ad blue NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 601 of 1767

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

FunctionActuator

Crankshaft position

sensor (TDC)Engine speed

Glow

controlGlow lamp,

Glow relay

"

Glow plugs Engine coolant tem-

perature sensorEngine coolant tem-

perature

When engine coolant temperature is more than approximately 75ÉC

(167ÉF), the glow relay turns off, inactivating the quick-glow control

until coolant temperature drops below approximately 55ÉC (131ÉF).

When coolant temperature is lower than approximately 75ÉC

(167ÉF):

IIgnition switch ON

After ignition switch has turned to ON, the glow relay turns ON

for a certain period of time in relation to engine coolant

temperature, allowing current to flow through glow plug.

ICranking

The glow relay turns ON, allowing current to flow through glow

plug.

IStarting

After engine has started, current continues to flow through glow

plug (after-glow mode) for a certain period in relation to engine

coolant temperature.

When engine speed exceeds approximately 4,800 rpm, current

flow through glow plug is interrupted.

The glow indicator lamp turns ON for a certain period of time in

relation to engine coolant temperature at the time glow relay is

turned ON.

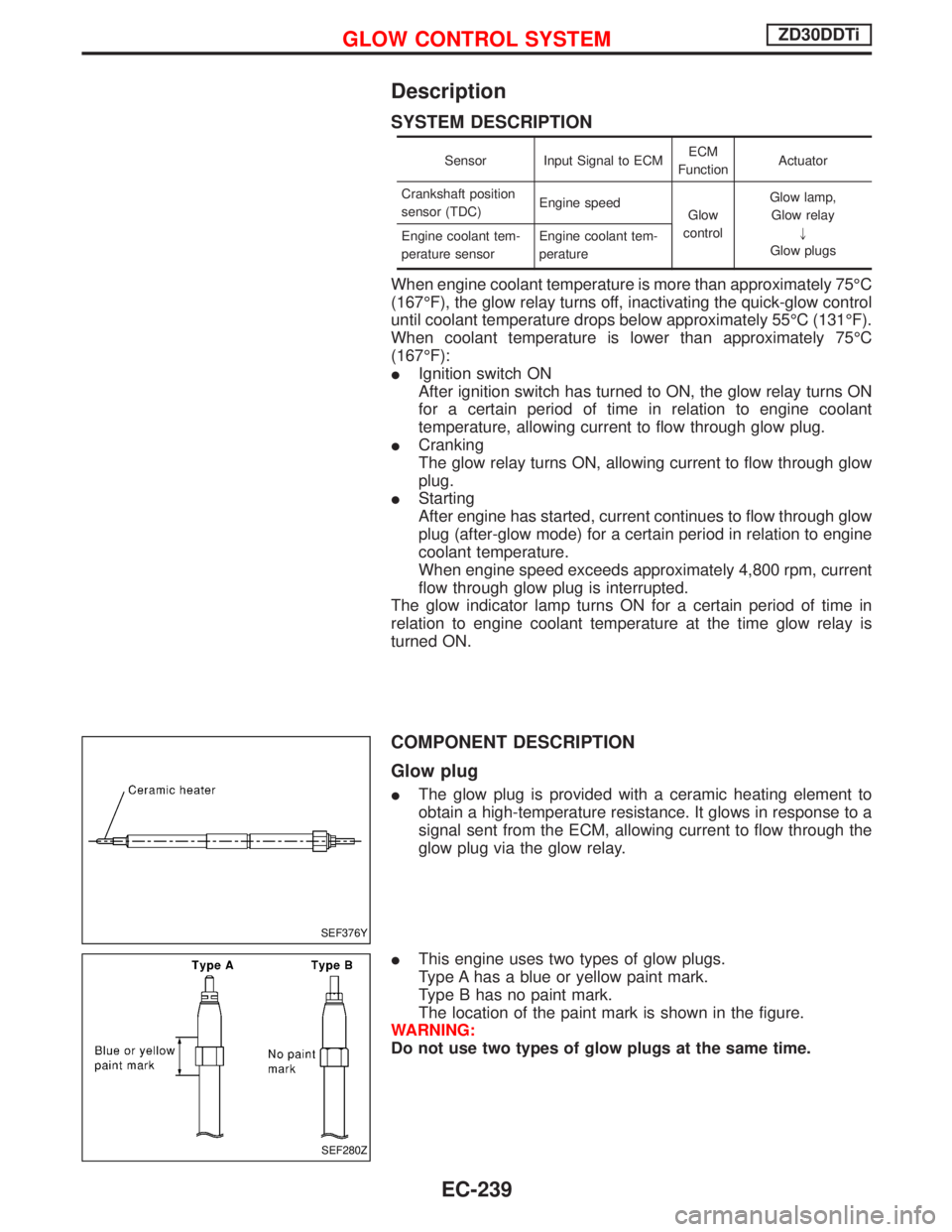

COMPONENT DESCRIPTION

Glow plug

IThe glow plug is provided with a ceramic heating element to

obtain a high-temperature resistance. It glows in response to a

signal sent from the ECM, allowing current to flow through the

glow plug via the glow relay.

IThis engine uses two types of glow plugs.

Type A has a blue or yellow paint mark.

Type B has no paint mark.

The location of the paint mark is shown in the figure.

WARNING:

Do not use two types of glow plugs at the same time.

SEF376Y

SEF280Z

GLOW CONTROL SYSTEMZD30DDTi

EC-239

Page 1228 of 1767

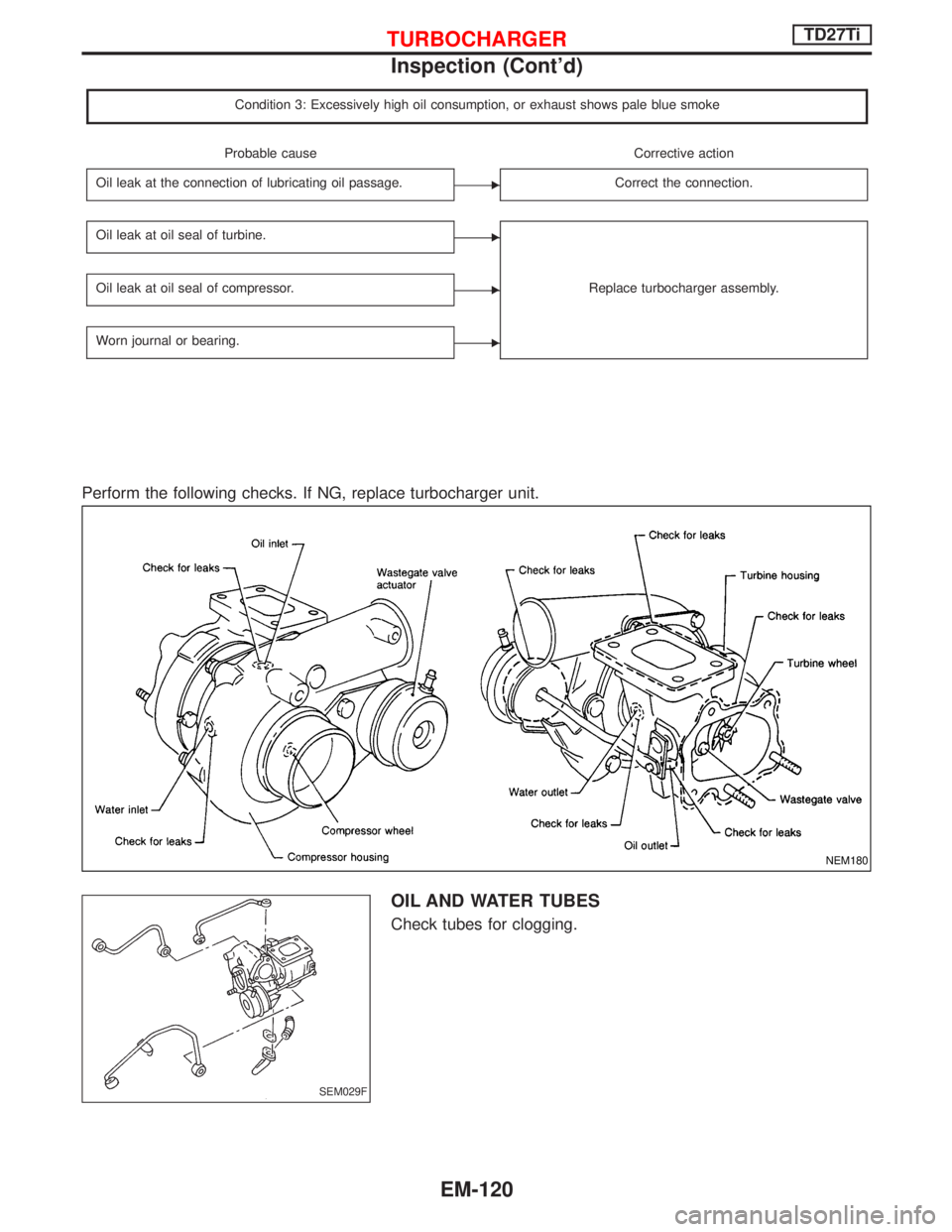

Condition 3: Excessively high oil consumption, or exhaust shows pale blue smoke

Probable cause Corrective action

Oil leak at the connection of lubricating oil passage.

ECorrect the connection.

Oil leak at oil seal of turbine.E

Replace turbocharger assembly.Oil leak at oil seal of compressor.E

Worn journal or bearing.E

Perform the following checks. If NG, replace turbocharger unit.

OIL AND WATER TUBES

Check tubes for clogging.

NEM180

SEM029F

TURBOCHARGERTD27Ti

Inspection (Cont'd)

EM-120

Page 1327 of 1767

Description

Number Item Description

q1Power conditionIThis shows the condition when the system receives battery positive voltage (can

be operated).

q2Fusible linkIThe double line shows that this is a fusible link.

IThe open circle shows current flow in, and the shaded circle shows current flow

out.

q3Fusible link/fuse locationIThis shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (ªPOWER SUPPLY ROUTINGº).

q4FuseIThe single line shows that this is a fuse.

IThe open circle shows current flow in, and the shaded circle shows current flow

out.

q5Current ratingIThis shows the current rating of the fusible link or fuse.

q6ConnectorsIThis shows that connector

E3is female and connectorM1is male.

IThe G/R wire is located in the 1A terminal of both connectors.

ITerminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-18.

q7Optional spliceIThe open circle shows that the splice is optional depending on vehicle application.

q8SpliceIThe shaded circle shows that the splice is always on the vehicle.

q9Page crossingIThis arrow shows that the circuit continues to an adjacent page.

IThe A will match with the A on the preceding or next page.

q10Common connectorIThe dotted lines between terminals show that these terminals are part of the same

connector.

q11Option abbreviationIThis shows that the circuit is optional depending on vehicle application.

q12RelayIThis shows an internal representation of the relay. For details, refer to EL section

(ªSTANDARDIZED RELAYº).

q13ConnectorsIThis shows that the connector is connected to the body or a terminal with bolt or

nut.

q14Wire colorIThis shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

q15Option descriptionIThis shows a description of the option abbreviation used on the page.

q16SwitchIThis shows that continuity exists between terminals 1 and 2 when the switch is in

the A position. Continuity exists between terminals 1 and 3 when the switch is in

the B position.

q17Assembly partsIConnector terminal in component shows that it is a harness incorporated assem-

bly.

q18Cell codeIThis identifies each page of the wiring diagram by section, system and wiring dia-

gram page number.

HOW TO READ WIRING DIAGRAMS

GI-12

Page 1364 of 1767

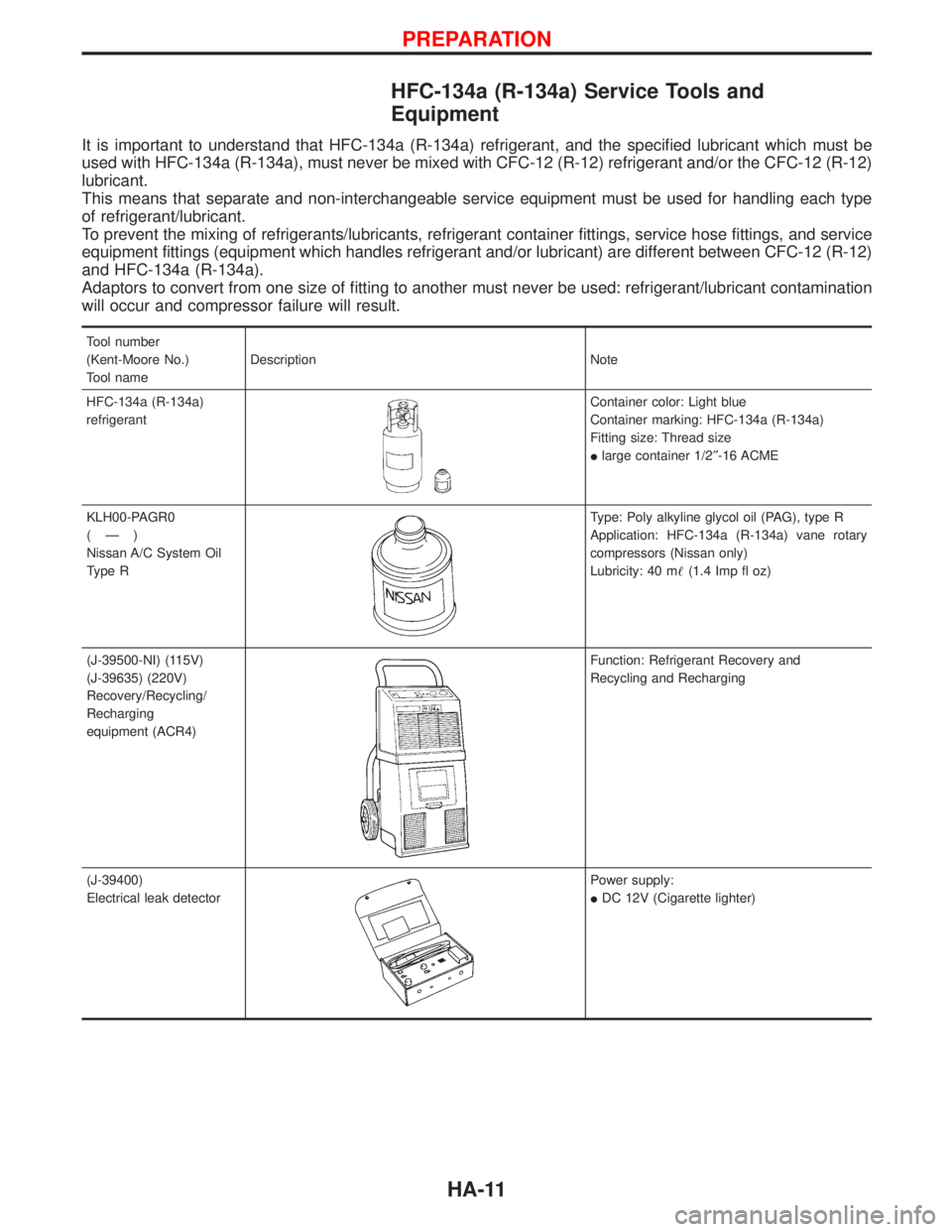

HFC-134a (R-134a) Service Tools and

Equipment

It is important to understand that HFC-134a (R-134a) refrigerant, and the specified lubricant which must be

used with HFC-134a (R-134a), must never be mixed with CFC-12 (R-12) refrigerant and/or the CFC-12 (R-12)

lubricant.

This means that separate and non-interchangeable service equipment must be used for handling each type

of refrigerant/lubricant.

To prevent the mixing of refrigerants/lubricants, refrigerant container fittings, service hose fittings, and service

equipment fittings (equipment which handles refrigerant and/or lubricant) are different between CFC-12 (R-12)

and HFC-134a (R-134a).

Adaptors to convert from one size of fitting to another must never be used: refrigerant/lubricant contamination

will occur and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool nameDescription Note

HFC-134a (R-134a)

refrigerant

Container color: Light blue

Container marking: HFC-134a (R-134a)

Fitting size: Thread size

Ilarge container 1/2²-16 ACME

KLH00-PAGR0

(Ð)

Nissan A/C System Oil

Type R

Type: Poly alkyline glycol oil (PAG), type R

Application: HFC-134a (R-134a) vane rotary

compressors (Nissan only)

Lubricity: 40 m(1.4 Imp fl oz)

(J-39500-NI) (115V)

(J-39635) (220V)

Recovery/Recycling/

Recharging

equipment (ACR4)

Function: Refrigerant Recovery and

Recycling and Recharging

(J-39400)

Electrical leak detector

Power supply:

IDC 12V (Cigarette lighter)

PREPARATION

HA-11

Page 1365 of 1767

Tool number

(Kent-Moore No.)

Tool nameDescription Note

(J-39183)

Manifold gauge set (with

hoses and couplers)

Identification:

IThe gauge face indicates R-134a.

Fitting size: Thread size

I1/2²-16 ACME

Service hoses

IHigh side hose

(J-39501-72)

ILow side hose

(J-39502-72)

IUtility hose

(J-39476-72)

Hose color:

ILow hose: Blue with black stripe

IHigh hose: Red with black stripe

IUtility hose: Yellow with black stripe or green

with black stripe

Hose fitting to gauge:

I1/2²-16 ACME

Service couplers

IHigh side coupler

(J-39500-20)

ILow side coupler

(J-39500-24)

Hose fitting to service hose:

IM14 x 1.5 fitting (optional) or permanently

attached

(J-39650) (115V)

(J-39656) (220V)

Refrigerant weight scale

For measuring of refrigerant

Fitting size: Thread size

I1/2²-16 ACME

(J-39649) (115V)

(J-39655) (220V)

Vacuum pump

(Including the isolator

valve)

Capacity:

IAir displacement: 4 CFM

IMicron rating: 20 microns

IOil capacity: 482 g (17 oz)

Fitting size: Thread size

I1/2²-16 ACME

PREPARATION

HFC-134a (R-134a) Service Tools and

Equipment (Cont'd)

HA-12

Page 1602 of 1767

Propeller Shaft

GENERAL SPECIFICATIONS

Unit: mm (in)

MODEL ALL H/T WAGON

Portion Front Rear

Propeller shaft

model0F71H 2S80B

Number of joints 2

Coupling

method with

transmissionFlange type Sleeve type

Types of journal

bearingsSolid type (dis-

assembly type)Solid type

Shaft length

(Spider to spi-

der) mm (in)542 (21.34) 725 (28.54) 925 (36.42)

Shaft outer

diameter mm (in)65 (2.56) 65 (2.56)

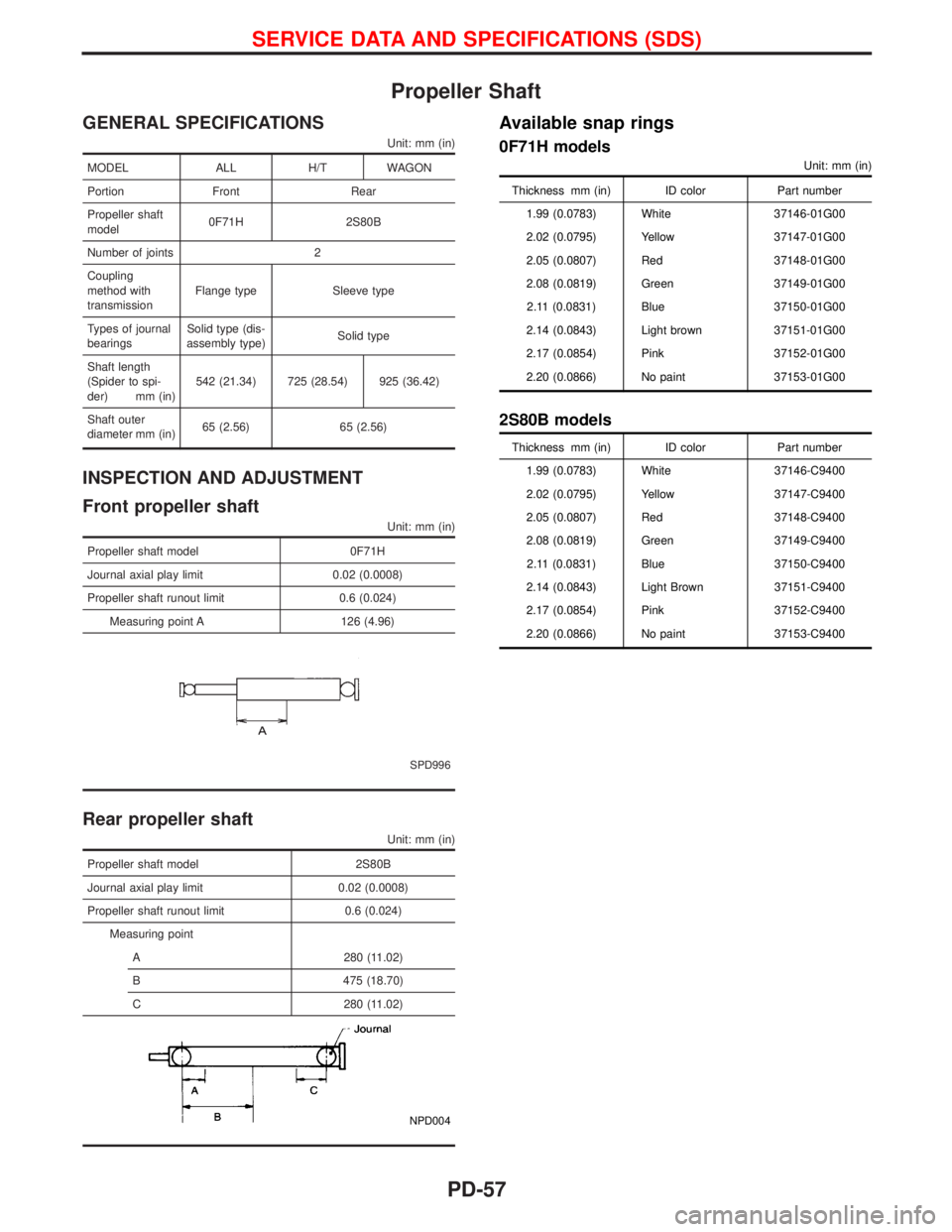

INSPECTION AND ADJUSTMENT

Front propeller shaft

Unit: mm (in)

Propeller shaft model 0F71H

Journal axial play limit 0.02 (0.0008)

Propeller shaft runout limit 0.6 (0.024)

Measuring point A 126 (4.96)

SPD996

Rear propeller shaft

Unit: mm (in)

Propeller shaft model 2S80B

Journal axial play limit 0.02 (0.0008)

Propeller shaft runout limit 0.6 (0.024)

Measuring point

A 280 (11.02)

B 475 (18.70)

C 280 (11.02)

NPD004

Available snap rings

0F71H models

Unit: mm (in)

Thickness mm (in) ID color Part number

1.99 (0.0783) White 37146-01G00

2.02 (0.0795) Yellow 37147-01G00

2.05 (0.0807) Red 37148-01G00

2.08 (0.0819) Green 37149-01G00

2.11 (0.0831) Blue 37150-01G00

2.14 (0.0843) Light brown 37151-01G00

2.17 (0.0854) Pink 37152-01G00

2.20 (0.0866) No paint 37153-01G00

2S80B models

Thickness mm (in) ID color Part number

1.99 (0.0783) White 37146-C9400

2.02 (0.0795) Yellow 37147-C9400

2.05 (0.0807) Red 37148-C9400

2.08 (0.0819) Green 37149-C9400

2.11 (0.0831) Blue 37150-C9400

2.14 (0.0843) Light Brown 37151-C9400

2.17 (0.0854) Pink 37152-C9400

2.20 (0.0866) No paint 37153-C9400

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-57