NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: sensor, air filter, run flat, service indicator, air bleeding, remote, parking brake

Page 1721 of 1767

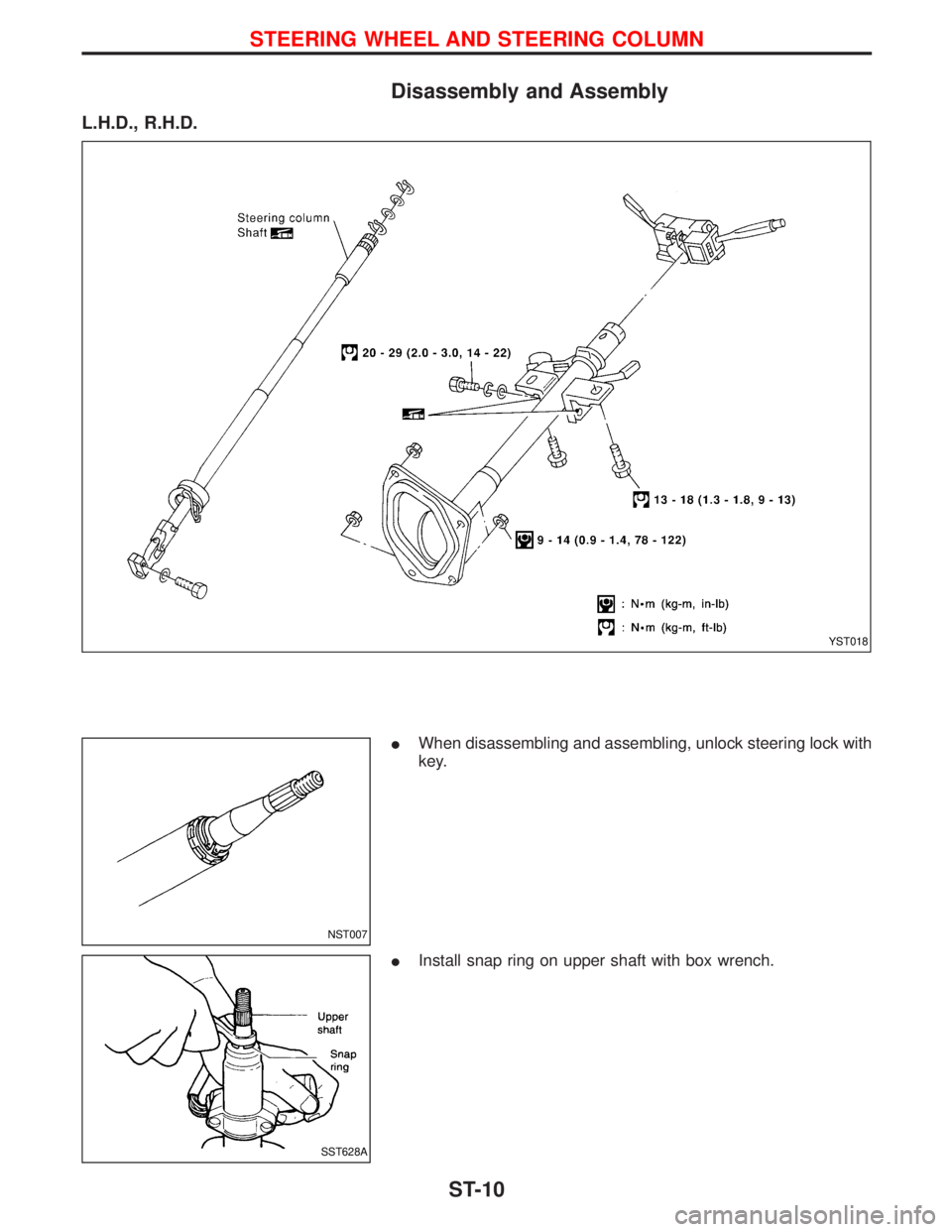

Disassembly and Assembly

L.H.D., R.H.D.

IWhen disassembling and assembling, unlock steering lock with

key.

IInstall snap ring on upper shaft with box wrench.

YST018

NST007

SST628A

STEERING WHEEL AND STEERING COLUMN

ST-10

Page 1722 of 1767

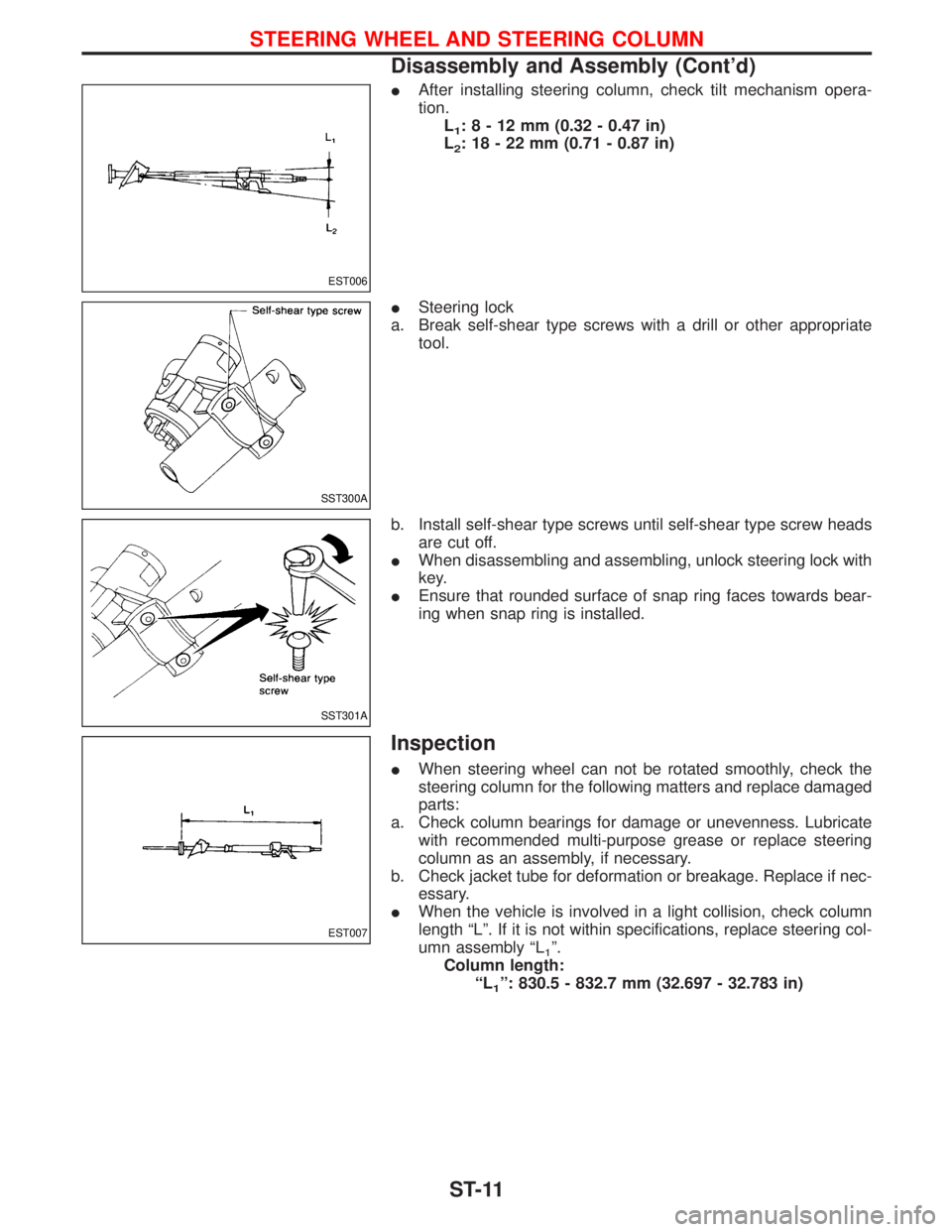

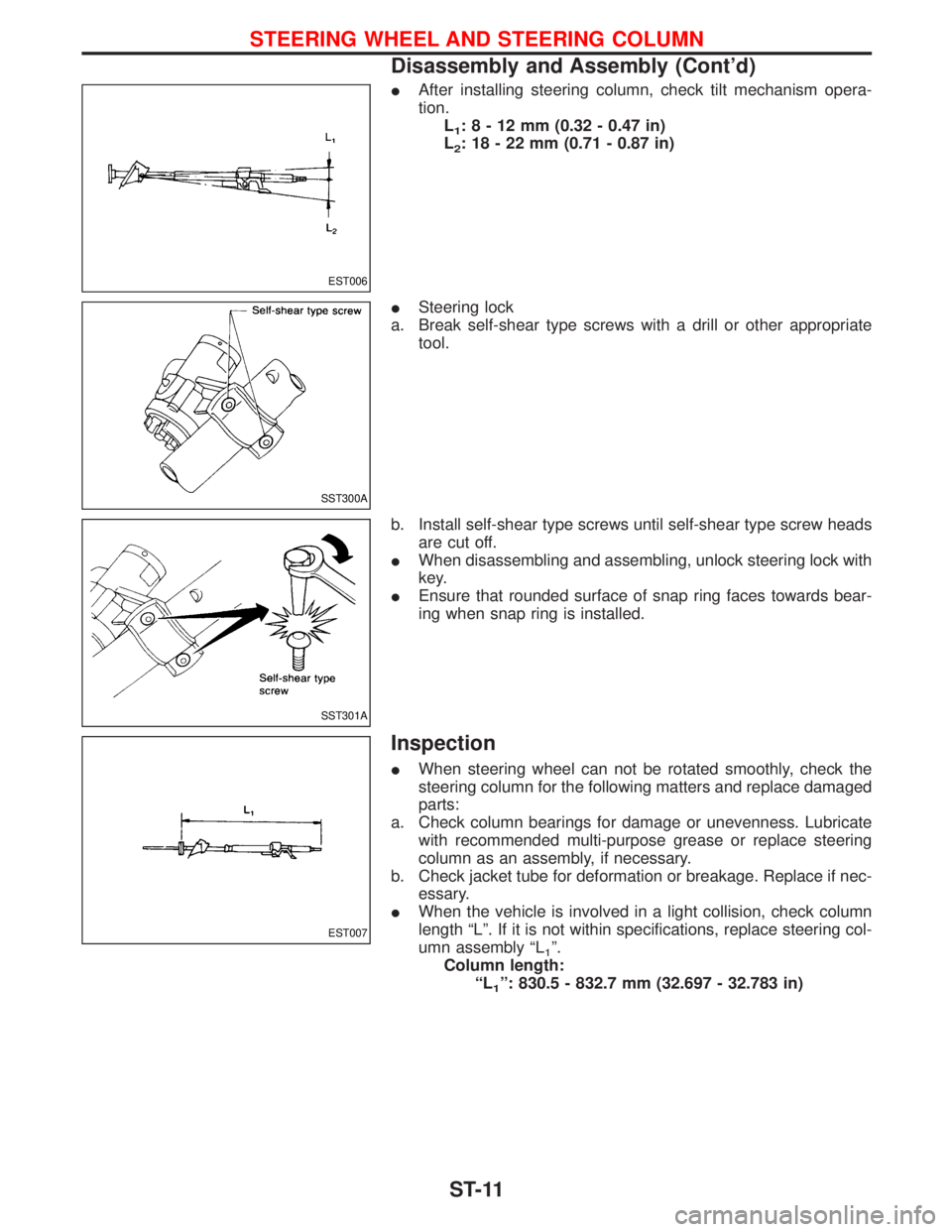

IAfter installing steering column, check tilt mechanism opera-

tion.

L

1:8-12mm(0.32 - 0.47 in)

L

2: 18 - 22 mm (0.71 - 0.87 in)

ISteering lock

a. Break self-shear type screws with a drill or other appropriate

tool.

b. Install self-shear type screws until self-shear type screw heads

are cut off.

IWhen disassembling and assembling, unlock steering lock with

key.

IEnsure that rounded surface of snap ring faces towards bear-

ing when snap ring is installed.

Inspection

IWhen steering wheel can not be rotated smoothly, check the

steering column for the following matters and replace damaged

parts:

a. Check column bearings for damage or unevenness. Lubricate

with recommended multi-purpose grease or replace steering

column as an assembly, if necessary.

b. Check jacket tube for deformation or breakage. Replace if nec-

essary.

IWhen the vehicle is involved in a light collision, check column

length ªLº. If it is not within specifications, replace steering col-

umn assembly ªL

1º.

Column length:

ªL

1º: 830.5 - 832.7 mm (32.697 - 32.783 in)

EST006

SST300A

SST301A

EST007

STEERING WHEEL AND STEERING COLUMN

Disassembly and Assembly (Cont'd)

ST-11

Page 1723 of 1767

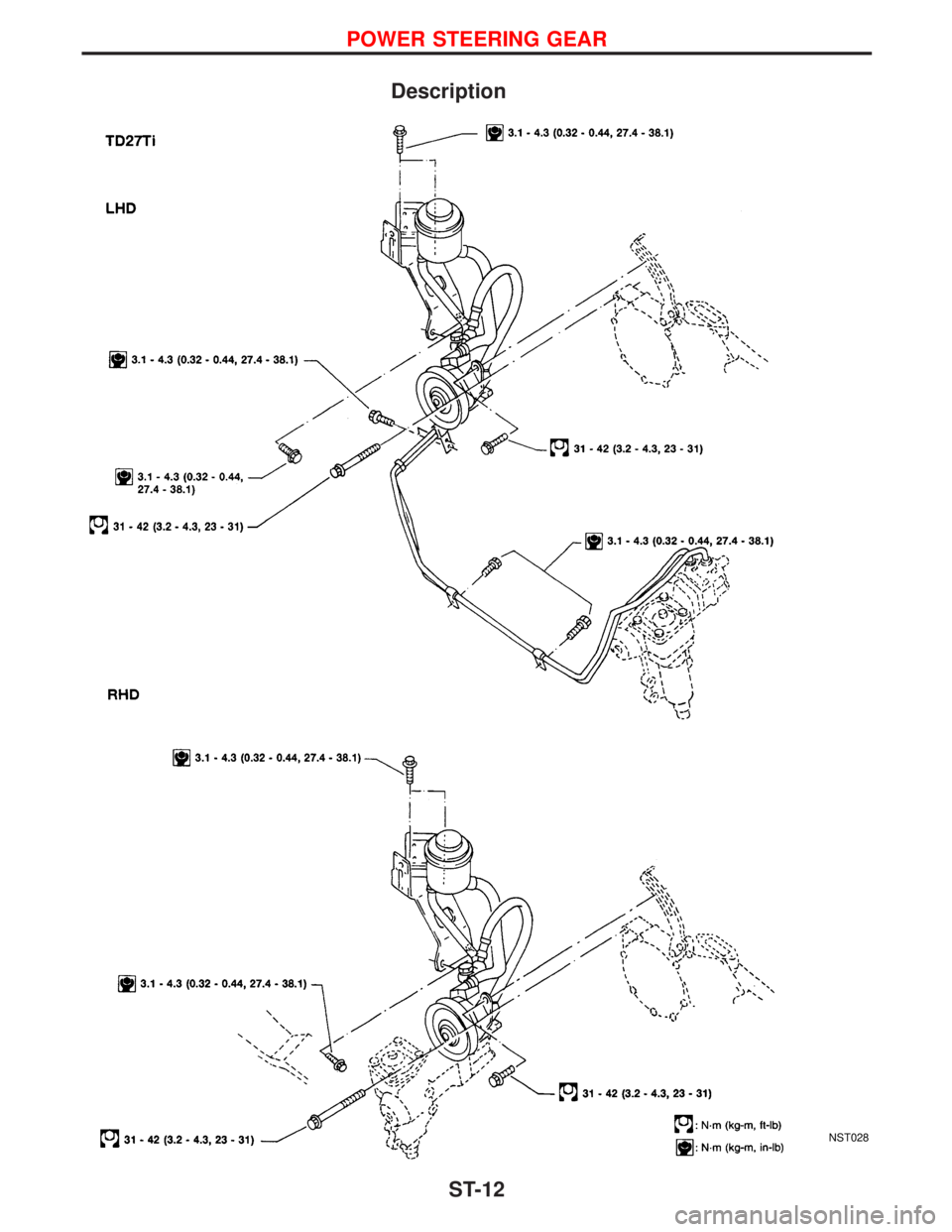

Description

NST028

POWER STEERING GEAR

ST-12

Page 1724 of 1767

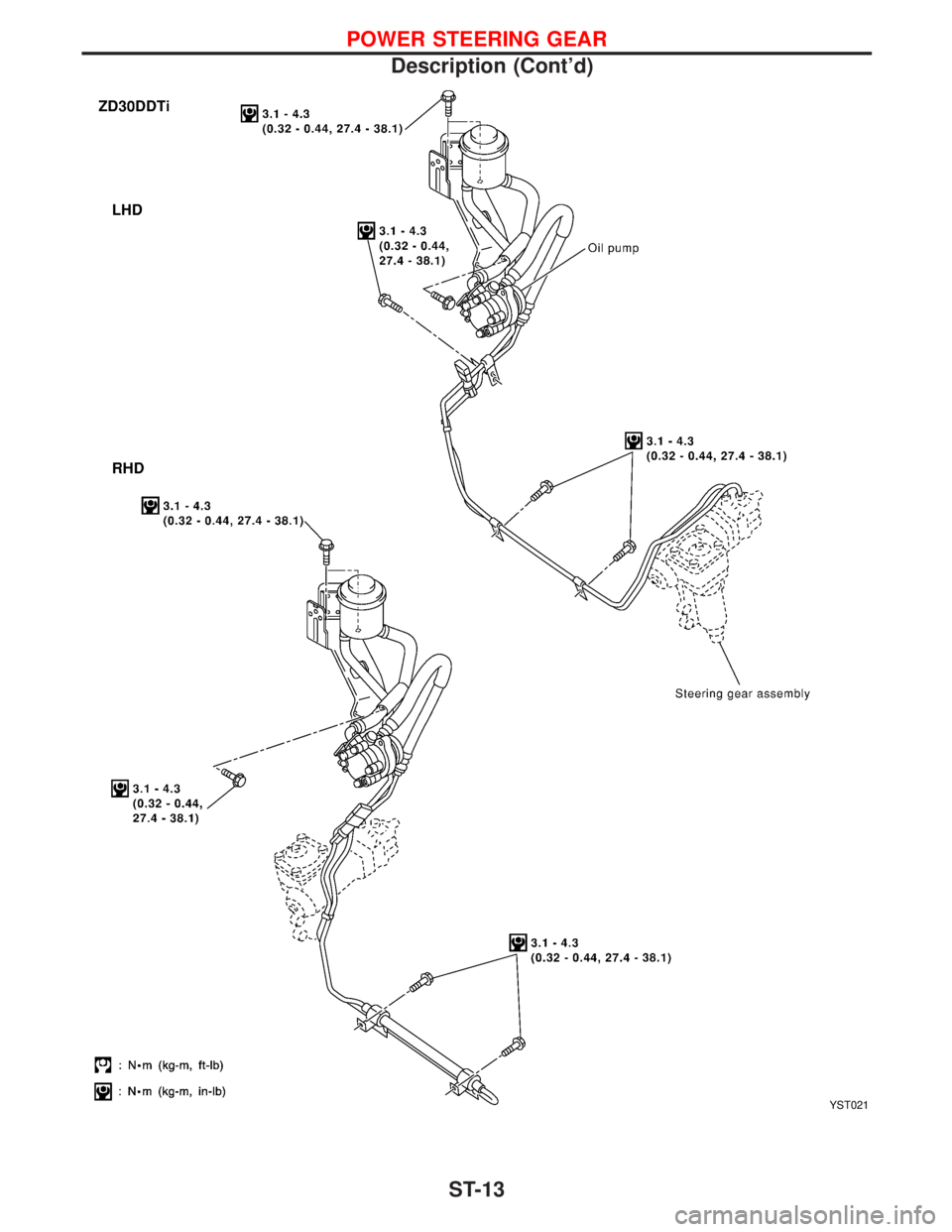

YST021

POWER STEERING GEAR

Description (Cont'd)

ST-13

Page 1725 of 1767

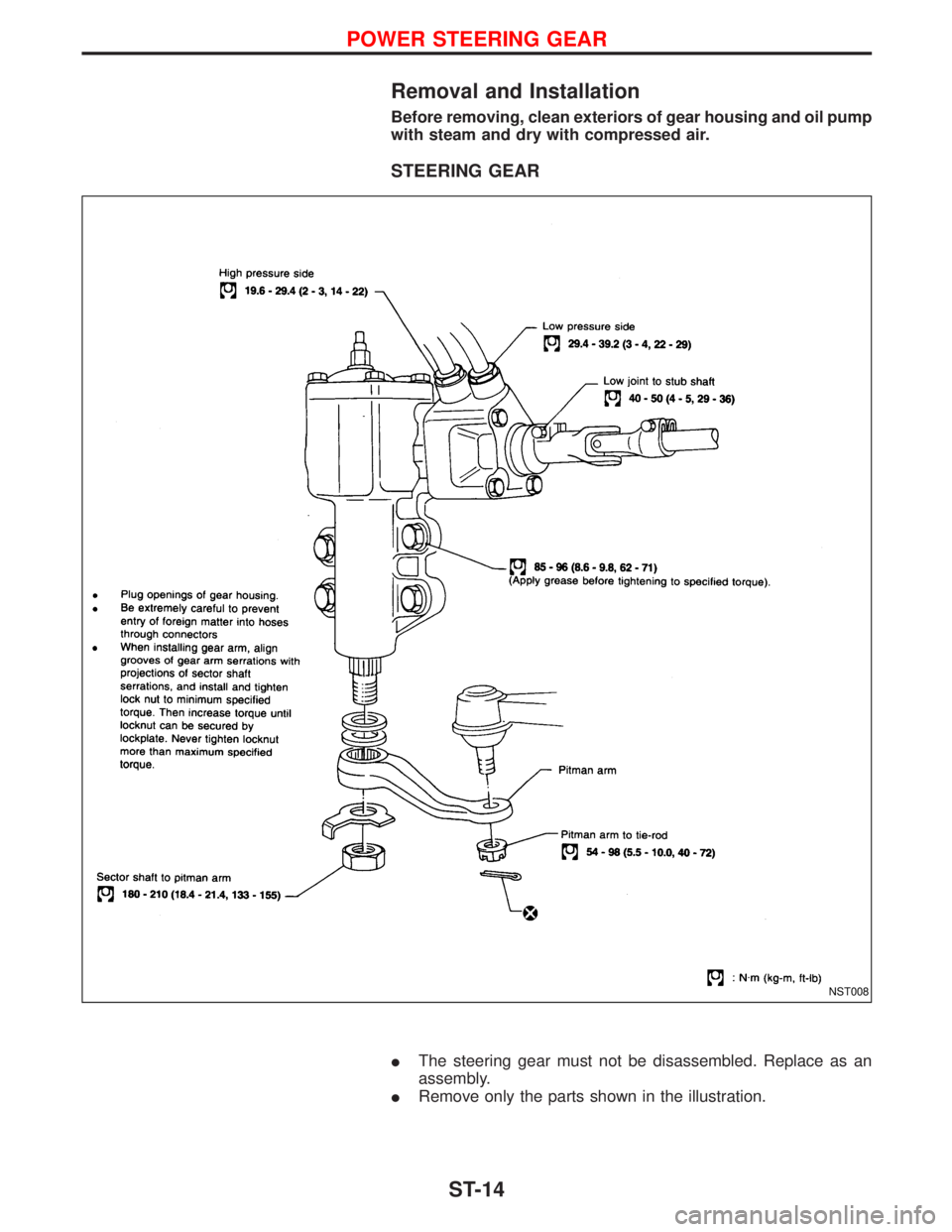

Removal and Installation

Before removing, clean exteriors of gear housing and oil pump

with steam and dry with compressed air.

STEERING GEAR

IThe steering gear must not be disassembled. Replace as an

assembly.

IRemove only the parts shown in the illustration.

NST008

POWER STEERING GEAR

ST-14

Page 1726 of 1767

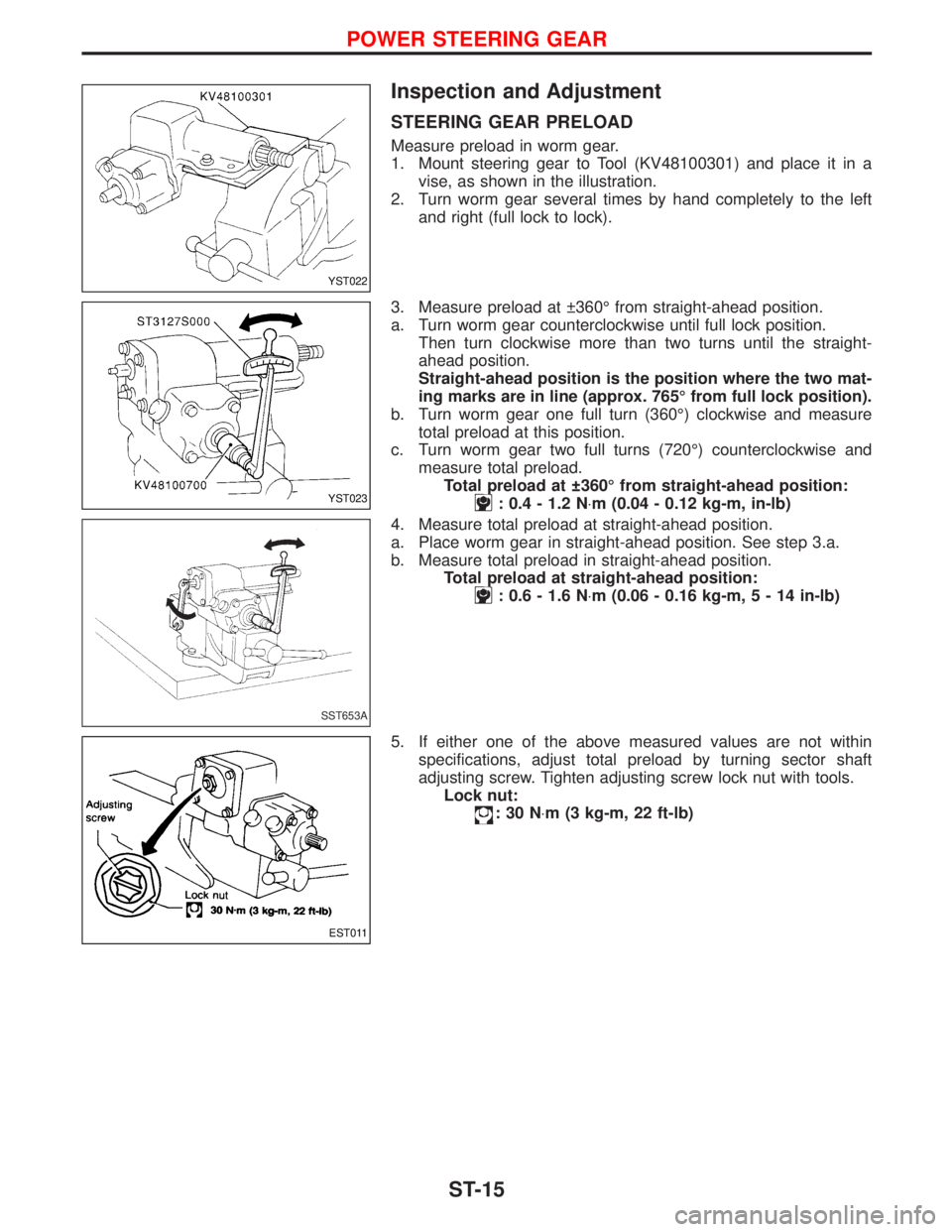

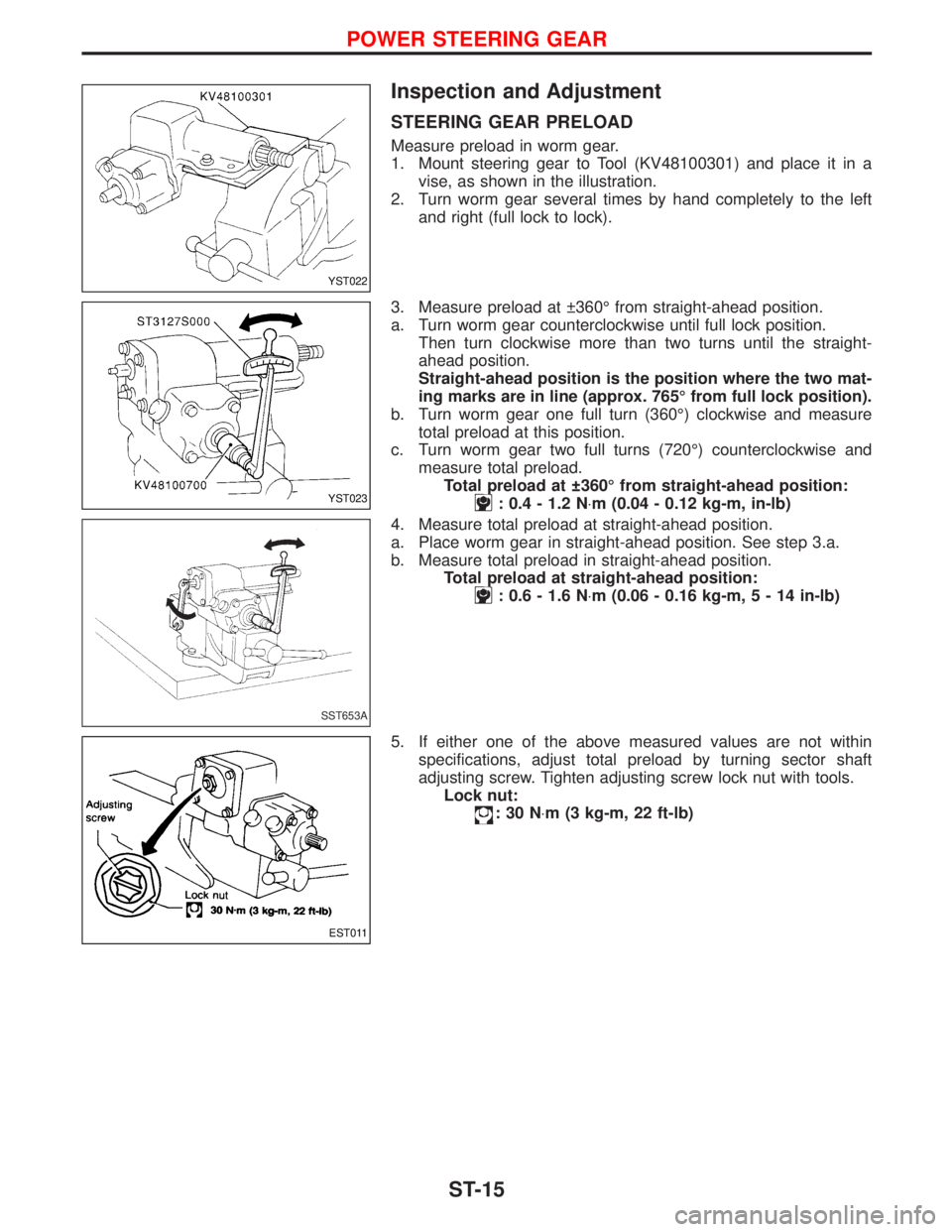

Inspection and Adjustment

STEERING GEAR PRELOAD

Measure preload in worm gear.

1. Mount steering gear to Tool (KV48100301) and place it in a

vise, as shown in the illustration.

2. Turn worm gear several times by hand completely to the left

and right (full lock to lock).

3. Measure preload at 360É from straight-ahead position.

a. Turn worm gear counterclockwise until full lock position.

Then turn clockwise more than two turns until the straight-

ahead position.

Straight-ahead position is the position where the two mat-

ing marks are in line (approx. 765É from full lock position).

b. Turn worm gear one full turn (360É) clockwise and measure

total preload at this position.

c. Turn worm gear two full turns (720É) counterclockwise and

measure total preload.

Total preload at 360É from straight-ahead position:

: 0.4 - 1.2 N×m (0.04 - 0.12 kg-m, in-lb)

4. Measure total preload at straight-ahead position.

a. Place worm gear in straight-ahead position. See step 3.a.

b. Measure total preload in straight-ahead position.

Total preload at straight-ahead position:

: 0.6 - 1.6 N×m (0.06 - 0.16 kg-m,5-14in-lb)

5. If either one of the above measured values are not within

specifications, adjust total preload by turning sector shaft

adjusting screw. Tighten adjusting screw lock nut with tools.

Lock nut:

:30N×m (3 kg-m, 22 ft-lb)

YST022

YST023

SST653A

EST011

POWER STEERING GEAR

ST-15

Page 1727 of 1767

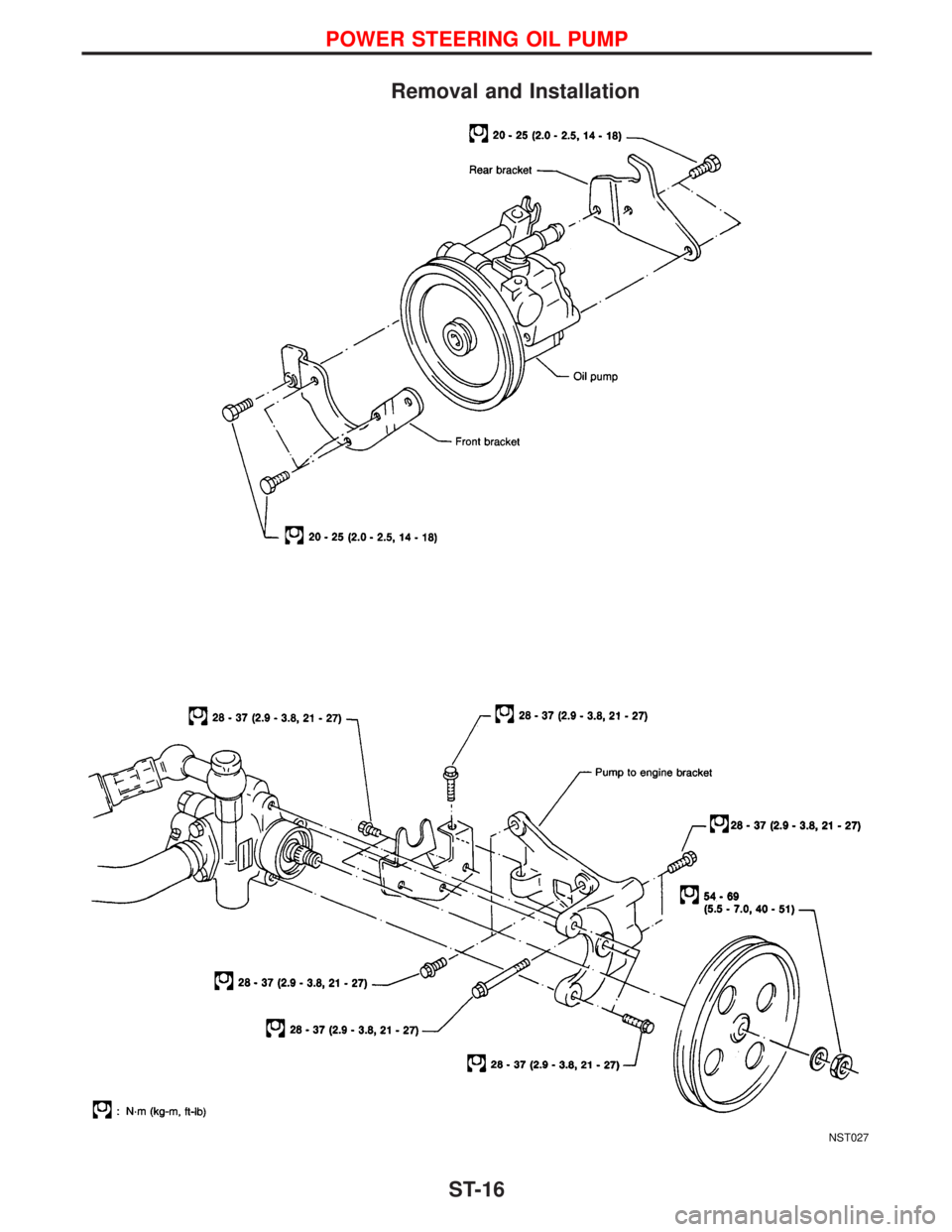

Removal and Installation

NST027

POWER STEERING OIL PUMP

ST-16

Page 1728 of 1767

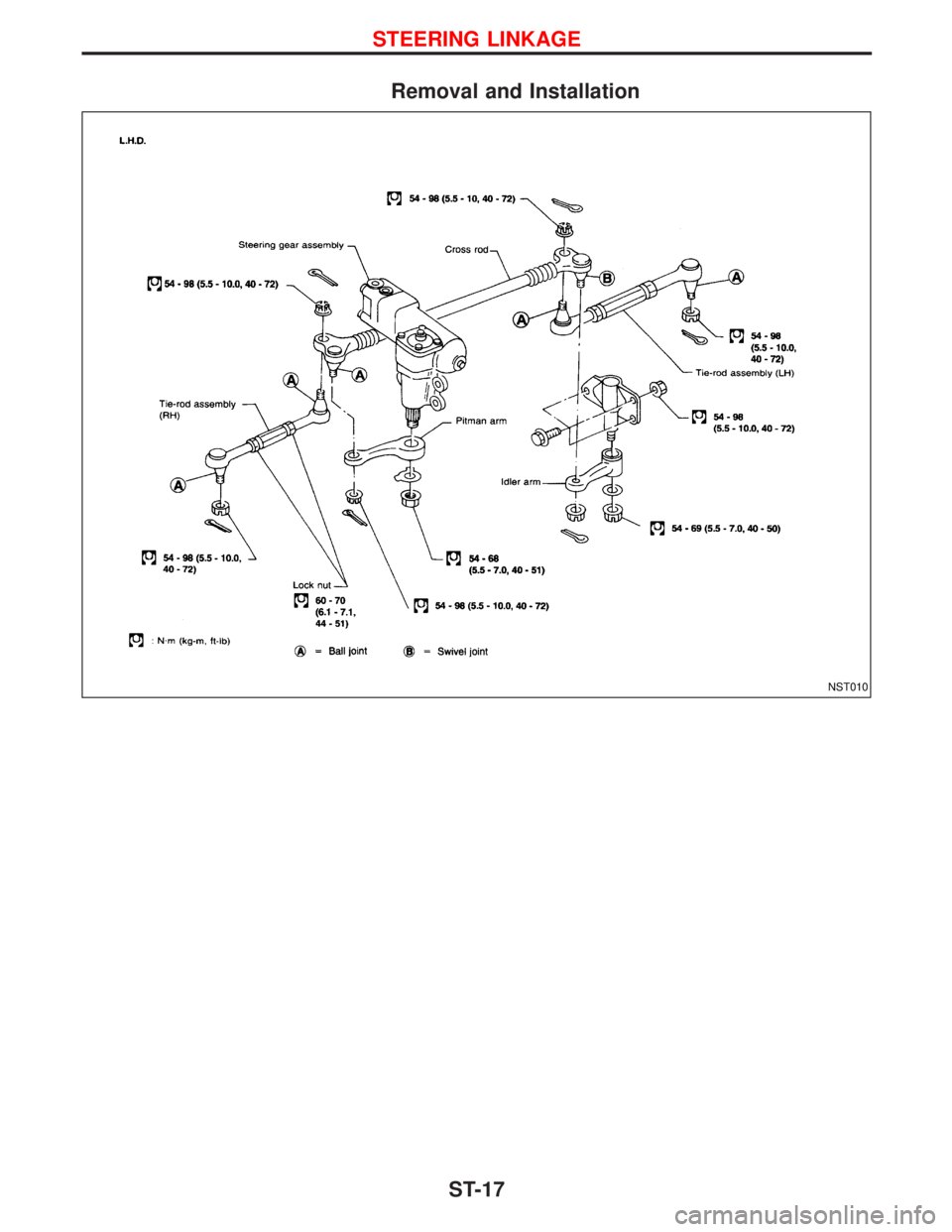

Removal and Installation

NST010

STEERING LINKAGE

ST-17

Page 1729 of 1767

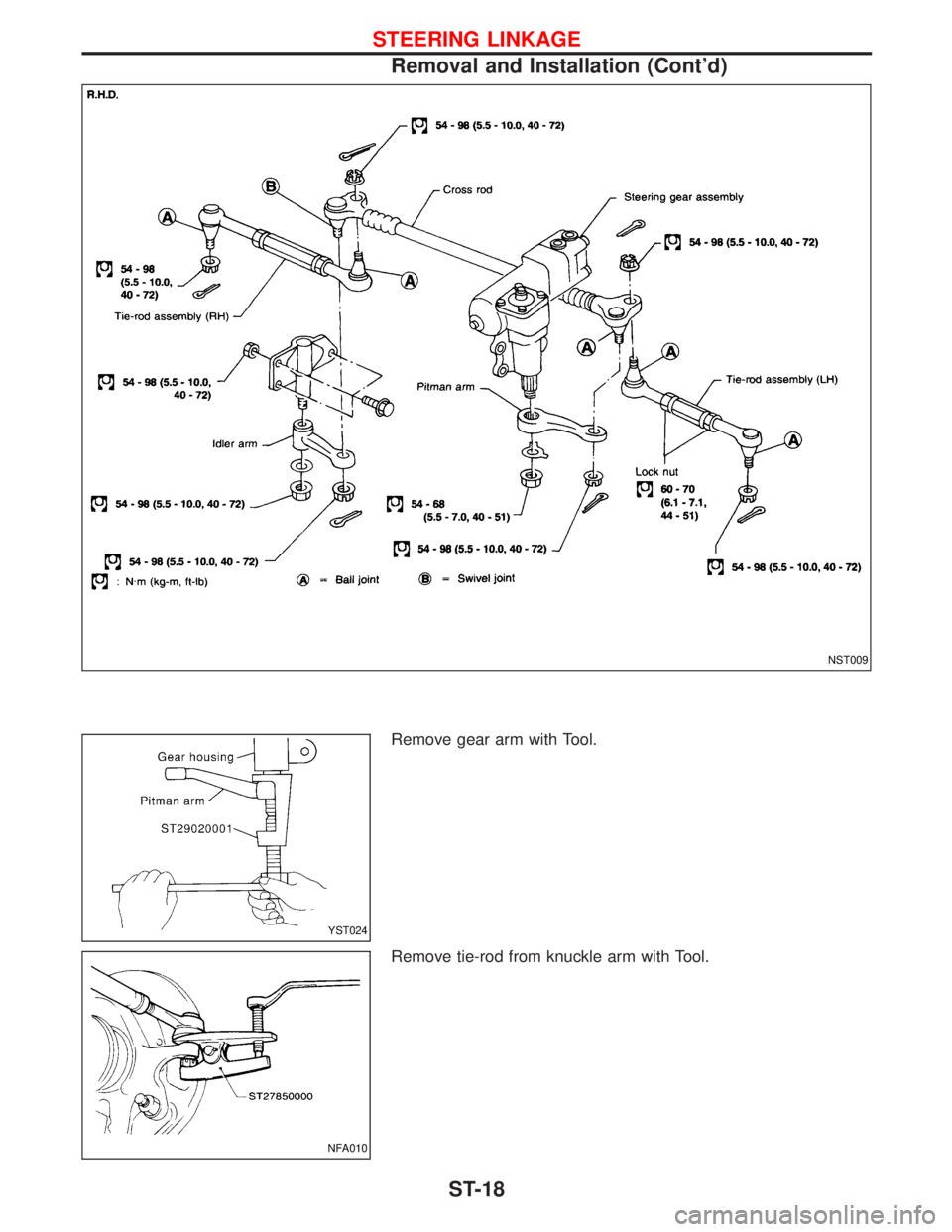

Remove gear arm with Tool.

Remove tie-rod from knuckle arm with Tool.

NST009

YST024

NFA010

STEERING LINKAGE

Removal and Installation (Cont'd)

ST-18

Page 1730 of 1767

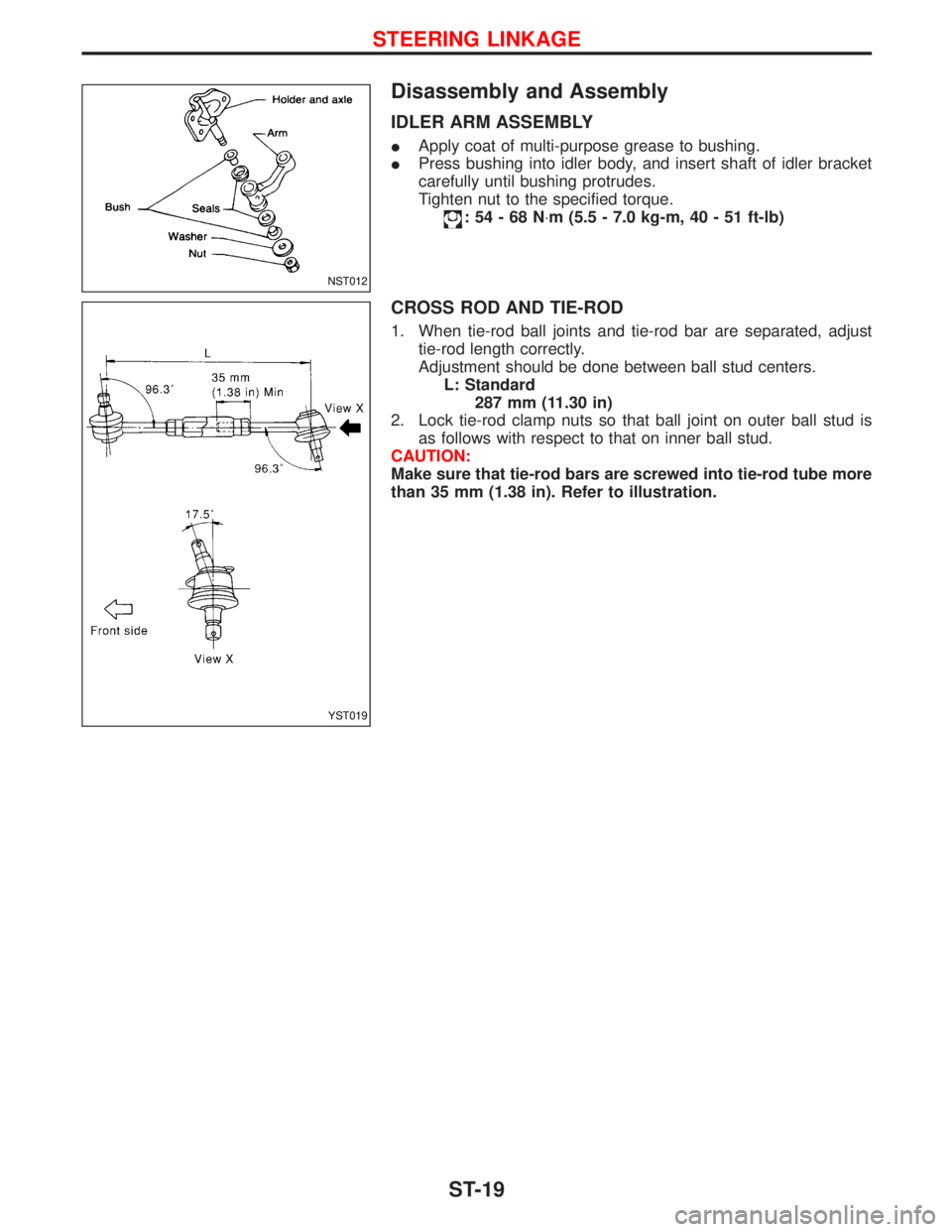

Disassembly and Assembly

IDLER ARM ASSEMBLY

IApply coat of multi-purpose grease to bushing.

IPress bushing into idler body, and insert shaft of idler bracket

carefully until bushing protrudes.

Tighten nut to the specified torque.

:54-68N×m (5.5 - 7.0 kg-m, 40 - 51 ft-lb)

CROSS ROD AND TIE-ROD

1. When tie-rod ball joints and tie-rod bar are separated, adjust

tie-rod length correctly.

Adjustment should be done between ball stud centers.

L: Standard

287 mm (11.30 in)

2. Lock tie-rod clamp nuts so that ball joint on outer ball stud is

as follows with respect to that on inner ball stud.

CAUTION:

Make sure that tie-rod bars are screwed into tie-rod tube more

than 35 mm (1.38 in). Refer to illustration.

NST012

YST019

STEERING LINKAGE

ST-19

Trending: oil, fuse, key, dimensions, odometer, remote, CD player