engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1144 of 1767

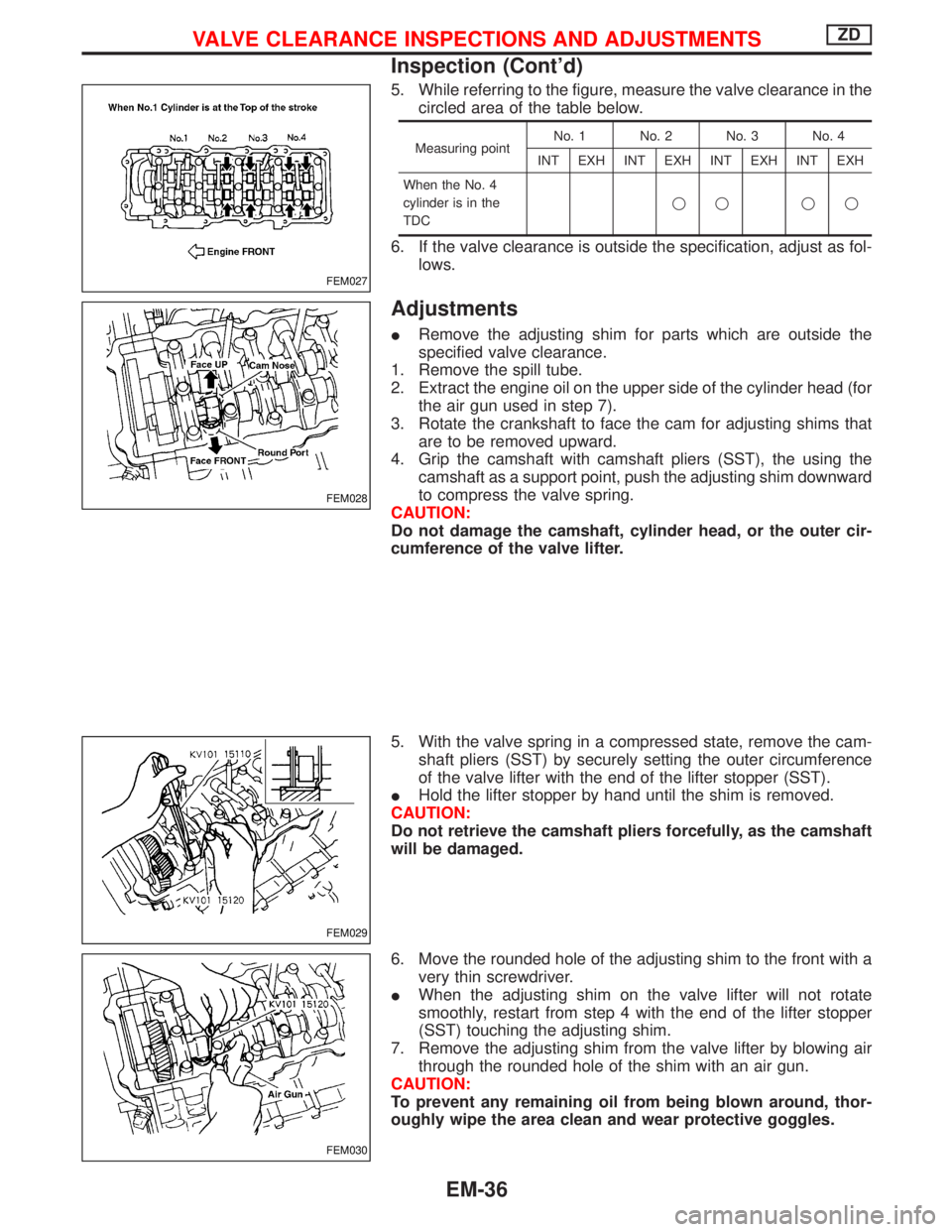

5. While referring to the figure, measure the valve clearance in the

circled area of the table below.

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 4

cylinder is in the

TDCqq qq

6. If the valve clearance is outside the specification, adjust as fol-

lows.

Adjustments

IRemove the adjusting shim for parts which are outside the

specified valve clearance.

1. Remove the spill tube.

2. Extract the engine oil on the upper side of the cylinder head (for

the air gun used in step 7).

3. Rotate the crankshaft to face the cam for adjusting shims that

are to be removed upward.

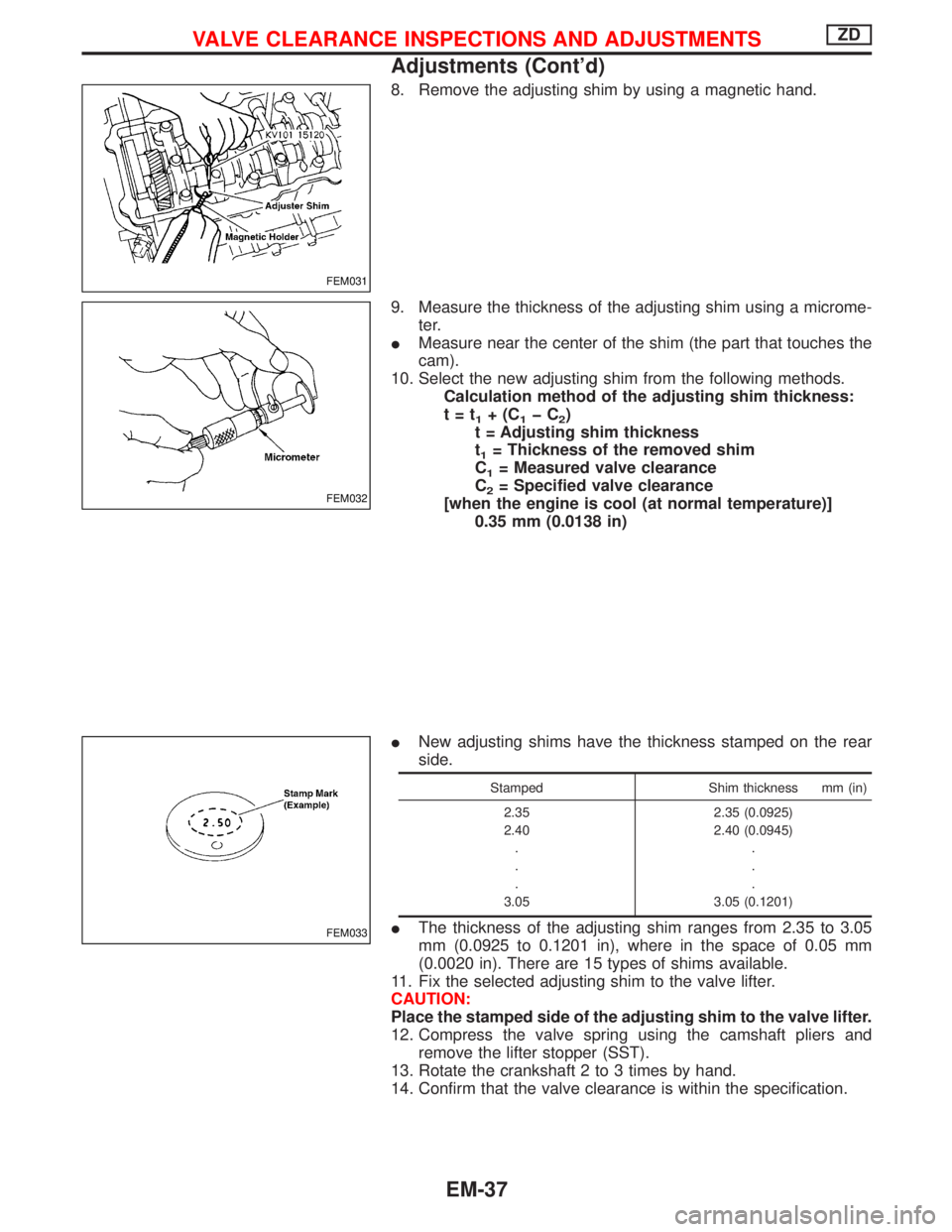

4. Grip the camshaft with camshaft pliers (SST), the using the

camshaft as a support point, push the adjusting shim downward

to compress the valve spring.

CAUTION:

Do not damage the camshaft, cylinder head, or the outer cir-

cumference of the valve lifter.

5. With the valve spring in a compressed state, remove the cam-

shaft pliers (SST) by securely setting the outer circumference

of the valve lifter with the end of the lifter stopper (SST).

IHold the lifter stopper by hand until the shim is removed.

CAUTION:

Do not retrieve the camshaft pliers forcefully, as the camshaft

will be damaged.

6. Move the rounded hole of the adjusting shim to the front with a

very thin screwdriver.

IWhen the adjusting shim on the valve lifter will not rotate

smoothly, restart from step 4 with the end of the lifter stopper

(SST) touching the adjusting shim.

7. Remove the adjusting shim from the valve lifter by blowing air

through the rounded hole of the shim with an air gun.

CAUTION:

To prevent any remaining oil from being blown around, thor-

oughly wipe the area clean and wear protective goggles.

FEM027

FEM028

FEM029

FEM030

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

Inspection (Cont'd)

EM-36

Page 1145 of 1767

8. Remove the adjusting shim by using a magnetic hand.

9. Measure the thickness of the adjusting shim using a microme-

ter.

IMeasure near the center of the shim (the part that touches the

cam).

10. Select the new adjusting shim from the following methods.

Calculation method of the adjusting shim thickness:

t=t

1+(C1þC2)

t = Adjusting shim thickness

t

1= Thickness of the removed shim

C

1= Measured valve clearance

C

2= Specified valve clearance

[when the engine is cool (at normal temperature)]

0.35 mm (0.0138 in)

INew adjusting shims have the thickness stamped on the rear

side.

Stamped Shim thickness mm (in)

2.35

2.40

.

.

.

3.052.35 (0.0925)

2.40 (0.0945)

.

.

.

3.05 (0.1201)

IThe thickness of the adjusting shim ranges from 2.35 to 3.05

mm (0.0925 to 0.1201 in), where in the space of 0.05 mm

(0.0020 in). There are 15 types of shims available.

11. Fix the selected adjusting shim to the valve lifter.

CAUTION:

Place the stamped side of the adjusting shim to the valve lifter.

12. Compress the valve spring using the camshaft pliers and

remove the lifter stopper (SST).

13. Rotate the crankshaft 2 to 3 times by hand.

14. Confirm that the valve clearance is within the specification.

FEM031

FEM032

FEM033

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

Adjustments (Cont'd)

EM-37

Page 1147 of 1767

Removal

1. Remove the engine assembly.

Refer to ªENGINE REMOVALº, EM-63.

2. Place the engine on an engine stand (SST).

Refer to ªCYLINDER BLOCKº, EM-67.

3. Remove the following.

IAuto tensioner bracket

IAir conditioner bracket

IAlternator bracket

IOil tube

IVacuum pump

IRocker cover

IOil pan (upper, lower)

IInjection tube

ISpill tube

IHigh pressure nozzle assembly

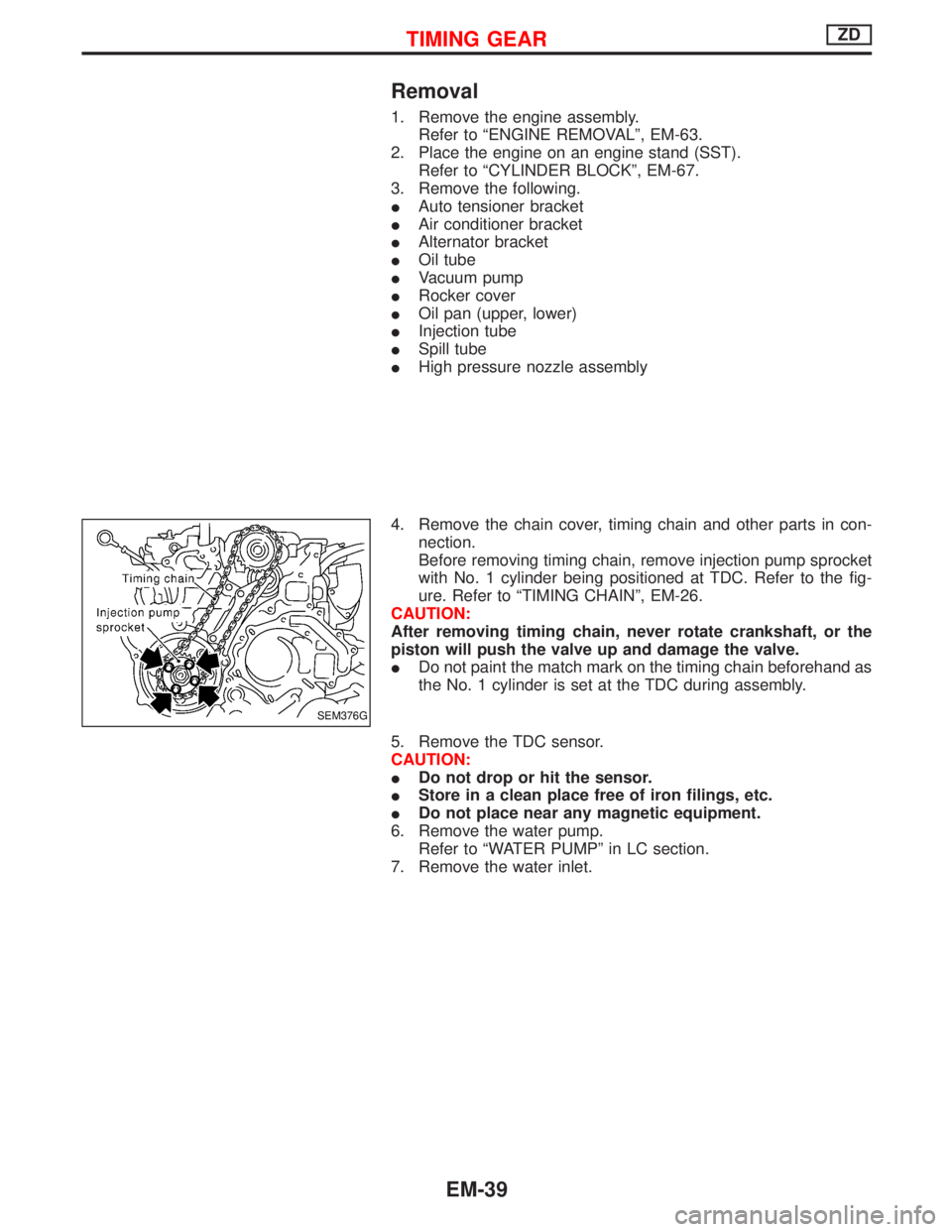

4. Remove the chain cover, timing chain and other parts in con-

nection.

Before removing timing chain, remove injection pump sprocket

with No. 1 cylinder being positioned at TDC. Refer to the fig-

ure. Refer to ªTIMING CHAINº, EM-26.

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

IDo not paint the match mark on the timing chain beforehand as

the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

IDo not drop or hit the sensor.

IStore in a clean place free of iron filings, etc.

IDo not place near any magnetic equipment.

6. Remove the water pump.

Refer to ªWATER PUMPº in LC section.

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-39

Page 1148 of 1767

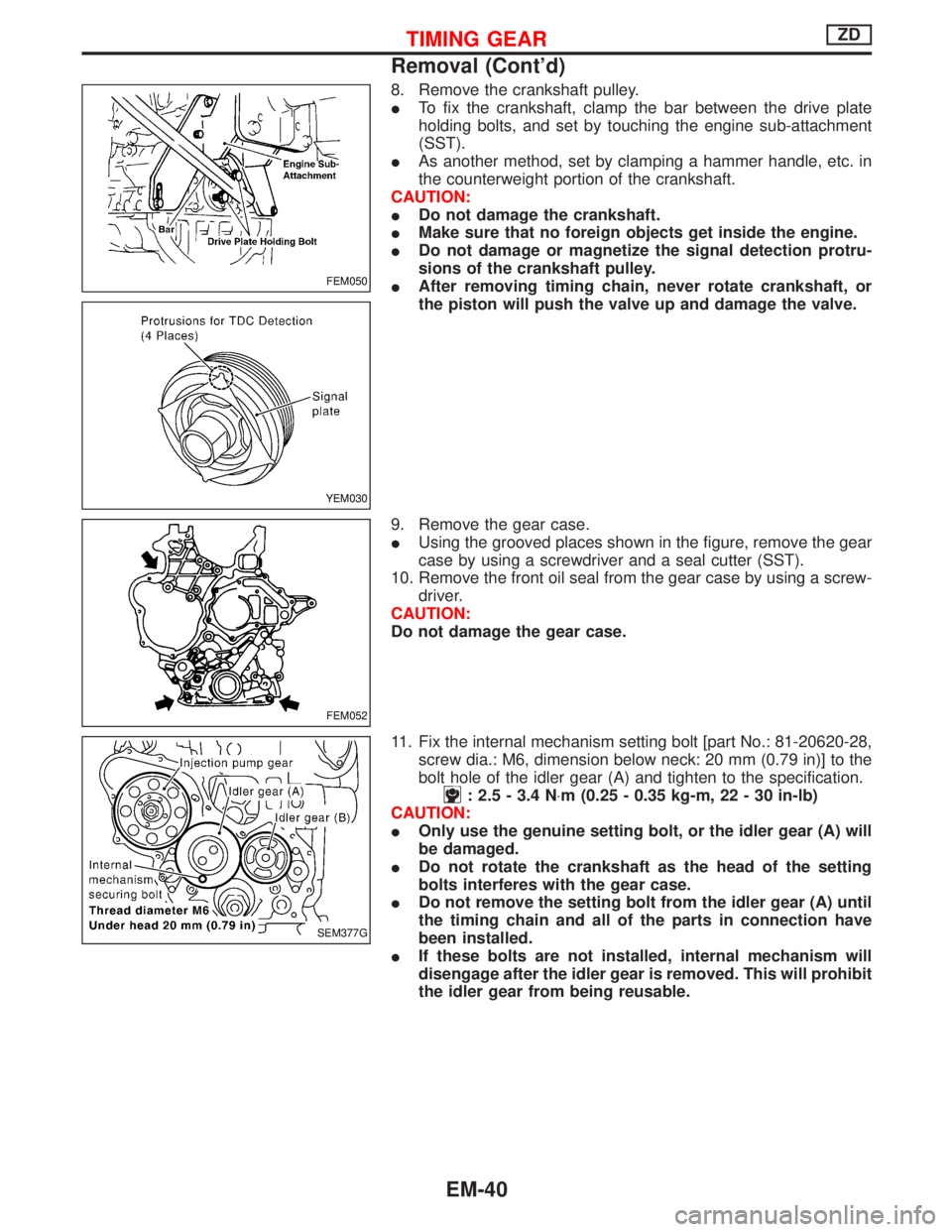

8. Remove the crankshaft pulley.

ITo fix the crankshaft, clamp the bar between the drive plate

holding bolts, and set by touching the engine sub-attachment

(SST).

IAs another method, set by clamping a hammer handle, etc. in

the counterweight portion of the crankshaft.

CAUTION:

IDo not damage the crankshaft.

IMake sure that no foreign objects get inside the engine.

IDo not damage or magnetize the signal detection protru-

sions of the crankshaft pulley.

IAfter removing timing chain, never rotate crankshaft, or

the piston will push the valve up and damage the valve.

9. Remove the gear case.

IUsing the grooved places shown in the figure, remove the gear

case by using a screwdriver and a seal cutter (SST).

10. Remove the front oil seal from the gear case by using a screw-

driver.

CAUTION:

Do not damage the gear case.

11. Fix the internal mechanism setting bolt [part No.: 81-20620-28,

screw dia.: M6, dimension below neck: 20 mm (0.79 in)] to the

bolt hole of the idler gear (A) and tighten to the specification.

: 2.5 - 3.4 N×m (0.25 - 0.35 kg-m, 22 - 30 in-lb)

CAUTION:

IOnly use the genuine setting bolt, or the idler gear (A) will

be damaged.

IDo not rotate the crankshaft as the head of the setting

bolts interferes with the gear case.

IDo not remove the setting bolt from the idler gear (A) until

the timing chain and all of the parts in connection have

been installed.

IIf these bolts are not installed, internal mechanism will

disengage after the idler gear is removed. This will prohibit

the idler gear from being reusable.

FEM050

YEM030

FEM052

SEM377G

TIMING GEARZD

Removal (Cont'd)

EM-40

Page 1152 of 1767

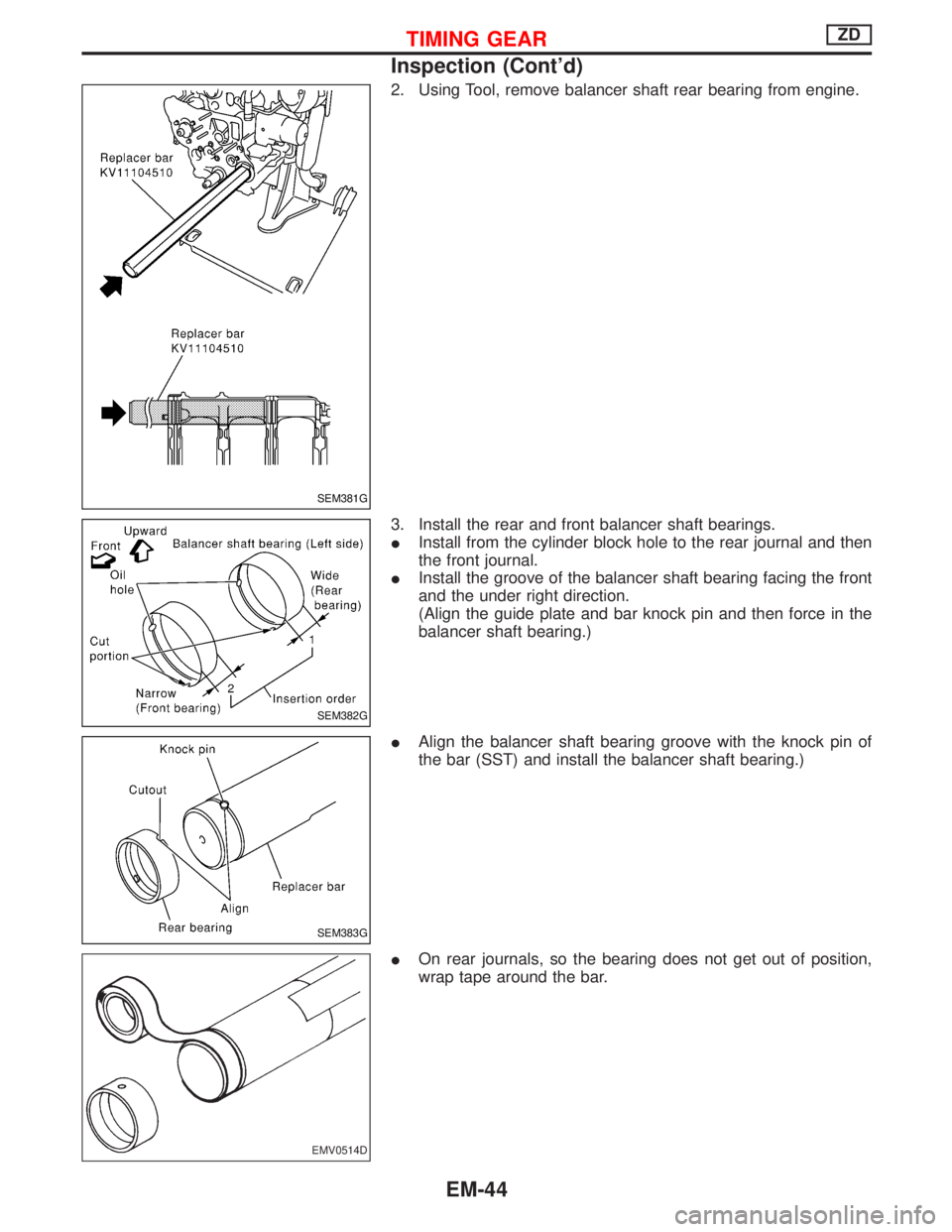

2. Using Tool, remove balancer shaft rear bearing from engine.

3. Install the rear and front balancer shaft bearings.

IInstall from the cylinder block hole to the rear journal and then

the front journal.

IInstall the groove of the balancer shaft bearing facing the front

and the under right direction.

(Align the guide plate and bar knock pin and then force in the

balancer shaft bearing.)

IAlign the balancer shaft bearing groove with the knock pin of

the bar (SST) and install the balancer shaft bearing.)

IOn rear journals, so the bearing does not get out of position,

wrap tape around the bar.

SEM381G

SEM382G

SEM383G

EMV0514D

TIMING GEARZD

Inspection (Cont'd)

EM-44

Page 1155 of 1767

![NISSAN TERRANO 2002 Service Repair Manual 4. Install the front oil seal to the gear case.

IApply engine oil to the fitting side.

IEvenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s NISSAN TERRANO 2002 Service Repair Manual 4. Install the front oil seal to the gear case.

IApply engine oil to the fitting side.

IEvenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s](/img/5/57393/w960_57393-1154.png)

4. Install the front oil seal to the gear case.

IApply engine oil to the fitting side.

IEvenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make sure the oil seal does not spill off the end side of the gear

case.

5. Install the gear case.

1) Before installing gear case, remove all traces of liquid gasket

from mating surface using a scraper.

2) Align gasket with dowel and install.

3) Install the O-rings to the gear case.

IThe O-ring at the top position shown in the figure can be

installed in during cylinder head installation.

4) Apply a continuous bead of liquid gasket to gear case.

IUse Genuine Liquid Gasket or equivalent.

a. Coat of liquid gasket should be maintained within 2.0 to 3.0

mm (0.079 to 0.118 in) dia. range.

b. Attach gear case to cylinder block within 5 minutes after

coating.

c. Wait at least 30 minutes before refilling engine oil or start-

ing engine.

FEM043

FEM044

SEM353G

FEM045

TIMING GEARZD

Installation (Cont'd)

EM-47

Page 1159 of 1767

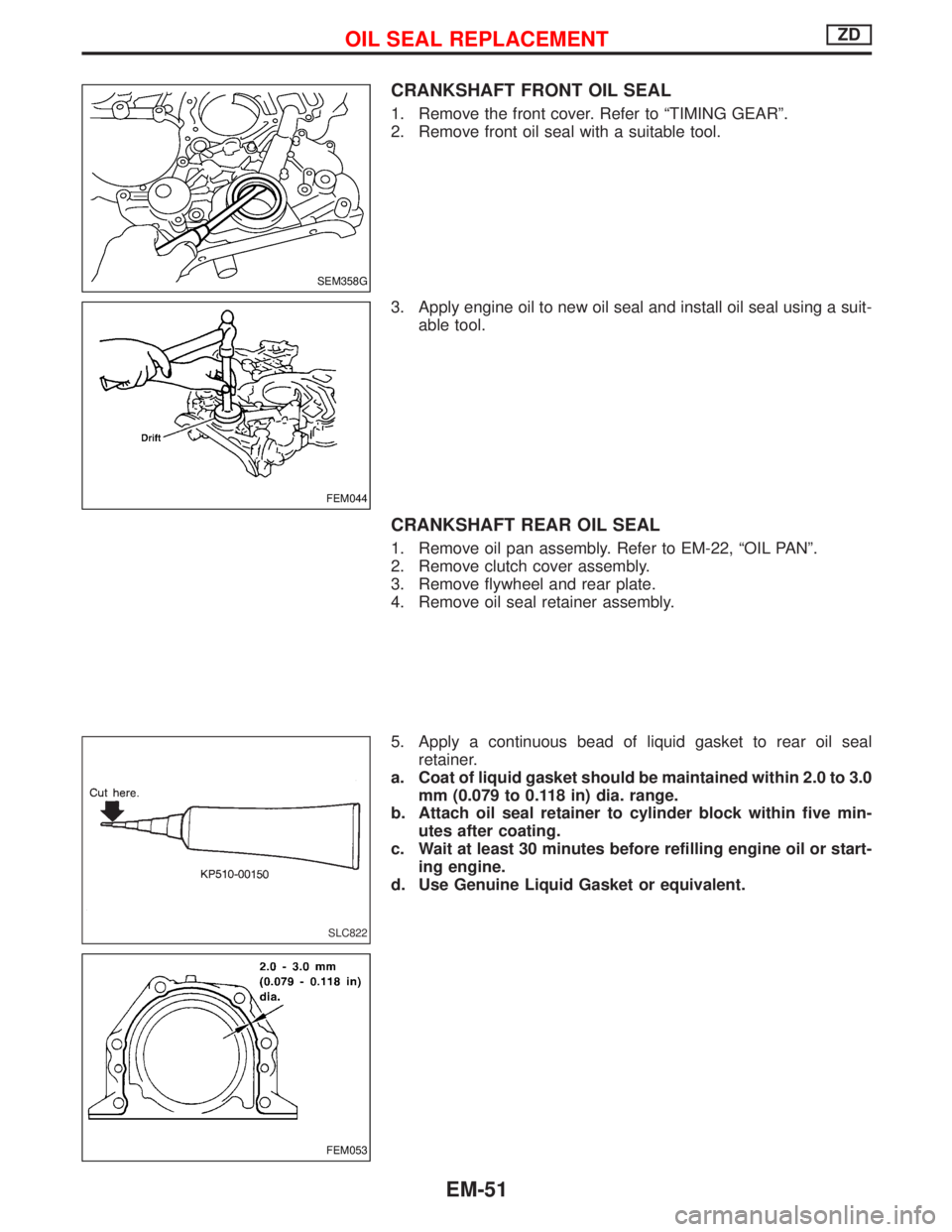

CRANKSHAFT FRONT OIL SEAL

1. Remove the front cover. Refer to ªTIMING GEARº.

2. Remove front oil seal with a suitable tool.

3. Apply engine oil to new oil seal and install oil seal using a suit-

able tool.

CRANKSHAFT REAR OIL SEAL

1. Remove oil pan assembly. Refer to EM-22, ªOIL PANº.

2. Remove clutch cover assembly.

3. Remove flywheel and rear plate.

4. Remove oil seal retainer assembly.

5. Apply a continuous bead of liquid gasket to rear oil seal

retainer.

a. Coat of liquid gasket should be maintained within 2.0 to 3.0

mm (0.079 to 0.118 in) dia. range.

b. Attach oil seal retainer to cylinder block within five min-

utes after coating.

c. Wait at least 30 minutes before refilling engine oil or start-

ing engine.

d. Use Genuine Liquid Gasket or equivalent.

SEM358G

FEM044

SLC822

FEM053

OIL SEAL REPLACEMENTZD

EM-51

Page 1161 of 1767

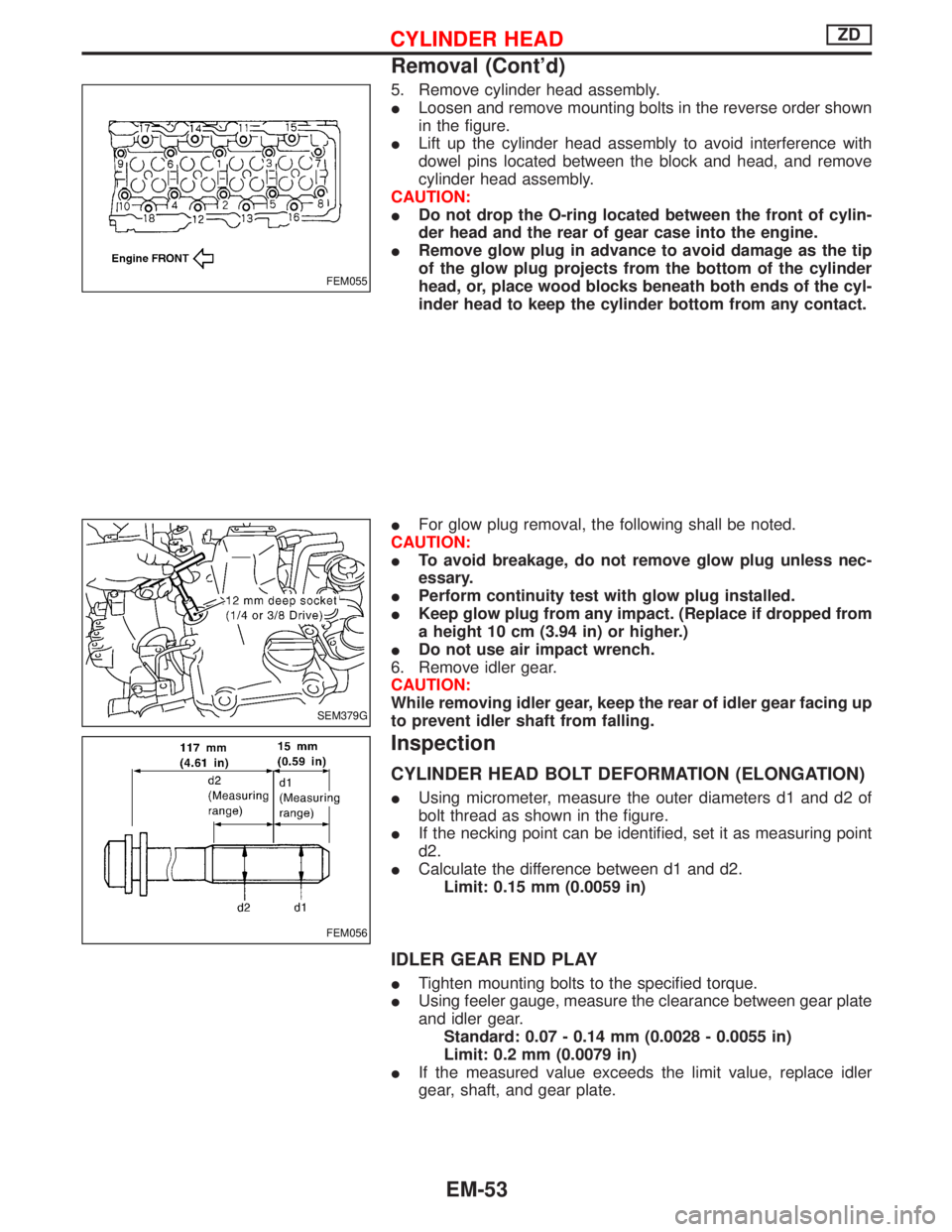

5. Remove cylinder head assembly.

ILoosen and remove mounting bolts in the reverse order shown

in the figure.

ILift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

IDo not drop the O-ring located between the front of cylin-

der head and the rear of gear case into the engine.

IRemove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylinder

head, or, place wood blocks beneath both ends of the cyl-

inder head to keep the cylinder bottom from any contact.

IFor glow plug removal, the following shall be noted.

CAUTION:

ITo avoid breakage, do not remove glow plug unless nec-

essary.

IPerform continuity test with glow plug installed.

IKeep glow plug from any impact. (Replace if dropped from

a height 10 cm (3.94 in) or higher.)

IDo not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing up

to prevent idler shaft from falling.

Inspection

CYLINDER HEAD BOLT DEFORMATION (ELONGATION)

IUsing micrometer, measure the outer diameters d1 and d2 of

bolt thread as shown in the figure.

IIf the necking point can be identified, set it as measuring point

d2.

ICalculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

ITighten mounting bolts to the specified torque.

IUsing feeler gauge, measure the clearance between gear plate

and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

IIf the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-53

Page 1163 of 1767

Unit: mm (in)

GradePiston crown

depressionGasket thick-

ness*1No. of notches

1Less than þ0.078

(þ0.0031)*20.65 (0.0256) 1

2More than þ0.078

(þ0.0031)*30.70 (0.0276) 2

*1: Thickness of gasket tightened with head bolts

*2: Indicates values such as þ0.080 mm (þ0.0031 in).

*3: Indicates values such as þ0.075 mm (þ0.0030 in).

2. Install idler gear and idler shaft.

ICheck that the counter marks with cam gear, ªAAº and ªBBº, are

located on the front side of the engine.

Refer to EM-52.

CAUTION:

Since idler gear cannot be installed or removed with cylinder

head assembly mounted on the engine because of interfer-

ence with gear case, make sure that there are no reverse

installations or uninstalled parts.

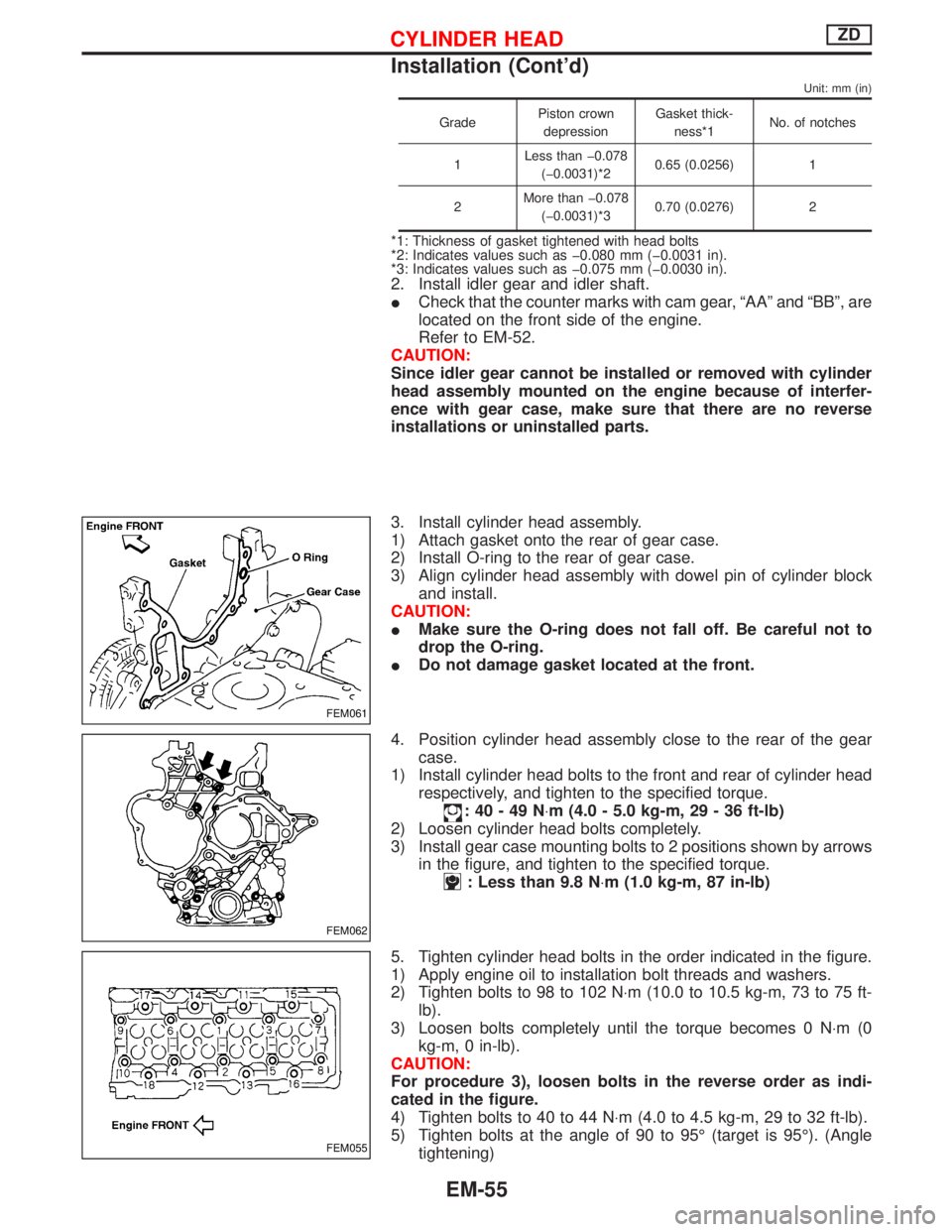

3. Install cylinder head assembly.

1) Attach gasket onto the rear of gear case.

2) Install O-ring to the rear of gear case.

3) Align cylinder head assembly with dowel pin of cylinder block

and install.

CAUTION:

IMake sure the O-ring does not fall off. Be careful not to

drop the O-ring.

IDo not damage gasket located at the front.

4. Position cylinder head assembly close to the rear of the gear

case.

1) Install cylinder head bolts to the front and rear of cylinder head

respectively, and tighten to the specified torque.

:40-49N×m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

2) Loosen cylinder head bolts completely.

3) Install gear case mounting bolts to 2 positions shown by arrows

in the figure, and tighten to the specified torque.

: Less than 9.8 N×m (1.0 kg-m, 87 in-lb)

5. Tighten cylinder head bolts in the order indicated in the figure.

1) Apply engine oil to installation bolt threads and washers.

2) Tighten bolts to 98 to 102 N×m (10.0 to 10.5 kg-m, 73 to 75 ft-

lb).

3) Loosen bolts completely until the torque becomes 0 N×m(0

kg-m, 0 in-lb).

CAUTION:

For procedure 3), loosen bolts in the reverse order as indi-

cated in the figure.

4) Tighten bolts to 40 to 44 N×m (4.0 to 4.5 kg-m, 29 to 32 ft-lb).

5) Tighten bolts at the angle of 90 to 95É (target is 95É). (Angle

tightening)

FEM061

FEM062

FEM055

CYLINDER HEADZD

Installation (Cont'd)

EM-55

Page 1164 of 1767

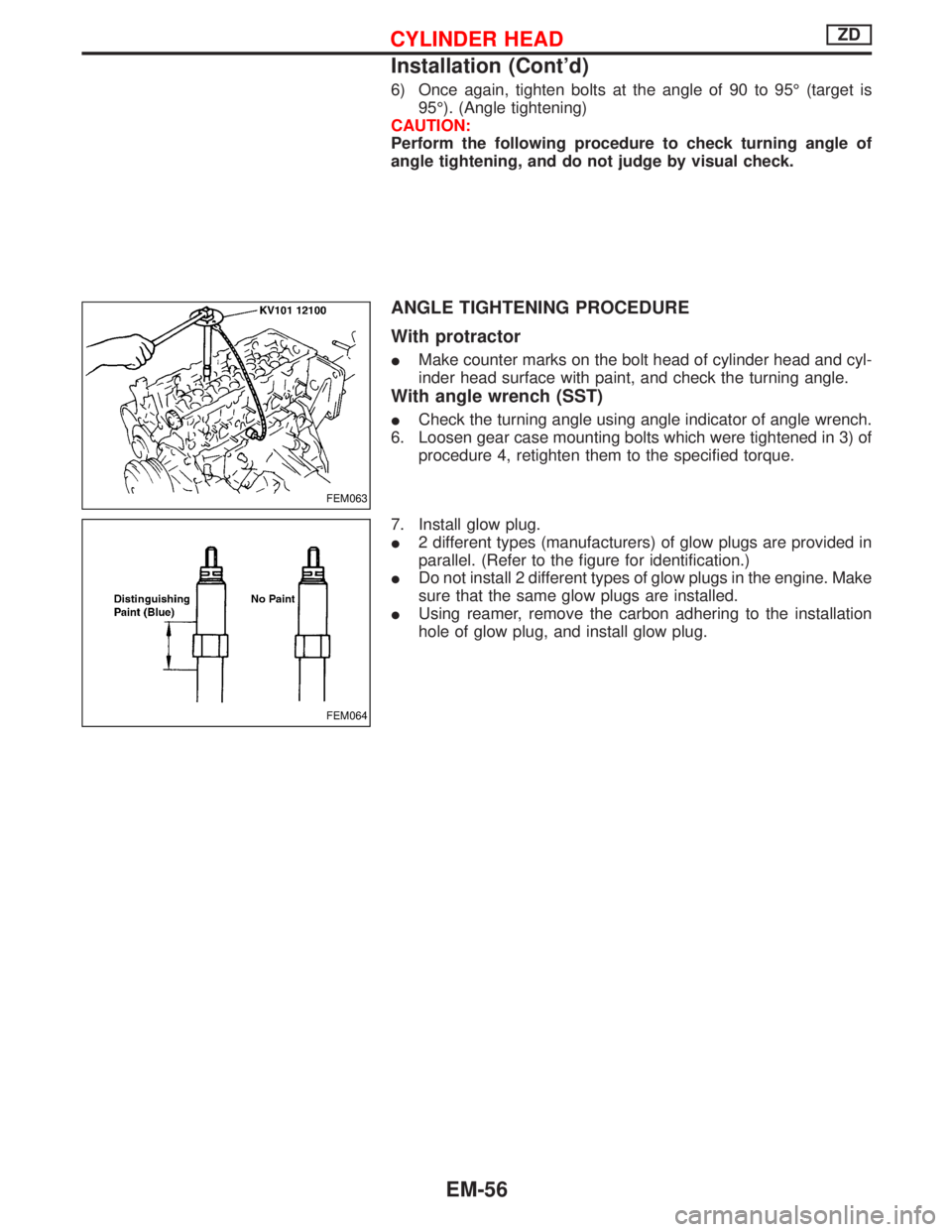

6) Once again, tighten bolts at the angle of 90 to 95É (target is

95É). (Angle tightening)

CAUTION:

Perform the following procedure to check turning angle of

angle tightening, and do not judge by visual check.

ANGLE TIGHTENING PROCEDURE

With protractor

IMake counter marks on the bolt head of cylinder head and cyl-

inder head surface with paint, and check the turning angle.

With angle wrench (SST)

ICheck the turning angle using angle indicator of angle wrench.

6. Loosen gear case mounting bolts which were tightened in 3) of

procedure 4, retighten them to the specified torque.

7. Install glow plug.

I2 different types (manufacturers) of glow plugs are provided in

parallel. (Refer to the figure for identification.)

IDo not install 2 different types of glow plugs in the engine. Make

sure that the same glow plugs are installed.

IUsing reamer, remove the carbon adhering to the installation

hole of glow plug, and install glow plug.

FEM063

FEM064

CYLINDER HEADZD

Installation (Cont'd)

EM-56