wheel NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 6 of 1767

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL R20 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

IDisassembly should be done in a clean work area.

IUse lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

IPlace disassembled parts in order for easier and proper assembly.

IAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

IGaskets, seals and O-rings should be replaced any time the transmission is disassembled.

IIt is very important to perform functional tests whenever they are indicated.

IThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

IProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

IExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

PREPARATION AND PRECAUTIONS

AT- 4

Page 7 of 1767

Service Notice or Precautions

FAIL-SAFE

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear even with a shift lever position of ª1º, ª2º or ªDº. Cus-

tomer may complain of ªsluggish or poor accelerationº.

When the Fail-Safe operation occurs the next time the key is turned to the ªONº position, the SPORT indica-

tor lamp will blink for about 8 seconds. (For diagnosis, refer to AT-33.)

Fail-Safe may activate without electrical circuit damages if the vehicle is driven under extreme conditions (such

as excessive wheel spins and emergency braking immediately afterwards). In this case, turn the ignition key

ªOFFº for 5 seconds and then ªONº to recover normal shift pattern.

The blinking of the SPORT indicator lamp for about 8 seconds will appear only once and be cleared. The cus-

tomer may resume normal driving conditions by chance.

Always follow the ªWORK FLOWº (Refer to AT-26).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate the damage of the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS performed after checking the sensor, no damages will be indicated.

PREPARATION AND PRECAUTIONS

AT- 5

Page 29 of 1767

A/T Fluid Check

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water enter-

ing through filler tube or breather

Varnished fluid, light to dark

brown and tackyOxidation Ð Over or under filling, Ð Over-

heating

FLUID LEVEL CHECK

Refer to MA section (ªChecking A/T Fluidº, ªCHASSIS AND BODY

MAINTENANCEº).

Stall Test

STALL TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

IIt is good practice to put a mark on point of specified

engine rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in ªDº

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

IDuring test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

2,450 - 2,700 rpm

SAT801A

SAT638A

SAT647B

SAT513G

SAT514G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-27

Page 33 of 1767

4. Set parking brake and block wheels.

IContinue to depress brake pedal fully while line pressure

test is being performed at stall speed.

5. Start engine and measure line pressure at idle and stall speed.

IWhen measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure:

Refer to SDS, AT-196.

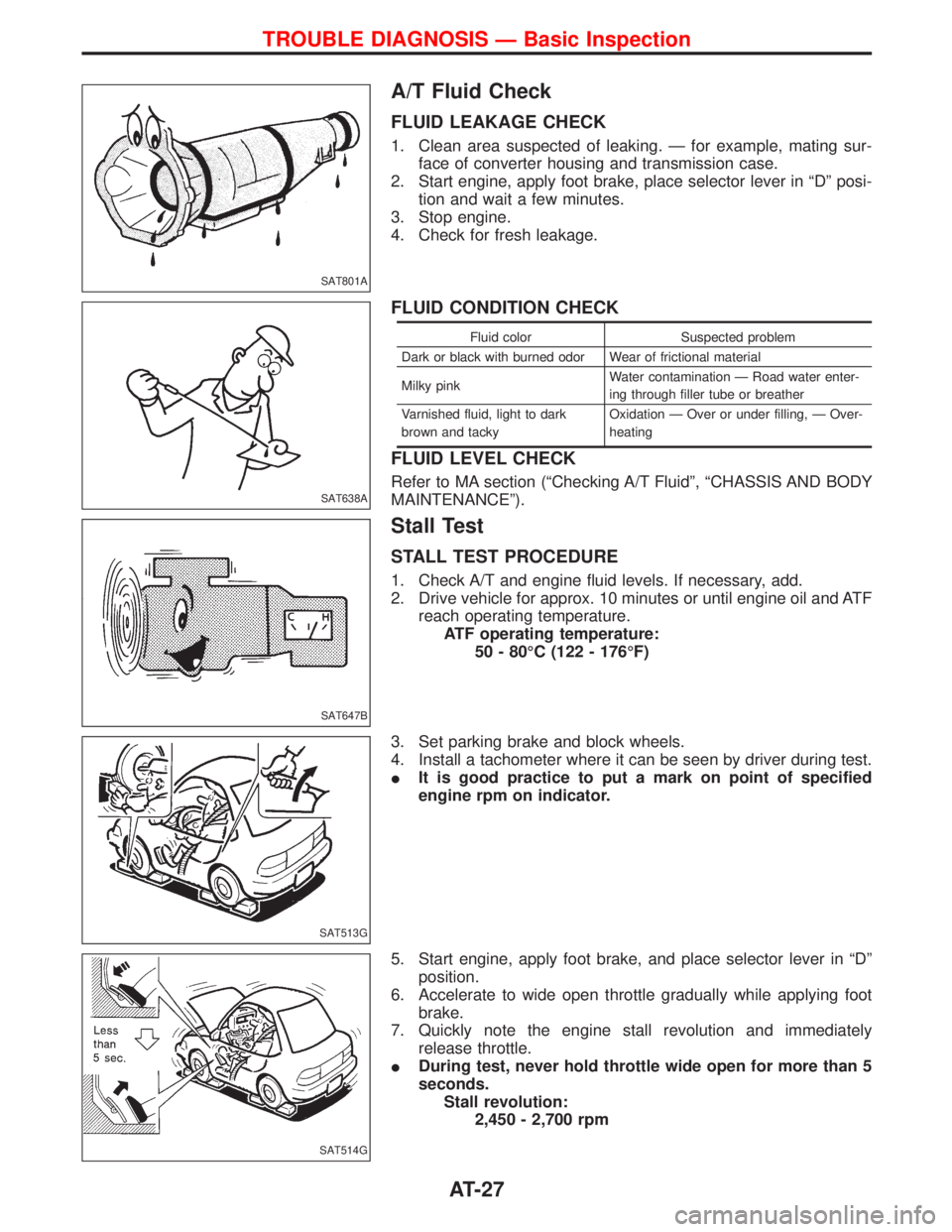

JUDGEMENT OF LINE PRESSURE TEST

Judgement Suspected parts

At idleLine pressure is low in all

positions.IOil pump wear

IControl piston damage

IPressure regulator valve or plug sticking

ISpring for pressure regulator valve damaged

IA/T fluid pressure leakage between oil strainer and pressure regulator valve

IClogged strainer

Line pressure is low in par-

ticular position.IFluid pressure leakage between manual valve and particular clutch

IFor example, line pressure is:

Ð Low in ªRº and ª1º positions,

Ð Normal in ªDº and ª2º positions.

Then, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-11.

Line pressure is high.IMal-adjustment of throttle position sensor

IA/T fluid temperature sensor damaged

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure modifier valve sticking

IPressure regulator valve or plug sticking

IOpen in dropping resistor circuit

At stall speedLine pressure is low.IMal-adjustment of throttle position sensor

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure regulator valve or plug sticking

IPressure modifier valve sticking

IPilot valve sticking

SAT513G

SAT493G

TROUBLE DIAGNOSIS Ð Basic Inspection

Line Pressure Test (Cont'd)

AT-31

Page 204 of 1767

Diagnostic Procedure 2 (Warning lamp stays on

when ignition switch is turned ON)............................69

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) .................................71

Diagnostic Procedure 4 (Wheel sensor or rotor) ......73

Diagnostic Procedure 5 (Motor Relay or motor) .......75

Diagnostic Procedure 7 (Low voltage) ......................77

Diagnostic Procedure 8 (G sensor) ...........................78

Diagnostic Procedure 9 (Control unit) .......................79

Diagnostic Procedure 10 (Pedal vibration and

noise) .........................................................................80Diagnostic Procedure 11 (Long stopping

distance) ....................................................................80

Diagnostic Procedure 12 (Unexpected pedal

action) ........................................................................81

Diagnostic Procedure 13 ...........................................82

Diagnostic Procedure 14 ...........................................82

Electrical Components Inspection .............................83

SERVICE DATA AND SPECIFICATIONS (SDS)..........84

General Specifications ...............................................84

Inspection and Adjustment ........................................85

CONTENTS(Cont'd)

BR-2

Page 205 of 1767

Supplement Restraint System (SRS) ªAIR BAGº

and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt, help

to reduce the risk or severity or injury to the driver and front passenger in a collision. The Supplemental

Restraint System consists of an air bag module (located in the center of the steering wheel and on the instru-

ment panel on the passenger side, where fitted), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

BT sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation), all maintenance must be per-

formed by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT-TENSIONERº connector) can be iden-

tified with yellow harness connector and with yellow harness protector or yellow insulation tape

before the harness connectors.

Precautions

IUse only ªDOT 4º fluid from a sealed container.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

ITo clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

INever use mineral oils such as Petrol or kerosene. They

will ruin rubber parts of hydraulic system.

IUse flare nut wrench when removing and installing brake

tubes.

IAlways torque brake lines when installing.

IBurnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low speed. Refer to ªBrake

Burnishing Procedureº, ªCheck and Adjustmentº, BR-5.

WARNING:

IClean brakes with a vacuum dust collector to minimize risk

of health hazard from airborne materials.

IAvoid prolonged and repeated skin contact with brake

fluid.

IWear protective clothing, including impervious gloves.

IWhere there is a risk of eye contact, eye protection should

be worn Ð for example chemical goggles or face shield.

YBR293

PRECAUTIONS AND PREPARATION

BR-3

Page 206 of 1767

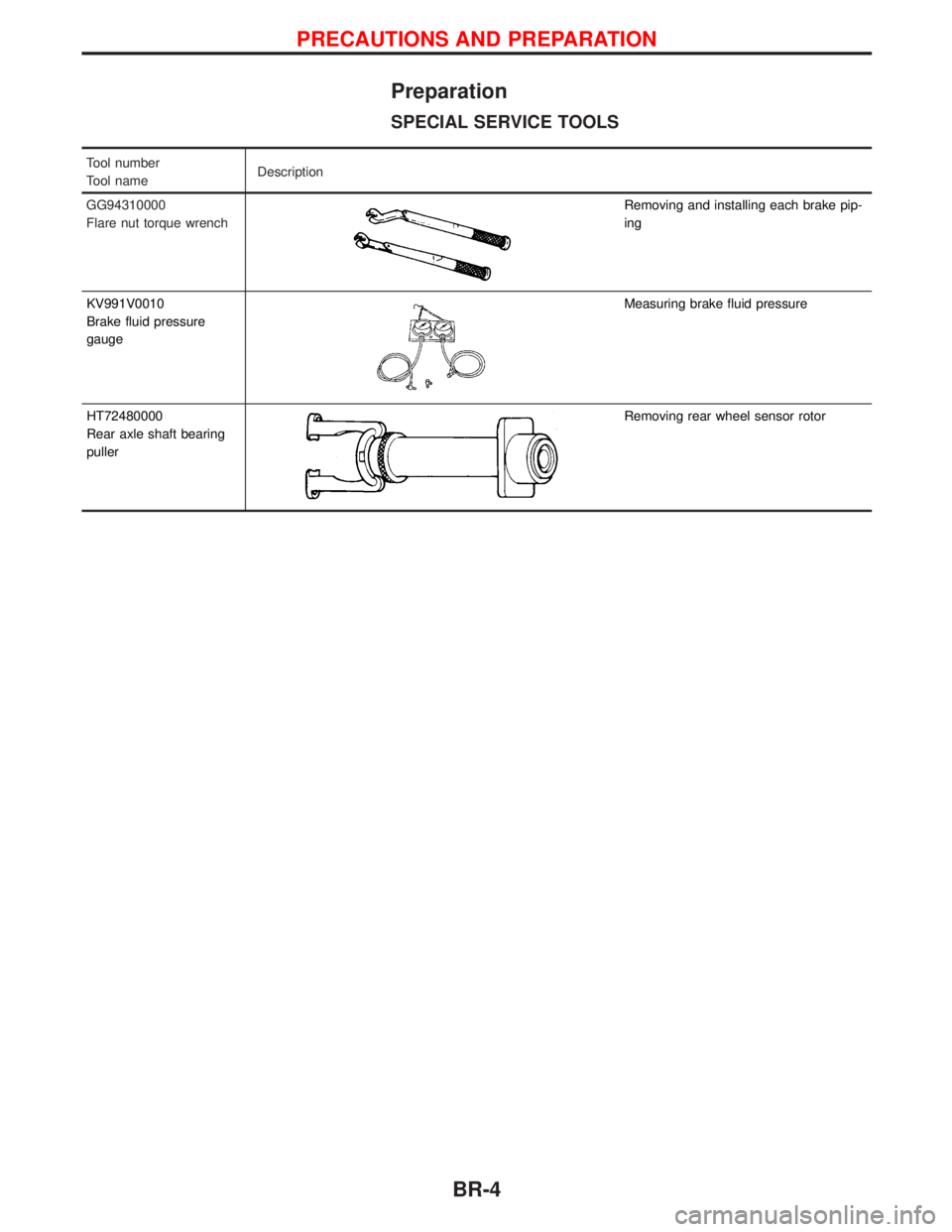

Preparation

SPECIAL SERVICE TOOLS

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

Removing and installing each brake pip-

ing

KV991V0010

Brake fluid pressure

gauge

Measuring brake fluid pressure

HT72480000

Rear axle shaft bearing

puller

Removing rear wheel sensor rotor

PRECAUTIONS AND PREPARATION

BR-4

Page 214 of 1767

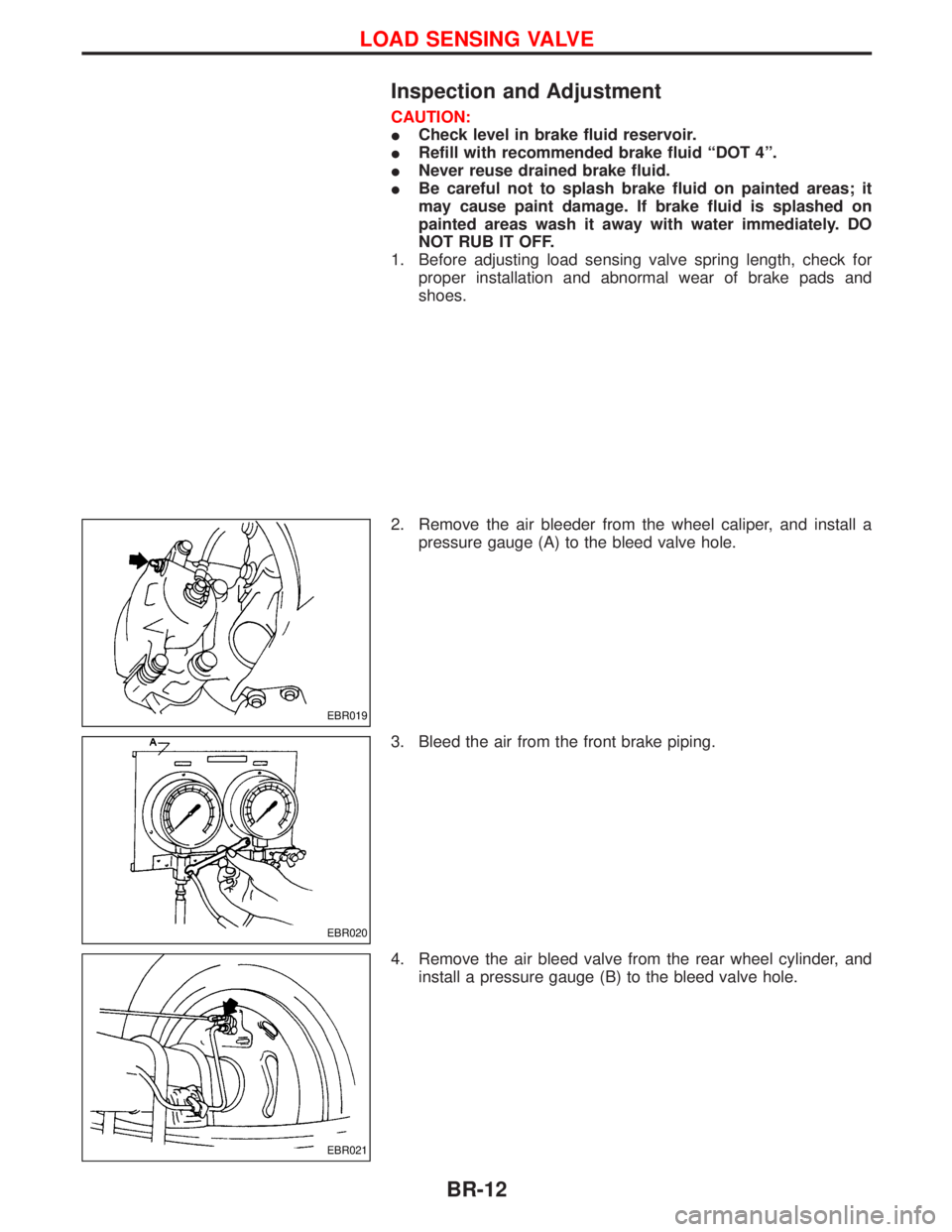

Inspection and Adjustment

CAUTION:

ICheck level in brake fluid reservoir.

IRefill with recommended brake fluid ªDOT 4º.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas wash it away with water immediately. DO

NOT RUB IT OFF.

1. Before adjusting load sensing valve spring length, check for

proper installation and abnormal wear of brake pads and

shoes.

2. Remove the air bleeder from the wheel caliper, and install a

pressure gauge (A) to the bleed valve hole.

3. Bleed the air from the front brake piping.

4. Remove the air bleed valve from the rear wheel cylinder, and

install a pressure gauge (B) to the bleed valve hole.

EBR019

EBR020

EBR021

LOAD SENSING VALVE

BR-12

Page 229 of 1767

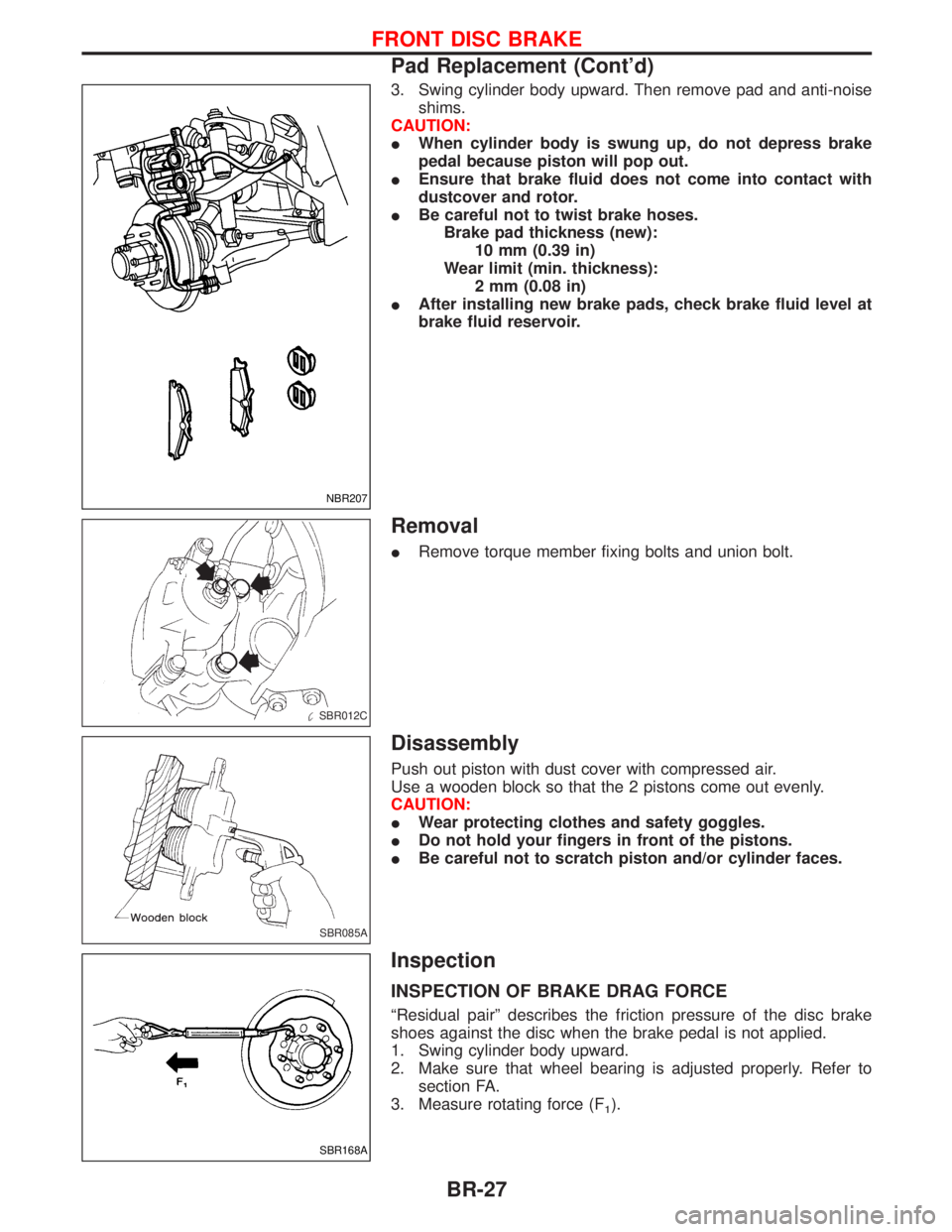

3. Swing cylinder body upward. Then remove pad and anti-noise

shims.

CAUTION:

IWhen cylinder body is swung up, do not depress brake

pedal because piston will pop out.

IEnsure that brake fluid does not come into contact with

dustcover and rotor.

IBe careful not to twist brake hoses.

Brake pad thickness (new):

10 mm (0.39 in)

Wear limit (min. thickness):

2 mm (0.08 in)

IAfter installing new brake pads, check brake fluid level at

brake fluid reservoir.

Removal

IRemove torque member fixing bolts and union bolt.

Disassembly

Push out piston with dust cover with compressed air.

Use a wooden block so that the 2 pistons come out evenly.

CAUTION:

IWear protecting clothes and safety goggles.

IDo not hold your fingers in front of the pistons.

IBe careful not to scratch piston and/or cylinder faces.

Inspection

INSPECTION OF BRAKE DRAG FORCE

ªResidual pairº describes the friction pressure of the disc brake

shoes against the disc when the brake pedal is not applied.

1. Swing cylinder body upward.

2. Make sure that wheel bearing is adjusted properly. Refer to

section FA.

3. Measure rotating force (F

1).

NBR207

SBR012C

SBR085A

SBR168A

FRONT DISC BRAKE

Pad Replacement (Cont'd)

BR-27

Page 230 of 1767

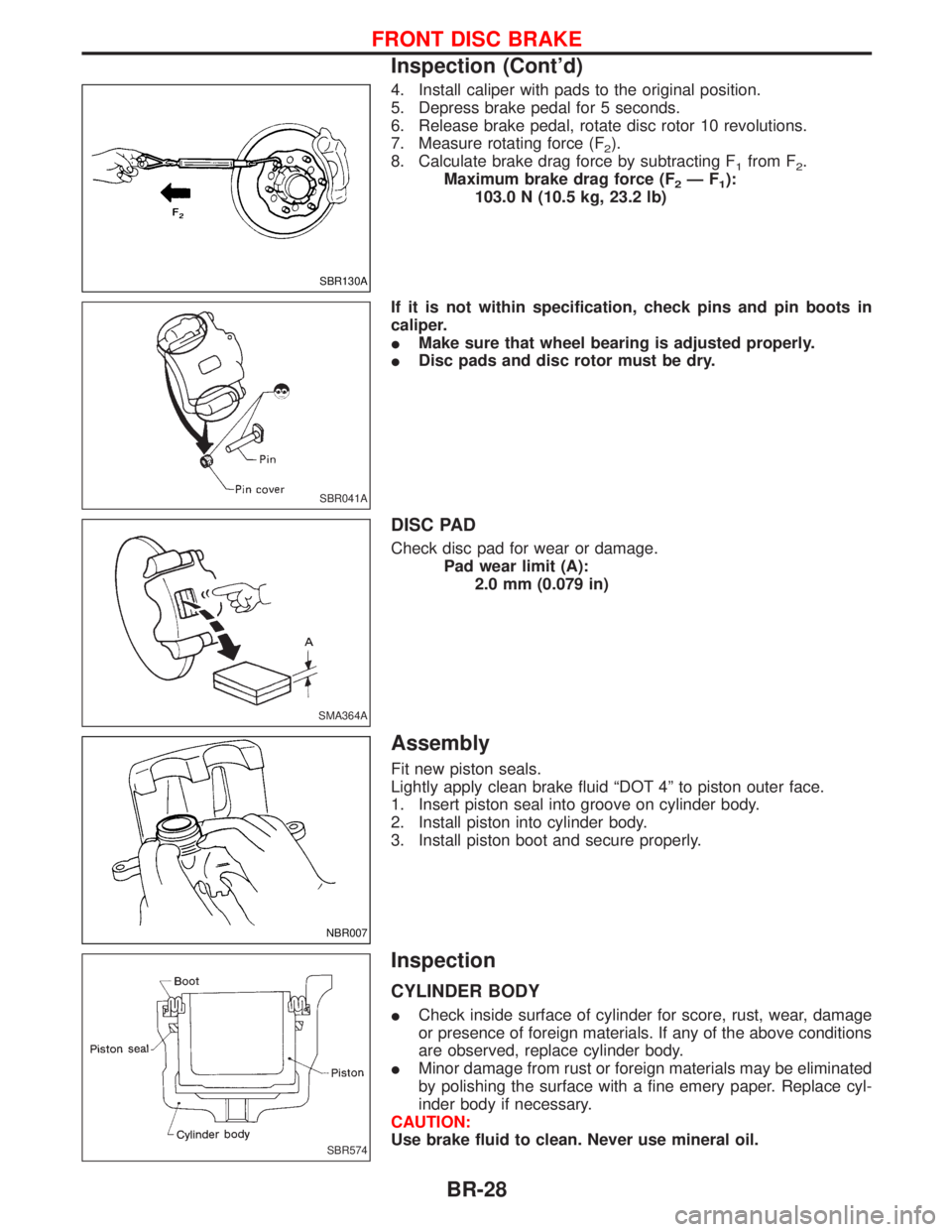

4. Install caliper with pads to the original position.

5. Depress brake pedal for 5 seconds.

6. Release brake pedal, rotate disc rotor 10 revolutions.

7. Measure rotating force (F

2).

8. Calculate brake drag force by subtracting F

1from F2.

Maximum brake drag force (F

2ÐF1):

103.0 N (10.5 kg, 23.2 lb)

If it is not within specification, check pins and pin boots in

caliper.

IMake sure that wheel bearing is adjusted properly.

IDisc pads and disc rotor must be dry.

DISC PAD

Check disc pad for wear or damage.

Pad wear limit (A):

2.0 mm (0.079 in)

Assembly

Fit new piston seals.

Lightly apply clean brake fluid ªDOT 4º to piston outer face.

1. Insert piston seal into groove on cylinder body.

2. Install piston into cylinder body.

3. Install piston boot and secure properly.

Inspection

CYLINDER BODY

ICheck inside surface of cylinder for score, rust, wear, damage

or presence of foreign materials. If any of the above conditions

are observed, replace cylinder body.

IMinor damage from rust or foreign materials may be eliminated

by polishing the surface with a fine emery paper. Replace cyl-

inder body if necessary.

CAUTION:

Use brake fluid to clean. Never use mineral oil.

SBR130A

SBR041A

SMA364A

NBR007

SBR574

FRONT DISC BRAKE

Inspection (Cont'd)

BR-28