NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: hood release, recommended oil, height, compression ratio, sc-27, spare tire, ECO mode

Page 1691 of 1767

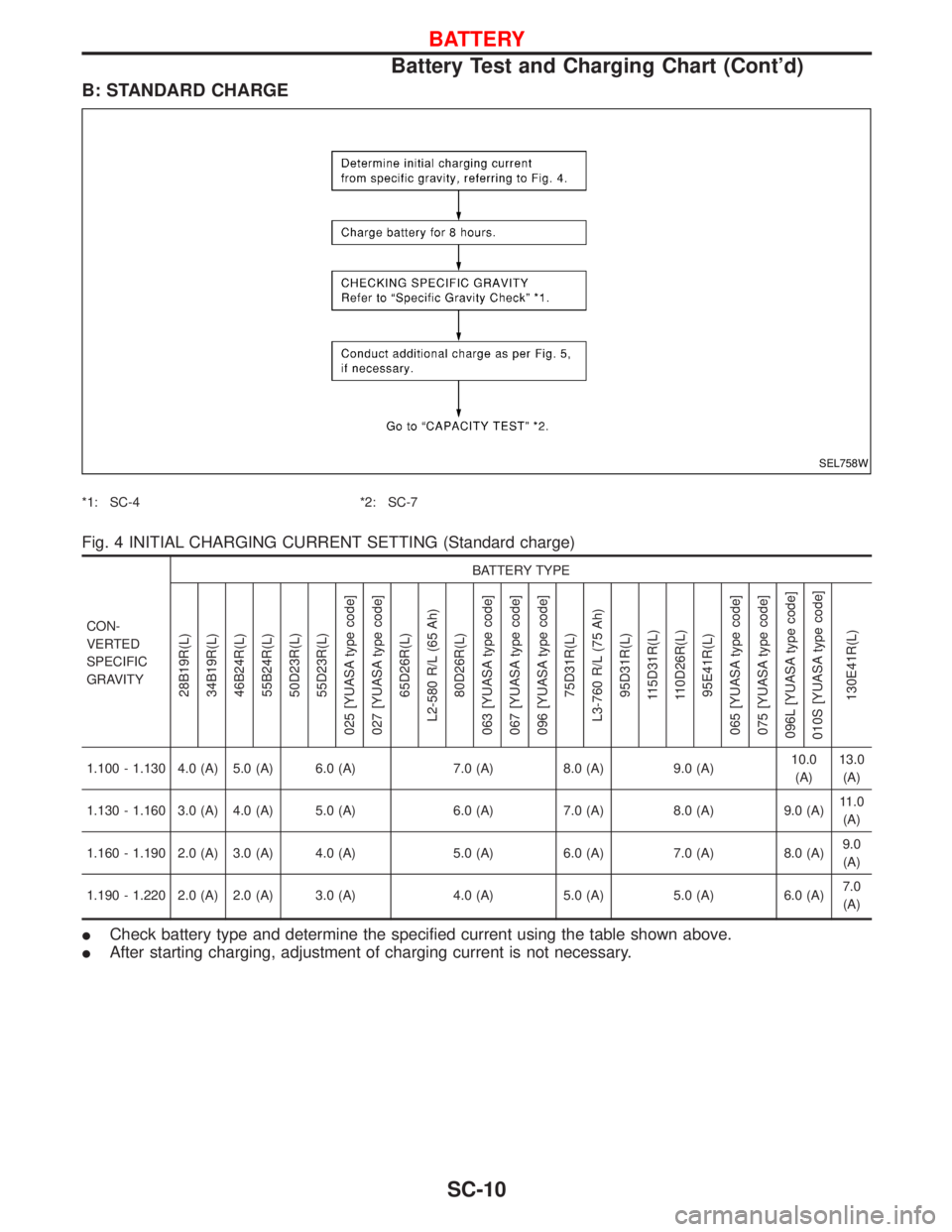

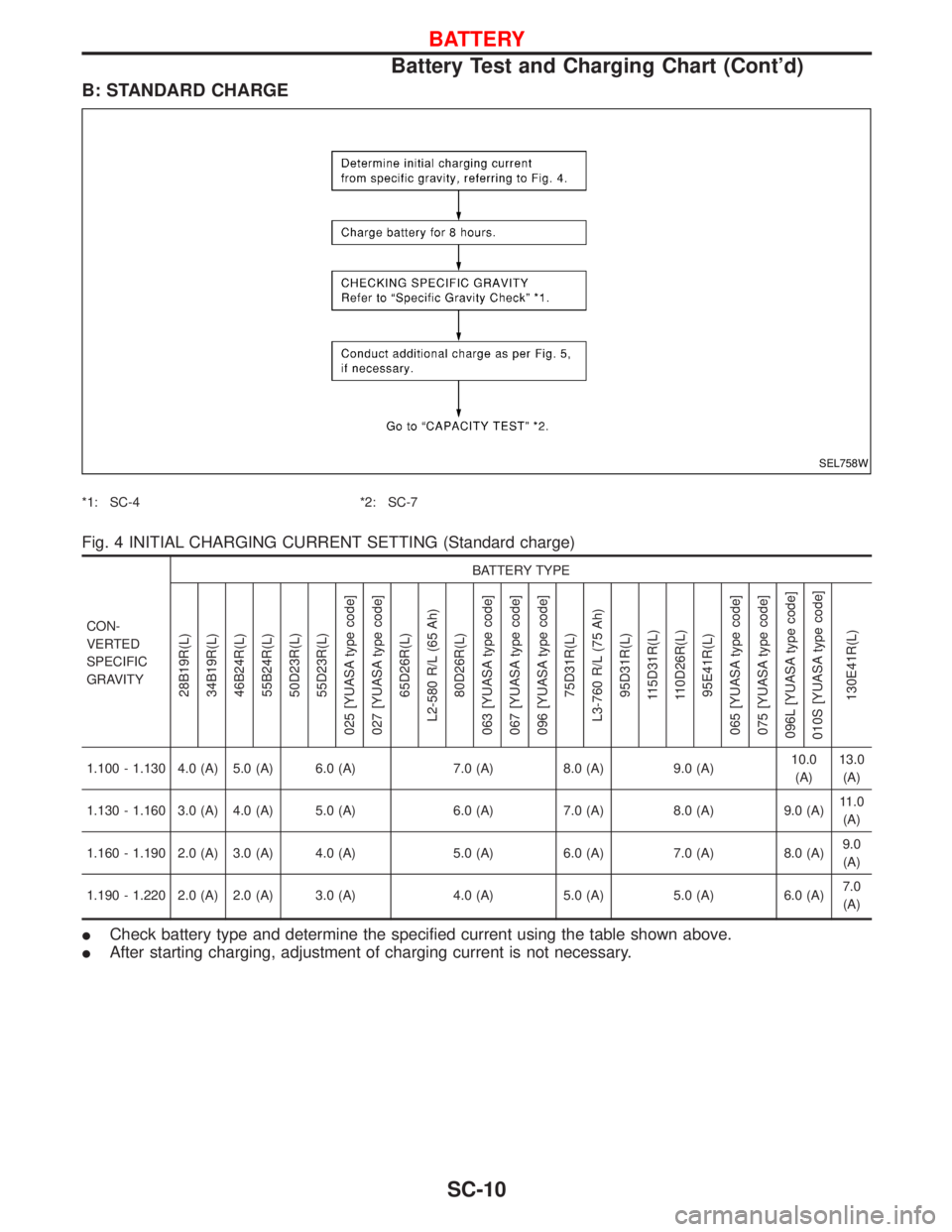

B: STANDARD CHARGE

*1: SC-4 *2: SC-7

Fig. 4 INITIAL CHARGING CURRENT SETTING (Standard charge)

CON-

VERTED

SPECIFIC

GRAVITYBATTERY TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

025 [YUASA type code]

027 [YUASA type code]

65D26R(L)

L2-580 R/L (65 Ah)

80D26R(L)

063 [YUASA type code]

067 [YUASA type code]

096 [YUASA type code]

75D31R(L)

L3-760 R/L (75 Ah)

95D31R(L)

115D31R(L)

110D26R(L)

95E41R(L)

065 [YUASA type code]

075 [YUASA type code]

096L [YUASA type code]

010S [YUASA type code]

130E41R(L)

1.100 - 1.130 4.0 (A) 5.0 (A) 6.0 (A) 7.0 (A) 8.0 (A) 9.0 (A)10.0

(A)13.0

(A)

1.130 - 1.160 3.0 (A) 4.0 (A) 5.0 (A) 6.0 (A) 7.0 (A) 8.0 (A) 9.0 (A)11.0

(A)

1.160 - 1.190 2.0 (A) 3.0 (A) 4.0 (A) 5.0 (A) 6.0 (A) 7.0 (A) 8.0 (A)9.0

(A)

1.190 - 1.220 2.0 (A) 2.0 (A) 3.0 (A) 4.0 (A) 5.0 (A) 5.0 (A) 6.0 (A)7.0

(A)

ICheck battery type and determine the specified current using the table shown above.

IAfter starting charging, adjustment of charging current is not necessary.

SEL758W

BATTERY

Battery Test and Charging Chart (Cont'd)

SC-10

Page 1692 of 1767

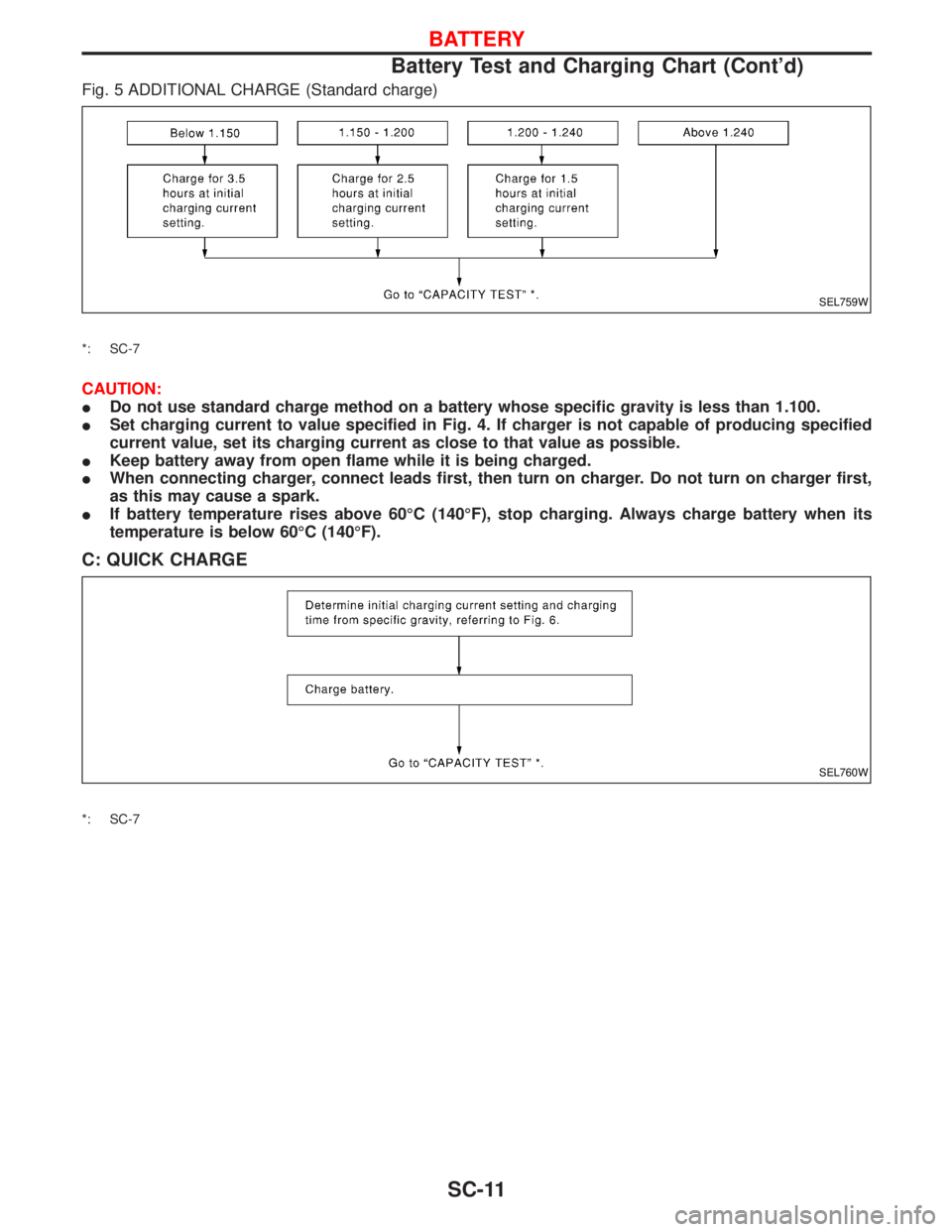

Fig. 5 ADDITIONAL CHARGE (Standard charge)

*: SC-7

CAUTION:

IDo not use standard charge method on a battery whose specific gravity is less than 1.100.

ISet charging current to value specified in Fig. 4. If charger is not capable of producing specified

current value, set its charging current as close to that value as possible.

IKeep battery away from open flame while it is being charged.

IWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

IIf battery temperature rises above 60ÉC (140ÉF), stop charging. Always charge battery when its

temperature is below 60ÉC (140ÉF).

C: QUICK CHARGE

*: SC-7

SEL759W

SEL760W

BATTERY

Battery Test and Charging Chart (Cont'd)

SC-11

Page 1693 of 1767

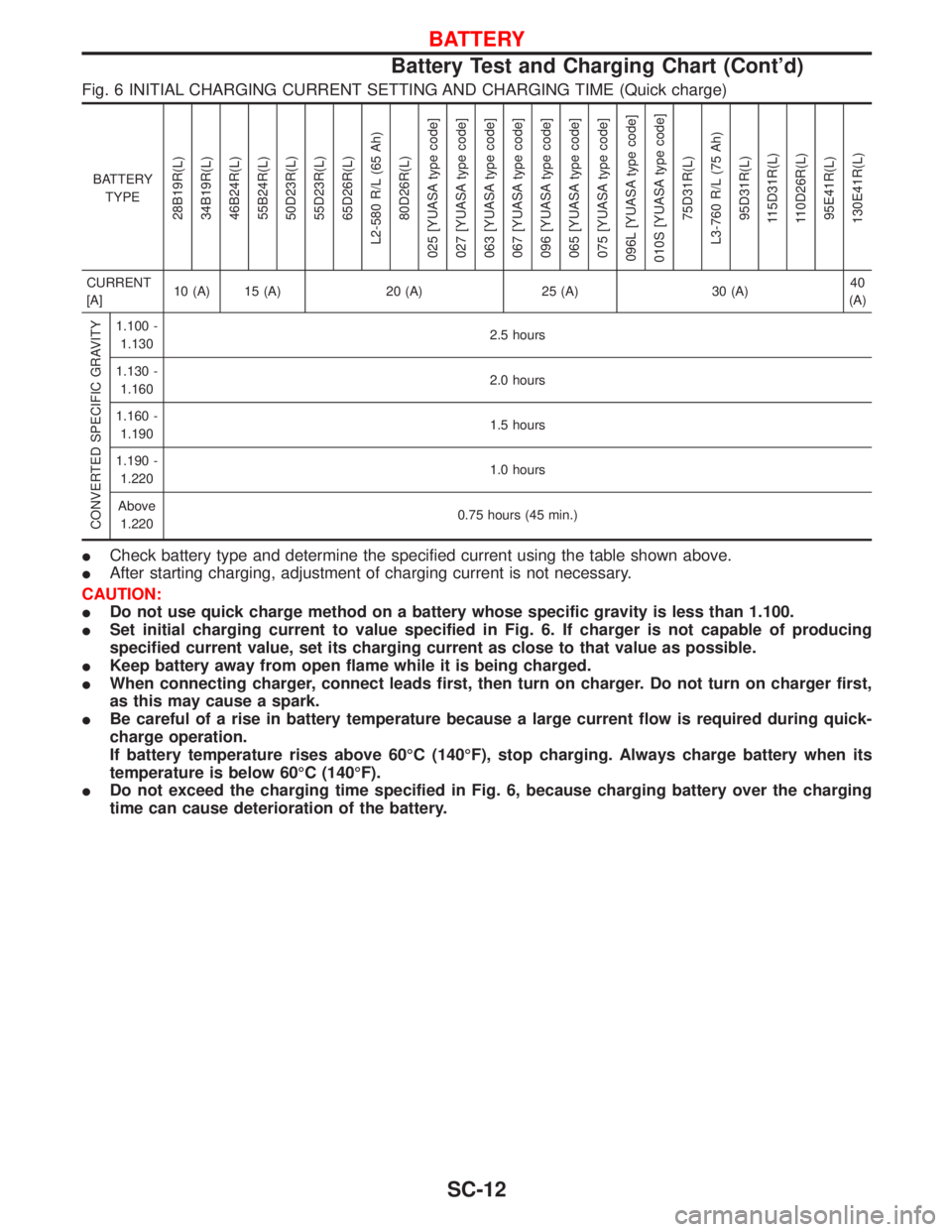

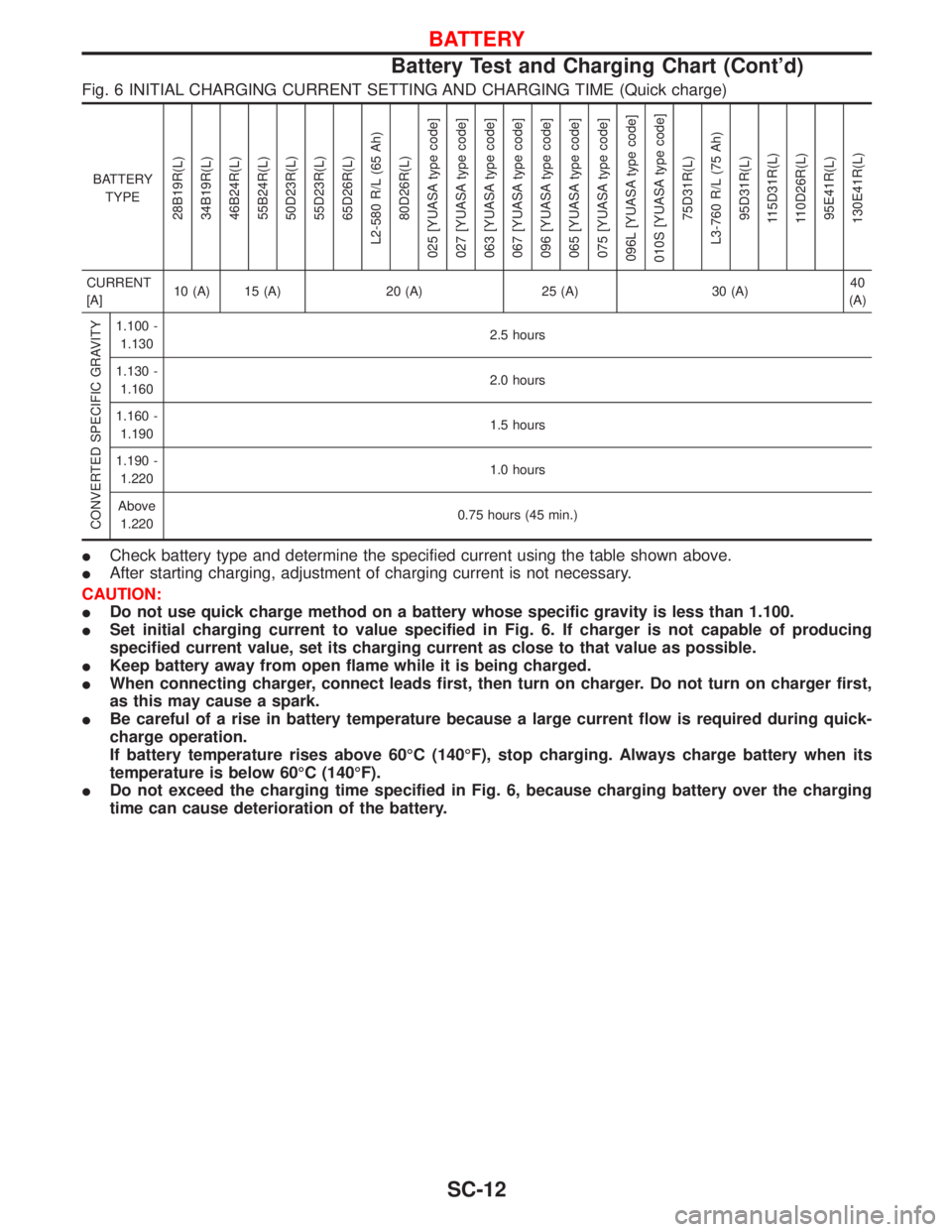

Fig. 6 INITIAL CHARGING CURRENT SETTING AND CHARGING TIME (Quick charge)

BATTERY

TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

65D26R(L)

L2-580 R/L (65 Ah)

80D26R(L)

025 [YUASA type code]

027 [YUASA type code]

063 [YUASA type code]

067 [YUASA type code]

096 [YUASA type code]

065 [YUASA type code]

075 [YUASA type code]

096L [YUASA type code]

010S [YUASA type code]

75D31R(L)

L3-760 R/L (75 Ah)

95D31R(L)

115D31R(L)

110D26R(L)

95E41R(L)

130E41R(L)

CURRENT

[A]10 (A) 15 (A) 20 (A) 25 (A) 30 (A)40

(A)

CONVERTED SPECIFIC GRAVITY

1.100 -

1.1302.5 hours

1.130 -

1.1602.0 hours

1.160 -

1.1901.5 hours

1.190 -

1.2201.0 hours

Above

1.2200.75 hours (45 min.)

ICheck battery type and determine the specified current using the table shown above.

IAfter starting charging, adjustment of charging current is not necessary.

CAUTION:

IDo not use quick charge method on a battery whose specific gravity is less than 1.100.

ISet initial charging current to value specified in Fig. 6. If charger is not capable of producing

specified current value, set its charging current as close to that value as possible.

IKeep battery away from open flame while it is being charged.

IWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

IBe careful of a rise in battery temperature because a large current flow is required during quick-

charge operation.

If battery temperature rises above 60ÉC (140ÉF), stop charging. Always charge battery when its

temperature is below 60ÉC (140ÉF).

IDo not exceed the charging time specified in Fig. 6, because charging battery over the charging

time can cause deterioration of the battery.

BATTERY

Battery Test and Charging Chart (Cont'd)

SC-12

Page 1694 of 1767

System Description

M/T MODELS

Power is supplied at all times

Ithrough 40A fusible link (letterC, located in the fuse and fusible link box)

Ito ignition switch terminal 1.

With the ignition switch in START position, power is supplied

Ifrom ignition switch terminal 1

Ito starter motor harness connector terminal 4.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

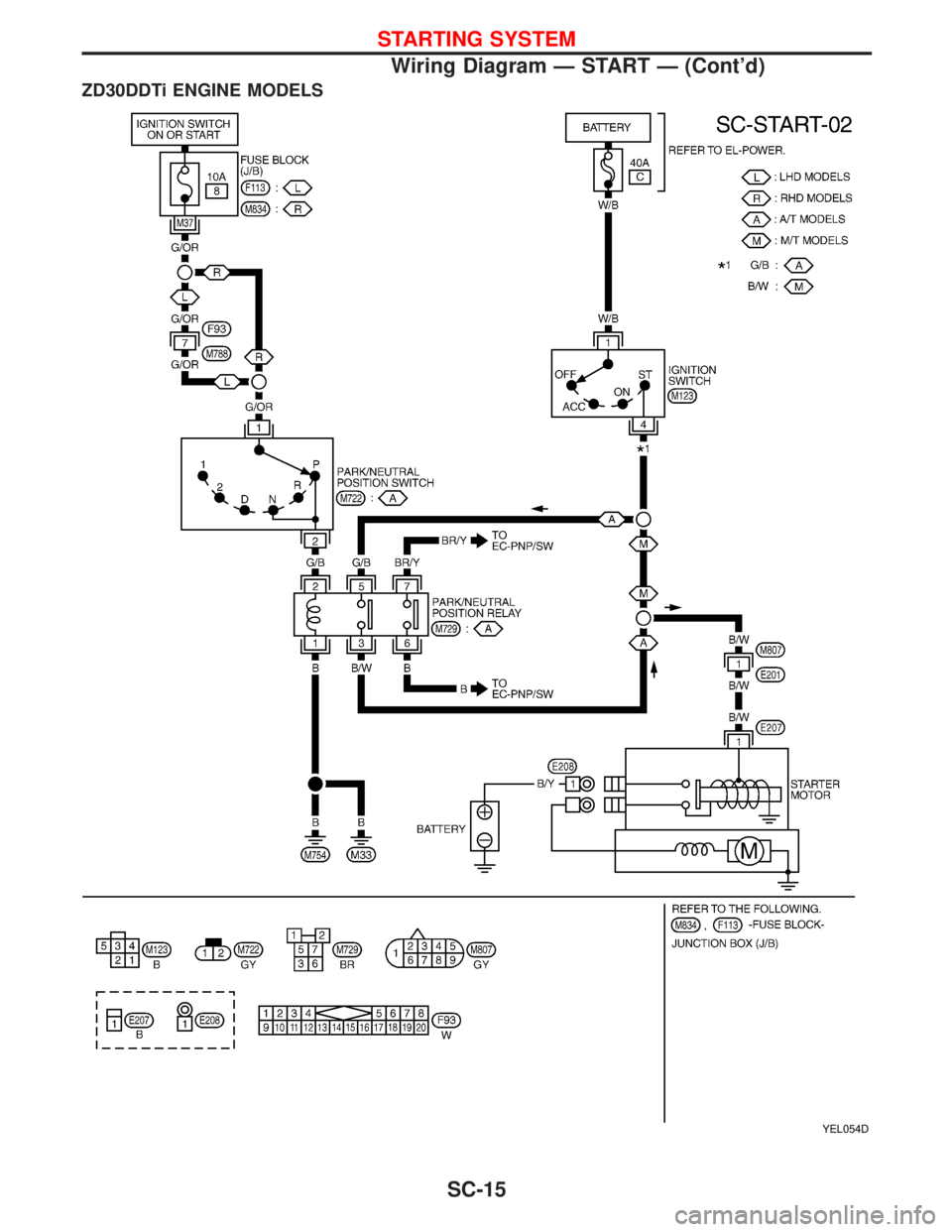

A/T MODELS

Power is supplied at all times

Ithrough 40A fusible link (letterC, located in the fuse and fusible link box)

Ito ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

Ifrom ignition switch terminal 1

Ito park/neutral position relay terminal 4.

With the ignition switch ON or START position, power is supplied

Ithrough 10A fuse [No. 8, located in the fuse block (J/B)]

Ito park/neutral position (PNP) relay terminal 1.

With the selector lever in the P or N position, ground is supplied

Ito park/neutral position relay terminal 2 through the park/neutral position switch

Ifrom body grounds, M754 and M33.

Then park/neutral position relay is energized and power is supplied

Ifrom park/neutral position relay terminal 3

Ito starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

STARTING SYSTEM

SC-13

Page 1695 of 1767

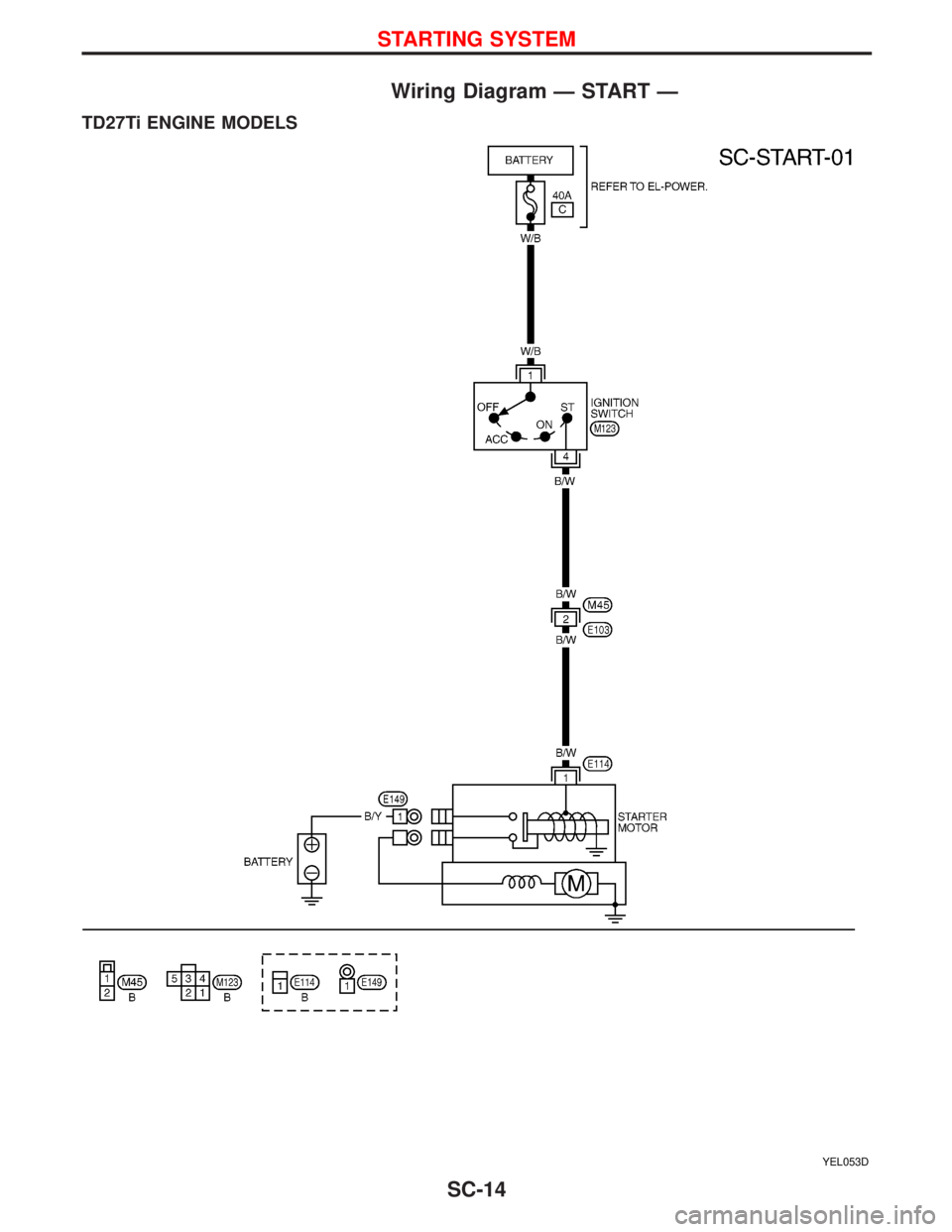

Wiring Diagram Ð START Ð

TD27Ti ENGINE MODELS

YEL053D

STARTING SYSTEM

SC-14

Page 1696 of 1767

ZD30DDTi ENGINE MODELS

YEL054D

STARTING SYSTEM

Wiring Diagram Ð START Ð (Cont'd)

SC-15

Page 1697 of 1767

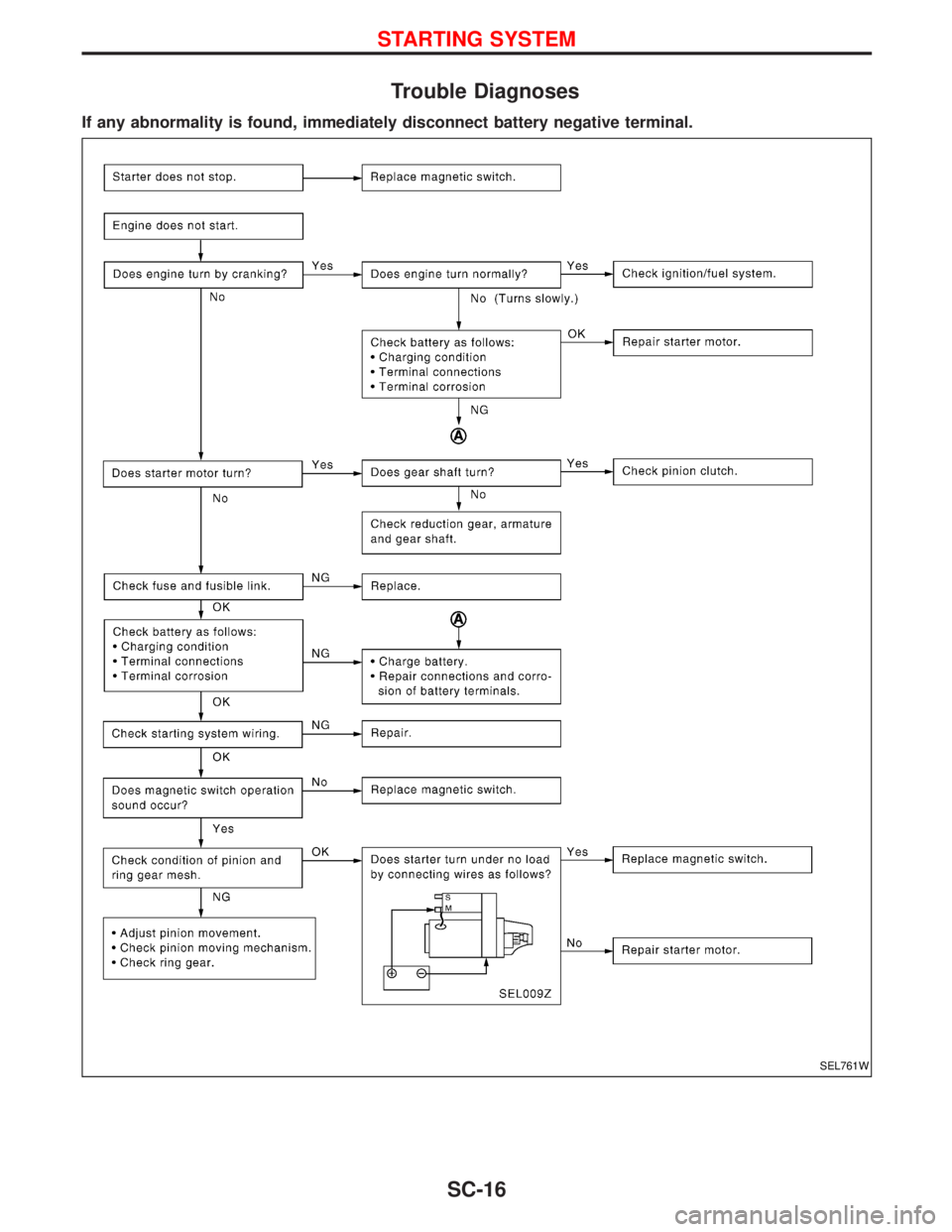

Trouble Diagnoses

If any abnormality is found, immediately disconnect battery negative terminal.

SEL761W

STARTING SYSTEM

SC-16

Page 1698 of 1767

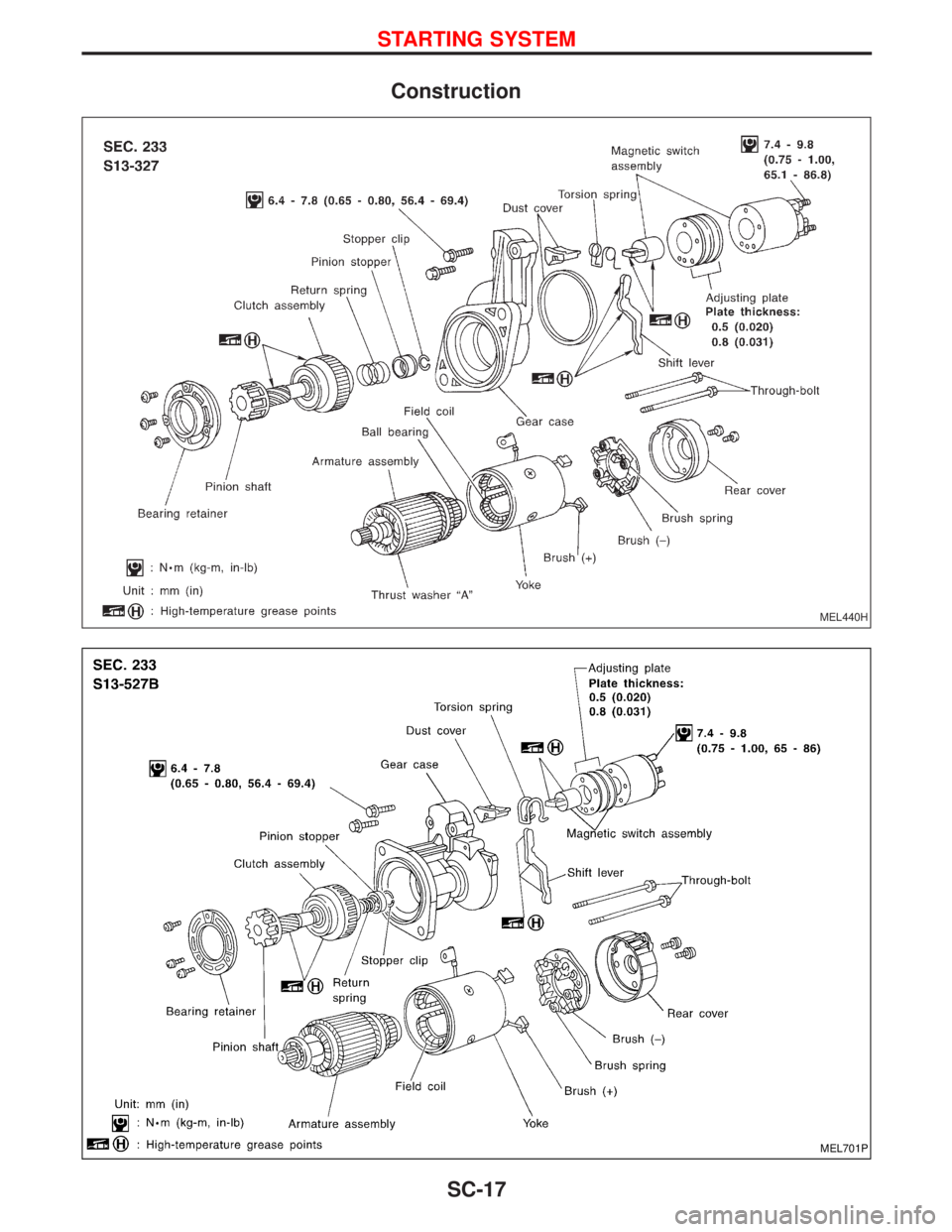

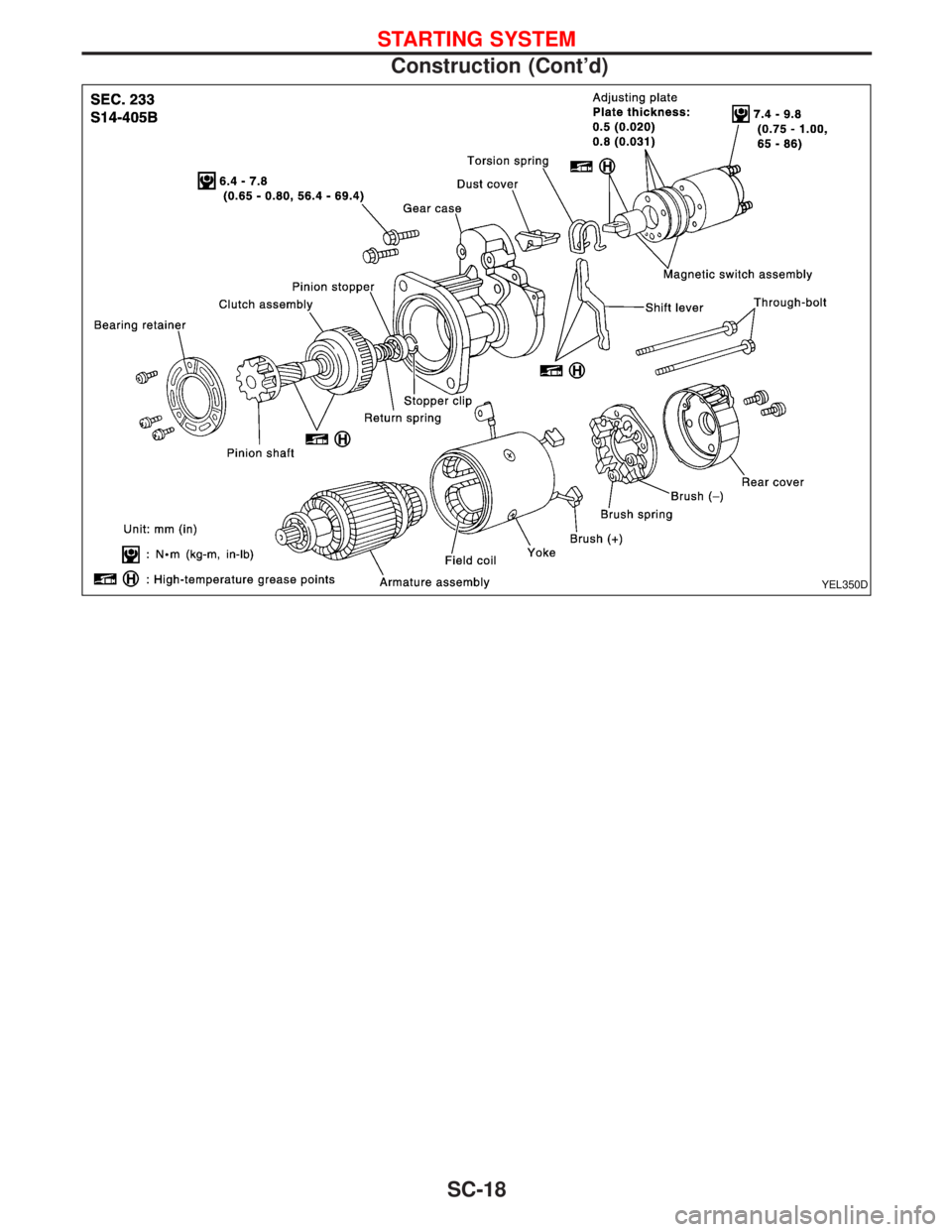

Construction

MEL440H

MEL701P

STARTING SYSTEM

SC-17

Page 1699 of 1767

YEL350D

STARTING SYSTEM

Construction (Cont'd)

SC-18

Page 1700 of 1767

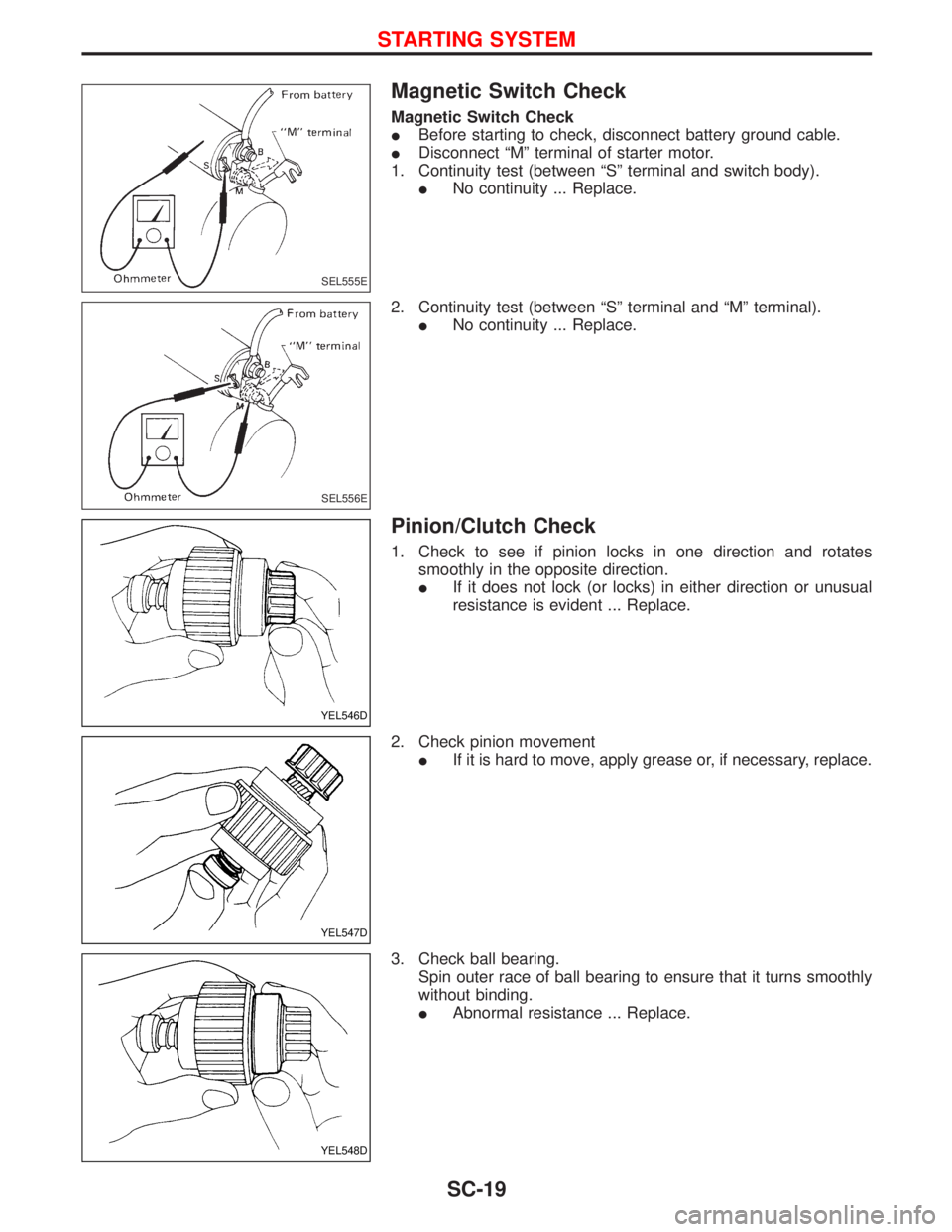

Magnetic Switch Check

Magnetic Switch Check

IBefore starting to check, disconnect battery ground cable.

IDisconnect ªMº terminal of starter motor.

1. Continuity test (between ªSº terminal and switch body).

INo continuity ... Replace.

2. Continuity test (between ªSº terminal and ªMº terminal).

INo continuity ... Replace.

Pinion/Clutch Check

1. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

IIf it does not lock (or locks) in either direction or unusual

resistance is evident ... Replace.

2. Check pinion movement

IIf it is hard to move, apply grease or, if necessary, replace.

3. Check ball bearing.

Spin outer race of ball bearing to ensure that it turns smoothly

without binding.

IAbnormal resistance ... Replace.

SEL555E

SEL556E

YEL546D

YEL547D

YEL548D

STARTING SYSTEM

SC-19

Trending: IDENTIFICATION INFORMATION, warning lights, wheel size, OBD port, sensor, auxiliary battery, service schedule