time control NISSAN TERRANO 2002 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1320 of 1767

Precautions for Multiport Fuel Injection System

or Engine Control System

1. Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ªOFFº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

2. Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure to eliminate danger.

3. Be careful not to jar components such as control unit and air

flow meter.

Precautions for Catalyst

If a large amount of unburned fuel enters the converter, the con-

verter temperature will rise to excessively high values. To prevent

this, follow the procedure below:

1. Use unleaded gasoline only. Leaded gasoline will seriously

damage the catalytic converter.

2. When checking for ignition spark or measuring engine

compression, perform tests quickly and only when necessary.

3. Do not run engine when the fuel tank level is low, as a result

the engine may misfire causing damage to the converter.

4. Do not place the vehicle on inflammable material. Keep inflam-

mable material off the exhaust pipe.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

For proper operation of the system, follow the procedure below:

1. Always use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

2. Avoid accelerating engine to a high rpm immediately after start-

ing.

3. If engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting it off.

SGI787

SGI290

SGI292

PRECAUTIONS

GI-5

Page 1383 of 1767

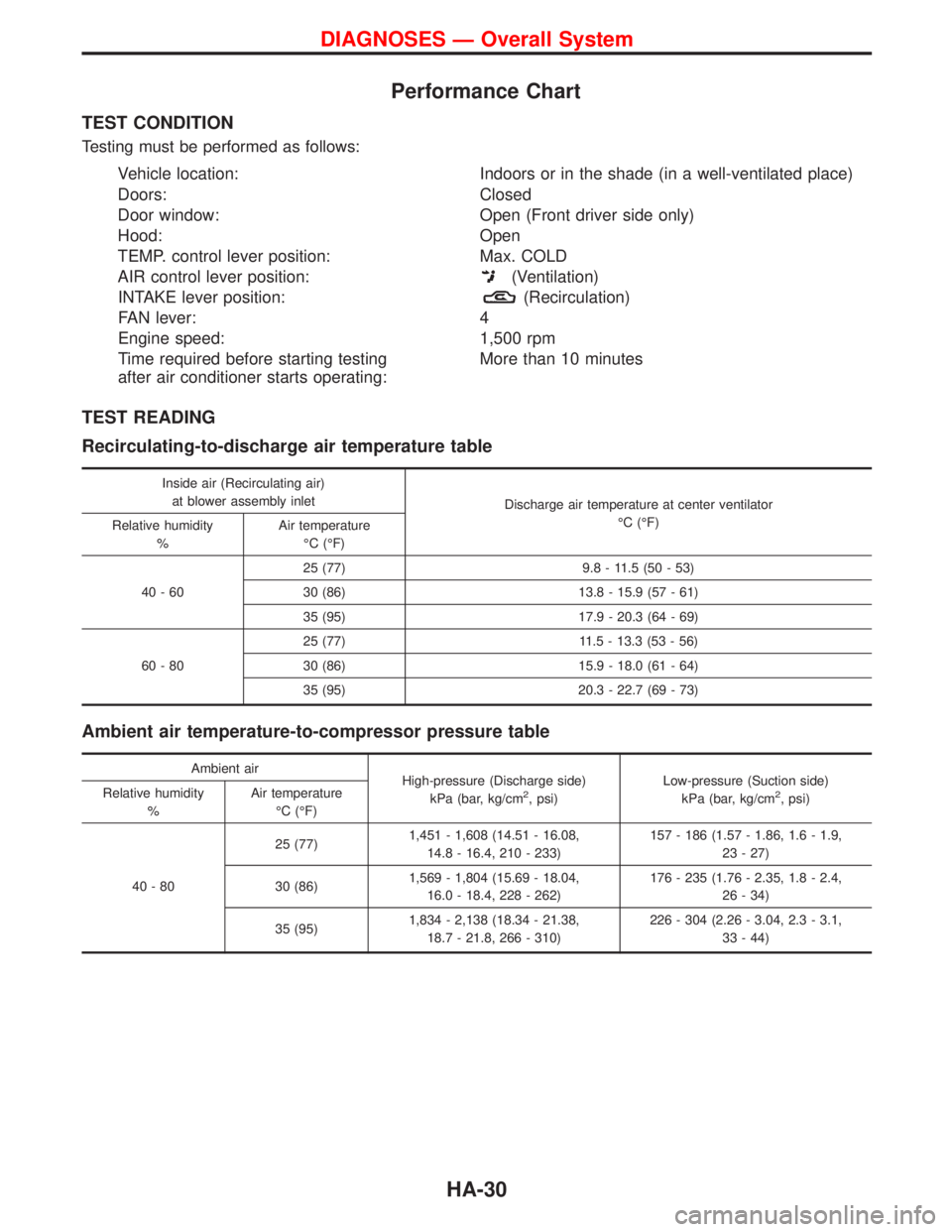

Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location: Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open (Front driver side only)

Hood: Open

TEMP. control lever position: Max. COLD

AIR control lever position:

(Ventilation)

INTAKE lever position:

(Recirculation)

FAN lever: 4

Engine speed: 1,500 rpm

Time required before starting testing

after air conditioner starts operating:More than 10 minutes

TEST READING

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet

Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

%Air temperature

ÉC (ÉF)

40-6025 (77) 9.8 - 11.5 (50 - 53)

30 (86) 13.8 - 15.9 (57 - 61)

35 (95) 17.9 - 20.3 (64 - 69)

60-8025 (77) 11.5 - 13.3 (53 - 56)

30 (86) 15.9 - 18.0 (61 - 64)

35 (95) 20.3 - 22.7 (69 - 73)

Ambient air temperature-to-compressor pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi)Low-pressure (Suction side)

kPa (bar, kg/cm2, psi) Relative humidity

%Air temperature

ÉC (ÉF)

40-8025 (77)1,451 - 1,608 (14.51 - 16.08,

14.8 - 16.4, 210 - 233)157 - 186 (1.57 - 1.86, 1.6 - 1.9,

23 - 27)

30 (86)1,569 - 1,804 (15.69 - 18.04,

16.0 - 18.4, 228 - 262)176 - 235 (1.76 - 2.35, 1.8 - 2.4,

26 - 34)

35 (95)1,834 - 2,138 (18.34 - 21.38,

18.7 - 21.8, 266 - 310)226 - 304 (2.26 - 3.04, 2.3 - 3.1,

33 - 44)

DIAGNOSES Ð Overall System

HA-30

Page 1420 of 1767

Clutch pedal .............................................CL-3, 4, 5

Clutch release mechanism ...............................CL-9

Coil spring (rear) ......................................RA-14, 16

Collision diagnosis..........................................RS-57

Combination lamp, front, removal and

installation .....................................................BT-6

Combination lamp, rear, removal and

installation .....................................................BT-8

Combination meter (needle type) ...................EL-70

Combination meter removal and instal-

lation - See Instrument panel......................BT-16

Combination switch...................................EL-23, 24

Component Location (manual A/C) ..................HA-7

Compression pressure ...................................EM-10

Compressor clutch removal and

installation ...................................................HA-24

Compressor mounting ....................................HA-21

Connecting rod...............................................EM-73

Connecting rod bearing clearance.................EM-77

Connecting rod bushing clearance ................EM-73

Console box - See Instrument panel ..............BT-16

CONSULT for ABS .........................................BR-58

CONSULT for engine .............................EC-39, 327

CONSULT-II general information.....................GI-26

Control lever (M/T) .........................................MT-13

Control lever (Transfer) .....................................TF-8

Control sleeve position sensor .....................EC-414

Control valve (A/T) ........................................AT-113

COOL/F - Wiring diagram ............................EC-112

Coolant mixture ratio ...................MA-17, 20, 22, 31

Coolant replacement ...............MA-5, 17, 20, 22, 31

Cooling circuit (engine)...............................LC-9, 27

Cooling fan ...............................................LC-15, 33

Cooling fan control .......................................EC-109

Cooling fan relay ..........................................EC-426

Corrosion protection..........................................BT-5

Counter gear (M/T) .........................................MT-11

Counter gear (Transfer) ............................TF-10, 20

Cowl top ..........................................................BT-21

Cowl top cover ................................................BT-21

Crankcase emission control system -

See positive crankcase ventilation .....EC-23, 312

Crankcase ventilation system - See

Positive crankcase ventilation ............EC-23, 312

Crankshaft ......................................................EM-76

Crankshaft position sensor (TDC) .......EC-145, 385

Cylinder block ................................................EM-66

Cylinder head .................................................EM-52

D

Data link connector ................................EC-39, 327

Daytime light system ..........................EL-29, 30, 31

DEF - Wiring diagram ...................................EL-107

Defroster door control rod adjustment ...........HA-62

Diagnosis sensor unit .....................................RS-11

Diagnostic trouble code (DTC) for OBD

system ................................................EC-33, 321

Differential carrier assembly ....................PD-29, 53Differential carrier disassembly..........PD-18, 38, 40

Differential gear oil replacement .......MA-36, 38, 39

Dimensions ......................................................GI-31

D/LOCK - Wiring diagram .............................EL-140

Door glass .......................................................BT-10

Door lock .........................................................BT-10

Door mirror ......................................................BT-48

Door trim .........................................................BT-19

Door, front .......................................................BT-10

Door, rear ........................................................BT-12

Drive belt inspection ................................MA-20, 28

Drive chain (Transfer) .....................................TF-10

Drive pinion diff. inspection ......................PD-20, 42

Drive pinion height ...................................PD-21, 49

Drive plate runout ..........................................EM-94

Drive shaft ........................................................MA-5

Drive shaft (front)..................................FA-4, 12, 22

Driver air bag..................................................RS-14

Dropping resistor (A/T)....................................AT-86

Dual pressure switch..................................HA-9, 61

E

ECM input/output signal .........................EC-69, 346

ECM relay ......................................EC-80, 209, 353

ECMRLY - Wiring diagram ...........................EC-210

ECTS - Wiring diagram ..................................EC-96

EGR control (EGRC) - solenoid valve .........EC-431

EGR control valve ........................................EC-439

EGR volume control valve ...........................EC-222

EGVC/V - Wiring diagram ............................EC-225

Electrical unit ................................................Foldout

Electronic fuel injection pump ......................EC-318

Engine compartment .......................................BT-50

Engine control circuit diagram ...............EC-16, 302

Engine control component parts

location ...............................................EC-12, 300

Engine control module (ECM) ......EC-69, 121, 200,

202, 213, 346,

407, 444

Engine control system diagram and

chart....................................................EC-17, 303

Engine coolant temperature sensor

(ECTS)................................................EC-95, 361

Engine oil filter replacement..........MA-5, 20, 21, 30

Engine oil precautions .......................................GI-6

Engine oil replacement ......................MA-20, 21, 29

Engine removal ..............................................EM-63

Engine room - See Engine

compartment ...............................................BT-50

Engine serial number ......................................GI-30

Exhaust manifold ...........................................EM-18

Exhaust system ..........................................FE-4, 10

Exhaust system inspection ............................MA-36

Extension tube diff. ..................................PD-19, 28

Exterior ............................................................BT-21

Exterior lamp.............................................EL-45, 60

ALPHABETICAL INDEX

IDX-3

Page 1424 of 1767

TAIL/L - Wiring diagram ..................................EL-45

TCM circuit diagram ..........................................AT-7

TCM inspection table ......................................AT-46

TDC Pulse Signal .........................................EC-168

Temperature control cable and linkage

adjustment ..................................................HA-63

THEFT - Wiring diagram...............................EL-214

Theft warning system ...........EL-209, 210, 213, 230

Thermo control amp .................................HA-51, 61

Thermostat................................................LC-12, 31

Third (3rd) seat ...............................................BT-39

THLCNT - Wiring diagram ...........................EC-435

Three way catalyst precautions.........................GI-5

Throttle control solenoid valve .....................EC-435

Throttle position switch ...................................AT-60

Tie-rod .......................................................ST-19, 21

Tie-rod ball joints.............................................ST-20

Tightening torque of standard bolts.................GI-38

Time control system .....................EL-180, 182, 184

Timing chain ...................................................EM-26

Timing gear ....................................................EM-38

Tire rotation ....................................................MA-43

Tooth contact diff. .....................................PD-27, 52

Torque convertor clutch solenoid valve ..AT-72, 141

Torsion bar spring .......................................FA-4, 30

Tow truck towing ..............................................GI-33

Towing point.....................................................GI-34

Transaxle fluid replacement.....................MA-36, 37

Transfer case ..............................................TF-9, 12

Transfer fluid replacement (Part time

4WD model) .........................................MA-36, 37

Transfer oil replacement ..........................MA-36, 38

Transmission case (M/T)..........................MT-10, 14

TRANSMT - Wiring diagram ...........................EL-80

Tread-FR&RR (Dimensions)............................GI-25

Trim...............................................BT-18, 19, 20, 21

Trunk room trim...............................................BT-47

Turbocharger ..................................................EM-14

Turbocharger charge air cooler......................EM-11

Turbocharger precautions..................................GI-5

TURN - Wiring diagram ..................................EL-56

Turn signal lamp .......................................EL-55, 56

U

Under body .....................................................BT-53

Upper link (front susp.) ...................................FA-33

V

Vacuum hose (brake system) ........................BR-19Vacuum hose drawing (Engine

control)................................................EC-18, 304

Vacuum pump .............................EM-24, BR-23, 25

Valve clearance..............................................EM-35

Valve clearance adjustment.....................MA-20, 28

Valve guide ....................................................EM-59

Valve lifter ......................................................EM-32

Valve seat ......................................................EM-60

Valve spring ...................................................EM-61

Variable nozzle turbocharger control

solenoid valve ...........................................EC-281

Vehicle identification number...........................GI-29

Vehicle speed sensor (VSS) ..................EC-99, 397

Ventilator door control rod adjustment ...........HA-61

Viscosity number (SAE)...........................MA-17, 18

VNT - Wiring diagram ..................................EC-283

VSS - Wiring diagram ..................................EC-101

W

WARN - Wiring diagram ...........................EL-82, 93

Warning chime ..........................................EL-81, 93

Warning lamps ..........................................EL-81, 82

Washer, front ...................................................EL-94

Washer, rear....................................................EL-96

Water cock control rod adjustment ................HA-63

Water pump ..............................................LC-11, 29

Water temperature gauge ...............................EL-72

Weatherstrip - See Exterior ............................BT-21

Wheel alignment (front) ....................................FA-8

Wheel balance ...............................................MA-43

Wheel bearing (front axle) ................................FA-6

Wheel bearing (rear) ..................................RA-5, 16

Wheel hub (front) ........................................FA-4, 18

Wheel sensors (ABS)...............................BR-38, 42

Wheel size .......................................................GI-31

WINDOW - Wiring diagram ..........................EL-134

Window, back door .........................................BT-47

Window, door ..................................................BT-42

Window, rear side .....................................BT-42, 43

Window, side - See Rear side window ...........BT-43

Windshield.......................................................BT-42

WIP/R - Wiring diagram ..................................EL-96

WIPER - Wiring diagram ........................EL-94, 100

Wiper and washer.....................................EL-94, 98

Wiper, front......................................................EL-94

Wiper, rear ......................................................EL-96

Wiring Diagram (Cell code) list .....................EL-291

ALPHABETICAL INDEX

IDX-7

Page 1481 of 1767

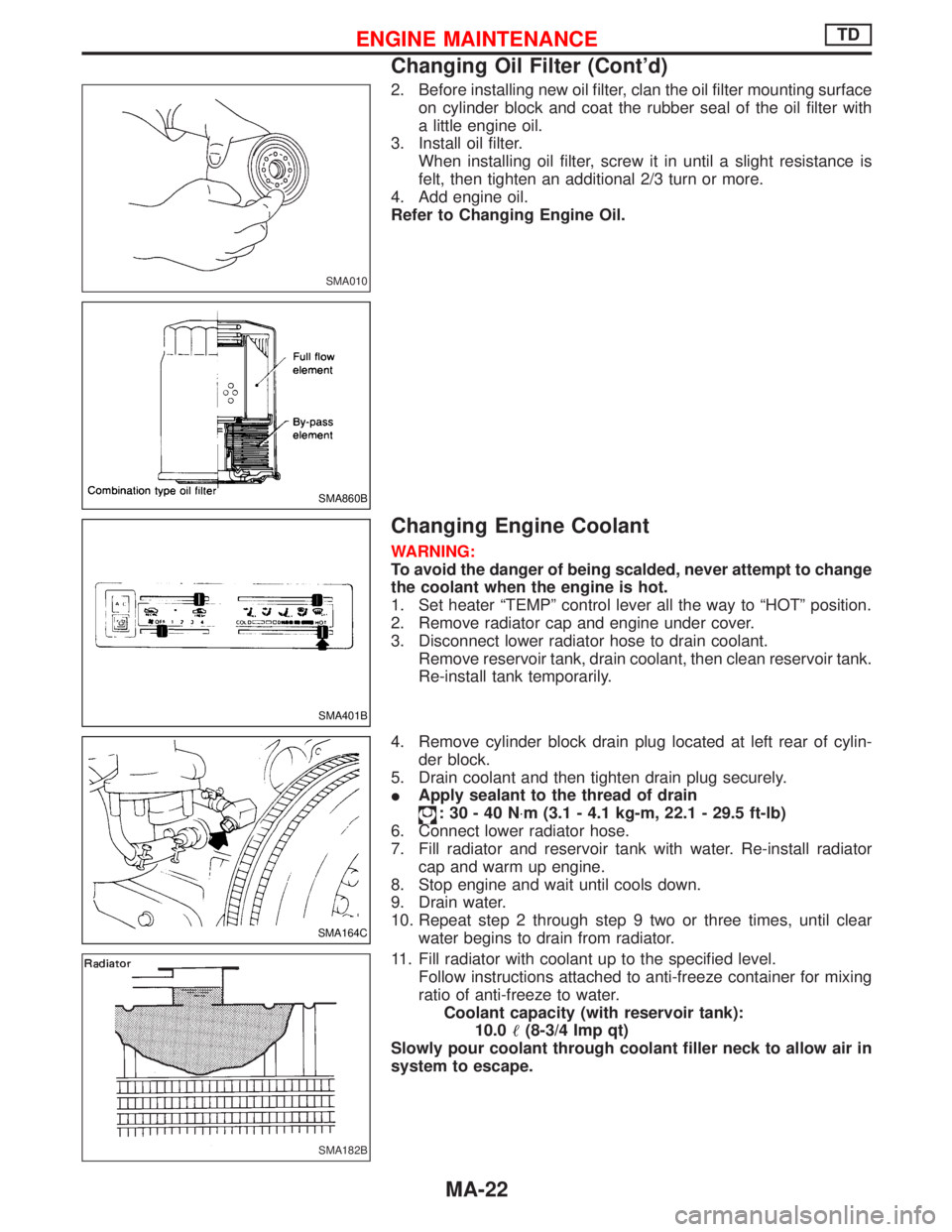

2. Before installing new oil filter, clan the oil filter mounting surface

on cylinder block and coat the rubber seal of the oil filter with

a little engine oil.

3. Install oil filter.

When installing oil filter, screw it in until a slight resistance is

felt, then tighten an additional 2/3 turn or more.

4. Add engine oil.

Refer to Changing Engine Oil.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never attempt to change

the coolant when the engine is hot.

1. Set heater ªTEMPº control lever all the way to ªHOTº position.

2. Remove radiator cap and engine under cover.

3. Disconnect lower radiator hose to drain coolant.

Remove reservoir tank, drain coolant, then clean reservoir tank.

Re-install tank temporarily.

4. Remove cylinder block drain plug located at left rear of cylin-

der block.

5. Drain coolant and then tighten drain plug securely.

IApply sealant to the thread of drain

:30-40N×m (3.1 - 4.1 kg-m, 22.1 - 29.5 ft-lb)

6. Connect lower radiator hose.

7. Fill radiator and reservoir tank with water. Re-install radiator

cap and warm up engine.

8. Stop engine and wait until cools down.

9. Drain water.

10. Repeat step 2 through step 9 two or three times, until clear

water begins to drain from radiator.

11. Fill radiator with coolant up to the specified level.

Follow instructions attached to anti-freeze container for mixing

ratio of anti-freeze to water.

Coolant capacity (with reservoir tank):

10.0(8-3/4 Imp qt)

Slowly pour coolant through coolant filler neck to allow air in

system to escape.

SMA010

SMA860B

SMA401B

SMA164C

SMA182B

ENGINE MAINTENANCETD

Changing Oil Filter (Cont'd)

MA-22

Page 1491 of 1767

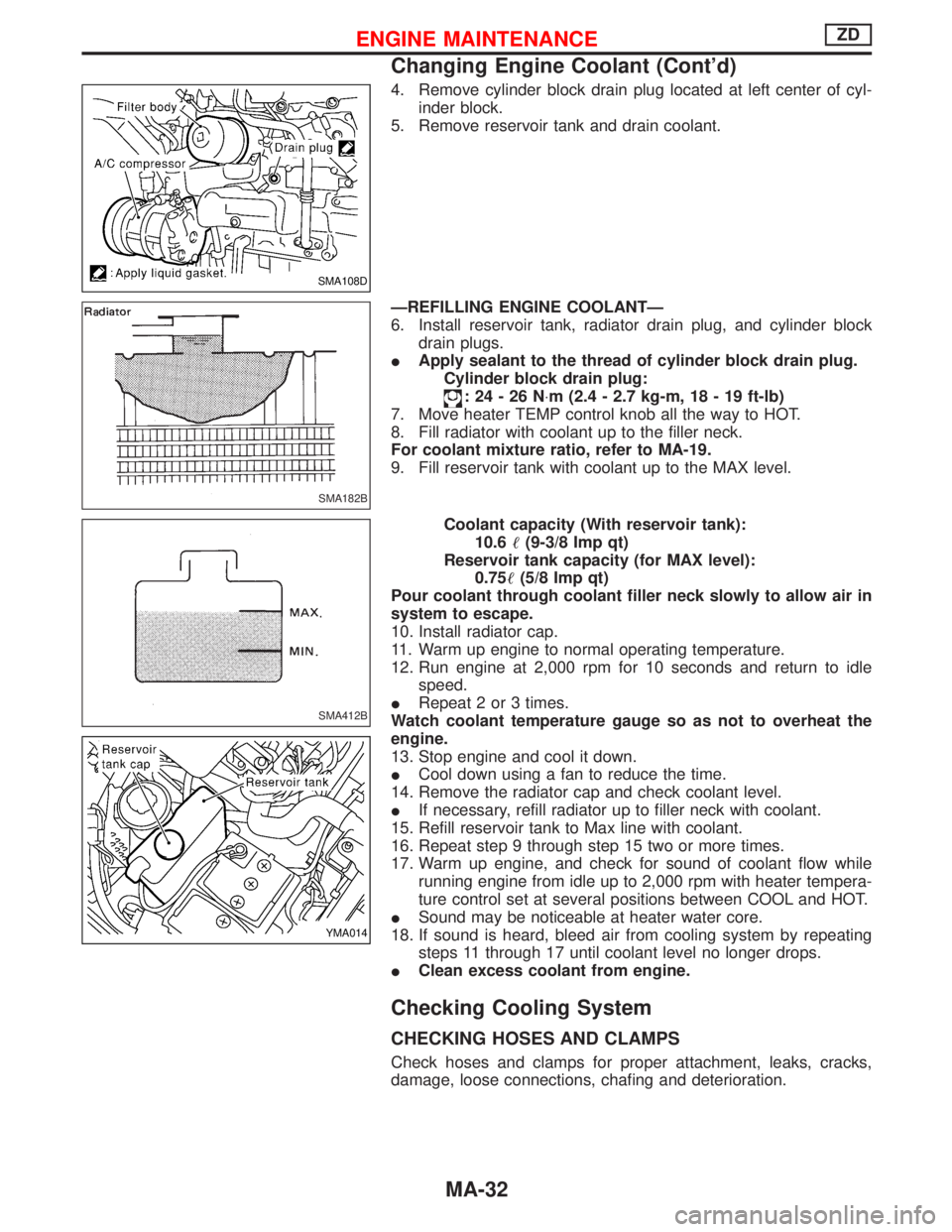

4. Remove cylinder block drain plug located at left center of cyl-

inder block.

5. Remove reservoir tank and drain coolant.

ÐREFILLING ENGINE COOLANTÐ

6. Install reservoir tank, radiator drain plug, and cylinder block

drain plugs.

IApply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:24-26N×m (2.4 - 2.7 kg-m, 18 - 19 ft-lb)

7. Move heater TEMP control knob all the way to HOT.

8. Fill radiator with coolant up to the filler neck.

For coolant mixture ratio, refer to MA-19.

9. Fill reservoir tank with coolant up to the MAX level.

Coolant capacity (With reservoir tank):

10.6(9-3/8 Imp qt)

Reservoir tank capacity (for MAX level):

0.75(5/8 Imp qt)

Pour coolant through coolant filler neck slowly to allow air in

system to escape.

10. Install radiator cap.

11. Warm up engine to normal operating temperature.

12. Run engine at 2,000 rpm for 10 seconds and return to idle

speed.

IRepeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

13. Stop engine and cool it down.

ICool down using a fan to reduce the time.

14. Remove the radiator cap and check coolant level.

IIf necessary, refill radiator up to filler neck with coolant.

15. Refill reservoir tank to Max line with coolant.

16. Repeat step 9 through step 15 two or more times.

17. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

ISound may be noticeable at heater water core.

18. If sound is heard, bleed air from cooling system by repeating

steps 11 through 17 until coolant level no longer drops.

IClean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

SMA108D

SMA182B

SMA412B

YMA014

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-32

Page 1661 of 1767

![NISSAN TERRANO 2002 Service Manual PDF Diagnostic item ExplanationRepair order

ªRecheck SRS at each replacement.º

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-tensioner is open or

shorted to a power supply circ NISSAN TERRANO 2002 Service Manual PDF Diagnostic item ExplanationRepair order

ªRecheck SRS at each replacement.º

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-tensioner is open or

shorted to a power supply circ](/img/5/57393/w960_57393-1660.png)

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replacement.º

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-tensioner is open or

shorted to a power supply circuit.1. Visually check the wiring harness

connections.

2. Replace the harness if it has visible

damage.

3. Replace front RH seat belt.

(Before disposal, it must be deacti-

vated.)

4. Replace the diagnosis sensor unit.

5. Replace the related harness. PRE-TEN FRONT RH

[GND-SHORT]IThe circuit for front RH seat belt pre-tensioner is shorted to

ground.

INDEFINITE FAIL-

URES (AIR BAG)IA problem which cannot be specified occurs because more

than two parts are out of order.1. Visually check wiring harness con-

nections.

2. Replace diagnosis sensor unit.

3. Replace spiral cable and air bag

modules.

4. Replace air bag and pre-tensioner

harness.

5. Replace main harness.

INDEFINITE FAIL-

URES

(PRE-TENSIONER)Driver's and front passenger seat belt pre-tensioners are out of

order.1. Visually check wiring harness con-

nections.

2. Replace diagnosis sensor unit.

3. Replace spiral cable and air bag

modules.

4. Replace air bag and pre-tensioner

harness.

5. Replace main harness.

CONTROL UNITILow battery voltage (Less than 9V)IGo to DIAGNOSTIC PROCEDURE 3

(RS-40) after charging battery.

IDiagnosis sensor unit is malfunctioning. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace diagnosis sensor unit.

4. Replace the related harness.

* Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is eliminated using the

air bag warning lamp or CONSULT-II each time repair is finished. If malfunction is still observed, proceed to the next step. When mal-

function is eliminated, further repair work is not required.

DIAGNOSTIC PROCEDURE 3

Final checking after repairing SRS by using CONSULT-II Ð

Diagnosis mode

1. After repairing SRS, connect both battery cables.

2. Connect CONSULT-II to data link connector.

3. Turn ignition switch from ªOFFº to ªONº.

NRS122

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-40

Page 1667 of 1767

![NISSAN TERRANO 2002 Service Manual PDF Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring ha NISSAN TERRANO 2002 Service Manual PDF Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring ha](/img/5/57393/w960_57393-1666.png)

Diagnostic item Explanation Repair order

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-

tensioner is open or shorted to a power

supply circuit.1. Visually check the wiring harness con-

nections.

2. Replace the harness if it has visible

damage.

3. If the harness check is OK, replace the

diagnosis sensor unit and front RH seat

belt. (Before disposing of the front RH

seat belt pre-tensioner, if must be

deployed.) PRE-TEN FRONT RH

[GND-SHORT]IThe circuit for front RH seat belt pre-

tensioner is shorted to ground.

CONTROL UNITIDiagnosis sensor unit is malfunctioning. 1. Visually check the wiring harness con-

nection.

2. Replace the harness if it has visible

damage.

3. If the harness check is OK, replace the

diagnosis sensor unit.

* Follow the procedures in numerical order when repairing malfunctioning parts, then make the final system check.

Trouble Diagnoses without CONSULT-II

DIAGNOSTIC PROCEDURE 6

Inspecting SRS malfunctioning parts by using ªAIR BAGº

warning lamp Ð Diagnosis mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is

detected in User mode.

1. Turn ignition switch ªONº.

2. After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition

switch ªOFFº within 1 second.

3. Wait more than 3 seconds.

4. Repeat steps 1 to 3 three times.

5. Turn ignition switch ªONº.

SRS is now in Diagnosis mode.

6. ªAIR BAGº warning lamp operates in Diagnosis mode as fol-

lows:

NOTE:

If SRS does not enter Diagnosis mode even though malfunc-

tion is detected in User mode, check the battery voltage.

If the battery voltage is less than 9V, charge the battery. Then

go to DIAGNOSTIC PROCEDURE 7, page RS-51.

If the battery voltage is OK, replace the diagnosis sensor unit.

SRS800

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-46

Page 1704 of 1767

System Description

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

I10A fuse (No. 31, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage (ZD30DDTi engine models). The

charging circuit is protected by the 100A (A/T models) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

Ithrough 10A fuse [No. 12, located in the fuse block (J/B)]

Ito combination meter terminal 28 for the charge warning lamp.

Ground is supplied to terminal 2 of the combination meter through terminal 1(L) (TD27Ti engine models) or

3(L) (ZD30DDTi engine model) of the alternator. With power and ground supplied, the charge warning lamp

will illuminate. When the alternator is providing sufficient voltage with the engine running, the ground is opened

and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

CHARGING SYSTEM

SC-23