

3. Maintain no-load in vehicle.

4. Check if coolant and engine oil are filled up to correct level and fuel tank is full.

5. Situate vehicle where the camera is ex posed at an atmosphere temperature between 0 °C (32 °F) and

30 °C (86 °F)

6. Move the shift selector to P (Park) and release the parking brake.

7. Clean the rear view camera.

>> GO TO 3.

3.PREPARATION OF CALIBRATION TARGET MARK

Prepare the calibration target mark according to the following figure:

ALOIA0186ZZ

(1) : Left and right targets

(2) : Center target

(A) : Side of the black or white area = 200 mm (7.87 in)

(B) : Side of the square target = 400 mm (15.75 in)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 615 of 4801

![NISSAN TEANA 2014 Service Manual

DAS-182

< BASIC INSPECTION >[BSW]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464825

Always perform the calibration after removing and installing or replacin NISSAN TEANA 2014 Service Manual

DAS-182

< BASIC INSPECTION >[BSW]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464825

Always perform the calibration after removing and installing or replacin](/img/5/57390/w960_57390-614.png)

DAS-182

< BASIC INSPECTION >[BSW]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464825

Always perform the calibration after removing and installing or replacing the rear view camera.

CAUTION:

• Place the vehicle on level ground wh en the calibration is performed.

• Follow the CONSULT when performing the calib ration. (Rear view camera calibration cannot be

operated without CONSULT).

Work Procedure (Preparation)INFOID:0000000009464826

1.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis of the ITS control unit.

Is any DTC detected?

Except "U1308">> Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to

DAS-164, "DTC Index"

.

"U1308" or no DTC>>GO TO 2.

2.PREPARATION BEFORE REAR VIEW CAMERA CALIBRATION

NOTE:

Select the "AVM" to diagnose the ITS control unit by CONSULT.

1. Perform pre-inspection for diagnosis. Refer to DAS-158, "CONSULT Function (AVM)"

.

2. Adjust the tire pressure to the specified pressure value.

3. Maintain no-load in vehicle.

4. Check if coolant and engine oil are filled up to correct level and fuel tank is full.

5. Situate vehicle where the camera is ex posed at an atmosphere temperature between 0 °C (32 °F) and

30 °C (86 °F)

6. Move the shift selector to P (Park) and release the parking brake.

7. Clean the rear view camera.

>> GO TO 3.

3.PREPARATION OF CALIBRATION TARGET MARK

Prepare the calibration target mark according to the following figure:

ALOIA0186ZZ

(1) : Left and right targets

(2) : Center target

(A) : Side of the black or white area = 200 mm (7.87 in)

(B) : Side of the square target = 400 mm (15.75 in)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 689 of 4801

![NISSAN TEANA 2014 Service Manual

DAS-256

< BASIC INSPECTION >[MOD]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464906

Always perform the calibration after removing and installing or replacin NISSAN TEANA 2014 Service Manual

DAS-256

< BASIC INSPECTION >[MOD]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464906

Always perform the calibration after removing and installing or replacin](/img/5/57390/w960_57390-688.png)

DAS-256

< BASIC INSPECTION >[MOD]

REAR VIEW CAMERA CALIBRATION

REAR VIEW CAMERA CALIBRATION

DescriptionINFOID:0000000009464906

Always perform the calibration after removing and installing or replacing the rear view camera.

CAUTION:

• Place the vehicle on level ground wh en the calibration is performed.

• Follow the CONSULT when performing the calib ration. (Rear view camera calibration cannot be

operated without CONSULT).

Work Procedure (Preparation)INFOID:0000000009464907

1.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis of the ITS control unit.

Is any DTC detected?

Except "U1308">> Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to

DAS-239, "DTC Index"

.

"U1308" or no DTC>>GO TO 2.

2.PREPARATION BEFORE REAR VIEW CAMERA CALIBRATION

NOTE:

Select the "AVM" to diagnose the ITS control unit by CONSULT.

1. Perform pre-inspection for diagnosis. Refer to DAS-253, "Inspection Procedure"

.

2. Adjust the tire pressure to the specified pressure value.

3. Maintain no-load in vehicle.

4. Check if coolant and engine oil are filled up to correct level and fuel tank is full.

5. Situate vehicle where the camera is ex posed at an atmosphere temperature between 0 °C (32 °F) and

30 °C (86 °F)

6. Move the shift selector to P (Park) and release the parking brake.

7. Clean the rear view camera.

>> GO TO 3.

3.PREPARATION OF CALIBRATION TARGET MARK

Prepare the calibration target mark according to the following figure:

ALOIA0186ZZ

(1) : Left and right targets

(2) : Center target

(A) : Side of the black or white area = 200 mm (7.87 in)

(B) : Side of the square target = 400 mm (15.75 in)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1001 of 4801

EC-1

ENGINE

C

D E

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

QR25DE

PRECAUTION ................ ..............................

15

PRECAUTIONS .............................................. ....15

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

15

Precaution for Procedure without Cowl Top Cover ....15

On Board Diagnostic (OBD) System of Engine

and CVT .............................................................. ....

15

General Precautions ...............................................16

PREPARATION ...........................................19

PREPARATION .............................................. ....19

Special Service Tools .......................................... ....19

Commercial Service Tools ......................................19

SYSTEM DESCRIPTION .............................21

COMPONENT PARTS ................................... ....21

Component Parts Location ................................ ....21

ECM ........................................................................25

Accelerator Pedal Position Sensor ...................... ....25

Electric Throttle Control Actuator ........................ ....25

Ignition Coil With Power Transistor .........................26

Fuel Injector ........................................................ ....26

Fuel Level Sensor Unit and Fuel Pump .............. ....26

Fuel Tank Temperature Sensor .......................... ....27

Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor) ........................................................ ....

27

Manifold Absolute Pressure Sensor ........................28

Engine Coolant Temperature Sensor .................. ....28

Crankshaft Position Sensor (POS) ..........................29

Camshaft Position Sens or (PHASE) .......................29

Intake Valve Timing Cont rol Solenoid Valve ...........30

Intake Valve Timing Intermediate Lock Control

Solenoid Valve .................................................... ....

30

Exhaust Valve Timing Control Position Sensor .......30

Exhaust Valve Timing Control Solenoid Valve ........31

Intake Manifold Runner Control Valve ................. ....31

Intake Manifold Tuning Valve ..................................31

Air Fuel Ratio (A/F) Sensor 1 ..................................32

Heated Oxygen Sensor 2 ........................................32

Knock Sensor ..........................................................33

Engine Oil Pressure Sensor ....................................33

Engine Oil Temperature Sensor .......................... ....33

Cooling Fan .............................................................34

EVAP Canister .........................................................34

EVAP Canister Purge Volu me Control Solenoid

Valve .................................................................... ....

34

EVAP Canister Vent Control Valve ..........................35

EVAP Control System Pres sure Sensor ..................35

Battery Current Sensor (With Battery Tempera-

ture Sensor) ......................................................... ....

35

Malfunction Indicator lamp (MIL) .............................36

Oil Pressure Warning Lamp ....................................36

Refrigerant Pressure Sensor ............................... ....36

Stop Lamp Switch & Brake Pedal Position Switch ....36

ASCD Steering Switch .............................................37

Information Display ..................................................37

STRUCTURE AND OPERATION .....................38

Positive Crankcase Ventilation ................................38

On Board Refueling Vapor Recovery (ORVR) ........39

SYSTEM ............................................................40

ENGINE CONTROL SYSTEM ........................ ...........40

ENGINE CONTROL SYSTEM : System Descrip-

tion ....................................................................... ....

40

ENGINE CONTROL SYSTEM : Fail Safe ..............41

MULTIPORT FUEL INJECTION SYSTEM ................43

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description (with auto matic air conditioner) ......

43

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description (with manual air conditioner) .........

46

ELECTRIC IGNITION SYSTEM .................................48

ELECTRIC IGNITION SYSTEM : System De-

scription ............................................................... ....

48

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1005 of 4801

EC-5

C

D E

F

G H

I

J

K L

M

EC A

N

O P

P0447 EVAP CANISTER VENT CONTROL

VALVE ............................................................ ..

350

DTC Logic ........................................................... ..350

Diagnosis Procedure .............................................350

Component Inspection ..........................................352

P0448 EVAP CANISTER VENT CONTROL

VALVE ............................................................ ..

354

DTC Logic ........................................................... ..354

Diagnosis Procedure .............................................355

Component Inspection ..........................................356

P0451 EVAP CONTROL SYSTEM PRES-

SURE SENSOR .............................................. ..

358

DTC Logic ........................................................... ..358

Diagnosis Procedure .............................................359

Component Inspection ..........................................361

P0452 EVAP CONTROL SYSTEM PRES-

SURE SENSOR .............................................. ..

362

DTC Logic ........................................................... ..362

Diagnosis Procedure .............................................363

Component Inspection ..........................................364

P0453 EVAP CONTROL SYSTEM PRES-

SURE SENSOR .............................................. ..

366

DTC Logic ........................................................... ..366

Diagnosis Procedure .............................................367

Component Inspection ..........................................369

P0456 EVAP CONTROL SYSTEM ..................370

DTC Logic ........................................................... ..370

Diagnosis Procedure .............................................371

Component Inspection ..........................................375

P0460 FUEL LEVEL SENSOR ........................376

DTC Logic ........................................................... ..376

Diagnosis Procedure .............................................376

P0461 FUEL LEVEL SENSOR ........................377

DTC Logic ........................................................... ..377

Component Function Check ..................................377

Diagnosis Procedure .............................................378

P0462, P0463 FUEL LEVEL SENSOR ............379

DTC Logic ........................................................... ..379

Diagnosis Procedure .............................................379

P0500 VSS .......................................................380

Description .......................................................... ..380

DTC Logic .............................................................380

Diagnosis Procedure .............................................380

P0506 ISC SYSTEM .........................................382

Description .......................................................... ..382

DTC Logic .............................................................382

Diagnosis Procedure .............................................382

P0507 ISC SYSTEM .........................................384

Description .......................................................... ..384

DTC Logic .............................................................384

Diagnosis Procedure ........................................... ..384

P050A, P050B, P050E COLD START CON-

TROL ...............................................................

386

Description ........................................................... ..386

DTC Logic ..............................................................386

Diagnosis Procedure .............................................387

P0520 EOP SENSOR ......................................388

DTC Logic ..............................................................388

Diagnosis Procedure .............................................388

Component Inspection ...........................................390

P0524 ENGINE OIL PRESSURE ....................391

DTC Logic ..............................................................391

Diagnosis Procedure .............................................392

Component Inspection ...........................................393

P052A, P052B INTAKE VALVE TIMING CON-

TROL ...............................................................

394

DTC Logic ............................................................ ..394

Diagnosis Procedure .............................................394

Component Inspection (Intake Valve Timing Con-

trol Solenoid Valve) ............................................. ..

396

Component Inspection (Intake Valve Timing Inter-

mediate Lock Control Solenoid Valve) ................ ..

397

Component Inspection (Crankshaft Position sen-

sor) ...................................................................... ..

397

Component Inspection (Camshaft position sen-

sor) ...................................................................... ..

398

P0603 ECM .....................................................400

DTC Logic ..............................................................400

Diagnosis Procedure .............................................400

P0604 ECM .....................................................401

DTC Logic ..............................................................401

Diagnosis Procedure .............................................401

P0605 ECM .....................................................402

DTC Logic ..............................................................402

Diagnosis Procedure .............................................402

P0606 ECM .....................................................403

DTC Logic ..............................................................403

Diagnosis Procedure .............................................403

P0607 ECM .....................................................404

DTC Logic ..............................................................404

Diagnosis Procedure .............................................404

P060A ECM .....................................................405

DTC Logic ..............................................................405

Diagnosis Procedure .............................................405

P060B ECM .....................................................406

DTC Logic ..............................................................406

Diagnosis Procedure .............................................406

P0643 SENSOR POWER SUPPLY ................407

Description .............................................................407

DTC Logic ..............................................................407

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM