light NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1648 of 1767

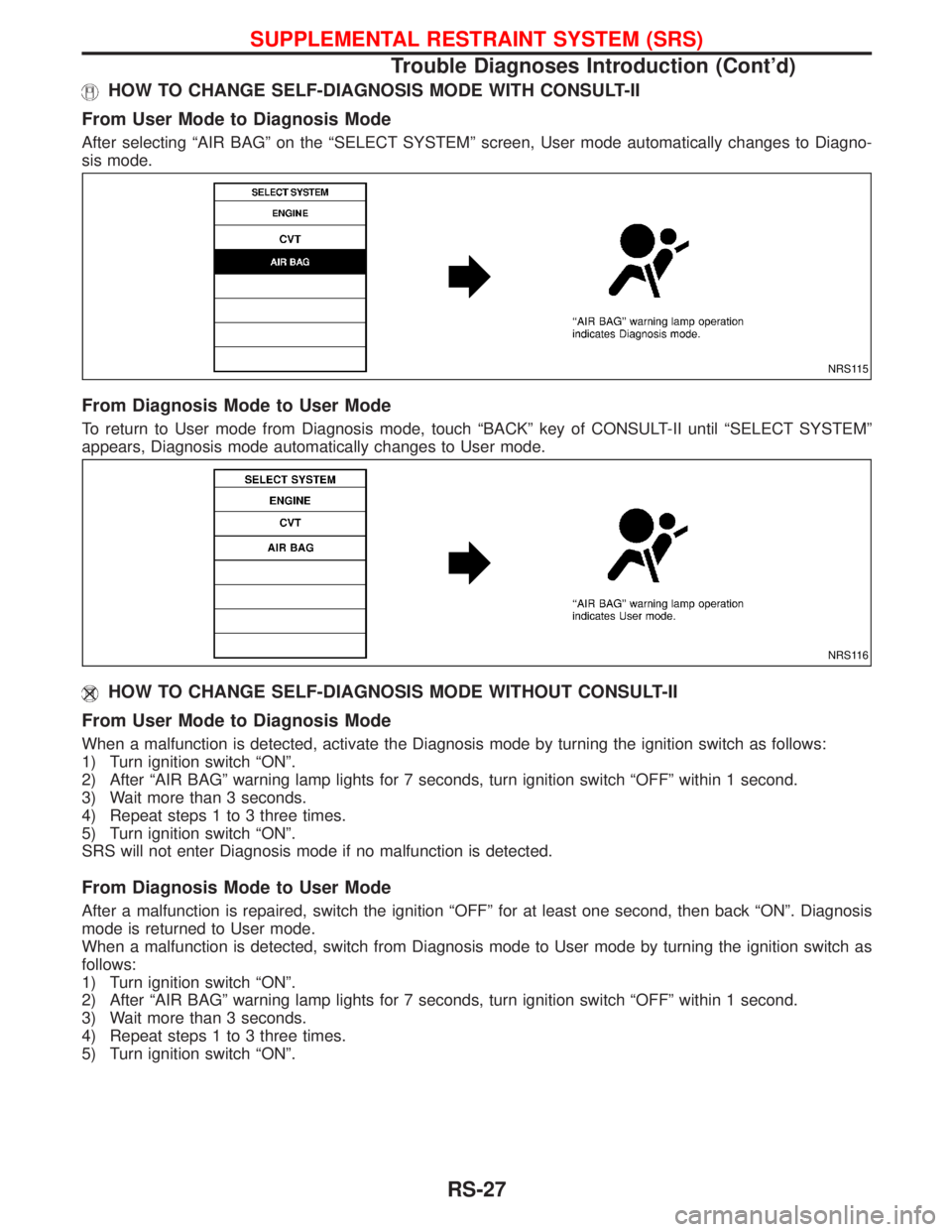

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting ªAIR BAGº on the ªSELECT SYSTEMº screen, User mode automatically changes to Diagno-

sis mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears, Diagnosis mode automatically changes to User mode.

HOW TO CHANGE SELF-DIAGNOSIS MODE WITHOUT CONSULT-II

From User Mode to Diagnosis Mode

When a malfunction is detected, activate the Diagnosis mode by turning the ignition switch as follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

SRS will not enter Diagnosis mode if no malfunction is detected.

From Diagnosis Mode to User Mode

After a malfunction is repaired, switch the ignition ªOFFº for at least one second, then back ªONº. Diagnosis

mode is returned to User mode.

When a malfunction is detected, switch from Diagnosis mode to User mode by turning the ignition switch as

follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

NRS115

NRS116

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses Introduction (Cont'd)

RS-27

Page 1667 of 1767

![NISSAN TERRANO 2002 Service Repair Manual Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring ha NISSAN TERRANO 2002 Service Repair Manual Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring ha](/img/5/57393/w960_57393-1666.png)

Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring harness con-

nections.

2. Replace the harness if it has visible

damage.

3. If the harness check is OK, replace the

diagnosis sensor unit and front RH seat

belt. (Before disposing of the front RH

seat belt pre-tensioner, if must be

deployed.) PRE-TEN FRONT RH

[GND-SHORT]IThe circuit for front RH seat belt pre-

tensioner is shorted to ground.

CONTROL UNITIDiagnosis sensor unit is malfunctioning. 1. Visually check the wiring harness con-

nection.

2. Replace the harness if it has visible

damage.

3. If the harness check is OK, replace the

diagnosis sensor unit.

* Follow the procedures in numerical order when repairing malfunctioning parts, then make the final system check.

Trouble Diagnoses without CONSULT-II

DIAGNOSTIC PROCEDURE 6

Inspecting SRS malfunctioning parts by using ªAIR BAGº

warning lamp Ð Diagnosis mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is

detected in User mode.

1. Turn ignition switch ªONº.

2. After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition

switch ªOFFº within 1 second.

3. Wait more than 3 seconds.

4. Repeat steps 1 to 3 three times.

5. Turn ignition switch ªONº.

SRS is now in Diagnosis mode.

6. ªAIR BAGº warning lamp operates in Diagnosis mode as fol-

lows:

NOTE:

If SRS does not enter Diagnosis mode even though malfunc-

tion is detected in User mode, check the battery voltage.

If the battery voltage is less than 9V, charge the battery. Then

go to DIAGNOSTIC PROCEDURE 7, page RS-51.

If the battery voltage is OK, replace the diagnosis sensor unit.

SRS800

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-46

Page 1674 of 1767

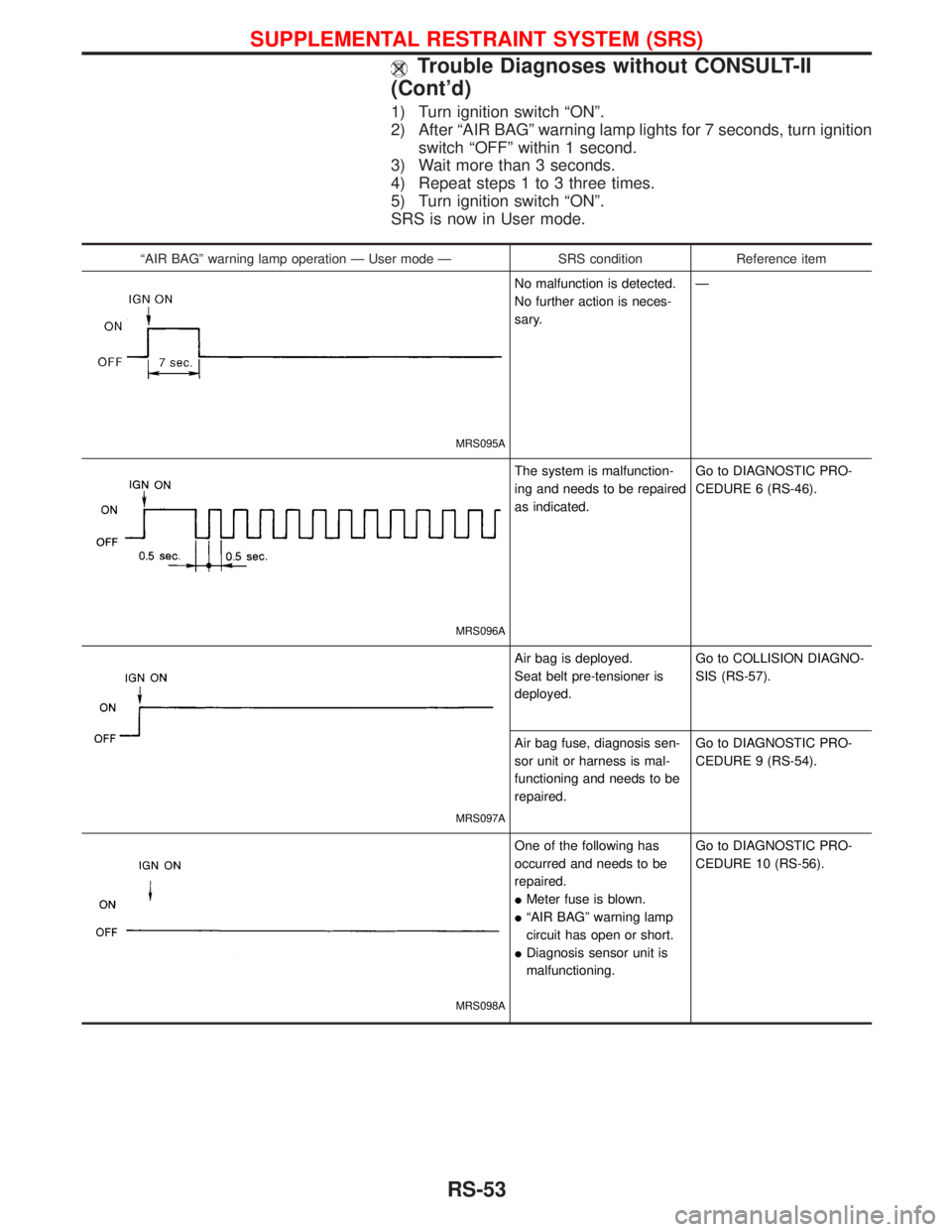

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition

switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

SRS is now in User mode.

ªAIR BAGº warning lamp operation Ð User mode Ð SRS condition Reference item

MRS095A

No malfunction is detected.

No further action is neces-

sary.Ð

MRS096A

The system is malfunction-

ing and needs to be repaired

as indicated.Go to DIAGNOSTIC PRO-

CEDURE 6 (RS-46).

MRS097A

Air bag is deployed.

Seat belt pre-tensioner is

deployed.Go to COLLISION DIAGNO-

SIS (RS-57).

Air bag fuse, diagnosis sen-

sor unit or harness is mal-

functioning and needs to be

repaired.Go to DIAGNOSTIC PRO-

CEDURE 9 (RS-54).

MRS098A

One of the following has

occurred and needs to be

repaired.

IMeter fuse is blown.

IªAIR BAGº warning lamp

circuit has open or short.

IDiagnosis sensor unit is

malfunctioning.Go to DIAGNOSTIC PRO-

CEDURE 10 (RS-56).

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II

(Cont'd)

RS-53

Page 1702 of 1767

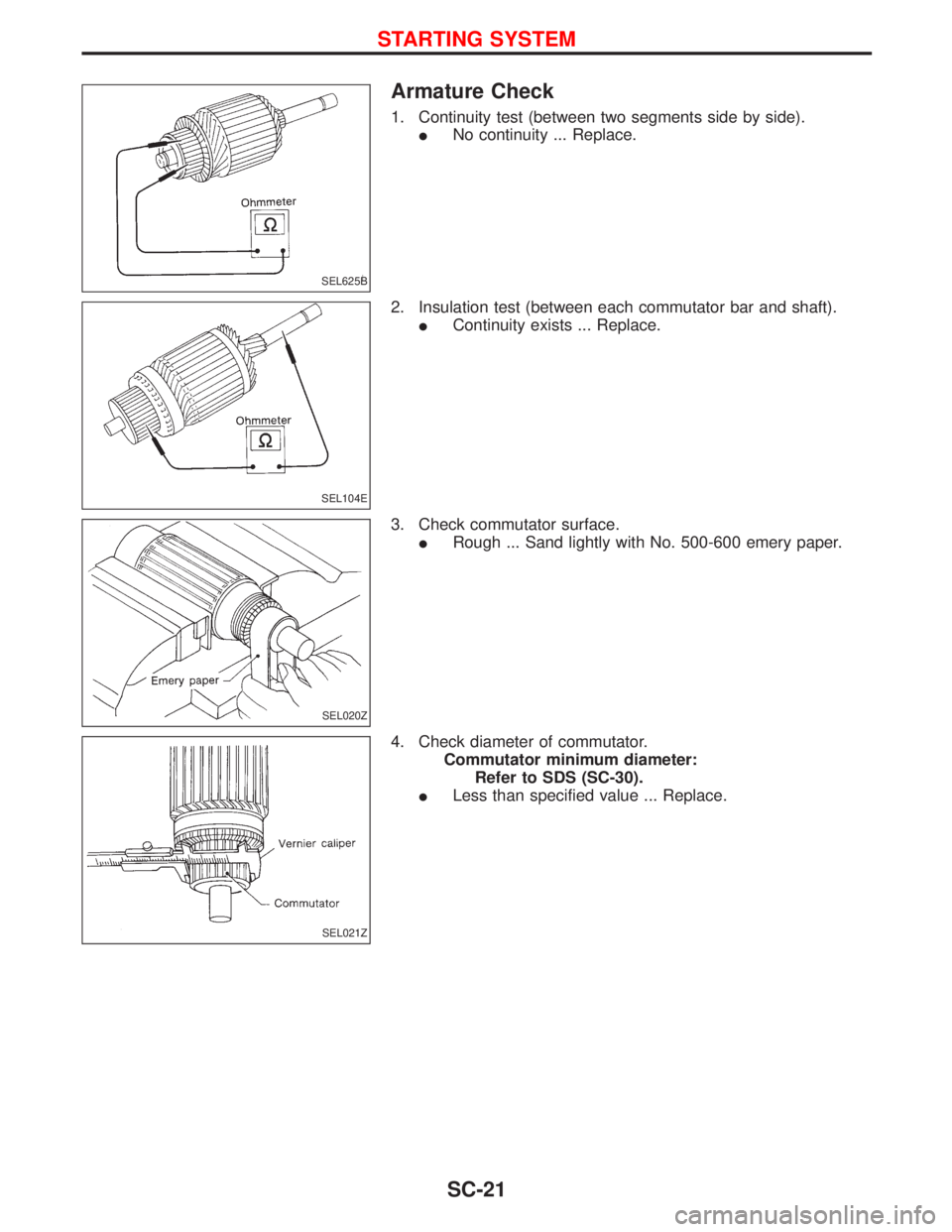

Armature Check

1. Continuity test (between two segments side by side).

INo continuity ... Replace.

2. Insulation test (between each commutator bar and shaft).

IContinuity exists ... Replace.

3. Check commutator surface.

IRough ... Sand lightly with No. 500-600 emery paper.

4. Check diameter of commutator.

Commutator minimum diameter:

Refer to SDS (SC-30).

ILess than specified value ... Replace.

SEL625B

SEL104E

SEL020Z

SEL021Z

STARTING SYSTEM

SC-21

Page 1716 of 1767

Checking Fluid Leakage

Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing or deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds and

carefully check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Meanwhile quickly turn

steering wheel fully to right and left and lightly touch steering

stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

IIncomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a. Generation of air bubbles in reservoir tank

b. Generation of clicking noise in oil pump

c. Excessive buzzing in oil pump

While the vehicle is stationary or while moving the steering wheel

slowly, fluid noise may occur in the valve or oil pump. This noise is

inherent in this steering system, and it will not affect performance

or durability of the system.

SST621A

ON-VEHICLE SERVICE

ST-5

Page 1722 of 1767

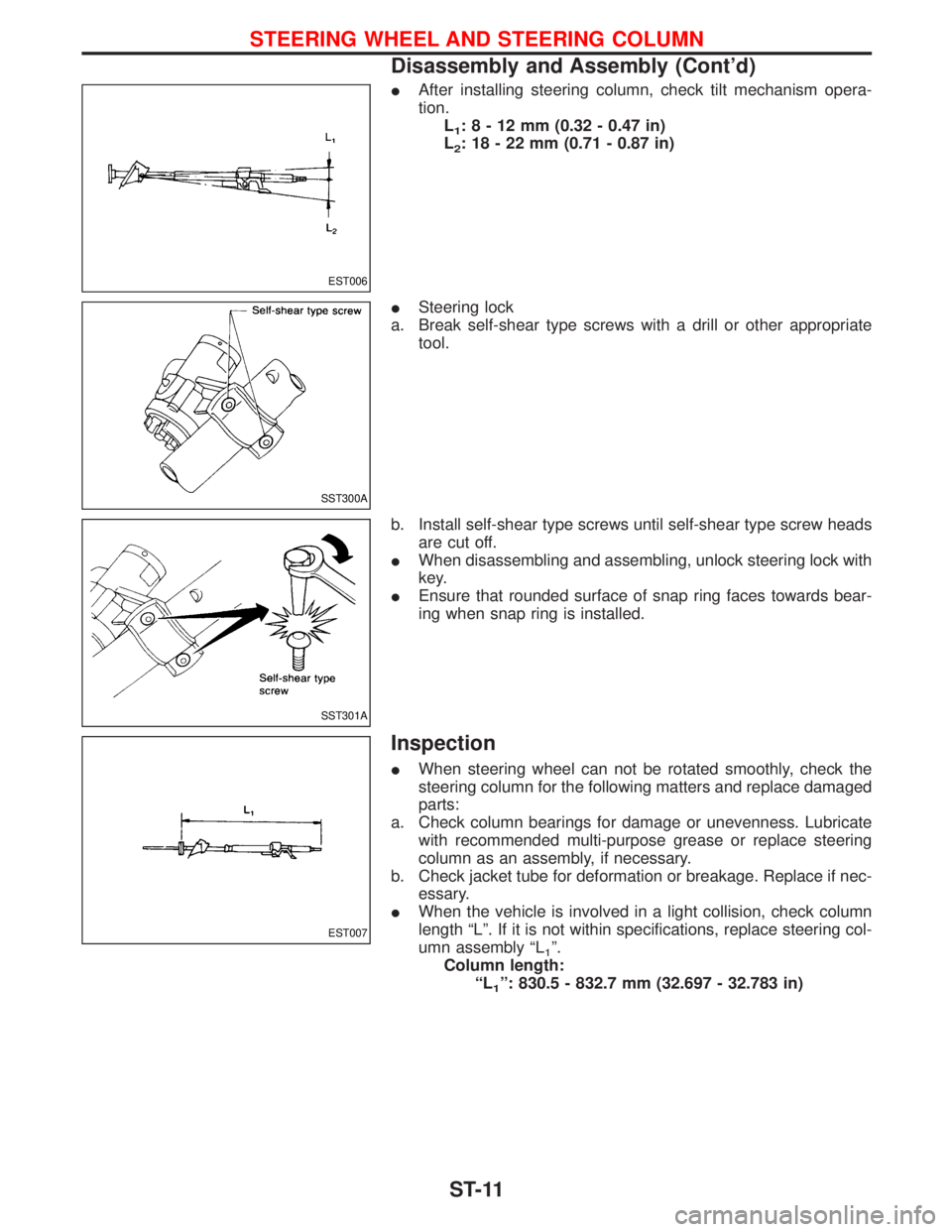

IAfter installing steering column, check tilt mechanism opera-

tion.

L

1:8-12mm(0.32 - 0.47 in)

L

2: 18 - 22 mm (0.71 - 0.87 in)

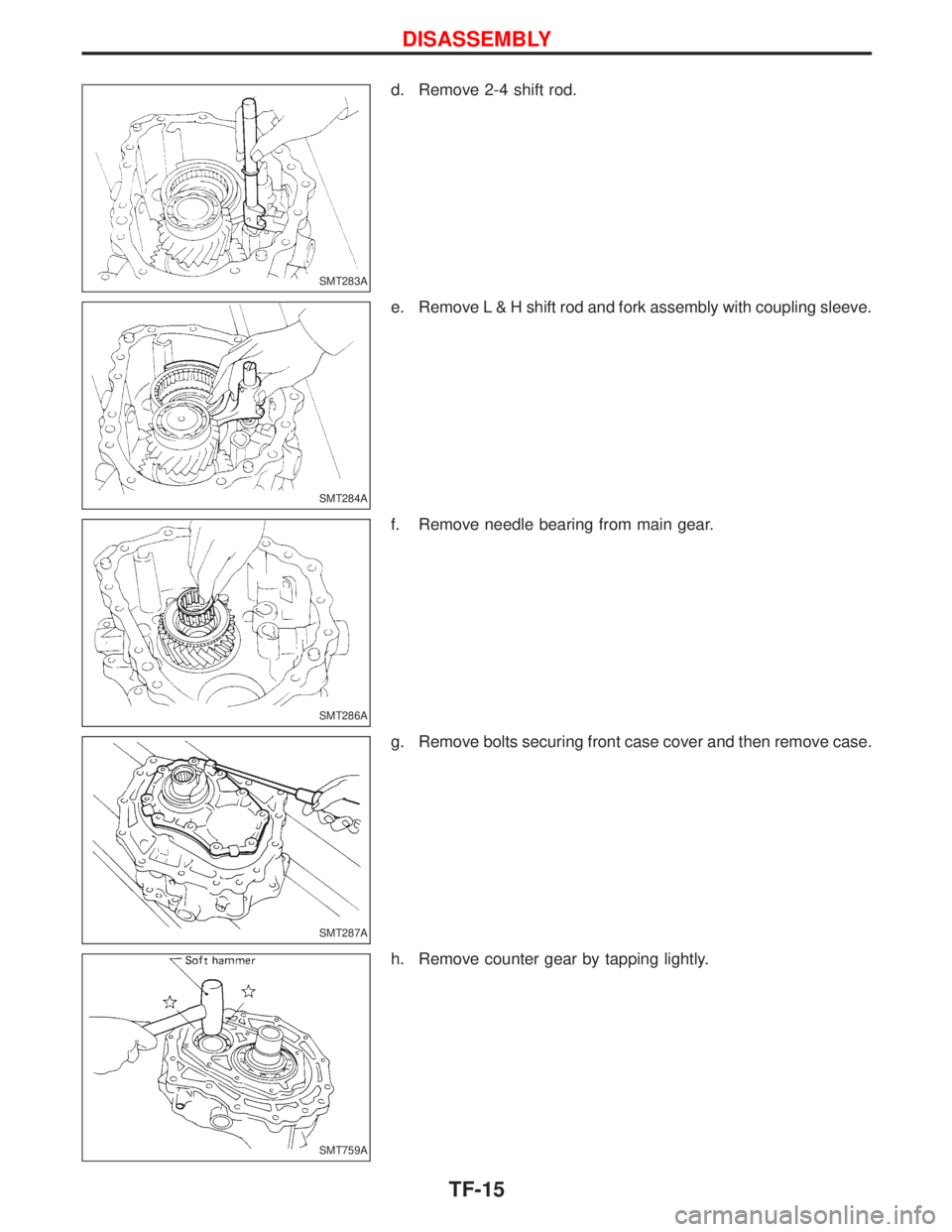

ISteering lock

a. Break self-shear type screws with a drill or other appropriate

tool.

b. Install self-shear type screws until self-shear type screw heads

are cut off.

IWhen disassembling and assembling, unlock steering lock with

key.

IEnsure that rounded surface of snap ring faces towards bear-

ing when snap ring is installed.

Inspection

IWhen steering wheel can not be rotated smoothly, check the

steering column for the following matters and replace damaged

parts:

a. Check column bearings for damage or unevenness. Lubricate

with recommended multi-purpose grease or replace steering

column as an assembly, if necessary.

b. Check jacket tube for deformation or breakage. Replace if nec-

essary.

IWhen the vehicle is involved in a light collision, check column

length ªLº. If it is not within specifications, replace steering col-

umn assembly ªL

1º.

Column length:

ªL

1º: 830.5 - 832.7 mm (32.697 - 32.783 in)

EST006

SST300A

SST301A

EST007

STEERING WHEEL AND STEERING COLUMN

Disassembly and Assembly (Cont'd)

ST-11

Page 1748 of 1767

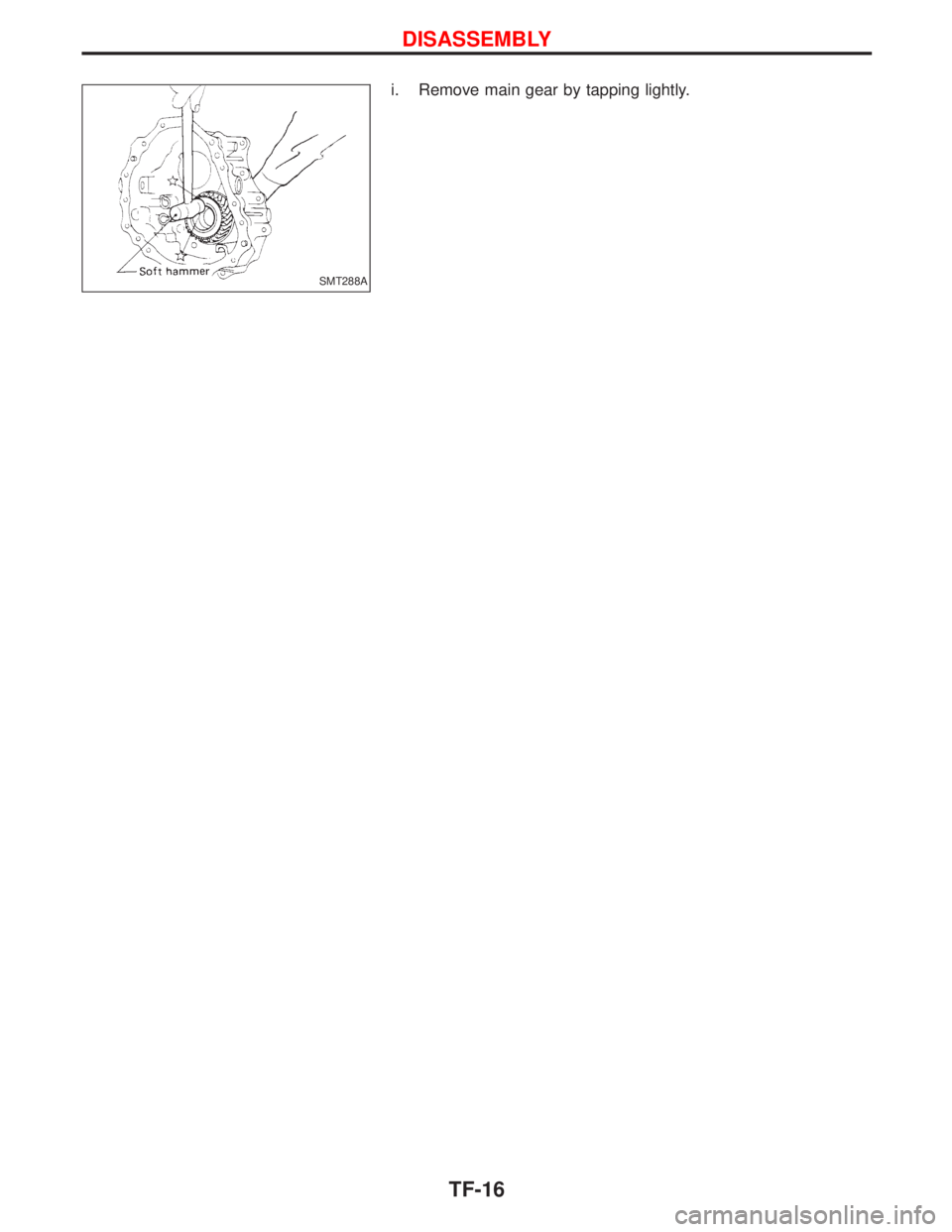

d. Remove 2-4 shift rod.

e. Remove L & H shift rod and fork assembly with coupling sleeve.

f. Remove needle bearing from main gear.

g. Remove bolts securing front case cover and then remove case.

h. Remove counter gear by tapping lightly.

SMT283A

SMT284A

SMT286A

SMT287A

SMT759A

DISASSEMBLY

TF-15

Page 1749 of 1767

i. Remove main gear by tapping lightly.

SMT288A

DISASSEMBLY

TF-16

Page 1759 of 1767

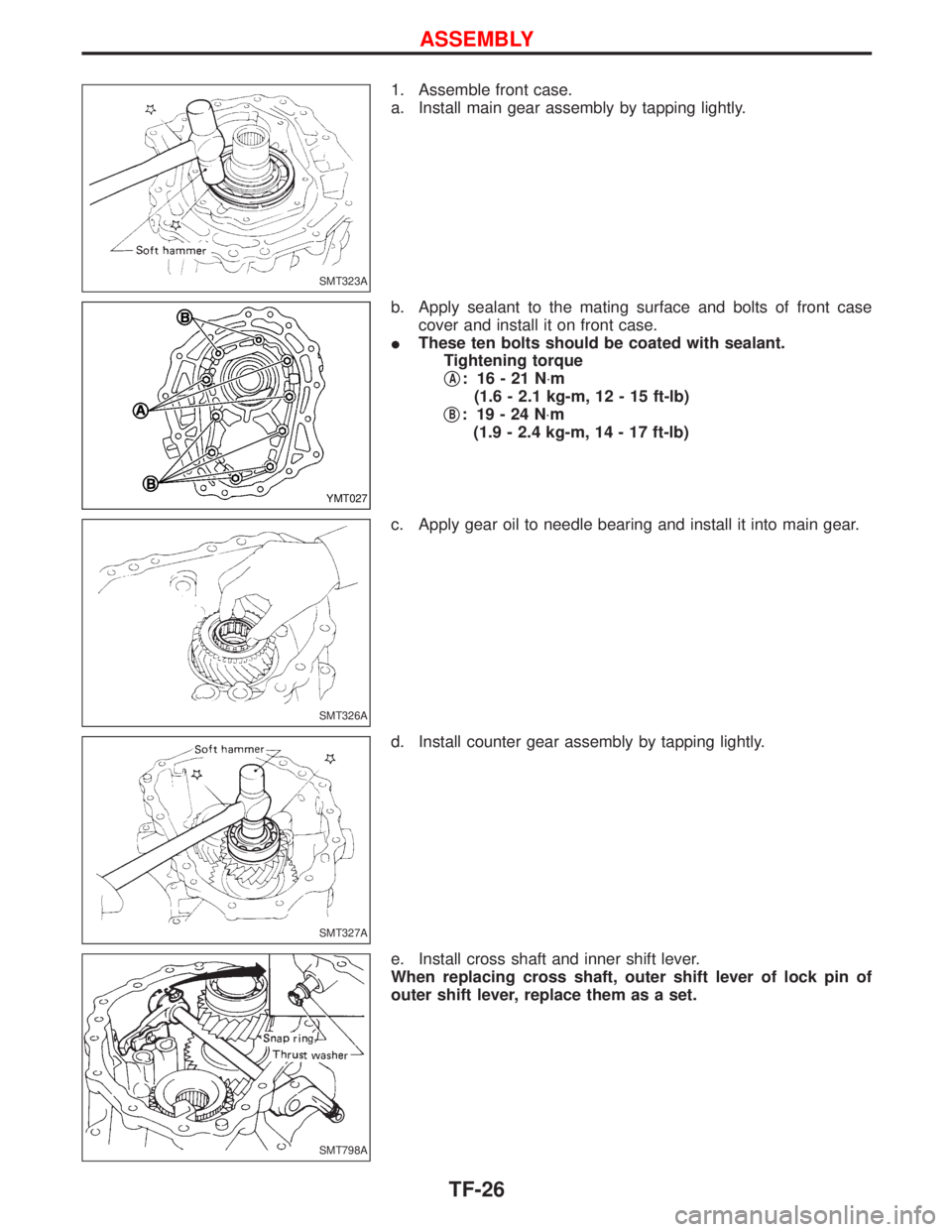

1. Assemble front case.

a. Install main gear assembly by tapping lightly.

b. Apply sealant to the mating surface and bolts of front case

cover and install it on front case.

IThese ten bolts should be coated with sealant.

Tightening torque

q

A: 16-21N×m

(1.6 - 2.1 kg-m, 12 - 15 ft-lb)

q

B: 19-24N×m

(1.9 - 2.4 kg-m, 14 - 17 ft-lb)

c. Apply gear oil to needle bearing and install it into main gear.

d. Install counter gear assembly by tapping lightly.

e. Install cross shaft and inner shift lever.

When replacing cross shaft, outer shift lever of lock pin of

outer shift lever, replace them as a set.

SMT323A

YMT027

SMT326A

SMT327A

SMT798A

ASSEMBLY

TF-26

Page 1761 of 1767

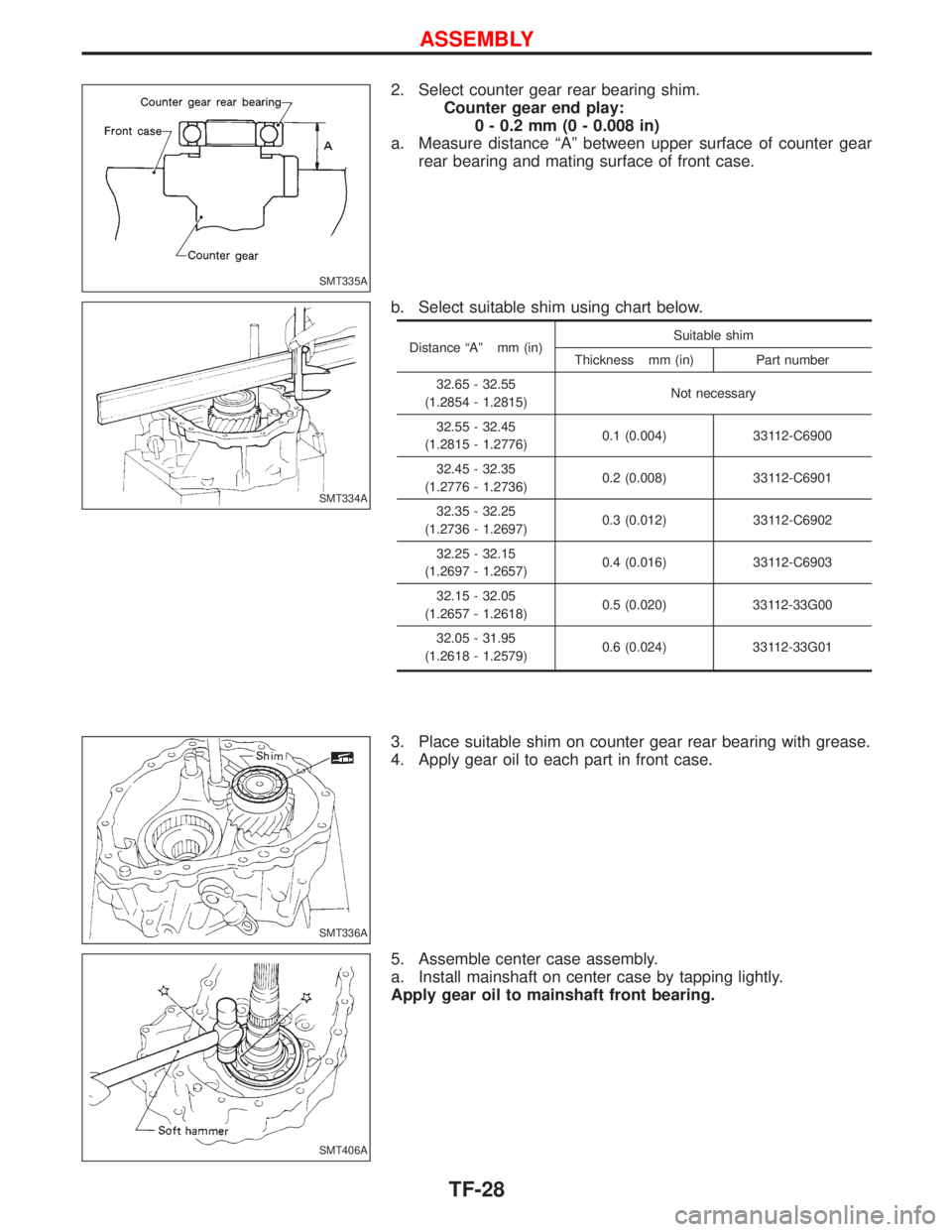

2. Select counter gear rear bearing shim.

Counter gear end play:

0 - 0.2 mm (0 - 0.008 in)

a. Measure distance ªAº between upper surface of counter gear

rear bearing and mating surface of front case.

b. Select suitable shim using chart below.

Distance ªAº mm (in)Suitable shim

Thickness mm (in) Part number

32.65 - 32.55

(1.2854 - 1.2815)Not necessary

32.55 - 32.45

(1.2815 - 1.2776)0.1 (0.004) 33112-C6900

32.45 - 32.35

(1.2776 - 1.2736)0.2 (0.008) 33112-C6901

32.35 - 32.25

(1.2736 - 1.2697)0.3 (0.012) 33112-C6902

32.25 - 32.15

(1.2697 - 1.2657)0.4 (0.016) 33112-C6903

32.15 - 32.05

(1.2657 - 1.2618)0.5 (0.020) 33112-33G00

32.05 - 31.95

(1.2618 - 1.2579)0.6 (0.024) 33112-33G01

3. Place suitable shim on counter gear rear bearing with grease.

4. Apply gear oil to each part in front case.

5. Assemble center case assembly.

a. Install mainshaft on center case by tapping lightly.

Apply gear oil to mainshaft front bearing.

SMT335A

SMT334A

SMT336A

SMT406A

ASSEMBLY

TF-28