Electrical system NISSAN TERRANO 2002 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 411 of 1767

DESCRIPTION FOR WORK FLOW

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using

the ªDIAGNOSTIC WORKSHEETº, EC-46.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the DTC, then erase the

DTC. Refer to EC-33.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

Study the relationship between the cause, specified by DTC, and the symptom described by the customer. (The

ªSymptom Matrix Chartº will be useful. Refer to EC-56.) Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº is useful to verify the incident. Connect CONSULT-II to the vehicle in DATA

MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the DTC by driving in (or performing) the ªDTC Confirmation Procedureº. Check and read the DTC

by using CONSULT-II.

During the DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG)

mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

In case the ªDTC Confirmation Procedureº is not available, perform the ªOverall Function Checkº instead. The

DTC cannot be displayed by this check, however, this simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOverall Function Checkº is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC XXXX.

If the normal code is indicated, proceed to the Basic Inspection, EC-50. Then perform inspections according to

the Symptom Matrix Chart. Refer to EC-56.

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-69 or EC-66.

The ªDiagnostic Procedureº in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI section (ªCir-

cuit Inspectionº, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº).

Repair or replace the malfunction parts.

If the malfunctioning part cannot be detected, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENTº, EC-78.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDTC Confirmation Procedureº and confirm the normal code (DTC No. 0505) is detected. If the inci-

dent is still detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) DTC in ECM.

(Refer to EC-33.)

TROUBLE DIAGNOSIS Ð INTRODUCTIONZD30DDTi

Work Flow (Cont'd)

EC-49

Page 516 of 1767

2 CHECK BATTERY AND ALTERNATOR

Check that the proper type of battery and alternator is installed.

Refer to EL section (ªBATTERYº and ªCHARGING SYSTEMº).

OK or NG

OKEGO TO 5.

NGEReplace with a proper one.

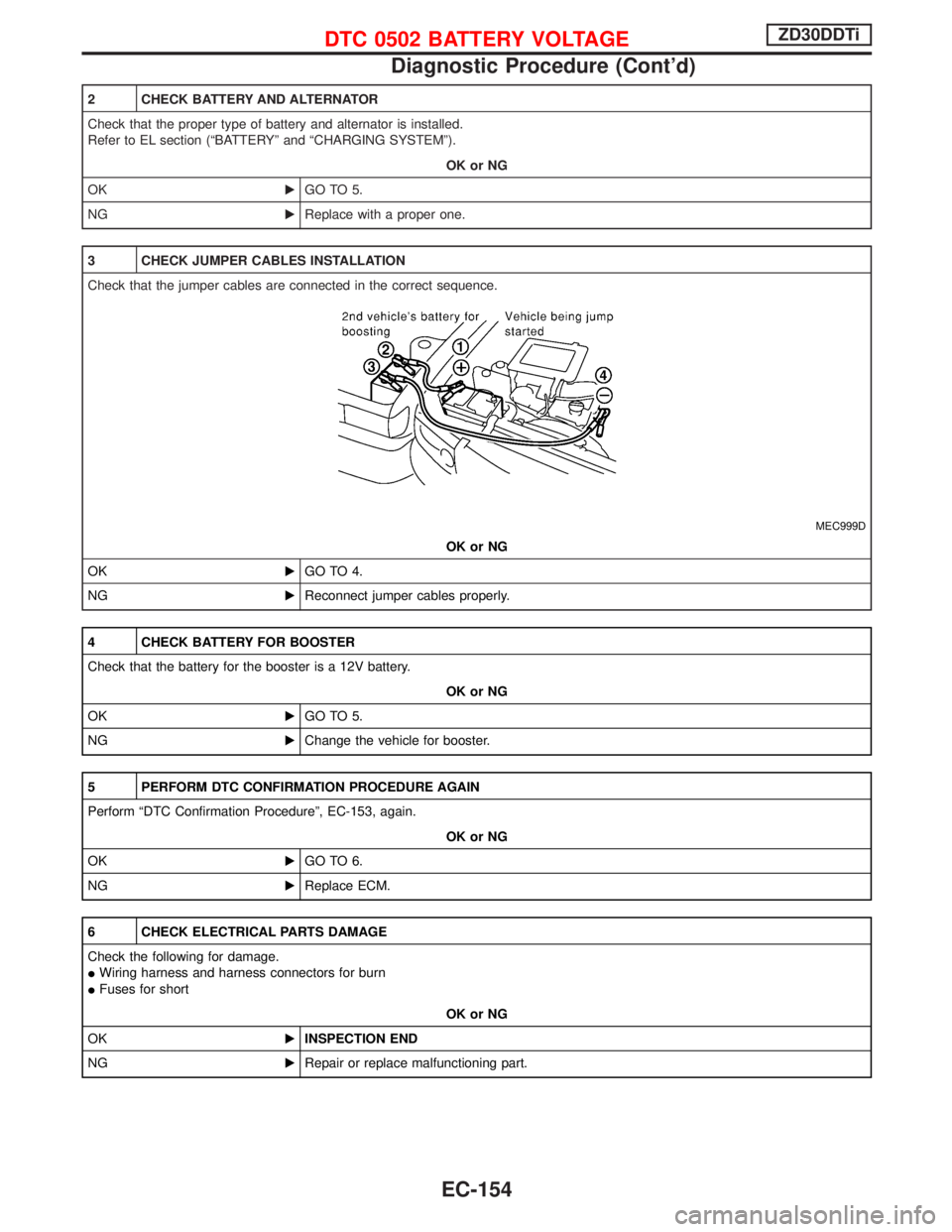

3 CHECK JUMPER CABLES INSTALLATION

Check that the jumper cables are connected in the correct sequence.

MEC999D

OK or NG

OKEGO TO 4.

NGEReconnect jumper cables properly.

4 CHECK BATTERY FOR BOOSTER

Check that the battery for the booster is a 12V battery.

OK or NG

OKEGO TO 5.

NGEChange the vehicle for booster.

5 PERFORM DTC CONFIRMATION PROCEDURE AGAIN

Perform ªDTC Confirmation Procedureº, EC-153, again.

OK or NG

OKEGO TO 6.

NGEReplace ECM.

6 CHECK ELECTRICAL PARTS DAMAGE

Check the following for damage.

IWiring harness and harness connectors for burn

IFuses for short

OK or NG

OKEINSPECTION END

NGERepair or replace malfunctioning part.

DTC 0502 BATTERY VOLTAGEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-154

Page 584 of 1767

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECM ECM Function Actuator

Electronic controlled fuel injection pump Fuel injection signal

EGR volume

controlEGR volume control valve Crankshaft position sensor (TDC) Engine speed

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Battery Battery voltage

Mass air flow sensor Amount of intake air

Air conditioner switch Air conditioner operation

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

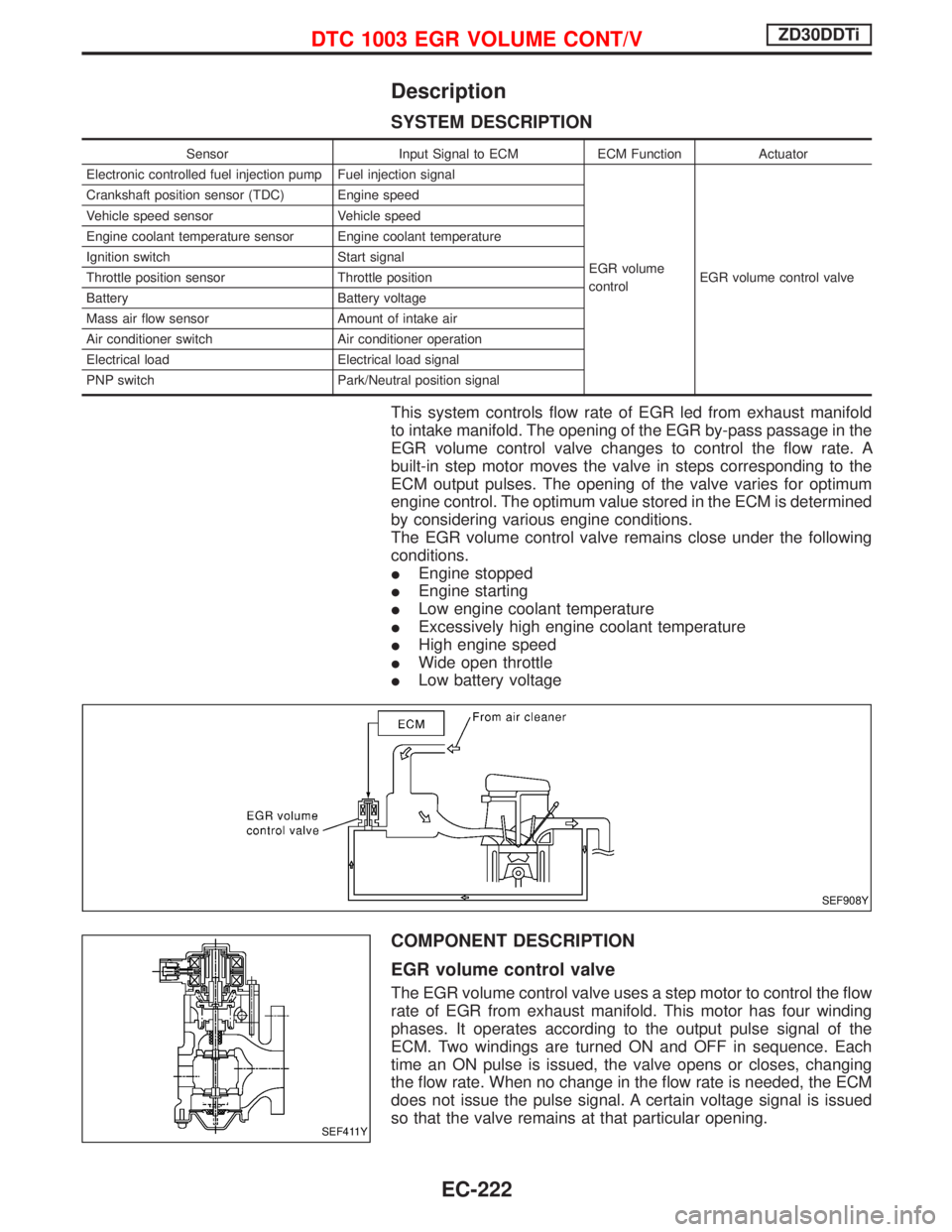

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions.

The EGR volume control valve remains close under the following

conditions.

IEngine stopped

IEngine starting

ILow engine coolant temperature

IExcessively high engine coolant temperature

IHigh engine speed

IWide open throttle

ILow battery voltage

COMPONENT DESCRIPTION

EGR volume control valve

The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

SEF908Y

SEF411Y

DTC 1003 EGR VOLUME CONT/VZD30DDTi

EC-222

Page 700 of 1767

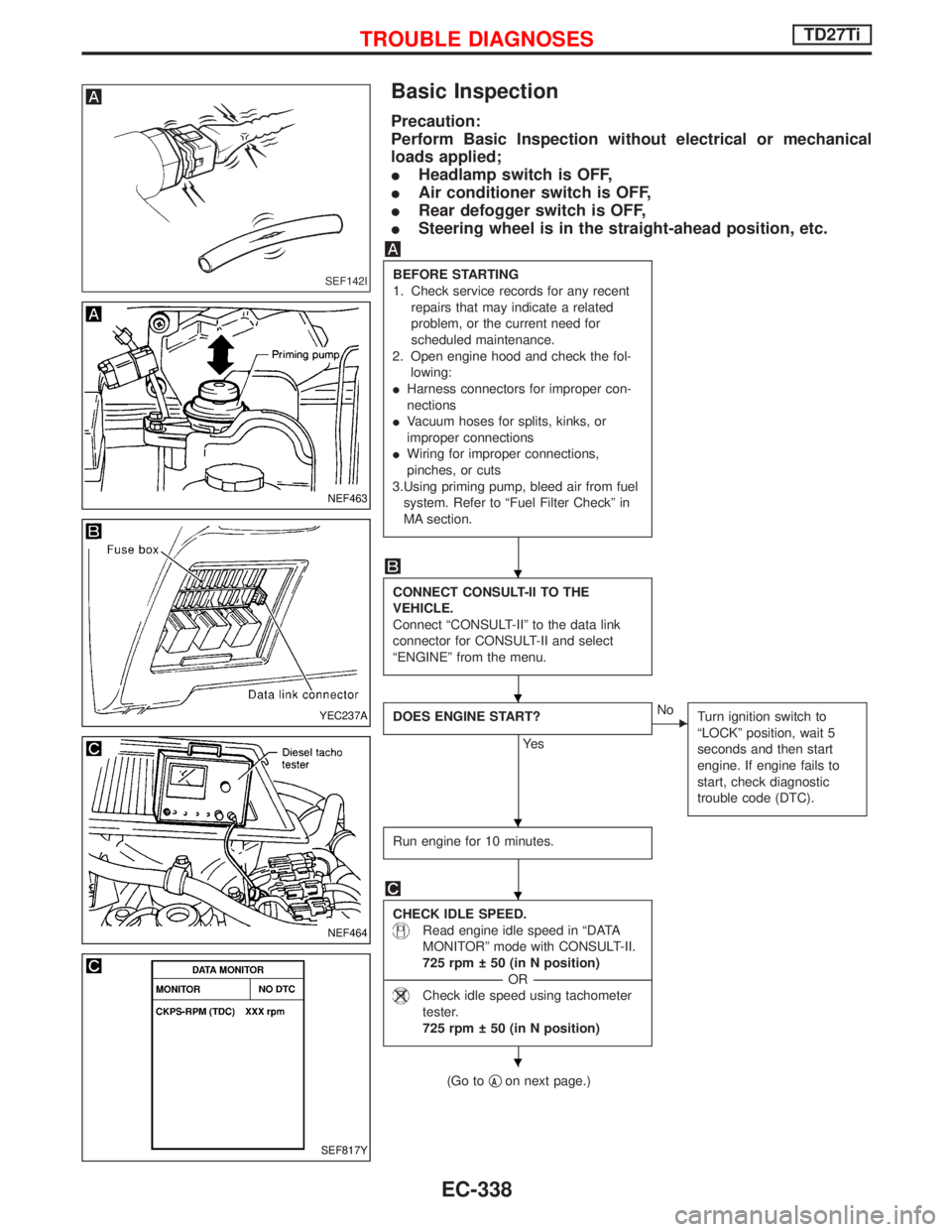

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

IAir conditioner switch is OFF,

IRear defogger switch is OFF,

ISteering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for

scheduled maintenance.

2. Open engine hood and check the fol-

lowing:

IHarness connectors for improper con-

nections

IVacuum hoses for splits, kinks, or

improper connections

IWiring for improper connections,

pinches, or cuts

3.Using priming pump, bleed air from fuel

system. Refer to ªFuel Filter Checkº in

MA section.

CONNECT CONSULT-II TO THE

VEHICLE.

Connect ªCONSULT-IIº to the data link

connector for CONSULT-II and select

ªENGINEº from the menu.

DOES ENGINE START?

Ye s

ENo

Turn ignition switch to

ªLOCKº position, wait 5

seconds and then start

engine. If engine fails to

start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

Read engine idle speed in ªDATA

MONITORº mode with CONSULT-II.

725 rpm 50 (in N position)

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachometer

tester.

725 rpm 50 (in N position)

(Go toqAon next page.)

SEF142I

NEF463

YEC237A

NEF464

SEF817Y

H

H

H

H

H

TROUBLE DIAGNOSESTD27Ti

EC-338

Page 817 of 1767

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

IRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

CONTENTS

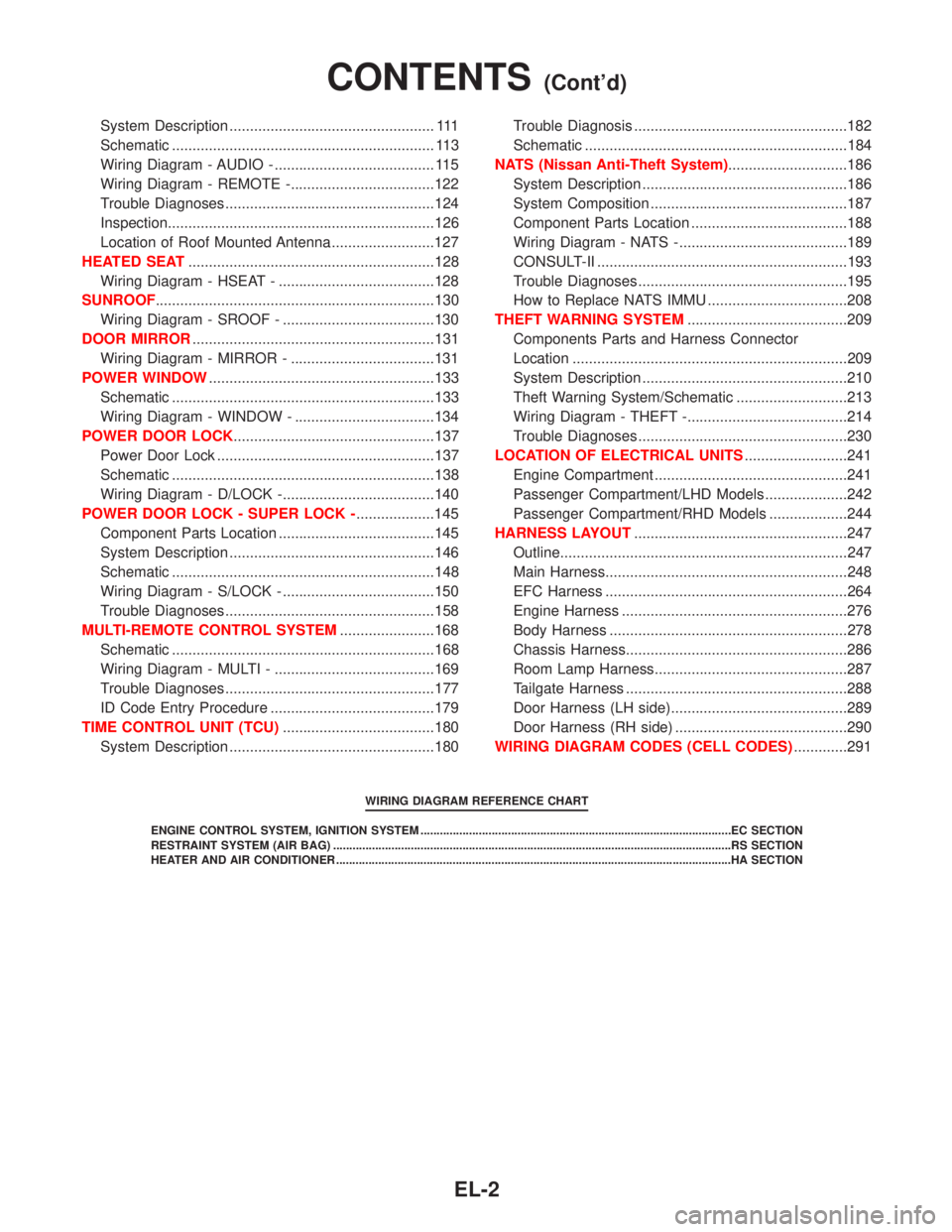

HARNESS CONNECTOR................................................3

Description ...................................................................3

STANDARDIZED RELAYS..............................................4

Description ...................................................................4

POWER SUPPLY ROUTING...........................................6

Schematic ....................................................................6

Wiring Diagram - POWER - ........................................8

Fuse ...........................................................................17

Fusible Link................................................................17

Circuit Breaker Inspection .........................................17

GROUND DISTRIBUTION.............................................18

COMBINATION SWITCH...............................................23

Check .........................................................................23

Replacement ..............................................................24

STEERING SWITCH......................................................25

Check .........................................................................25

HEADLAMP - Without Daytime Light System -.........26

Wiring Diagram - H/LAMP -.......................................26

HEADLAMP - Daytime Light System -.......................29

Operation ...................................................................29

Schematic ..................................................................30

Wiring Diagram - DTRL - ...........................................31

HEADLAMP - Headlamp Aiming Control -.................37

Description .................................................................37

Replacing Headlamp Aiming Actuator .......................38

Wiring Diagram - H/AIM - ..........................................39

Trouble Diagnoses.....................................................42

HEADLAMP...................................................................43

Bulb Replacement .....................................................43

Aiming Adjustment .....................................................43

EXTERIOR LAMP..........................................................45

Wiring Diagram - TAIL/L - ..........................................45

Wiring Diagram - STOP/L - .......................................48

Wiring Diagram - BACK/L - .......................................49

Wiring Diagram - F/FOG - .........................................51

Front Fog Lamp Aiming Adjustment ..........................53

Wiring Diagram - R/FOG -.........................................54

Schematic ..................................................................55Wiring Diagram - TURN - ..........................................56

Bulb Specifications ....................................................60

INTERIOR LAMP...........................................................61

Schematic ..................................................................61

Wiring Diagram - ILL - ...............................................62

Wiring Diagram - INT/L - ...........................................66

METER AND GAUGES.................................................70

Combination Meter ....................................................70

Schematic ..................................................................71

Wiring Diagram - METER - .......................................72

Combination Meter Self-Diagnosis ............................76

Components Inspection .............................................78

Trouble Diagnoses.....................................................79

Fuel Tank Gauge Unit Check ....................................80

Thermal Transmitter Check .......................................80

Oil Pressure Switch Check ........................................80

WARNING LAMPS AND CHIME...................................81

Schematic ..................................................................81

Wiring Diagram - WARN - .........................................82

Diode Check ..............................................................92

Wiring Diagram - CHIME - ........................................93

WIPER AND WASHER..................................................94

Wiring Diagram - WIPER - ........................................94

Wiring Diagram - WIP/R -..........................................96

Installation ..................................................................98

Washer Nozzle Adjustment .......................................99

Check Valve ...............................................................99

Wiring Diagram - HLC - ...........................................100

HORN, CIGARETTE LIGHTER AND CLOCK............104

Wiring Diagram - HORN - .......................................104

Wiring Diagram - CIGAR -.......................................105

Wiring Diagram - CLOCK -......................................106

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER.................................................107

Wiring Diagram - DEF - ...........................................107

Filament Check ........................................................109

Filament Repair ....................................................... 110

AUDIO.......................................................................... 111

Page 818 of 1767

System Description .................................................. 111

Schematic ................................................................ 113

Wiring Diagram - AUDIO - ....................................... 115

Wiring Diagram - REMOTE -...................................122

Trouble Diagnoses...................................................124

Inspection.................................................................126

Location of Roof Mounted Antenna .........................127

HEATED SEAT............................................................128

Wiring Diagram - HSEAT - ......................................128

SUNROOF....................................................................130

Wiring Diagram - SROOF - .....................................130

DOOR MIRROR...........................................................131

Wiring Diagram - MIRROR - ...................................131

POWER WINDOW.......................................................133

Schematic ................................................................133

Wiring Diagram - WINDOW - ..................................134

POWER DOOR LOCK.................................................137

Power Door Lock .....................................................137

Schematic ................................................................138

Wiring Diagram - D/LOCK -.....................................140

POWER DOOR LOCK - SUPER LOCK -...................145

Component Parts Location ......................................145

System Description ..................................................146

Schematic ................................................................148

Wiring Diagram - S/LOCK - .....................................150

Trouble Diagnoses...................................................158

MULTI-REMOTE CONTROL SYSTEM.......................168

Schematic ................................................................168

Wiring Diagram - MULTI - .......................................169

Trouble Diagnoses...................................................177

ID Code Entry Procedure ........................................179

TIME CONTROL UNIT (TCU).....................................180

System Description ..................................................180Trouble Diagnosis ....................................................182

Schematic ................................................................184

NATS (Nissan Anti-Theft System).............................186

System Description ..................................................186

System Composition ................................................187

Component Parts Location ......................................188

Wiring Diagram - NATS -.........................................189

CONSULT-II .............................................................193

Trouble Diagnoses...................................................195

How to Replace NATS IMMU ..................................208

THEFT WARNING SYSTEM.......................................209

Components Parts and Harness Connector

Location ...................................................................209

System Description ..................................................210

Theft Warning System/Schematic ...........................213

Wiring Diagram - THEFT -.......................................214

Trouble Diagnoses...................................................230

LOCATION OF ELECTRICAL UNITS.........................241

Engine Compartment ...............................................241

Passenger Compartment/LHD Models ....................242

Passenger Compartment/RHD Models ...................244

HARNESS LAYOUT....................................................247

Outline......................................................................247

Main Harness...........................................................248

EFC Harness ...........................................................264

Engine Harness .......................................................276

Body Harness ..........................................................278

Chassis Harness......................................................286

Room Lamp Harness...............................................287

Tailgate Harness ......................................................288

Door Harness (LH side)...........................................289

Door Harness (RH side) ..........................................290

WIRING DIAGRAM CODES (CELL CODES).............291

WIRING DIAGRAM REFERENCE CHART

ENGINE CONTROL SYSTEM, IGNITION SYSTEM ................................................................................................EC SECTION

RESTRAINT SYSTEM (AIR BAG) ...........................................................................................................................RS SECTION

HEATER AND AIR CONDITIONER ..........................................................................................................................HA SECTION

CONTENTS(Cont'd)

EL-2

Page 1316 of 1767

GENERAL INFORMATION

SECTION

GI

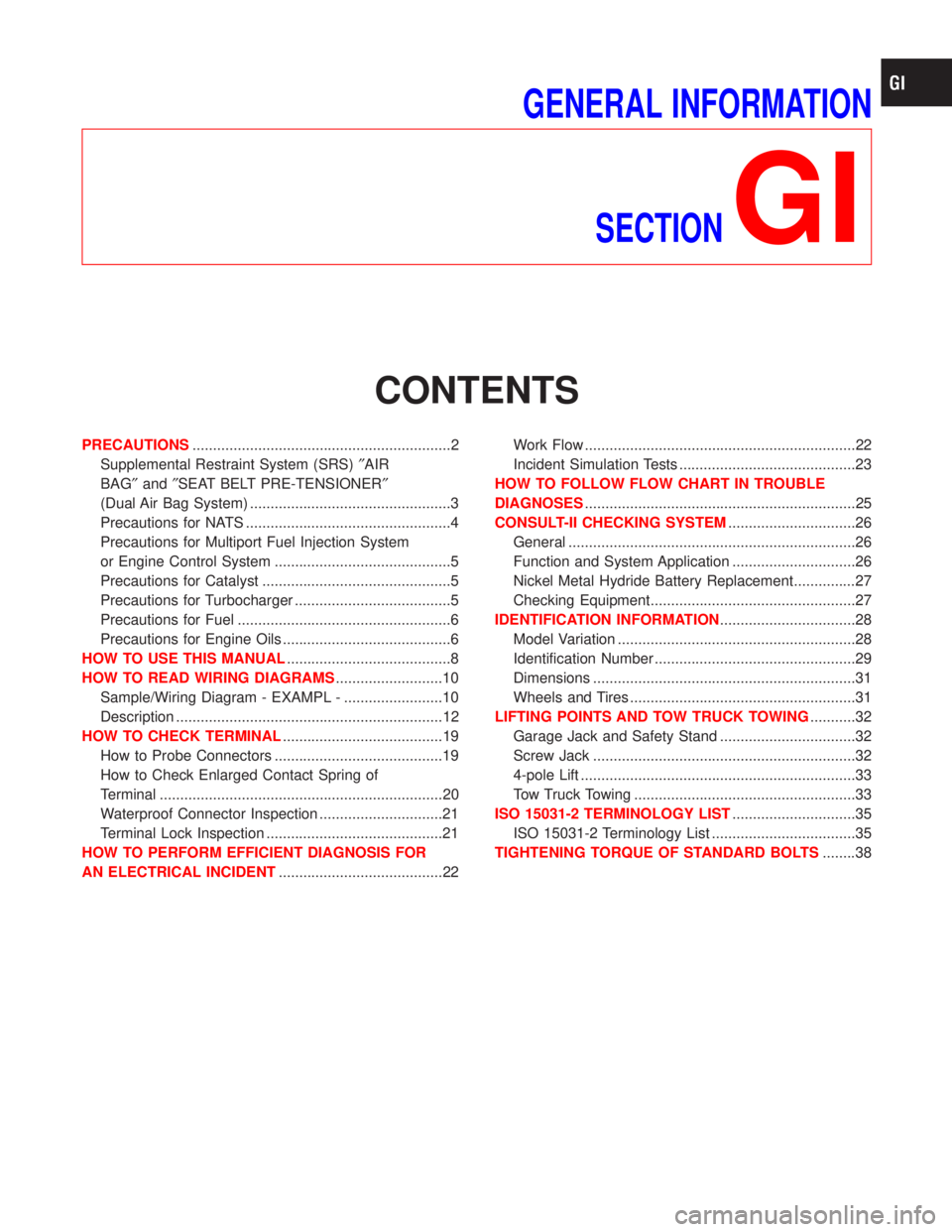

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL........................................8

HOW TO READ WIRING DIAGRAMS..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL.......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT........................................22Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES..................................................................25

CONSULT-II CHECKING SYSTEM...............................26

General ......................................................................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............27

Checking Equipment..................................................27

IDENTIFICATION INFORMATION.................................28

Model Variation ..........................................................28

Identification Number .................................................29

Dimensions ................................................................31

Wheels and Tires .......................................................31

LIFTING POINTS AND TOW TRUCK TOWING...........32

Garage Jack and Safety Stand .................................32

Screw Jack ................................................................32

4-pole Lift ...................................................................33

Tow Truck Towing ......................................................33

ISO 15031-2 TERMINOLOGY LIST..............................35

ISO 15031-2 Terminology List ...................................35

TIGHTENING TORQUE OF STANDARD BOLTS........38

Page 1318 of 1767

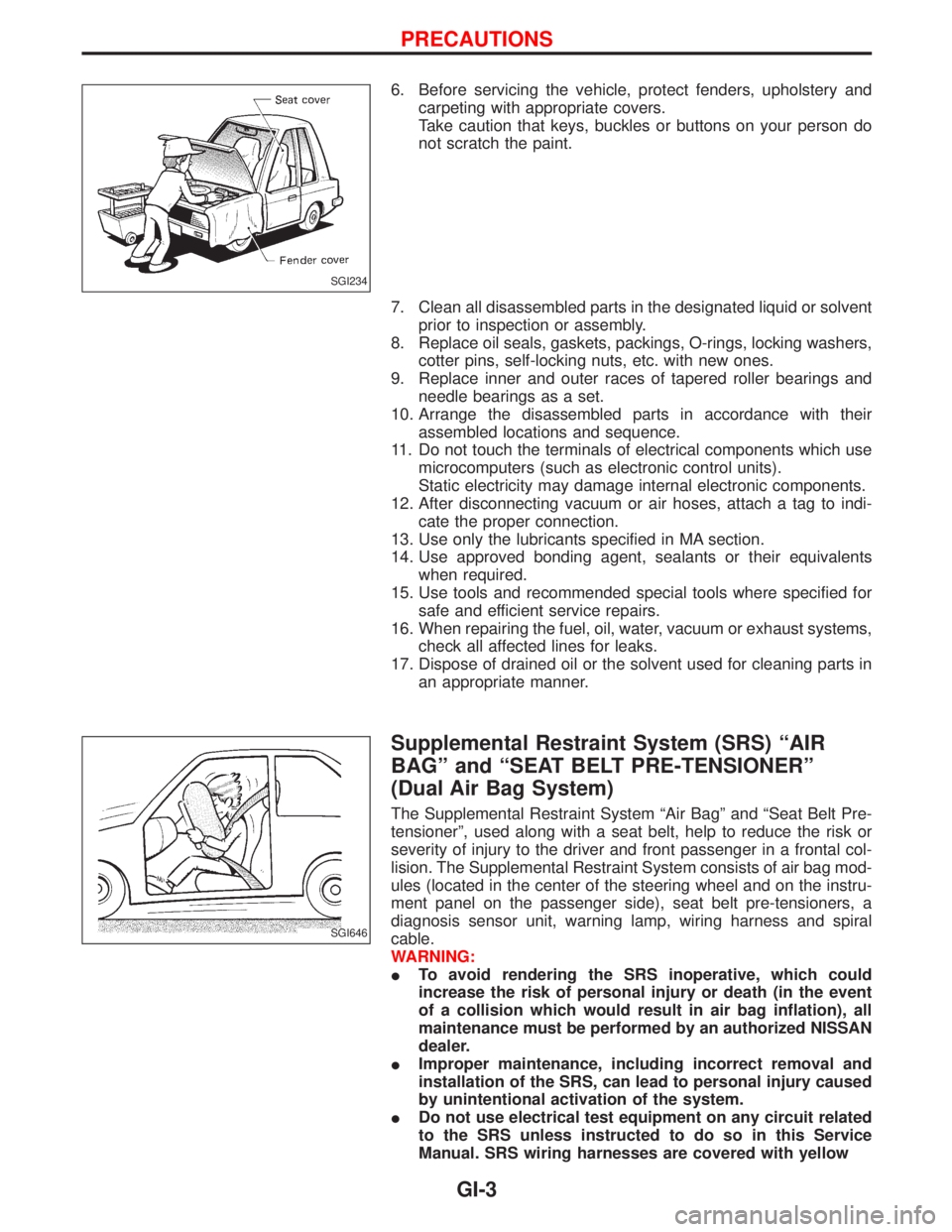

6. Before servicing the vehicle, protect fenders, upholstery and

carpeting with appropriate covers.

Take caution that keys, buckles or buttons on your person do

not scratch the paint.

7. Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

8. Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

9. Replace inner and outer races of tapered roller bearings and

needle bearings as a set.

10. Arrange the disassembled parts in accordance with their

assembled locations and sequence.

11. Do not touch the terminals of electrical components which use

microcomputers (such as electronic control units).

Static electricity may damage internal electronic components.

12. After disconnecting vacuum or air hoses, attach a tag to indi-

cate the proper connection.

13. Use only the lubricants specified in MA section.

14. Use approved bonding agent, sealants or their equivalents

when required.

15. Use tools and recommended special tools where specified for

safe and efficient service repairs.

16. When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

17. Dispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

(Dual Air Bag System)

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-

tensionerº, used along with a seat belt, help to reduce the risk or

severity of injury to the driver and front passenger in a frontal col-

lision. The Supplemental Restraint System consists of air bag mod-

ules (located in the center of the steering wheel and on the instru-

ment panel on the passenger side), seat belt pre-tensioners, a

diagnosis sensor unit, warning lamp, wiring harness and spiral

cable.

WARNING:

ITo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death (in the event

of a collision which would result in air bag inflation), all

maintenance must be performed by an authorized NISSAN

dealer.

IImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related

to the SRS unless instructed to do so in this Service

Manual. SRS wiring harnesses are covered with yellow

SGI234

SGI646

PRECAUTIONS

GI-3

Page 1337 of 1767

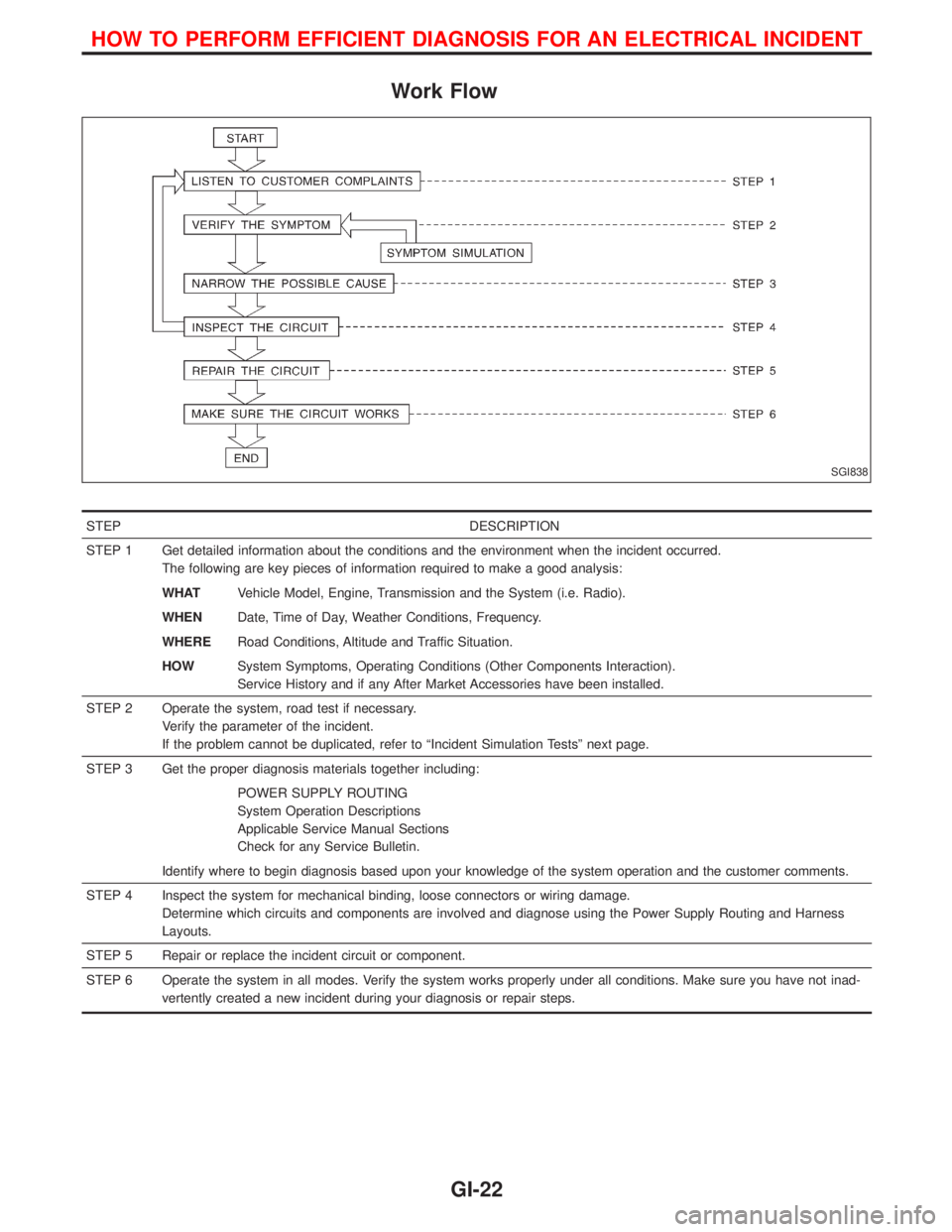

Work Flow

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to ªIncident Simulation Testsº next page.

STEP 3 Get the proper diagnosis materials together including:

POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

SGI838

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-22

Page 1338 of 1767

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

IHeat sensitive

IFreezing

IWater intrusion

IElectrical load

ICold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

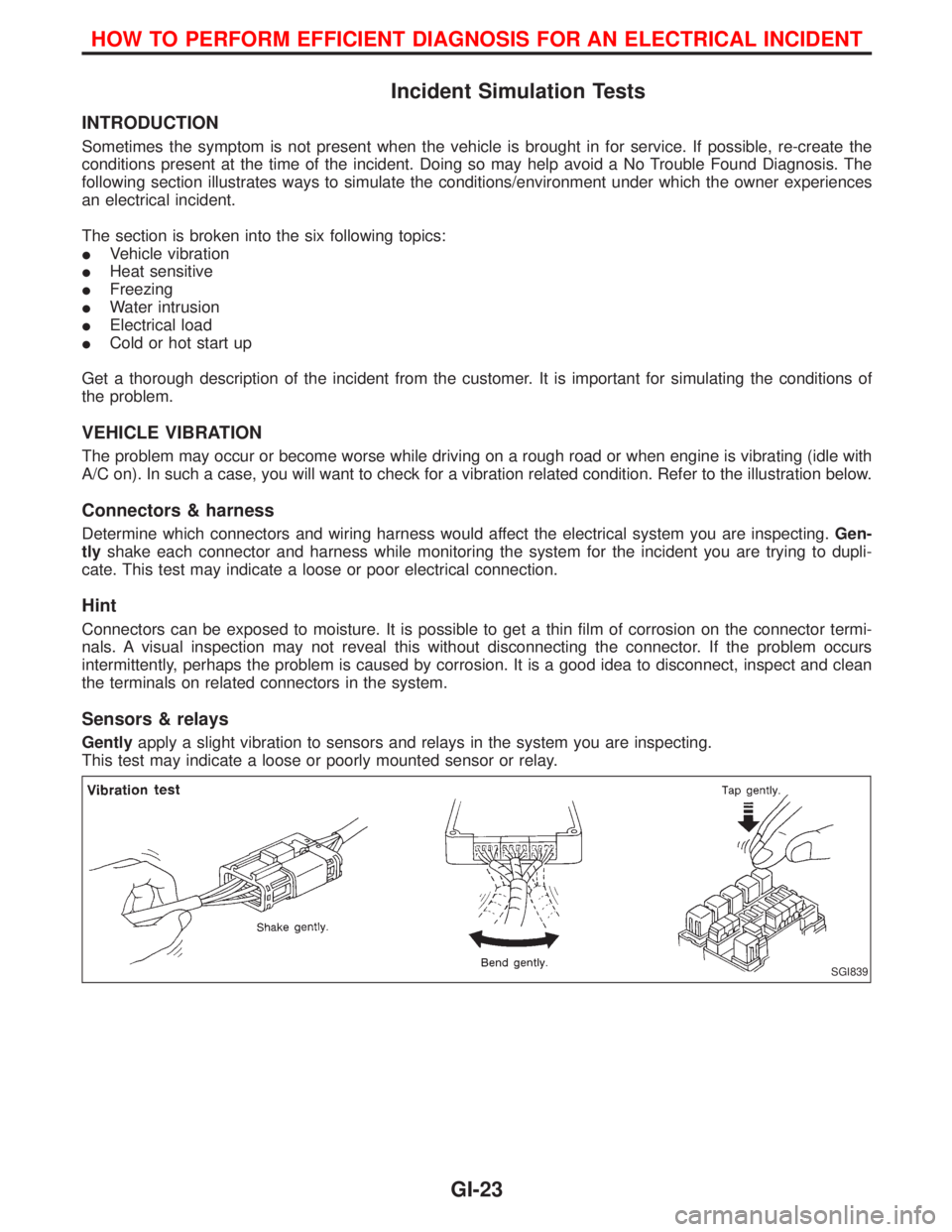

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23