ABS NISSAN TERRANO 2002 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1424 of 1767

TAIL/L - Wiring diagram ..................................EL-45

TCM circuit diagram ..........................................AT-7

TCM inspection table ......................................AT-46

TDC Pulse Signal .........................................EC-168

Temperature control cable and linkage

adjustment ..................................................HA-63

THEFT - Wiring diagram...............................EL-214

Theft warning system ...........EL-209, 210, 213, 230

Thermo control amp .................................HA-51, 61

Thermostat................................................LC-12, 31

Third (3rd) seat ...............................................BT-39

THLCNT - Wiring diagram ...........................EC-435

Three way catalyst precautions.........................GI-5

Throttle control solenoid valve .....................EC-435

Throttle position switch ...................................AT-60

Tie-rod .......................................................ST-19, 21

Tie-rod ball joints.............................................ST-20

Tightening torque of standard bolts.................GI-38

Time control system .....................EL-180, 182, 184

Timing chain ...................................................EM-26

Timing gear ....................................................EM-38

Tire rotation ....................................................MA-43

Tooth contact diff. .....................................PD-27, 52

Torque convertor clutch solenoid valve ..AT-72, 141

Torsion bar spring .......................................FA-4, 30

Tow truck towing ..............................................GI-33

Towing point.....................................................GI-34

Transaxle fluid replacement.....................MA-36, 37

Transfer case ..............................................TF-9, 12

Transfer fluid replacement (Part time

4WD model) .........................................MA-36, 37

Transfer oil replacement ..........................MA-36, 38

Transmission case (M/T)..........................MT-10, 14

TRANSMT - Wiring diagram ...........................EL-80

Tread-FR&RR (Dimensions)............................GI-25

Trim...............................................BT-18, 19, 20, 21

Trunk room trim...............................................BT-47

Turbocharger ..................................................EM-14

Turbocharger charge air cooler......................EM-11

Turbocharger precautions..................................GI-5

TURN - Wiring diagram ..................................EL-56

Turn signal lamp .......................................EL-55, 56

U

Under body .....................................................BT-53

Upper link (front susp.) ...................................FA-33

V

Vacuum hose (brake system) ........................BR-19Vacuum hose drawing (Engine

control)................................................EC-18, 304

Vacuum pump .............................EM-24, BR-23, 25

Valve clearance..............................................EM-35

Valve clearance adjustment.....................MA-20, 28

Valve guide ....................................................EM-59

Valve lifter ......................................................EM-32

Valve seat ......................................................EM-60

Valve spring ...................................................EM-61

Variable nozzle turbocharger control

solenoid valve ...........................................EC-281

Vehicle identification number...........................GI-29

Vehicle speed sensor (VSS) ..................EC-99, 397

Ventilator door control rod adjustment ...........HA-61

Viscosity number (SAE)...........................MA-17, 18

VNT - Wiring diagram ..................................EC-283

VSS - Wiring diagram ..................................EC-101

W

WARN - Wiring diagram ...........................EL-82, 93

Warning chime ..........................................EL-81, 93

Warning lamps ..........................................EL-81, 82

Washer, front ...................................................EL-94

Washer, rear....................................................EL-96

Water cock control rod adjustment ................HA-63

Water pump ..............................................LC-11, 29

Water temperature gauge ...............................EL-72

Weatherstrip - See Exterior ............................BT-21

Wheel alignment (front) ....................................FA-8

Wheel balance ...............................................MA-43

Wheel bearing (front axle) ................................FA-6

Wheel bearing (rear) ..................................RA-5, 16

Wheel hub (front) ........................................FA-4, 18

Wheel sensors (ABS)...............................BR-38, 42

Wheel size .......................................................GI-31

WINDOW - Wiring diagram ..........................EL-134

Window, back door .........................................BT-47

Window, door ..................................................BT-42

Window, rear side .....................................BT-42, 43

Window, side - See Rear side window ...........BT-43

Windshield.......................................................BT-42

WIP/R - Wiring diagram ..................................EL-96

WIPER - Wiring diagram ........................EL-94, 100

Wiper and washer.....................................EL-94, 98

Wiper, front......................................................EL-94

Wiper, rear ......................................................EL-96

Wiring Diagram (Cell code) list .....................EL-291

ALPHABETICAL INDEX

IDX-7

Page 1438 of 1767

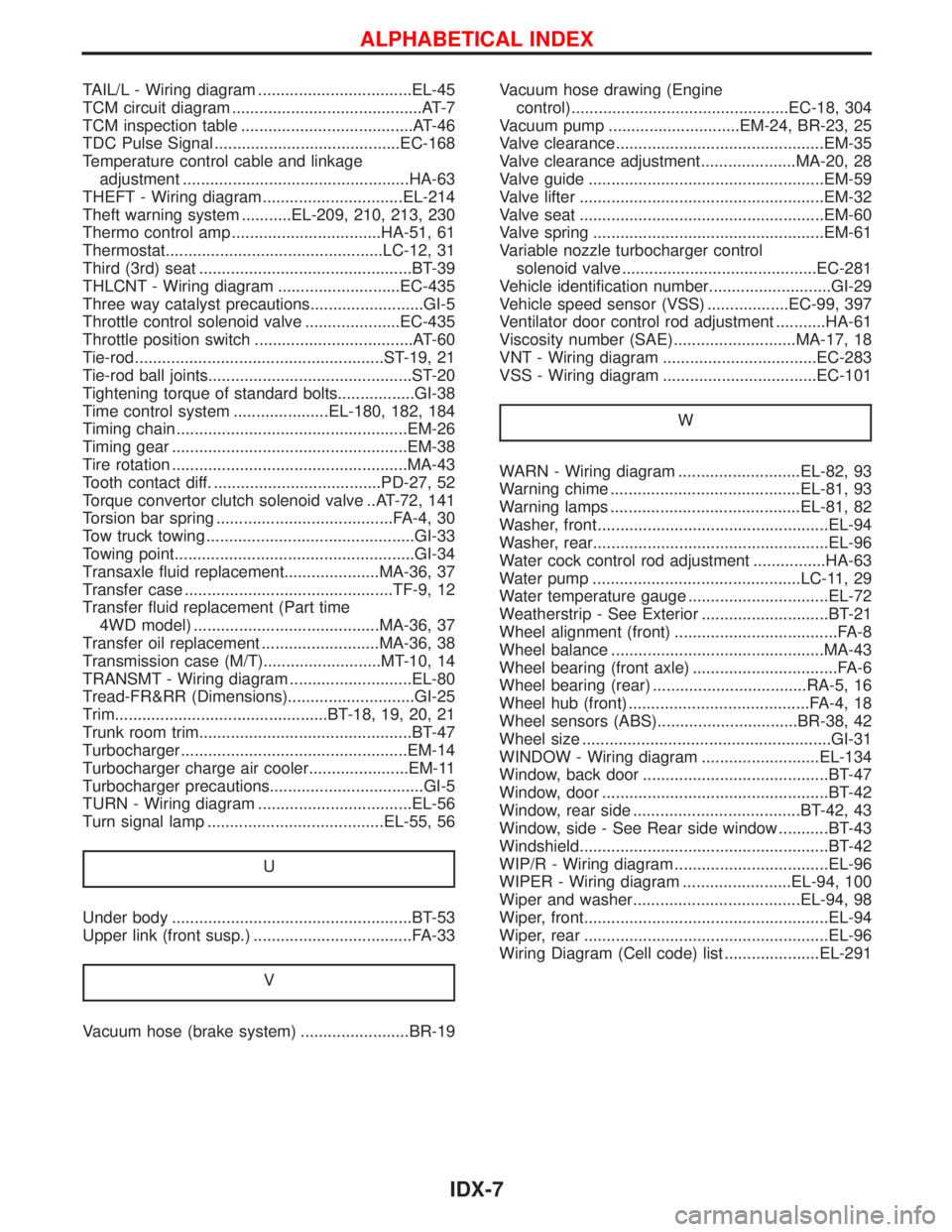

REMOVAL AND INSTALLATION

1. Drain engine coolant. Refer to MA section, ªChanging Engine

Coolantº.

2. Remove left side battery. (If so equipped)

3. Remove radiator upper hose.

4. Remove radiator shroud.

5. Remove intake air duct, inlet pipe.

6. Remove harness and connectors.

7. Install in reverse order of removal.

IAfter installation, run engine for a few minutes and check

for leaks.

IBe careful not to spill coolant in engine compartment. Use

a rag to absorb coolant.

INSPECTION

1. Check valve seating condition at ordinary temperatures. It

should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Valve opening temperature ÉC (ÉF) 82 (180)

Maximum valve lift mm/ÉC (in/ÉF) 10/95 (0.39/203)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

Water Outlet

INSPECTION

Visual inspection for water leaks. If there is leakage, replace gas-

ket.

JLC384B

SLC695A

YLC033

ENGINE COOLING SYSTEMZD

Thermostat (Cont'd)

LC-13

Page 1456 of 1767

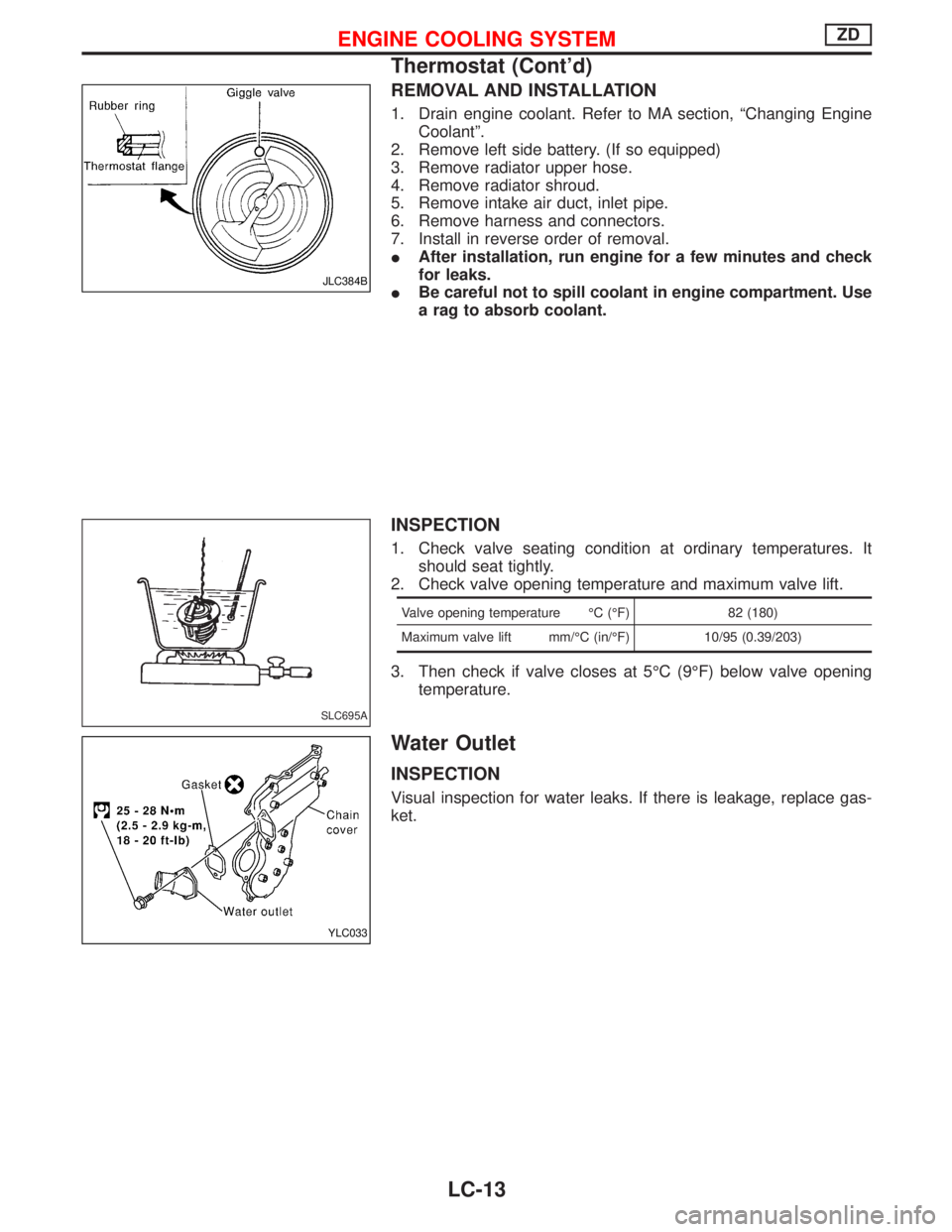

Thermostat

q1Water outlet

q

2Thermostat with jiggle valve

q

3Rubber sealq

4Water connector

q

5Thermostat housingq

6Engine coolant temperature sen-

sor

q

7Thermal transmitter

CAUTION:

IAfter installation, run engine for a few minutes, and check

for leaks.

IBe careful not to spill coolant over engine compartment.

Place a rag to absorb coolant.

INSPECTION

1. Check for valve seating condition at ordinary temperatures. It

should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Standard type Optional type

Valve opening temperature ÉC (ÉF) 82 (180) 88 (190)

Max. valve lift

mm/ÉC (in/ÉF)8/95

(0.315/203)8/100

(0.315/212)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

NLC059

SLC343

ENGINE COOLING SYSTEMTD27Ti

LC-31

Page 1482 of 1767

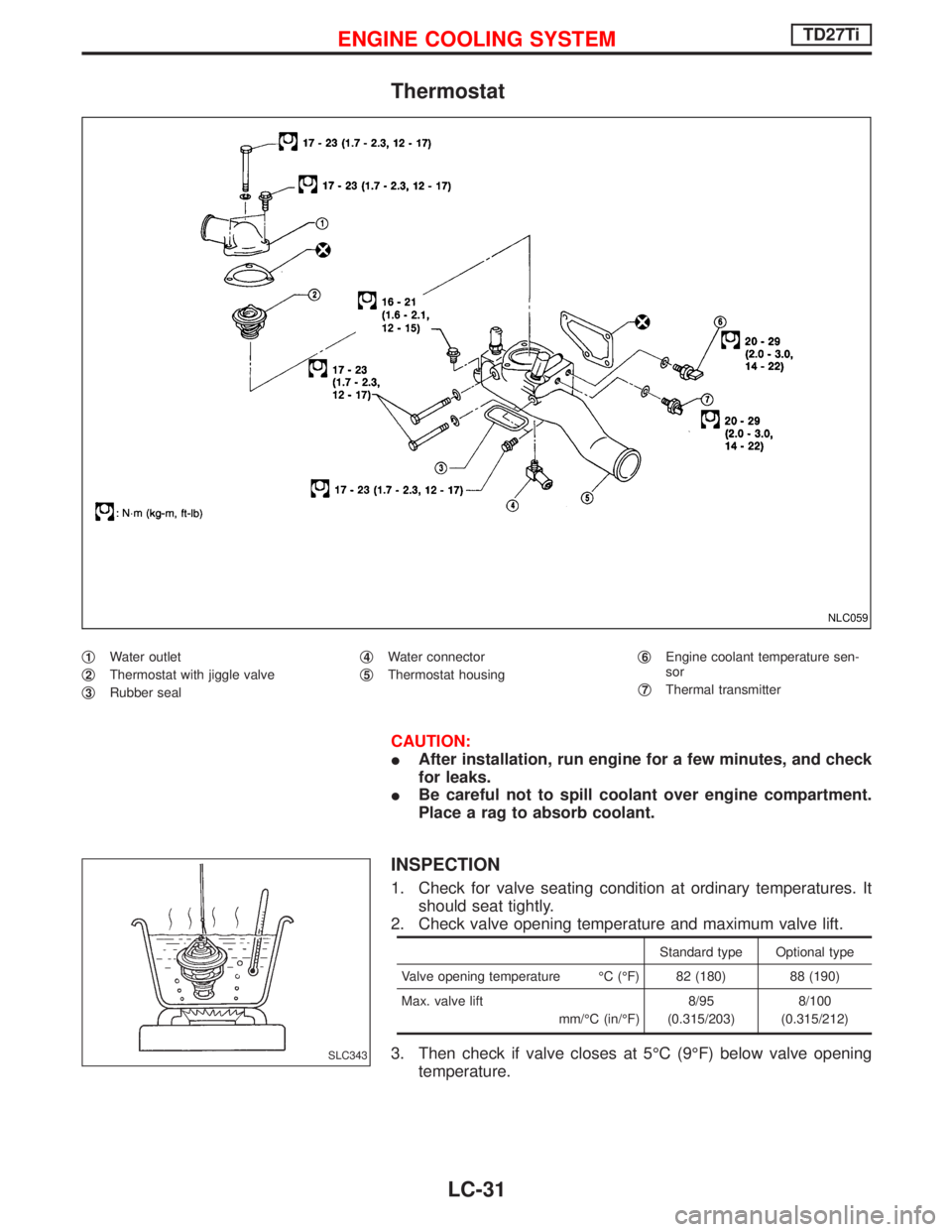

12. Fill reservoir tank up to ªMAXº level, and re-install radiator cap.

13. Run the engine at approximately 2,000 rpm for about one

minute.

14. Stop engine and cool it down, then refill the radiator and the

reservoir tank up to the specified level.

Checking Cooling System

CHECKING HOSES

Check hoses for proper attachment, leaks, cracks, damage, loose

connections, chafing and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see if it

is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 1.0 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to check

for leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Higher than the specified pressure may cause radiator dam-

age.

Checking and Replacing fuel filter and Draining

Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

REPLACING FUEL FILTER

1. Remove fuel filter sensor and drain fuel.

YMA008

SLC613

SMA990A

NMA009

ENGINE MAINTENANCETD

Changing Engine Coolant (Cont'd)

MA-23

Page 1492 of 1767

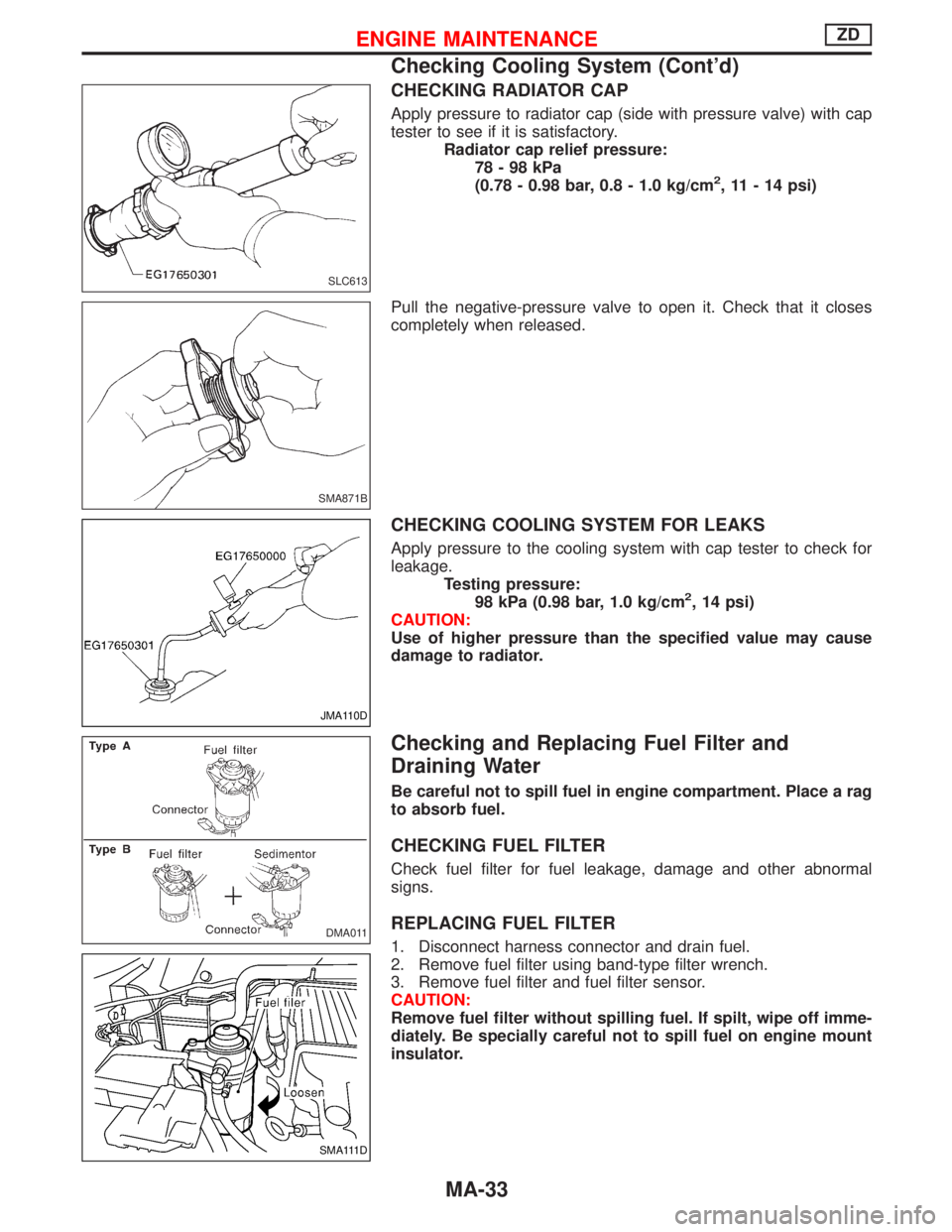

CHECKING RADIATOR CAP

Apply pressure to radiator cap (side with pressure valve) with cap

tester to see if it is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off imme-

diately. Be specially careful not to spill fuel on engine mount

insulator.

SLC613

SMA871B

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-33

Page 1566 of 1767

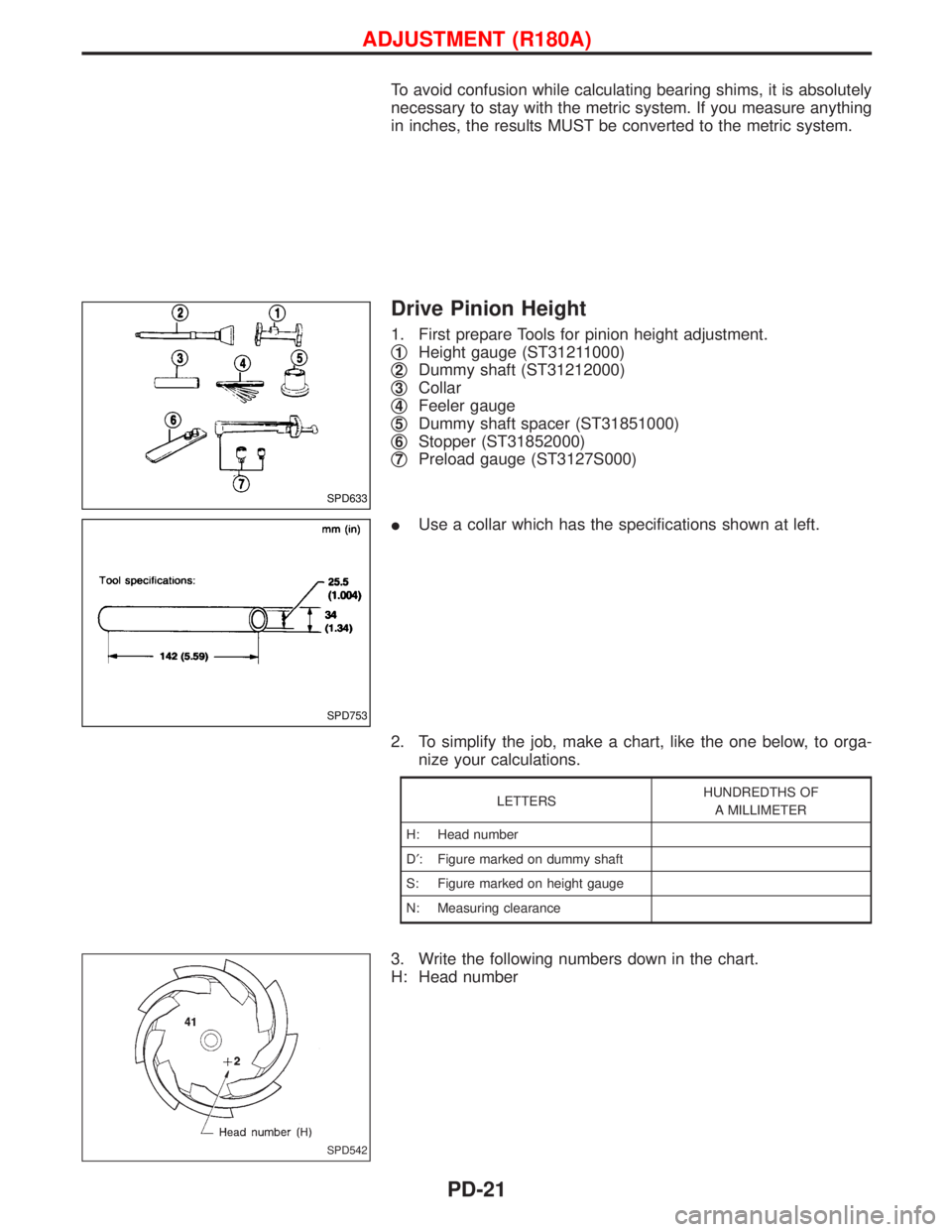

To avoid confusion while calculating bearing shims, it is absolutely

necessary to stay with the metric system. If you measure anything

in inches, the results MUST be converted to the metric system.

Drive Pinion Height

1. First prepare Tools for pinion height adjustment.

q

1Height gauge (ST31211000)

q

2Dummy shaft (ST31212000)

q

3Collar

q

4Feeler gauge

q

5Dummy shaft spacer (ST31851000)

q

6Stopper (ST31852000)

q

7Preload gauge (ST3127S000)

IUse a collar which has the specifications shown at left.

2. To simplify the job, make a chart, like the one below, to orga-

nize your calculations.

LETTERSHUNDREDTHS OF

A MILLIMETER

H: Head number

D¢: Figure marked on dummy shaft

S: Figure marked on height gauge

N: Measuring clearance

3. Write the following numbers down in the chart.

H: Head number

SPD633

SPD753

SPD542

ADJUSTMENT (R180A)

PD-21

Page 1594 of 1767

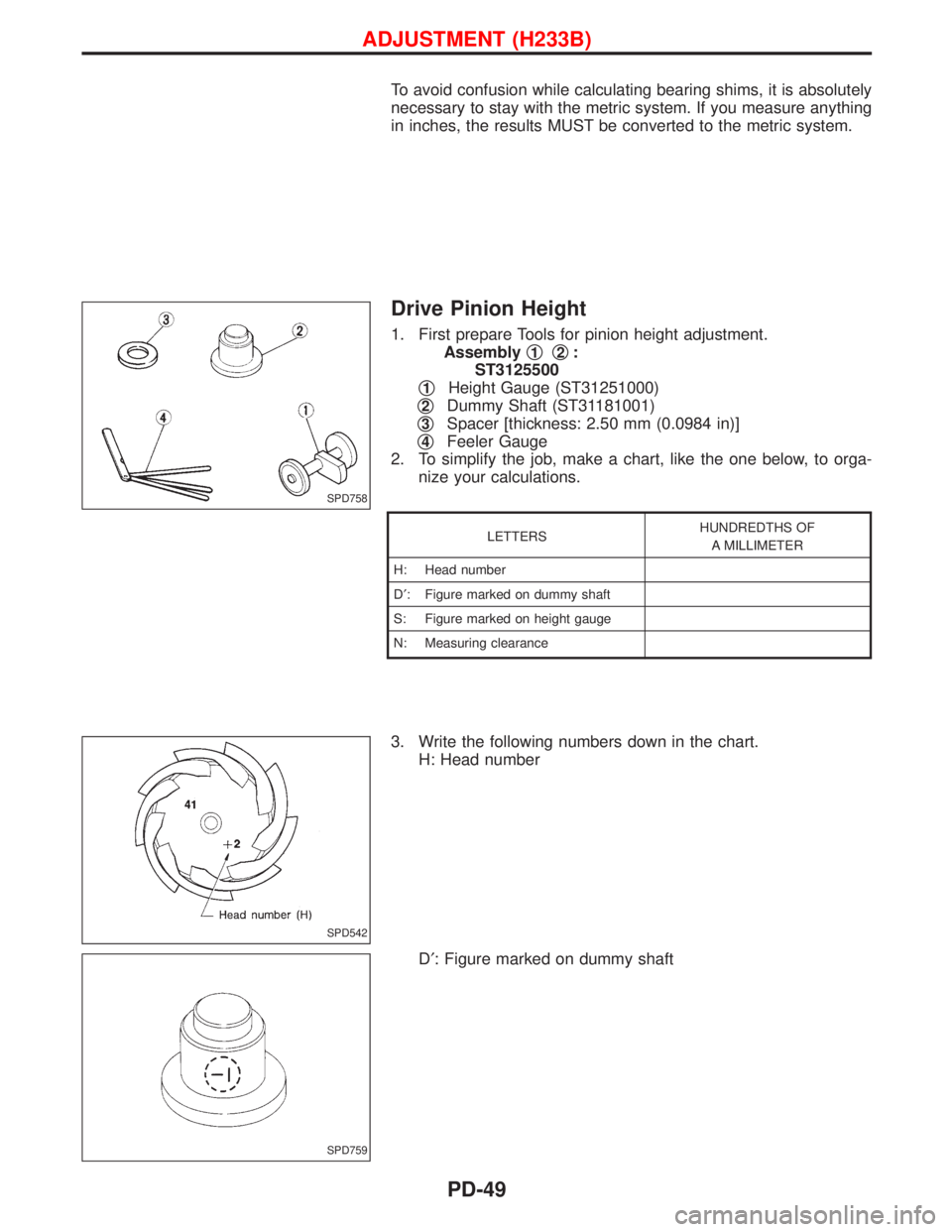

To avoid confusion while calculating bearing shims, it is absolutely

necessary to stay with the metric system. If you measure anything

in inches, the results MUST be converted to the metric system.

Drive Pinion Height

1. First prepare Tools for pinion height adjustment.

Assemblyq

1q2:

ST3125500

q

1Height Gauge (ST31251000)

q

2Dummy Shaft (ST31181001)

q

3Spacer [thickness: 2.50 mm (0.0984 in)]

q

4Feeler Gauge

2. To simplify the job, make a chart, like the one below, to orga-

nize your calculations.

LETTERSHUNDREDTHS OF

A MILLIMETER

H: Head number

D¢: Figure marked on dummy shaft

S: Figure marked on height gauge

N: Measuring clearance

3. Write the following numbers down in the chart.

H: Head number

D¢: Figure marked on dummy shaft

SPD758

SPD542

SPD759

ADJUSTMENT (H233B)

PD-49

Page 1606 of 1767

REAR AXLE &

REAR SUSPENSION

SECTION

RA

CONTENTS

PRECAUTIONS AND PREPARATION............................2

Precautions ..................................................................2

Preparation ..................................................................2

REAR AXLE AND REAR SUSPENSION........................4

CHECK AND ADJUSTMENT..........................................5

Rear Axle and Rear Suspension Parts .......................5

Rear Wheel Bearing ....................................................5

REAR AXLE.....................................................................6

Components.................................................................6

Removal .......................................................................7

Inspection.....................................................................8Installation ....................................................................9

REAR AXLE AND REAR SUSPENSION......................12

Removal and Installation ...........................................12

REAR SUSPENSION.....................................................13

Components...............................................................13

Coil Spring Shock Absorber ......................................14

Upper Link, Lower Link and Panhard Rod ................14

Stabilizer Bar .............................................................15

SERVICE DATA AND SPECIFICATIONS (SDS)..........16

General Specifications ...............................................16

Inspection and Adjustment ........................................16

Page 1607 of 1767

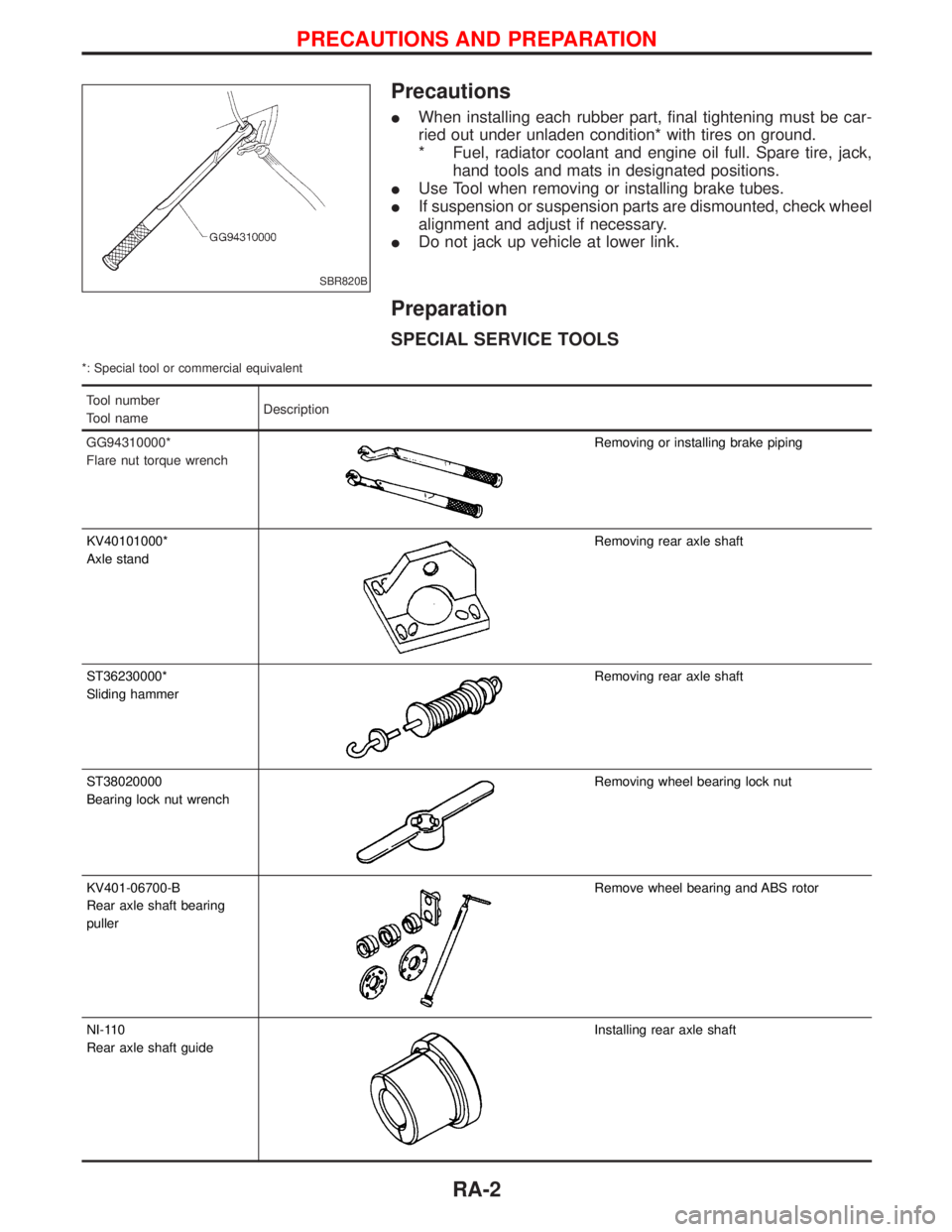

Precautions

IWhen installing each rubber part, final tightening must be car-

ried out under unladen condition* with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse Tool when removing or installing brake tubes.

IIf suspension or suspension parts are dismounted, check wheel

alignment and adjust if necessary.

IDo not jack up vehicle at lower link.

Preparation

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

GG94310000*

Flare nut torque wrench

Removing or installing brake piping

KV40101000*

Axle stand

Removing rear axle shaft

ST36230000*

Sliding hammer

Removing rear axle shaft

ST38020000

Bearing lock nut wrench

Removing wheel bearing lock nut

KV401-06700-B

Rear axle shaft bearing

puller

Remove wheel bearing and ABS rotor

NI-110

Rear axle shaft guide

Installing rear axle shaft

SBR820B

PRECAUTIONS AND PREPARATION

RA-2

Page 1610 of 1767

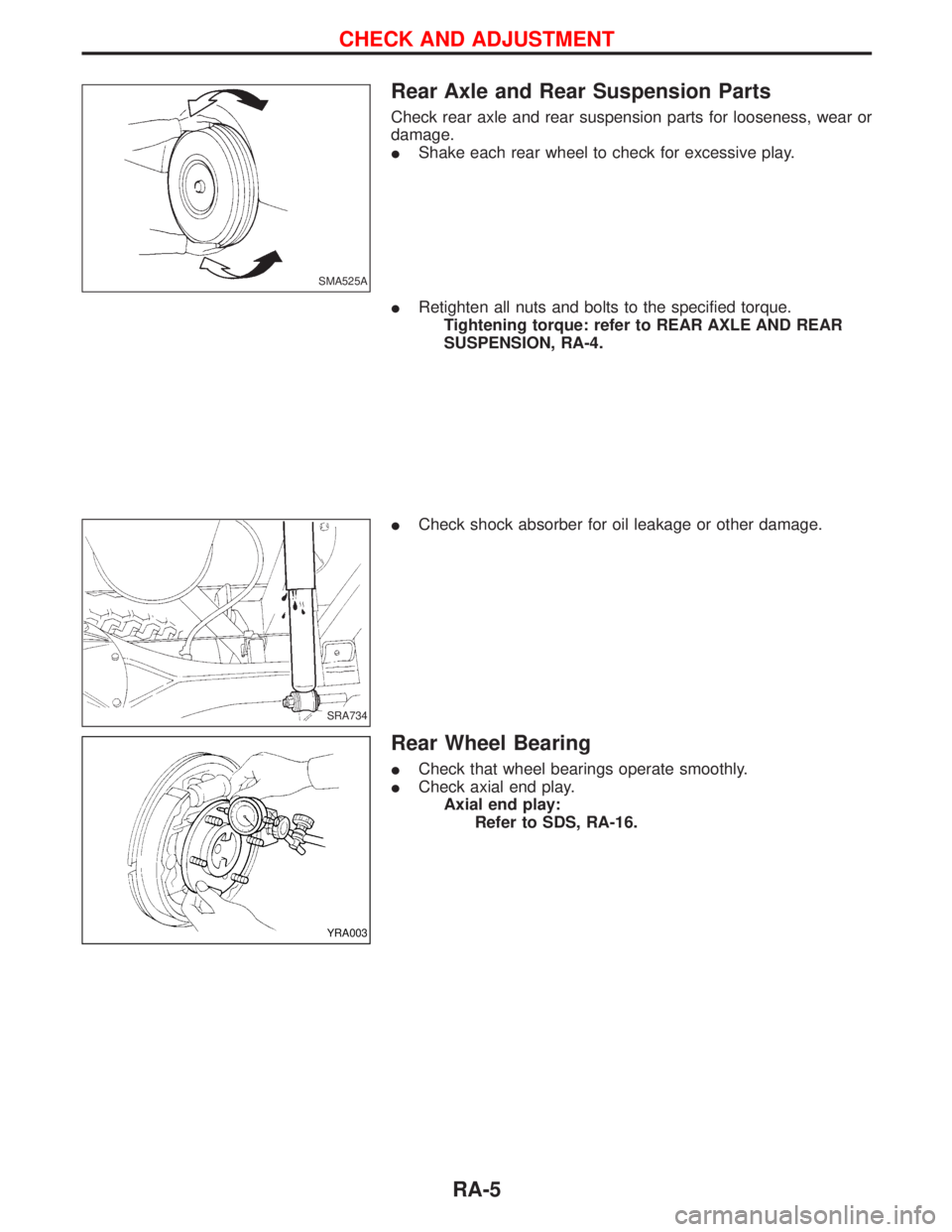

Rear Axle and Rear Suspension Parts

Check rear axle and rear suspension parts for looseness, wear or

damage.

IShake each rear wheel to check for excessive play.

IRetighten all nuts and bolts to the specified torque.

Tightening torque: refer to REAR AXLE AND REAR

SUSPENSION, RA-4.

ICheck shock absorber for oil leakage or other damage.

Rear Wheel Bearing

ICheck that wheel bearings operate smoothly.

ICheck axial end play.

Axial end play:

Refer to SDS, RA-16.

SMA525A

SRA734

YRA003

CHECK AND ADJUSTMENT

RA-5