light NISSAN TERRANO 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 239 of 1767

Purpose

The Anti-lock Brake System (ABS) with an integrated Electronic Brake force Distribution (EBD) system con-

sists of electronic and hydraulic components. It allows you to control the braking force so that wheel lock can

be avoided during braking.

The advantages of ABS with EBD

1) Better tracking performance through improved steering wheel control.

2) Improved maneuverability and safer vehicle control.

3) Improved vehicle stability by preventing flat spins.

4) Shorter stopping distance and optimal utilisation of the rear brakes under many different circumstances.

Operation

IABS with EBD has self-test capabilities. The ABS warning lamp is illuminated for 1 second each time the

ignition switch is turned ªONº. After the engine is started, the ABS warning lamp turns off. An ABS self-test

is performed the first time the vehicle reaches 6 km/h (4 MPH) to ensure the system is operational. A

mechanical noise may be heard as the ABS performs this self-test and is a normal part of the self-test

feature. If a malfunction is detected during this check, the ABS warning lamp will stay on.

During the self-test, it also performs a EBD check when it detects a failure the ABS warning light will go

on simultaneously with the brake warning light and an audible sound will sound constantly.

IEBD system will only operate when the ABS is not in active status and it uses the inlet valves of ABS con-

trol unit to limit the pressure to the rear wheels when they tend to go into slip.

IWhen the vehicle speed is less than 10 km/h (6 MPH) the ABS system does not operate.

IWhile driving, a mechanical noise may be heard during ABS operation, this is a normal system condition.

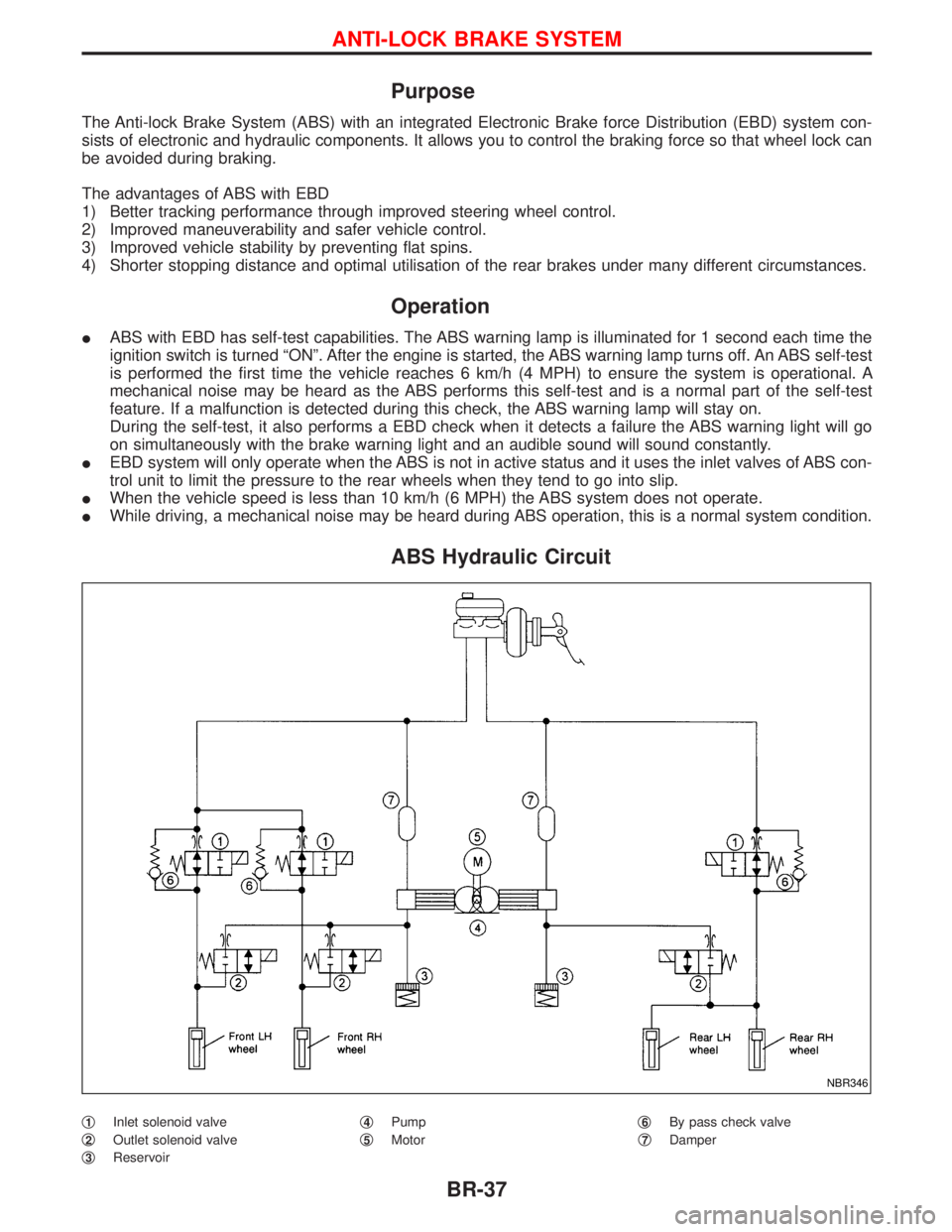

ABS Hydraulic Circuit

q1Inlet solenoid valve

q

2Outlet solenoid valve

q

3Reservoirq

4Pump

q

5Motorq

6By pass check valve

q

7Damper

NBR346

ANTI-LOCK BRAKE SYSTEM

BR-37

Page 240 of 1767

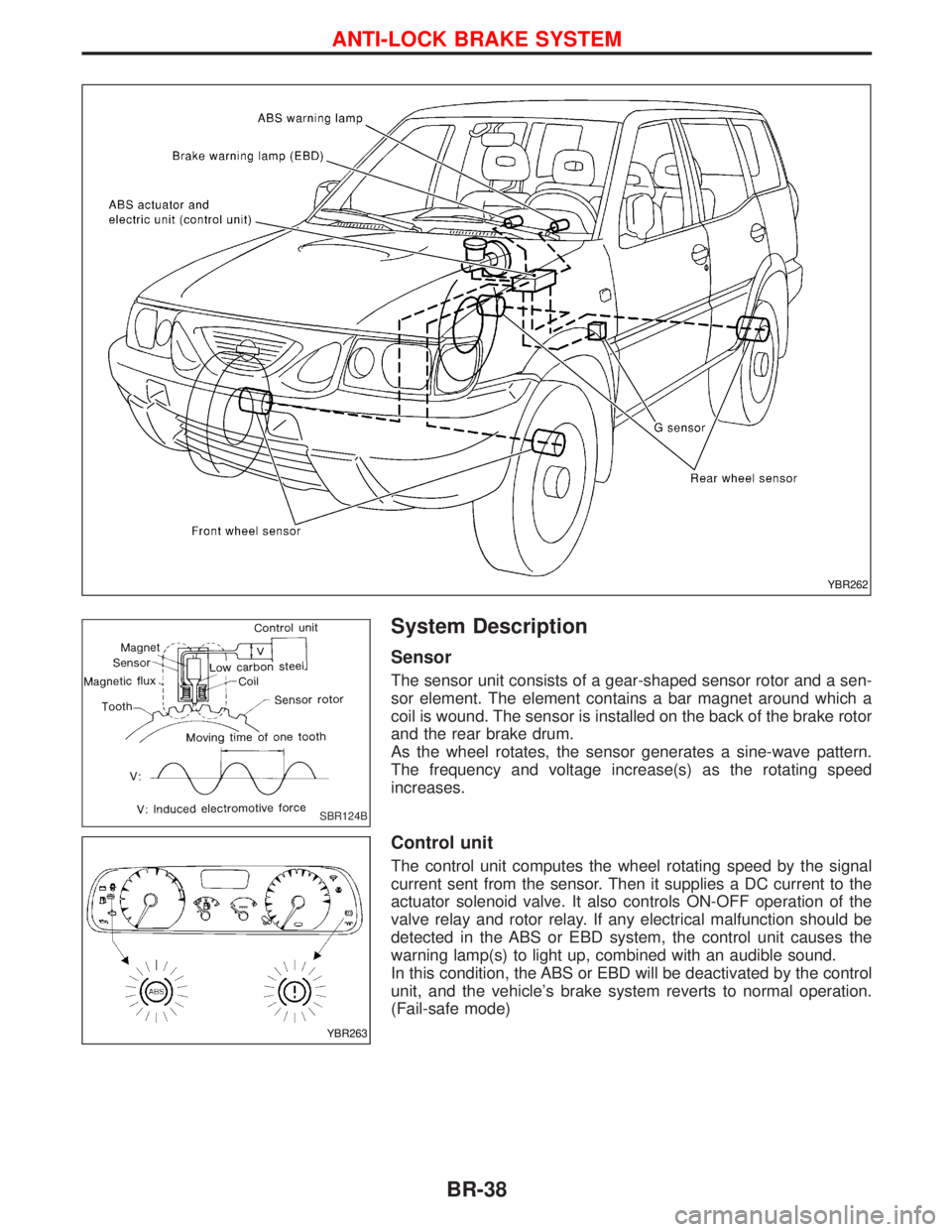

System Description

Sensor

The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The sensor is installed on the back of the brake rotor

and the rear brake drum.

As the wheel rotates, the sensor generates a sine-wave pattern.

The frequency and voltage increase(s) as the rotating speed

increases.

Control unit

The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and rotor relay. If any electrical malfunction should be

detected in the ABS or EBD system, the control unit causes the

warning lamp(s) to light up, combined with an audible sound.

In this condition, the ABS or EBD will be deactivated by the control

unit, and the vehicle's brake system reverts to normal operation.

(Fail-safe mode)

YBR262

SBR124B

YBR263

ANTI-LOCK BRAKE SYSTEM

BR-38

Page 360 of 1767

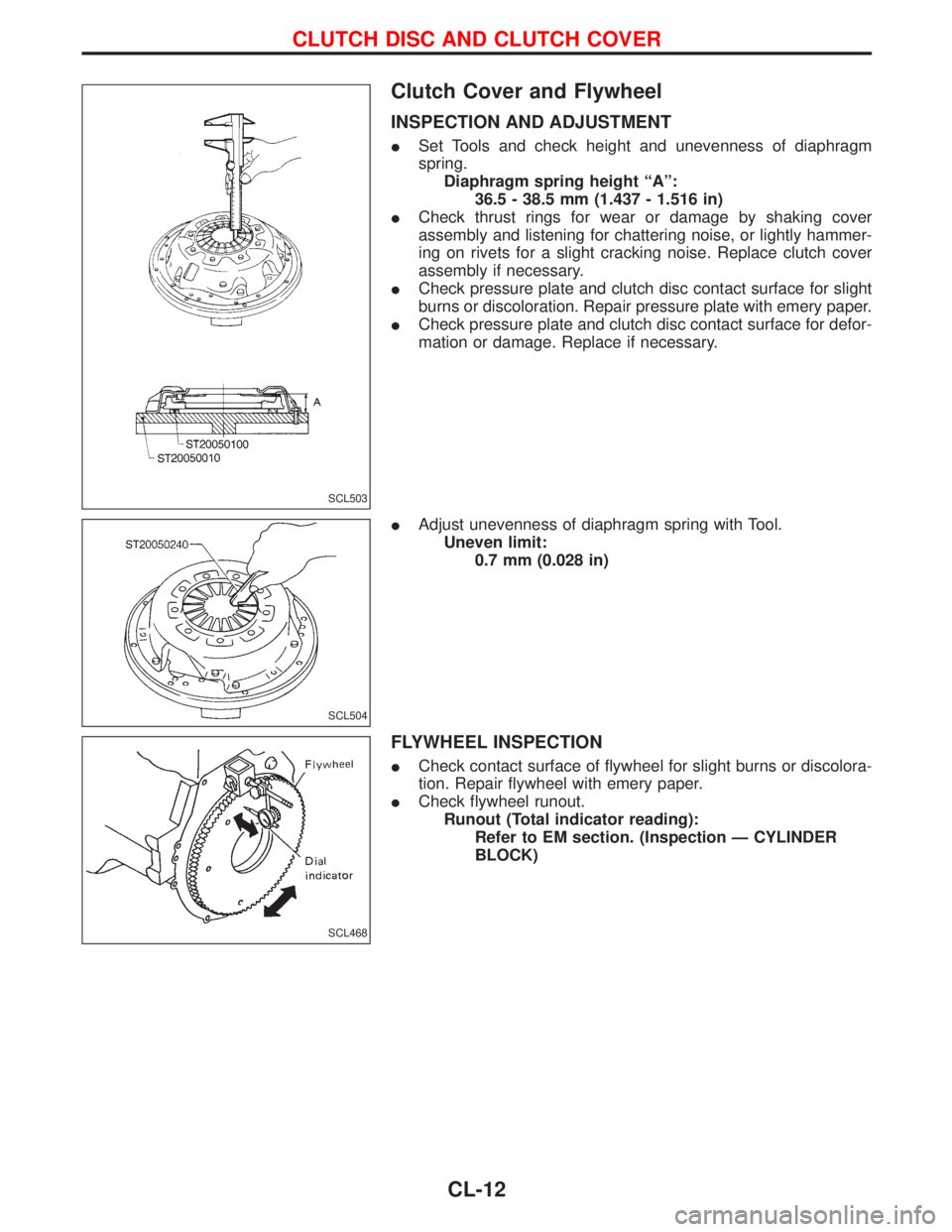

Clutch Cover and Flywheel

INSPECTION AND ADJUSTMENT

ISet Tools and check height and unevenness of diaphragm

spring.

Diaphragm spring height ªAº:

36.5 - 38.5 mm (1.437 - 1.516 in)

ICheck thrust rings for wear or damage by shaking cover

assembly and listening for chattering noise, or lightly hammer-

ing on rivets for a slight cracking noise. Replace clutch cover

assembly if necessary.

ICheck pressure plate and clutch disc contact surface for slight

burns or discoloration. Repair pressure plate with emery paper.

ICheck pressure plate and clutch disc contact surface for defor-

mation or damage. Replace if necessary.

IAdjust unevenness of diaphragm spring with Tool.

Uneven limit:

0.7 mm (0.028 in)

FLYWHEEL INSPECTION

ICheck contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

ICheck flywheel runout.

Runout (Total indicator reading):

Refer to EM section. (Inspection Ð CYLINDER

BLOCK)

SCL503

SCL504

SCL468

CLUTCH DISC AND CLUTCH COVER

CL-12

Page 371 of 1767

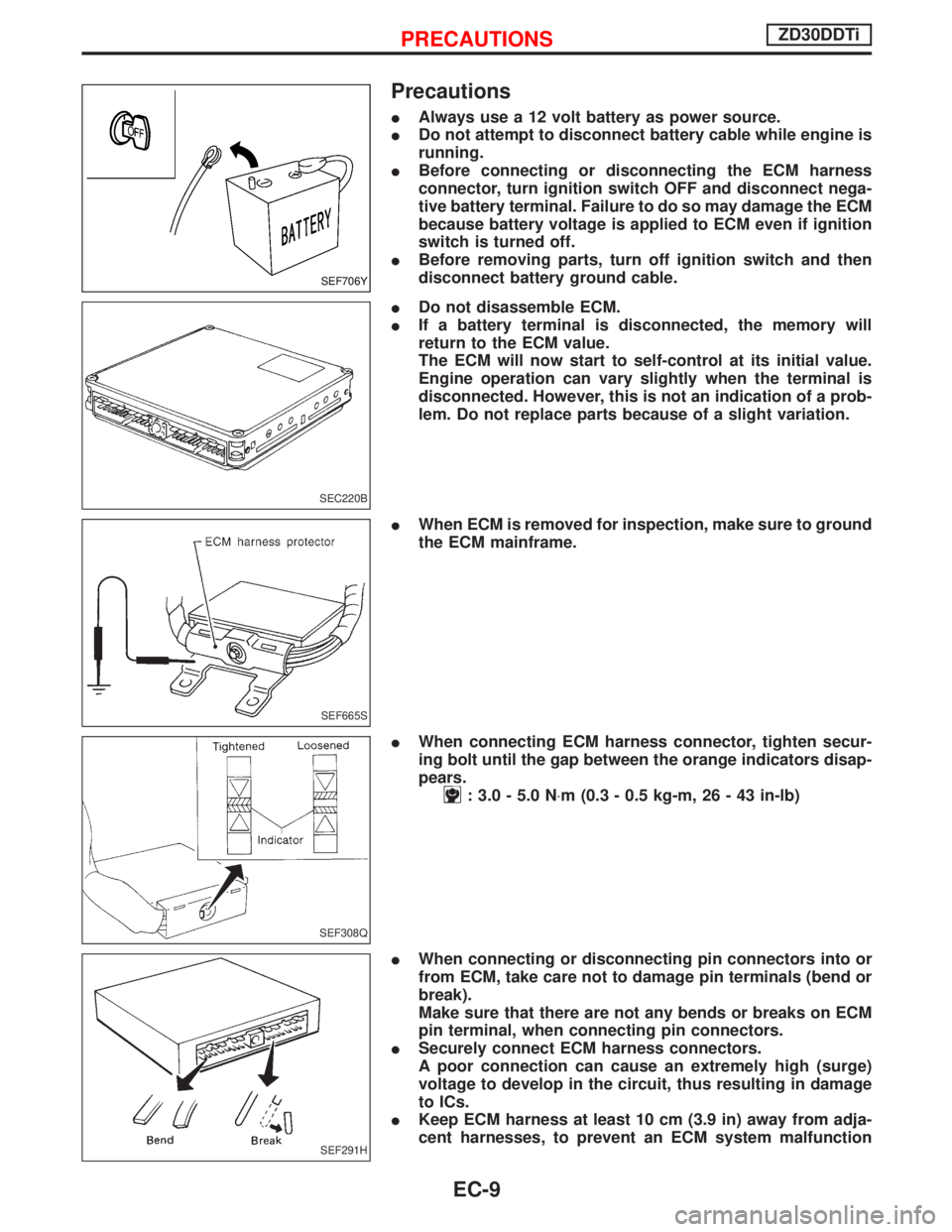

Precautions

IAlways use a 12 volt battery as power source.

IDo not attempt to disconnect battery cable while engine is

running.

IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

IBefore removing parts, turn off ignition switch and then

disconnect battery ground cable.

IDo not disassemble ECM.

IIf a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

IWhen ECM is removed for inspection, make sure to ground

the ECM mainframe.

IWhen connecting ECM harness connector, tighten secur-

ing bolt until the gap between the orange indicators disap-

pears.

: 3.0 - 5.0 N×m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

IWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

ISecurely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in damage

to ICs.

IKeep ECM harness at least 10 cm (3.9 in) away from adja-

cent harnesses, to prevent an ECM system malfunction

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-9

Page 373 of 1767

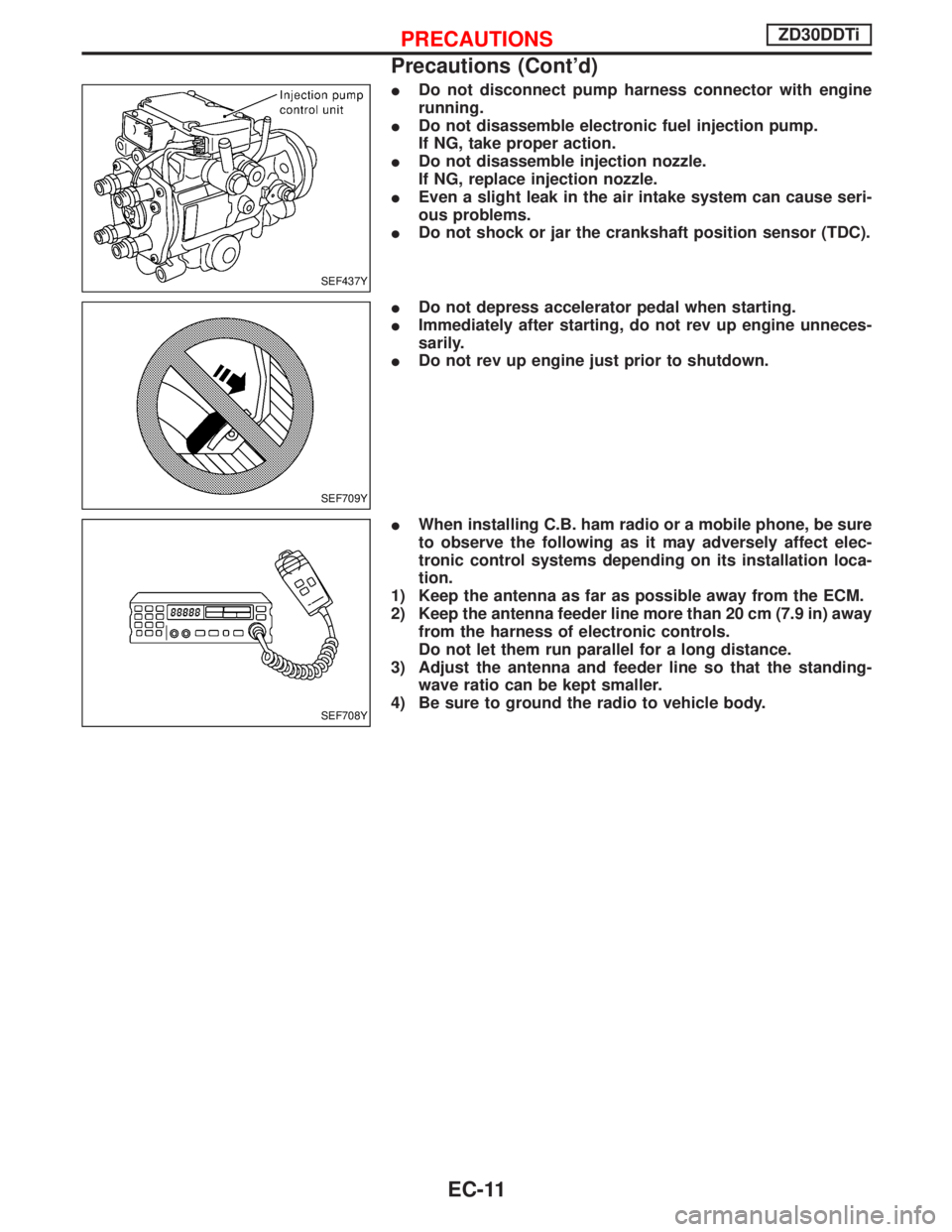

IDo not disconnect pump harness connector with engine

running.

IDo not disassemble electronic fuel injection pump.

If NG, take proper action.

IDo not disassemble injection nozzle.

If NG, replace injection nozzle.

IEven a slight leak in the air intake system can cause seri-

ous problems.

IDo not shock or jar the crankshaft position sensor (TDC).

IDo not depress accelerator pedal when starting.

IImmediately after starting, do not rev up engine unneces-

sarily.

IDo not rev up engine just prior to shutdown.

IWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on its installation loca-

tion.

1) Keep the antenna as far as possible away from the ECM.

2) Keep the antenna feeder line more than 20 cm (7.9 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

3) Adjust the antenna and feeder line so that the standing-

wave ratio can be kept smaller.

4) Be sure to ground the radio to vehicle body.

SEF437Y

SEF709Y

SEF708Y

PRECAUTIONSZD30DDTi

Precautions (Cont'd)

EC-11

Page 395 of 1767

DTC and MI Detection Logic

When a malfunction is detected, the malfunction (DTC) is stored in the ECM memory.

The MI will light up each time the ECM detects malfunction. For diagnostic items causing the MI to light up,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-7.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MI illumination in the diagnostic test mode II (Self-

diagnostic results). Example: 0102, 0407, 1004, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: ªCRANK POS SEN (TDC)º, etc.

IOutput of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT-II can identify them. Therefore, using CONSULT-II (if available) is recommended.

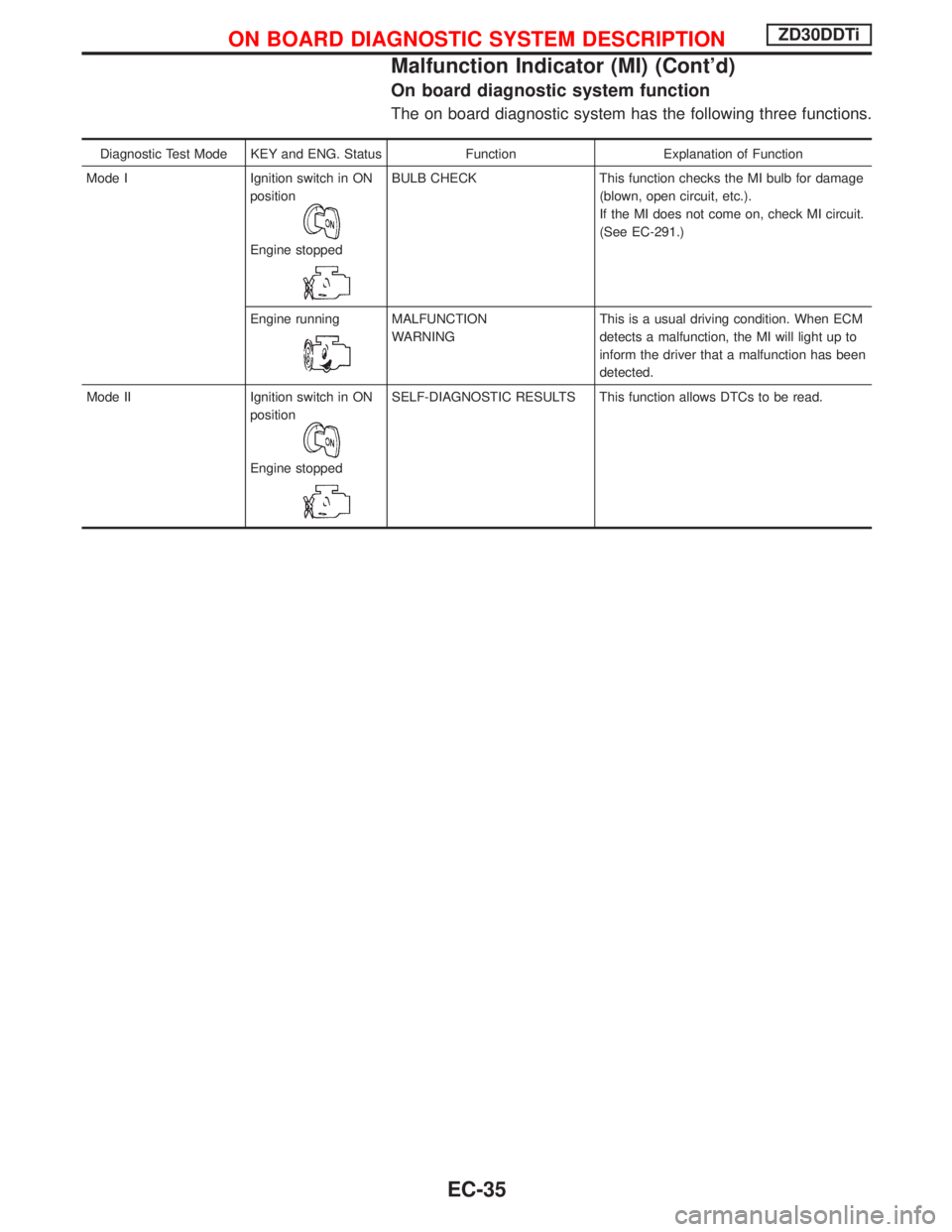

HOW TO ERASE DTC

How to erase DTC (

With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

How to erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-36.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

SEF371Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

EC-33

Page 396 of 1767

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

IConfirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

IWhen replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

IIf the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-291.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34

Page 397 of 1767

On board diagnostic system function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-291.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-35

Page 400 of 1767

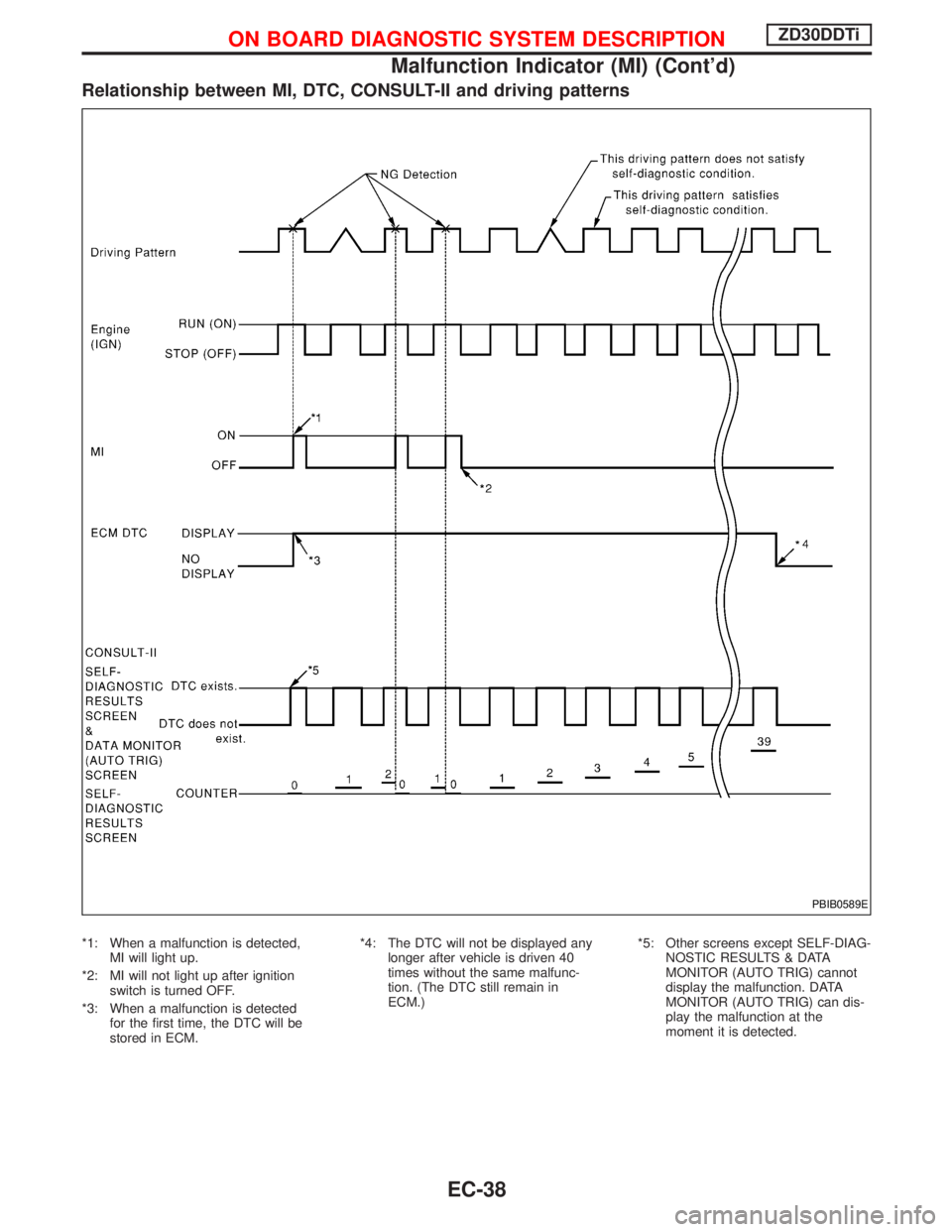

Relationship between MI, DTC, CONSULT-II and driving patterns

*1: When a malfunction is detected,

MI will light up.

*2: MI will not light up after ignition

switch is turned OFF.

*3: When a malfunction is detected

for the first time, the DTC will be

stored in ECM.*4: The DTC will not be displayed any

longer after vehicle is driven 40

times without the same malfunc-

tion. (The DTC still remain in

ECM.)*5: Other screens except SELF-DIAG-

NOSTIC RESULTS & DATA

MONITOR (AUTO TRIG) cannot

display the malfunction. DATA

MONITOR (AUTO TRIG) can dis-

play the malfunction at the

moment it is detected.

PBIB0589E

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-38

Page 428 of 1767

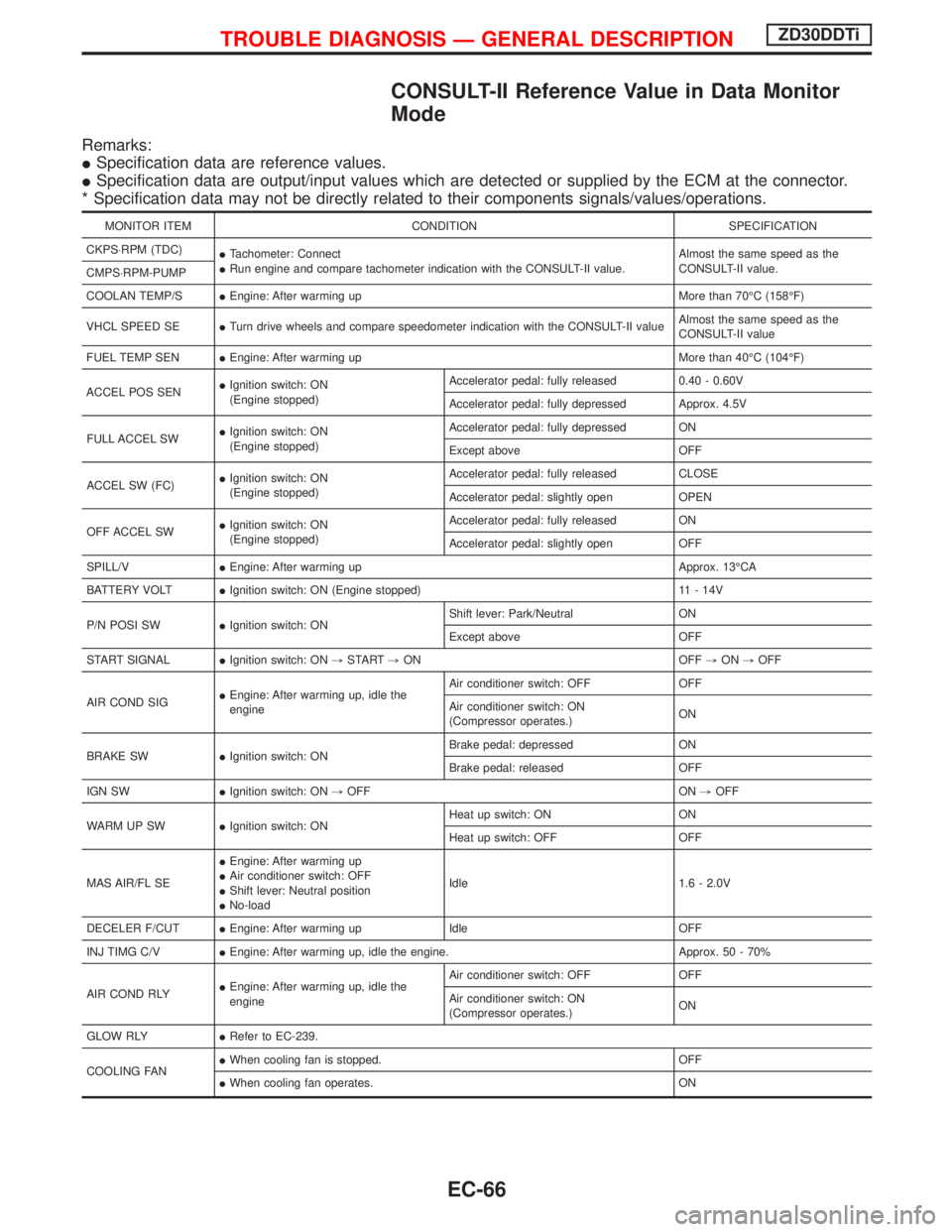

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPS×RPM (TDC)

ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II value.Almost the same speed as the

CONSULT-II value.

CMPS×RPM-PUMP

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SEITurn drive wheels and compare speedometer indication with the CONSULT-II valueAlmost the same speed as the

CONSULT-II value

FUEL TEMP SENIEngine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SENIIgnition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.40 - 0.60V

Accelerator pedal: fully depressed Approx. 4.5V

FULL ACCEL SWIIgnition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

ACCEL SW (FC)IIgnition switch: ON

(Engine stopped)Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SWIIgnition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SPILL/VIEngine: After warming up Approx. 13ÉCA

BATTERY VOLTIIgnition switch: ON (Engine stopped) 11 - 14V

P/N POSI SWIIgnition switch: ONShift lever: Park/Neutral ON

Except above OFF

START SIGNALIIgnition switch: ON,START,ON OFF,ON,OFF

AIR COND SIGIEngine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SWIIgnition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

IGN SWIIgnition switch: ON,OFF ON,OFF

WARM UP SWIIgnition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SEIEngine: After warming up

IAir conditioner switch: OFF

IShift lever: Neutral position

INo-loadIdle 1.6 - 2.0V

DECELER F/CUTIEngine: After warming up Idle OFF

INJ TIMG C/VIEngine: After warming up, idle the engine. Approx. 50 - 70%

AIR COND RLYIEngine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

GLOW RLYIRefer to EC-239.

COOLING FANIWhen cooling fan is stopped. OFF

IWhen cooling fan operates. ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-66