NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1681 of 1767

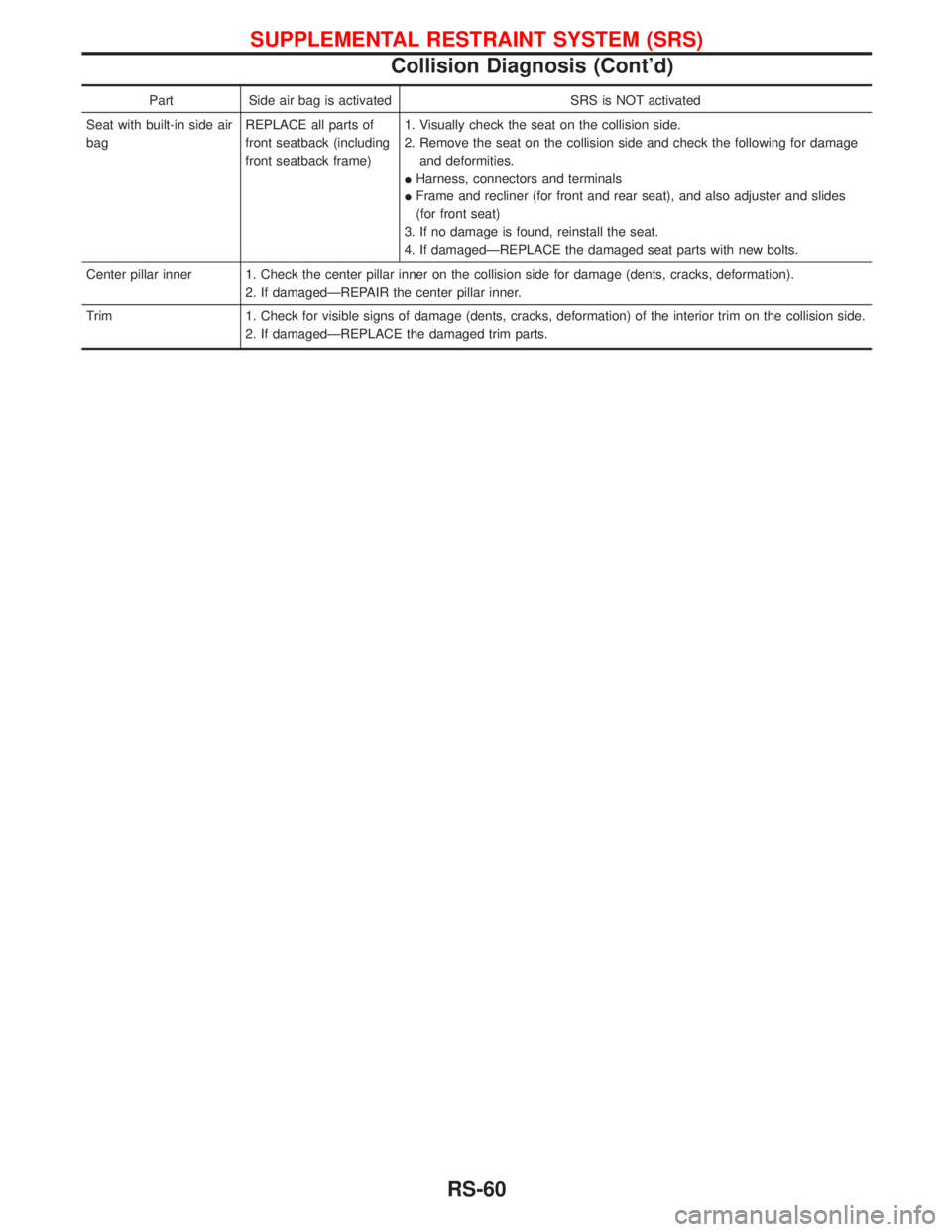

Part Side air bag is activated SRS is NOT activated

Seat with built-in side air

bagREPLACE all parts of

front seatback (including

front seatback frame)1. Visually check the seat on the collision side.

2. Remove the seat on the collision side and check the following for damage

and deformities.

IHarness, connectors and terminals

IFrame and recliner (for front and rear seat), and also adjuster and slides

(for front seat)

3. If no damage is found, reinstall the seat.

4. If damagedÐREPLACE the damaged seat parts with new bolts.

Center pillar inner 1. Check the center pillar inner on the collision side for damage (dents, cracks, deformation).

2. If damagedÐREPAIR the center pillar inner.

Trim 1. Check for visible signs of damage (dents, cracks, deformation) of the interior trim on the collision side.

2. If damagedÐREPLACE the damaged trim parts.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Collision Diagnosis (Cont'd)

RS-60

Page 1682 of 1767

STARTING & CHARGING SYSTEMS

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY.........................................................................3

How to Handle Battery ................................................3

Battery Test and Charging Chart .................................6

STARTING SYSTEM.....................................................13

System Description ....................................................13

Wiring Diagram - START -.........................................14

Trouble Diagnoses.....................................................16

Construction ...............................................................17

Magnetic Switch Check .............................................19

Pinion/Clutch Check ..................................................19

Brush Check ..............................................................20Field Coil Check ........................................................20

Armature Check .........................................................21

Assembly ...................................................................22

CHARGING SYSTEM....................................................23

System Description ....................................................23

Wiring Diagram - CHARGE -.....................................24

Trouble Diagnoses.....................................................26

Construction ...............................................................27

Disassembly...............................................................28

Inspection...................................................................28

Assembly ...................................................................29

SERVICE DATA AND SPECIFICATIONS (SDS)..........30

Battery........................................................................30

Starter ........................................................................30

Alternator ...................................................................30

Page 1683 of 1767

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL R20 is as follows (The compo-

sition varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Wiring Diagrams and Trouble Diagnoses

When you read wiring diagrams, refer to the following:

IGI-10, ªHOW TO READ WIRING DIAGRAMSº

IEL-6, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnoses, refer to the following:

IGI-25, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

IGI-22, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

PRECAUTIONS

SC-2

Page 1684 of 1767

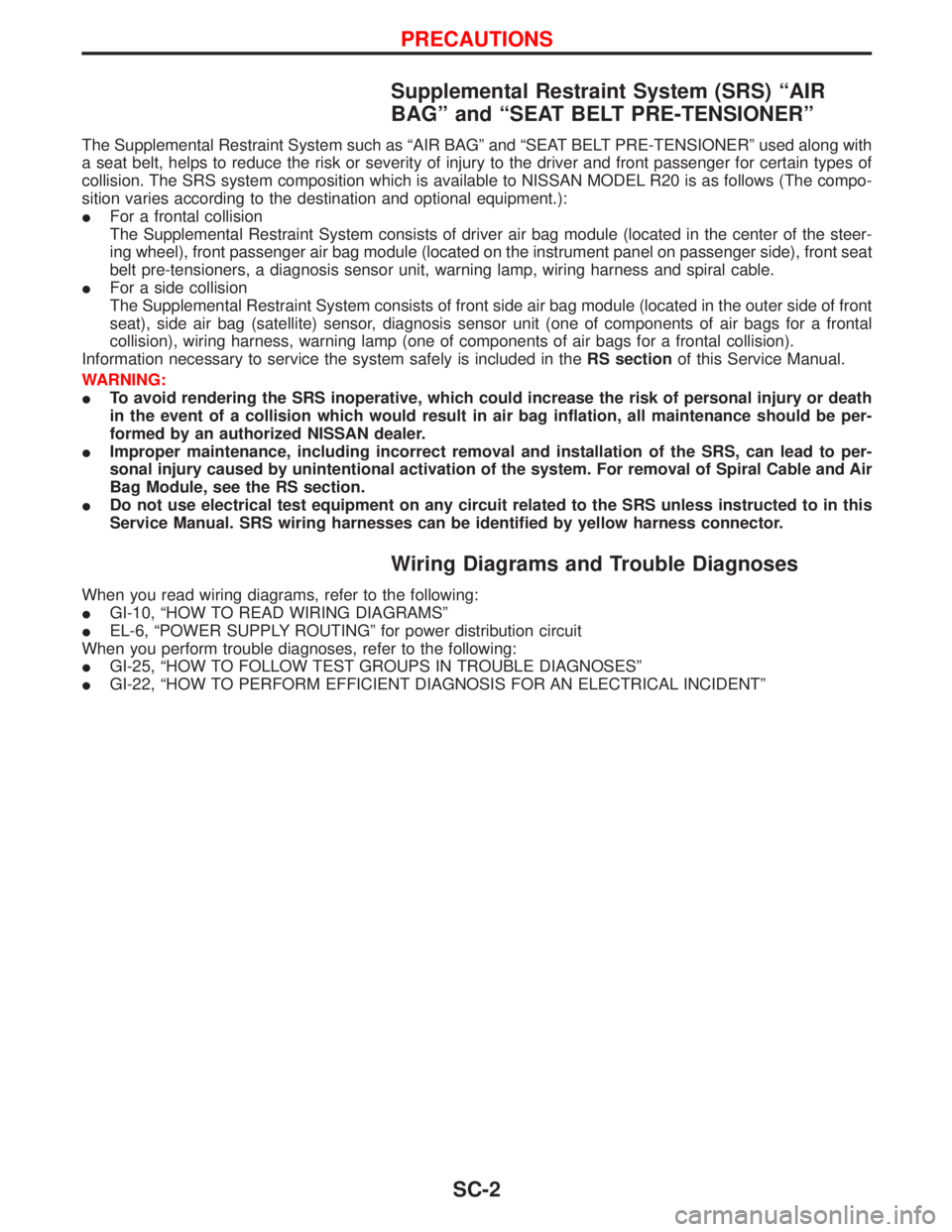

How to Handle Battery

CAUTION:

If it becomes necessary to start the engine with a booster bat-

tery and jumper cables,

1) Use a 12-volt booster battery.

2) After connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharg-

ing a battery.

IThe battery surface (particularly its top) should always be kept

clean and dry.

IThe terminal connections should be clean and tight.

IAt every routine maintenance, check the electrolyte level.

This also applies to batteries designated as ªlow maintenanceº

and ªmaintenance-freeº.

IWhen the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal.

ICheck the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

MEL040F

MEL041F

MEL042F

BATTERY

SC-3

Page 1685 of 1767

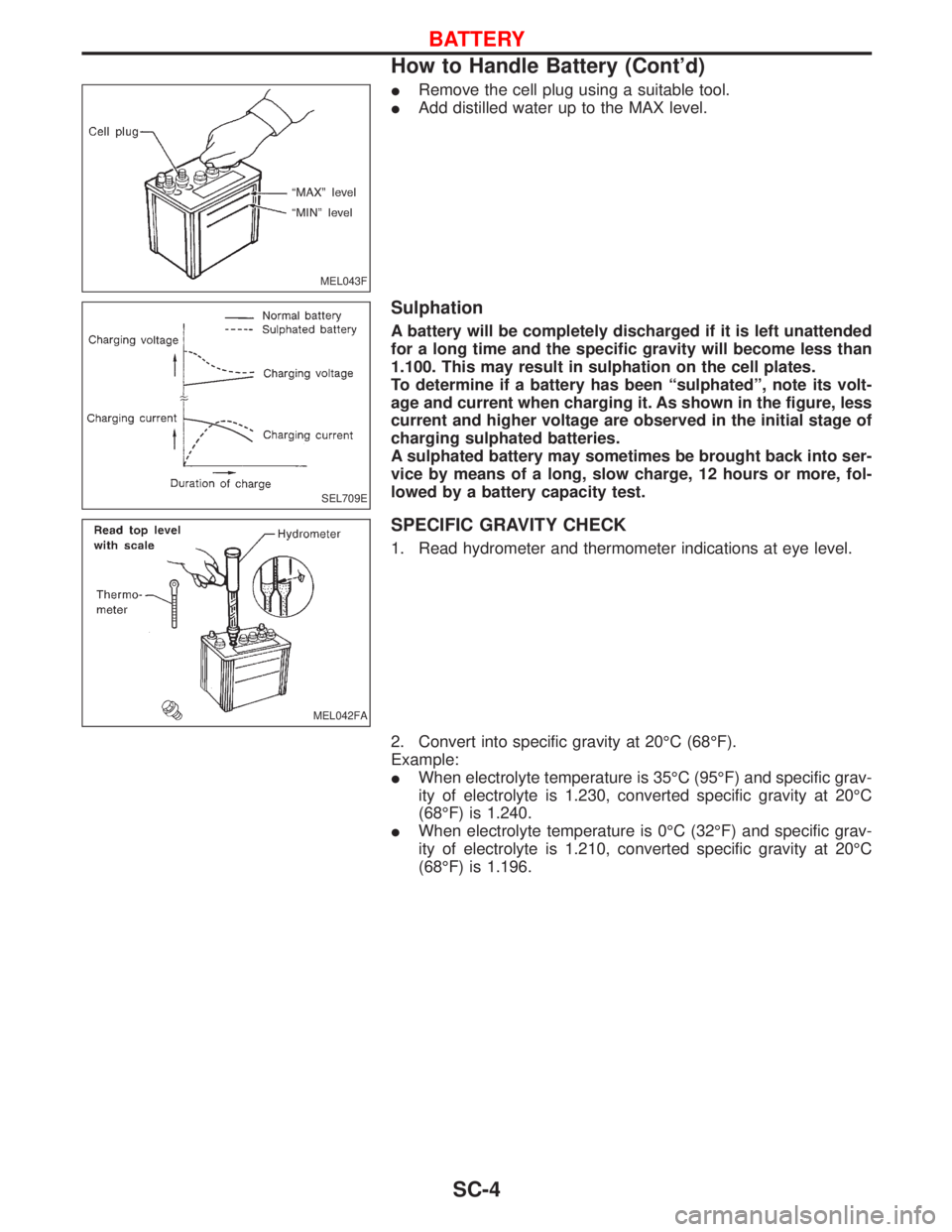

IRemove the cell plug using a suitable tool.

IAdd distilled water up to the MAX level.

Sulphation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been ªsulphatedº, note its volt-

age and current when charging it. As shown in the figure, less

current and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

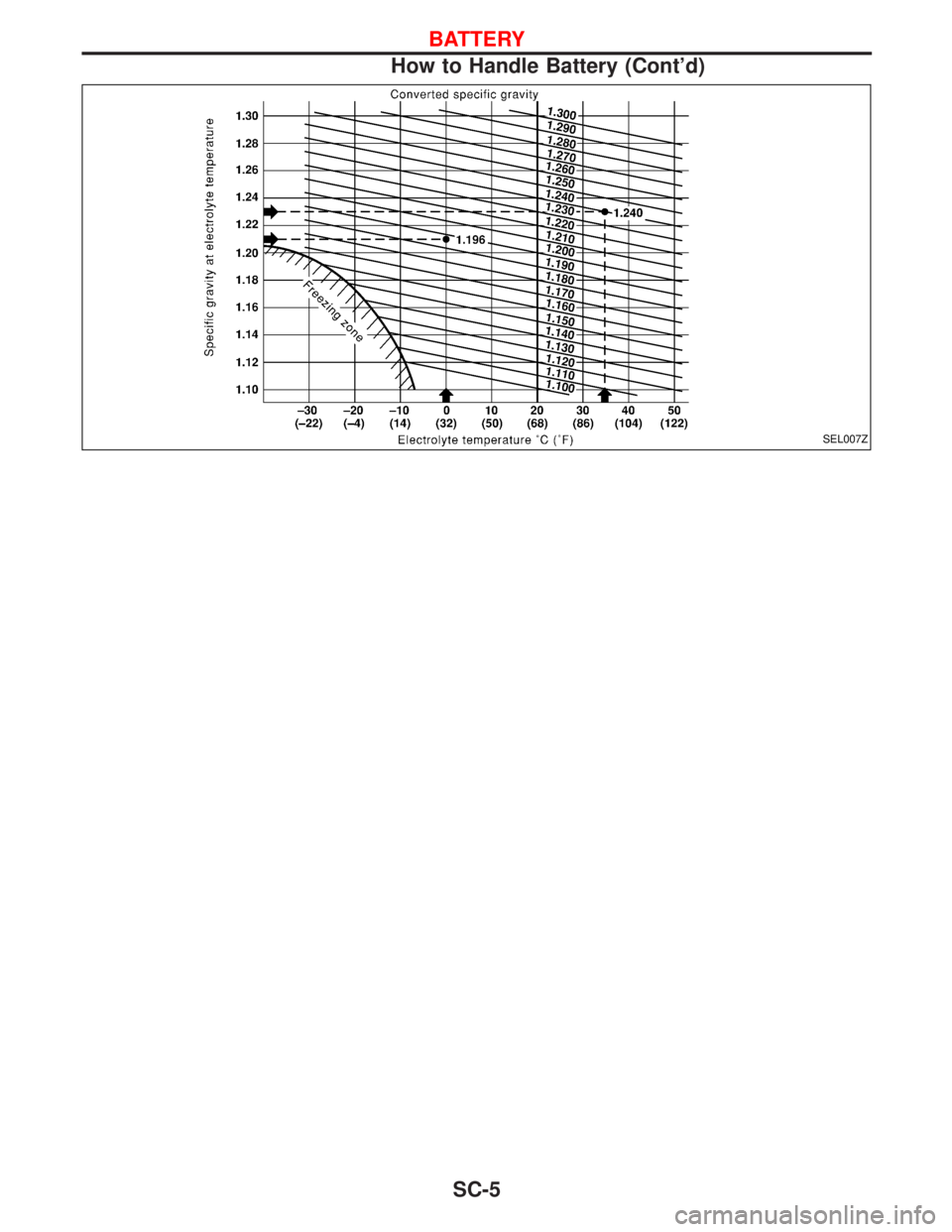

2. Convert into specific gravity at 20ÉC (68ÉF).

Example:

IWhen electrolyte temperature is 35ÉC (95ÉF) and specific grav-

ity of electrolyte is 1.230, converted specific gravity at 20ÉC

(68ÉF) is 1.240.

IWhen electrolyte temperature is 0ÉC (32ÉF) and specific grav-

ity of electrolyte is 1.210, converted specific gravity at 20ÉC

(68ÉF) is 1.196.

MEL043F

SEL709E

MEL042FA

BATTERY

How to Handle Battery (Cont'd)

SC-4

Page 1686 of 1767

SEL007Z

BATTERY

How to Handle Battery (Cont'd)

SC-5

Page 1687 of 1767

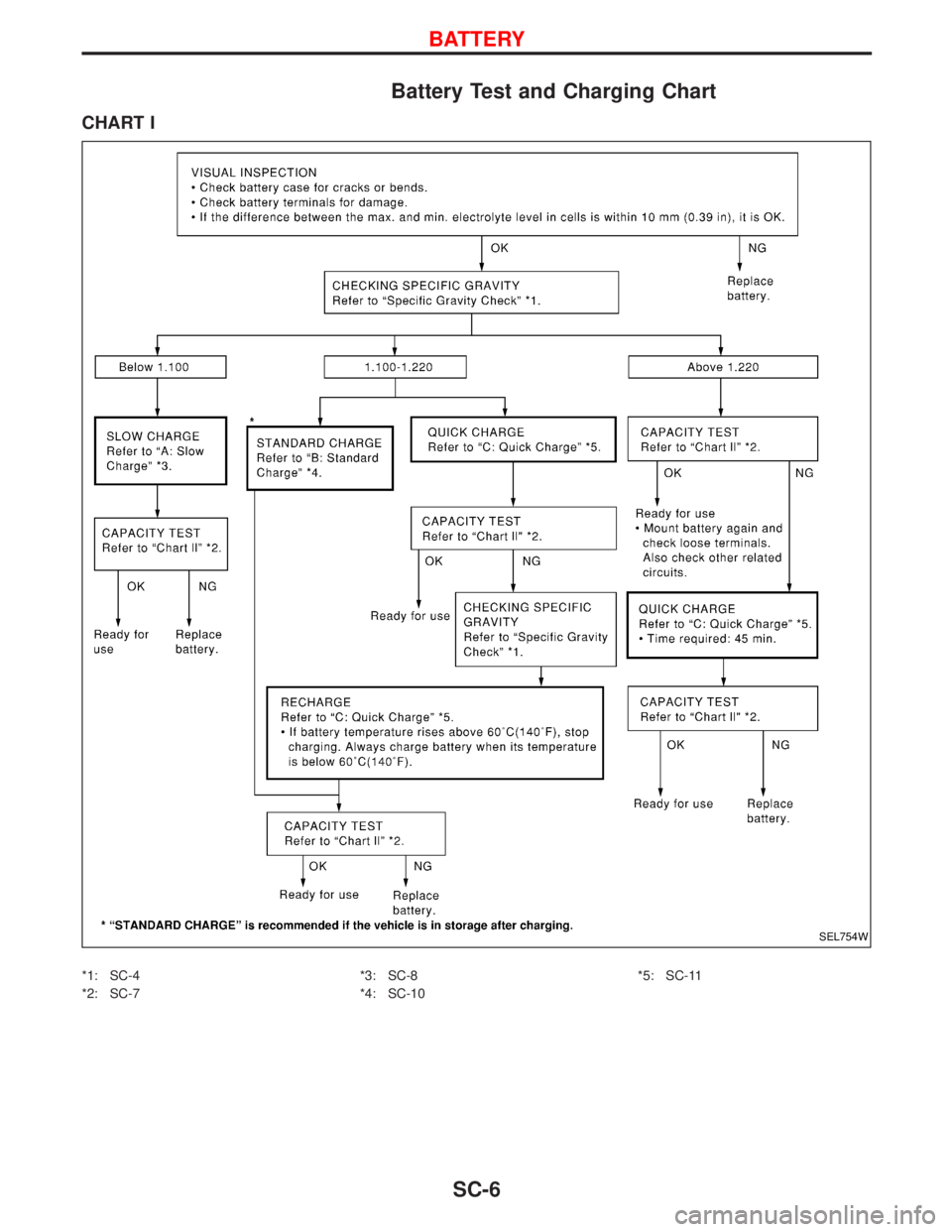

Battery Test and Charging Chart

CHART I

*1: SC-4

*2: SC-7*3: SC-8

*4: SC-10*5: SC-11

SEL754W

BATTERY

SC-6

Page 1688 of 1767

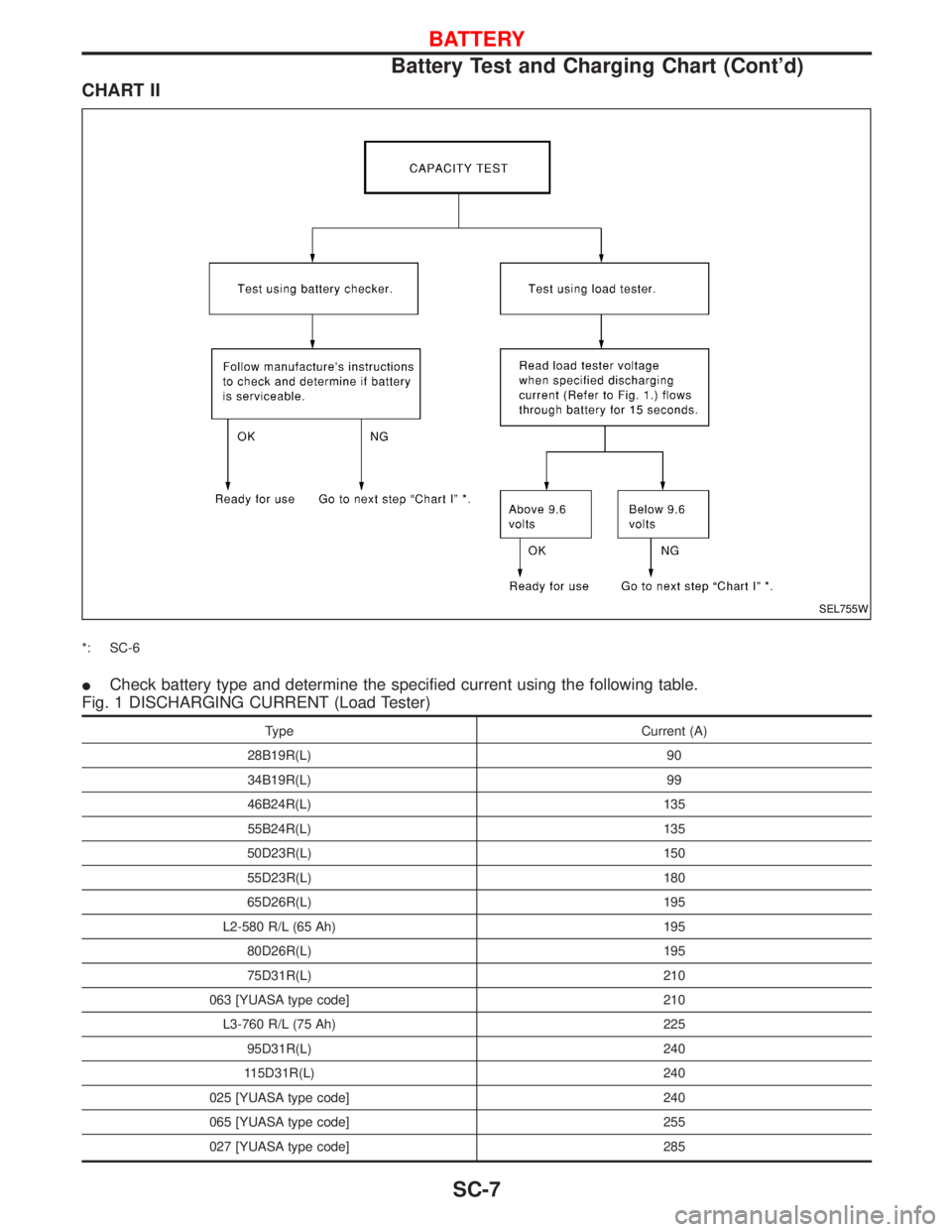

CHART II

*: SC-6

ICheck battery type and determine the specified current using the following table.

Fig. 1 DISCHARGING CURRENT (Load Tester)

Type Current (A)

28B19R(L) 90

34B19R(L) 99

46B24R(L) 135

55B24R(L) 135

50D23R(L) 150

55D23R(L) 180

65D26R(L) 195

L2-580 R/L (65 Ah) 195

80D26R(L) 195

75D31R(L) 210

063 [YUASA type code] 210

L3-760 R/L (75 Ah) 225

95D31R(L) 240

115D31R(L) 240

025 [YUASA type code] 240

065 [YUASA type code] 255

027 [YUASA type code] 285

SEL755W

BATTERY

Battery Test and Charging Chart (Cont'd)

SC-7

Page 1689 of 1767

![NISSAN TERRANO 2002 Service Repair Manual Type Current (A)

075 [YUASA type code] 300

110D26R(L) 300

95E41R(L) 300

067 [YUASA type code] 325

130E41R(L) 330

096 [YUASA type code] 375

096L [YUASA type code] 375

010S [YUASA type code] 360

A: SLOW NISSAN TERRANO 2002 Service Repair Manual Type Current (A)

075 [YUASA type code] 300

110D26R(L) 300

95E41R(L) 300

067 [YUASA type code] 325

130E41R(L) 330

096 [YUASA type code] 375

096L [YUASA type code] 375

010S [YUASA type code] 360

A: SLOW](/img/5/57393/w960_57393-1688.png)

Type Current (A)

075 [YUASA type code] 300

110D26R(L) 300

95E41R(L) 300

067 [YUASA type code] 325

130E41R(L) 330

096 [YUASA type code] 375

096L [YUASA type code] 375

010S [YUASA type code] 360

A: SLOW CHARGE

*1: SC-4 *2: SC-7

SEL756W

BATTERY

Battery Test and Charging Chart (Cont'd)

SC-8

Page 1690 of 1767

![NISSAN TERRANO 2002 Service Repair Manual Fig. 2 INITIAL CHARGING CURRENT SETTING (Slow charge)

CON-

VERTED

SPECIFIC

GRAVITYBATTERY TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

025 [YUASA type code]

027 [YUASA type code]

6 NISSAN TERRANO 2002 Service Repair Manual Fig. 2 INITIAL CHARGING CURRENT SETTING (Slow charge)

CON-

VERTED

SPECIFIC

GRAVITYBATTERY TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

025 [YUASA type code]

027 [YUASA type code]

6](/img/5/57393/w960_57393-1689.png)

Fig. 2 INITIAL CHARGING CURRENT SETTING (Slow charge)

CON-

VERTED

SPECIFIC

GRAVITYBATTERY TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

025 [YUASA type code]

027 [YUASA type code]

65D26R(L)

80D26R(L)

L2-580 R/L (65 Ah)

063 [YUASA type code]

067 [YUASA type code]

096 [YUASA type code]

75D31R(L)

L3-760 R/L (75 Ah)

95D31R(L)

115D31R(L)

110D26R(L)

95E41R(L)

065 [YUASA type code]

075 [YUASA type code]

096L [YUASA type code]

010S [YUASA type code]

130E41R(L)

Below 1.100 4.0 (A) 5.0 (A) 7.0 (A) 8.0 (A)8.5

(A)9.0 (A) 10.0 (A)11.0

(A)14.0

(A)

ICheck battery type and determine the specified current using the table shown above.

IAfter starting charging, adjustment of charging current is not necessary.

Fig. 3 ADDITIONAL CHARGE (Slow charge)

*: SC-7

CAUTION:

ISet charging current to value specified in Fig. 2. If charger is not capable of producing specified

current value, set its charging current as close to that value as possible.

IKeep battery away from open flame while it is being charged.

IWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

IIf battery temperature rises above 60ÉC (140ÉF), stop charging. Always charge battery when its

temperature is below 60ÉC (140ÉF).

SEL757W

BATTERY

Battery Test and Charging Chart (Cont'd)

SC-9