NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1131 of 1767

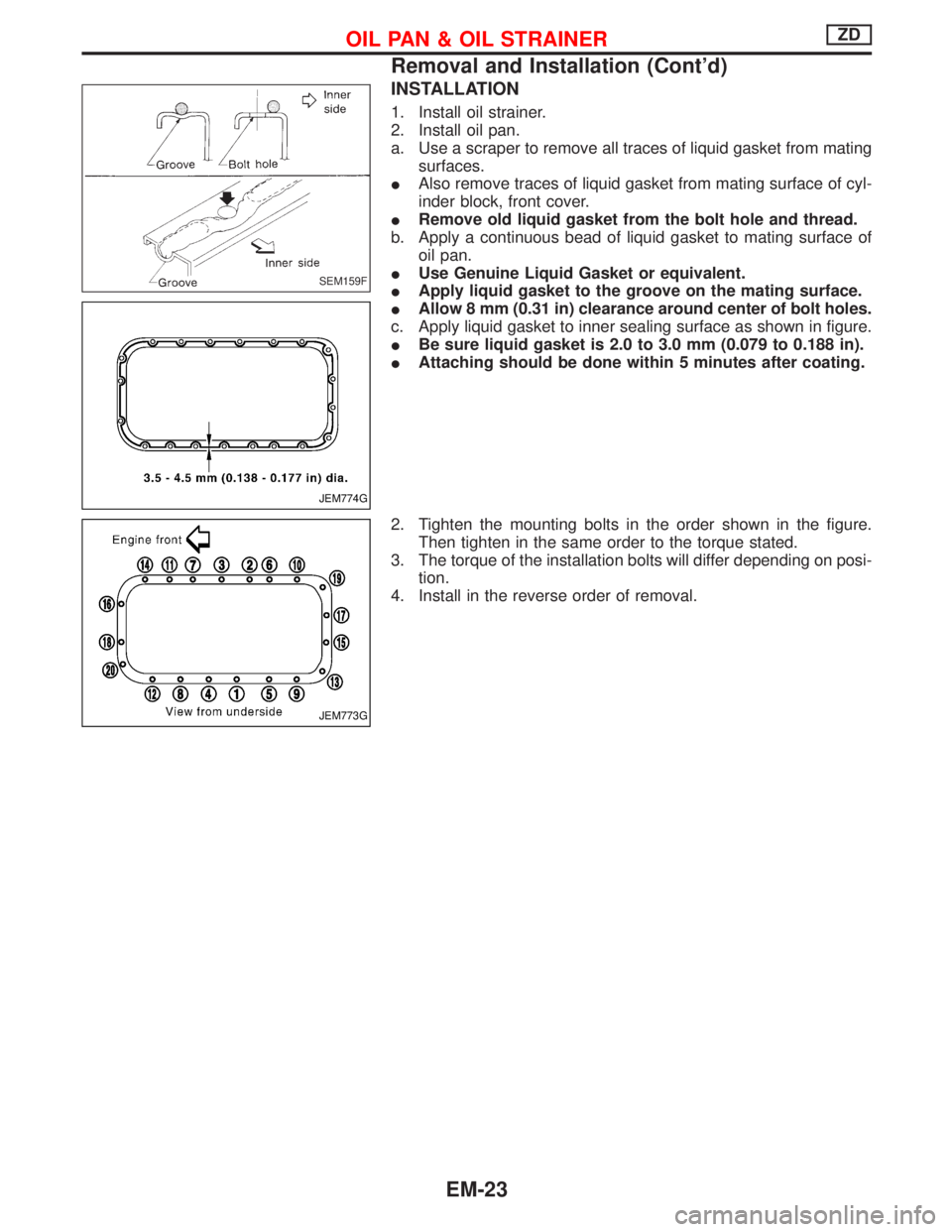

INSTALLATION

1. Install oil strainer.

2. Install oil pan.

a. Use a scraper to remove all traces of liquid gasket from mating

surfaces.

IAlso remove traces of liquid gasket from mating surface of cyl-

inder block, front cover.

IRemove old liquid gasket from the bolt hole and thread.

b. Apply a continuous bead of liquid gasket to mating surface of

oil pan.

IUse Genuine Liquid Gasket or equivalent.

IApply liquid gasket to the groove on the mating surface.

IAllow 8 mm (0.31 in) clearance around center of bolt holes.

c. Apply liquid gasket to inner sealing surface as shown in figure.

IBe sure liquid gasket is 2.0 to 3.0 mm (0.079 to 0.188 in).

IAttaching should be done within 5 minutes after coating.

2. Tighten the mounting bolts in the order shown in the figure.

Then tighten in the same order to the torque stated.

3. The torque of the installation bolts will differ depending on posi-

tion.

4. Install in the reverse order of removal.

SEM159F

JEM774G

JEM773G

OIL PAN & OIL STRAINERZD

Removal and Installation (Cont'd)

EM-23

Page 1132 of 1767

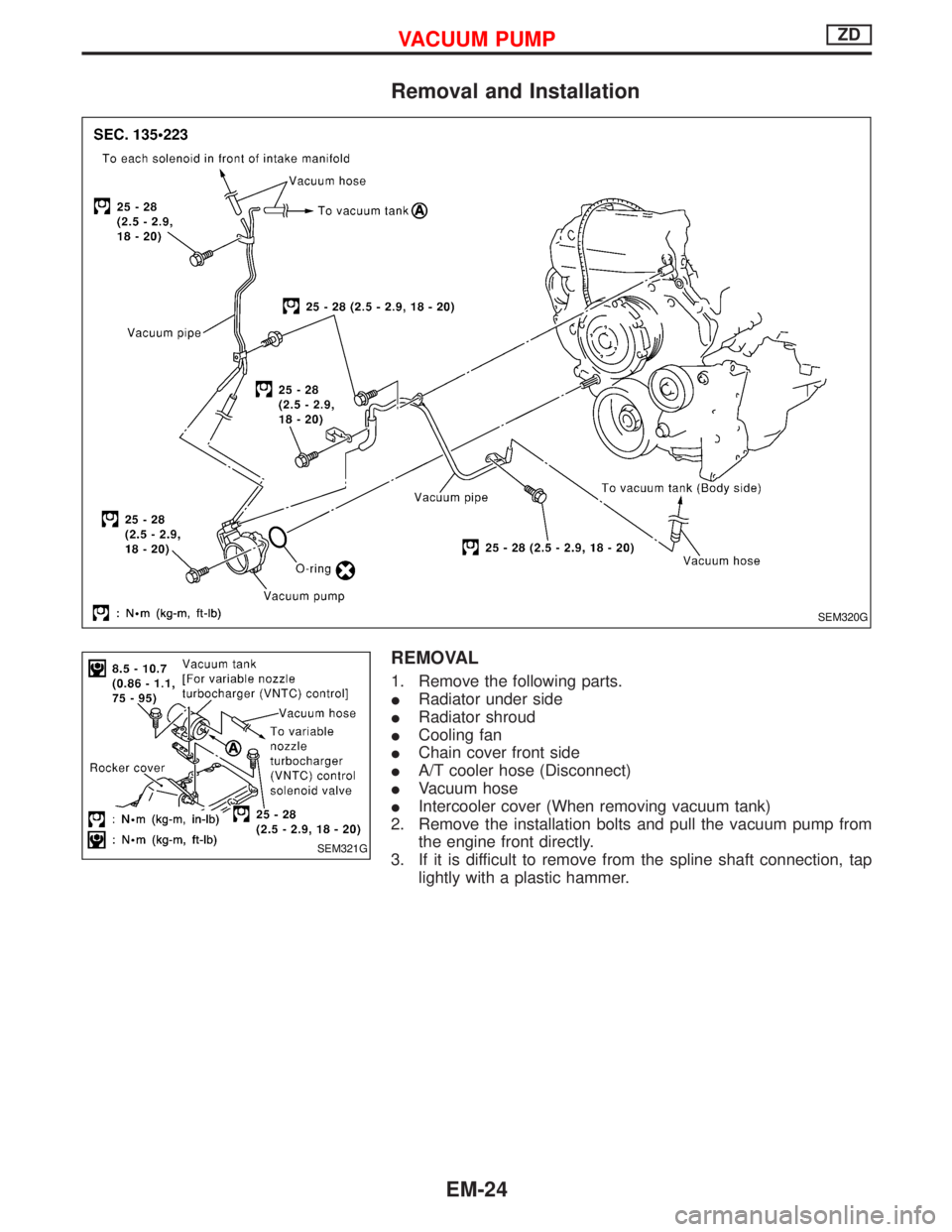

Removal and Installation

REMOVAL

1. Remove the following parts.

IRadiator under side

IRadiator shroud

ICooling fan

IChain cover front side

IA/T cooler hose (Disconnect)

IVacuum hose

IIntercooler cover (When removing vacuum tank)

2. Remove the installation bolts and pull the vacuum pump from

the engine front directly.

3. If it is difficult to remove from the spline shaft connection, tap

lightly with a plastic hammer.

SEM320G

SEM321G

VACUUM PUMPZD

EM-24

Page 1133 of 1767

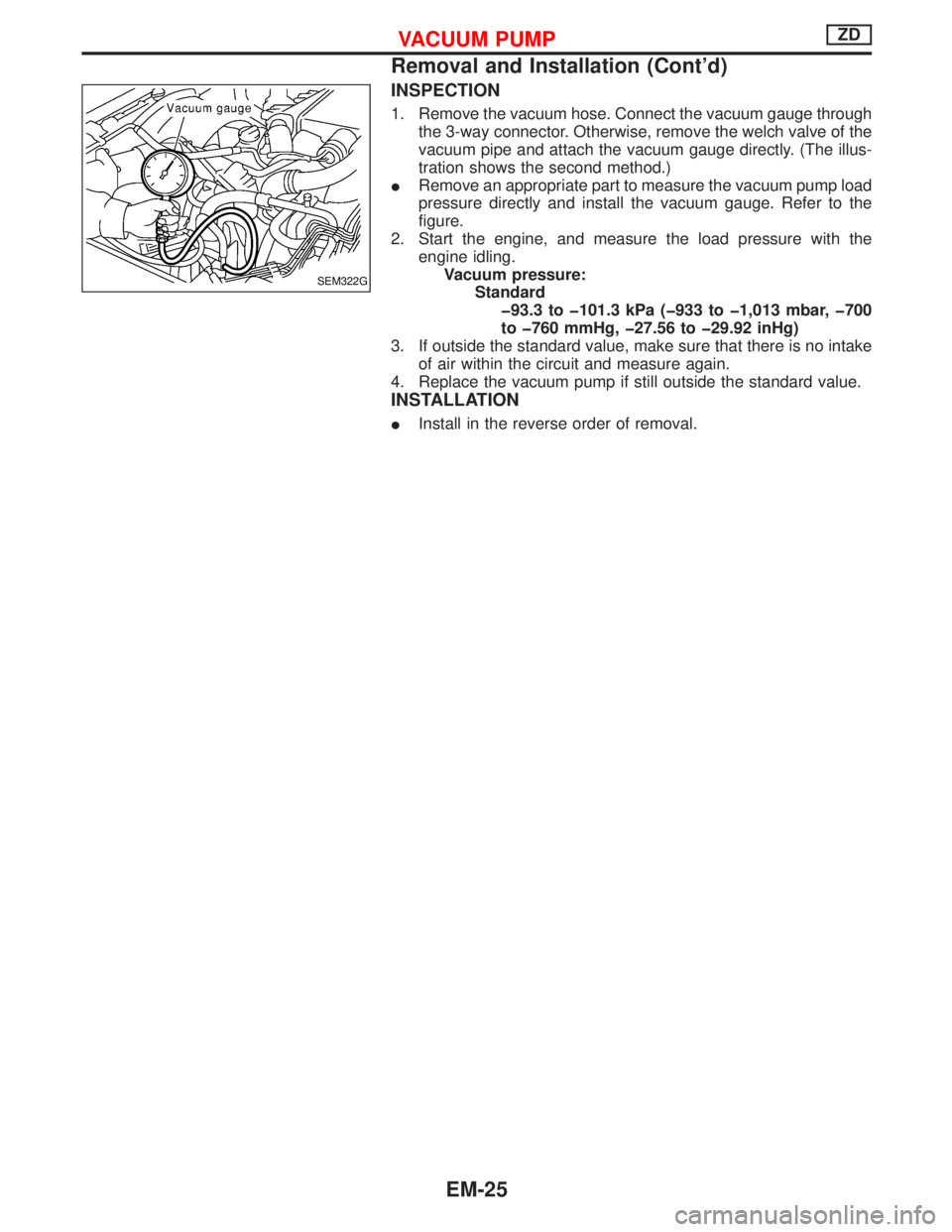

INSPECTION

1. Remove the vacuum hose. Connect the vacuum gauge through

the 3-way connector. Otherwise, remove the welch valve of the

vacuum pipe and attach the vacuum gauge directly. (The illus-

tration shows the second method.)

IRemove an appropriate part to measure the vacuum pump load

pressure directly and install the vacuum gauge. Refer to the

figure.

2. Start the engine, and measure the load pressure with the

engine idling.

Vacuum pressure:

Standard

þ93.3 to þ101.3 kPa (þ933 to þ1,013 mbar, þ700

to þ760 mmHg, þ27.56 to þ29.92 inHg)

3. If outside the standard value, make sure that there is no intake

of air within the circuit and measure again.

4. Replace the vacuum pump if still outside the standard value.

INSTALLATION

IInstall in the reverse order of removal.

SEM322G

VACUUM PUMPZD

Removal and Installation (Cont'd)

EM-25

Page 1134 of 1767

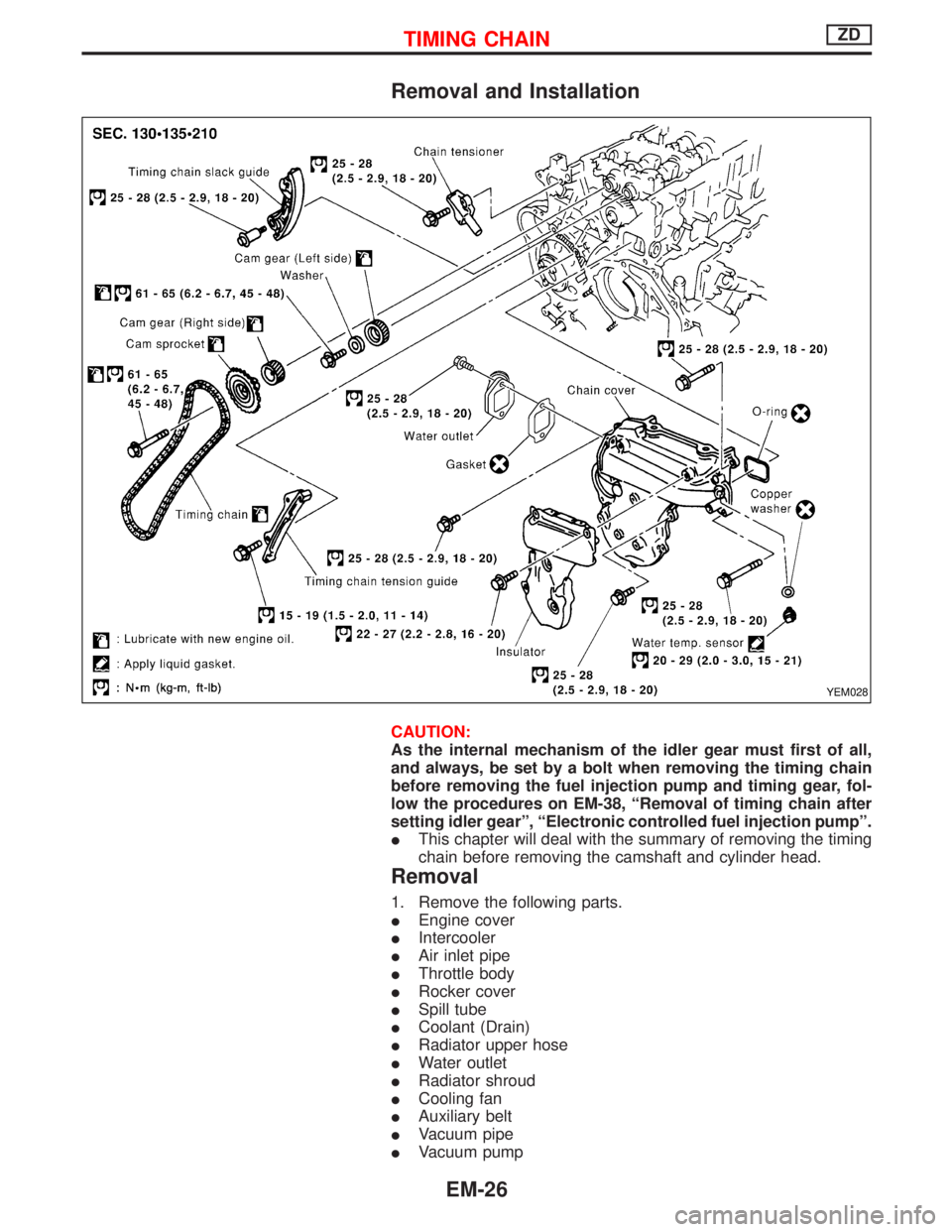

Removal and Installation

CAUTION:

As the internal mechanism of the idler gear must first of all,

and always, be set by a bolt when removing the timing chain

before removing the fuel injection pump and timing gear, fol-

low the procedures on EM-38, ªRemoval of timing chain after

setting idler gearº, ªElectronic controlled fuel injection pumpº.

IThis chapter will deal with the summary of removing the timing

chain before removing the camshaft and cylinder head.

Removal

1. Remove the following parts.

IEngine cover

IIntercooler

IAir inlet pipe

IThrottle body

IRocker cover

ISpill tube

ICoolant (Drain)

IRadiator upper hose

IWater outlet

IRadiator shroud

ICooling fan

IAuxiliary belt

IVacuum pipe

IVacuum pump

YEM028

TIMING CHAINZD

EM-26

Page 1135 of 1767

2. Move the following parts.

ITDC sensor harness

IPower steering oil pump

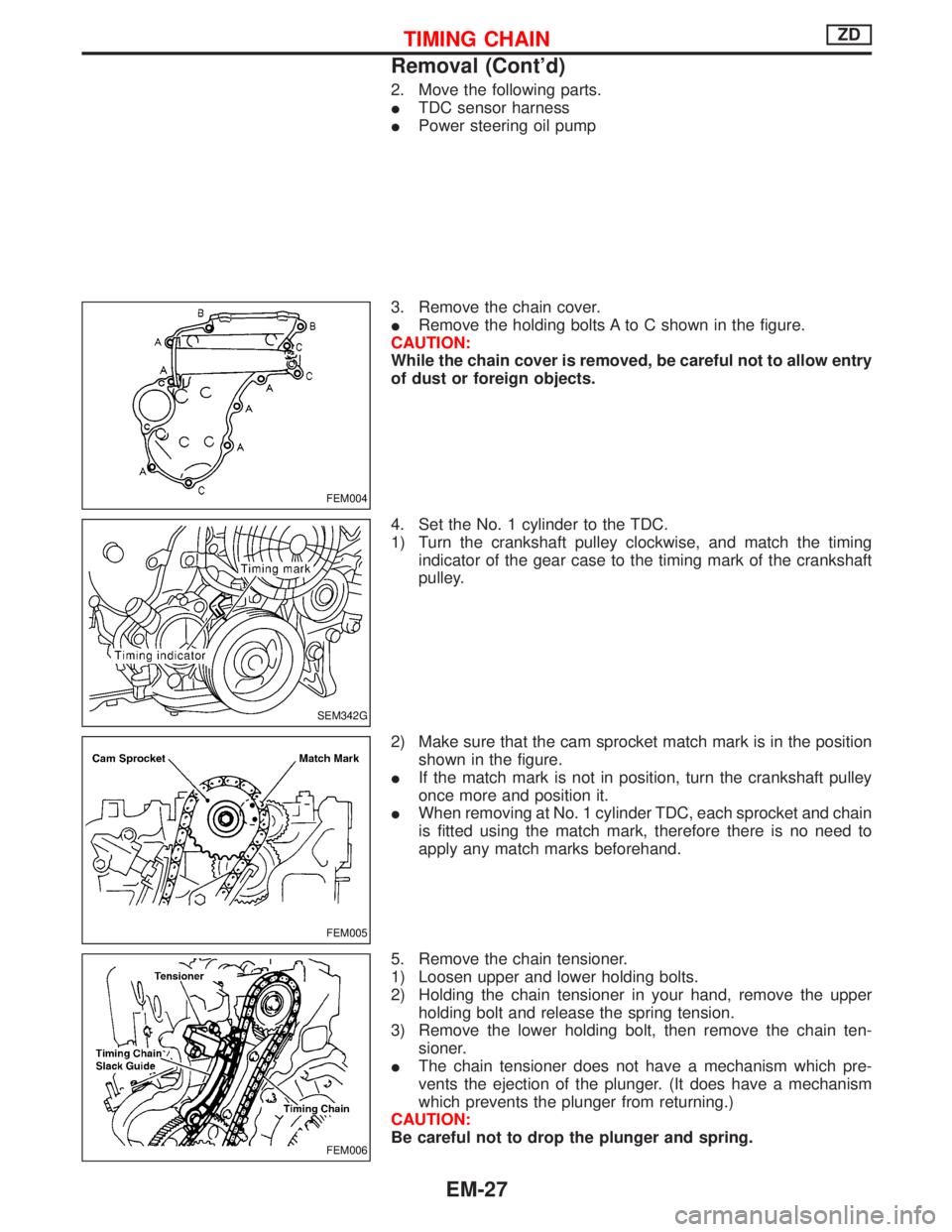

3. Remove the chain cover.

IRemove the holding bolts A to C shown in the figure.

CAUTION:

While the chain cover is removed, be careful not to allow entry

of dust or foreign objects.

4. Set the No. 1 cylinder to the TDC.

1) Turn the crankshaft pulley clockwise, and match the timing

indicator of the gear case to the timing mark of the crankshaft

pulley.

2) Make sure that the cam sprocket match mark is in the position

shown in the figure.

IIf the match mark is not in position, turn the crankshaft pulley

once more and position it.

IWhen removing at No. 1 cylinder TDC, each sprocket and chain

is fitted using the match mark, therefore there is no need to

apply any match marks beforehand.

5. Remove the chain tensioner.

1) Loosen upper and lower holding bolts.

2) Holding the chain tensioner in your hand, remove the upper

holding bolt and release the spring tension.

3) Remove the lower holding bolt, then remove the chain ten-

sioner.

IThe chain tensioner does not have a mechanism which pre-

vents the ejection of the plunger. (It does have a mechanism

which prevents the plunger from returning.)

CAUTION:

Be careful not to drop the plunger and spring.

FEM004

SEM342G

FEM005

FEM006

TIMING CHAINZD

Removal (Cont'd)

EM-27

Page 1136 of 1767

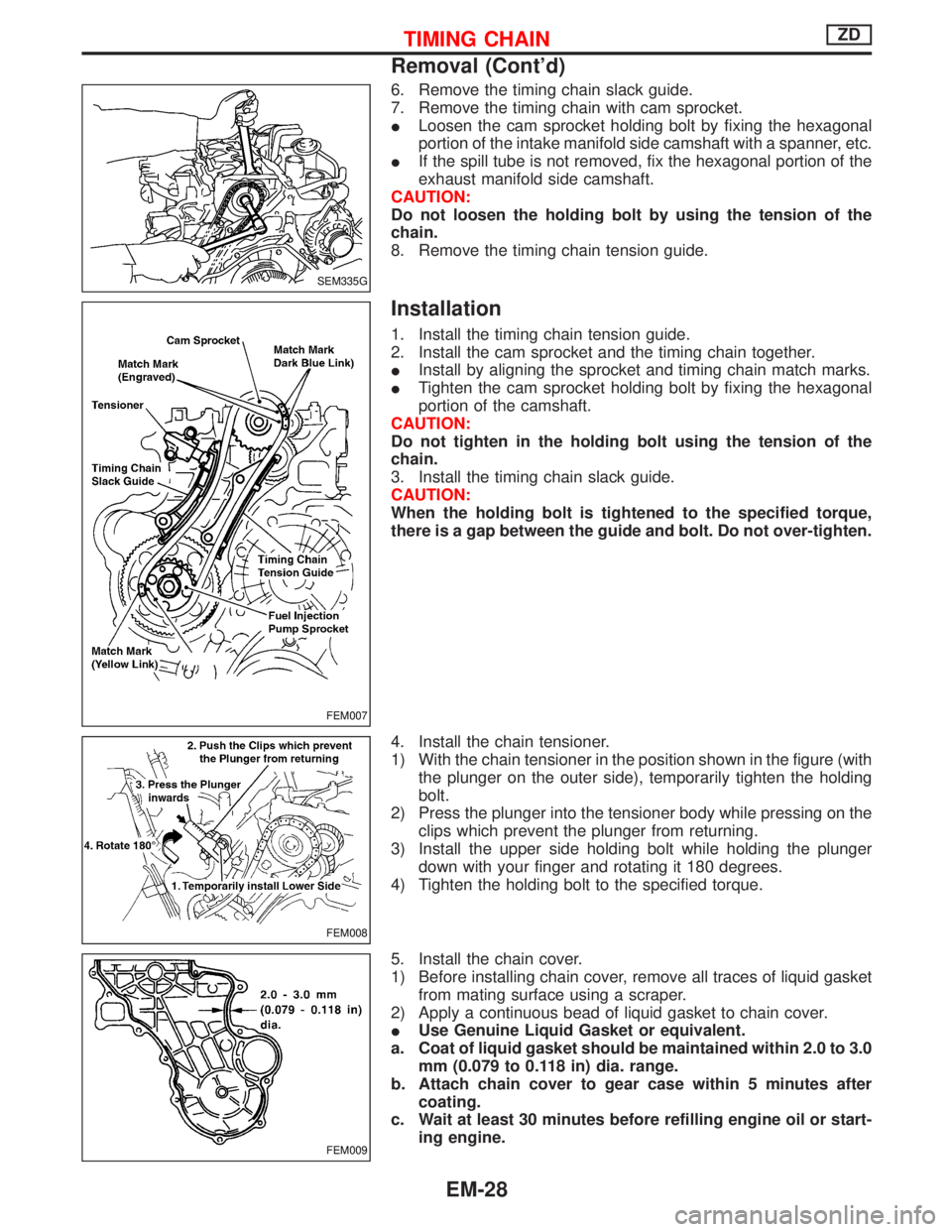

6. Remove the timing chain slack guide.

7. Remove the timing chain with cam sprocket.

ILoosen the cam sprocket holding bolt by fixing the hexagonal

portion of the intake manifold side camshaft with a spanner, etc.

IIf the spill tube is not removed, fix the hexagonal portion of the

exhaust manifold side camshaft.

CAUTION:

Do not loosen the holding bolt by using the tension of the

chain.

8. Remove the timing chain tension guide.

Installation

1. Install the timing chain tension guide.

2. Install the cam sprocket and the timing chain together.

IInstall by aligning the sprocket and timing chain match marks.

ITighten the cam sprocket holding bolt by fixing the hexagonal

portion of the camshaft.

CAUTION:

Do not tighten in the holding bolt using the tension of the

chain.

3. Install the timing chain slack guide.

CAUTION:

When the holding bolt is tightened to the specified torque,

there is a gap between the guide and bolt. Do not over-tighten.

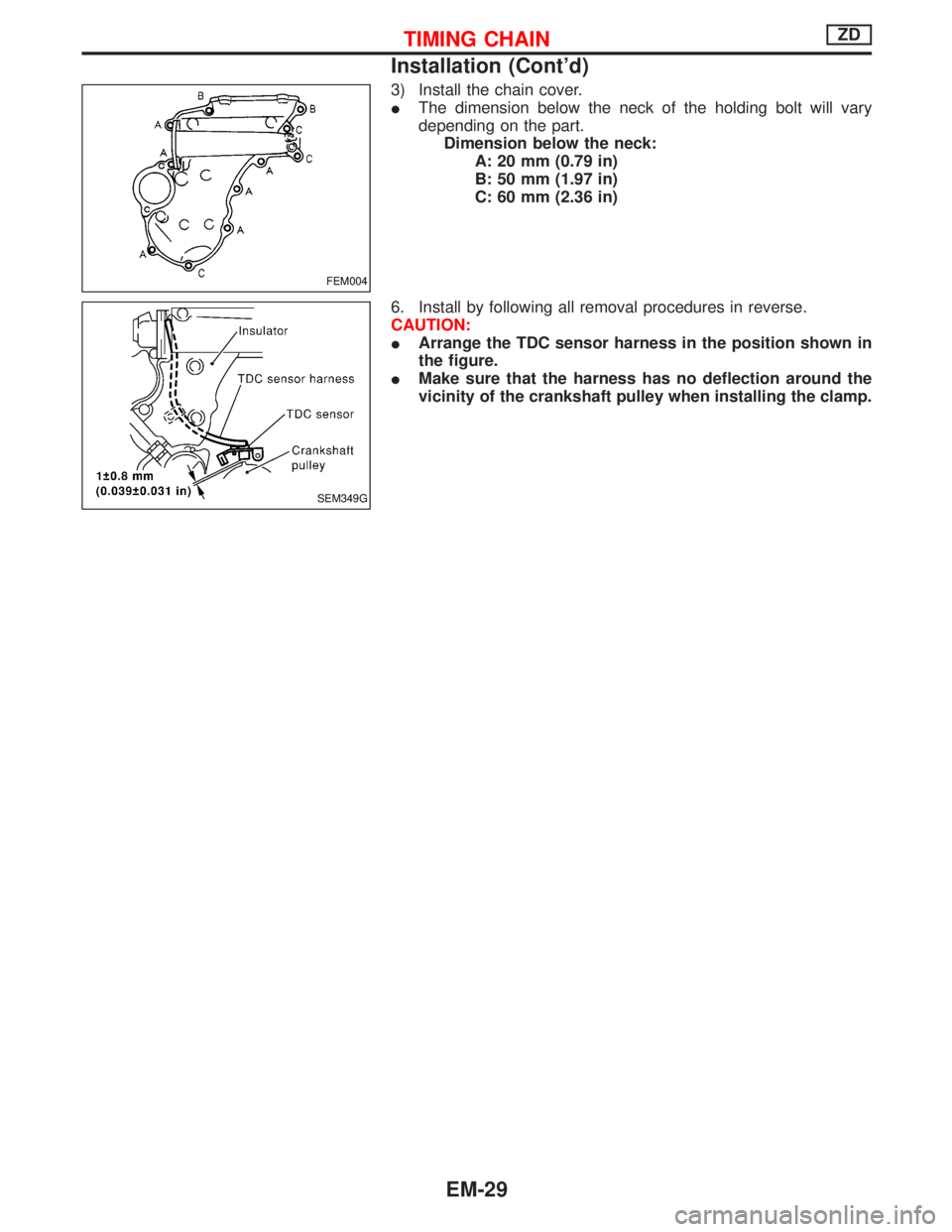

4. Install the chain tensioner.

1) With the chain tensioner in the position shown in the figure (with

the plunger on the outer side), temporarily tighten the holding

bolt.

2) Press the plunger into the tensioner body while pressing on the

clips which prevent the plunger from returning.

3) Install the upper side holding bolt while holding the plunger

down with your finger and rotating it 180 degrees.

4) Tighten the holding bolt to the specified torque.

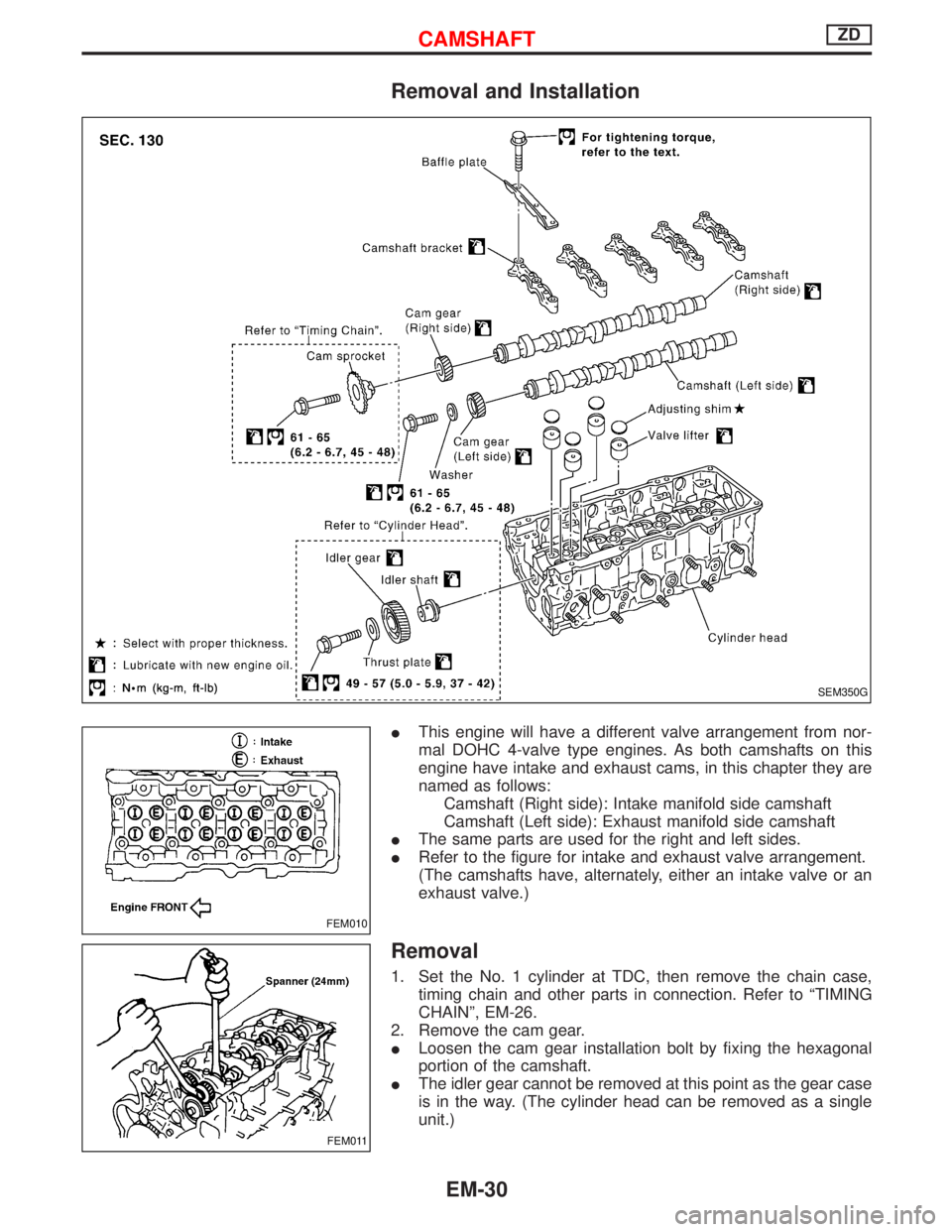

5. Install the chain cover.

1) Before installing chain cover, remove all traces of liquid gasket

from mating surface using a scraper.

2) Apply a continuous bead of liquid gasket to chain cover.

IUse Genuine Liquid Gasket or equivalent.

a. Coat of liquid gasket should be maintained within 2.0 to 3.0

mm (0.079 to 0.118 in) dia. range.

b. Attach chain cover to gear case within 5 minutes after

coating.

c. Wait at least 30 minutes before refilling engine oil or start-

ing engine.

SEM335G

FEM007

FEM008

FEM009

TIMING CHAINZD

Removal (Cont'd)

EM-28

Page 1137 of 1767

3) Install the chain cover.

IThe dimension below the neck of the holding bolt will vary

depending on the part.

Dimension below the neck:

A: 20 mm (0.79 in)

B: 50 mm (1.97 in)

C: 60 mm (2.36 in)

6. Install by following all removal procedures in reverse.

CAUTION:

IArrange the TDC sensor harness in the position shown in

the figure.

IMake sure that the harness has no deflection around the

vicinity of the crankshaft pulley when installing the clamp.

FEM004

SEM349G

TIMING CHAINZD

Installation (Cont'd)

EM-29

Page 1138 of 1767

Removal and Installation

IThis engine will have a different valve arrangement from nor-

mal DOHC 4-valve type engines. As both camshafts on this

engine have intake and exhaust cams, in this chapter they are

named as follows:

Camshaft (Right side): Intake manifold side camshaft

Camshaft (Left side): Exhaust manifold side camshaft

IThe same parts are used for the right and left sides.

IRefer to the figure for intake and exhaust valve arrangement.

(The camshafts have, alternately, either an intake valve or an

exhaust valve.)

Removal

1. Set the No. 1 cylinder at TDC, then remove the chain case,

timing chain and other parts in connection. Refer to ªTIMING

CHAINº, EM-26.

2. Remove the cam gear.

ILoosen the cam gear installation bolt by fixing the hexagonal

portion of the camshaft.

IThe idler gear cannot be removed at this point as the gear case

is in the way. (The cylinder head can be removed as a single

unit.)

SEM350G

FEM010

FEM011

CAMSHAFTZD

EM-30

Page 1139 of 1767

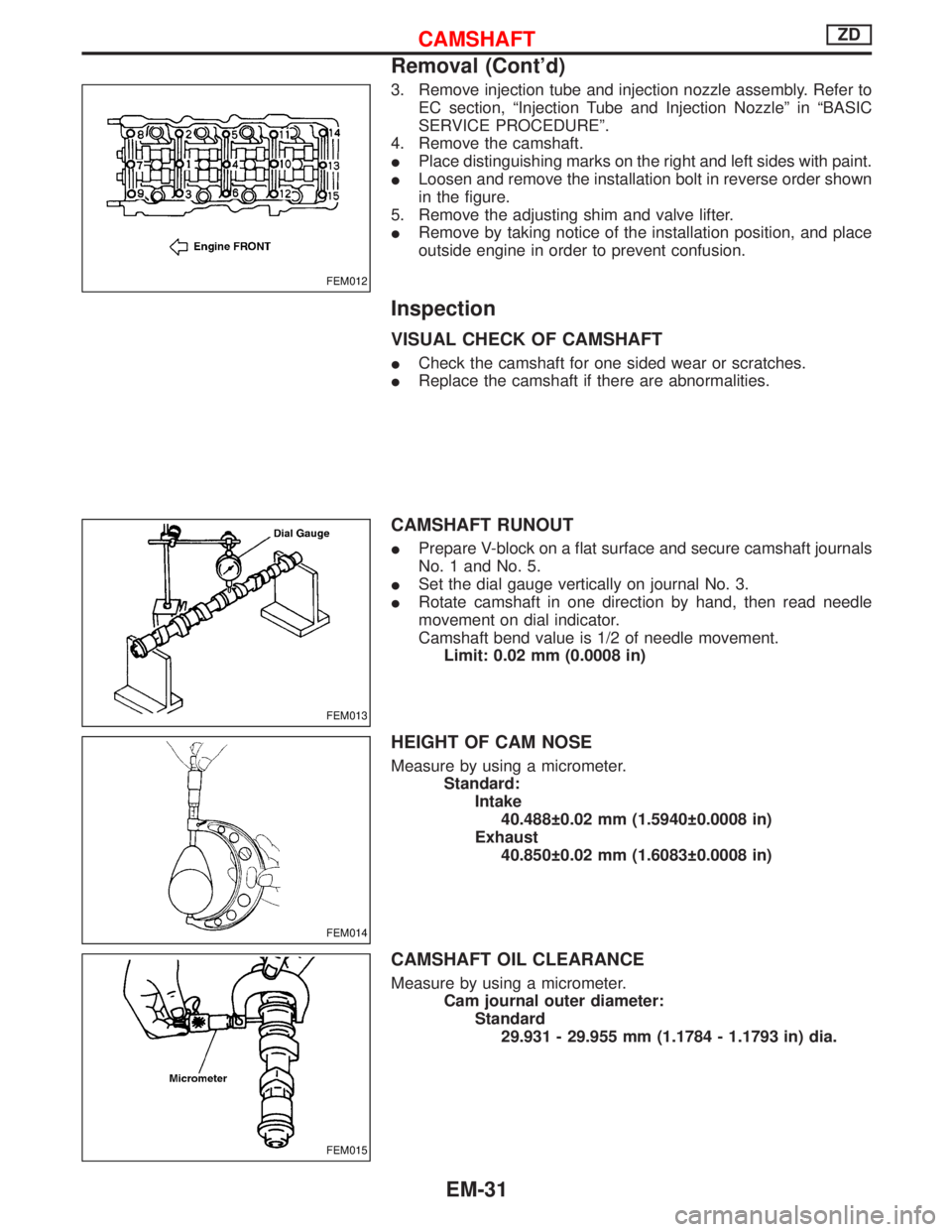

3. Remove injection tube and injection nozzle assembly. Refer to

EC section, ªInjection Tube and Injection Nozzleº in ªBASIC

SERVICE PROCEDUREº.

4. Remove the camshaft.

IPlace distinguishing marks on the right and left sides with paint.

ILoosen and remove the installation bolt in reverse order shown

in the figure.

5. Remove the adjusting shim and valve lifter.

IRemove by taking notice of the installation position, and place

outside engine in order to prevent confusion.

Inspection

VISUAL CHECK OF CAMSHAFT

ICheck the camshaft for one sided wear or scratches.

IReplace the camshaft if there are abnormalities.

CAMSHAFT RUNOUT

IPrepare V-block on a flat surface and secure camshaft journals

No. 1 and No. 5.

ISet the dial gauge vertically on journal No. 3.

IRotate camshaft in one direction by hand, then read needle

movement on dial indicator.

Camshaft bend value is 1/2 of needle movement.

Limit: 0.02 mm (0.0008 in)

HEIGHT OF CAM NOSE

Measure by using a micrometer.

Standard:

Intake

40.488 0.02 mm (1.5940 0.0008 in)

Exhaust

40.850 0.02 mm (1.6083 0.0008 in)

CAMSHAFT OIL CLEARANCE

Measure by using a micrometer.

Cam journal outer diameter:

Standard

29.931 - 29.955 mm (1.1784 - 1.1793 in) dia.

FEM012

FEM013

FEM014

FEM015

CAMSHAFTZD

Removal (Cont'd)

EM-31

Page 1140 of 1767

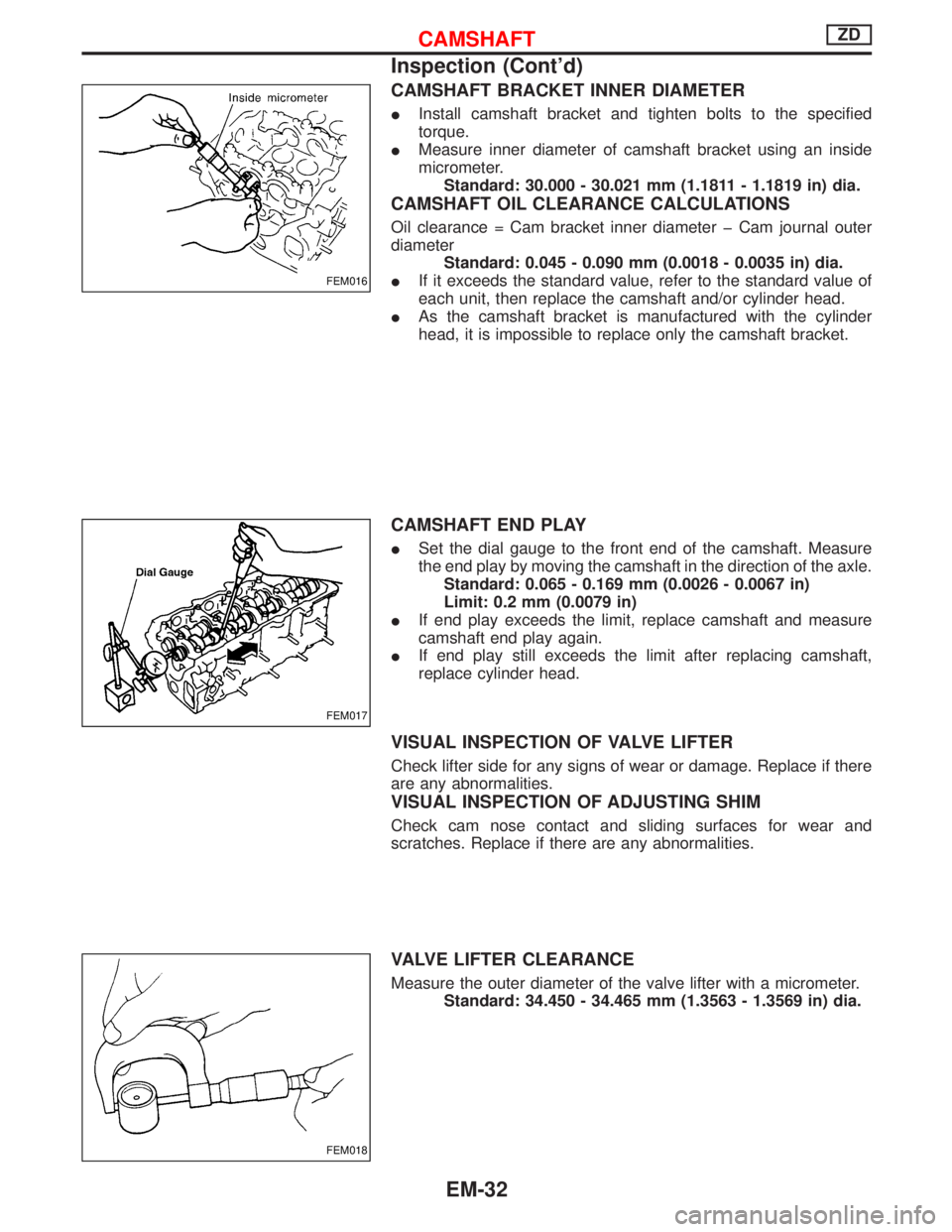

CAMSHAFT BRACKET INNER DIAMETER

IInstall camshaft bracket and tighten bolts to the specified

torque.

IMeasure inner diameter of camshaft bracket using an inside

micrometer.

Standard: 30.000 - 30.021 mm (1.1811 - 1.1819 in) dia.

CAMSHAFT OIL CLEARANCE CALCULATIONS

Oil clearance = Cam bracket inner diameter þ Cam journal outer

diameter

Standard: 0.045 - 0.090 mm (0.0018 - 0.0035 in) dia.

IIf it exceeds the standard value, refer to the standard value of

each unit, then replace the camshaft and/or cylinder head.

IAs the camshaft bracket is manufactured with the cylinder

head, it is impossible to replace only the camshaft bracket.

CAMSHAFT END PLAY

ISet the dial gauge to the front end of the camshaft. Measure

the end play by moving the camshaft in the direction of the axle.

Standard: 0.065 - 0.169 mm (0.0026 - 0.0067 in)

Limit: 0.2 mm (0.0079 in)

IIf end play exceeds the limit, replace camshaft and measure

camshaft end play again.

IIf end play still exceeds the limit after replacing camshaft,

replace cylinder head.

VISUAL INSPECTION OF VALVE LIFTER

Check lifter side for any signs of wear or damage. Replace if there

are any abnormalities.

VISUAL INSPECTION OF ADJUSTING SHIM

Check cam nose contact and sliding surfaces for wear and

scratches. Replace if there are any abnormalities.

VALVE LIFTER CLEARANCE

Measure the outer diameter of the valve lifter with a micrometer.

Standard: 34.450 - 34.465 mm (1.3563 - 1.3569 in) dia.

FEM016

FEM017

FEM018

CAMSHAFTZD

Inspection (Cont'd)

EM-32