ABS NISSAN TERRANO 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 268 of 1767

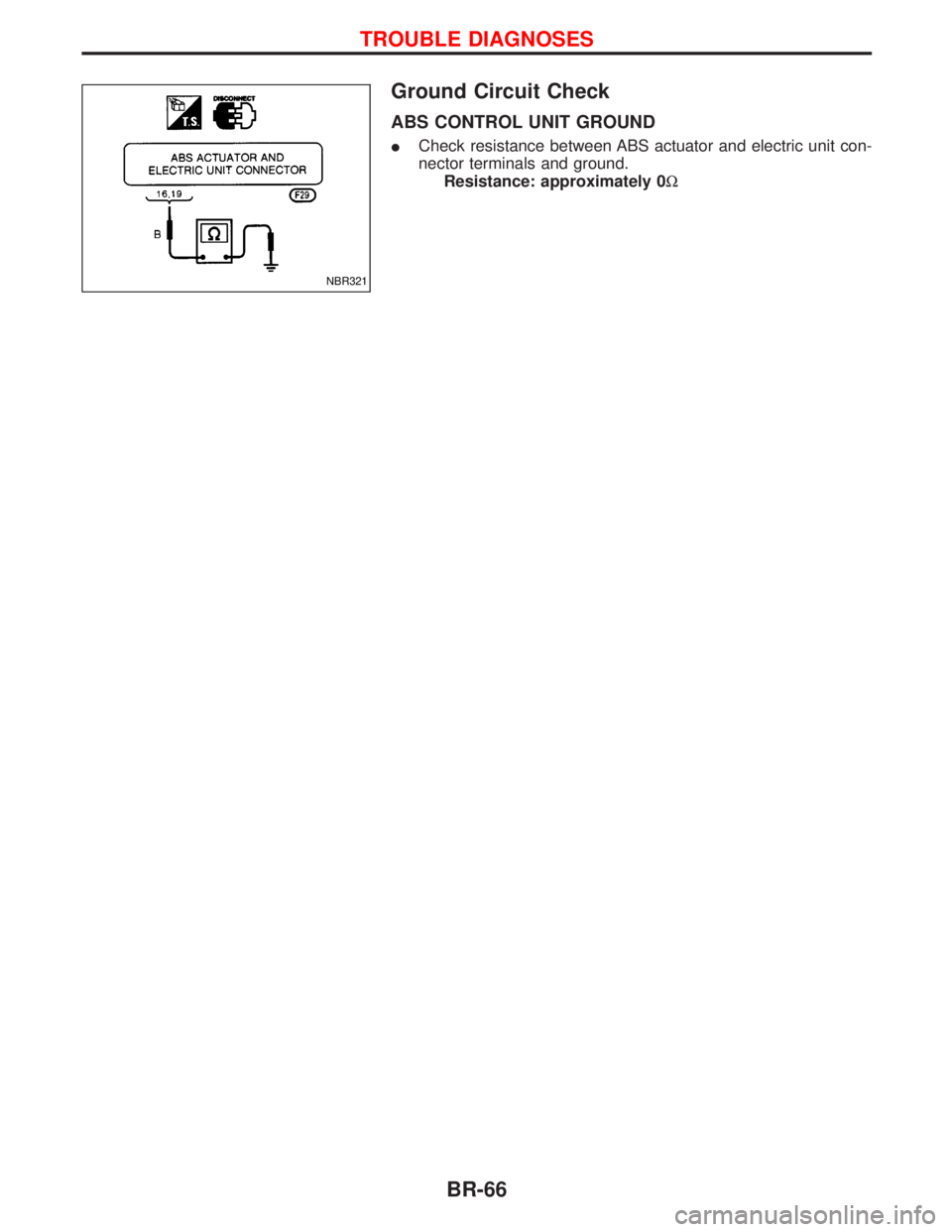

Ground Circuit Check

ABS CONTROL UNIT GROUND

ICheck resistance between ABS actuator and electric unit con-

nector terminals and ground.

Resistance: approximately 0W

NBR321

TROUBLE DIAGNOSES

BR-66

Page 269 of 1767

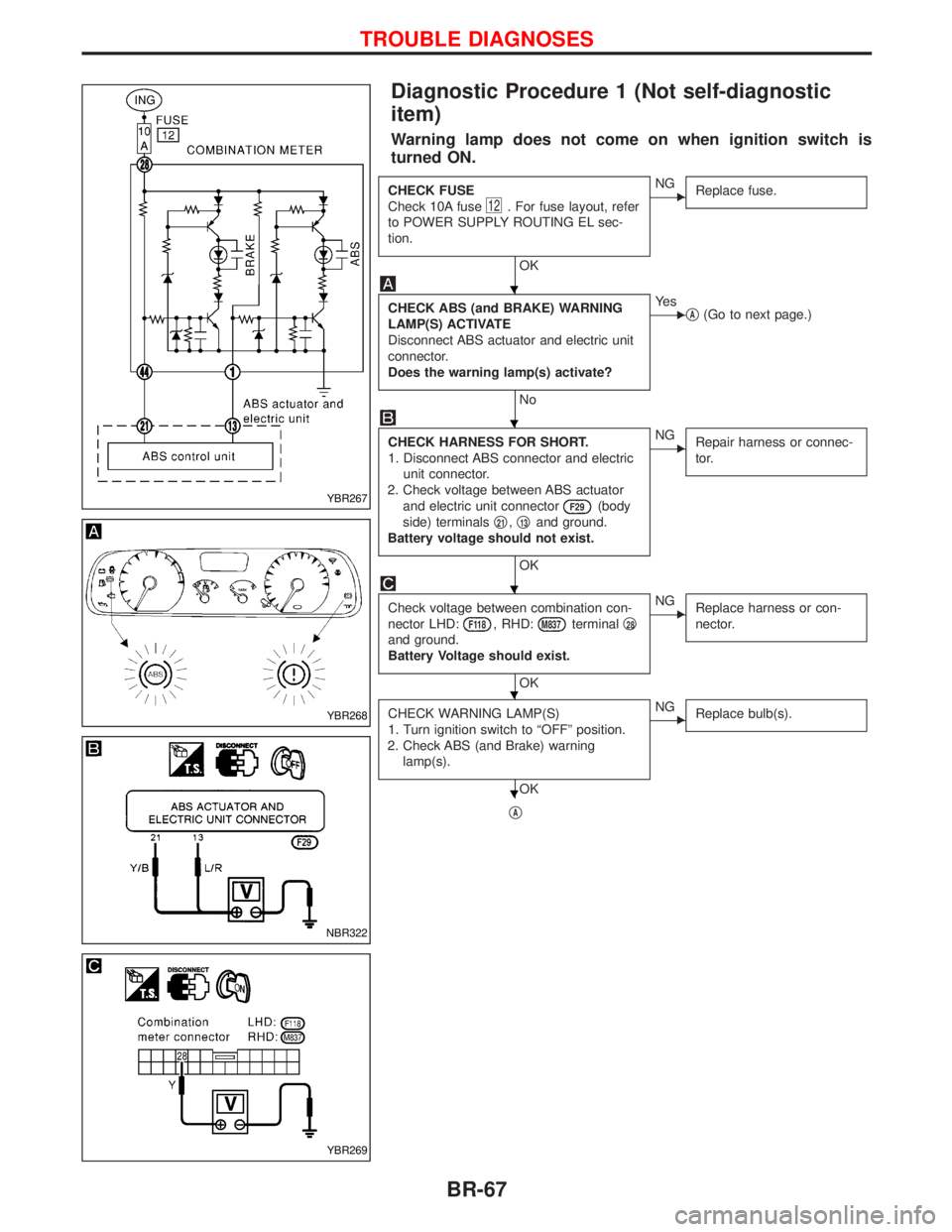

Diagnostic Procedure 1 (Not self-diagnostic

item)

Warning lamp does not come on when ignition switch is

turned ON.

CHECK FUSE

Check 10A fuse

12. For fuse layout, refer

to POWER SUPPLY ROUTING EL sec-

tion.

OK

ENG

Replace fuse.

CHECK ABS (and BRAKE) WARNING

LAMP(S) ACTIVATE

Disconnect ABS actuator and electric unit

connector.

Does the warning lamp(s) activate?

No

EYe s

qA(Go to next page.)

CHECK HARNESS FOR SHORT.

1. Disconnect ABS connector and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29(body

side) terminalsq

21,q13and ground.

Battery voltage should not exist.

OK

ENG

Repair harness or connec-

tor.

Check voltage between combination con-

nector LHD:

F118, RHD:M837terminalq28

and ground.

Battery Voltage should exist.

OK

ENG

Replace harness or con-

nector.

CHECK WARNING LAMP(S)

1. Turn ignition switch to ªOFFº position.

2. Check ABS (and Brake) warning

lamp(s).

OK

ENG

Replace bulb(s).

qA

YBR267

YBR268

NBR322

YBR269

H

H

H

H

H

TROUBLE DIAGNOSES

BR-67

Page 270 of 1767

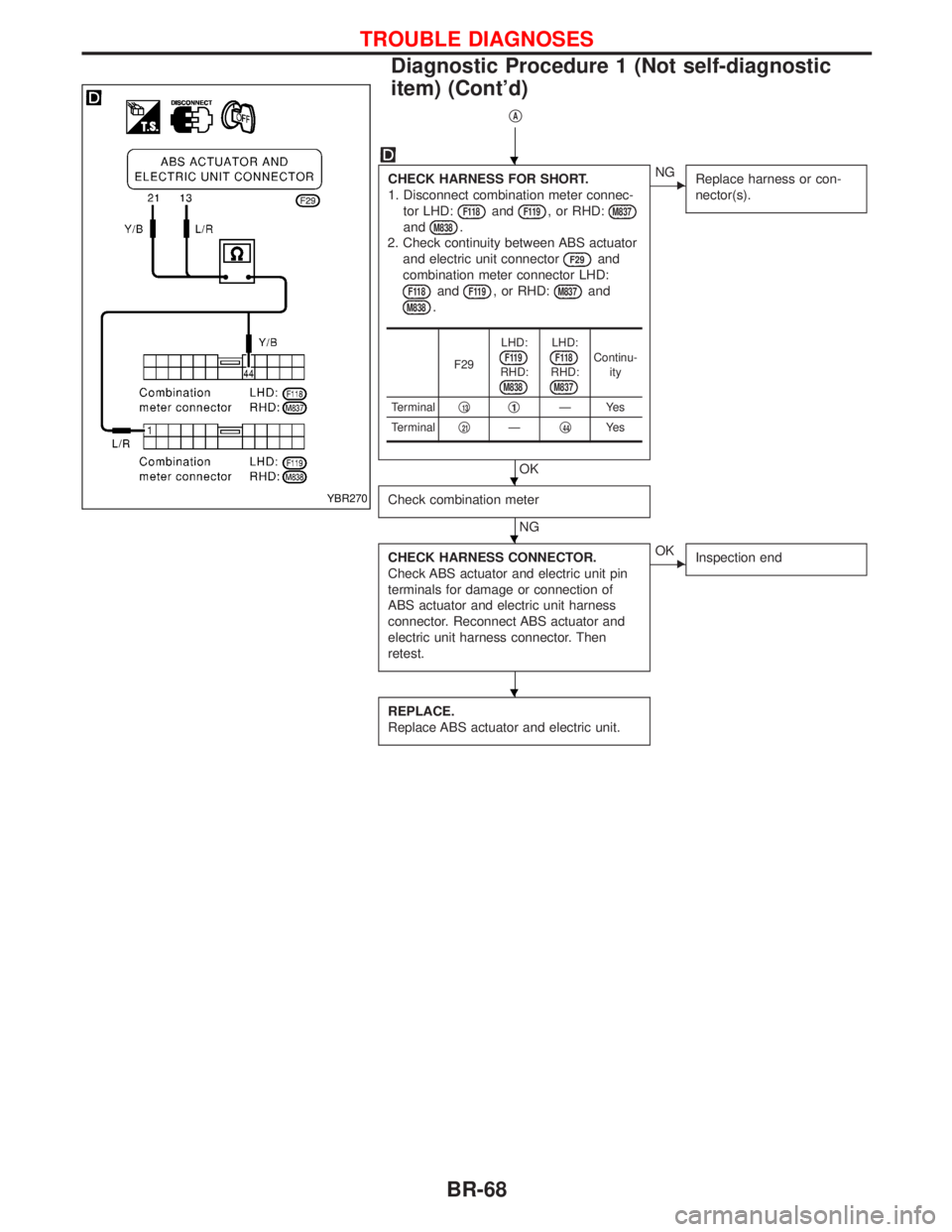

qA

CHECK HARNESS FOR SHORT.

1. Disconnect combination meter connec-

tor LHD:

F118andF119, or RHD:M837

andM838.

2. Check continuity between ABS actuator

and electric unit connector

F29and

combination meter connector LHD:

F118andF119, or RHD:M837and

M838.

OK

ENG

Replace harness or con-

nector(s).

Check combination meter

NG

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

EOK

Inspection end

REPLACE.

Replace ABS actuator and electric unit.

F29LHD:F119RHD:M838

LHD:F118RHD:M837

Continu-

ity

Terminalq

13q1ÐYes

Terminalq

21Ðq44Ye s

YBR270

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 1 (Not self-diagnostic

item) (Cont'd)

BR-68

Page 271 of 1767

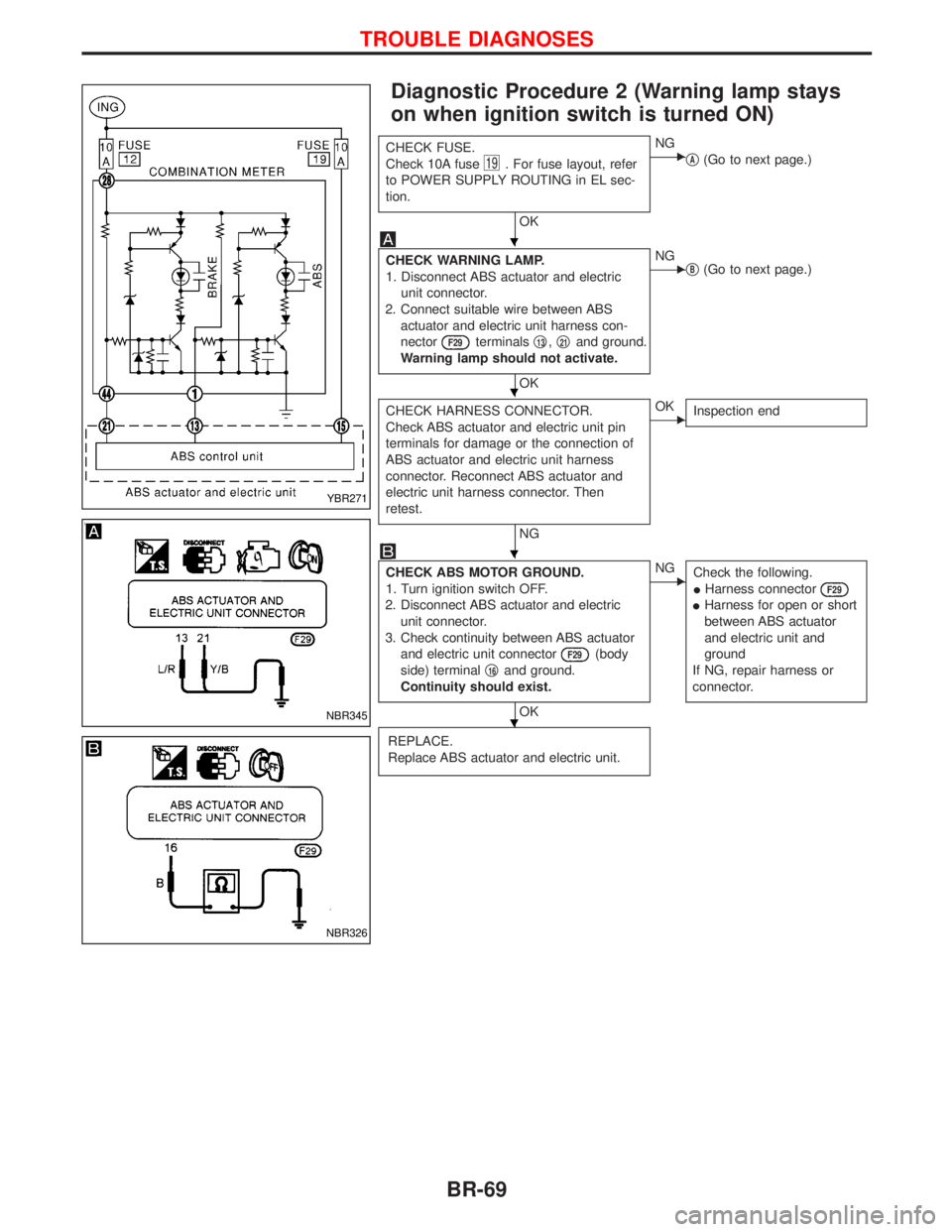

Diagnostic Procedure 2 (Warning lamp stays

on when ignition switch is turned ON)

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG

qA(Go to next page.)

CHECK WARNING LAMP.

1. Disconnect ABS actuator and electric

unit connector.

2. Connect suitable wire between ABS

actuator and electric unit harness con-

nector

F29terminalsq13,q21and ground.

Warning lamp should not activate.

OK

ENG

qB(Go to next page.)

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

NG

EOK

Inspection end

CHECK ABS MOTOR GROUND.

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and electric

unit connector.

3. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalq

16and ground.

Continuity should exist.

OK

ENG

Check the following.

IHarness connector

F29

IHarness for open or short

between ABS actuator

and electric unit and

ground

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

YBR271

NBR345

NBR326

H

H

H

H

TROUBLE DIAGNOSES

BR-69

Page 272 of 1767

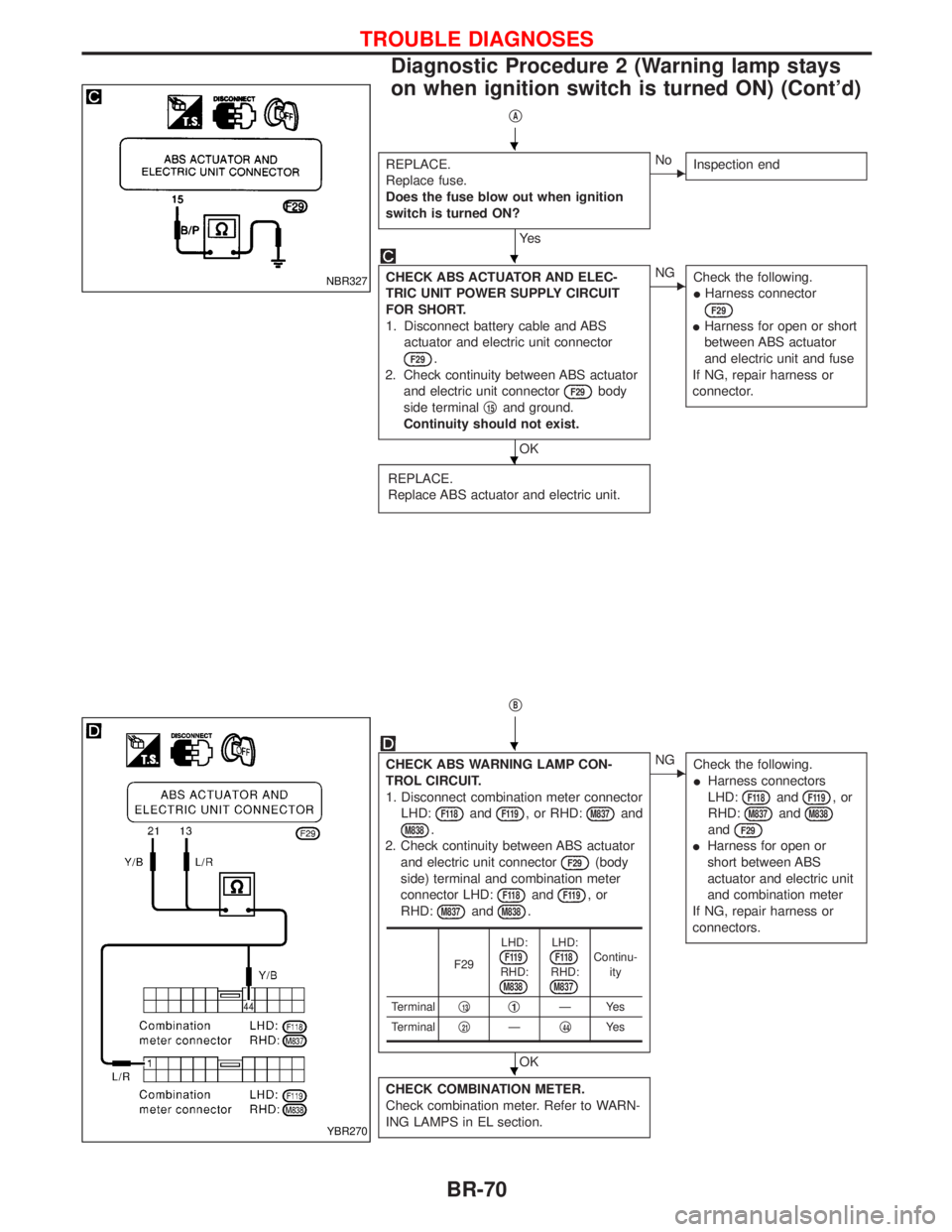

qA

REPLACE.

Replace fuse.

Does the fuse blow out when ignition

switch is turned ON?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT POWER SUPPLY CIRCUIT

FOR SHORT.

1. Disconnect battery cable and ABS

actuator and electric unit connector

F29.

2. Check continuity between ABS actuator

and electric unit connector

F29body

side terminalq

15and ground.

Continuity should not exist.

OK

ENG

Check the following.

IHarness connector

F29

IHarness for open or short

between ABS actuator

and electric unit and fuse

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

qB

CHECK ABS WARNING LAMP CON-

TROL CIRCUIT.

1. Disconnect combination meter connector

LHD:

F118andF119, or RHD:M837and

M838.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminal and combination meter

connector LHD:

F118andF119,or

RHD:

M837andM838.

OK

ENG

Check the following.

IHarness connectors

LHD:

F118andF119,or

RHD:

M837andM838

andF29

IHarness for open or

short between ABS

actuator and electric unit

and combination meter

If NG, repair harness or

connectors.

CHECK COMBINATION METER.

Check combination meter. Refer to WARN-

ING LAMPS in EL section.

F29LHD:F119RHD:M838

LHD:F118RHD:M837

Continu-

ity

Terminalq

13q1ÐYes

Terminalq

21Ðq44Ye s

NBR327

YBR270

H

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Warning lamp stays

on when ignition switch is turned ON) (Cont'd)

BR-70

Page 273 of 1767

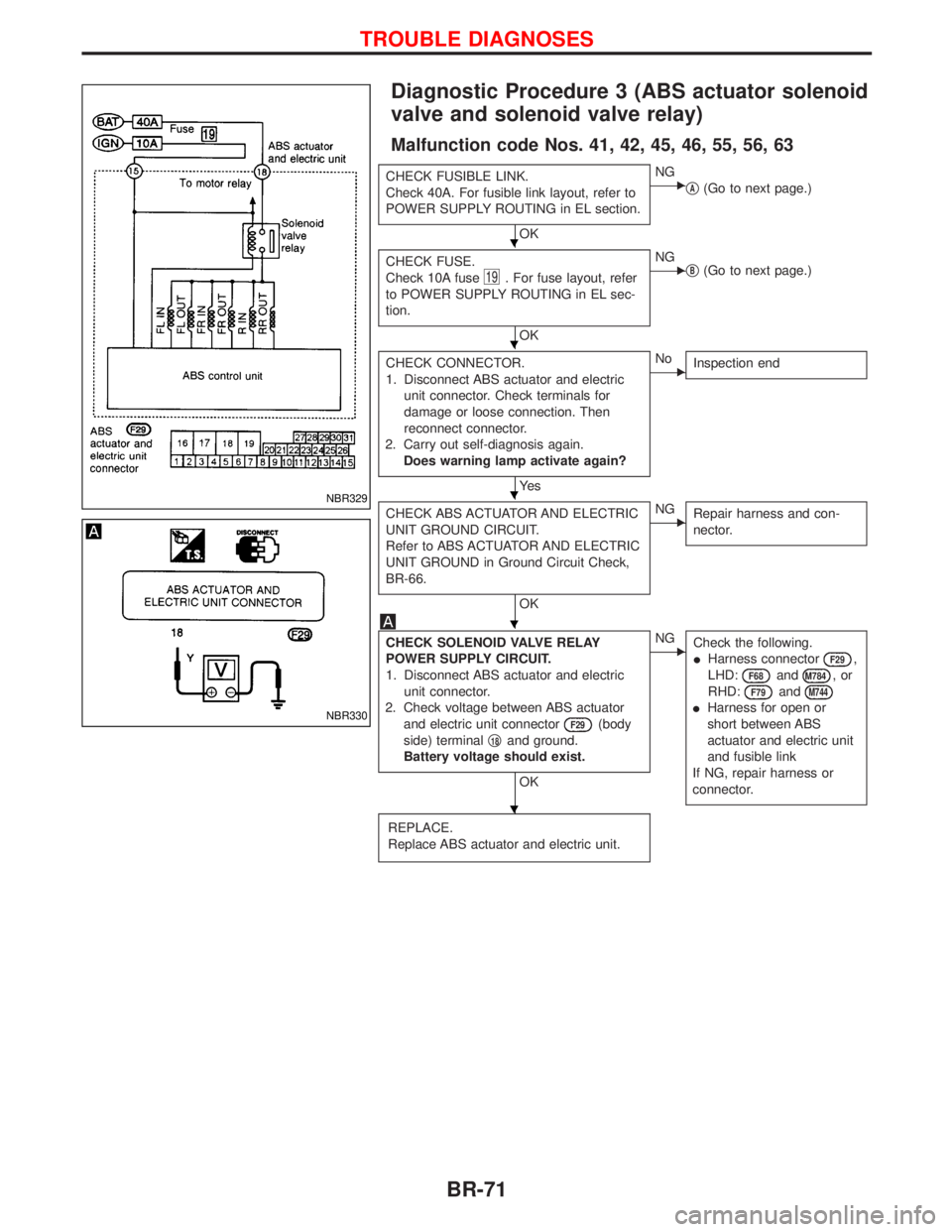

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay)

Malfunction code Nos. 41, 42, 45, 46, 55, 56, 63

CHECK FUSIBLE LINK.

Check 40A. For fusible link layout, refer to

POWER SUPPLY ROUTING in EL section.

OK

ENG

qA(Go to next page.)

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG

qB(Go to next page.)

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR AND ELECTRIC

UNIT GROUND CIRCUIT.

Refer to ABS ACTUATOR AND ELECTRIC

UNIT GROUND in Ground Circuit Check,

BR-66.

OK

ENG

Repair harness and con-

nector.

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29(body

side) terminalq

18and ground.

Battery voltage should exist.

OK

ENG

Check the following.

IHarness connector

F29,

LHD:

F68andM784,or

RHD:

F79andM744

IHarness for open or

short between ABS

actuator and electric unit

and fusible link

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

NBR329

NBR330

H

H

H

H

H

TROUBLE DIAGNOSES

BR-71

Page 274 of 1767

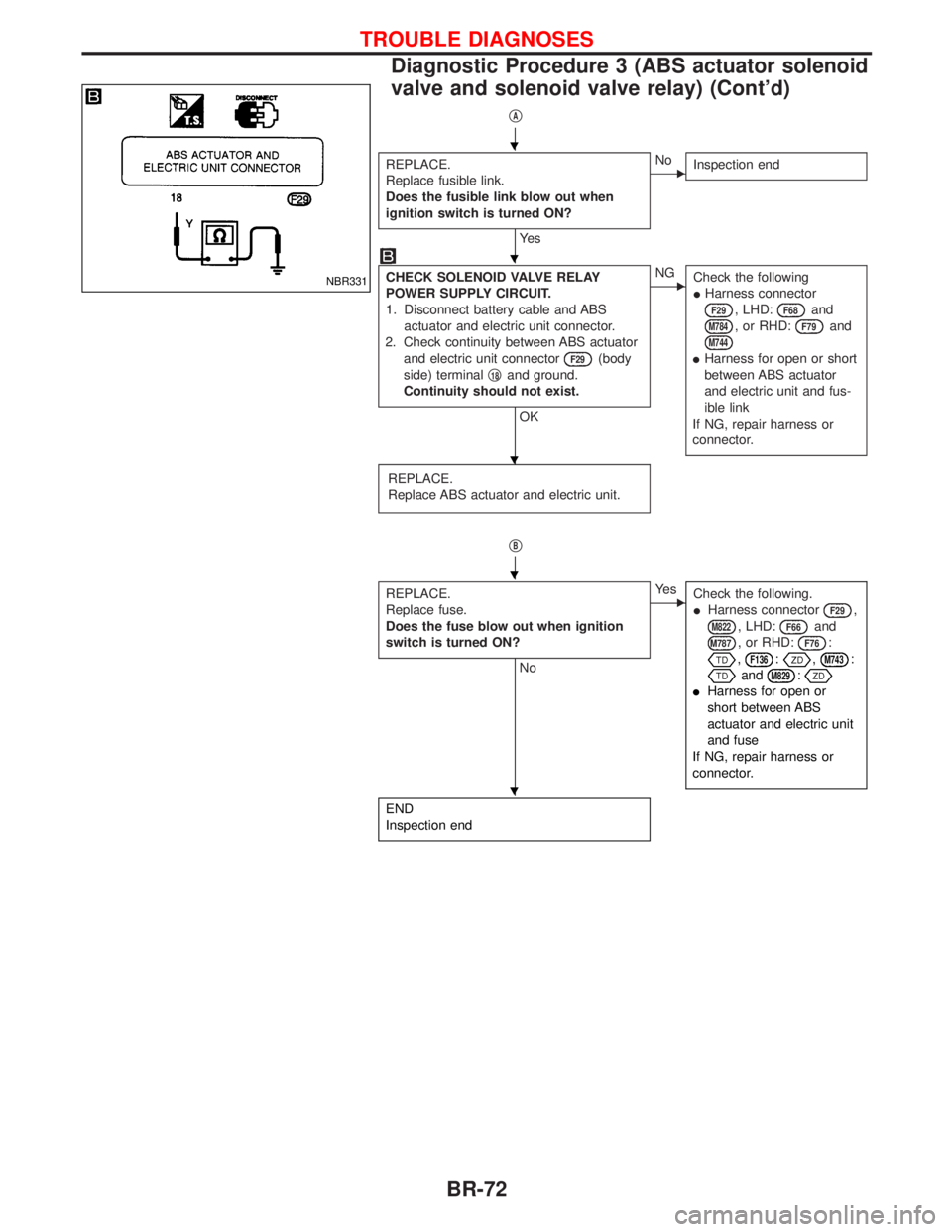

qA

REPLACE.

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ON?

Ye s

ENo

Inspection end

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

1. Disconnect battery cable and ABS

actuator and electric unit connector.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalq

18and ground.

Continuity should not exist.

OK

ENG

Check the following

IHarness connector

F29, LHD:F68and

M784, or RHD:F79and

M744

IHarness for open or short

between ABS actuator

and electric unit and fus-

ible link

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

qB

REPLACE.

Replace fuse.

Does the fuse blow out when ignition

switch is turned ON?

No

EYe s

Check the following.

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

END

Inspection end

NBR331

H

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) (Cont'd)

BR-72

Page 275 of 1767

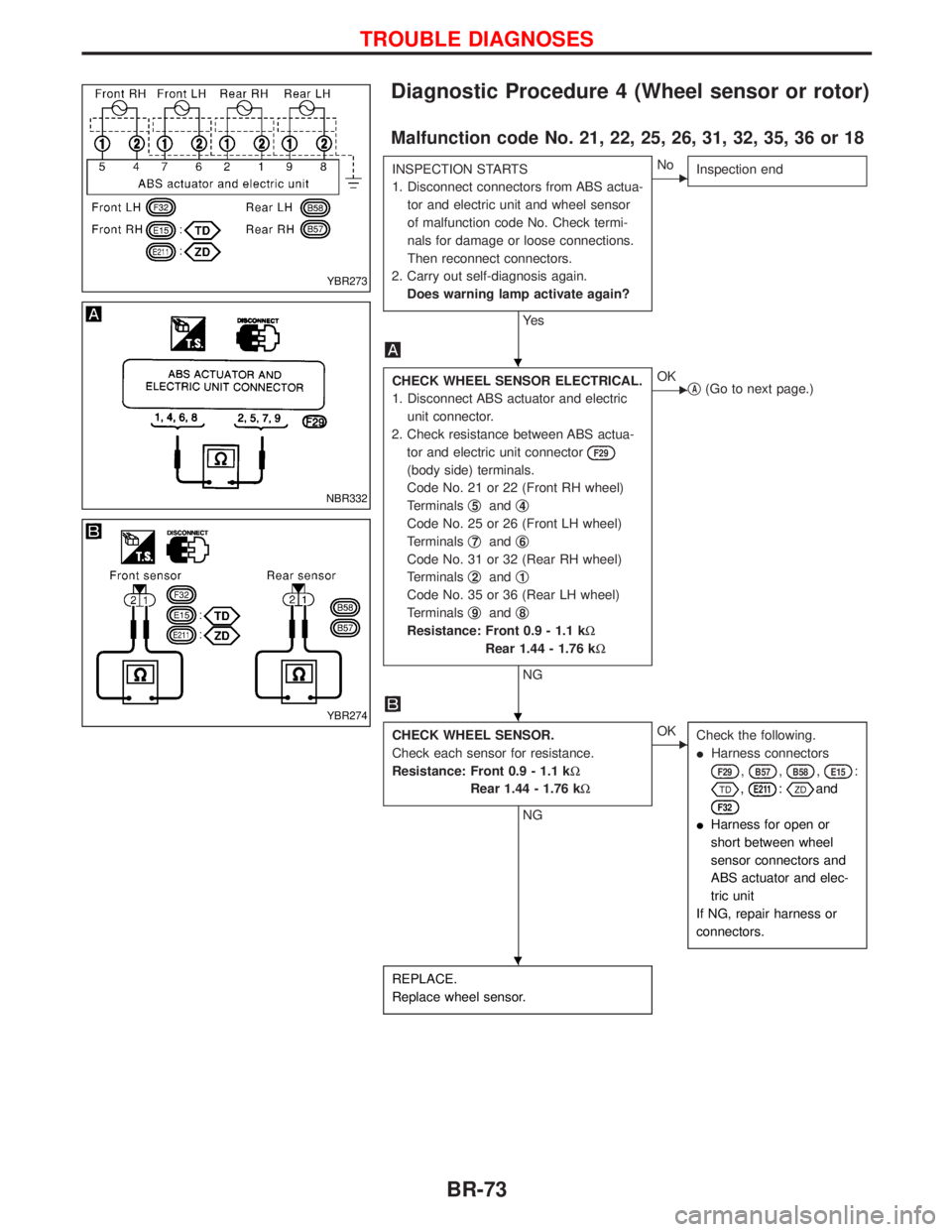

Diagnostic Procedure 4 (Wheel sensor or rotor)

Malfunction code No. 21, 22, 25, 26, 31, 32, 35, 36 or 18

INSPECTION STARTS

1. Disconnect connectors from ABS actua-

tor and electric unit and wheel sensor

of malfunction code No. Check termi-

nals for damage or loose connections.

Then reconnect connectors.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK WHEEL SENSOR ELECTRICAL.

1. Disconnect ABS actuator and electric

unit connector.

2. Check resistance between ABS actua-

tor and electric unit connector

F29

(body side) terminals.

Code No. 21 or 22 (Front RH wheel)

Terminalsq

5andq4

Code No. 25 or 26 (Front LH wheel)

Terminalsq

7andq6

Code No. 31 or 32 (Rear RH wheel)

Terminalsq

2andq1

Code No. 35 or 36 (Rear LH wheel)

Terminalsq

9andq8

Resistance: Front 0.9 - 1.1 kW

Rear 1.44 - 1.76 kW

NG

EOK

qA(Go to next page.)

CHECK WHEEL SENSOR.

Check each sensor for resistance.

Resistance: Front 0.9 - 1.1 kW

Rear 1.44 - 1.76 kW

NG

EOK

Check the following.

IHarness connectors

F29,B57,B58,E15:

,E211:and

F32

IHarness for open or

short between wheel

sensor connectors and

ABS actuator and elec-

tric unit

If NG, repair harness or

connectors.

REPLACE.

Replace wheel sensor.

YBR273

NBR332

YBR274

H

H

H

TROUBLE DIAGNOSES

BR-73

Page 276 of 1767

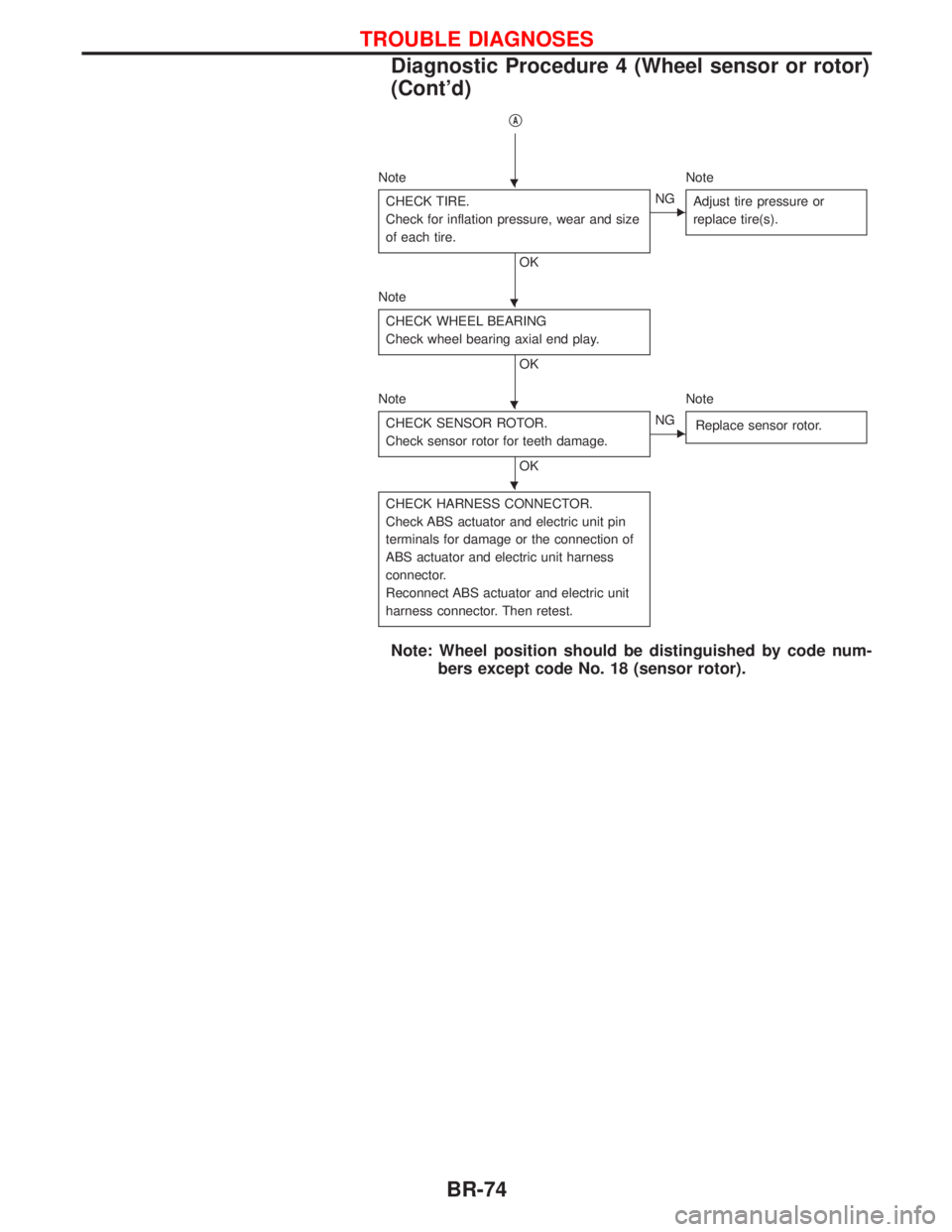

qA

Note Note

CHECK TIRE.

Check for inflation pressure, wear and size

of each tire.

OK

ENG

Adjust tire pressure or

replace tire(s).

Note

CHECK WHEEL BEARING

Check wheel bearing axial end play.

OK

Note Note

CHECK SENSOR ROTOR.

Check sensor rotor for teeth damage.

OK

ENG

Replace sensor rotor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

Note: Wheel position should be distinguished by code num-

bers except code No. 18 (sensor rotor).

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 4 (Wheel sensor or rotor)

(Cont'd)

BR-74

Page 277 of 1767

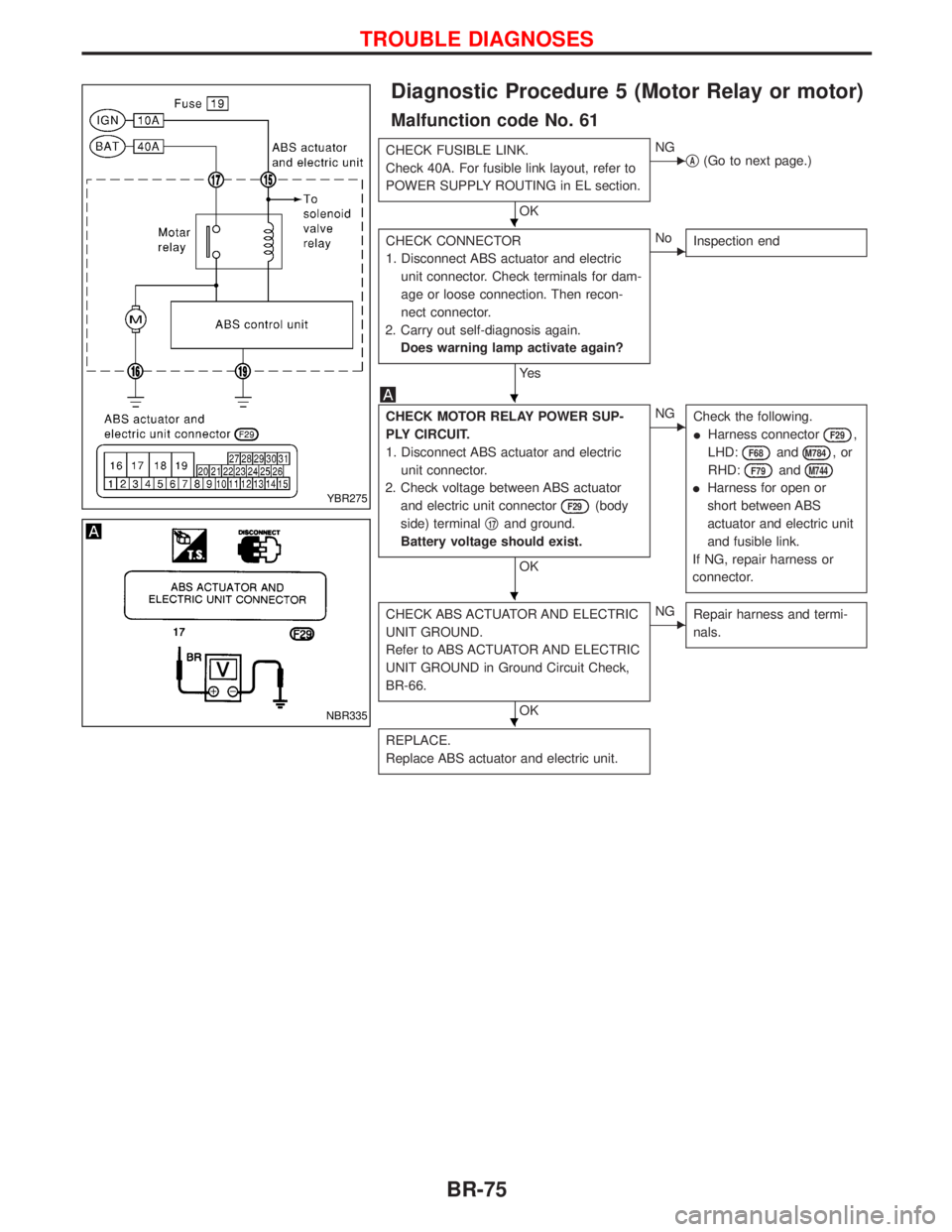

Diagnostic Procedure 5 (Motor Relay or motor)

Malfunction code No. 61

CHECK FUSIBLE LINK.

Check 40A. For fusible link layout, refer to

POWER SUPPLY ROUTING in EL section.

OK

ENG

qA(Go to next page.)

CHECK CONNECTOR

1. Disconnect ABS actuator and electric

unit connector. Check terminals for dam-

age or loose connection. Then recon-

nect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK MOTOR RELAY POWER SUP-

PLY CIRCUIT.

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29(body

side) terminalq

17and ground.

Battery voltage should exist.

OK

ENG

Check the following.

IHarness connector

F29,

LHD:

F68andM784,or

RHD:

F79andM744

IHarness for open or

short between ABS

actuator and electric unit

and fusible link.

If NG, repair harness or

connector.

CHECK ABS ACTUATOR AND ELECTRIC

UNIT GROUND.

Refer to ABS ACTUATOR AND ELECTRIC

UNIT GROUND in Ground Circuit Check,

BR-66.

OK

ENG

Repair harness and termi-

nals.

REPLACE.

Replace ABS actuator and electric unit.

YBR275

NBR335

H

H

H

H

TROUBLE DIAGNOSES

BR-75