fuse NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 79 of 1767

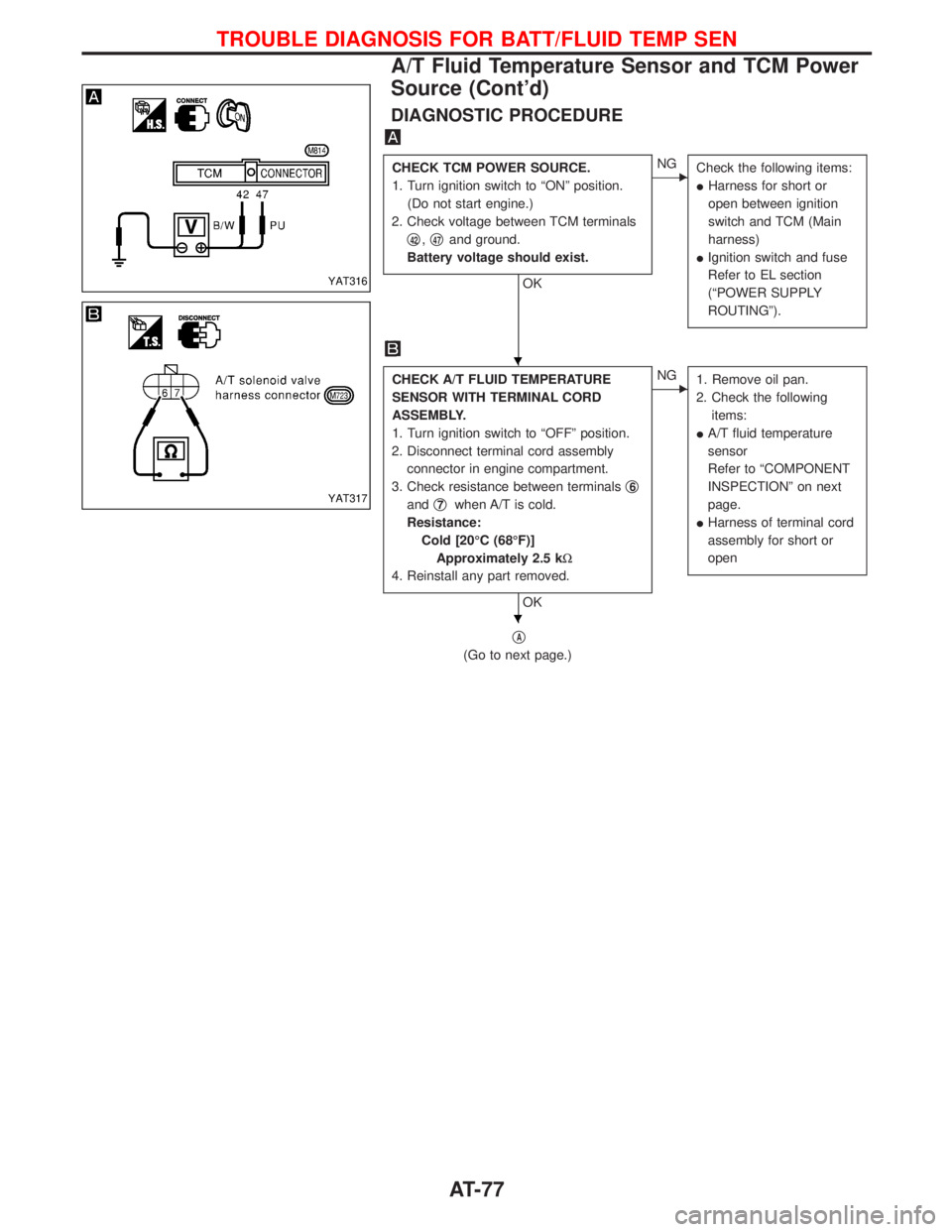

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

q

42,q47and ground.

Battery voltage should exist.

OK

ENG

Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

IIgnition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalsq

6

andq7when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

4. Reinstall any part removed.

OK

ENG

1. Remove oil pan.

2. Check the following

items:

IA/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

IHarness of terminal cord

assembly for short or

open

qA

(Go to next page.)

YAT316

YAT317

H

H

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM Power

Source (Cont'd)

AT-77

Page 96 of 1767

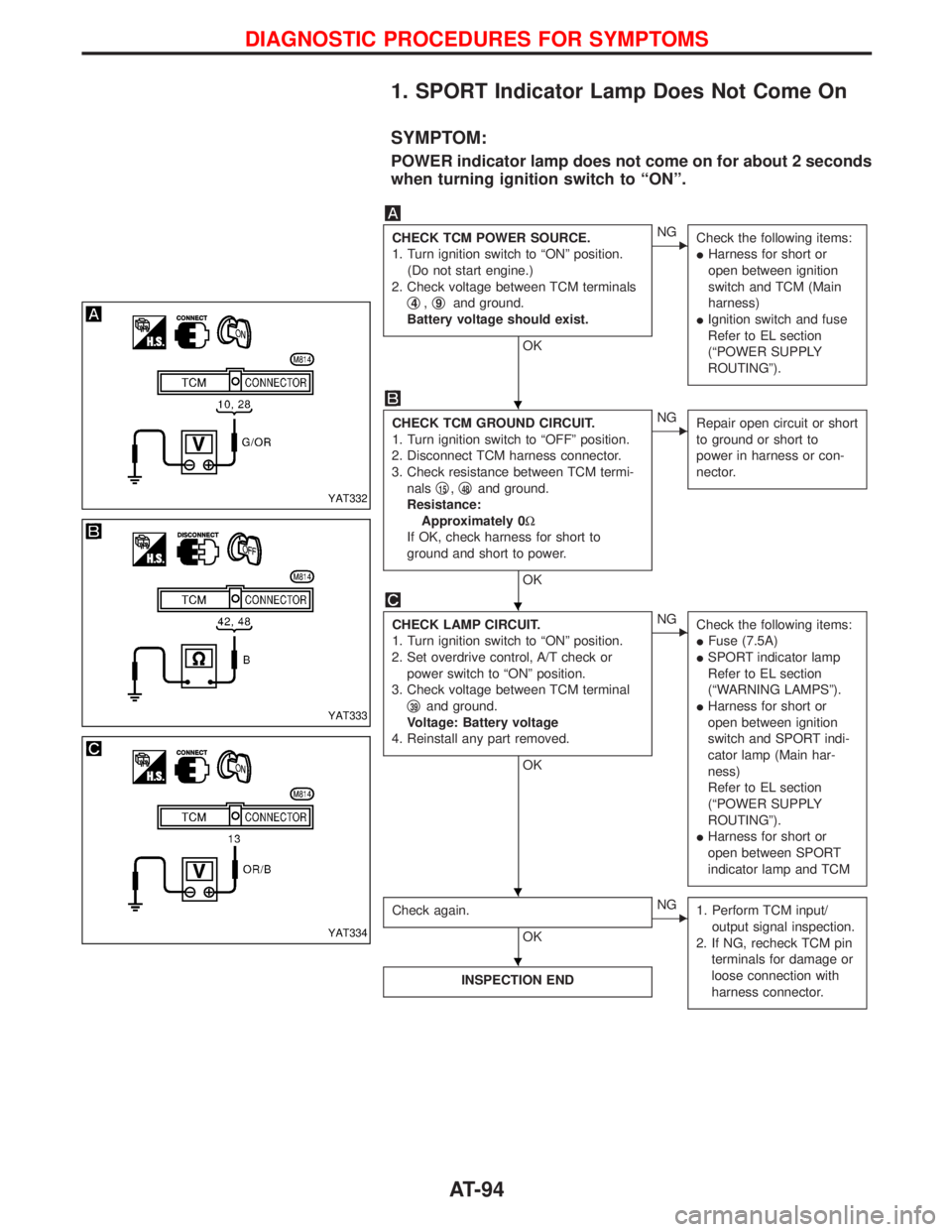

1. SPORT Indicator Lamp Does Not Come On

SYMPTOM:

POWER indicator lamp does not come on for about 2 seconds

when turning ignition switch to ªONº.

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

q

4,q9and ground.

Battery voltage should exist.

OK

ENG

Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

IIgnition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK TCM GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between TCM termi-

nalsq

15,q48and ground.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

OK

ENG

Repair open circuit or short

to ground or short to

power in harness or con-

nector.

CHECK LAMP CIRCUIT.

1. Turn ignition switch to ªONº position.

2. Set overdrive control, A/T check or

power switch to ªONº position.

3. Check voltage between TCM terminal

q

39and ground.

Voltage: Battery voltage

4. Reinstall any part removed.

OK

ENG

Check the following items:

IFuse (7.5A)

ISPORT indicator lamp

Refer to EL section

(ªWARNING LAMPSº).

IHarness for short or

open between ignition

switch and SPORT indi-

cator lamp (Main har-

ness)

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

IHarness for short or

open between SPORT

indicator lamp and TCM

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT332

YAT333

YAT334

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-94

Page 210 of 1767

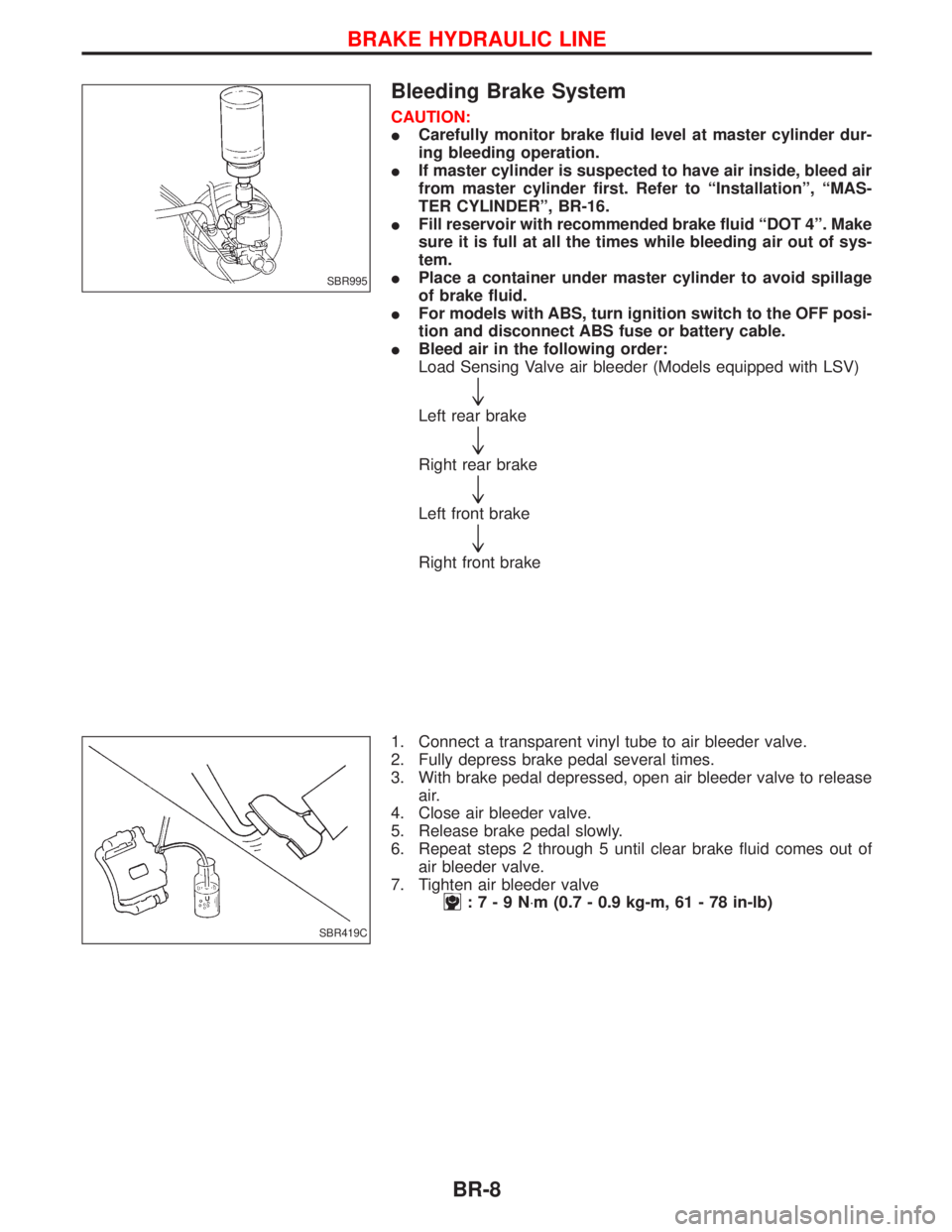

Bleeding Brake System

CAUTION:

ICarefully monitor brake fluid level at master cylinder dur-

ing bleeding operation.

IIf master cylinder is suspected to have air inside, bleed air

from master cylinder first. Refer to ªInstallationº, ªMAS-

TER CYLINDERº, BR-16.

IFill reservoir with recommended brake fluid ªDOT 4º. Make

sure it is full at all the times while bleeding air out of sys-

tem.

IPlace a container under master cylinder to avoid spillage

of brake fluid.

IFor models with ABS, turn ignition switch to the OFF posi-

tion and disconnect ABS fuse or battery cable.

IBleed air in the following order:

Load Sensing Valve air bleeder (Models equipped with LSV)

"

Left rear brake

"

Right rear brake

"

Left front brake

"

Right front brake

1. Connect a transparent vinyl tube to air bleeder valve.

2. Fully depress brake pedal several times.

3. With brake pedal depressed, open air bleeder valve to release

air.

4. Close air bleeder valve.

5. Release brake pedal slowly.

6. Repeat steps 2 through 5 until clear brake fluid comes out of

air bleeder valve.

7. Tighten air bleeder valve

:7-9N×m (0.7 - 0.9 kg-m, 61 - 78 in-lb)

SBR995

SBR419C

BRAKE HYDRAULIC LINE

BR-8

Page 267 of 1767

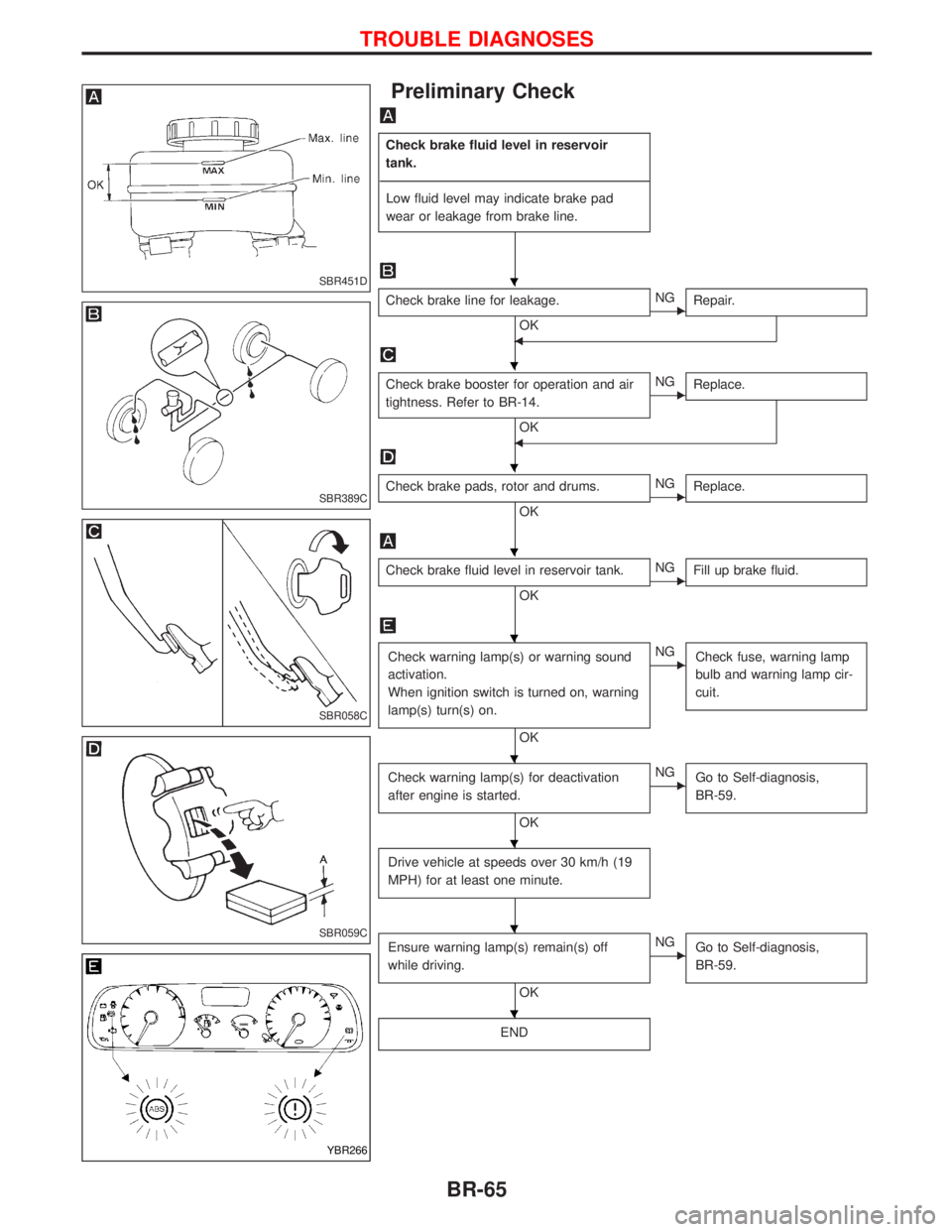

Preliminary Check

Check brake fluid level in reservoir

tank.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low fluid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKENG

Repair.

F

Check brake booster for operation and air

tightness. Refer to BR-14.

OK

ENG

Replace.

F

Check brake pads, rotor and drums.

OKENG

Replace.

Check brake fluid level in reservoir tank.

OKENG

Fill up brake fluid.

Check warning lamp(s) or warning sound

activation.

When ignition switch is turned on, warning

lamp(s) turn(s) on.

OK

ENG

Check fuse, warning lamp

bulb and warning lamp cir-

cuit.

Check warning lamp(s) for deactivation

after engine is started.

OK

ENG

Go to Self-diagnosis,

BR-59.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least one minute.

Ensure warning lamp(s) remain(s) off

while driving.

OK

ENG

Go to Self-diagnosis,

BR-59.

END

SBR451D

SBR389C

SBR058C

SBR059C

YBR266

H

H

H

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-65

Page 269 of 1767

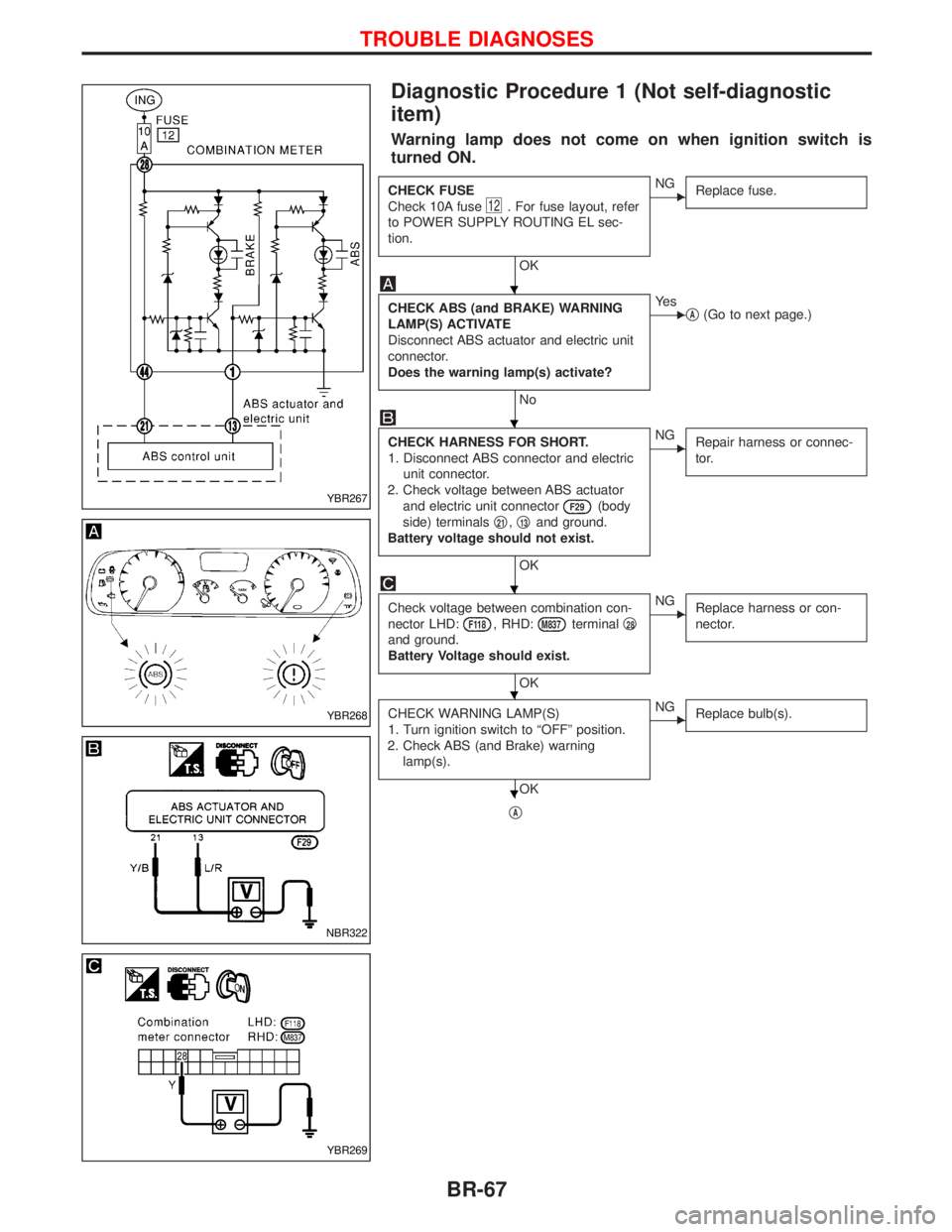

Diagnostic Procedure 1 (Not self-diagnostic

item)

Warning lamp does not come on when ignition switch is

turned ON.

CHECK FUSE

Check 10A fuse

12. For fuse layout, refer

to POWER SUPPLY ROUTING EL sec-

tion.

OK

ENG

Replace fuse.

CHECK ABS (and BRAKE) WARNING

LAMP(S) ACTIVATE

Disconnect ABS actuator and electric unit

connector.

Does the warning lamp(s) activate?

No

EYe s

qA(Go to next page.)

CHECK HARNESS FOR SHORT.

1. Disconnect ABS connector and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29(body

side) terminalsq

21,q13and ground.

Battery voltage should not exist.

OK

ENG

Repair harness or connec-

tor.

Check voltage between combination con-

nector LHD:

F118, RHD:M837terminalq28

and ground.

Battery Voltage should exist.

OK

ENG

Replace harness or con-

nector.

CHECK WARNING LAMP(S)

1. Turn ignition switch to ªOFFº position.

2. Check ABS (and Brake) warning

lamp(s).

OK

ENG

Replace bulb(s).

qA

YBR267

YBR268

NBR322

YBR269

H

H

H

H

H

TROUBLE DIAGNOSES

BR-67

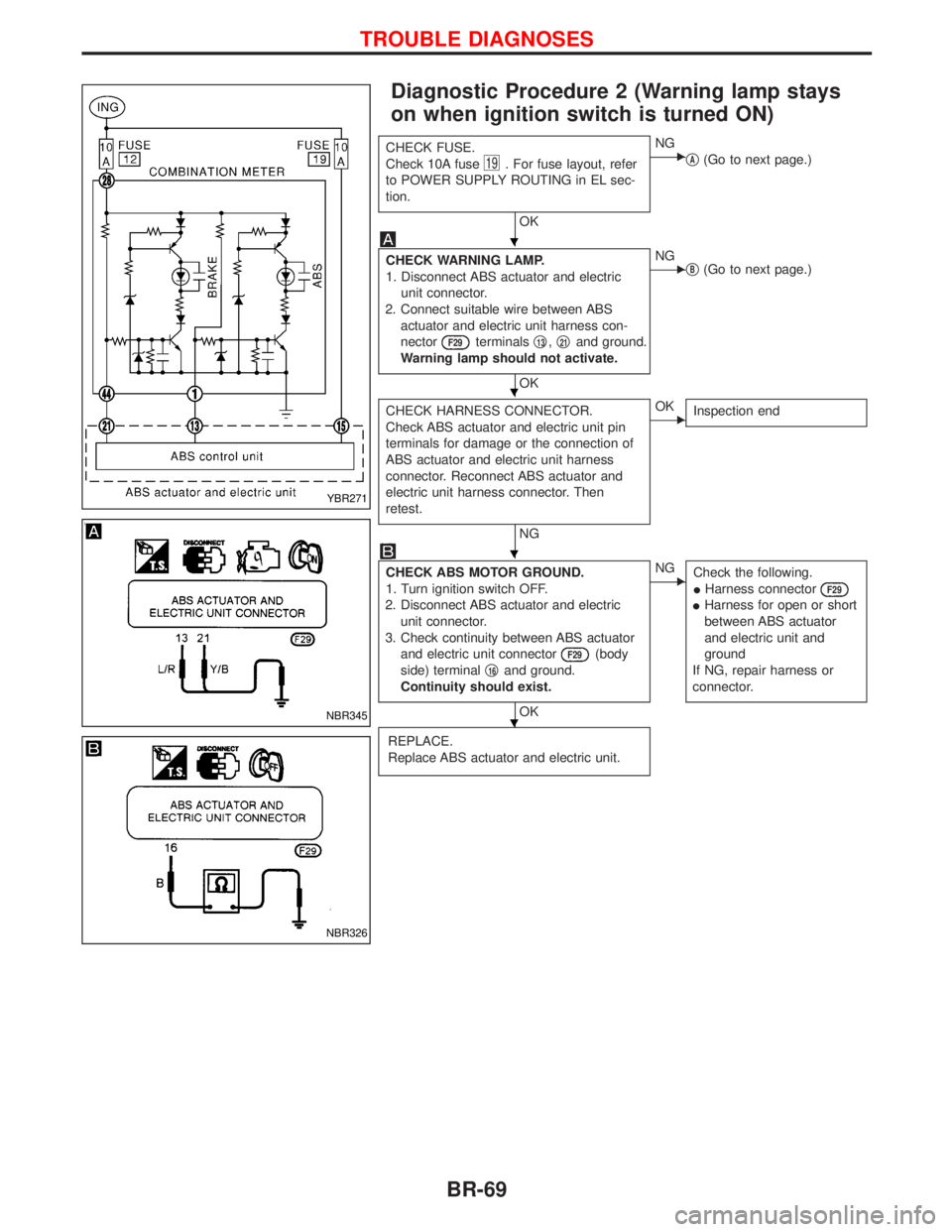

Page 271 of 1767

Diagnostic Procedure 2 (Warning lamp stays

on when ignition switch is turned ON)

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG

qA(Go to next page.)

CHECK WARNING LAMP.

1. Disconnect ABS actuator and electric

unit connector.

2. Connect suitable wire between ABS

actuator and electric unit harness con-

nector

F29terminalsq13,q21and ground.

Warning lamp should not activate.

OK

ENG

qB(Go to next page.)

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

NG

EOK

Inspection end

CHECK ABS MOTOR GROUND.

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and electric

unit connector.

3. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalq

16and ground.

Continuity should exist.

OK

ENG

Check the following.

IHarness connector

F29

IHarness for open or short

between ABS actuator

and electric unit and

ground

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

YBR271

NBR345

NBR326

H

H

H

H

TROUBLE DIAGNOSES

BR-69

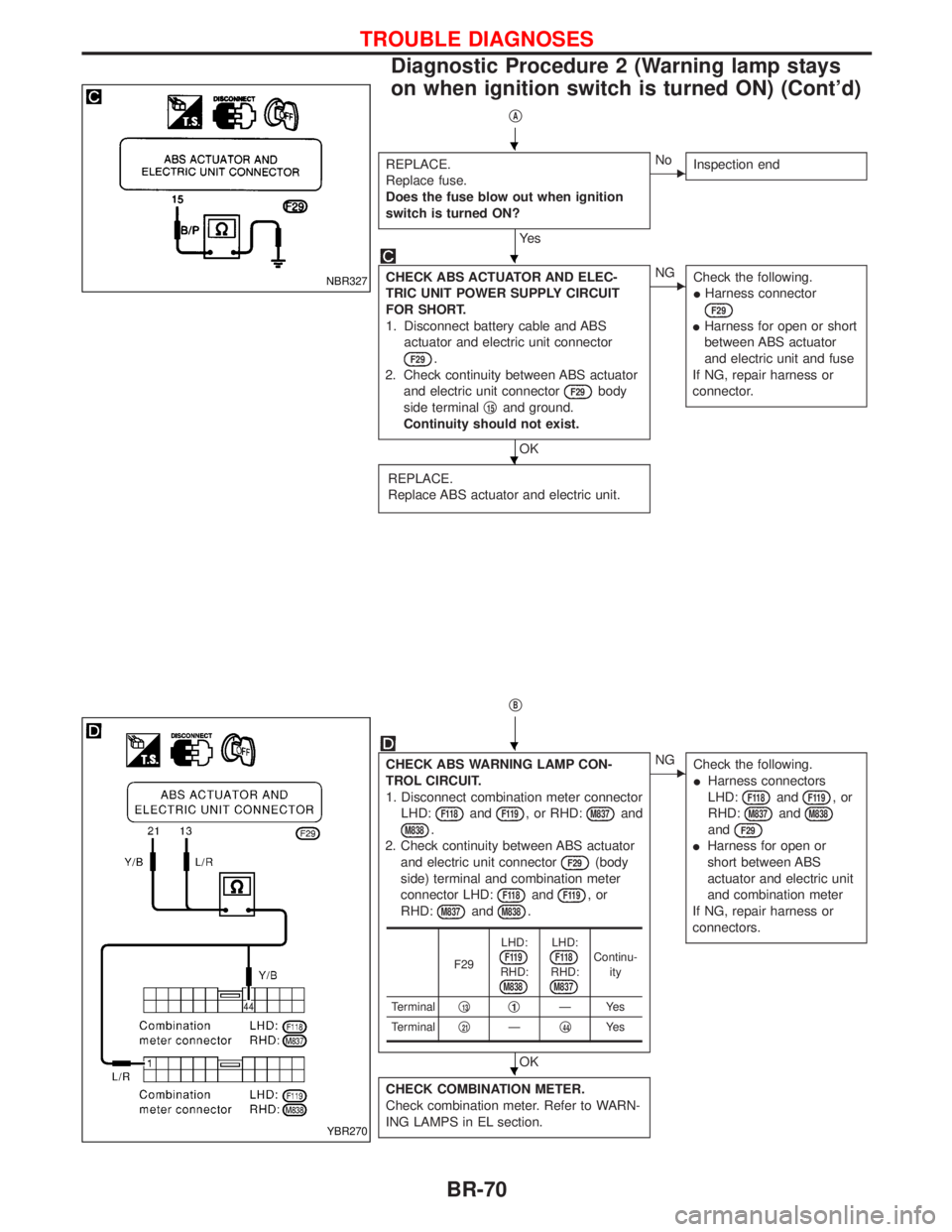

Page 272 of 1767

qA

REPLACE.

Replace fuse.

Does the fuse blow out when ignition

switch is turned ON?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT POWER SUPPLY CIRCUIT

FOR SHORT.

1. Disconnect battery cable and ABS

actuator and electric unit connector

F29.

2. Check continuity between ABS actuator

and electric unit connector

F29body

side terminalq

15and ground.

Continuity should not exist.

OK

ENG

Check the following.

IHarness connector

F29

IHarness for open or short

between ABS actuator

and electric unit and fuse

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

qB

CHECK ABS WARNING LAMP CON-

TROL CIRCUIT.

1. Disconnect combination meter connector

LHD:

F118andF119, or RHD:M837and

M838.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminal and combination meter

connector LHD:

F118andF119,or

RHD:

M837andM838.

OK

ENG

Check the following.

IHarness connectors

LHD:

F118andF119,or

RHD:

M837andM838

andF29

IHarness for open or

short between ABS

actuator and electric unit

and combination meter

If NG, repair harness or

connectors.

CHECK COMBINATION METER.

Check combination meter. Refer to WARN-

ING LAMPS in EL section.

F29LHD:F119RHD:M838

LHD:F118RHD:M837

Continu-

ity

Terminalq

13q1ÐYes

Terminalq

21Ðq44Ye s

NBR327

YBR270

H

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Warning lamp stays

on when ignition switch is turned ON) (Cont'd)

BR-70

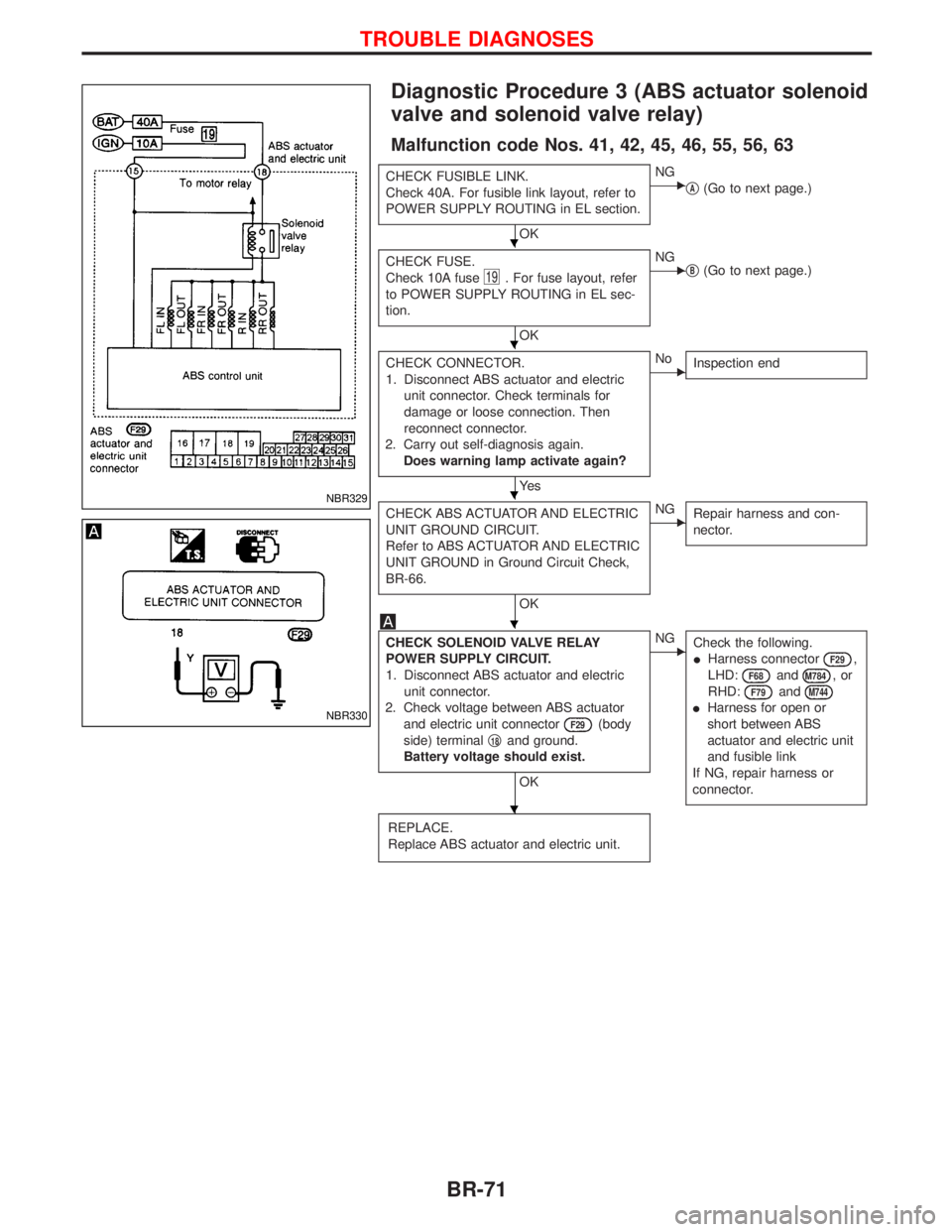

Page 273 of 1767

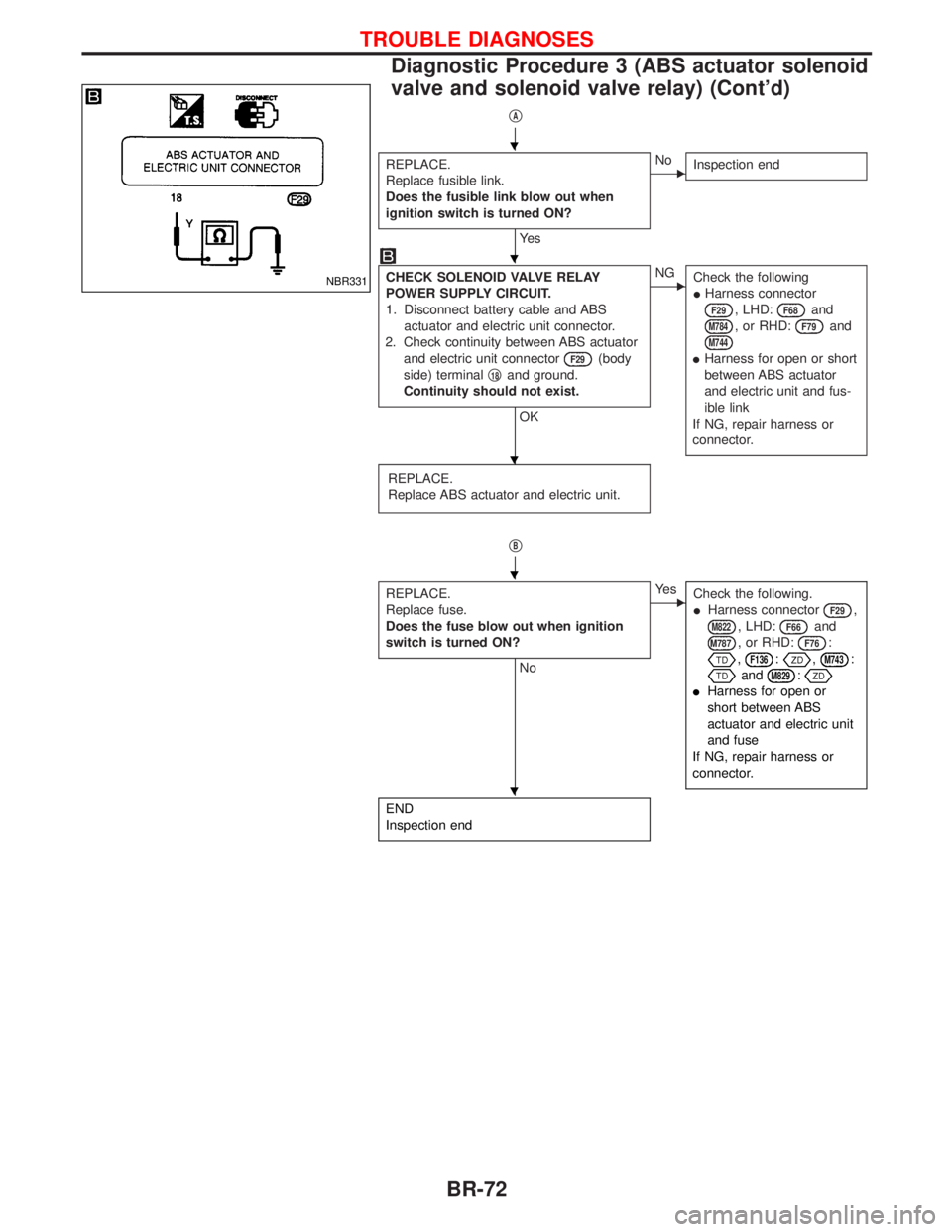

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay)

Malfunction code Nos. 41, 42, 45, 46, 55, 56, 63

CHECK FUSIBLE LINK.

Check 40A. For fusible link layout, refer to

POWER SUPPLY ROUTING in EL section.

OK

ENG

qA(Go to next page.)

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG

qB(Go to next page.)

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR AND ELECTRIC

UNIT GROUND CIRCUIT.

Refer to ABS ACTUATOR AND ELECTRIC

UNIT GROUND in Ground Circuit Check,

BR-66.

OK

ENG

Repair harness and con-

nector.

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29(body

side) terminalq

18and ground.

Battery voltage should exist.

OK

ENG

Check the following.

IHarness connector

F29,

LHD:

F68andM784,or

RHD:

F79andM744

IHarness for open or

short between ABS

actuator and electric unit

and fusible link

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

NBR329

NBR330

H

H

H

H

H

TROUBLE DIAGNOSES

BR-71

Page 274 of 1767

qA

REPLACE.

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ON?

Ye s

ENo

Inspection end

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

1. Disconnect battery cable and ABS

actuator and electric unit connector.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalq

18and ground.

Continuity should not exist.

OK

ENG

Check the following

IHarness connector

F29, LHD:F68and

M784, or RHD:F79and

M744

IHarness for open or short

between ABS actuator

and electric unit and fus-

ible link

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

qB

REPLACE.

Replace fuse.

Does the fuse blow out when ignition

switch is turned ON?

No

EYe s

Check the following.

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

END

Inspection end

NBR331

H

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) (Cont'd)

BR-72

Page 279 of 1767

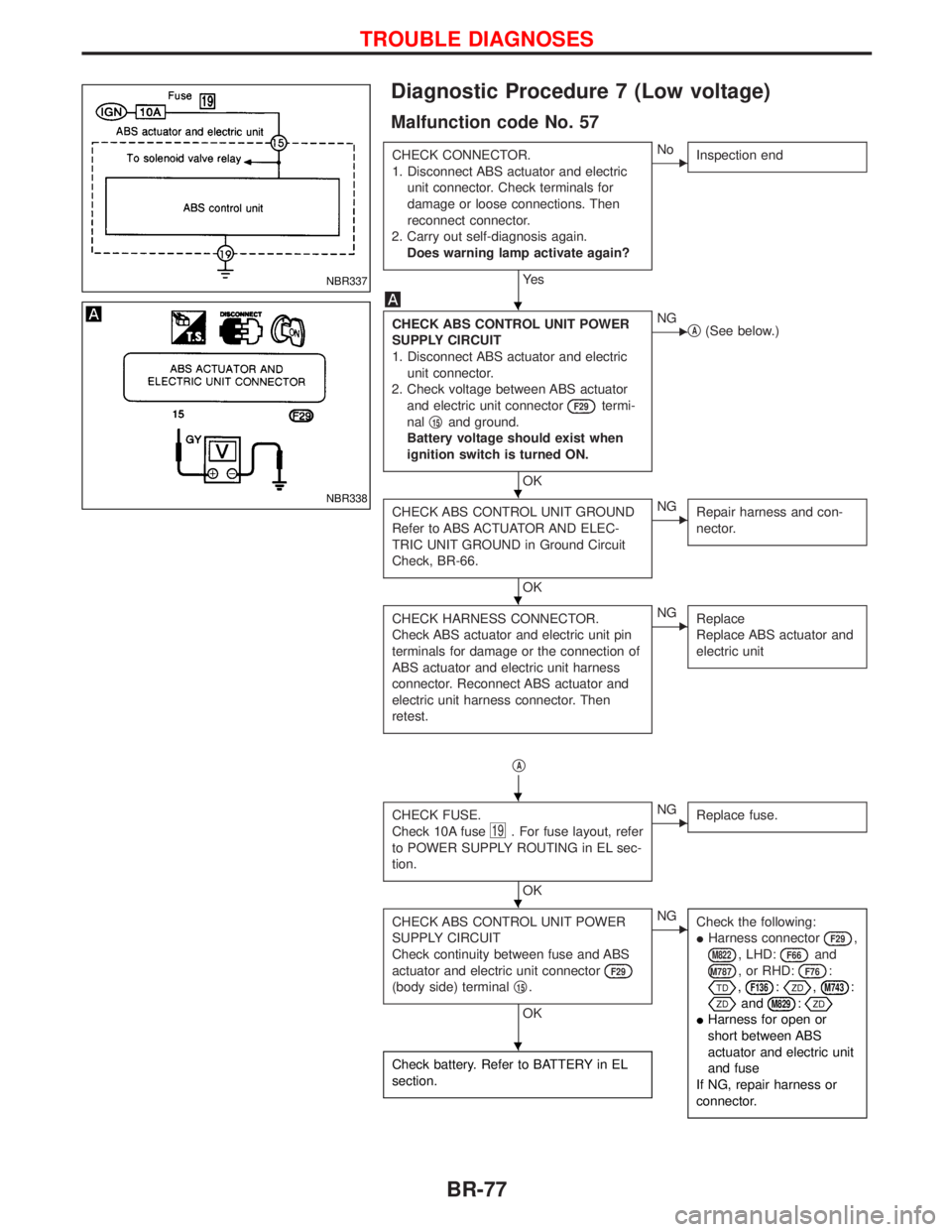

Diagnostic Procedure 7 (Low voltage)

Malfunction code No. 57

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connections. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29termi-

nalq

15and ground.

Battery voltage should exist when

ignition switch is turned ON.

OK

ENG

qA(See below.)

CHECK ABS CONTROL UNIT GROUND

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-66.

OK

ENG

Repair harness and con-

nector.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.ENG

Replace

Replace ABS actuator and

electric unit

qA

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG

Replace fuse.

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT

Check continuity between fuse and ABS

actuator and electric unit connector

F29

(body side) terminalq15.

OK

ENG

Check the following:

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

Check battery. Refer to BATTERY in EL

section.

NBR337

NBR338

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-77