ABS NISSAN TERRANO 2002 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 278 of 1767

qA

REPLACE.

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ON?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR MOTOR

POWER SUPPLY CIRCUIT.

1. Disconnect battery cable and ABS

actuator and electric unit connector

F29.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalq

17and ground.

Continuity should not exist.

OK

ENG

Check the following

IHarness connector

F29,

LHD:

F68andM784,or

RHD:

F79andM744

IHarness for open or

short between ABS

actuator and electric unit

and fusible link

If NG, repair harness or

connector.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

NBR336

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 5 (Motor Relay or motor)

(Cont'd)

BR-76

Page 279 of 1767

Diagnostic Procedure 7 (Low voltage)

Malfunction code No. 57

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connections. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29termi-

nalq

15and ground.

Battery voltage should exist when

ignition switch is turned ON.

OK

ENG

qA(See below.)

CHECK ABS CONTROL UNIT GROUND

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-66.

OK

ENG

Repair harness and con-

nector.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.ENG

Replace

Replace ABS actuator and

electric unit

qA

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG

Replace fuse.

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT

Check continuity between fuse and ABS

actuator and electric unit connector

F29

(body side) terminalq15.

OK

ENG

Check the following:

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

Check battery. Refer to BATTERY in EL

section.

NBR337

NBR338

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-77

Page 280 of 1767

Diagnostic Procedure 8 (G sensor)

Malfunction code No. 17

CHECK G SENSOR POWER SUPPLY

CIRCUIT.

Check 10A fuse

19. For fuse layout,

refer to POWER SUPPLY ROUTING in

EL section.

OK

ENG

Replace fuse.

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK G SENSOR.

Refer to G SENSOR in Electrical Compo-

nents Inspection, BR-83

OK

ENG

Replace G sensor.

CHECK G SENSOR POWER SUPPLY

CIRCUIT.

1. Disconnect G sensor connectors.

2. Check voltage between G sensor con-

nector terminalsq

1(B59),q3(B60)

and ground.

Battery voltage should exist.

OK

ENG

Check the following.

IHarness connectors

B59,B60, LHD:B73,

RHD:

B67, LHD:F66,

RHD:

F76:, RHD:

F136:, LHD:M787,

RHD:

M743:, RHD:

M829:, LHD:F45,

RHD:

F80andM822

IHarness for open or

short between G sensor

and ABS actuator and

electric unit

If NG, repair harness or

connectors.

CHECK G SENSOR GROUND.

1. Disconnect ABS actuator and electric

unit connector and G sensor connec-

tors.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalsq

20,q10and G sensor

connectors (body side) terminalsq

2

(B59),q4(B60).

Continuity should exist.

OK

ENG

Check the following.

IHarness connectors

B59,B60, LHD:B73,

RHD:

B67,F29, LHD:

F45and RHD:F80

IHarness for open or

short between G sensor

and ABS actuator and

electric unit

If NG, repair harness or

connectors.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

YBR276

YBR277

YBR278

H

H

H

H

H

TROUBLE DIAGNOSES

BR-78

Page 281 of 1767

Diagnostic Procedure 9 (Control unit)

Malfunctioning code No. 71

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector.

Check terminals for damage or loose

connections. Then reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT POWER SUPPLY CIRCUIT

Check voltage. Refer to

in Diagnostic

Procedure 7, BR-77.

CHECK SELF-DIAGNOSTIC RESULTS

Does warning lamp indicate code No. 71

again?

No

EYe s

Replace ABS actuator and

electric unit.

INSPECTION

Inspect the system according to the code

No.

NBR343H

H

H

TROUBLE DIAGNOSES

BR-79

Page 282 of 1767

Diagnostic Procedure 10 (Pedal vibration and

noise)

INSPECTION START

1. Apply brake.

2. Start engine.

3. Does the symptom appear only when

engine is started?

No

EYe s

Carry out self-diagnosis.

Refer to BR-59.

CHECK IF SYMPTOM APPEARS.

Does the symptom appear when electrical

equipment switches (such as headlamp)

are operated?

Ye s

ENo

Go toin Diagnostic

Procedure 12, BR-81.

CHECK WHEEL SENSOR.

Check wheel sensor shield ground. For

location of shield ground, refer to wiring

diagram and ªHARNESS LAYOUTº in EL

section.

OK

ENG

Repair wheel sensor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

Note: ABS may operate and cause vibration under any of the

following conditions.

Diagnostic Procedure 11 (Long stopping

distance)

CHECK ABS PERFORMANCE

Disconnect ABS actuator and electric unit

connector and check whether stopping

distance is still long.

Ye s

ENo

Go toin Diagnostic

Procedure 12, BR-81.

Perform Preliminary Check and air bleed-

ing.

Note: Stopping distance may be larger than vehicles without

ABS when road condition is slippery.

SAT797AH

H

H

H

TROUBLE DIAGNOSES

BR-80

Page 283 of 1767

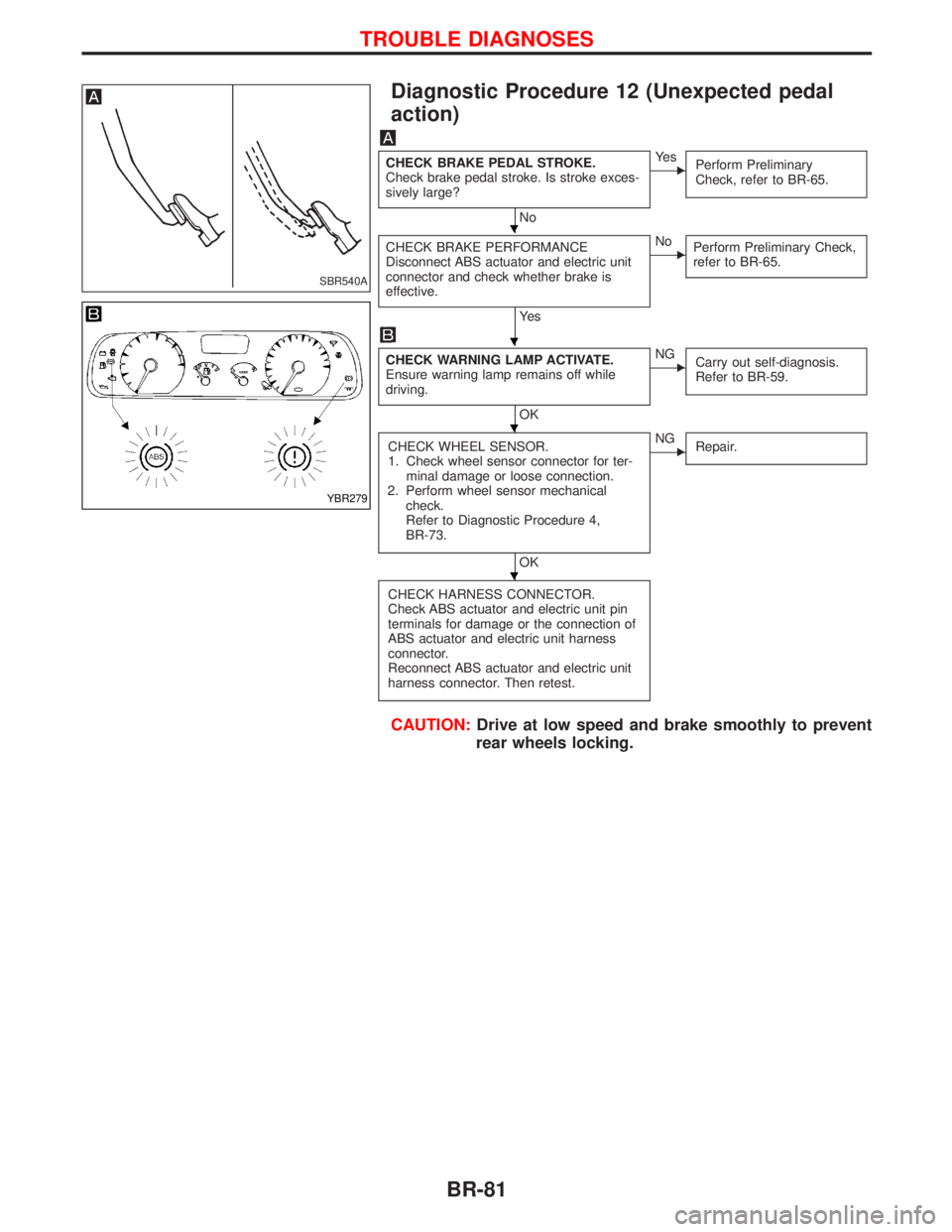

Diagnostic Procedure 12 (Unexpected pedal

action)

CHECK BRAKE PEDAL STROKE.

Check brake pedal stroke. Is stroke exces-

sively large?

No

EYe s

Perform Preliminary

Check, refer to BR-65.

CHECK BRAKE PERFORMANCE

Disconnect ABS actuator and electric unit

connector and check whether brake is

effective.

Ye s

ENo

Perform Preliminary Check,

refer to BR-65.

CHECK WARNING LAMP ACTIVATE.

Ensure warning lamp remains off while

driving.

OK

ENG

Carry out self-diagnosis.

Refer to BR-59.

CHECK WHEEL SENSOR.

1. Check wheel sensor connector for ter-

minal damage or loose connection.

2. Perform wheel sensor mechanical

check.

Refer to Diagnostic Procedure 4,

BR-73.

OK

ENG

Repair.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

CAUTION:Drive at low speed and brake smoothly to prevent

rear wheels locking.

SBR540A

YBR279

H

H

H

H

TROUBLE DIAGNOSES

BR-81

Page 284 of 1767

Diagnostic Procedure 13

SYMPTOM: ABS does not work.

Does the ABS warning lamp activate?

No

EYe s

Carry out self-diagnosis.

Refer to BR-59.

Go toin Diagnostic Procedure 12,

BR-81.

Note: ABS does not work when vehicle speed is under 10 km/h

(6 MPH).

Diagnostic Procedure 14

SYMPTOM: ABS works frequently.

CHECK WHEEL SENSOR.

1. Check wheel sensor connector for ter-

minal damage or loose connections.

2. Perform wheel sensor mechanical

check.

Refer to Diagnostic Procedure 4,

BR-73.

OK

ENG

Repair.

CHECK FRONT AXLES

Check front axles for excessive loose-

ness. Refer to FA section (ªFront Wheel

Bearingº, ªON-VEHICLE SERVICEº).

OK

ENG

Repair.

Go toin Diagnostic Procedure 12,

BR-81.

H

H

H

TROUBLE DIAGNOSES

BR-82

Page 286 of 1767

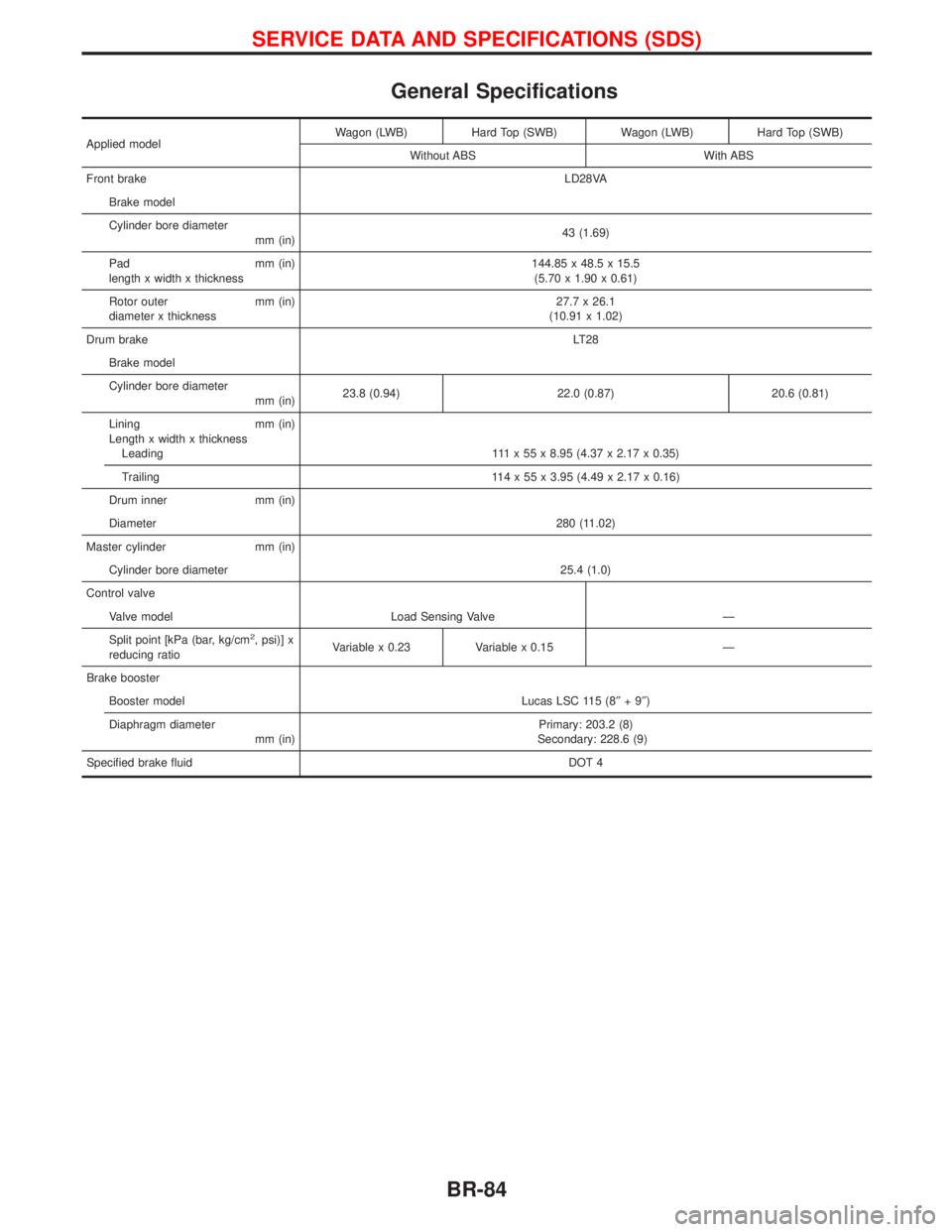

General Specifications

Applied modelWagon (LWB) Hard Top (SWB) Wagon (LWB) Hard Top (SWB)

Without ABS With ABS

Front brakeLD28VA

Brake model

Cylinder bore diameter

mm (in)43 (1.69)

Pad mm (in)

length x width x thickness144.85 x 48.5 x 15.5

(5.70 x 1.90 x 0.61)

Rotor outer mm (in)

diameter x thickness27.7 x 26.1

(10.91 x 1.02)

Drum brakeLT28

Brake model

Cylinder bore diameter

mm (in)23.8 (0.94) 22.0 (0.87) 20.6 (0.81)

Lining mm (in)

Length x width x thickness

Leading 111 x 55 x 8.95 (4.37 x 2.17 x 0.35)

Trailing 114 x 55 x 3.95 (4.49 x 2.17 x 0.16)

Drum inner mm (in)

Diameter280 (11.02)

Master cylinder mm (in)

Cylinder bore diameter 25.4 (1.0)

Control valve

Valve model Load Sensing Valve Ð

Split point [kPa (bar, kg/cm

2, psi)] x

reducing ratioVariable x 0.23 Variable x 0.15 Ð

Brake booster

Booster model Lucas LSC 115 (8²+9²)

Diaphragm diameter

mm (in)Primary: 203.2 (8)

Secondary: 228.6 (9)

Specified brake fluidDOT 4

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-84

Page 345 of 1767

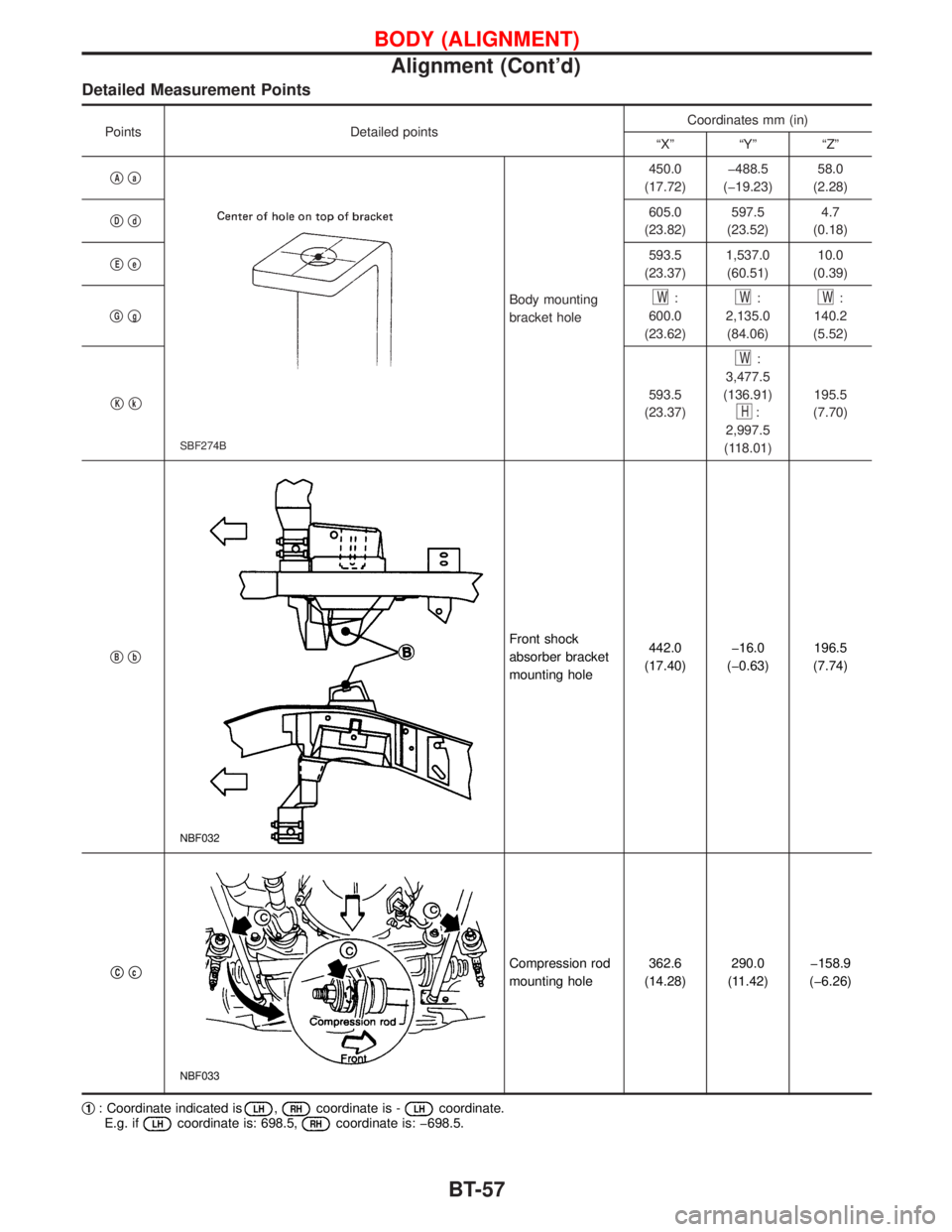

Detailed Measurement Points

Points Detailed pointsCoordinates mm (in)

ªXº ªYº ªZº

q

Aqa

SBF274B

Body mounting

bracket hole450.0

(17.72)þ488.5

(þ19.23)58.0

(2.28)

q

Dqd605.0

(23.82)597.5

(23.52)4.7

(0.18)

q

Eqe593.5

(23.37)1,537.0

(60.51)10.0

(0.39)

q

Gqg

W:

600.0

(23.62)W:

2,135.0

(84.06)W:

140.2

(5.52)

q

Kqk593.5

(23.37)

W:

3,477.5

(136.91)

H:

2,997.5

(118.01)195.5

(7.70)

q

Bqb

NBF032

Front shock

absorber bracket

mounting hole442.0

(17.40)þ16.0

(þ0.63)196.5

(7.74)

q

Cqc

NBF033

Compression rod

mounting hole362.6

(14.28)290.0

(11.42)þ158.9

(þ6.26)

q

1: Coordinate indicated isLH,RHcoordinate is -LHcoordinate.

E.g. ifLHcoordinate is: 698.5,RHcoordinate is: þ698.5.

BODY (ALIGNMENT)

Alignment (Cont'd)

BT-57

Page 562 of 1767

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

IAn excessively high or low voltage from the absolute pressure

sensor (built-into ECM) is sent to ECM.IECM

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-201.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-201.

SEC220B

SEF817Y

DTC 0802 ECM 10ZD30DDTi

EC-200