light NISSAN TERRANO 2002 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1493 of 1767

4. Wipe clean fuel filter mounting surface on fuel filter bracket and

smear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 or a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

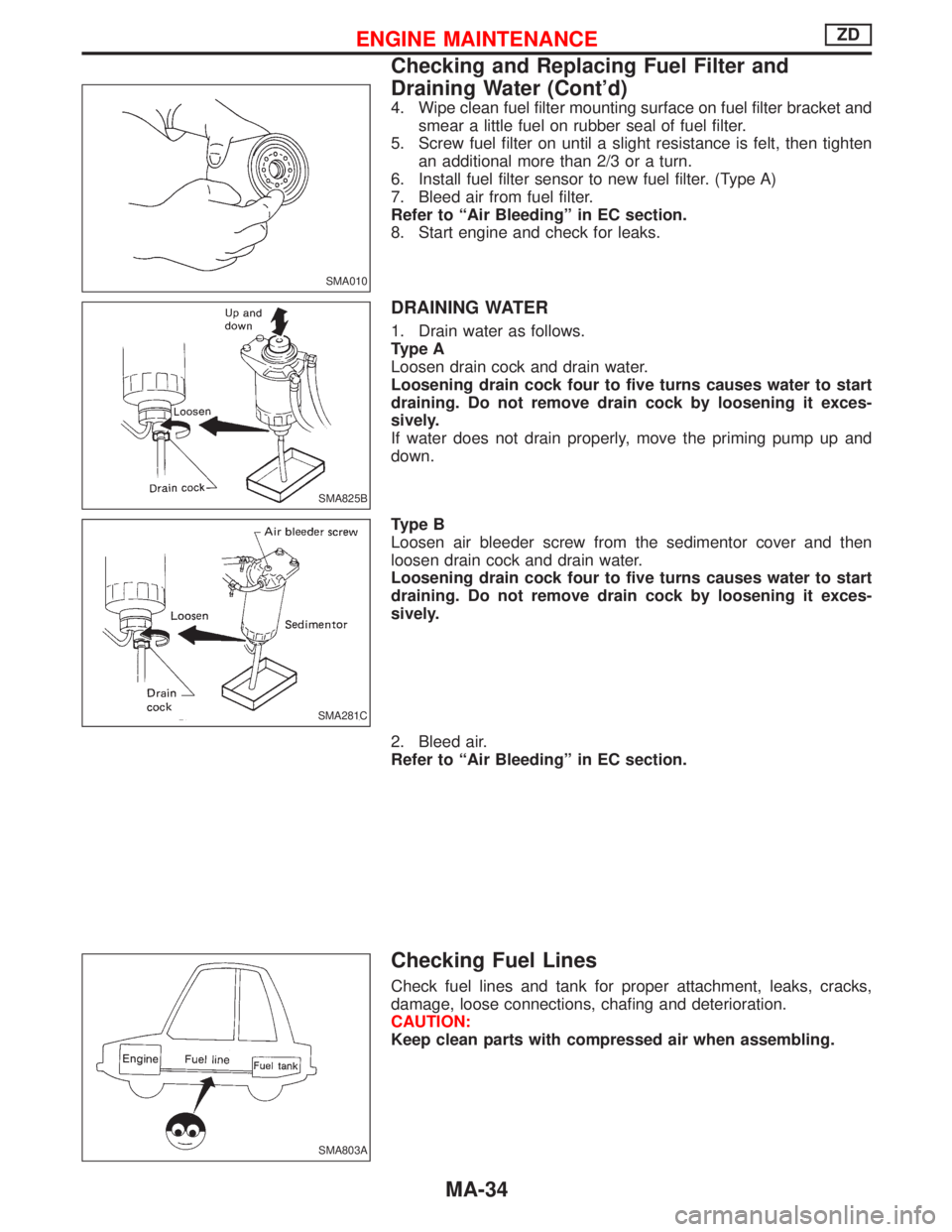

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-34

Page 1518 of 1767

IRaise the unit with a hoist.

IPosition the transmission assembly on a portable jack and

secure it with a suitable tool.

Lift the assembly until the gearbox input shaft faces its hous-

ing.

Move the assembly towards the engine. The assembly must be

rotated slightly so that the starter motor housing clears the

projection on the companion floor. Insert input shaft into its

housing (slightly raising the rear of the transfer box may facili-

tate the introduction of the shaft into its housing).

ITighten the screws securing the gearbox to the engine.

:39-49N×m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

IConnect the electrical wiring. Secure with the respective clips.

IFit the RPM-sensor to the transmission upper side.

IFit the exhaust pipe support bracket to the transfer box.

:13-16N×m (1.3 - 1.6 kg-m,9-12ft-lb)

IFit the starter motor. Secure the earth wire to the starter motor

lower screw.

:31-41N×m (3.2 - 4.2 kg-m, 23 - 30 ft-lb)

IFit the clutch slave cylinder.

:30-40N×m (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

IInstall fourth crossmember (Note the ªfrontº mark).

Crossmember fixing bolts to chassis:

:41-52N×m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

Crossmember fixing bolts to transmission:

:68-87N×m (6.9 - 8.9 kg-m, 50 - 64 ft-lb)

ITake away the portable jack holding boxes assembly.

IInstall fifth crossmember.

:59-78N×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

IInstall third crossmember.

: Screws: 41 - 52 N×m (4.2 - 5.3 kg-m,

30 - 38 ft-lb)

Nuts: 68 - 87 N×m (6.9 - 8.9 kg-m,

50 - 64 ft-lb)

IInstall torsion bar springs. Ð Refer to FA section.

IInstall front and rear propeller shafts. Ð Refer to PD section.

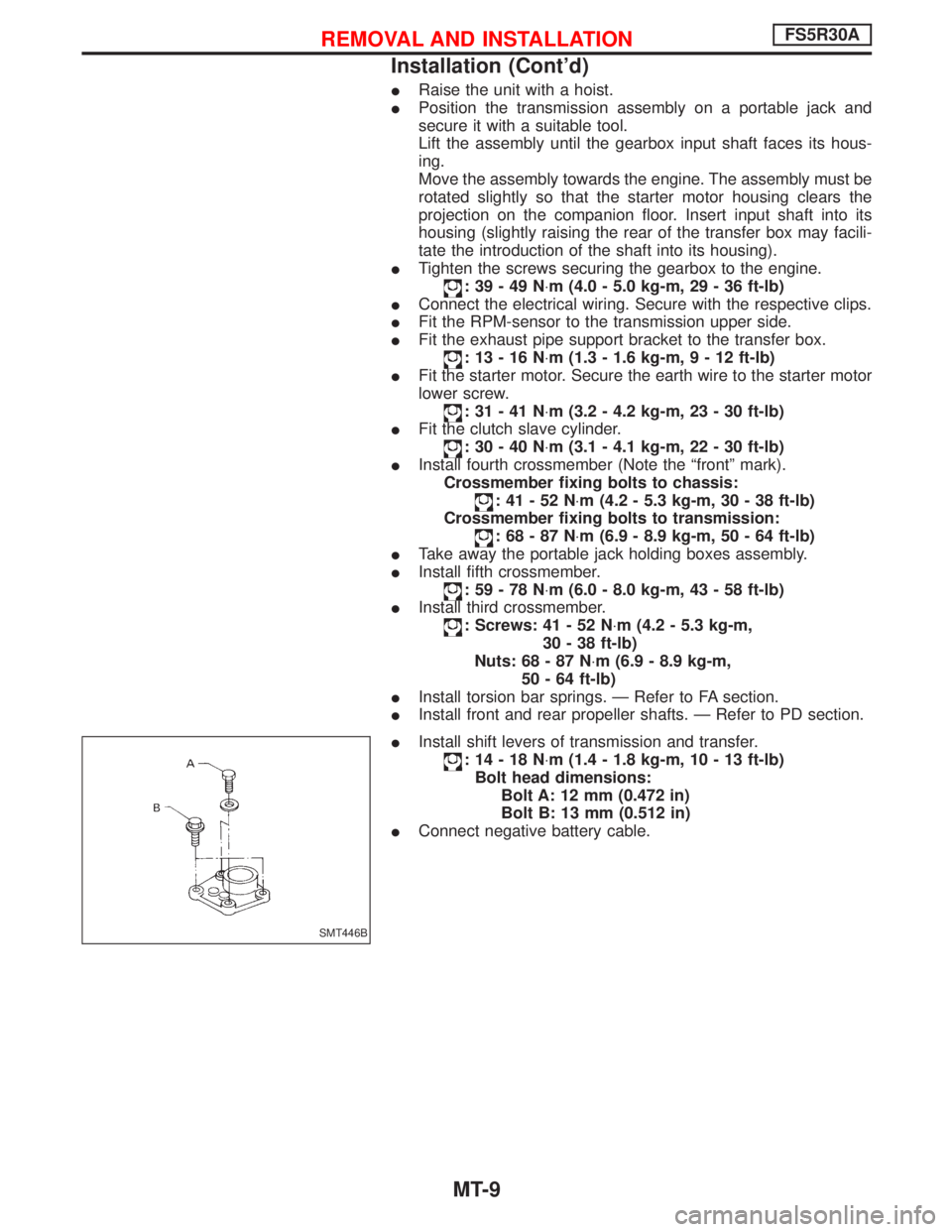

IInstall shift levers of transmission and transfer.

:14-18N×m (1.4 - 1.8 kg-m, 10 - 13 ft-lb)

Bolt head dimensions:

Bolt A: 12 mm (0.472 in)

Bolt B: 13 mm (0.512 in)

IConnect negative battery cable.

SMT446B

REMOVAL AND INSTALLATIONFS5R30A

Installation (Cont'd)

MT-9

Page 1523 of 1767

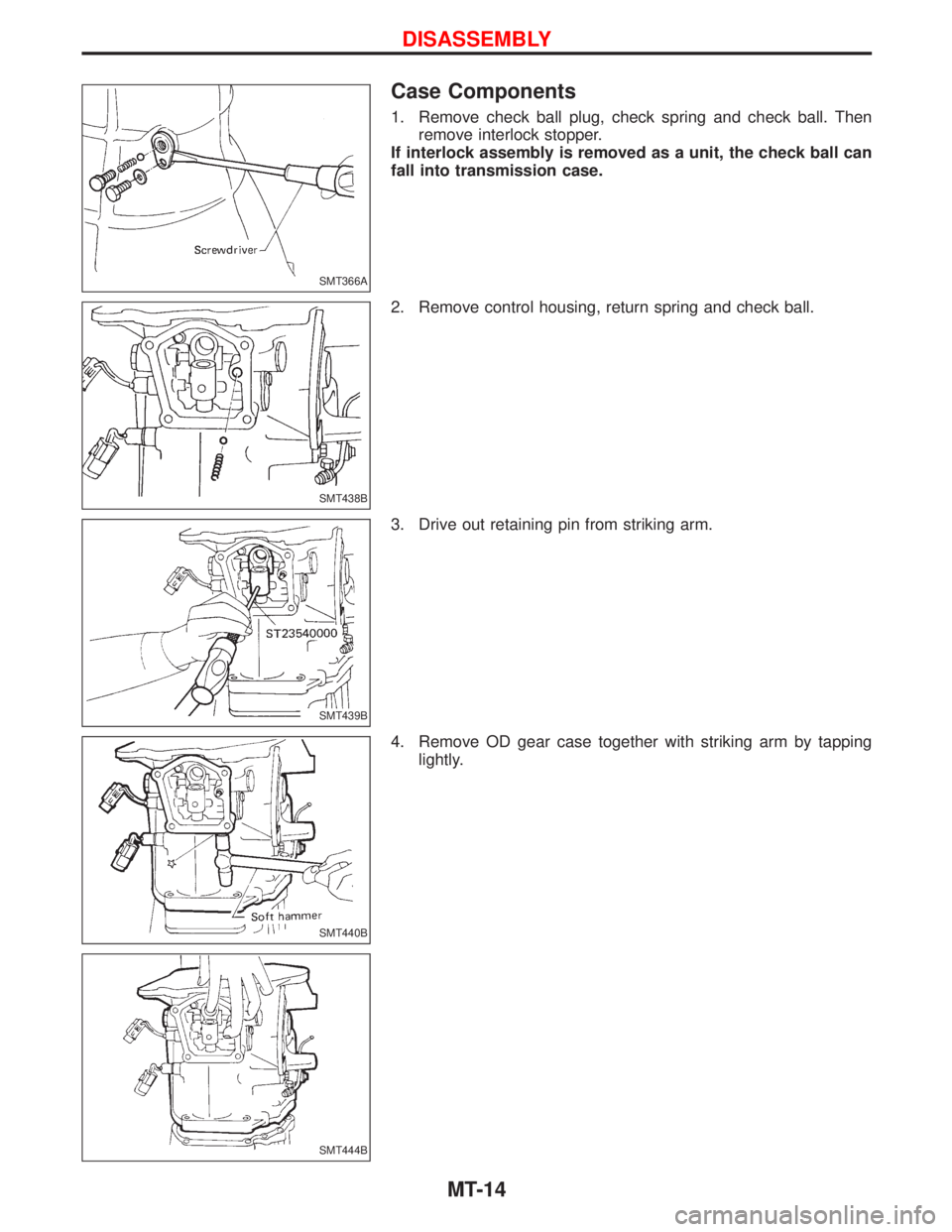

Case Components

1. Remove check ball plug, check spring and check ball. Then

remove interlock stopper.

If interlock assembly is removed as a unit, the check ball can

fall into transmission case.

2. Remove control housing, return spring and check ball.

3. Drive out retaining pin from striking arm.

4. Remove OD gear case together with striking arm by tapping

lightly.

SMT366A

SMT438B

SMT439B

SMT440B

SMT444B

DISASSEMBLY

MT-14

Page 1524 of 1767

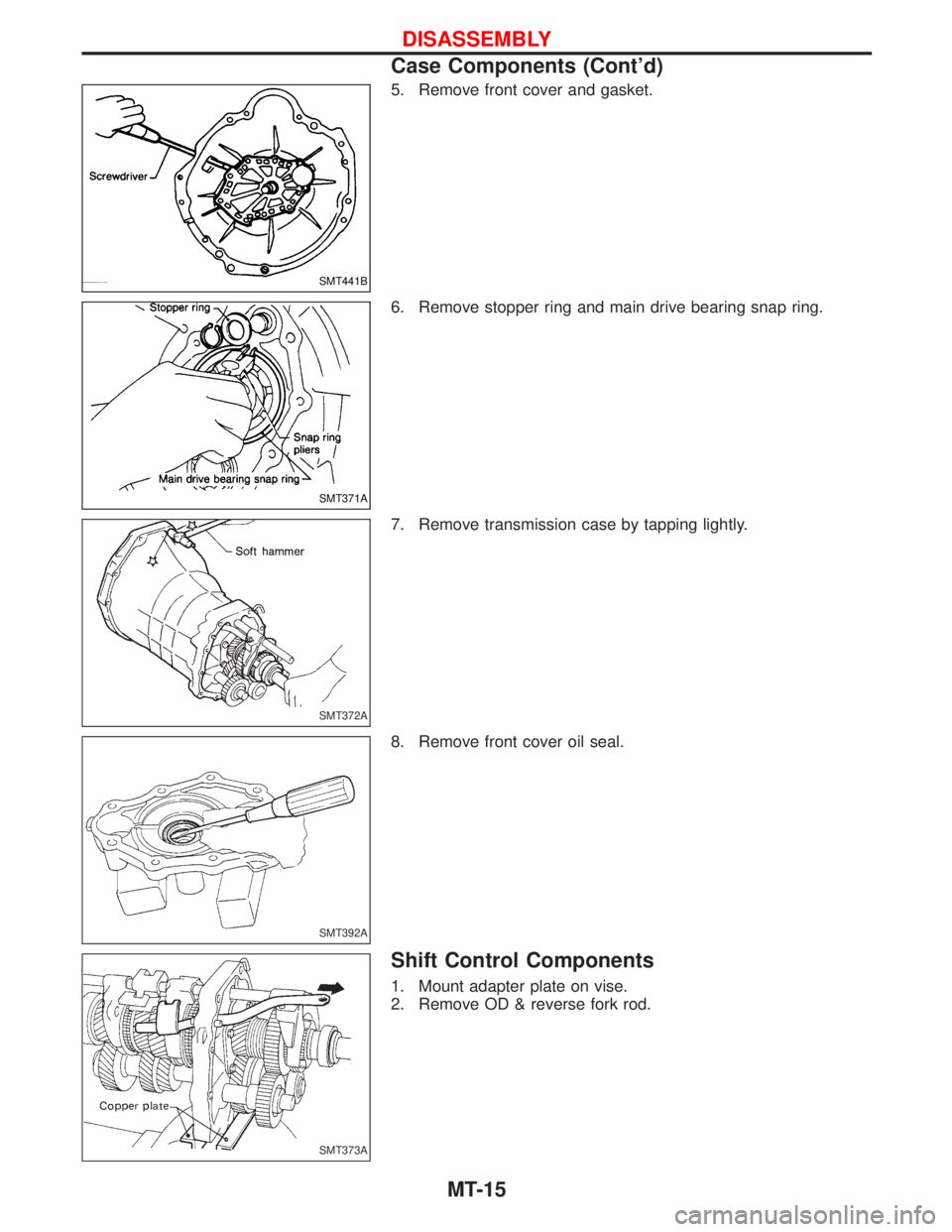

5. Remove front cover and gasket.

6. Remove stopper ring and main drive bearing snap ring.

7. Remove transmission case by tapping lightly.

8. Remove front cover oil seal.

Shift Control Components

1. Mount adapter plate on vise.

2. Remove OD & reverse fork rod.

SMT441B

SMT371A

SMT372A

SMT392A

SMT373A

DISASSEMBLY

Case Components (Cont'd)

MT-15

Page 1553 of 1767

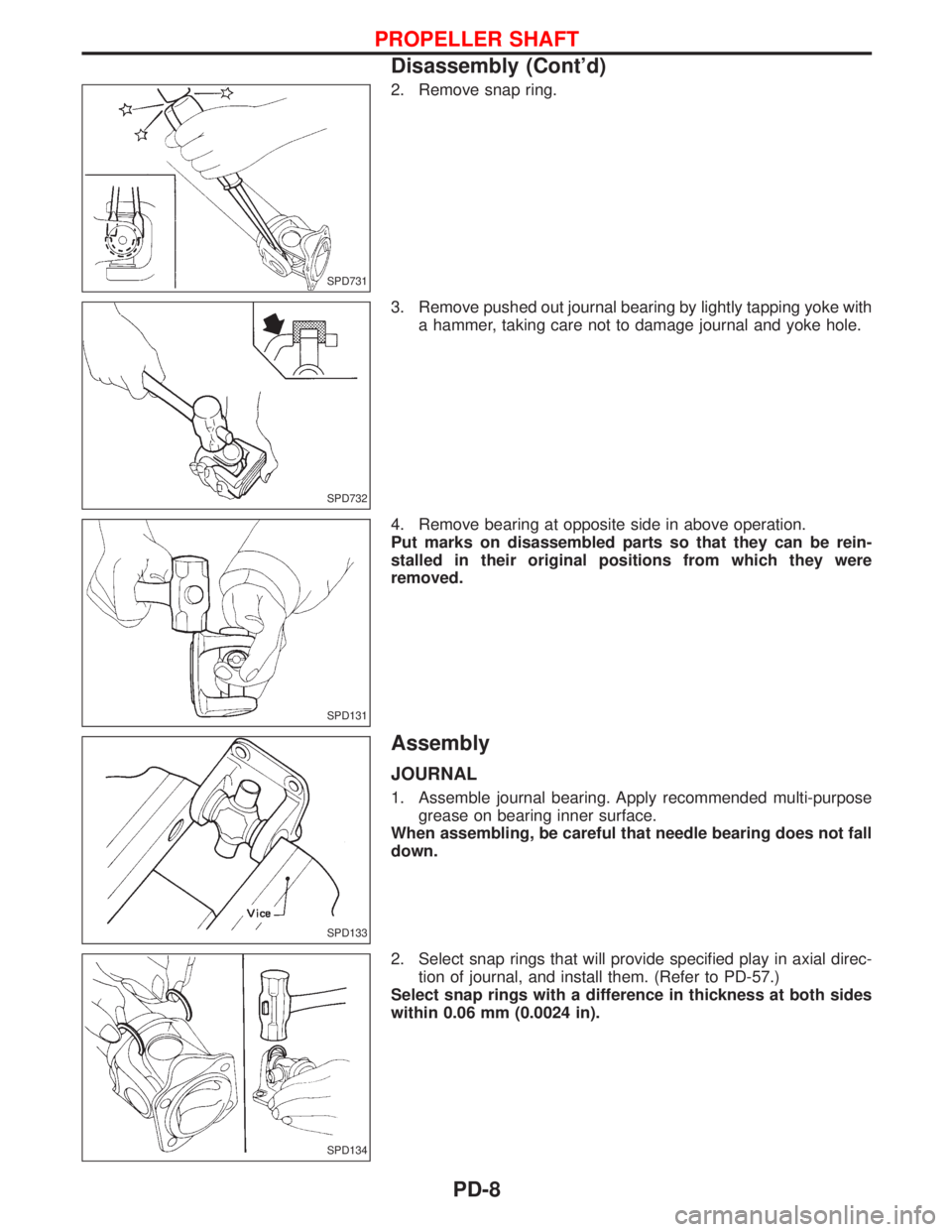

2. Remove snap ring.

3. Remove pushed out journal bearing by lightly tapping yoke with

a hammer, taking care not to damage journal and yoke hole.

4. Remove bearing at opposite side in above operation.

Put marks on disassembled parts so that they can be rein-

stalled in their original positions from which they were

removed.

Assembly

JOURNAL

1. Assemble journal bearing. Apply recommended multi-purpose

grease on bearing inner surface.

When assembling, be careful that needle bearing does not fall

down.

2. Select snap rings that will provide specified play in axial direc-

tion of journal, and install them. (Refer to PD-57.)

Select snap rings with a difference in thickness at both sides

within 0.06 mm (0.0024 in).

SPD731

SPD732

SPD131

SPD133

SPD134

PROPELLER SHAFT

Disassembly (Cont'd)

PD-8

Page 1574 of 1767

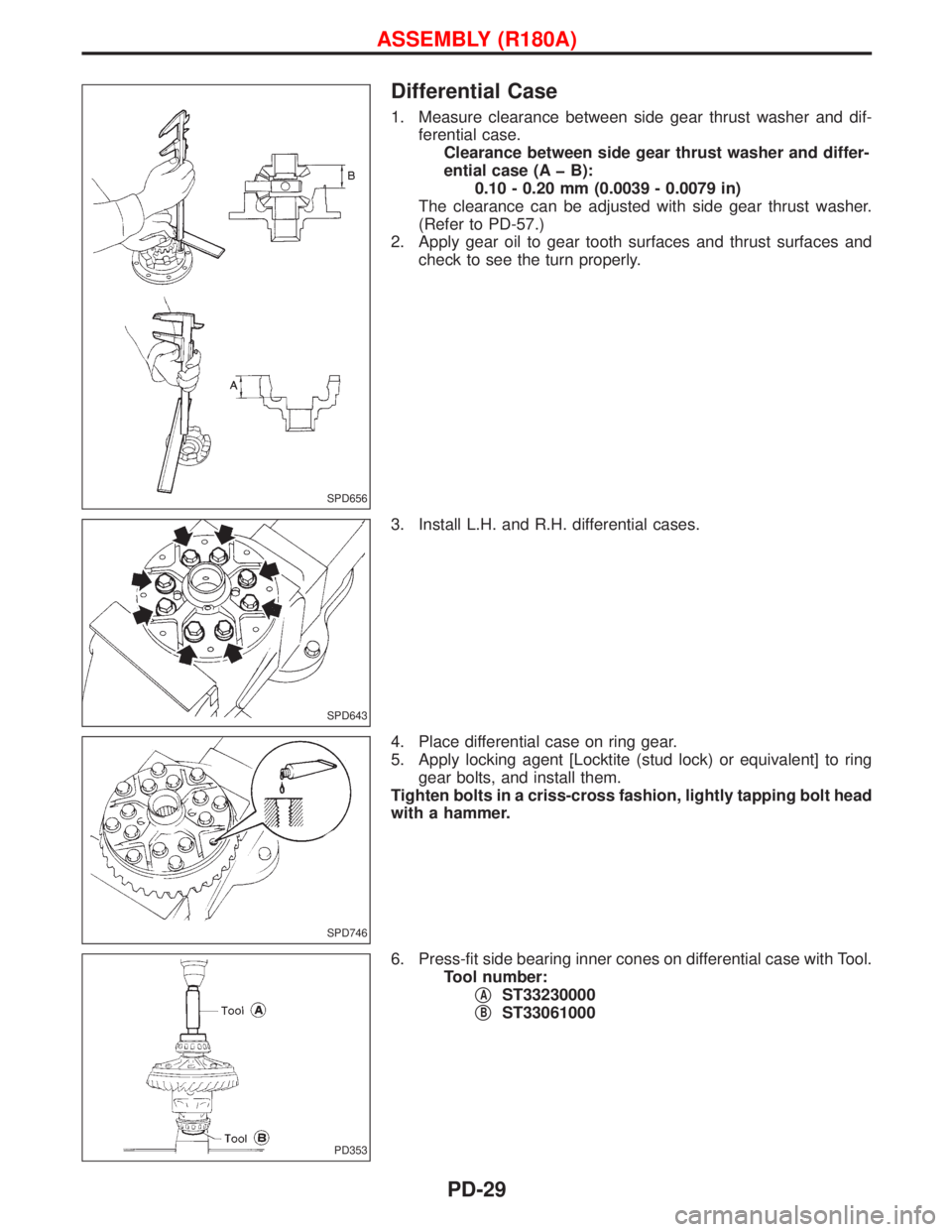

Differential Case

1. Measure clearance between side gear thrust washer and dif-

ferential case.

Clearance between side gear thrust washer and differ-

ential case (A þ B):

0.10 - 0.20 mm (0.0039 - 0.0079 in)

The clearance can be adjusted with side gear thrust washer.

(Refer to PD-57.)

2. Apply gear oil to gear tooth surfaces and thrust surfaces and

check to see the turn properly.

3. Install L.H. and R.H. differential cases.

4. Place differential case on ring gear.

5. Apply locking agent [Locktite (stud lock) or equivalent] to ring

gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

6. Press-fit side bearing inner cones on differential case with Tool.

Tool number:

q

AST33230000

q

BST33061000

SPD656

SPD643

SPD746

PD353

ASSEMBLY (R180A)

PD-29

Page 1593 of 1767

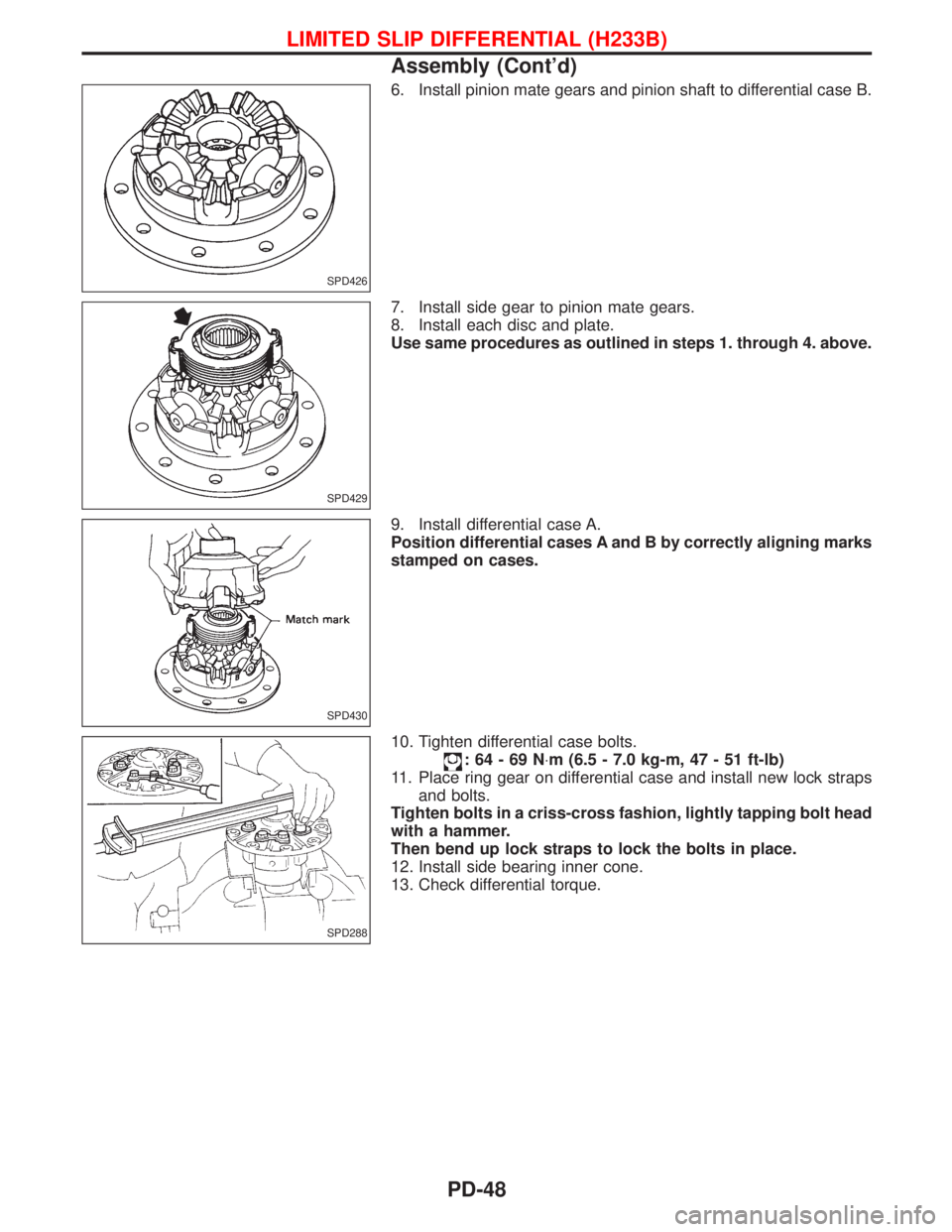

6. Install pinion mate gears and pinion shaft to differential case B.

7. Install side gear to pinion mate gears.

8. Install each disc and plate.

Use same procedures as outlined in steps 1. through 4. above.

9. Install differential case A.

Position differential cases A and B by correctly aligning marks

stamped on cases.

10. Tighten differential case bolts.

:64-69N×m (6.5 - 7.0 kg-m, 47 - 51 ft-lb)

11. Place ring gear on differential case and install new lock straps

and bolts.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

Then bend up lock straps to lock the bolts in place.

12. Install side bearing inner cone.

13. Check differential torque.

SPD426

SPD429

SPD430

SPD288

LIMITED SLIP DIFFERENTIAL (H233B)

Assembly (Cont'd)

PD-48

Page 1600 of 1767

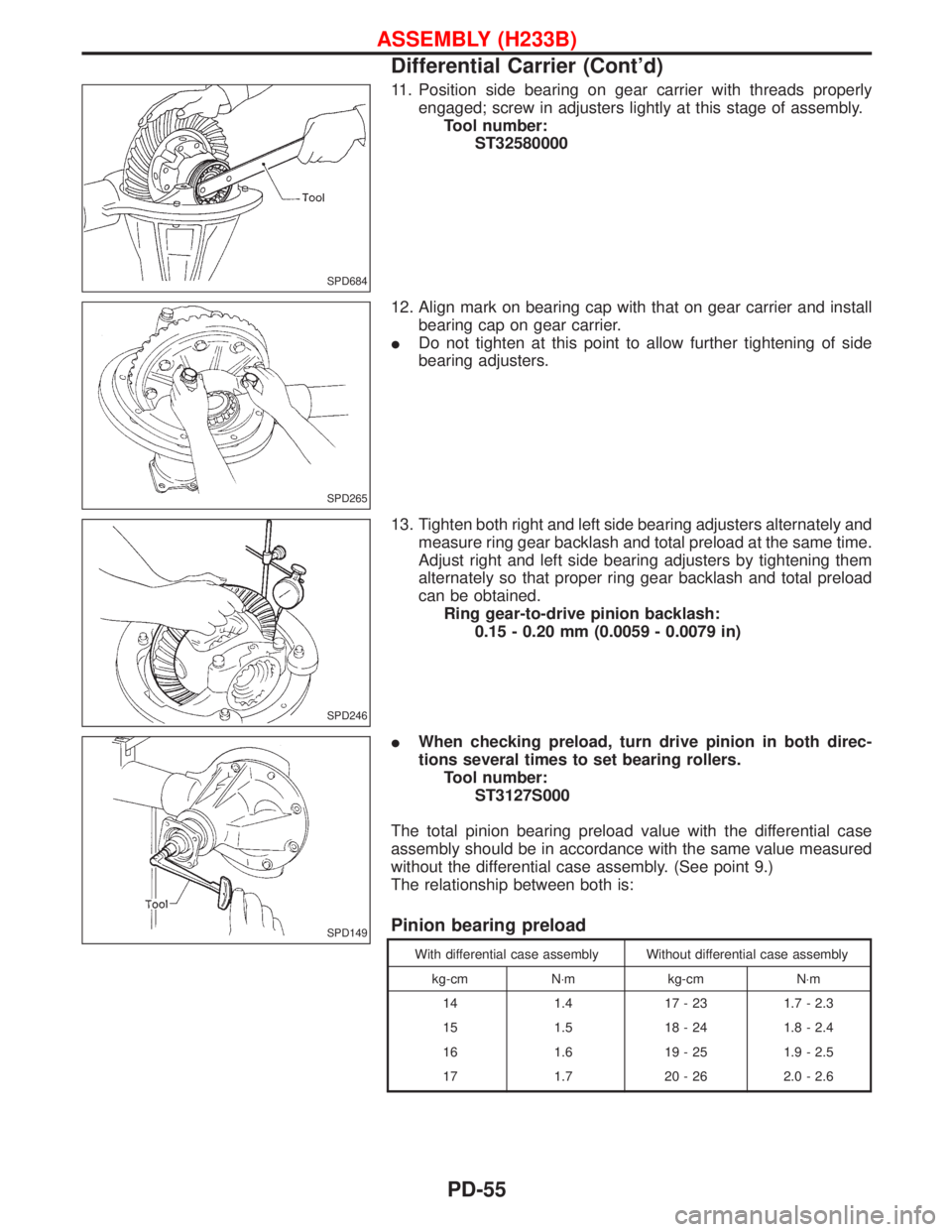

11. Position side bearing on gear carrier with threads properly

engaged; screw in adjusters lightly at this stage of assembly.

Tool number:

ST32580000

12. Align mark on bearing cap with that on gear carrier and install

bearing cap on gear carrier.

IDo not tighten at this point to allow further tightening of side

bearing adjusters.

13. Tighten both right and left side bearing adjusters alternately and

measure ring gear backlash and total preload at the same time.

Adjust right and left side bearing adjusters by tightening them

alternately so that proper ring gear backlash and total preload

can be obtained.

Ring gear-to-drive pinion backlash:

0.15 - 0.20 mm (0.0059 - 0.0079 in)

IWhen checking preload, turn drive pinion in both direc-

tions several times to set bearing rollers.

Tool number:

ST3127S000

The total pinion bearing preload value with the differential case

assembly should be in accordance with the same value measured

without the differential case assembly. (See point 9.)

The relationship between both is:

Pinion bearing preload

With differential case assembly Without differential case assembly

kg-cm N×m kg-cm N×m

14 1.4 17 - 23 1.7 - 2.3

15 1.5 18 - 24 1.8 - 2.4

16 1.6 19 - 25 1.9 - 2.5

17 1.7 20 - 26 2.0 - 2.6

SPD684

SPD265

SPD246

SPD149

ASSEMBLY (H233B)

Differential Carrier (Cont'd)

PD-55

Page 1602 of 1767

Propeller Shaft

GENERAL SPECIFICATIONS

Unit: mm (in)

MODEL ALL H/T WAGON

Portion Front Rear

Propeller shaft

model0F71H 2S80B

Number of joints 2

Coupling

method with

transmissionFlange type Sleeve type

Types of journal

bearingsSolid type (dis-

assembly type)Solid type

Shaft length

(Spider to spi-

der) mm (in)542 (21.34) 725 (28.54) 925 (36.42)

Shaft outer

diameter mm (in)65 (2.56) 65 (2.56)

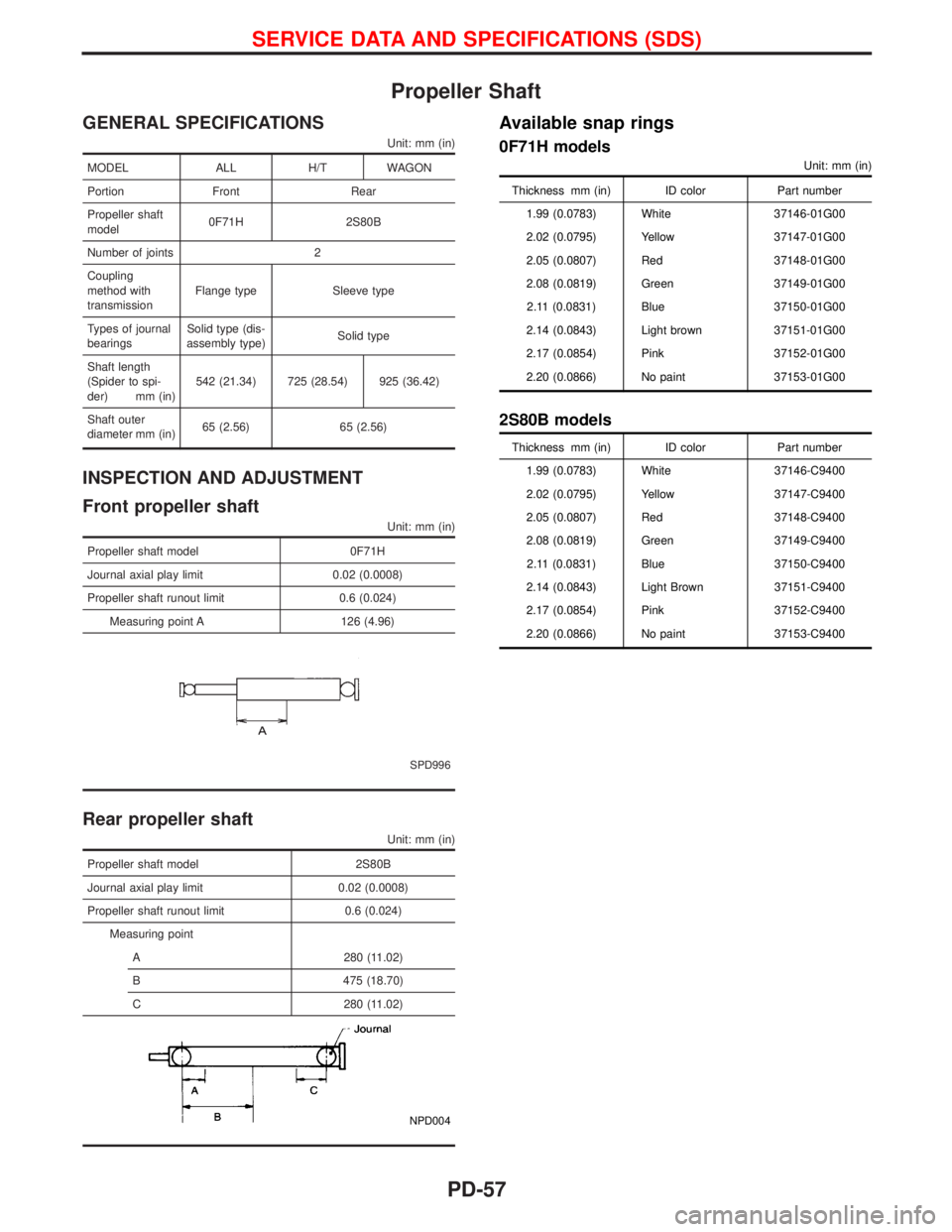

INSPECTION AND ADJUSTMENT

Front propeller shaft

Unit: mm (in)

Propeller shaft model 0F71H

Journal axial play limit 0.02 (0.0008)

Propeller shaft runout limit 0.6 (0.024)

Measuring point A 126 (4.96)

SPD996

Rear propeller shaft

Unit: mm (in)

Propeller shaft model 2S80B

Journal axial play limit 0.02 (0.0008)

Propeller shaft runout limit 0.6 (0.024)

Measuring point

A 280 (11.02)

B 475 (18.70)

C 280 (11.02)

NPD004

Available snap rings

0F71H models

Unit: mm (in)

Thickness mm (in) ID color Part number

1.99 (0.0783) White 37146-01G00

2.02 (0.0795) Yellow 37147-01G00

2.05 (0.0807) Red 37148-01G00

2.08 (0.0819) Green 37149-01G00

2.11 (0.0831) Blue 37150-01G00

2.14 (0.0843) Light brown 37151-01G00

2.17 (0.0854) Pink 37152-01G00

2.20 (0.0866) No paint 37153-01G00

2S80B models

Thickness mm (in) ID color Part number

1.99 (0.0783) White 37146-C9400

2.02 (0.0795) Yellow 37147-C9400

2.05 (0.0807) Red 37148-C9400

2.08 (0.0819) Green 37149-C9400

2.11 (0.0831) Blue 37150-C9400

2.14 (0.0843) Light Brown 37151-C9400

2.17 (0.0854) Pink 37152-C9400

2.20 (0.0866) No paint 37153-C9400

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-57

Page 1642 of 1767

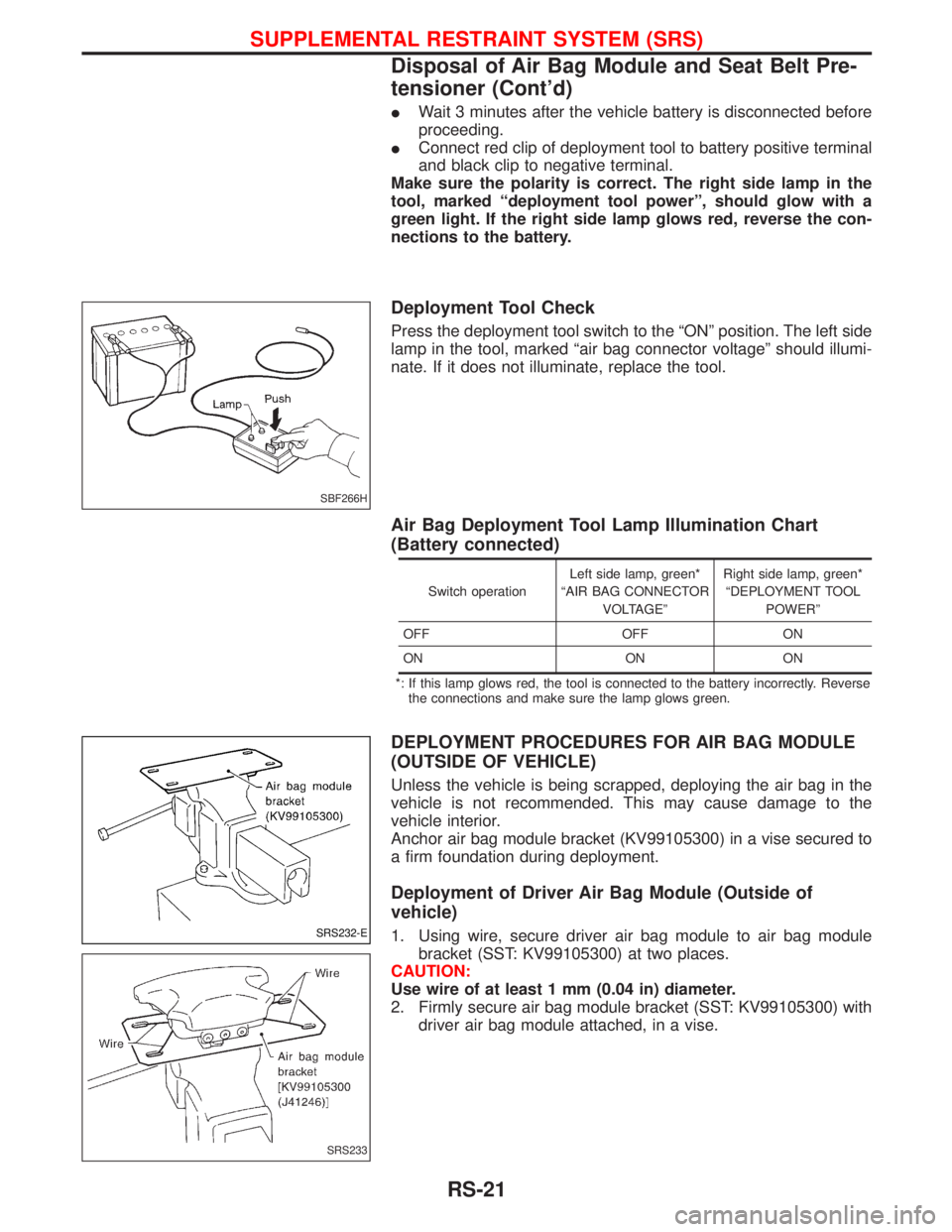

IWait 3 minutes after the vehicle battery is disconnected before

proceeding.

IConnect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

Make sure the polarity is correct. The right side lamp in the

tool, marked ªdeployment tool powerº, should glow with a

green light. If the right side lamp glows red, reverse the con-

nections to the battery.

Deployment Tool Check

Press the deployment tool switch to the ªONº position. The left side

lamp in the tool, marked ªair bag connector voltageº should illumi-

nate. If it does not illuminate, replace the tool.

Air Bag Deployment Tool Lamp Illumination Chart

(Battery connected)

Switch operationLeft side lamp, green*

ªAIR BAG CONNECTOR

VOLTAGEºRight side lamp, green*

ªDEPLOYMENT TOOL

POWERº

OFF OFF ON

ON ON ON

*: If this lamp glows red, the tool is connected to the battery incorrectly. Reverse

the connections and make sure the lamp glows green.

DEPLOYMENT PROCEDURES FOR AIR BAG MODULE

(OUTSIDE OF VEHICLE)

Unless the vehicle is being scrapped, deploying the air bag in the

vehicle is not recommended. This may cause damage to the

vehicle interior.

Anchor air bag module bracket (KV99105300) in a vise secured to

a firm foundation during deployment.

Deployment of Driver Air Bag Module (Outside of

vehicle)

1. Using wire, secure driver air bag module to air bag module

bracket (SST: KV99105300) at two places.

CAUTION:

Use wire of at least 1 mm (0.04 in) diameter.

2. Firmly secure air bag module bracket (SST: KV99105300) with

driver air bag module attached, in a vise.

SBF266H

SRS232-E

SRS233

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-

tensioner (Cont'd)

RS-21