time control NISSAN TERRANO 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 817 of 1767

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

IRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

CONTENTS

HARNESS CONNECTOR................................................3

Description ...................................................................3

STANDARDIZED RELAYS..............................................4

Description ...................................................................4

POWER SUPPLY ROUTING...........................................6

Schematic ....................................................................6

Wiring Diagram - POWER - ........................................8

Fuse ...........................................................................17

Fusible Link................................................................17

Circuit Breaker Inspection .........................................17

GROUND DISTRIBUTION.............................................18

COMBINATION SWITCH...............................................23

Check .........................................................................23

Replacement ..............................................................24

STEERING SWITCH......................................................25

Check .........................................................................25

HEADLAMP - Without Daytime Light System -.........26

Wiring Diagram - H/LAMP -.......................................26

HEADLAMP - Daytime Light System -.......................29

Operation ...................................................................29

Schematic ..................................................................30

Wiring Diagram - DTRL - ...........................................31

HEADLAMP - Headlamp Aiming Control -.................37

Description .................................................................37

Replacing Headlamp Aiming Actuator .......................38

Wiring Diagram - H/AIM - ..........................................39

Trouble Diagnoses.....................................................42

HEADLAMP...................................................................43

Bulb Replacement .....................................................43

Aiming Adjustment .....................................................43

EXTERIOR LAMP..........................................................45

Wiring Diagram - TAIL/L - ..........................................45

Wiring Diagram - STOP/L - .......................................48

Wiring Diagram - BACK/L - .......................................49

Wiring Diagram - F/FOG - .........................................51

Front Fog Lamp Aiming Adjustment ..........................53

Wiring Diagram - R/FOG -.........................................54

Schematic ..................................................................55Wiring Diagram - TURN - ..........................................56

Bulb Specifications ....................................................60

INTERIOR LAMP...........................................................61

Schematic ..................................................................61

Wiring Diagram - ILL - ...............................................62

Wiring Diagram - INT/L - ...........................................66

METER AND GAUGES.................................................70

Combination Meter ....................................................70

Schematic ..................................................................71

Wiring Diagram - METER - .......................................72

Combination Meter Self-Diagnosis ............................76

Components Inspection .............................................78

Trouble Diagnoses.....................................................79

Fuel Tank Gauge Unit Check ....................................80

Thermal Transmitter Check .......................................80

Oil Pressure Switch Check ........................................80

WARNING LAMPS AND CHIME...................................81

Schematic ..................................................................81

Wiring Diagram - WARN - .........................................82

Diode Check ..............................................................92

Wiring Diagram - CHIME - ........................................93

WIPER AND WASHER..................................................94

Wiring Diagram - WIPER - ........................................94

Wiring Diagram - WIP/R -..........................................96

Installation ..................................................................98

Washer Nozzle Adjustment .......................................99

Check Valve ...............................................................99

Wiring Diagram - HLC - ...........................................100

HORN, CIGARETTE LIGHTER AND CLOCK............104

Wiring Diagram - HORN - .......................................104

Wiring Diagram - CIGAR -.......................................105

Wiring Diagram - CLOCK -......................................106

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER.................................................107

Wiring Diagram - DEF - ...........................................107

Filament Check ........................................................109

Filament Repair ....................................................... 110

AUDIO.......................................................................... 111

Page 818 of 1767

System Description .................................................. 111

Schematic ................................................................ 113

Wiring Diagram - AUDIO - ....................................... 115

Wiring Diagram - REMOTE -...................................122

Trouble Diagnoses...................................................124

Inspection.................................................................126

Location of Roof Mounted Antenna .........................127

HEATED SEAT............................................................128

Wiring Diagram - HSEAT - ......................................128

SUNROOF....................................................................130

Wiring Diagram - SROOF - .....................................130

DOOR MIRROR...........................................................131

Wiring Diagram - MIRROR - ...................................131

POWER WINDOW.......................................................133

Schematic ................................................................133

Wiring Diagram - WINDOW - ..................................134

POWER DOOR LOCK.................................................137

Power Door Lock .....................................................137

Schematic ................................................................138

Wiring Diagram - D/LOCK -.....................................140

POWER DOOR LOCK - SUPER LOCK -...................145

Component Parts Location ......................................145

System Description ..................................................146

Schematic ................................................................148

Wiring Diagram - S/LOCK - .....................................150

Trouble Diagnoses...................................................158

MULTI-REMOTE CONTROL SYSTEM.......................168

Schematic ................................................................168

Wiring Diagram - MULTI - .......................................169

Trouble Diagnoses...................................................177

ID Code Entry Procedure ........................................179

TIME CONTROL UNIT (TCU).....................................180

System Description ..................................................180Trouble Diagnosis ....................................................182

Schematic ................................................................184

NATS (Nissan Anti-Theft System).............................186

System Description ..................................................186

System Composition ................................................187

Component Parts Location ......................................188

Wiring Diagram - NATS -.........................................189

CONSULT-II .............................................................193

Trouble Diagnoses...................................................195

How to Replace NATS IMMU ..................................208

THEFT WARNING SYSTEM.......................................209

Components Parts and Harness Connector

Location ...................................................................209

System Description ..................................................210

Theft Warning System/Schematic ...........................213

Wiring Diagram - THEFT -.......................................214

Trouble Diagnoses...................................................230

LOCATION OF ELECTRICAL UNITS.........................241

Engine Compartment ...............................................241

Passenger Compartment/LHD Models ....................242

Passenger Compartment/RHD Models ...................244

HARNESS LAYOUT....................................................247

Outline......................................................................247

Main Harness...........................................................248

EFC Harness ...........................................................264

Engine Harness .......................................................276

Body Harness ..........................................................278

Chassis Harness......................................................286

Room Lamp Harness...............................................287

Tailgate Harness ......................................................288

Door Harness (LH side)...........................................289

Door Harness (RH side) ..........................................290

WIRING DIAGRAM CODES (CELL CODES).............291

WIRING DIAGRAM REFERENCE CHART

ENGINE CONTROL SYSTEM, IGNITION SYSTEM ................................................................................................EC SECTION

RESTRAINT SYSTEM (AIR BAG) ...........................................................................................................................RS SECTION

HEATER AND AIR CONDITIONER ..........................................................................................................................HA SECTION

CONTENTS(Cont'd)

EL-2

Page 833 of 1767

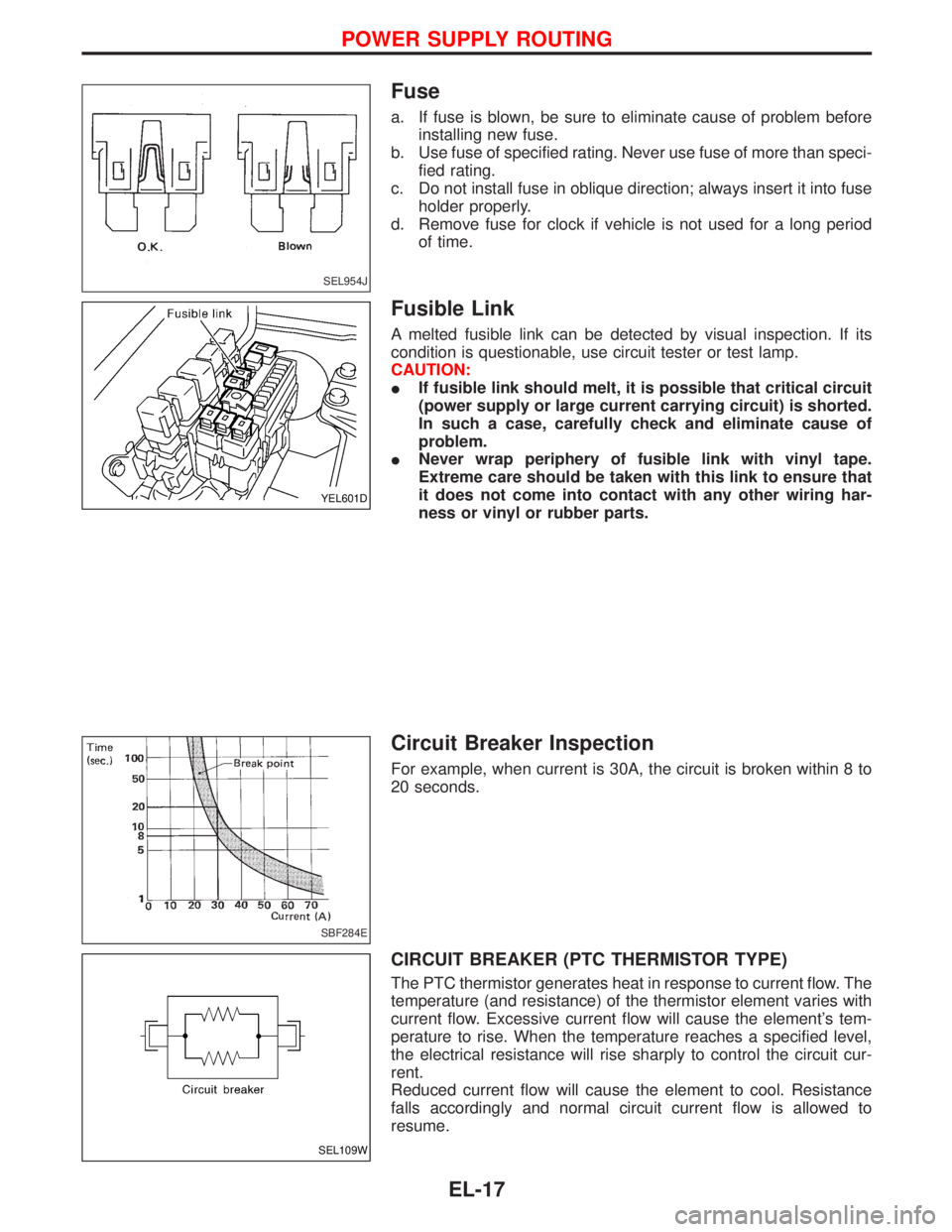

Fuse

a. If fuse is blown, be sure to eliminate cause of problem before

installing new fuse.

b. Use fuse of specified rating. Never use fuse of more than speci-

fied rating.

c. Do not install fuse in oblique direction; always insert it into fuse

holder properly.

d. Remove fuse for clock if vehicle is not used for a long period

of time.

Fusible Link

A melted fusible link can be detected by visual inspection. If its

condition is questionable, use circuit tester or test lamp.

CAUTION:

IIf fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of

problem.

INever wrap periphery of fusible link with vinyl tape.

Extreme care should be taken with this link to ensure that

it does not come into contact with any other wiring har-

ness or vinyl or rubber parts.

Circuit Breaker Inspection

For example, when current is 30A, the circuit is broken within 8 to

20 seconds.

CIRCUIT BREAKER (PTC THERMISTOR TYPE)

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of the thermistor element varies with

current flow. Excessive current flow will cause the element's tem-

perature to rise. When the temperature reaches a specified level,

the electrical resistance will rise sharply to control the circuit cur-

rent.

Reduced current flow will cause the element to cool. Resistance

falls accordingly and normal circuit current flow is allowed to

resume.

SEL954J

YEL601D

SBF284E

SEL109W

POWER SUPPLY ROUTING

EL-17

Page 835 of 1767

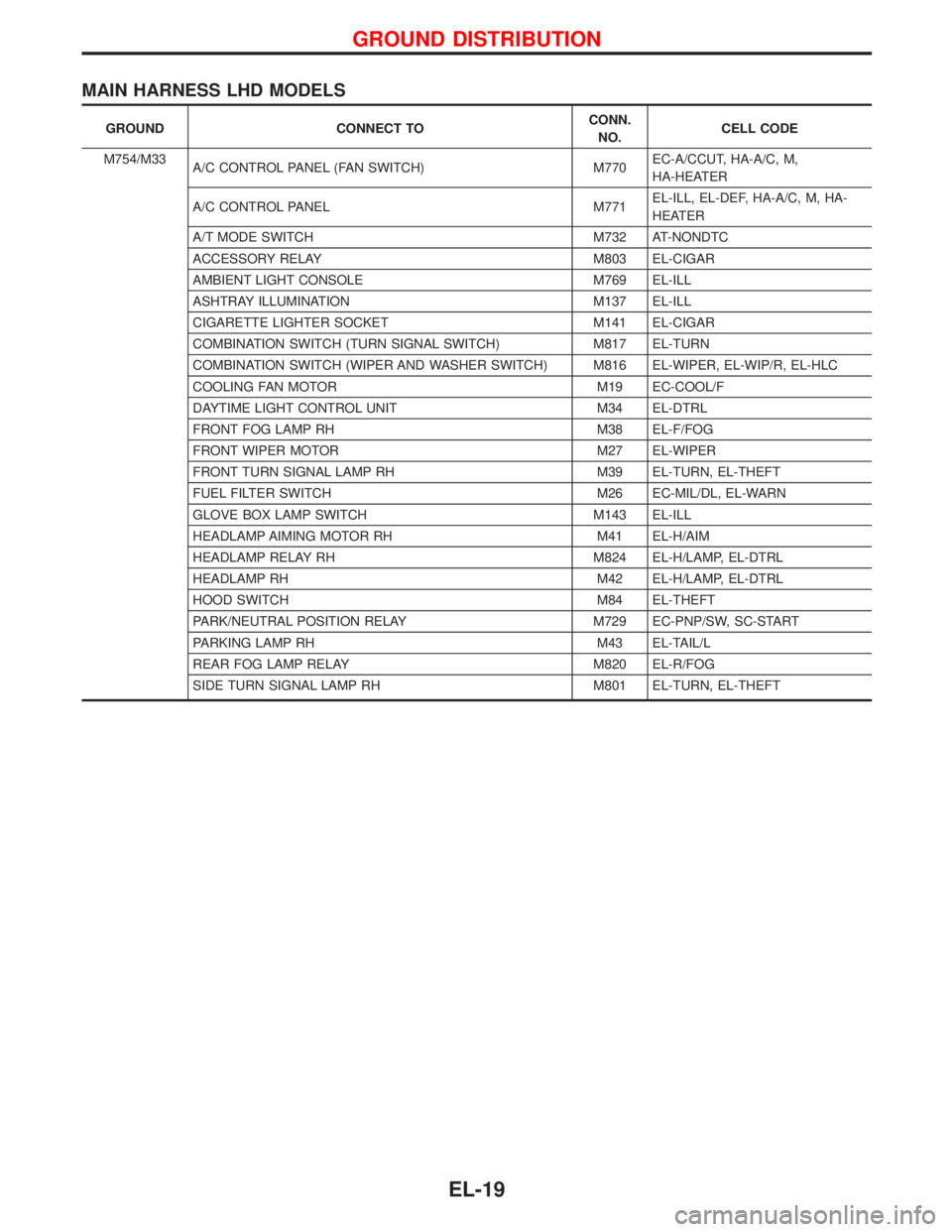

MAIN HARNESS LHD MODELS

GROUND CONNECT TOCONN.

NO.CELL CODE

M754/M33

A/C CONTROL PANEL (FAN SWITCH) M770EC-A/CCUT, HA-A/C, M,

HA-HEATER

A/C CONTROL PANEL M771EL-ILL, EL-DEF, HA-A/C, M, HA-

HEATER

A/T MODE SWITCH M732 AT-NONDTC

ACCESSORY RELAY M803 EL-CIGAR

AMBIENT LIGHT CONSOLE M769 EL-ILL

ASHTRAY ILLUMINATION M137 EL-ILL

CIGARETTE LIGHTER SOCKET M141 EL-CIGAR

COMBINATION SWITCH (TURN SIGNAL SWITCH) M817 EL-TURN

COMBINATION SWITCH (WIPER AND WASHER SWITCH) M816 EL-WIPER, EL-WIP/R, EL-HLC

COOLING FAN MOTOR M19 EC-COOL/F

DAYTIME LIGHT CONTROL UNIT M34 EL-DTRL

FRONT FOG LAMP RH M38 EL-F/FOG

FRONT WIPER MOTOR M27 EL-WIPER

FRONT TURN SIGNAL LAMP RH M39 EL-TURN, EL-THEFT

FUEL FILTER SWITCH M26 EC-MIL/DL, EL-WARN

GLOVE BOX LAMP SWITCH M143 EL-ILL

HEADLAMP AIMING MOTOR RH M41 EL-H/AIM

HEADLAMP RELAY RH M824 EL-H/LAMP, EL-DTRL

HEADLAMP RH M42 EL-H/LAMP, EL-DTRL

HOOD SWITCH M84 EL-THEFT

PARK/NEUTRAL POSITION RELAY M729 EC-PNP/SW, SC-START

PARKING LAMP RH M43 EL-TAIL/L

REAR FOG LAMP RELAY M820 EL-R/FOG

SIDE TURN SIGNAL LAMP RH M801 EL-TURN, EL-THEFT

GROUND DISTRIBUTION

EL-19

Page 927 of 1767

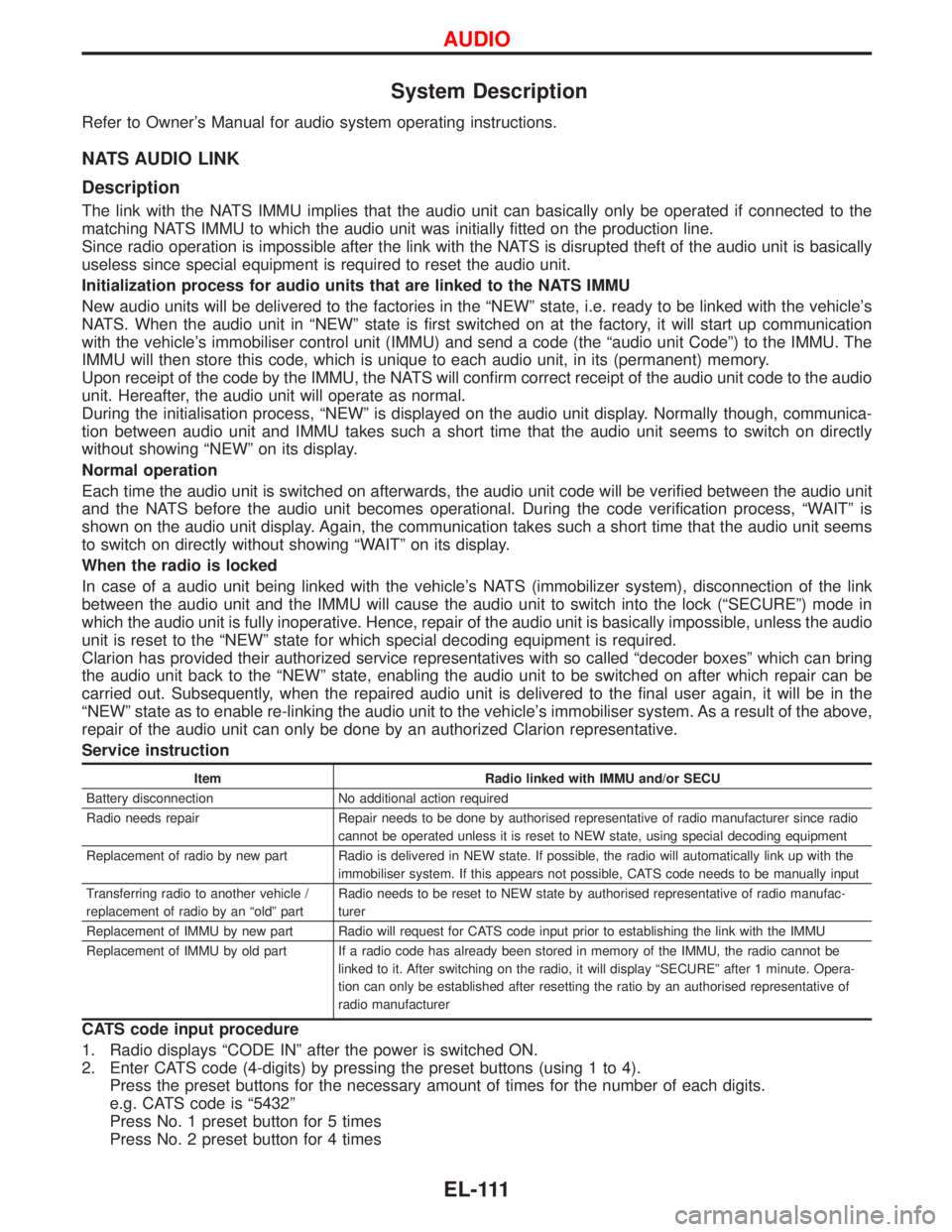

System Description

Refer to Owner's Manual for audio system operating instructions.

NATS AUDIO LINK

Description

The link with the NATS IMMU implies that the audio unit can basically only be operated if connected to the

matching NATS IMMU to which the audio unit was initially fitted on the production line.

Since radio operation is impossible after the link with the NATS is disrupted theft of the audio unit is basically

useless since special equipment is required to reset the audio unit.

Initialization process for audio units that are linked to the NATS IMMU

New audio units will be delivered to the factories in the ªNEWº state, i.e. ready to be linked with the vehicle's

NATS. When the audio unit in ªNEWº state is first switched on at the factory, it will start up communication

with the vehicle's immobiliser control unit (IMMU) and send a code (the ªaudio unit Codeº) to the IMMU. The

IMMU will then store this code, which is unique to each audio unit, in its (permanent) memory.

Upon receipt of the code by the IMMU, the NATS will confirm correct receipt of the audio unit code to the audio

unit. Hereafter, the audio unit will operate as normal.

During the initialisation process, ªNEWº is displayed on the audio unit display. Normally though, communica-

tion between audio unit and IMMU takes such a short time that the audio unit seems to switch on directly

without showing ªNEWº on its display.

Normal operation

Each time the audio unit is switched on afterwards, the audio unit code will be verified between the audio unit

and the NATS before the audio unit becomes operational. During the code verification process, ªWAITº is

shown on the audio unit display. Again, the communication takes such a short time that the audio unit seems

to switch on directly without showing ªWAITº on its display.

When the radio is locked

In case of a audio unit being linked with the vehicle's NATS (immobilizer system), disconnection of the link

between the audio unit and the IMMU will cause the audio unit to switch into the lock (ªSECUREº) mode in

which the audio unit is fully inoperative. Hence, repair of the audio unit is basically impossible, unless the audio

unit is reset to the ªNEWº state for which special decoding equipment is required.

Clarion has provided their authorized service representatives with so called ªdecoder boxesº which can bring

the audio unit back to the ªNEWº state, enabling the audio unit to be switched on after which repair can be

carried out. Subsequently, when the repaired audio unit is delivered to the final user again, it will be in the

ªNEWº state as to enable re-linking the audio unit to the vehicle's immobiliser system. As a result of the above,

repair of the audio unit can only be done by an authorized Clarion representative.

Service instruction

Item Radio linked with IMMU and/or SECU

Battery disconnection No additional action required

Radio needs repair Repair needs to be done by authorised representative of radio manufacturer since radio

cannot be operated unless it is reset to NEW state, using special decoding equipment

Replacement of radio by new part Radio is delivered in NEW state. If possible, the radio will automatically link up with the

immobiliser system. If this appears not possible, CATS code needs to be manually input

Transferring radio to another vehicle /

replacement of radio by an ªoldº partRadio needs to be reset to NEW state by authorised representative of radio manufac-

turer

Replacement of IMMU by new part Radio will request for CATS code input prior to establishing the link with the IMMU

Replacement of IMMU by old part If a radio code has already been stored in memory of the IMMU, the radio cannot be

linked to it. After switching on the radio, it will display ªSECUREº after 1 minute. Opera-

tion can only be established after resetting the ratio by an authorised representative of

radio manufacturer

CATS code input procedure

1. Radio displays ªCODE INº after the power is switched ON.

2. Enter CATS code (4-digits) by pressing the preset buttons (using 1 to 4).

Press the preset buttons for the necessary amount of times for the number of each digits.

e.g. CATS code is ª5432º

Press No. 1 preset button for 5 times

Press No. 2 preset button for 4 times

AUDIO

EL-111

Page 977 of 1767

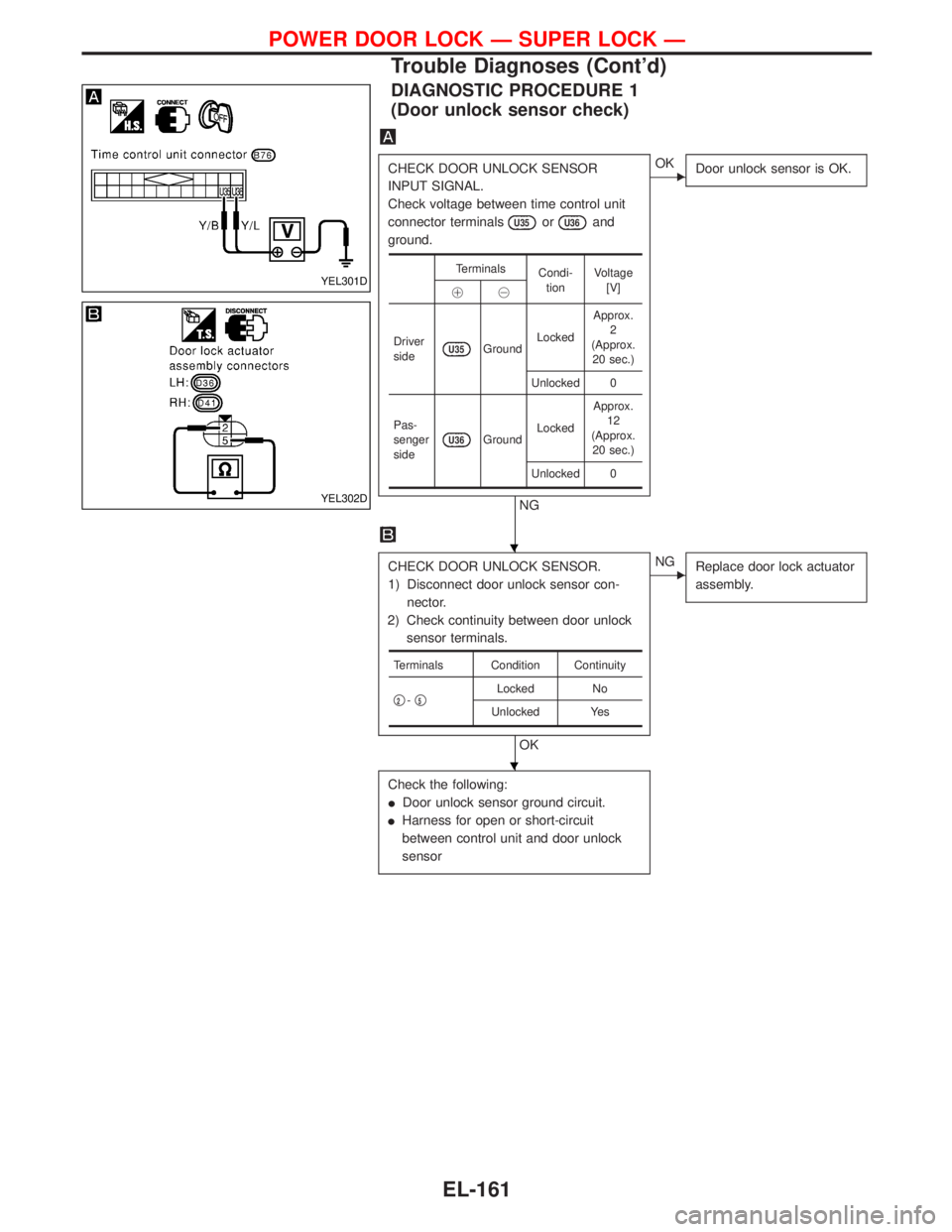

DIAGNOSTIC PROCEDURE 1

(Door unlock sensor check)

CHECK DOOR UNLOCK SENSOR

INPUT SIGNAL.

Check voltage between time control unit

connector terminals

U35orU36and

ground.

NG

EOK

Door unlock sensor is OK.

CHECK DOOR UNLOCK SENSOR.

1) Disconnect door unlock sensor con-

nector.

2) Check continuity between door unlock

sensor terminals.

OK

ENG

Replace door lock actuator

assembly.

Check the following:

IDoor unlock sensor ground circuit.

IHarness for open or short-circuit

between control unit and door unlock

sensor

Terminals

Condi-

tionVoltage

[V]

!@

Driver

side

U35GroundLockedApprox.

2

(Approx.

20 sec.)

Unlocked 0

Pas-

senger

side

U36GroundLockedApprox.

12

(Approx.

20 sec.)

Unlocked 0

Terminals Condition Continuity

q

2-q5Locked No

Unlocked Yes

YEL301D

YEL302D

H

H

POWER DOOR LOCK Ð SUPER LOCK Ð

Trouble Diagnoses (Cont'd)

EL-161

Page 978 of 1767

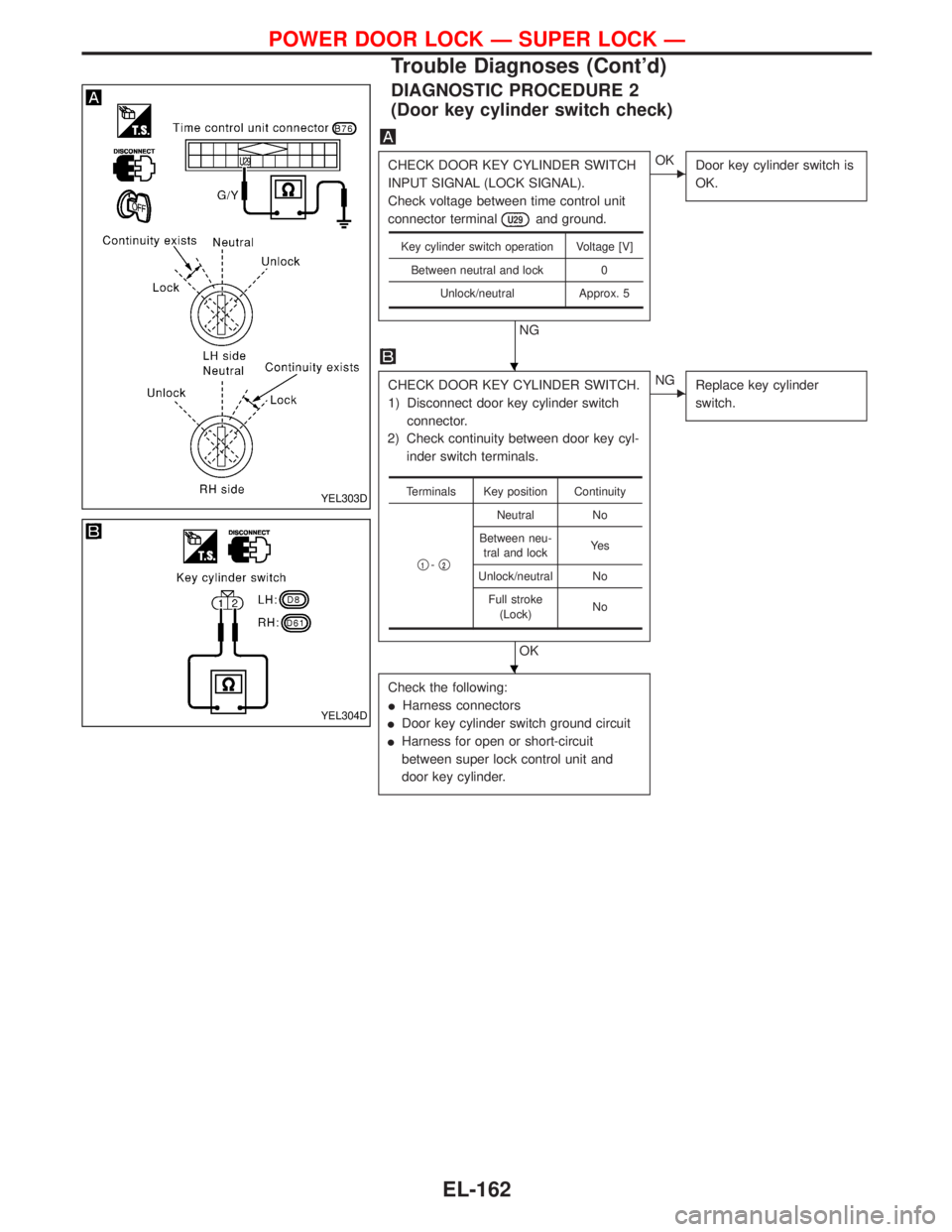

DIAGNOSTIC PROCEDURE 2

(Door key cylinder switch check)

CHECK DOOR KEY CYLINDER SWITCH

INPUT SIGNAL (LOCK SIGNAL).

Check voltage between time control unit

connector terminal

U29and ground.

NG

EOK

Door key cylinder switch is

OK.

CHECK DOOR KEY CYLINDER SWITCH.

1) Disconnect door key cylinder switch

connector.

2) Check continuity between door key cyl-

inder switch terminals.

OK

ENG

Replace key cylinder

switch.

Check the following:

IHarness connectors

IDoor key cylinder switch ground circuit

IHarness for open or short-circuit

between super lock control unit and

door key cylinder.

Key cylinder switch operation Voltage [V]

Between neutral and lock 0

Unlock/neutral Approx. 5

Terminals Key position Continuity

q

1-q2

Neutral No

Between neu-

tral and lockYe s

Unlock/neutral No

Full stroke

(Lock)No

YEL303D

YEL304D

H

H

POWER DOOR LOCK Ð SUPER LOCK Ð

Trouble Diagnoses (Cont'd)

EL-162

Page 993 of 1767

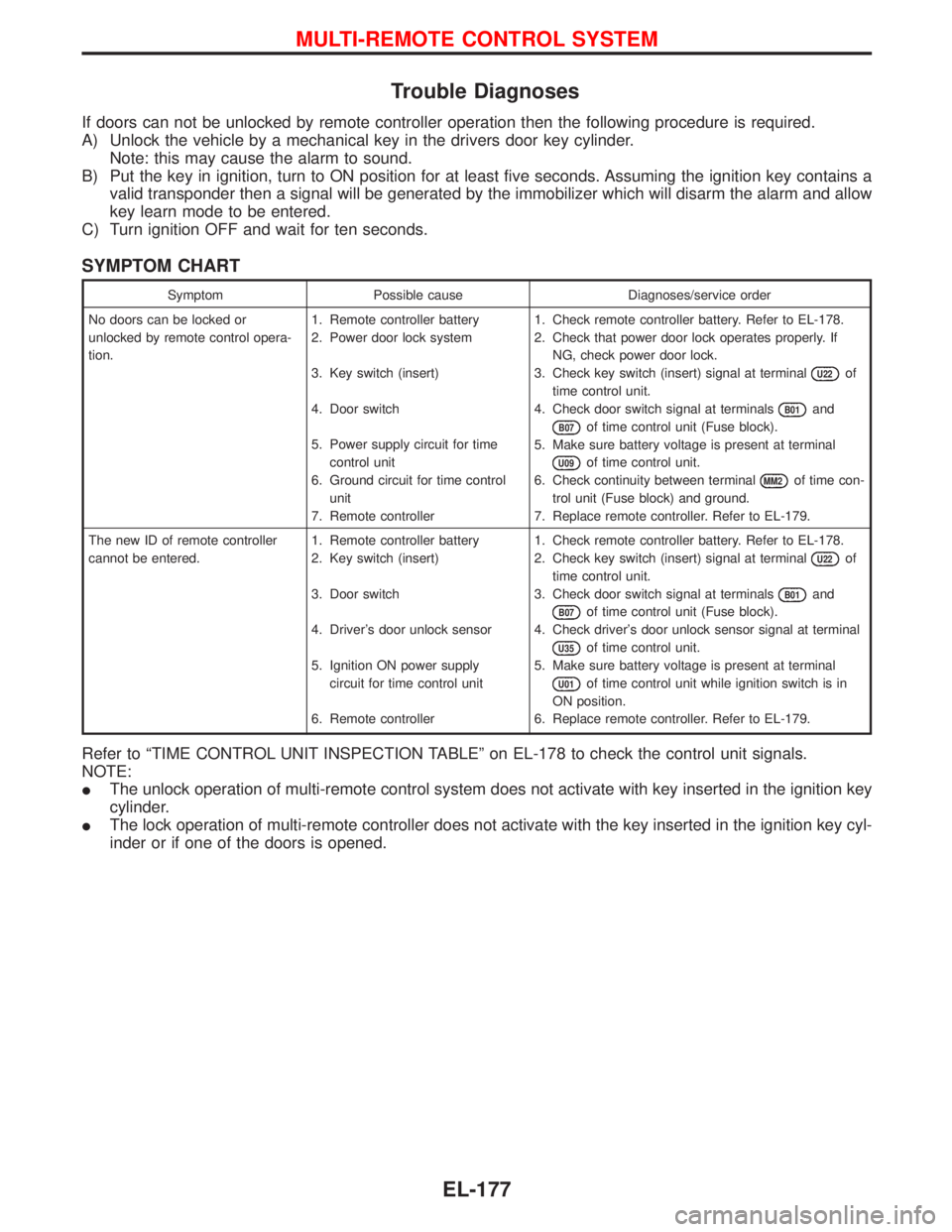

Trouble Diagnoses

If doors can not be unlocked by remote controller operation then the following procedure is required.

A) Unlock the vehicle by a mechanical key in the drivers door key cylinder.

Note: this may cause the alarm to sound.

B) Put the key in ignition, turn to ON position for at least five seconds. Assuming the ignition key contains a

valid transponder then a signal will be generated by the immobilizer which will disarm the alarm and allow

key learn mode to be entered.

C) Turn ignition OFF and wait for ten seconds.

SYMPTOM CHART

Symptom Possible cause Diagnoses/service order

No doors can be locked or

unlocked by remote control opera-

tion.1. Remote controller battery

2. Power door lock system

3. Key switch (insert)

4. Door switch

5. Power supply circuit for time

control unit

6. Ground circuit for time control

unit

7. Remote controller1. Check remote controller battery. Refer to EL-178.

2. Check that power door lock operates properly. If

NG, check power door lock.

3. Check key switch (insert) signal at terminal

U22of

time control unit.

4. Check door switch signal at terminals

B01and

B07of time control unit (Fuse block).

5. Make sure battery voltage is present at terminal

U09of time control unit.

6. Check continuity between terminal

MM2of time con-

trol unit (Fuse block) and ground.

7. Replace remote controller. Refer to EL-179.

The new ID of remote controller

cannot be entered.1. Remote controller battery

2. Key switch (insert)

3. Door switch

4. Driver's door unlock sensor

5. Ignition ON power supply

circuit for time control unit

6. Remote controller1. Check remote controller battery. Refer to EL-178.

2. Check key switch (insert) signal at terminal

U22of

time control unit.

3. Check door switch signal at terminals

B01and

B07of time control unit (Fuse block).

4. Check driver's door unlock sensor signal at terminal

U35of time control unit.

5. Make sure battery voltage is present at terminal

U01of time control unit while ignition switch is in

ON position.

6. Replace remote controller. Refer to EL-179.

Refer to ªTIME CONTROL UNIT INSPECTION TABLEº on EL-178 to check the control unit signals.

NOTE:

IThe unlock operation of multi-remote control system does not activate with key inserted in the ignition key

cylinder.

IThe lock operation of multi-remote controller does not activate with the key inserted in the ignition key cyl-

inder or if one of the doors is opened.

MULTI-REMOTE CONTROL SYSTEM

EL-177

Page 994 of 1767

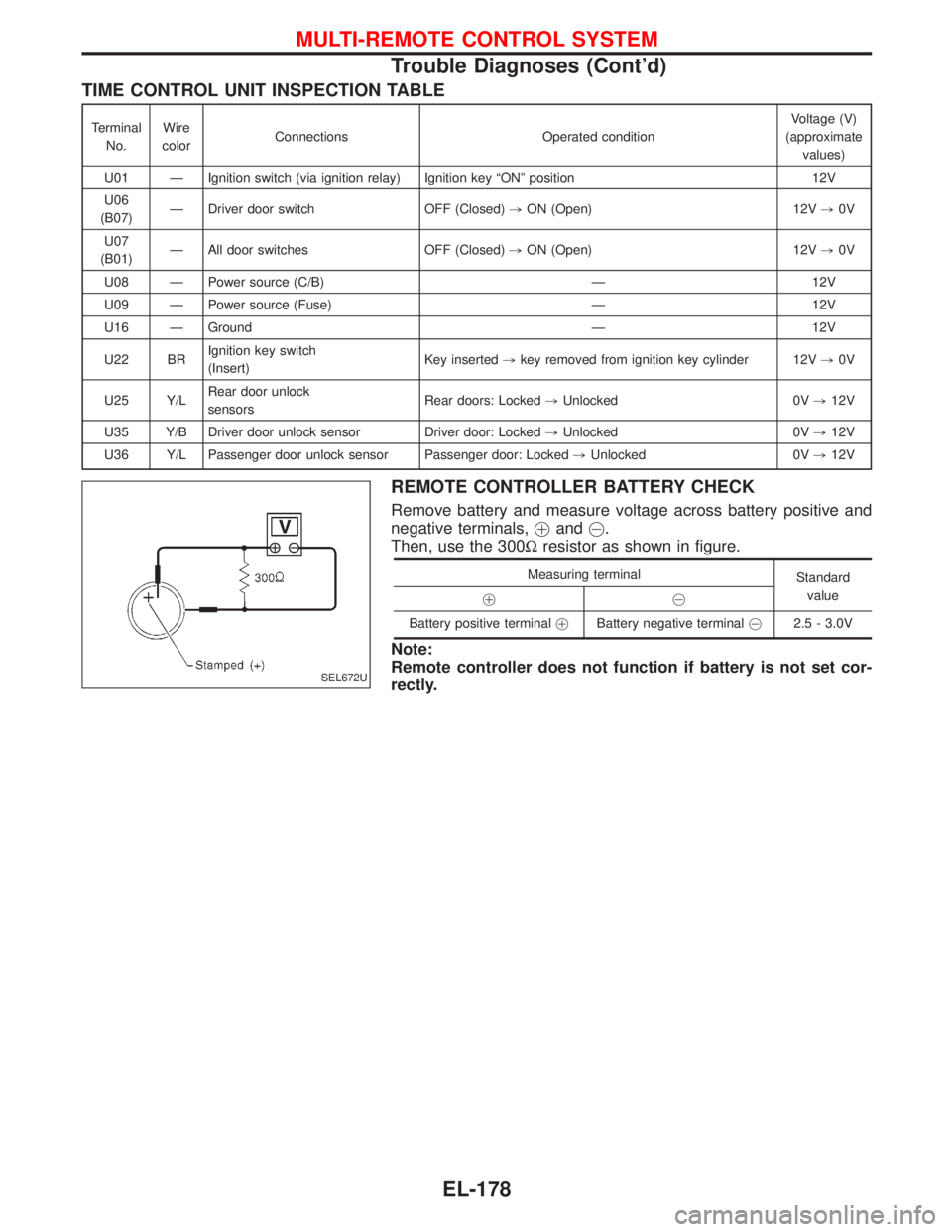

TIME CONTROL UNIT INSPECTION TABLE

Terminal

No.Wire

colorConnections Operated conditionVoltage (V)

(approximate

values)

U01 Ð Ignition switch (via ignition relay) Ignition key ªONº position 12V

U06

(B07)Ð Driver door switch OFF (Closed),ON (Open) 12V,0V

U07

(B01)Ð All door switches OFF (Closed),ON (Open) 12V,0V

U08 Ð Power source (C/B) Ð 12V

U09 Ð Power source (Fuse) Ð 12V

U16 Ð Ground Ð 12V

U22 BRIgnition key switch

(Insert)Key inserted,key removed from ignition key cylinder 12V,0V

U25 Y/LRear door unlock

sensorsRear doors: Locked,Unlocked 0V,12V

U35 Y/B Driver door unlock sensor Driver door: Locked,Unlocked 0V,12V

U36 Y/L Passenger door unlock sensor Passenger door: Locked,Unlocked 0V,12V

REMOTE CONTROLLER BATTERY CHECK

Remove battery and measure voltage across battery positive and

negative terminals,!and@.

Then, use the 300Wresistor as shown in figure.

Measuring terminal

Standard

value

!@

Battery positive terminal!Battery negative [email protected] - 3.0V

Note:

Remote controller does not function if battery is not set cor-

rectly.

SEL672U

MULTI-REMOTE CONTROL SYSTEM

Trouble Diagnoses (Cont'd)

EL-178

Page 995 of 1767

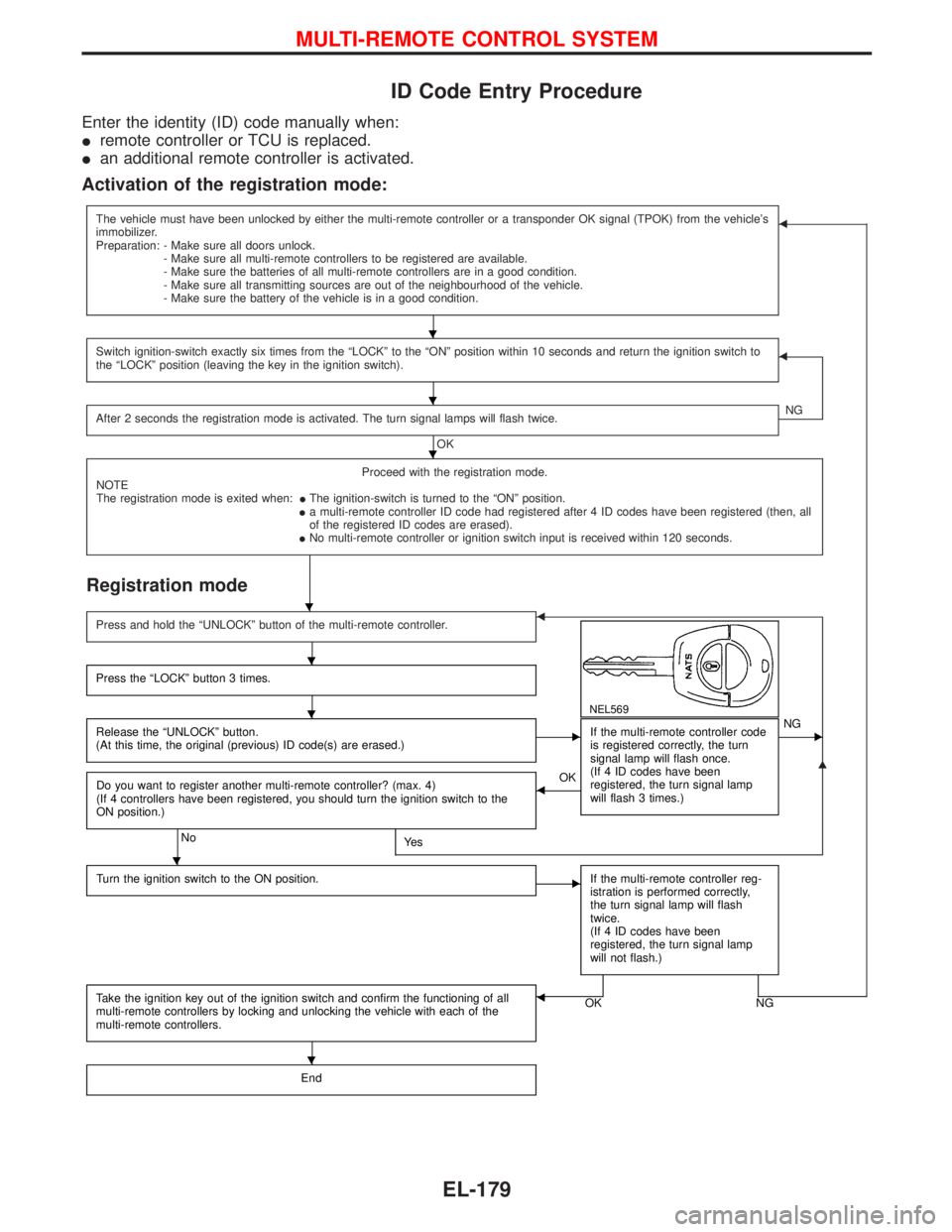

ID Code Entry Procedure

Enter the identity (ID) code manually when:

Iremote controller or TCU is replaced.

Ian additional remote controller is activated.

Activation of the registration mode:

The vehicle must have been unlocked by either the multi-remote controller or a transponder OK signal (TPOK) from the vehicle's

immobilizer.

Preparation: - Make sure all doors unlock.

- Make sure all multi-remote controllers to be registered are available.

- Make sure the batteries of all multi-remote controllers are in a good condition.

- Make sure all transmitting sources are out of the neighbourhood of the vehicle.

- Make sure the battery of the vehicle is in a good condition.F

Switch ignition-switch exactly six times from the ªLOCKº to the ªONº position within 10 seconds and return the ignition switch to

the ªLOCKº position (leaving the key in the ignition switch).F

After 2 seconds the registration mode is activated. The turn signal lamps will flash twice.

OKNG

Proceed with the registration mode.

NOTE

The registration mode is exited when:IThe ignition-switch is turned to the ªONº position.

Ia multi-remote controller ID code had registered after 4 ID codes have been registered (then, all

of the registered ID codes are erased).

INo multi-remote controller or ignition switch input is received within 120 seconds.

Registration mode

G

Press and hold the ªUNLOCKº button of the multi-remote controller.F

NEL569

Press the ªLOCKº button 3 times.

Release the ªUNLOCKº button.

(At this time, the original (previous) ID code(s) are erased.)EIf the multi-remote controller code

is registered correctly, the turn

signal lamp will flash once.

(If 4 ID codes have been

registered, the turn signal lamp

will flash 3 times.)ENG

Do you want to register another multi-remote controller? (max. 4)

(If 4 controllers have been registered, you should turn the ignition switch to the

ON position.)

NoYe s

FOK

Turn the ignition switch to the ON position.

EIf the multi-remote controller reg-

istration is performed correctly,

the turn signal lamp will flash

twice.

(If 4 ID codes have been

registered, the turn signal lamp

will not flash.)

Take the ignition key out of the ignition switch and confirm the functioning of all

multi-remote controllers by locking and unlocking the vehicle with each of the

multi-remote controllers.OK NGF

End

H

H

H

H

H

H

H

H

MULTI-REMOTE CONTROL SYSTEM

EL-179