light NISSAN TERRANO 2002 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 999 of 1767

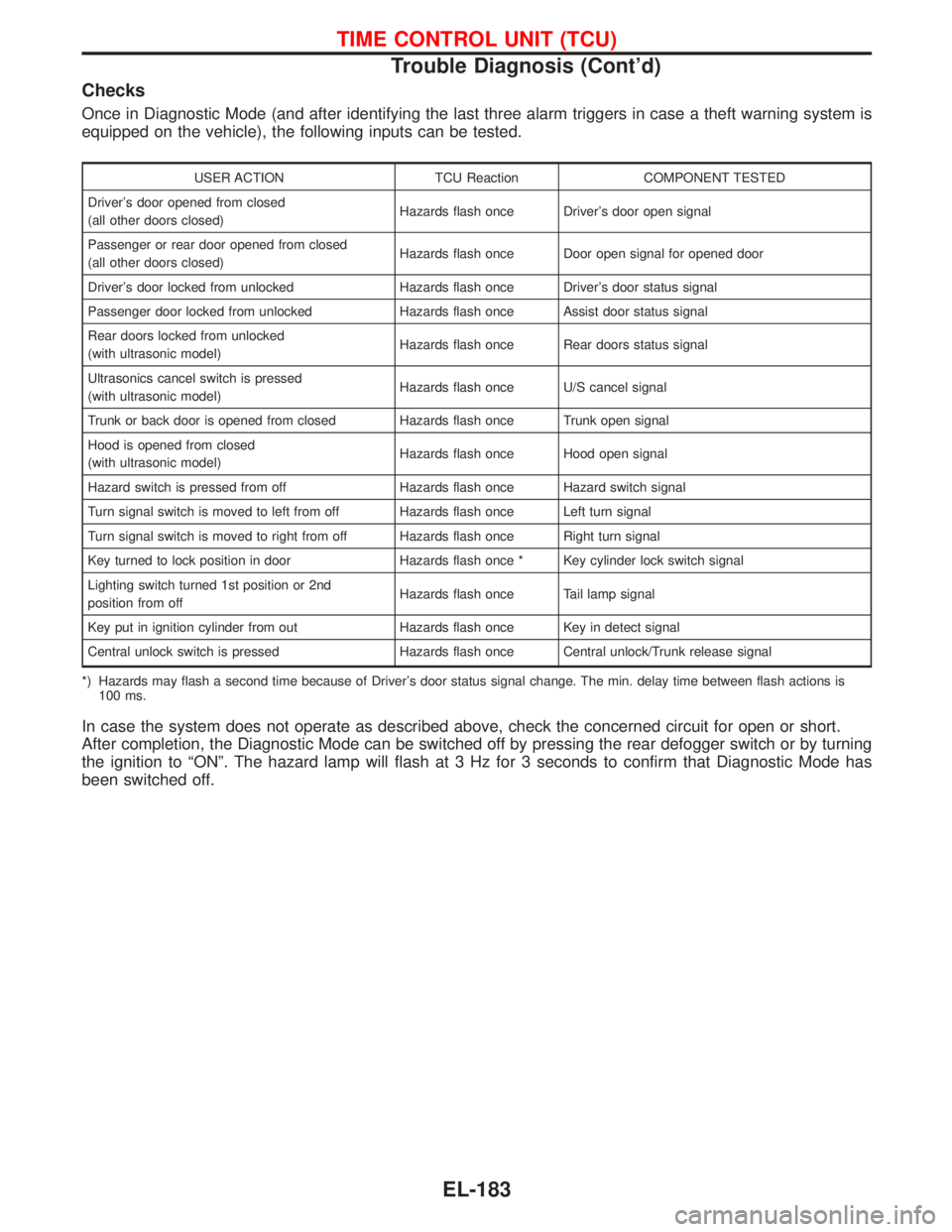

Checks

Once in Diagnostic Mode (and after identifying the last three alarm triggers in case a theft warning system is

equipped on the vehicle), the following inputs can be tested.

USER ACTION TCU Reaction COMPONENT TESTED

Driver's door opened from closed

(all other doors closed)Hazards flash once Driver's door open signal

Passenger or rear door opened from closed

(all other doors closed)Hazards flash once Door open signal for opened door

Driver's door locked from unlocked Hazards flash once Driver's door status signal

Passenger door locked from unlocked Hazards flash once Assist door status signal

Rear doors locked from unlocked

(with ultrasonic model)Hazards flash once Rear doors status signal

Ultrasonics cancel switch is pressed

(with ultrasonic model)Hazards flash once U/S cancel signal

Trunk or back door is opened from closed Hazards flash once Trunk open signal

Hood is opened from closed

(with ultrasonic model)Hazards flash once Hood open signal

Hazard switch is pressed from off Hazards flash once Hazard switch signal

Turn signal switch is moved to left from off Hazards flash once Left turn signal

Turn signal switch is moved to right from off Hazards flash once Right turn signal

Key turned to lock position in door Hazards flash once * Key cylinder lock switch signal

Lighting switch turned 1st position or 2nd

position from offHazards flash once Tail lamp signal

Key put in ignition cylinder from out Hazards flash once Key in detect signal

Central unlock switch is pressed Hazards flash once Central unlock/Trunk release signal

*) Hazards may flash a second time because of Driver's door status signal change. The min. delay time between flash actions is

100 ms.

In case the system does not operate as described above, check the concerned circuit for open or short.

After completion, the Diagnostic Mode can be switched off by pressing the rear defogger switch or by turning

the ignition to ªONº. The hazard lamp will flash at 3 Hz for 3 seconds to confirm that Diagnostic Mode has

been switched off.

TIME CONTROL UNIT (TCU)

Trouble Diagnosis (Cont'd)

EL-183

Page 1002 of 1767

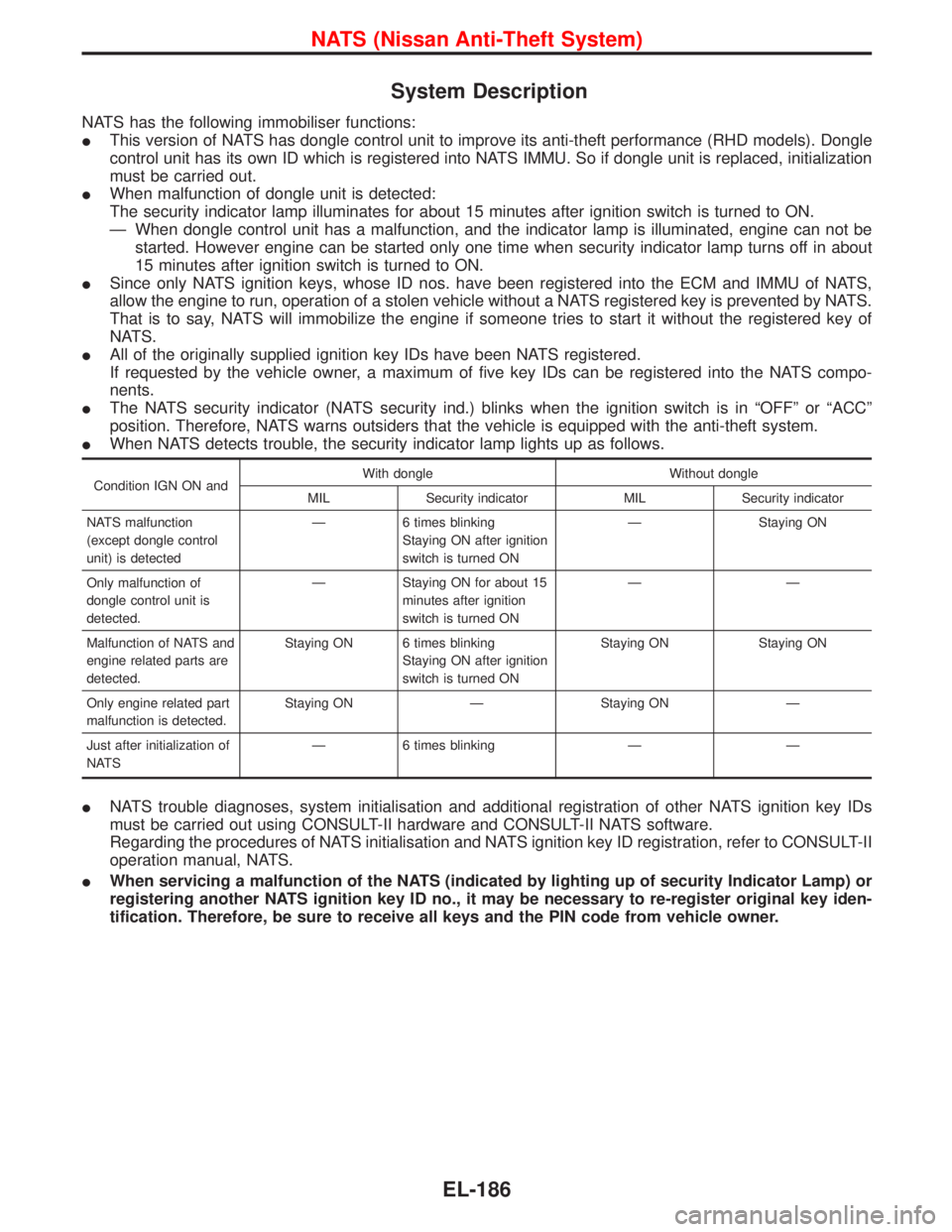

System Description

NATS has the following immobiliser functions:

IThis version of NATS has dongle control unit to improve its anti-theft performance (RHD models). Dongle

control unit has its own ID which is registered into NATS IMMU. So if dongle unit is replaced, initialization

must be carried out.

IWhen malfunction of dongle unit is detected:

The security indicator lamp illuminates for about 15 minutes after ignition switch is turned to ON.

Ð When dongle control unit has a malfunction, and the indicator lamp is illuminated, engine can not be

started. However engine can be started only one time when security indicator lamp turns off in about

15 minutes after ignition switch is turned to ON.

ISince only NATS ignition keys, whose ID nos. have been registered into the ECM and IMMU of NATS,

allow the engine to run, operation of a stolen vehicle without a NATS registered key is prevented by NATS.

That is to say, NATS will immobilize the engine if someone tries to start it without the registered key of

NATS.

IAll of the originally supplied ignition key IDs have been NATS registered.

If requested by the vehicle owner, a maximum of five key IDs can be registered into the NATS compo-

nents.

IThe NATS security indicator (NATS security ind.) blinks when the ignition switch is in ªOFFº or ªACCº

position. Therefore, NATS warns outsiders that the vehicle is equipped with the anti-theft system.

IWhen NATS detects trouble, the security indicator lamp lights up as follows.

Condition IGN ON andWith dongle Without dongle

MIL Security indicator MIL Security indicator

NATS malfunction

(except dongle control

unit) is detectedÐ 6 times blinking

Staying ON after ignition

switch is turned ONÐ Staying ON

Only malfunction of

dongle control unit is

detected.Ð Staying ON for about 15

minutes after ignition

switch is turned ONÐÐ

Malfunction of NATS and

engine related parts are

detected.Staying ON 6 times blinking

Staying ON after ignition

switch is turned ONStaying ON Staying ON

Only engine related part

malfunction is detected.Staying ON Ð Staying ON Ð

Just after initialization of

NATSÐ 6 times blinking Ð Ð

INATS trouble diagnoses, system initialisation and additional registration of other NATS ignition key IDs

must be carried out using CONSULT-II hardware and CONSULT-II NATS software.

Regarding the procedures of NATS initialisation and NATS ignition key ID registration, refer to CONSULT-II

operation manual, NATS.

IWhen servicing a malfunction of the NATS (indicated by lighting up of security Indicator Lamp) or

registering another NATS ignition key ID no., it may be necessary to re-register original key iden-

tification. Therefore, be sure to receive all keys and the PIN code from vehicle owner.

NATS (Nissan Anti-Theft System)

EL-186

Page 1011 of 1767

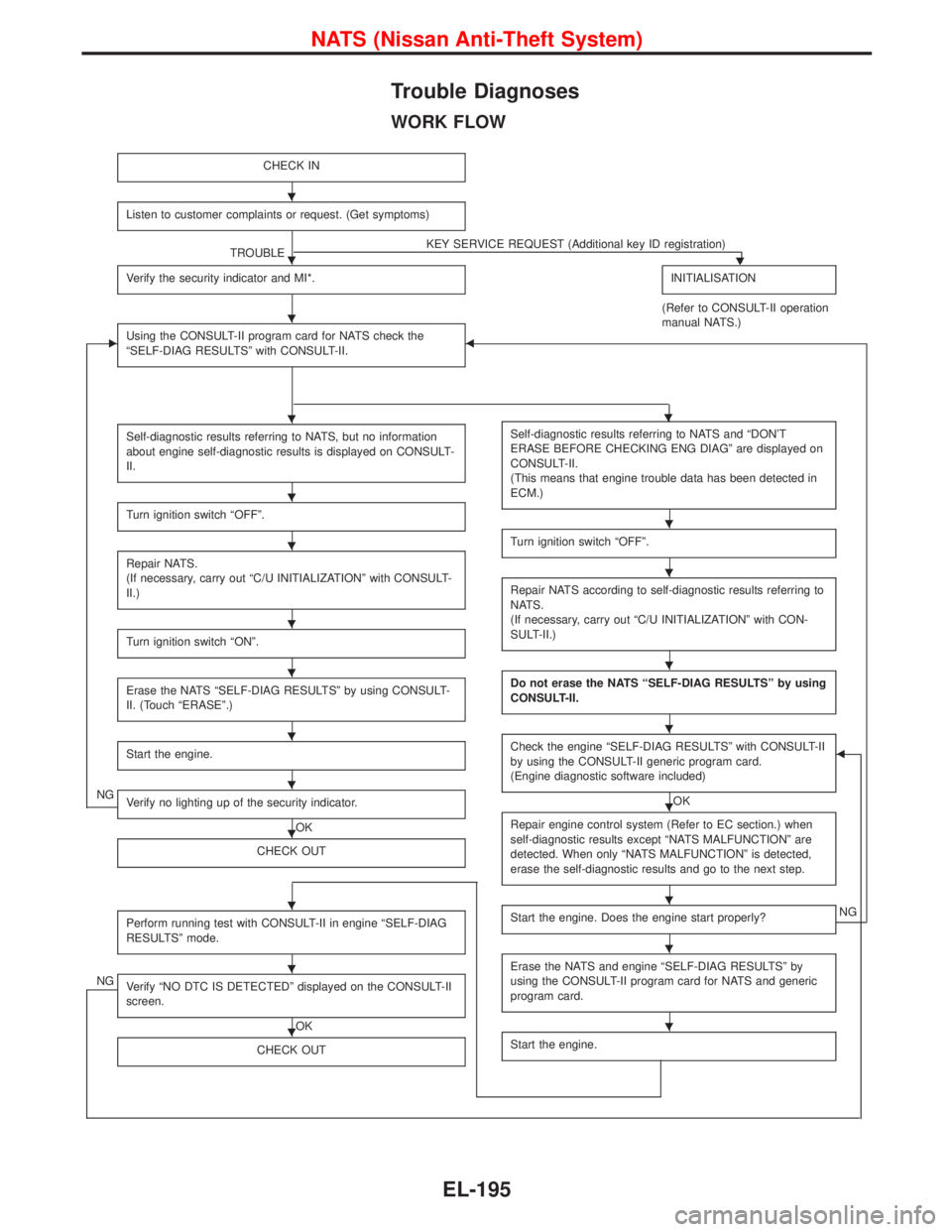

Trouble Diagnoses

WORK FLOW

CHECK IN

Listen to customer complaints or request. (Get symptoms)

TROUBLEKEY SERVICE REQUEST (Additional key ID registration)H

Verify the security indicator and MI*.INITIALISATION

(Refer to CONSULT-II operation

manual NATS.)

EUsing the CONSULT-II program card for NATS check the

ªSELF-DIAG RESULTSº with CONSULT-II.F

Self-diagnostic results referring to NATS, but no information

about engine self-diagnostic results is displayed on CONSULT-

II.

Turn ignition switch ªOFFº.

Repair NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CONSULT-

II.)

Turn ignition switch ªONº.

Erase the NATS ªSELF-DIAG RESULTSº by using CONSULT-

II. (Touch ªERASEº.)

Start the engine.

NGVerify no lighting up of the security indicator.

OK

CHECK OUT

Perform running test with CONSULT-II in engine ªSELF-DIAG

RESULTSº mode.

NGVerify ªNO DTC IS DETECTEDº displayed on the CONSULT-II

screen.

OK

CHECK OUT

Self-diagnostic results referring to NATS and ªDON'T

ERASE BEFORE CHECKING ENG DIAGº are displayed on

CONSULT-II.

(This means that engine trouble data has been detected in

ECM.)

Turn ignition switch ªOFFº.

Repair NATS according to self-diagnostic results referring to

NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CON-

SULT-II.)

Do not erase the NATS ªSELF-DIAG RESULTSº by using

CONSULT-II.

Check the engine ªSELF-DIAG RESULTSº with CONSULT-II

by using the CONSULT-II generic program card.

(Engine diagnostic software included)

OK

F

Repair engine control system (Refer to EC section.) when

self-diagnostic results except ªNATS MALFUNCTIONº are

detected. When only ªNATS MALFUNCTIONº is detected,

erase the self-diagnostic results and go to the next step.

Start the engine. Does the engine start properly?NG

Erase the NATS and engine ªSELF-DIAG RESULTSº by

using the CONSULT-II program card for NATS and generic

program card.

Start the engine.

H

H

H

HH

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

NATS (Nissan Anti-Theft System)

EL-195

Page 1012 of 1767

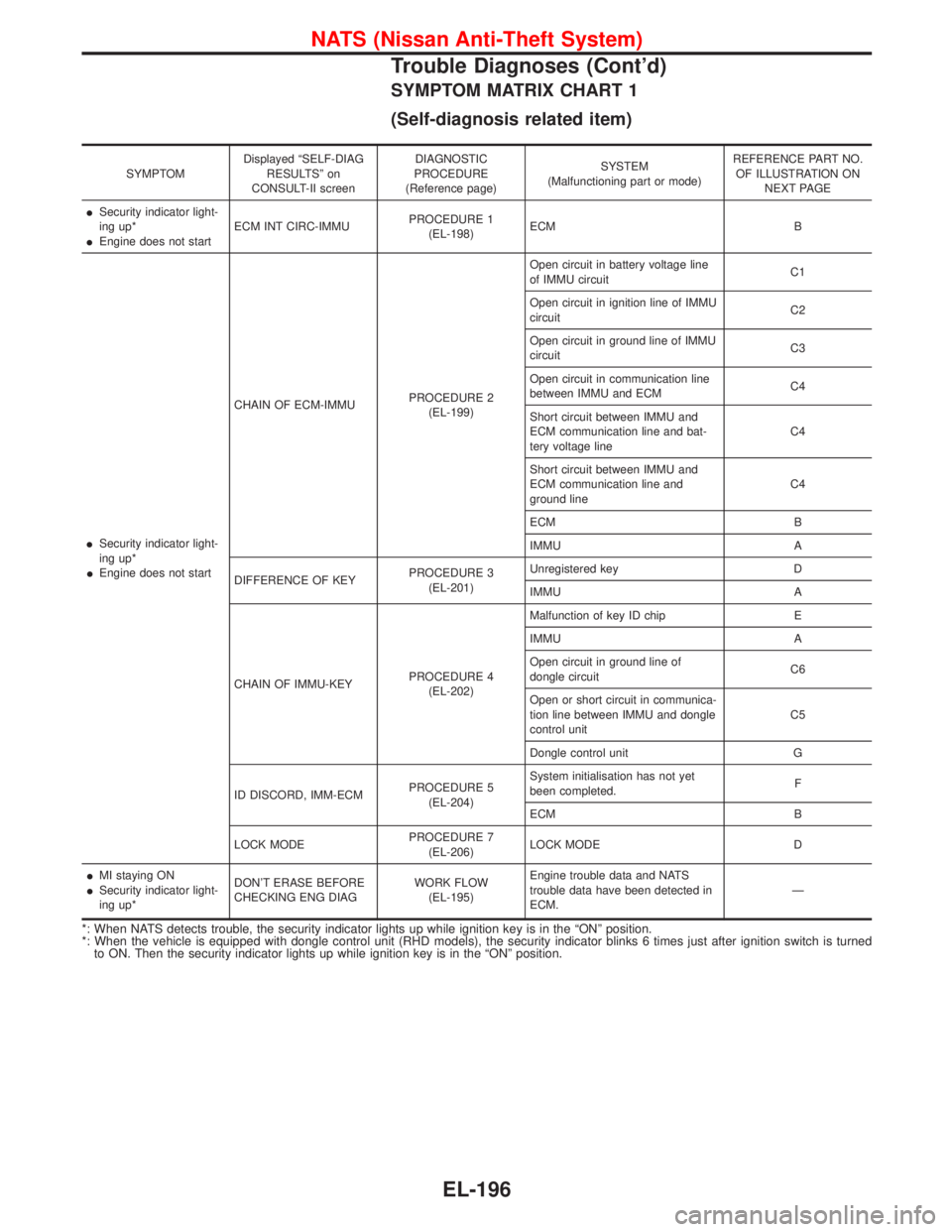

SYMPTOM MATRIX CHART 1

(Self-diagnosis related item)

SYMPTOMDisplayed ªSELF-DIAG

RESULTSº on

CONSULT-II screenDIAGNOSTIC

PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)REFERENCE PART NO.

OF ILLUSTRATION ON

NEXT PAGE

ISecurity indicator light-

ing up*

IEngine does not startECM INT CIRC-IMMUPROCEDURE 1

(EL-198)ECM B

ISecurity indicator light-

ing up*

IEngine does not startCHAIN OF ECM-IMMUPROCEDURE 2

(EL-199)Open circuit in battery voltage line

of IMMU circuitC1

Open circuit in ignition line of IMMU

circuitC2

Open circuit in ground line of IMMU

circuitC3

Open circuit in communication line

between IMMU and ECMC4

Short circuit between IMMU and

ECM communication line and bat-

tery voltage lineC4

Short circuit between IMMU and

ECM communication line and

ground lineC4

ECM B

IMMU A

DIFFERENCE OF KEYPROCEDURE 3

(EL-201)Unregistered key D

IMMU A

CHAIN OF IMMU-KEYPROCEDURE 4

(EL-202)Malfunction of key ID chip E

IMMU A

Open circuit in ground line of

dongle circuitC6

Open or short circuit in communica-

tion line between IMMU and dongle

control unitC5

Dongle control unit G

ID DISCORD, IMM-ECMPROCEDURE 5

(EL-204)System initialisation has not yet

been completed.F

ECM B

LOCK MODEPROCEDURE 7

(EL-206)LOCK MODE D

IMI staying ON

ISecurity indicator light-

ing up*DON'T ERASE BEFORE

CHECKING ENG DIAGWORK FLOW

(EL-195)Engine trouble data and NATS

trouble data have been detected in

ECM.Ð

*: When NATS detects trouble, the security indicator lights up while ignition key is in the ªONº position.

*: When the vehicle is equipped with dongle control unit (RHD models), the security indicator blinks 6 times just after ignition switch is turned

to ON. Then the security indicator lights up while ignition key is in the ªONº position.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-196

Page 1013 of 1767

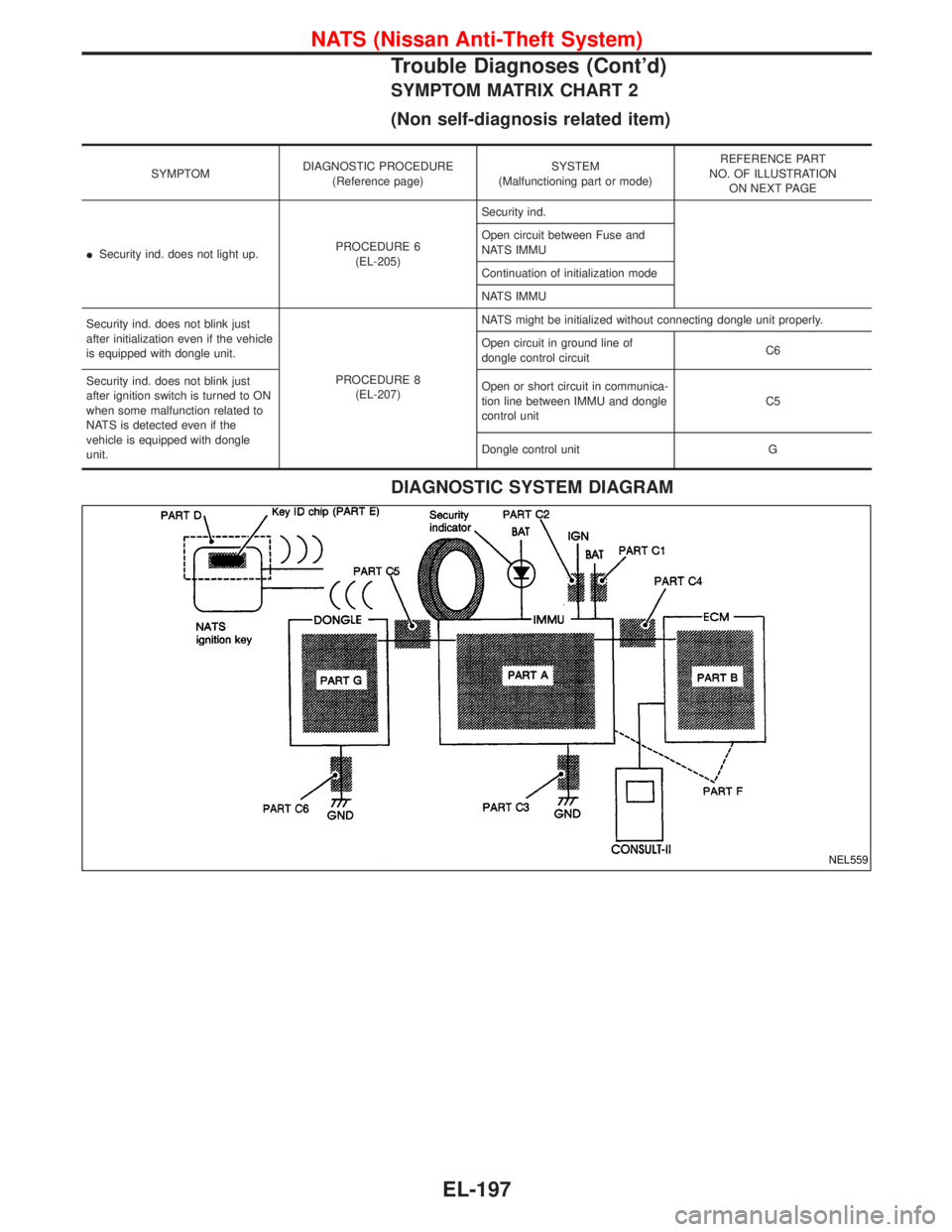

SYMPTOM MATRIX CHART 2

(Non self-diagnosis related item)

SYMPTOMDIAGNOSTIC PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)REFERENCE PART

NO. OF ILLUSTRATION

ON NEXT PAGE

ISecurity ind. does not light up.PROCEDURE 6

(EL-205)Security ind.

Open circuit between Fuse and

NATS IMMU

Continuation of initialization mode

NATS IMMU

Security ind. does not blink just

after initialization even if the vehicle

is equipped with dongle unit.

PROCEDURE 8

(EL-207)NATS might be initialized without connecting dongle unit properly.

Open circuit in ground line of

dongle control circuitC6

Security ind. does not blink just

after ignition switch is turned to ON

when some malfunction related to

NATS is detected even if the

vehicle is equipped with dongle

unit.Open or short circuit in communica-

tion line between IMMU and dongle

control unitC5

Dongle control unit G

DIAGNOSTIC SYSTEM DIAGRAM

NEL559

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-197

Page 1021 of 1767

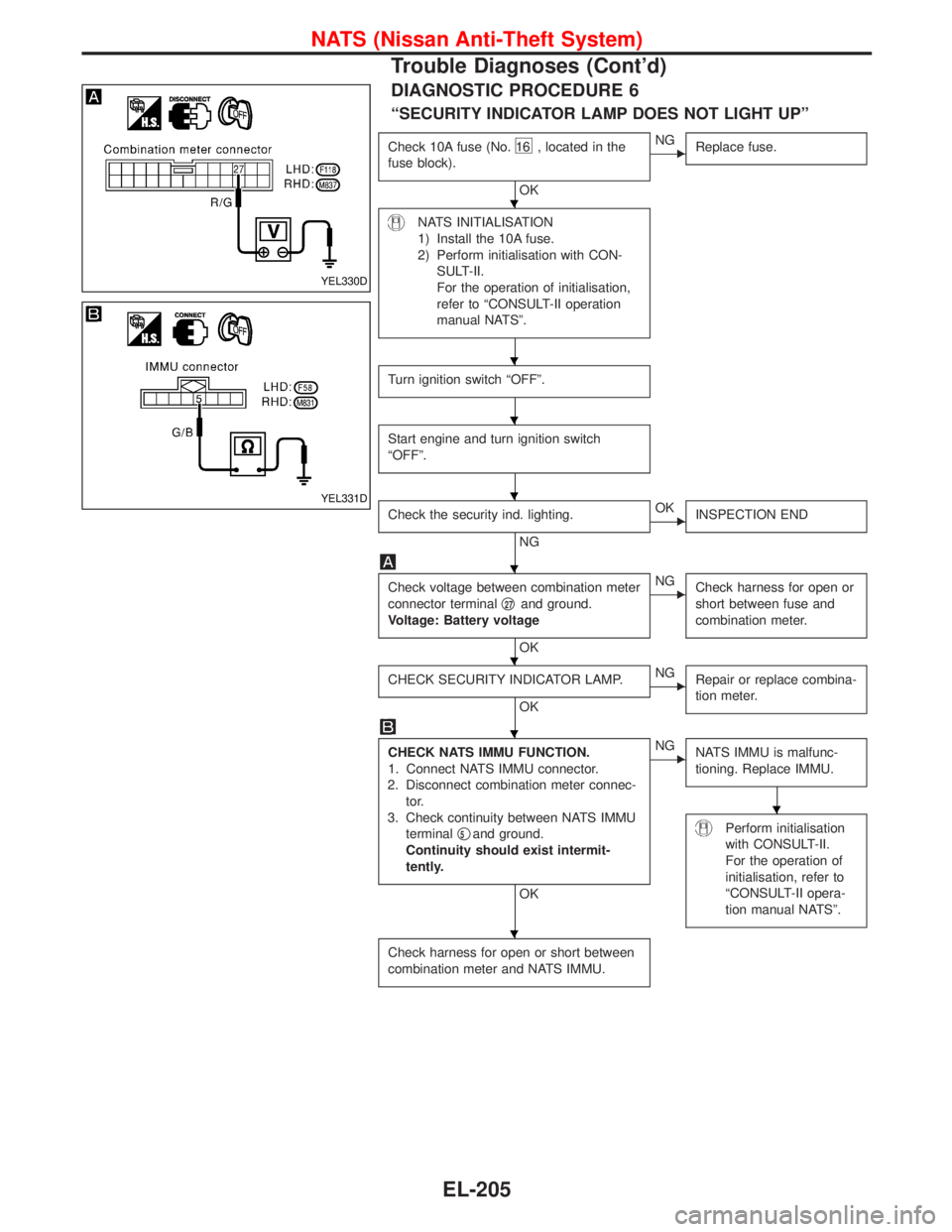

DIAGNOSTIC PROCEDURE 6

ªSECURITY INDICATOR LAMP DOES NOT LIGHT UPº

Check 10A fuse (No.16 , located in the

fuse block).

OK

ENG

Replace fuse.

NATS INITIALISATION

1) Install the 10A fuse.

2) Perform initialisation with CON-

SULT-II.

For the operation of initialisation,

refer to ªCONSULT-II operation

manual NATSº.

Turn ignition switch ªOFFº.

Start engine and turn ignition switch

ªOFFº.

Check the security ind. lighting.

NG

EOK

INSPECTION END

Check voltage between combination meter

connector terminalq

27and ground.

Voltage: Battery voltage

OK

ENG

Check harness for open or

short between fuse and

combination meter.

CHECK SECURITY INDICATOR LAMP.

OK

ENG

Repair or replace combina-

tion meter.

CHECK NATS IMMU FUNCTION.

1. Connect NATS IMMU connector.

2. Disconnect combination meter connec-

tor.

3. Check continuity between NATS IMMU

terminalq

5and ground.

Continuity should exist intermit-

tently.

OK

ENG

NATS IMMU is malfunc-

tioning. Replace IMMU.

Perform initialisation

with CONSULT-II.

For the operation of

initialisation, refer to

ªCONSULT-II opera-

tion manual NATSº.

Check harness for open or short between

combination meter and NATS IMMU.

YEL330D

YEL331D

H

H

H

H

H

H

H

H

H

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-205

Page 1107 of 1767

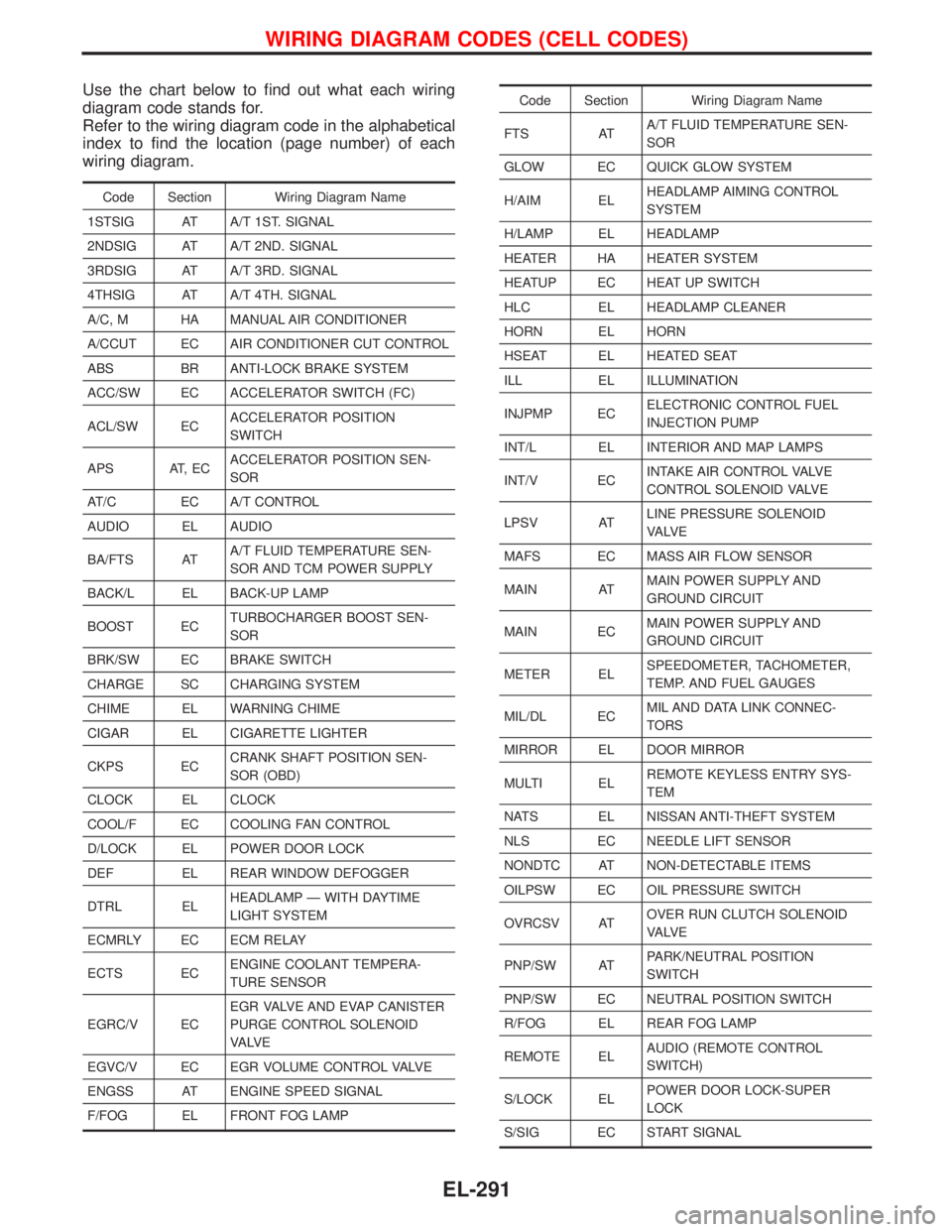

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

1STSIG AT A/T 1ST. SIGNAL

2NDSIG AT A/T 2ND. SIGNAL

3RDSIG AT A/T 3RD. SIGNAL

4THSIG AT A/T 4TH. SIGNAL

A/C, M HA MANUAL AIR CONDITIONER

A/CCUT EC AIR CONDITIONER CUT CONTROL

ABS BR ANTI-LOCK BRAKE SYSTEM

ACC/SW EC ACCELERATOR SWITCH (FC)

ACL/SW ECACCELERATOR POSITION

SWITCH

APS AT, ECACCELERATOR POSITION SEN-

SOR

AT/C EC A/T CONTROL

AUDIO EL AUDIO

BA/FTS ATA/T FLUID TEMPERATURE SEN-

SOR AND TCM POWER SUPPLY

BACK/L EL BACK-UP LAMP

BOOST ECTURBOCHARGER BOOST SEN-

SOR

BRK/SW EC BRAKE SWITCH

CHARGE SC CHARGING SYSTEM

CHIME EL WARNING CHIME

CIGAR EL CIGARETTE LIGHTER

CKPS ECCRANK SHAFT POSITION SEN-

SOR (OBD)

CLOCK EL CLOCK

COOL/F EC COOLING FAN CONTROL

D/LOCK EL POWER DOOR LOCK

DEF EL REAR WINDOW DEFOGGER

DTRL ELHEADLAMP Ð WITH DAYTIME

LIGHT SYSTEM

ECMRLY EC ECM RELAY

ECTS ECENGINE COOLANT TEMPERA-

TURE SENSOR

EGRC/V ECEGR VALVE AND EVAP CANISTER

PURGE CONTROL SOLENOID

VA LV E

EGVC/V EC EGR VOLUME CONTROL VALVE

ENGSS AT ENGINE SPEED SIGNAL

F/FOG EL FRONT FOG LAMP

Code Section Wiring Diagram Name

FTS ATA/T FLUID TEMPERATURE SEN-

SOR

GLOW EC QUICK GLOW SYSTEM

H/AIM ELHEADLAMP AIMING CONTROL

SYSTEM

H/LAMP EL HEADLAMP

HEATER HA HEATER SYSTEM

HEATUP EC HEAT UP SWITCH

HLC EL HEADLAMP CLEANER

HORN EL HORN

HSEAT EL HEATED SEAT

ILL EL ILLUMINATION

INJPMP ECELECTRONIC CONTROL FUEL

INJECTION PUMP

INT/L EL INTERIOR AND MAP LAMPS

INT/V ECINTAKE AIR CONTROL VALVE

CONTROL SOLENOID VALVE

LPSV ATLINE PRESSURE SOLENOID

VA LV E

MAFS EC MASS AIR FLOW SENSOR

MAIN ATMAIN POWER SUPPLY AND

GROUND CIRCUIT

MAIN ECMAIN POWER SUPPLY AND

GROUND CIRCUIT

METER ELSPEEDOMETER, TACHOMETER,

TEMP. AND FUEL GAUGES

MIL/DL ECMIL AND DATA LINK CONNEC-

TORS

MIRROR EL DOOR MIRROR

MULTI ELREMOTE KEYLESS ENTRY SYS-

TEM

NATS EL NISSAN ANTI-THEFT SYSTEM

NLS EC NEEDLE LIFT SENSOR

NONDTC AT NON-DETECTABLE ITEMS

OILPSW EC OIL PRESSURE SWITCH

OVRCSV ATOVER RUN CLUTCH SOLENOID

VA LV E

PNP/SW ATPARK/NEUTRAL POSITION

SWITCH

PNP/SW EC NEUTRAL POSITION SWITCH

R/FOG EL REAR FOG LAMP

REMOTE ELAUDIO (REMOTE CONTROL

SWITCH)

S/LOCK ELPOWER DOOR LOCK-SUPER

LOCK

S/SIG EC START SIGNAL

WIRING DIAGRAM CODES (CELL CODES)

EL-291

Page 1132 of 1767

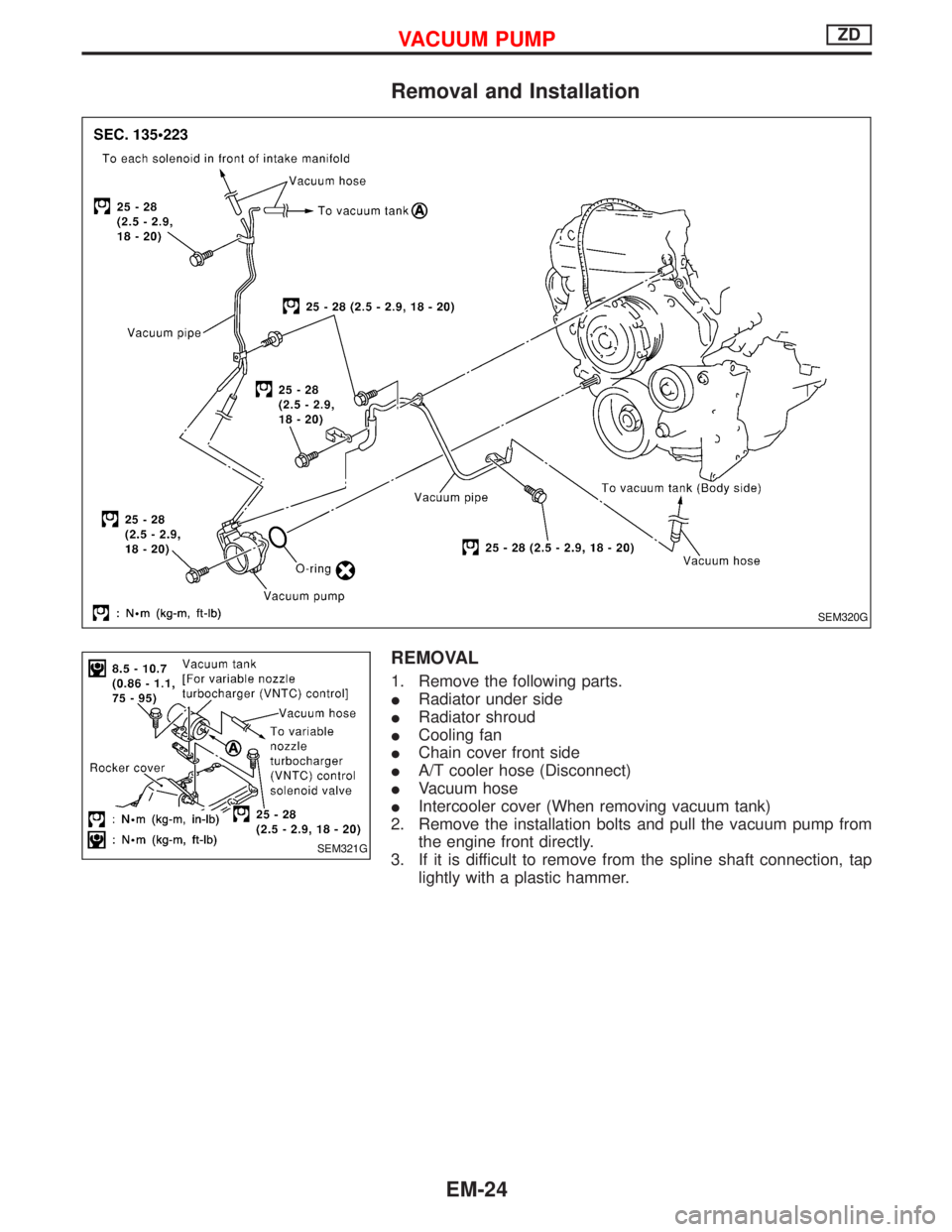

Removal and Installation

REMOVAL

1. Remove the following parts.

IRadiator under side

IRadiator shroud

ICooling fan

IChain cover front side

IA/T cooler hose (Disconnect)

IVacuum hose

IIntercooler cover (When removing vacuum tank)

2. Remove the installation bolts and pull the vacuum pump from

the engine front directly.

3. If it is difficult to remove from the spline shaft connection, tap

lightly with a plastic hammer.

SEM320G

SEM321G

VACUUM PUMPZD

EM-24

Page 1154 of 1767

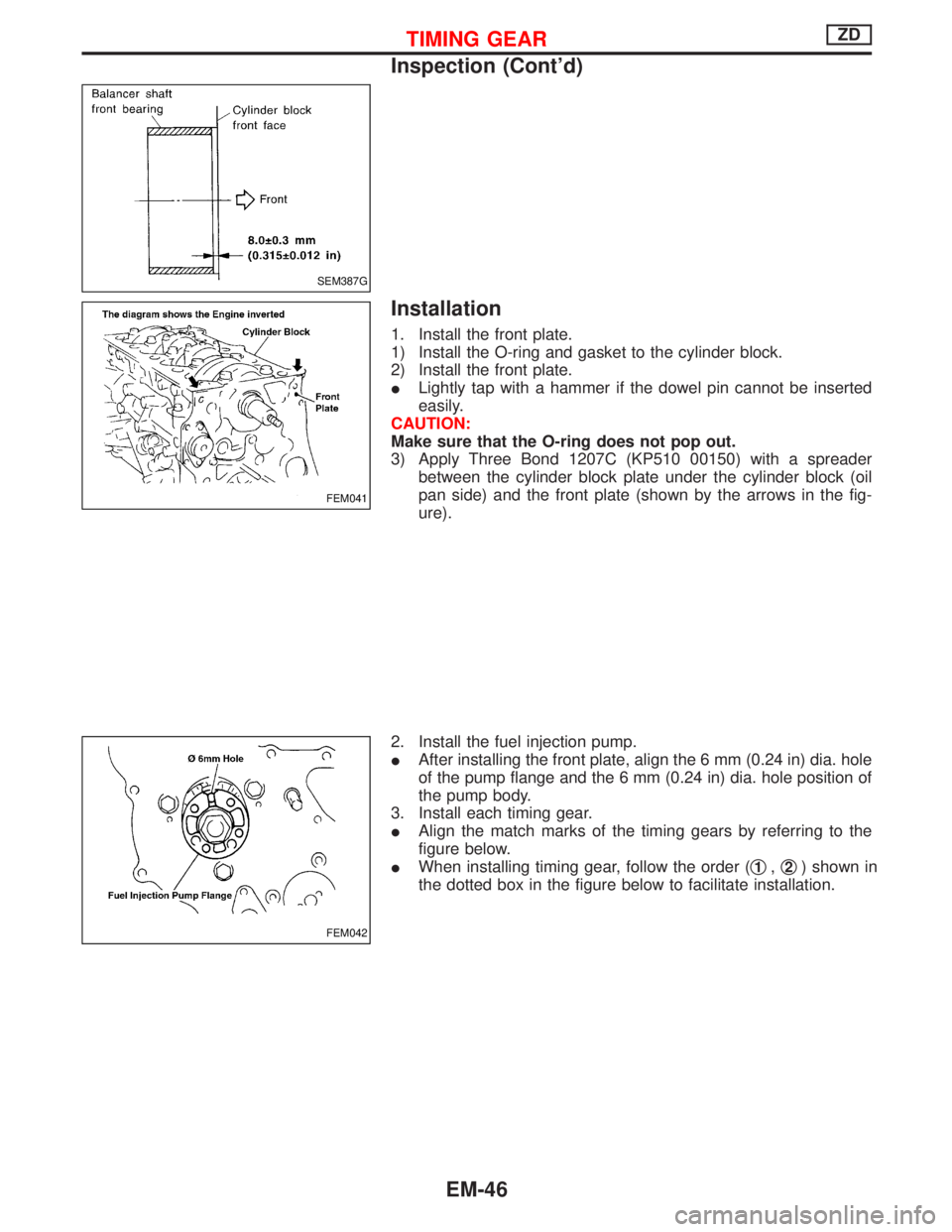

Installation

1. Install the front plate.

1) Install the O-ring and gasket to the cylinder block.

2) Install the front plate.

ILightly tap with a hammer if the dowel pin cannot be inserted

easily.

CAUTION:

Make sure that the O-ring does not pop out.

3) Apply Three Bond 1207C (KP510 00150) with a spreader

between the cylinder block plate under the cylinder block (oil

pan side) and the front plate (shown by the arrows in the fig-

ure).

2. Install the fuel injection pump.

IAfter installing the front plate, align the 6 mm (0.24 in) dia. hole

of the pump flange and the 6 mm (0.24 in) dia. hole position of

the pump body.

3. Install each timing gear.

IAlign the match marks of the timing gears by referring to the

figure below.

IWhen installing timing gear, follow the order (q

1,q2) shown in

the dotted box in the figure below to facilitate installation.

SEM387G

FEM041

FEM042

TIMING GEARZD

Inspection (Cont'd)

EM-46

Page 1185 of 1767

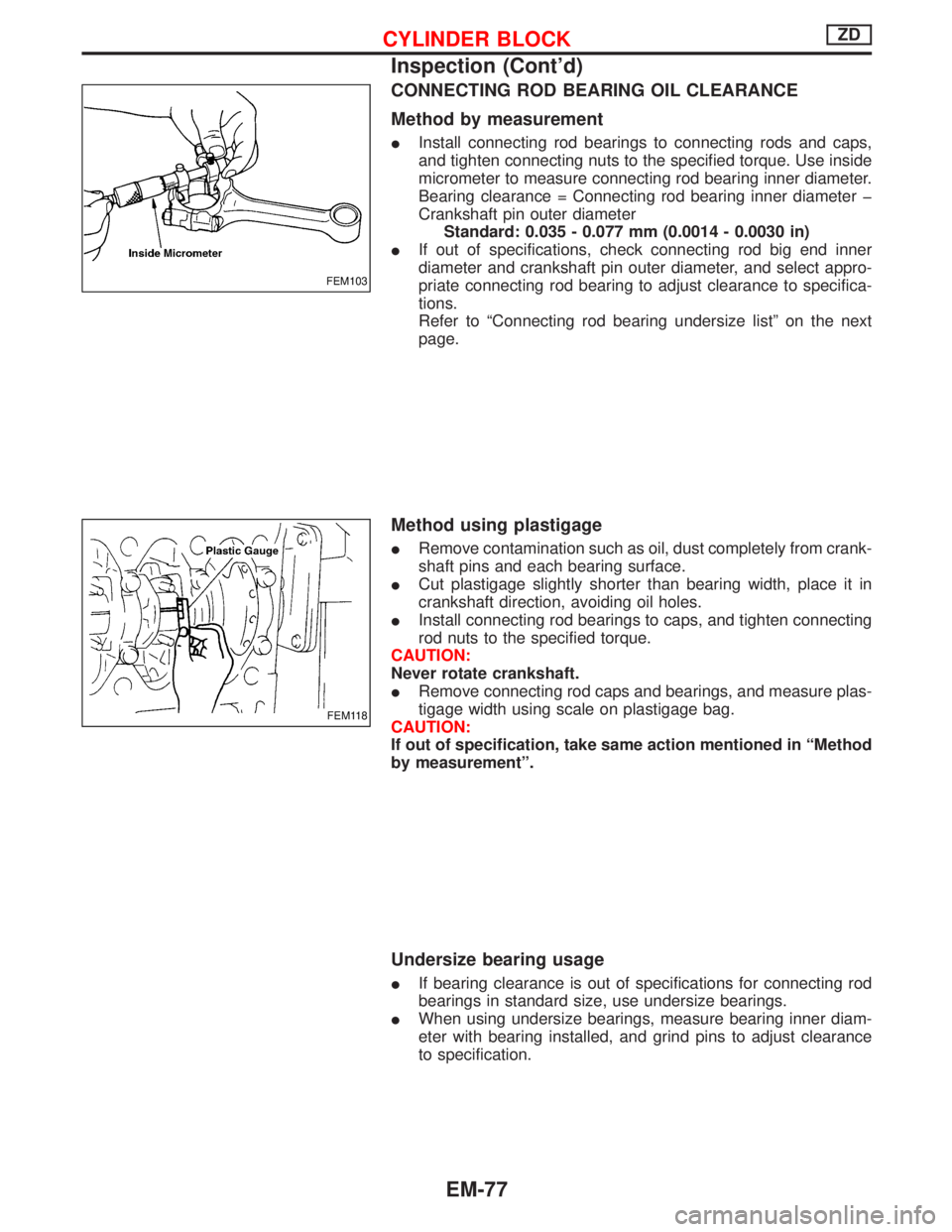

CONNECTING ROD BEARING OIL CLEARANCE

Method by measurement

IInstall connecting rod bearings to connecting rods and caps,

and tighten connecting nuts to the specified torque. Use inside

micrometer to measure connecting rod bearing inner diameter.

Bearing clearance = Connecting rod bearing inner diameter þ

Crankshaft pin outer diameter

Standard: 0.035 - 0.077 mm (0.0014 - 0.0030 in)

IIf out of specifications, check connecting rod big end inner

diameter and crankshaft pin outer diameter, and select appro-

priate connecting rod bearing to adjust clearance to specifica-

tions.

Refer to ªConnecting rod bearing undersize listº on the next

page.

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft pins and each bearing surface.

ICut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

IInstall connecting rod bearings to caps, and tighten connecting

rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

IRemove connecting rod caps and bearings, and measure plas-

tigage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

IIf bearing clearance is out of specifications for connecting rod

bearings in standard size, use undersize bearings.

IWhen using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind pins to adjust clearance

to specification.

FEM103

FEM118

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-77