light NISSAN TERRANO 2002 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 147 of 1767

DISASSEMBLY

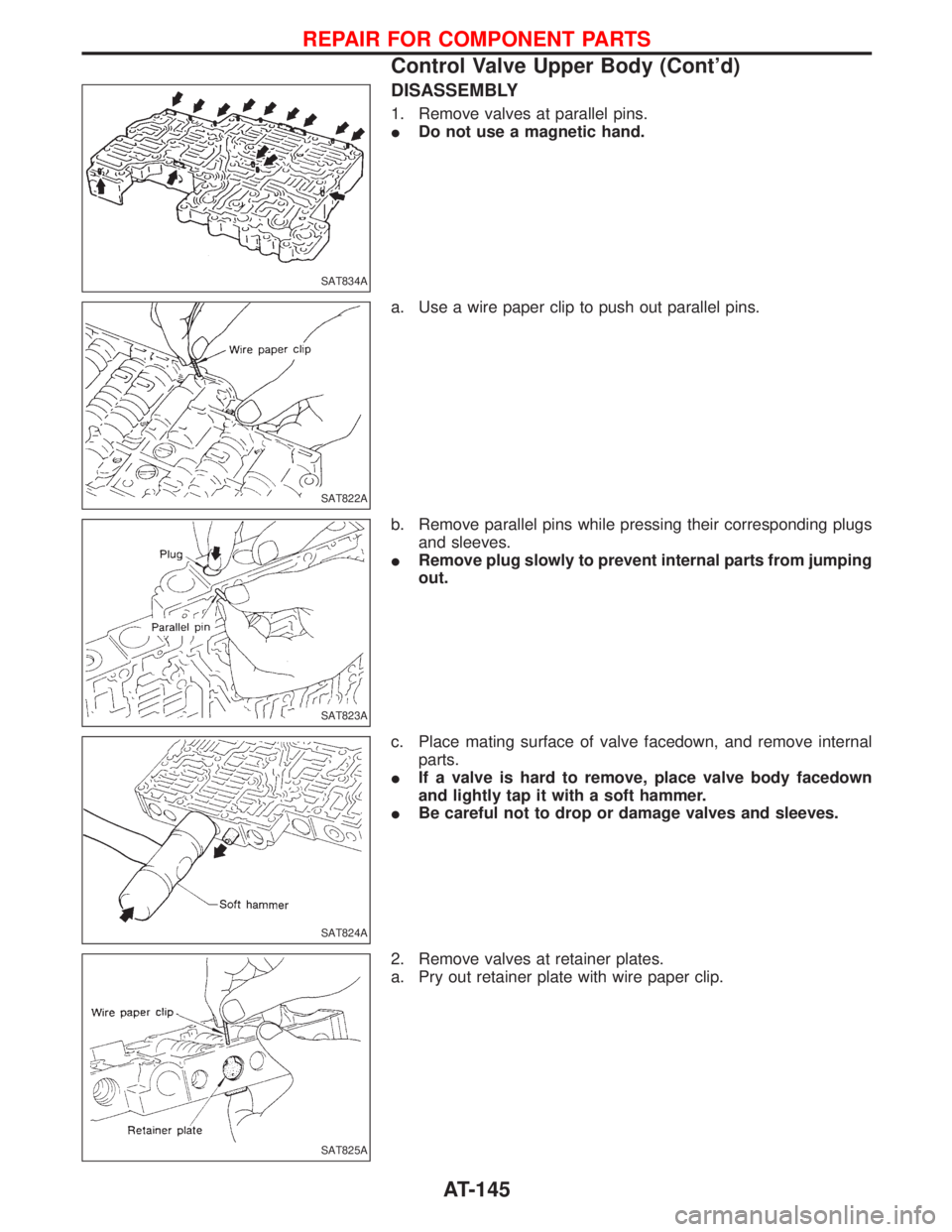

1. Remove valves at parallel pins.

IDo not use a magnetic hand.

a. Use a wire paper clip to push out parallel pins.

b. Remove parallel pins while pressing their corresponding plugs

and sleeves.

IRemove plug slowly to prevent internal parts from jumping

out.

c. Place mating surface of valve facedown, and remove internal

parts.

IIf a valve is hard to remove, place valve body facedown

and lightly tap it with a soft hammer.

IBe careful not to drop or damage valves and sleeves.

2. Remove valves at retainer plates.

a. Pry out retainer plate with wire paper clip.

SAT834A

SAT822A

SAT823A

SAT824A

SAT825A

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-145

Page 148 of 1767

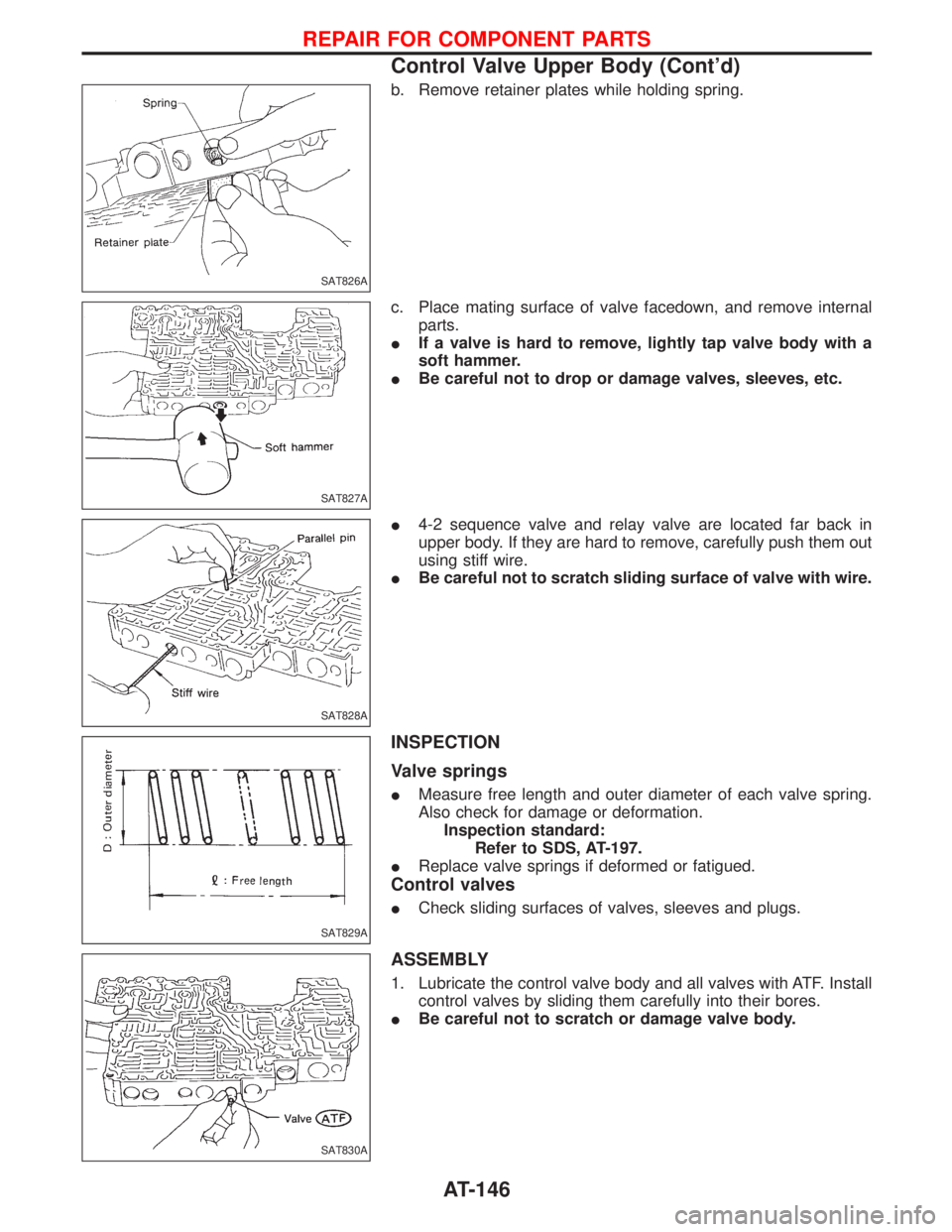

b. Remove retainer plates while holding spring.

c. Place mating surface of valve facedown, and remove internal

parts.

IIf a valve is hard to remove, lightly tap valve body with a

soft hammer.

IBe careful not to drop or damage valves, sleeves, etc.

I4-2 sequence valve and relay valve are located far back in

upper body. If they are hard to remove, carefully push them out

using stiff wire.

IBe careful not to scratch sliding surface of valve with wire.

INSPECTION

Valve springs

IMeasure free length and outer diameter of each valve spring.

Also check for damage or deformation.

Inspection standard:

Refer to SDS, AT-197.

IReplace valve springs if deformed or fatigued.

Control valves

ICheck sliding surfaces of valves, sleeves and plugs.

ASSEMBLY

1. Lubricate the control valve body and all valves with ATF. Install

control valves by sliding them carefully into their bores.

IBe careful not to scratch or damage valve body.

SAT826A

SAT827A

SAT828A

SAT829A

SAT830A

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-146

Page 149 of 1767

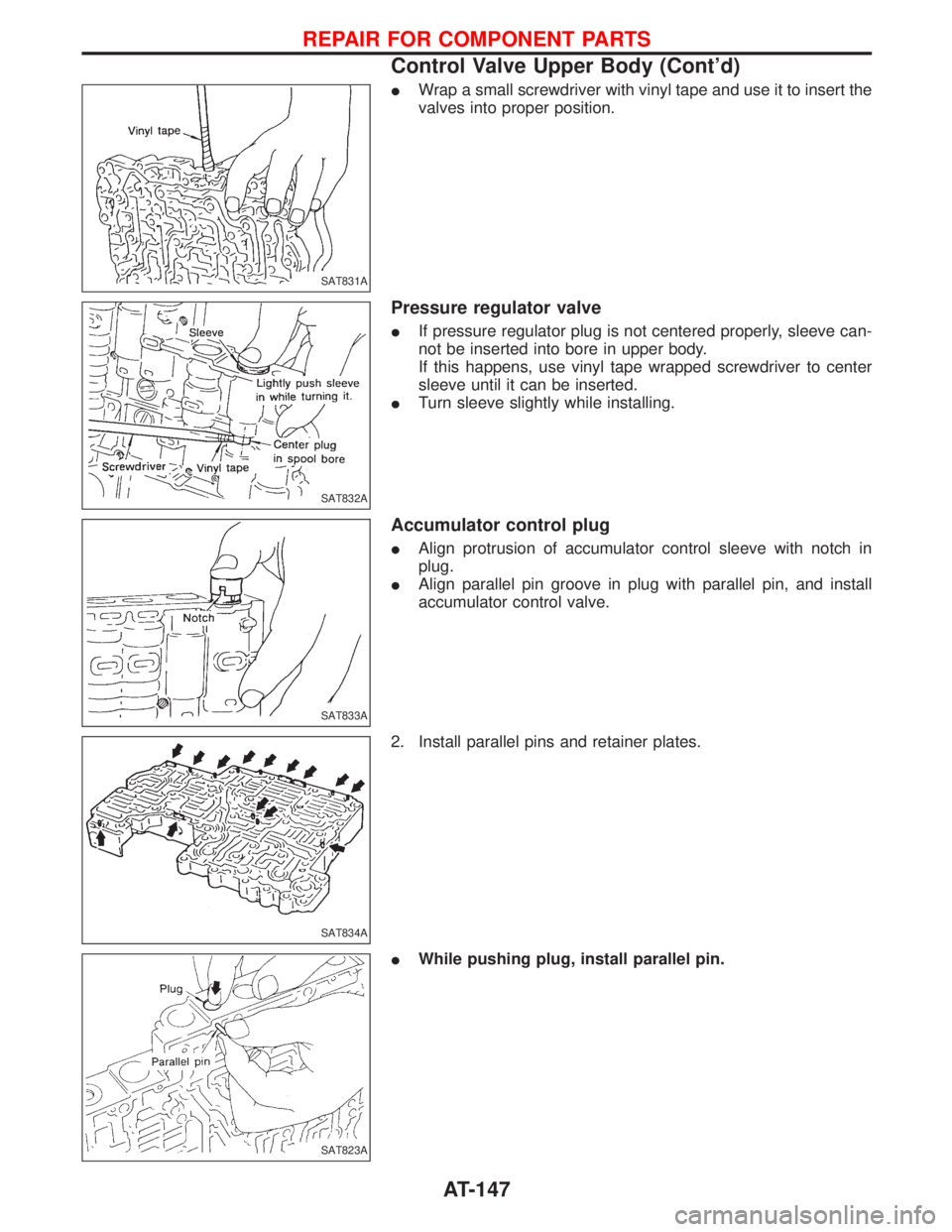

IWrap a small screwdriver with vinyl tape and use it to insert the

valves into proper position.

Pressure regulator valve

IIf pressure regulator plug is not centered properly, sleeve can-

not be inserted into bore in upper body.

If this happens, use vinyl tape wrapped screwdriver to center

sleeve until it can be inserted.

ITurn sleeve slightly while installing.

Accumulator control plug

IAlign protrusion of accumulator control sleeve with notch in

plug.

IAlign parallel pin groove in plug with parallel pin, and install

accumulator control valve.

2. Install parallel pins and retainer plates.

IWhile pushing plug, install parallel pin.

SAT831A

SAT832A

SAT833A

SAT834A

SAT823A

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-147

Page 181 of 1767

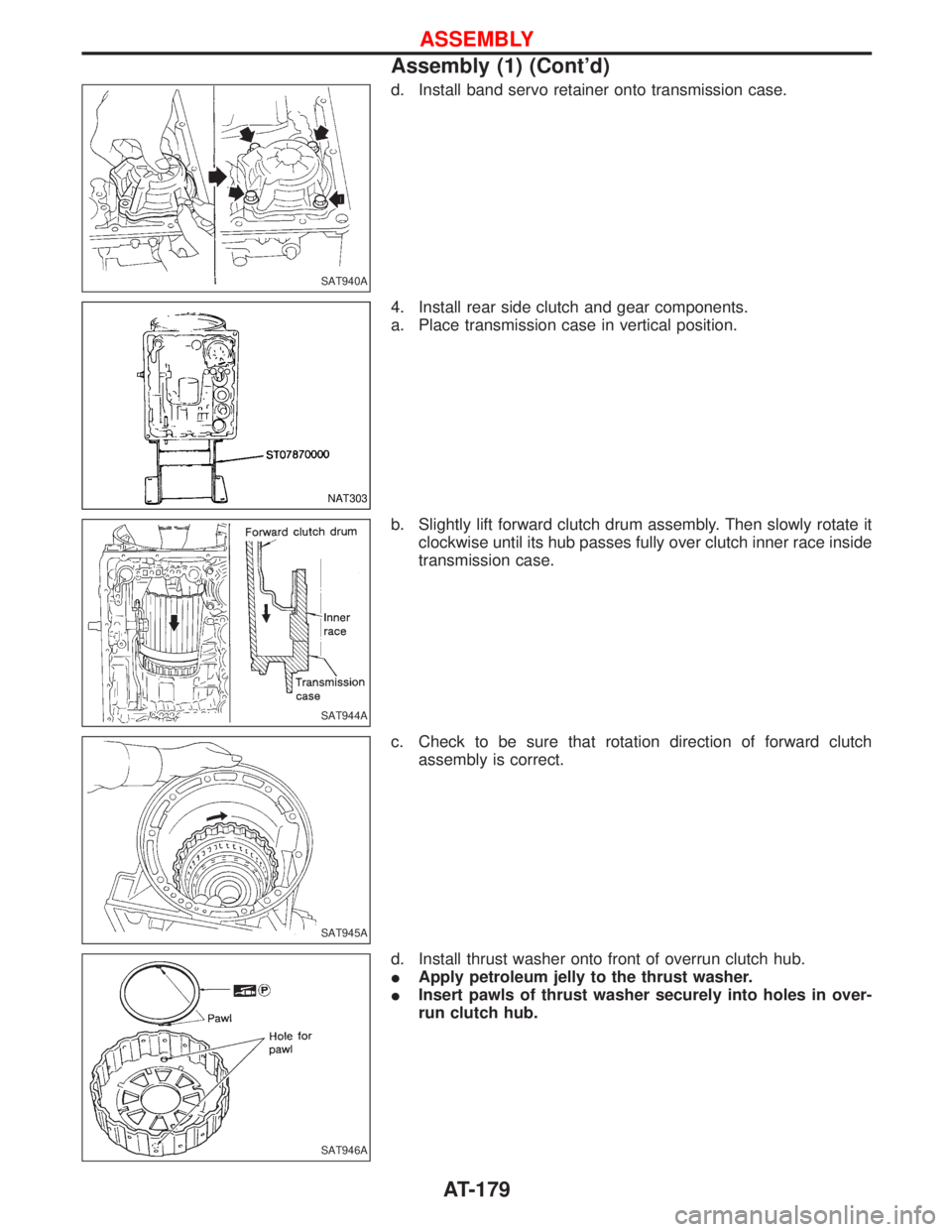

d. Install band servo retainer onto transmission case.

4. Install rear side clutch and gear components.

a. Place transmission case in vertical position.

b. Slightly lift forward clutch drum assembly. Then slowly rotate it

clockwise until its hub passes fully over clutch inner race inside

transmission case.

c. Check to be sure that rotation direction of forward clutch

assembly is correct.

d. Install thrust washer onto front of overrun clutch hub.

IApply petroleum jelly to the thrust washer.

IInsert pawls of thrust washer securely into holes in over-

run clutch hub.

SAT940A

NAT303

SAT944A

SAT945A

SAT946A

ASSEMBLY

Assembly (1) (Cont'd)

AT-179

Page 183 of 1767

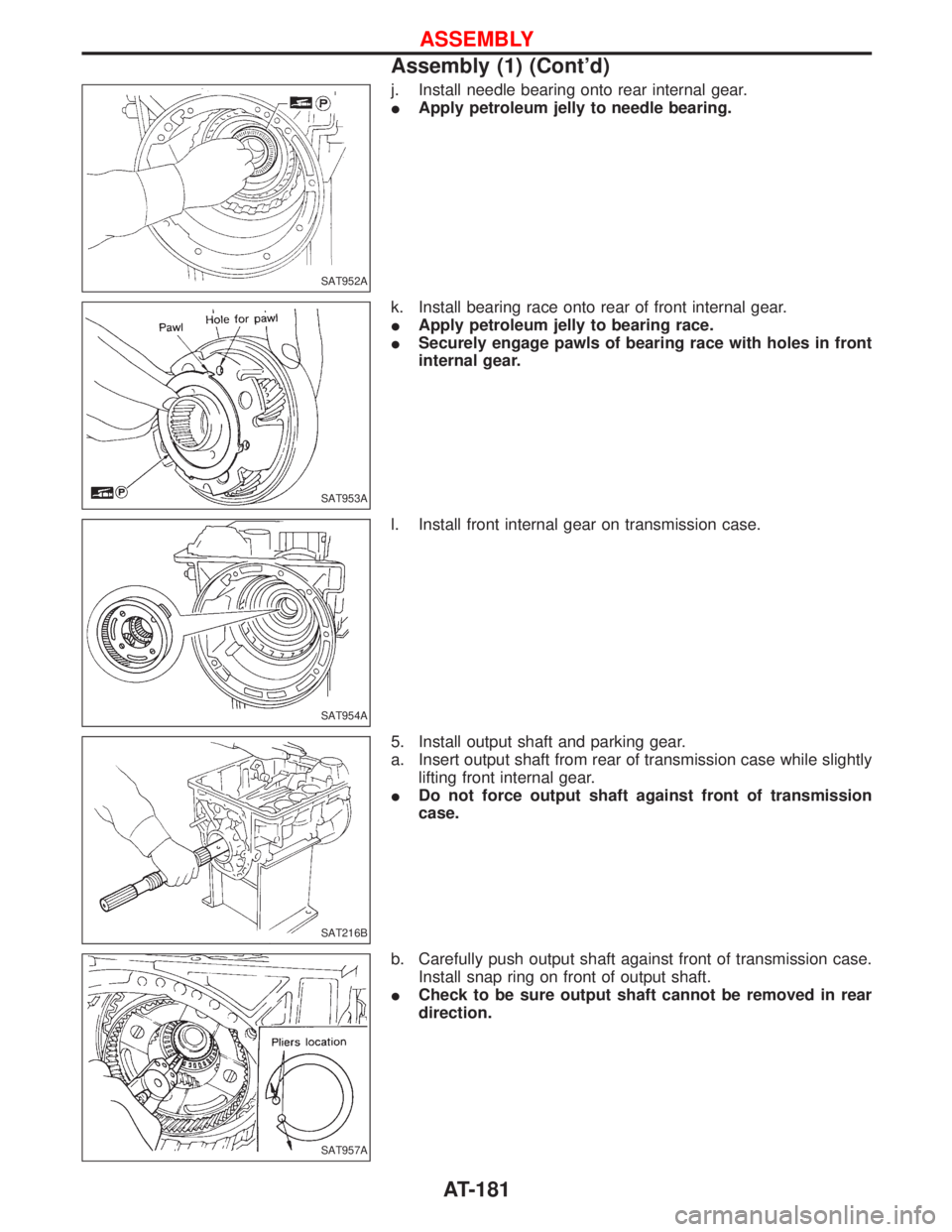

j. Install needle bearing onto rear internal gear.

IApply petroleum jelly to needle bearing.

k. Install bearing race onto rear of front internal gear.

IApply petroleum jelly to bearing race.

ISecurely engage pawls of bearing race with holes in front

internal gear.

l. Install front internal gear on transmission case.

5. Install output shaft and parking gear.

a. Insert output shaft from rear of transmission case while slightly

lifting front internal gear.

IDo not force output shaft against front of transmission

case.

b. Carefully push output shaft against front of transmission case.

Install snap ring on front of output shaft.

ICheck to be sure output shaft cannot be removed in rear

direction.

SAT952A

SAT953A

SAT954A

SAT216B

SAT957A

ASSEMBLY

Assembly (1) (Cont'd)

AT-181

Page 218 of 1767

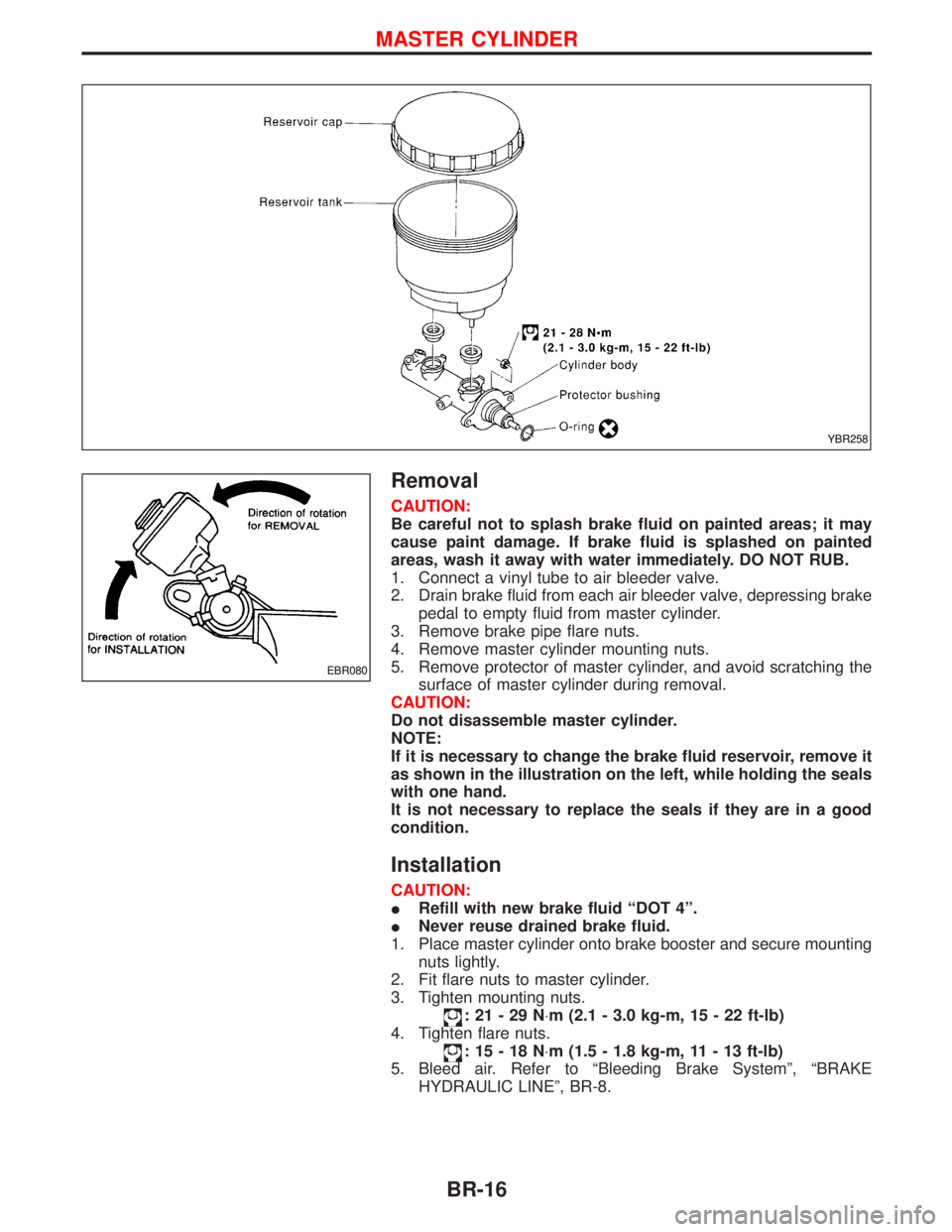

Removal

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately. DO NOT RUB.

1. Connect a vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve, depressing brake

pedal to empty fluid from master cylinder.

3. Remove brake pipe flare nuts.

4. Remove master cylinder mounting nuts.

5. Remove protector of master cylinder, and avoid scratching the

surface of master cylinder during removal.

CAUTION:

Do not disassemble master cylinder.

NOTE:

If it is necessary to change the brake fluid reservoir, remove it

as shown in the illustration on the left, while holding the seals

with one hand.

It is not necessary to replace the seals if they are in a good

condition.

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mounting

nuts lightly.

2. Fit flare nuts to master cylinder.

3. Tighten mounting nuts.

:21-29N×m (2.1 - 3.0 kg-m, 15 - 22 ft-lb)

4. Tighten flare nuts.

:15-18N×m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

5. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

YBR258

EBR080

MASTER CYLINDER

BR-16

Page 219 of 1767

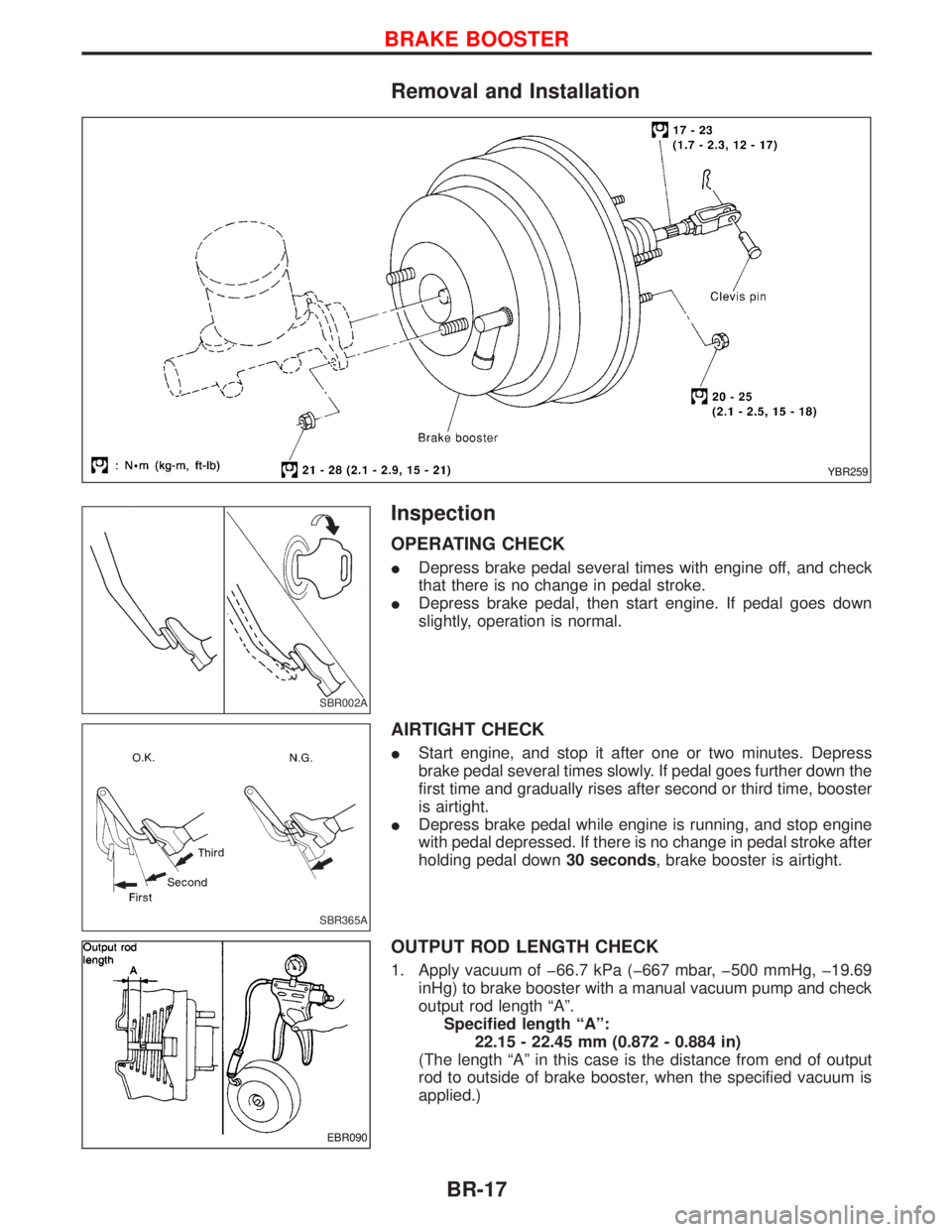

Removal and Installation

Inspection

OPERATING CHECK

IDepress brake pedal several times with engine off, and check

that there is no change in pedal stroke.

IDepress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECK

IStart engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. If pedal goes further down the

first time and gradually rises after second or third time, booster

is airtight.

IDepress brake pedal while engine is running, and stop engine

with pedal depressed. If there is no change in pedal stroke after

holding pedal down30 seconds, brake booster is airtight.

OUTPUT ROD LENGTH CHECK

1. Apply vacuum of þ66.7 kPa (þ667 mbar, þ500 mmHg, þ19.69

inHg) to brake booster with a manual vacuum pump and check

output rod length ªAº.

Specified length ªAº:

22.15 - 22.45 mm (0.872 - 0.884 in)

(The length ªAº in this case is the distance from end of output

rod to outside of brake booster, when the specified vacuum is

applied.)

YBR259

SBR002A

SBR365A

EBR090

BRAKE BOOSTER

BR-17

Page 220 of 1767

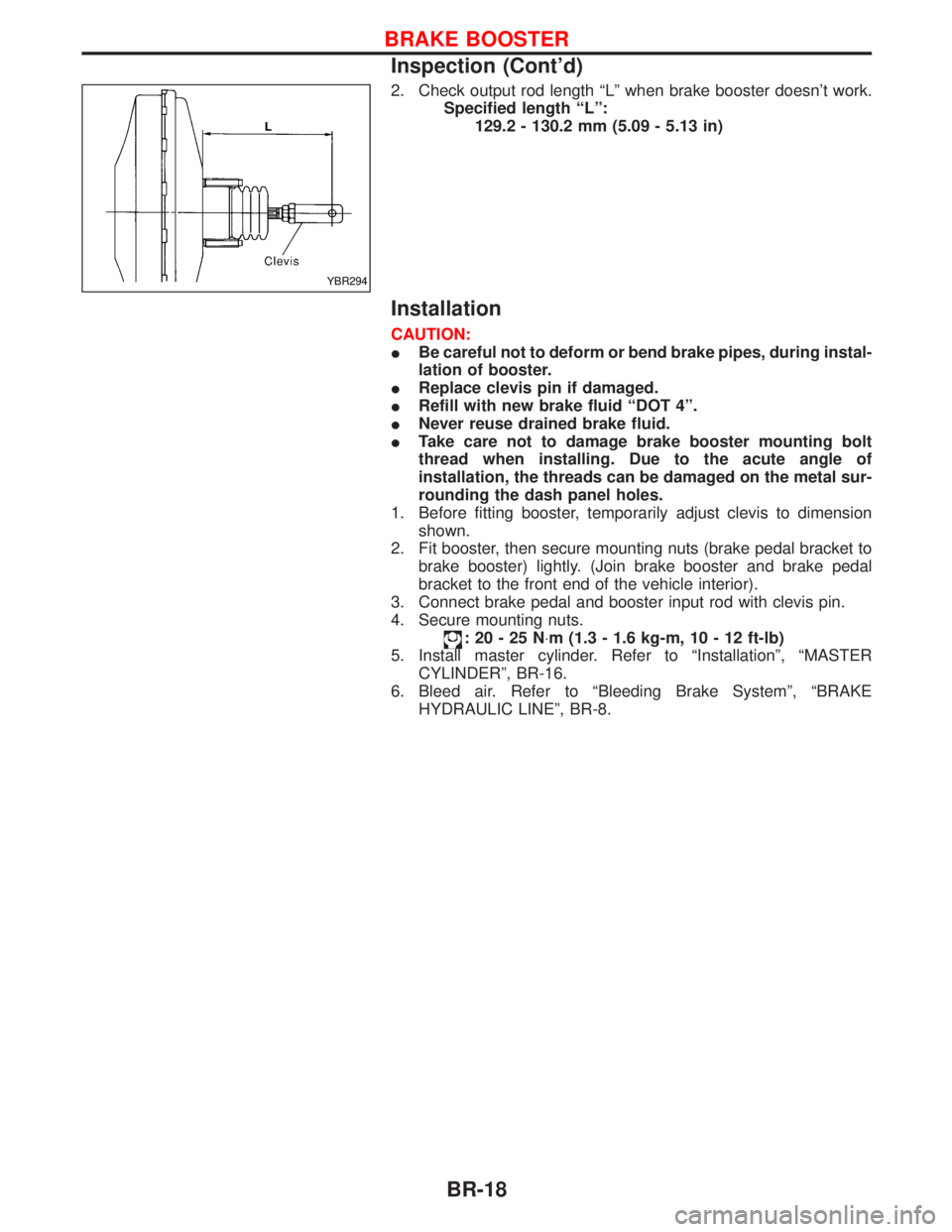

2. Check output rod length ªLº when brake booster doesn't work.

Specified length ªLº:

129.2 - 130.2 mm (5.09 - 5.13 in)

Installation

CAUTION:

IBe careful not to deform or bend brake pipes, during instal-

lation of booster.

IReplace clevis pin if damaged.

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

ITake care not to damage brake booster mounting bolt

thread when installing. Due to the acute angle of

installation, the threads can be damaged on the metal sur-

rounding the dash panel holes.

1. Before fitting booster, temporarily adjust clevis to dimension

shown.

2. Fit booster, then secure mounting nuts (brake pedal bracket to

brake booster) lightly. (Join brake booster and brake pedal

bracket to the front end of the vehicle interior).

3. Connect brake pedal and booster input rod with clevis pin.

4. Secure mounting nuts.

:20-25N×m (1.3 - 1.6 kg-m, 10 - 12 ft-lb)

5. Install master cylinder. Refer to ªInstallationº, ªMASTER

CYLINDERº, BR-16.

6. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

YBR294

BRAKE BOOSTER

Inspection (Cont'd)

BR-18

Page 226 of 1767

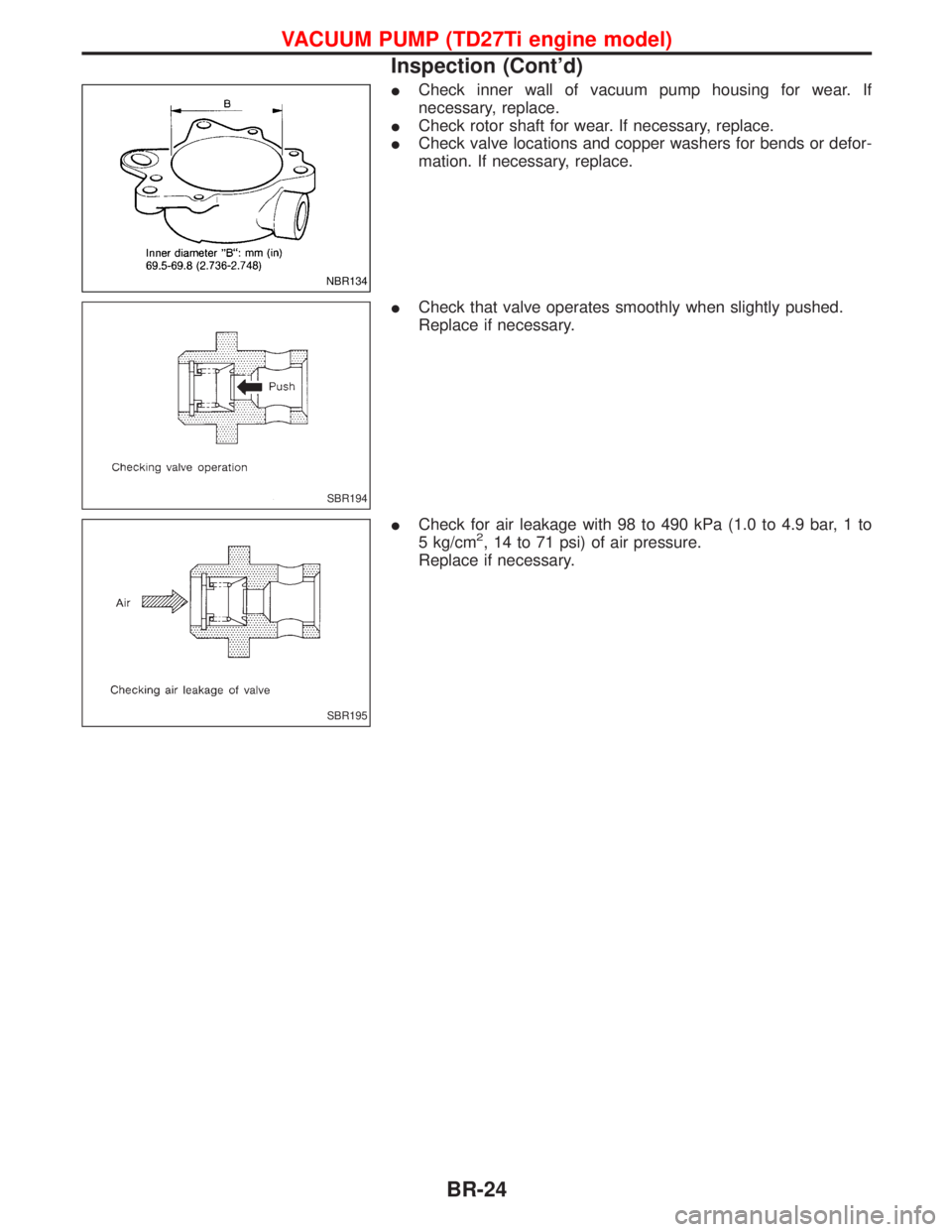

ICheck inner wall of vacuum pump housing for wear. If

necessary, replace.

ICheck rotor shaft for wear. If necessary, replace.

ICheck valve locations and copper washers for bends or defor-

mation. If necessary, replace.

ICheck that valve operates smoothly when slightly pushed.

Replace if necessary.

ICheck for air leakage with 98 to 490 kPa (1.0 to 4.9 bar, 1 to

5 kg/cm

2, 14 to 71 psi) of air pressure.

Replace if necessary.

NBR134

SBR194

SBR195

VACUUM PUMP (TD27Ti engine model)

Inspection (Cont'd)

BR-24

Page 230 of 1767

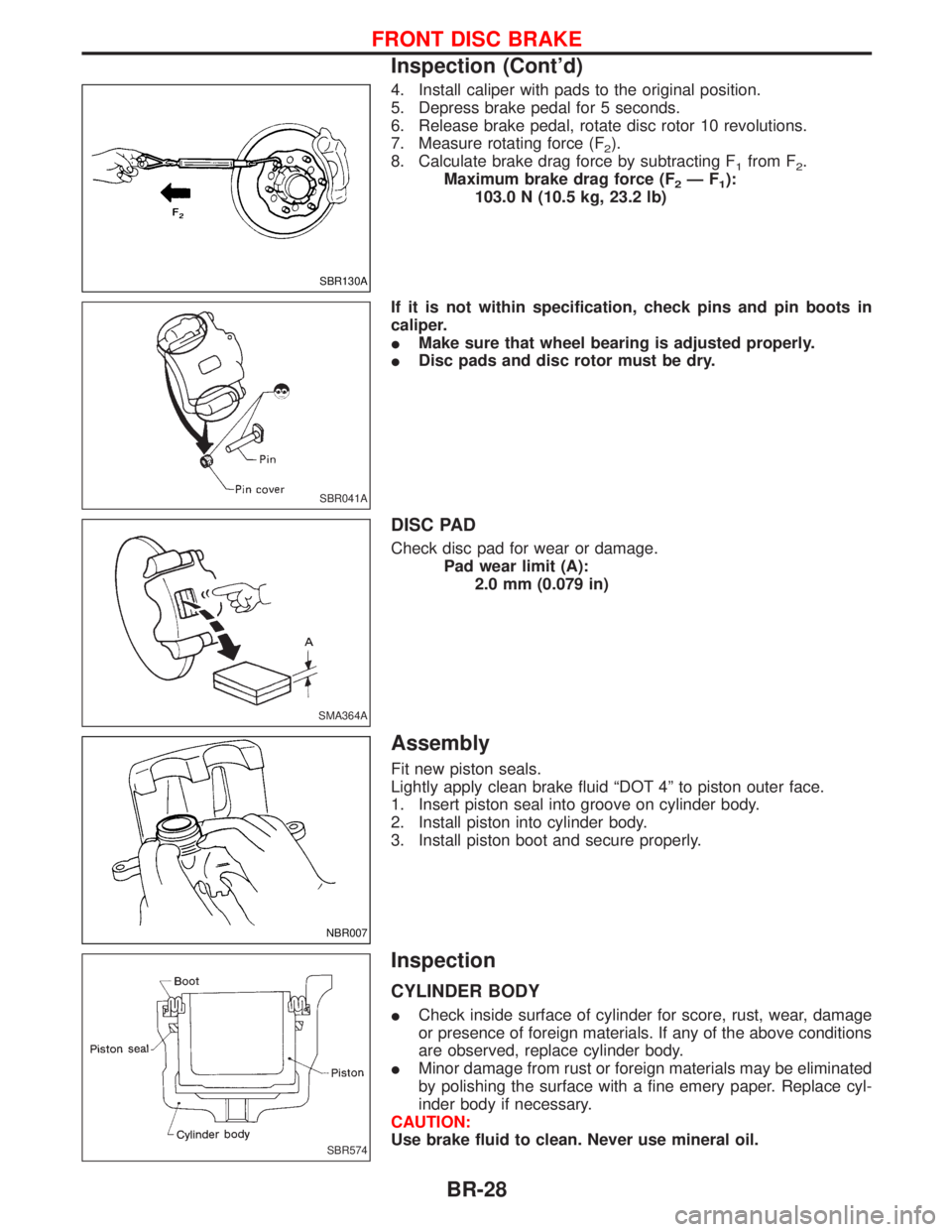

4. Install caliper with pads to the original position.

5. Depress brake pedal for 5 seconds.

6. Release brake pedal, rotate disc rotor 10 revolutions.

7. Measure rotating force (F

2).

8. Calculate brake drag force by subtracting F

1from F2.

Maximum brake drag force (F

2ÐF1):

103.0 N (10.5 kg, 23.2 lb)

If it is not within specification, check pins and pin boots in

caliper.

IMake sure that wheel bearing is adjusted properly.

IDisc pads and disc rotor must be dry.

DISC PAD

Check disc pad for wear or damage.

Pad wear limit (A):

2.0 mm (0.079 in)

Assembly

Fit new piston seals.

Lightly apply clean brake fluid ªDOT 4º to piston outer face.

1. Insert piston seal into groove on cylinder body.

2. Install piston into cylinder body.

3. Install piston boot and secure properly.

Inspection

CYLINDER BODY

ICheck inside surface of cylinder for score, rust, wear, damage

or presence of foreign materials. If any of the above conditions

are observed, replace cylinder body.

IMinor damage from rust or foreign materials may be eliminated

by polishing the surface with a fine emery paper. Replace cyl-

inder body if necessary.

CAUTION:

Use brake fluid to clean. Never use mineral oil.

SBR130A

SBR041A

SMA364A

NBR007

SBR574

FRONT DISC BRAKE

Inspection (Cont'd)

BR-28