system NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1323 of 1767

1.A QUICK REFERENCE INDEX, a black tab (e.g.) is provided on the first page. You can quickly find

the first page of each section by mating it to the section's black tab.

2.THE CONTENTSare listed on the first page of each section.

3.THE TITLEis indicated on the upper portion of each page and shows the part or system.

4.THE PAGE NUMBERof each section consists of two letters which designate the particular section and a

number (e.g. ªBR-5º).

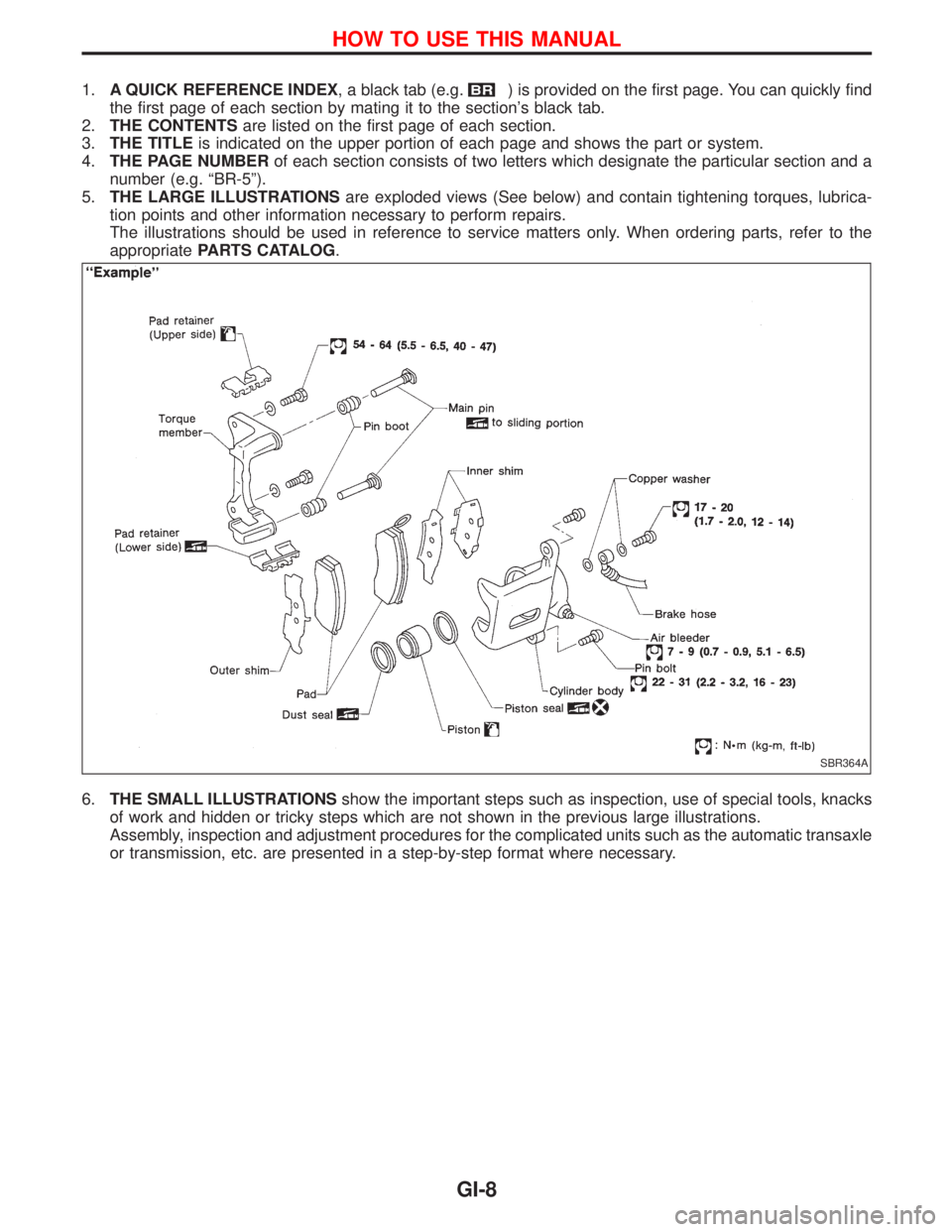

5.THE LARGE ILLUSTRATIONSare exploded views (See below) and contain tightening torques, lubrica-

tion points and other information necessary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriatePARTS CATALOG.

6.THE SMALL ILLUSTRATIONSshow the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary.

SBR364A

HOW TO USE THIS MANUAL

GI-8

Page 1324 of 1767

7. The followingSYMBOLS AND ABBREVIATIONSare used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disassem-

bly.

L.H., R.H.: Left-Hand, Right-Hand

FR, RR : Front, Rear

2WD : 2-Wheel Drive

4WD : 4-Wheel Drive

qP: Apply petroleum jelly.

: Apply A.T.F.

A.T.F. : Automatic Transmission Fluid

H: Select with proper thickness.

I: Adjustment is required.

M/T : Manual Transaxle/Transmission

A/C : Air Conditioner

P/S : Power Steering

S.S.T. : Special Service Tools

S.D.S. : Service Data and Specifications

SAE : Society of Automotive Engineers, Inc.

L.H.D. : Left-Hand Drive

R.H.D. : Right-Hand Drive

8. TheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

ªExampleº

Tightening torque:

59-78N×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

9.TROUBLE DIAGNOSESare included in sections dealing with complicated components.

10.SERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

11. The captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

IWARNINGindicates the possibility of personal injury if instructions are not followed.

ICAUTIONindicates the possibility of component damage if instructions are not followed.

IBOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

HOW TO USE THIS MANUAL

GI-9

Page 1327 of 1767

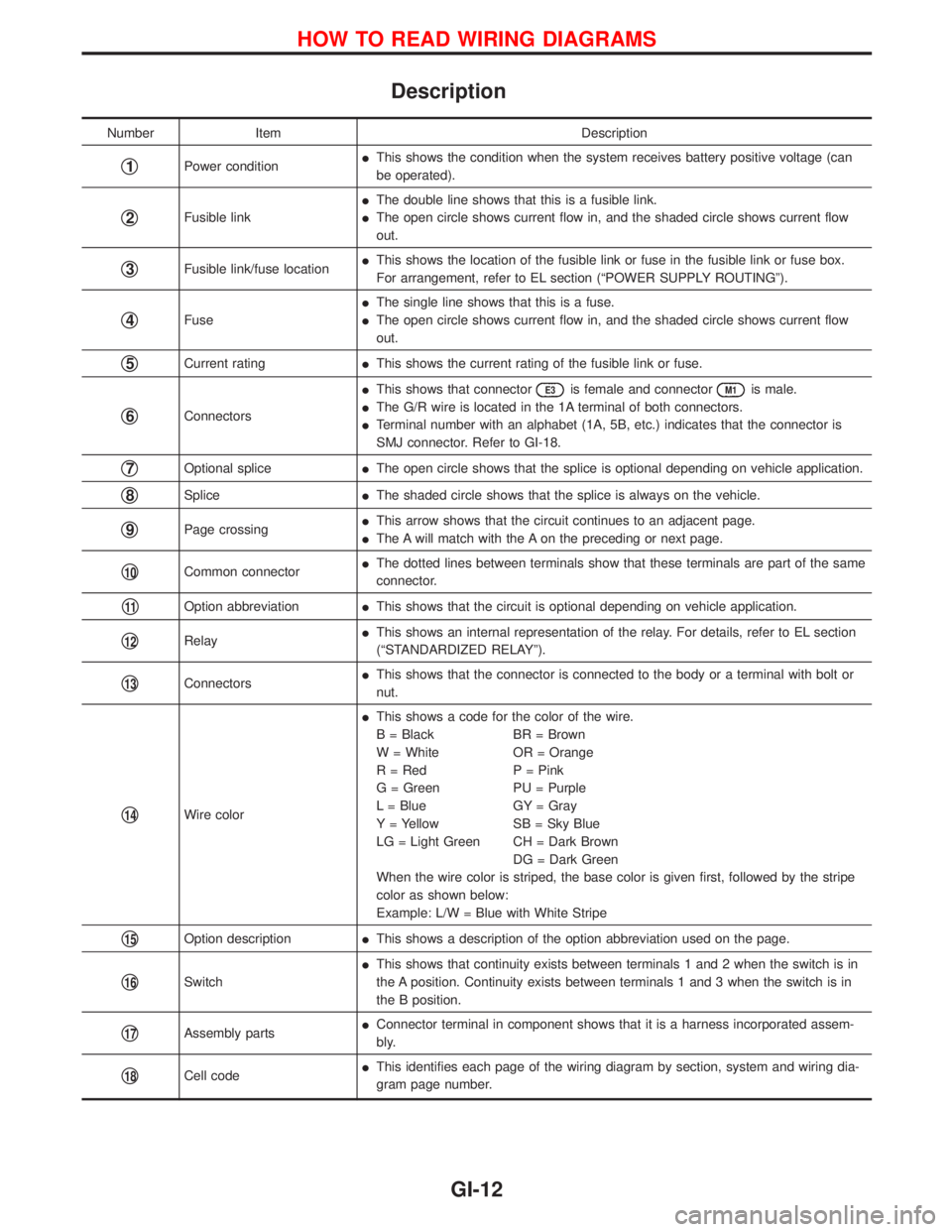

Description

Number Item Description

q1Power conditionIThis shows the condition when the system receives battery positive voltage (can

be operated).

q2Fusible linkIThe double line shows that this is a fusible link.

IThe open circle shows current flow in, and the shaded circle shows current flow

out.

q3Fusible link/fuse locationIThis shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (ªPOWER SUPPLY ROUTINGº).

q4FuseIThe single line shows that this is a fuse.

IThe open circle shows current flow in, and the shaded circle shows current flow

out.

q5Current ratingIThis shows the current rating of the fusible link or fuse.

q6ConnectorsIThis shows that connector

E3is female and connectorM1is male.

IThe G/R wire is located in the 1A terminal of both connectors.

ITerminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-18.

q7Optional spliceIThe open circle shows that the splice is optional depending on vehicle application.

q8SpliceIThe shaded circle shows that the splice is always on the vehicle.

q9Page crossingIThis arrow shows that the circuit continues to an adjacent page.

IThe A will match with the A on the preceding or next page.

q10Common connectorIThe dotted lines between terminals show that these terminals are part of the same

connector.

q11Option abbreviationIThis shows that the circuit is optional depending on vehicle application.

q12RelayIThis shows an internal representation of the relay. For details, refer to EL section

(ªSTANDARDIZED RELAYº).

q13ConnectorsIThis shows that the connector is connected to the body or a terminal with bolt or

nut.

q14Wire colorIThis shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

q15Option descriptionIThis shows a description of the option abbreviation used on the page.

q16SwitchIThis shows that continuity exists between terminals 1 and 2 when the switch is in

the A position. Continuity exists between terminals 1 and 3 when the switch is in

the B position.

q17Assembly partsIConnector terminal in component shows that it is a harness incorporated assem-

bly.

q18Cell codeIThis identifies each page of the wiring diagram by section, system and wiring dia-

gram page number.

HOW TO READ WIRING DIAGRAMS

GI-12

Page 1328 of 1767

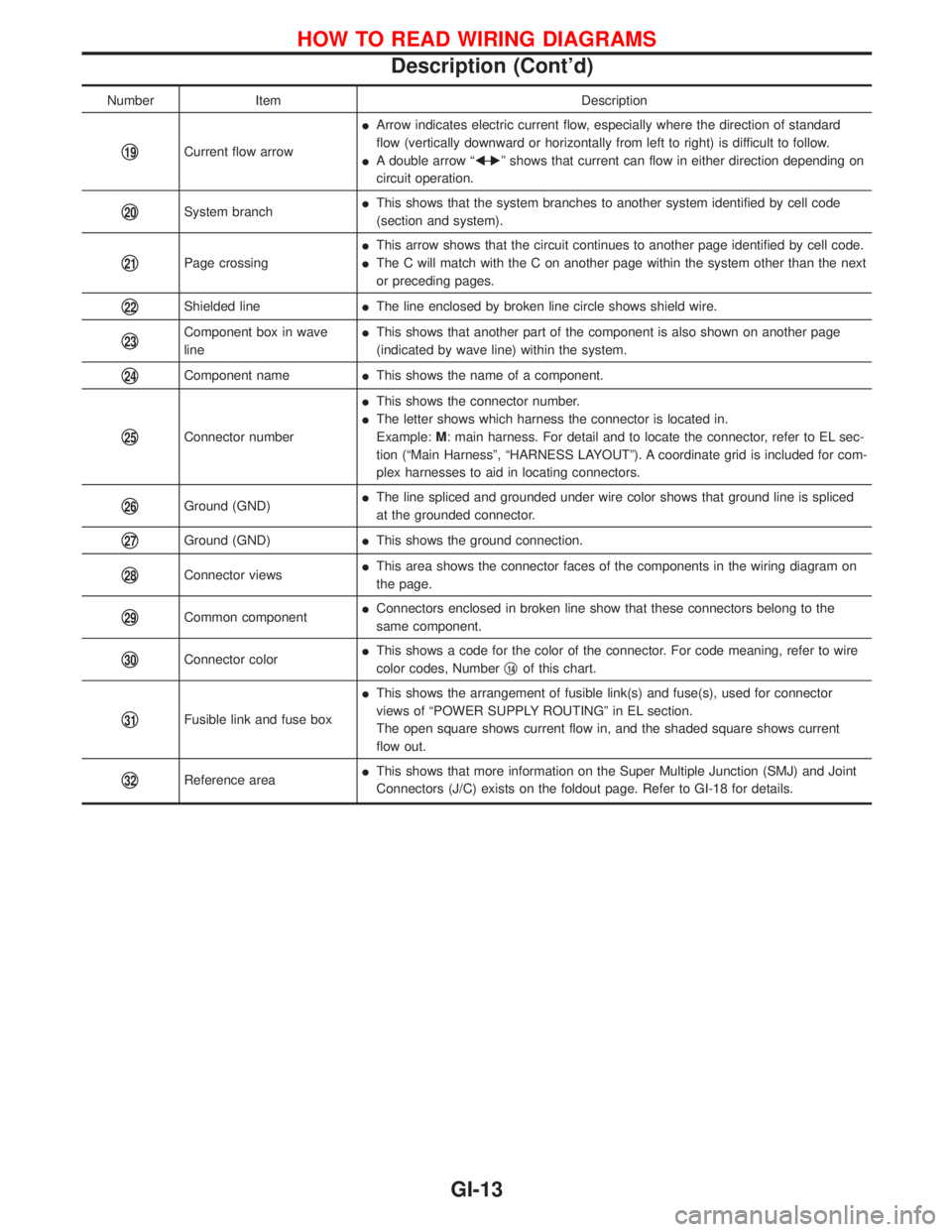

Number Item Description

q19Current flow arrowIArrow indicates electric current flow, especially where the direction of standard

flow (vertically downward or horizontally from left to right) is difficult to follow.

IA double arrow ªFÐ

Eº shows that current can flow in either direction depending on

circuit operation.

q20System branchIThis shows that the system branches to another system identified by cell code

(section and system).

q21Page crossingIThis arrow shows that the circuit continues to another page identified by cell code.

IThe C will match with the C on another page within the system other than the next

or preceding pages.

q22Shielded lineIThe line enclosed by broken line circle shows shield wire.

q23Component box in wave

lineIThis shows that another part of the component is also shown on another page

(indicated by wave line) within the system.

q24Component nameIThis shows the name of a component.

q25Connector numberIThis shows the connector number.

IThe letter shows which harness the connector is located in.

Example:M: main harness. For detail and to locate the connector, refer to EL sec-

tion (ªMain Harnessº, ªHARNESS LAYOUTº). A coordinate grid is included for com-

plex harnesses to aid in locating connectors.

q26Ground (GND)IThe line spliced and grounded under wire color shows that ground line is spliced

at the grounded connector.

q27Ground (GND)IThis shows the ground connection.

q28Connector viewsIThis area shows the connector faces of the components in the wiring diagram on

the page.

q29Common componentIConnectors enclosed in broken line show that these connectors belong to the

same component.

q30Connector colorIThis shows a code for the color of the connector. For code meaning, refer to wire

color codes, Numberq14of this chart.

q31Fusible link and fuse boxIThis shows the arrangement of fusible link(s) and fuse(s), used for connector

views of ªPOWER SUPPLY ROUTINGº in EL section.

The open square shows current flow in, and the shaded square shows current

flow out.

q32Reference areaIThis shows that more information on the Super Multiple Junction (SMJ) and Joint

Connectors (J/C) exists on the foldout page. Refer to GI-18 for details.

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-13

Page 1331 of 1767

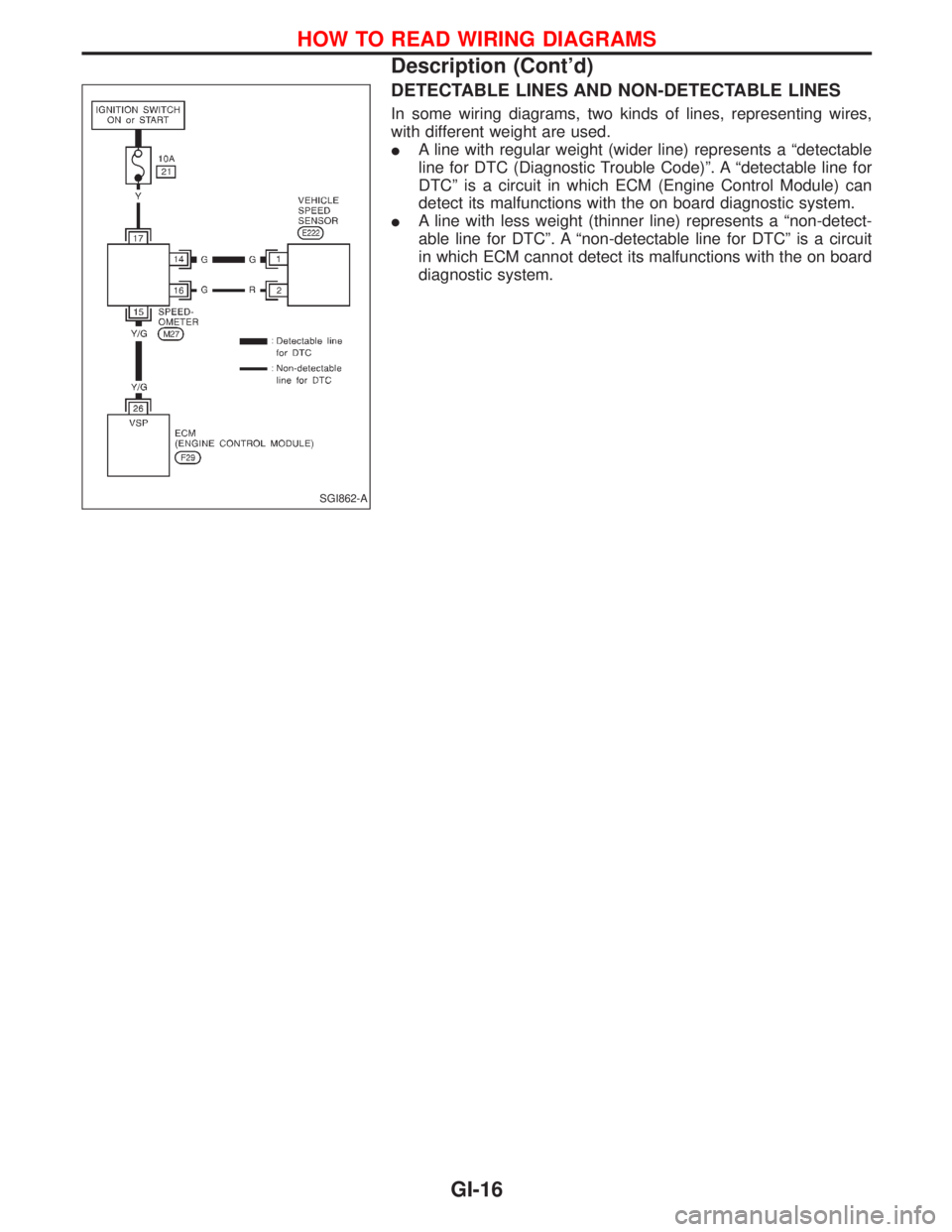

DETECTABLE LINES AND NON-DETECTABLE LINES

In some wiring diagrams, two kinds of lines, representing wires,

with different weight are used.

IA line with regular weight (wider line) represents a ªdetectable

line for DTC (Diagnostic Trouble Code)º. A ªdetectable line for

DTCº is a circuit in which ECM (Engine Control Module) can

detect its malfunctions with the on board diagnostic system.

IA line with less weight (thinner line) represents a ªnon-detect-

able line for DTCº. A ªnon-detectable line for DTCº is a circuit

in which ECM cannot detect its malfunctions with the on board

diagnostic system.

SGI862-A

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-16

Page 1337 of 1767

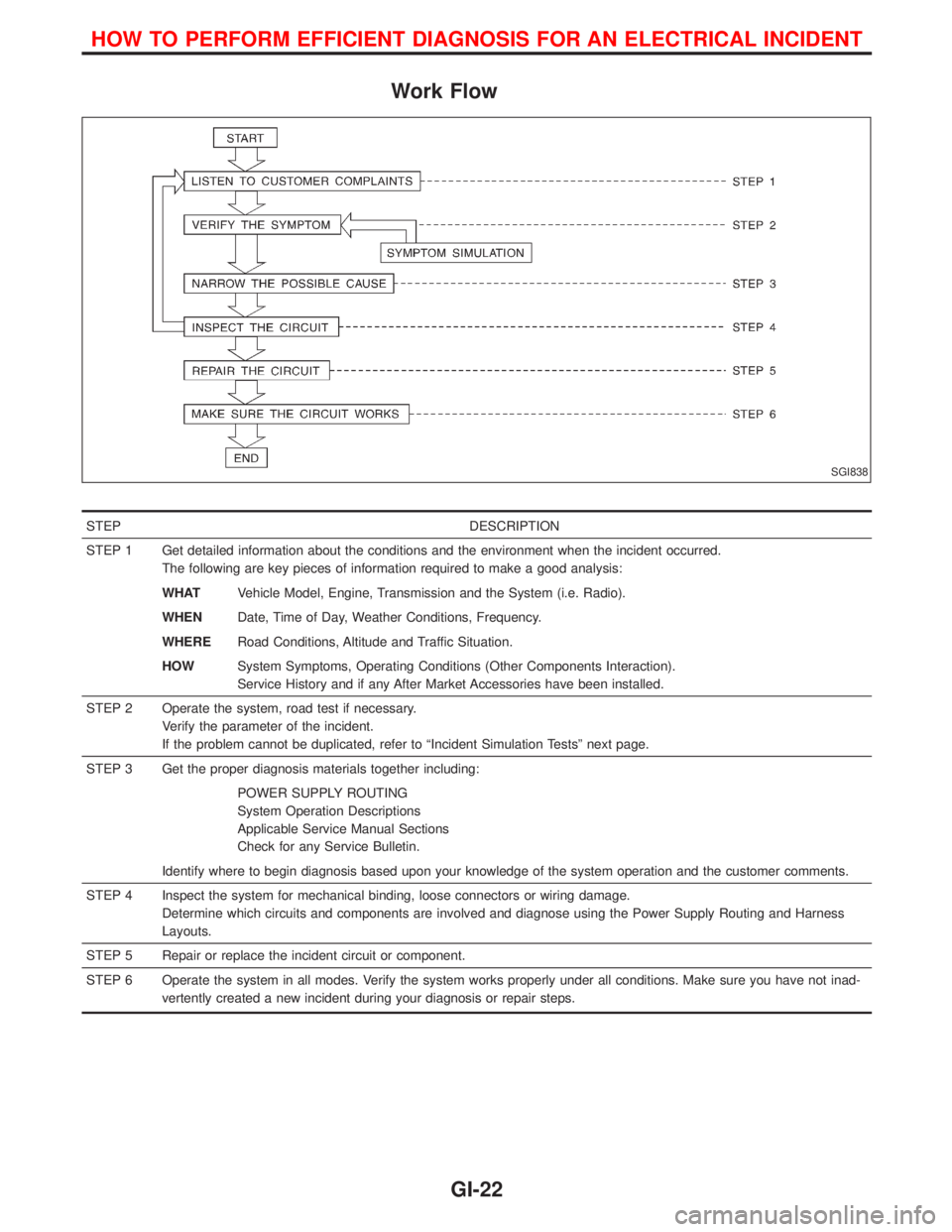

Work Flow

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to ªIncident Simulation Testsº next page.

STEP 3 Get the proper diagnosis materials together including:

POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

SGI838

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-22

Page 1338 of 1767

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

IHeat sensitive

IFreezing

IWater intrusion

IElectrical load

ICold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

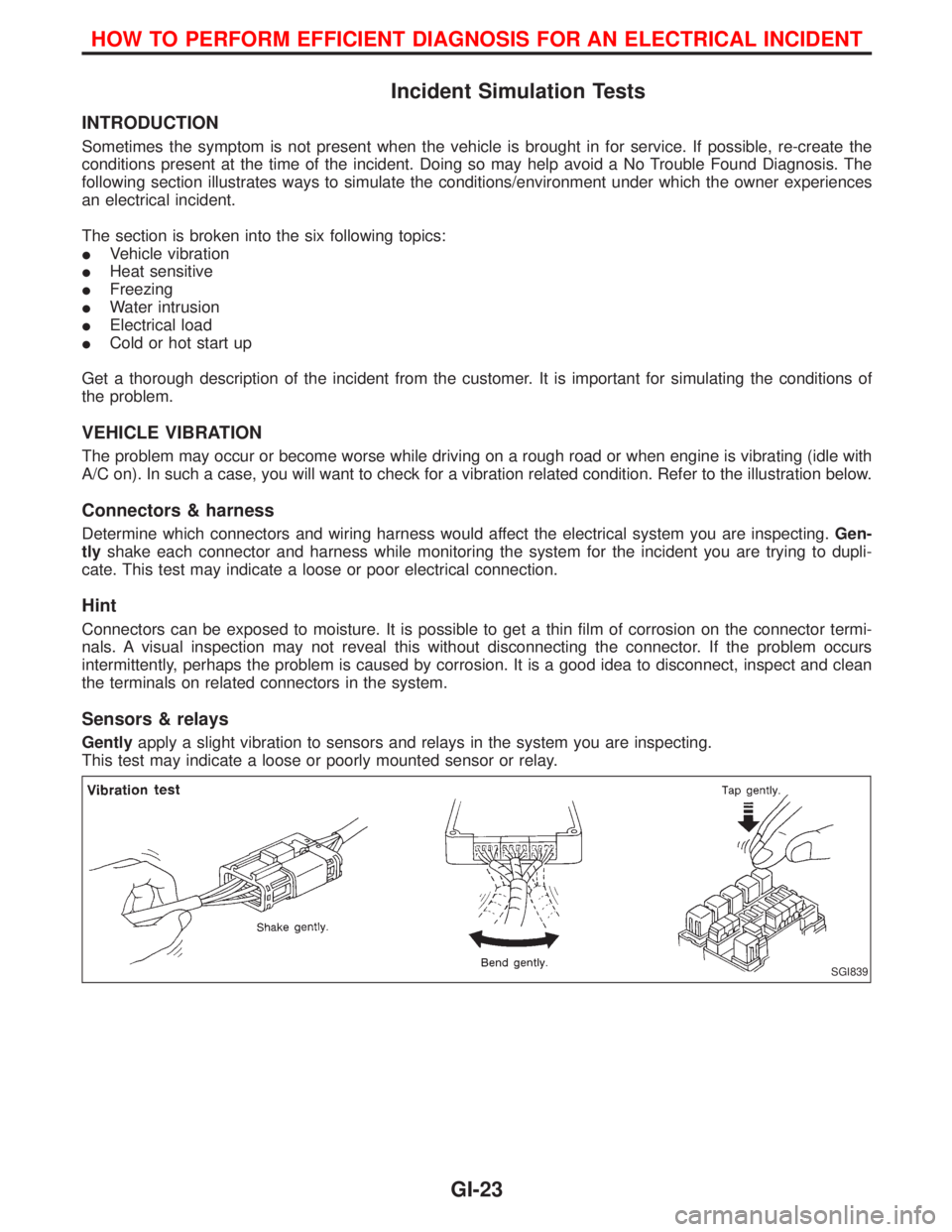

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23

Page 1339 of 1767

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

IConnectors not fully seated.

IWiring harness not long enough and is being stressed due to

engine vibrations or rocking.

IWires laying across brackets or moving components.

ILoose, dirty or corroded ground wires.

IWires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection bygently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

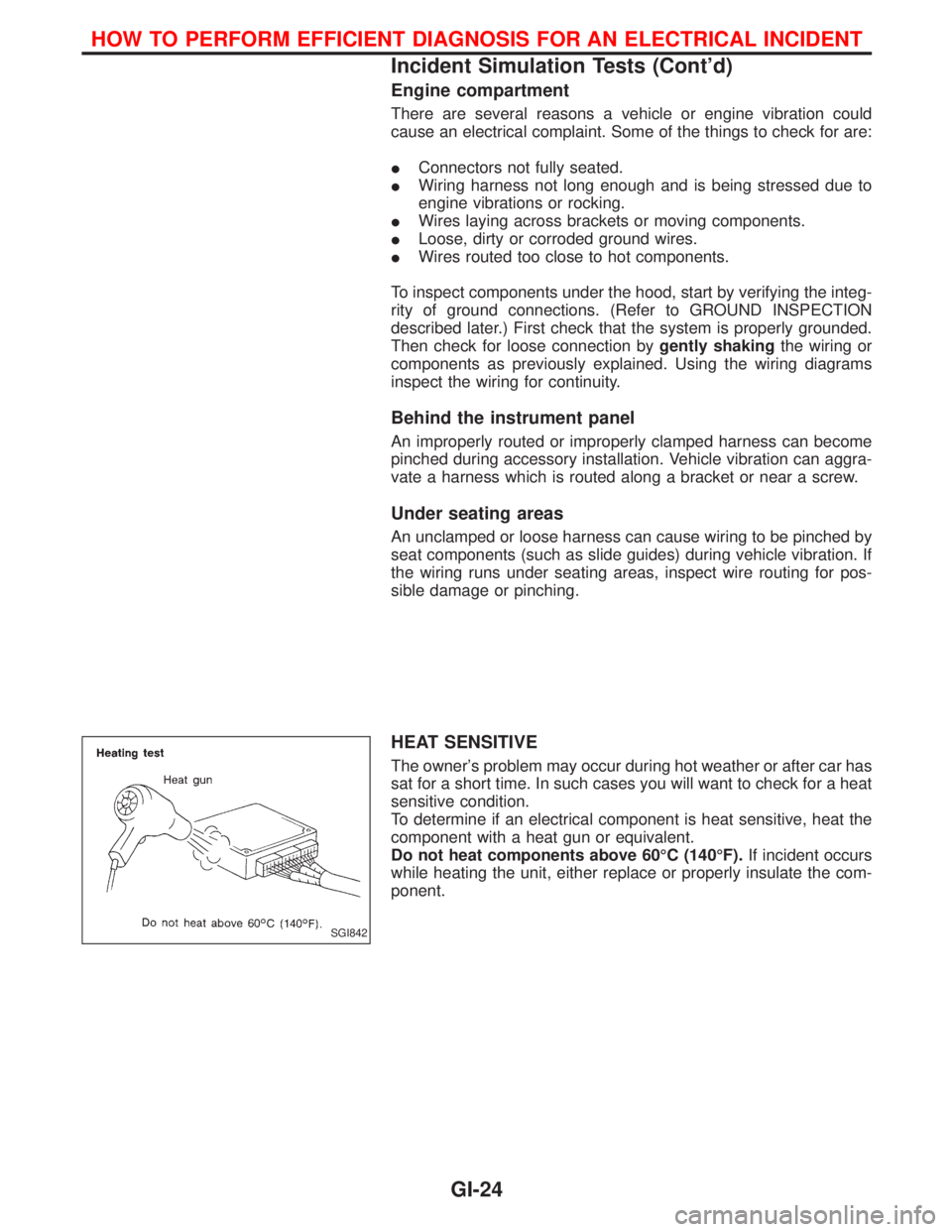

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF).If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI842

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-24

Page 1341 of 1767

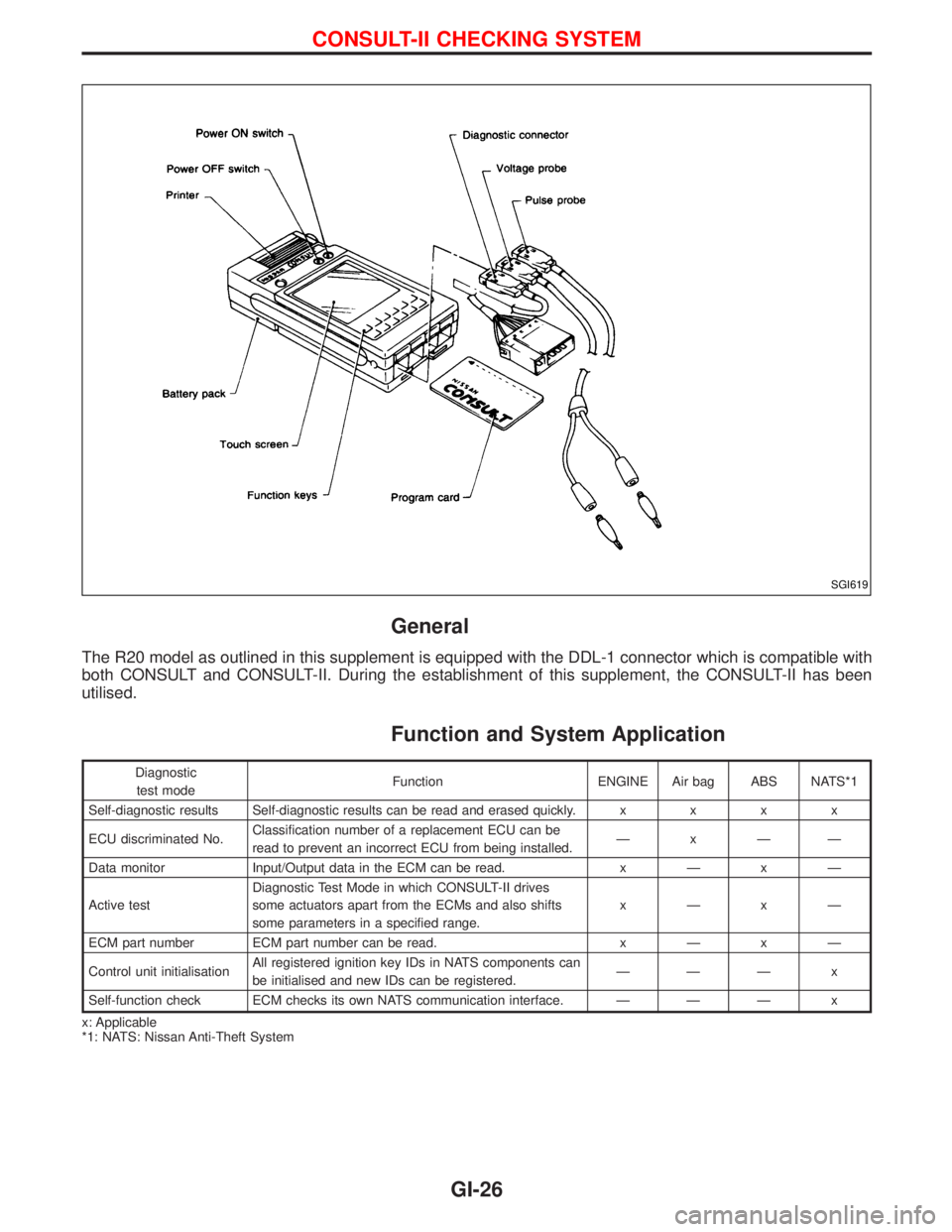

General

The R20 model as outlined in this supplement is equipped with the DDL-1 connector which is compatible with

both CONSULT and CONSULT-II. During the establishment of this supplement, the CONSULT-II has been

utilised.

Function and System Application

Diagnostic

test modeFunction ENGINE Air bag ABS NATS*1

Self-diagnostic results Self-diagnostic results can be read and erased quickly.xxxx

ECU discriminated No.Classification number of a replacement ECU can be

read to prevent an incorrect ECU from being installed.ÐxÐÐ

Data monitor Input/Output data in the ECM can be read.xÐxÐ

Active testDiagnostic Test Mode in which CONSULT-II drives

some actuators apart from the ECMs and also shifts

some parameters in a specified range.xÐxÐ

ECM part number ECM part number can be read.xÐxÐ

Control unit initialisationAll registered ignition key IDs in NATS components can

be initialised and new IDs can be registered.ÐÐÐ x

Self-function check ECM checks its own NATS communication interface. Ð Ð Ð x

x: Applicable

*1: NATS: Nissan Anti-Theft System

SGI619

CONSULT-II CHECKING SYSTEM

GI-26

Page 1342 of 1767

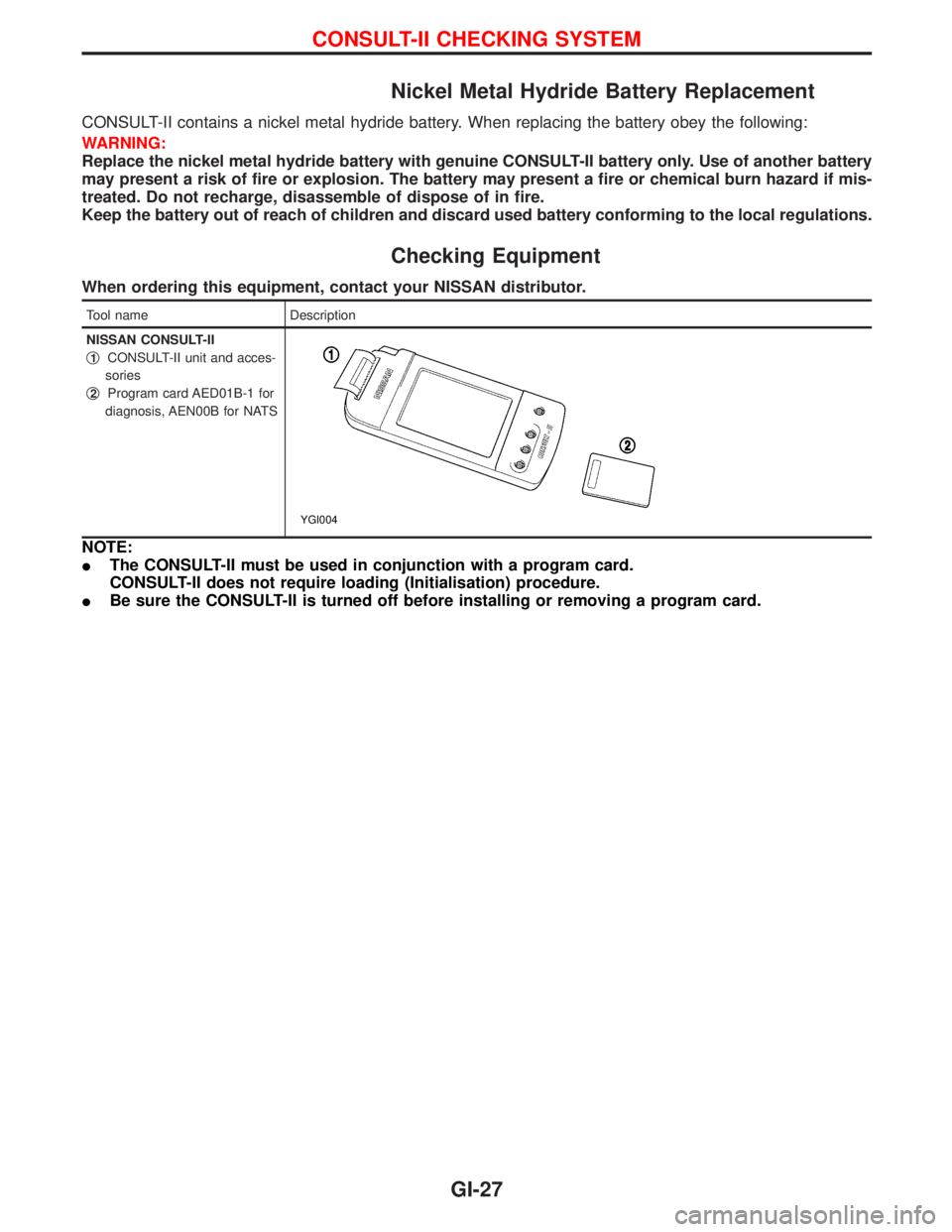

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with genuine CONSULT-II battery only. Use of another battery

may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mis-

treated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking Equipment

When ordering this equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

q

1CONSULT-II unit and acces-

sories

q

2Program card AED01B-1 for

diagnosis, AEN00B for NATS

YGI004

NOTE:

IThe CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialisation) procedure.

IBe sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II CHECKING SYSTEM

GI-27