system NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1473 of 1767

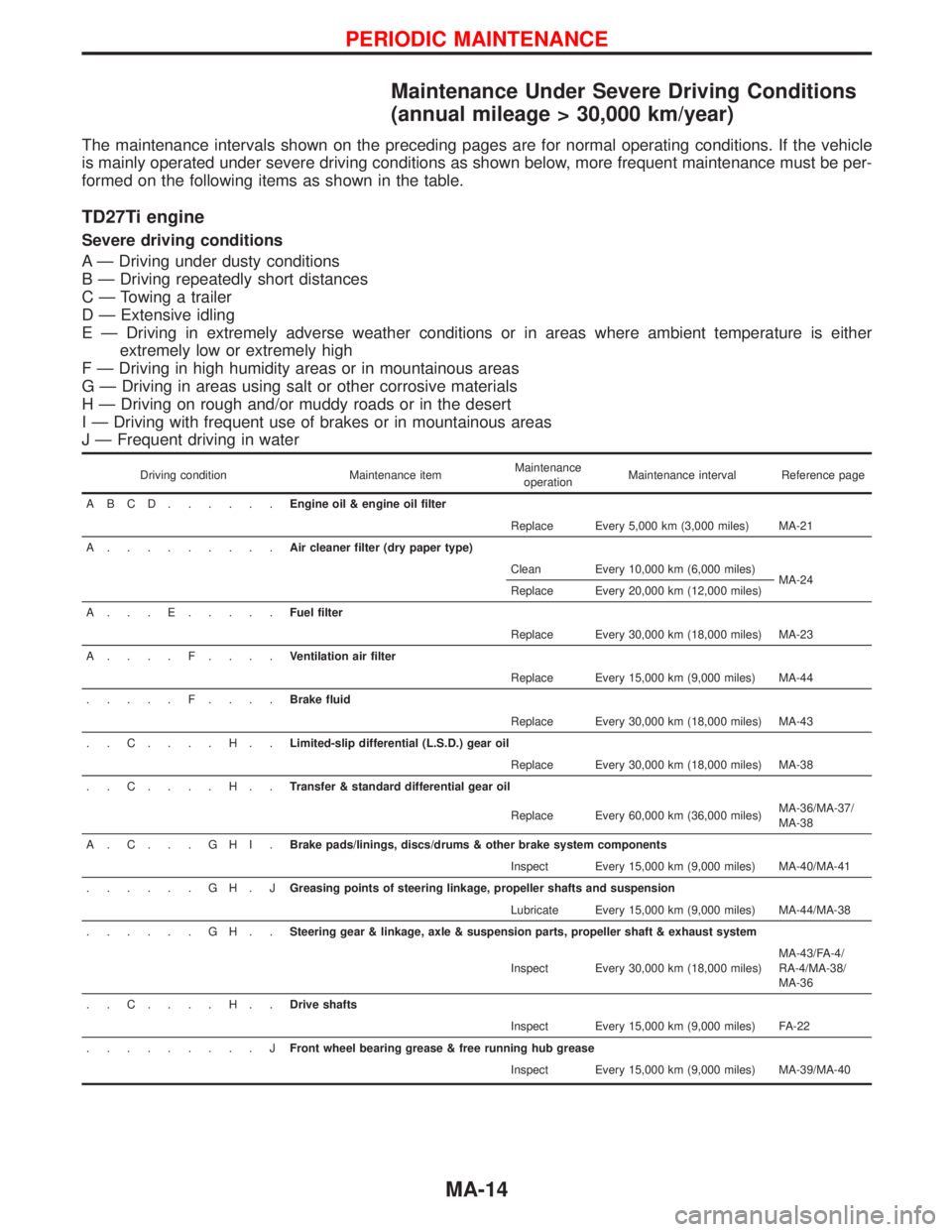

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

TD27Ti engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperature is either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of brakes or in mountainous areas

J Ð Frequent driving in water

Driving condition Maintenance itemMaintenance

operationMaintenance interval Reference page

ABCD......Engine oil & engine oil filter

Replace Every 5,000 km (3,000 miles) MA-21

A.........Air cleaner filter (dry paper type)

Clean Every 10,000 km (6,000 miles)

MA-24

Replace Every 20,000 km (12,000 miles)

A...E.....Fuel filter

Replace Every 30,000 km (18,000 miles) MA-23

A....F....Ventilation air filter

Replace Every 15,000 km (9,000 miles) MA-44

.....F....Brake fluid

Replace Every 30,000 km (18,000 miles) MA-43

..C....H..Limited-slip differential (L.S.D.) gear oil

Replace Every 30,000 km (18,000 miles) MA-38

..C....H..Transfer & standard differential gear oil

Replace Every 60,000 km (36,000 miles)MA-36/MA-37/

MA-38

A.C...GHI.Brake pads/linings, discs/drums & other brake system components

Inspect Every 15,000 km (9,000 miles) MA-40/MA-41

......GH.JGreasing points of steering linkage, propeller shafts and suspension

Lubricate Every 15,000 km (9,000 miles) MA-44/MA-38

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

Inspect Every 30,000 km (18,000 miles)MA-43/FA-4/

RA-4/MA-38/

MA-36

..C....H..Drive shafts

Inspect Every 15,000 km (9,000 miles) FA-22

.........JFront wheel bearing grease & free running hub grease

Inspect Every 15,000 km (9,000 miles) MA-39/MA-40

PERIODIC MAINTENANCE

MA-14

Page 1474 of 1767

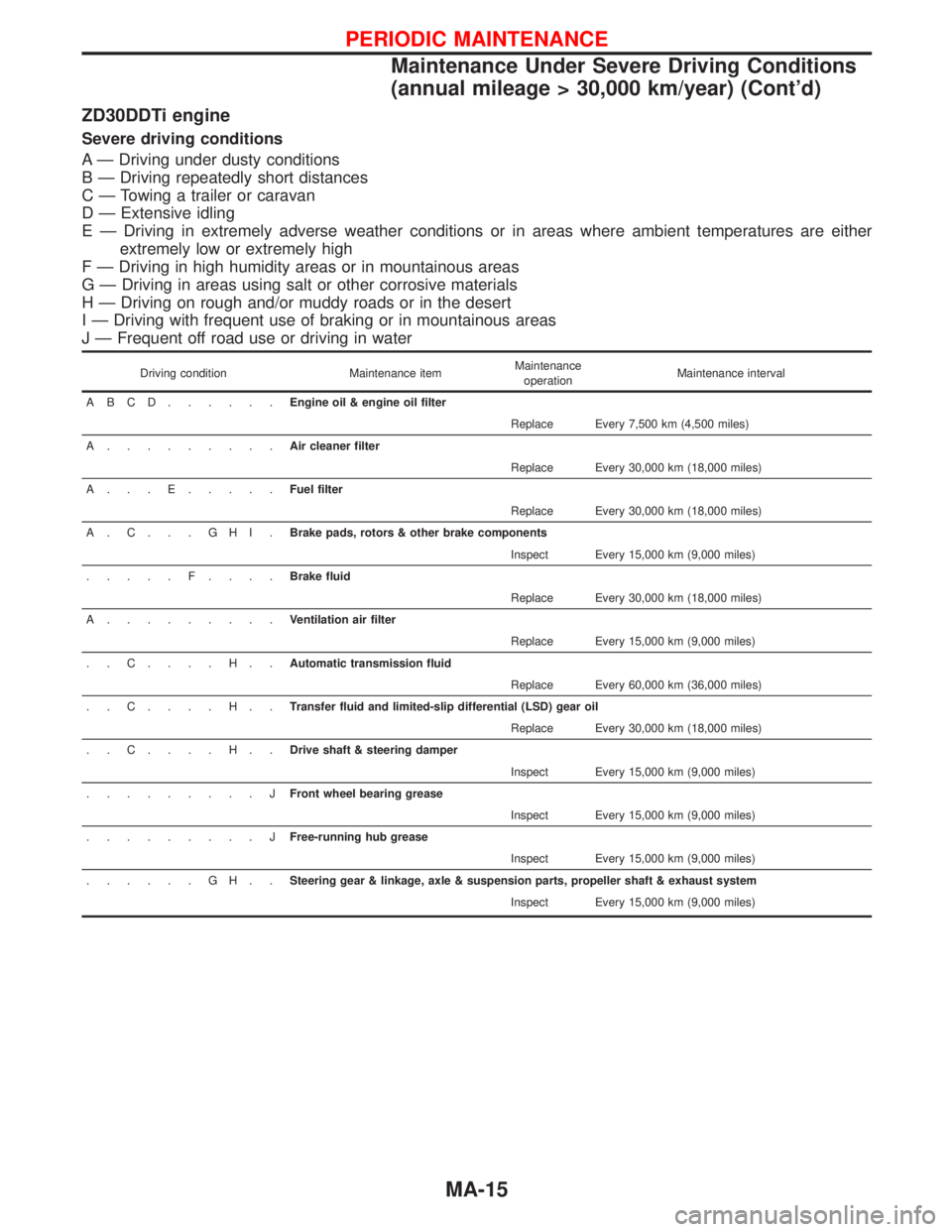

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operationMaintenance interval

ABCD......Engine oil & engine oil filter

Replace Every 7,500 km (4,500 miles)

A.........Air cleaner filter

Replace Every 30,000 km (18,000 miles)

A...E.....Fuel filter

Replace Every 30,000 km (18,000 miles)

A.C...GHI.Brake pads, rotors & other brake components

Inspect Every 15,000 km (9,000 miles)

.....F....Brake fluid

Replace Every 30,000 km (18,000 miles)

A.........Ventilation air filter

Replace Every 15,000 km (9,000 miles)

..C....H..Automatic transmission fluid

Replace Every 60,000 km (36,000 miles)

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil

Replace Every 30,000 km (18,000 miles)

..C....H..Drive shaft & steering damper

Inspect Every 15,000 km (9,000 miles)

.........JFront wheel bearing grease

Inspect Every 15,000 km (9,000 miles)

.........JFree-running hub grease

Inspect Every 15,000 km (9,000 miles)

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

Inspect Every 15,000 km (9,000 miles)

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) (Cont'd)

MA-15

Page 1476 of 1767

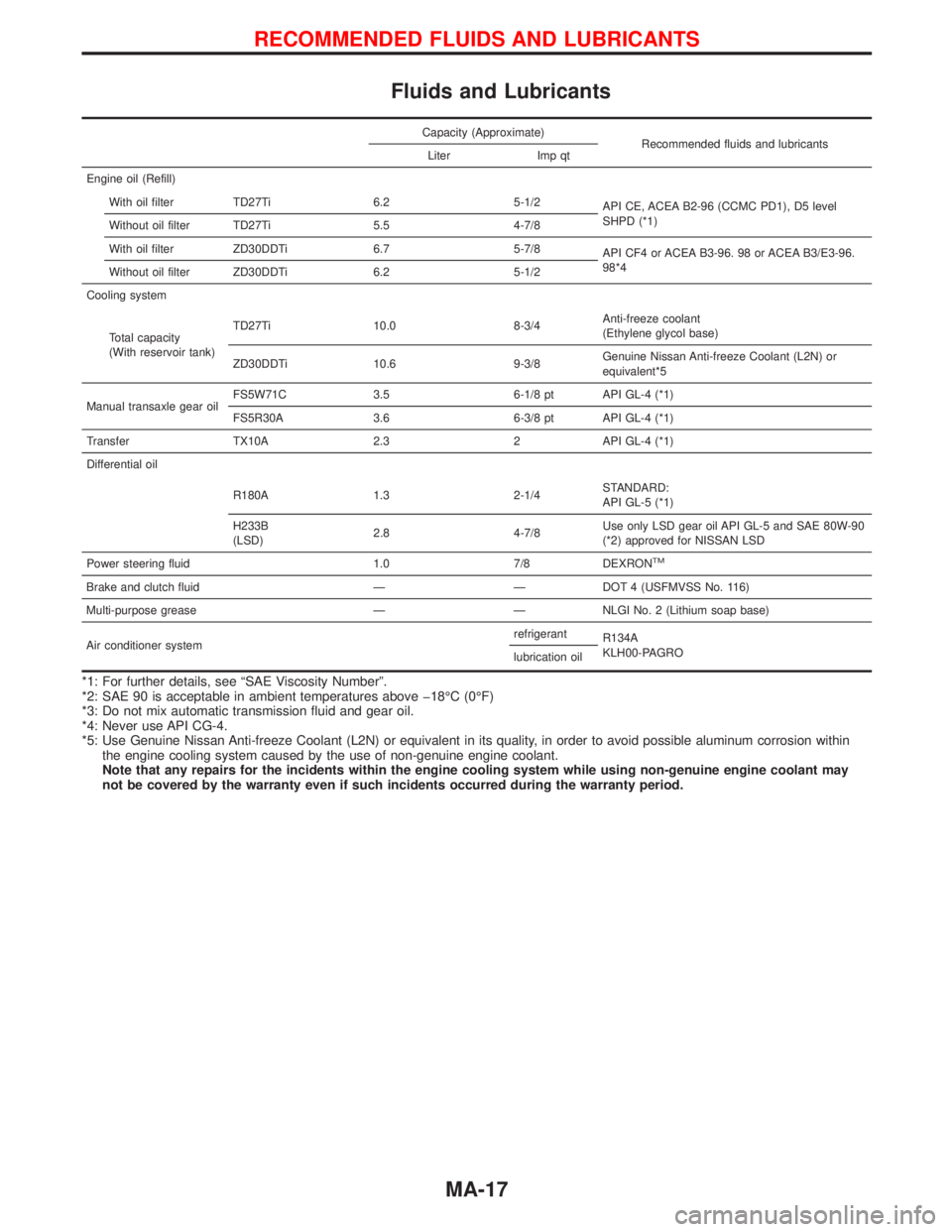

Fluids and Lubricants

Capacity (Approximate)

Recommended fluids and lubricants

Liter Imp qt

Engine oil (Refill)

With oil filter TD27Ti 6.2 5-1/2

API CE, ACEA B2-96 (CCMC PD1), D5 level

SHPD (*1)

Without oil filter TD27Ti 5.5 4-7/8

With oil filter ZD30DDTi 6.7 5-7/8

API CF4 or ACEA B3-96. 98 or ACEA B3/E3-96.

98*4

Without oil filter ZD30DDTi 6.2 5-1/2

Cooling system

Total capacity

(With reservoir tank)TD27Ti 10.0 8-3/4Anti-freeze coolant

(Ethylene glycol base)

ZD30DDTi 10.6 9-3/8Genuine Nissan Anti-freeze Coolant (L2N) or

equivalent*5

Manual transaxle gear oilFS5W71C 3.5 6-1/8 pt API GL-4 (*1)

FS5R30A 3.6 6-3/8 pt API GL-4 (*1)

Transfer TX10A 2.3 2 API GL-4 (*1)

Differential oil

R180A 1.3 2-1/4STANDARD:

API GL-5 (*1)

H233B

(LSD)2.8 4-7/8Use only LSD gear oil API GL-5 and SAE 80W-90

(*2) approved for NISSAN LSD

Power steering fluid 1.0 7/8 DEXRON

TM

Brake and clutch fluid Ð Ð DOT 4 (USFMVSS No. 116)

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Air conditioner systemrefrigerant

R134A

KLH00-PAGRO

lubrication oil

*1: For further details, see ªSAE Viscosity Numberº.

*2: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF)

*3: Do not mix automatic transmission fluid and gear oil.

*4: Never use API CG-4.

*5: Use Genuine Nissan Anti-freeze Coolant (L2N) or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may

not be covered by the warranty even if such incidents occurred during the warranty period.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

Page 1478 of 1767

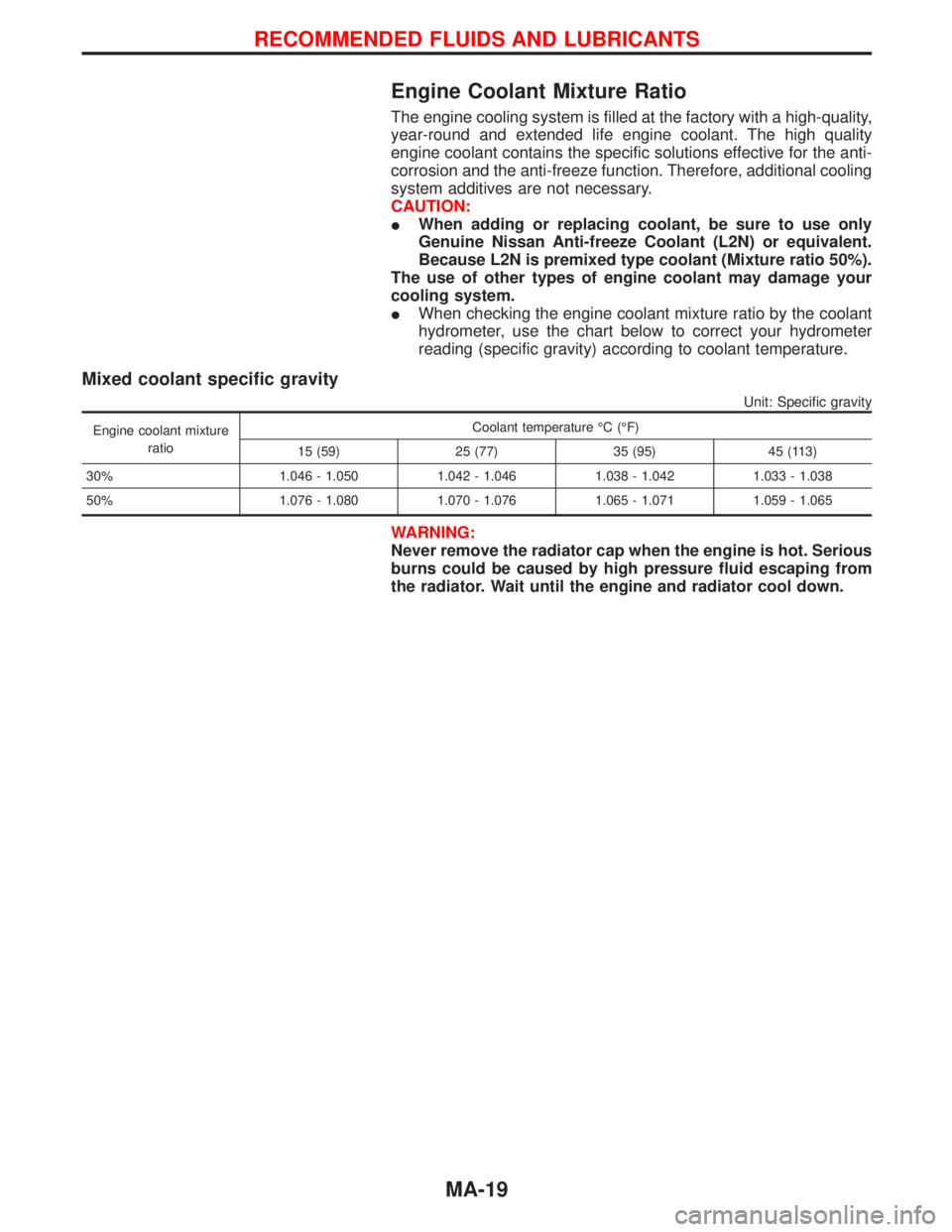

Engine Coolant Mixture Ratio

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality

engine coolant contains the specific solutions effective for the anti-

corrosion and the anti-freeze function. Therefore, additional cooling

system additives are not necessary.

CAUTION:

IWhen adding or replacing coolant, be sure to use only

Genuine Nissan Anti-freeze Coolant (L2N) or equivalent.

Because L2N is premixed type coolant (Mixture ratio 50%).

The use of other types of engine coolant may damage your

cooling system.

IWhen checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer

reading (specific gravity) according to coolant temperature.

Mixed coolant specific gravity

Unit: Specific gravity

Engine coolant mixture

ratioCoolant temperature ÉC (ÉF)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator. Wait until the engine and radiator cool down.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-19

Page 1481 of 1767

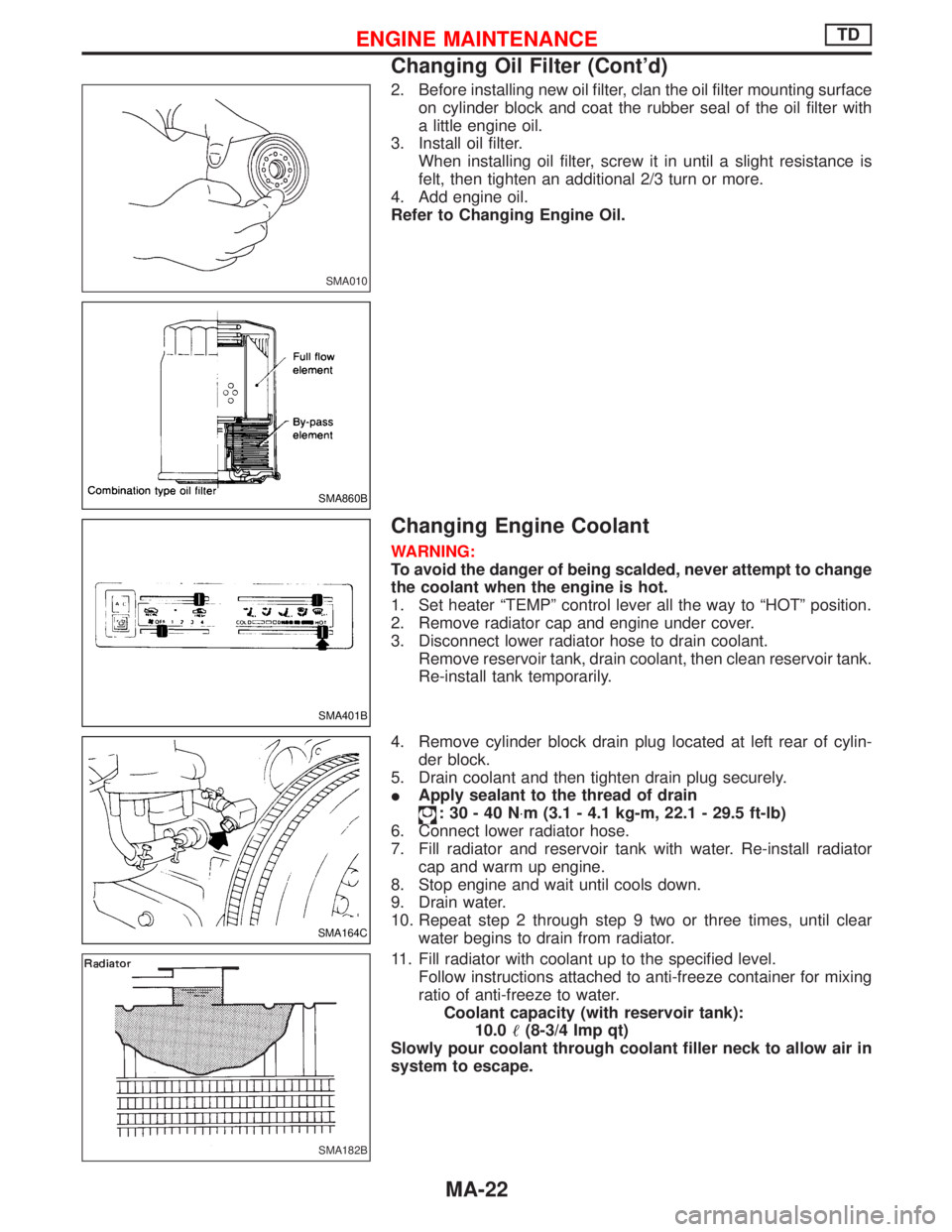

2. Before installing new oil filter, clan the oil filter mounting surface

on cylinder block and coat the rubber seal of the oil filter with

a little engine oil.

3. Install oil filter.

When installing oil filter, screw it in until a slight resistance is

felt, then tighten an additional 2/3 turn or more.

4. Add engine oil.

Refer to Changing Engine Oil.

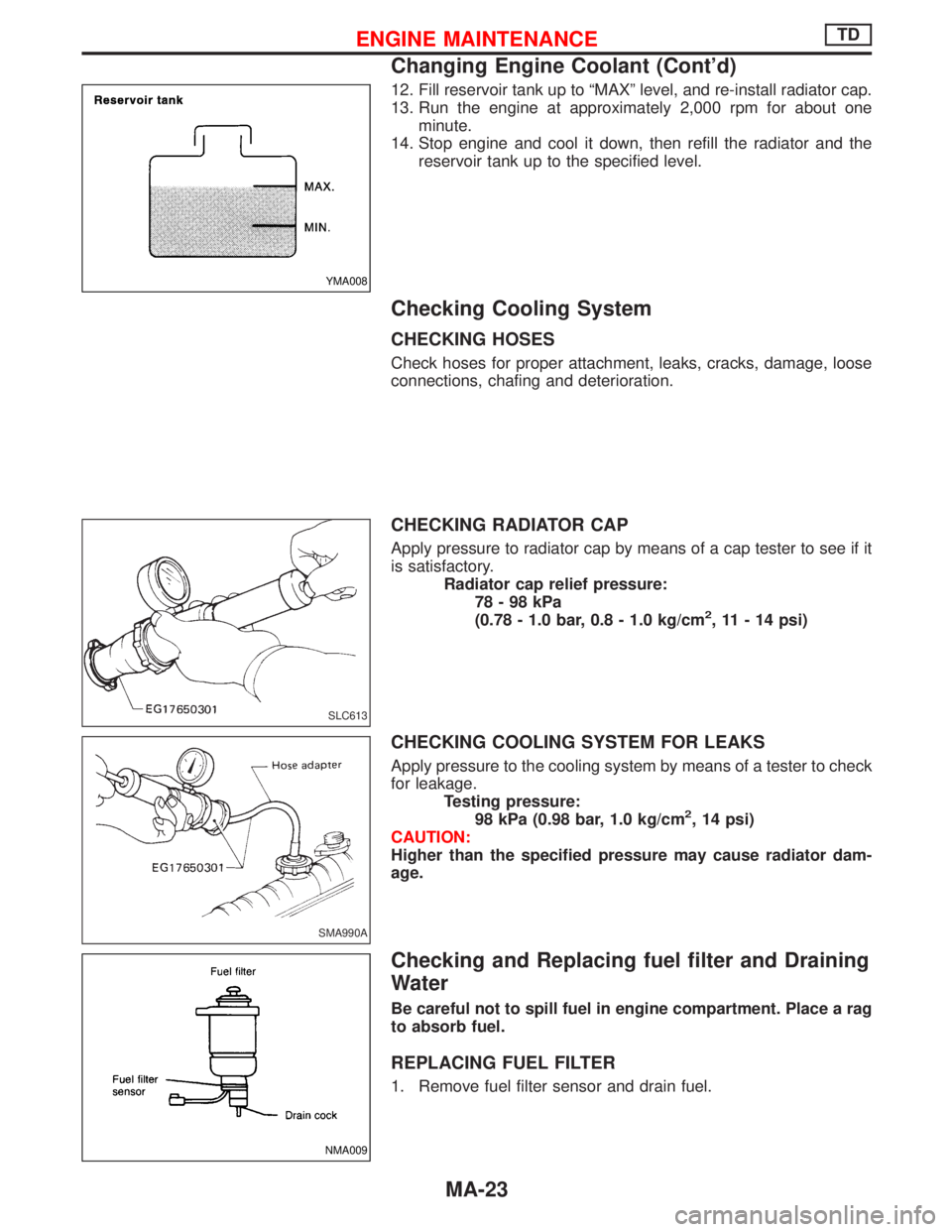

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never attempt to change

the coolant when the engine is hot.

1. Set heater ªTEMPº control lever all the way to ªHOTº position.

2. Remove radiator cap and engine under cover.

3. Disconnect lower radiator hose to drain coolant.

Remove reservoir tank, drain coolant, then clean reservoir tank.

Re-install tank temporarily.

4. Remove cylinder block drain plug located at left rear of cylin-

der block.

5. Drain coolant and then tighten drain plug securely.

IApply sealant to the thread of drain

:30-40N×m (3.1 - 4.1 kg-m, 22.1 - 29.5 ft-lb)

6. Connect lower radiator hose.

7. Fill radiator and reservoir tank with water. Re-install radiator

cap and warm up engine.

8. Stop engine and wait until cools down.

9. Drain water.

10. Repeat step 2 through step 9 two or three times, until clear

water begins to drain from radiator.

11. Fill radiator with coolant up to the specified level.

Follow instructions attached to anti-freeze container for mixing

ratio of anti-freeze to water.

Coolant capacity (with reservoir tank):

10.0(8-3/4 Imp qt)

Slowly pour coolant through coolant filler neck to allow air in

system to escape.

SMA010

SMA860B

SMA401B

SMA164C

SMA182B

ENGINE MAINTENANCETD

Changing Oil Filter (Cont'd)

MA-22

Page 1482 of 1767

12. Fill reservoir tank up to ªMAXº level, and re-install radiator cap.

13. Run the engine at approximately 2,000 rpm for about one

minute.

14. Stop engine and cool it down, then refill the radiator and the

reservoir tank up to the specified level.

Checking Cooling System

CHECKING HOSES

Check hoses for proper attachment, leaks, cracks, damage, loose

connections, chafing and deterioration.

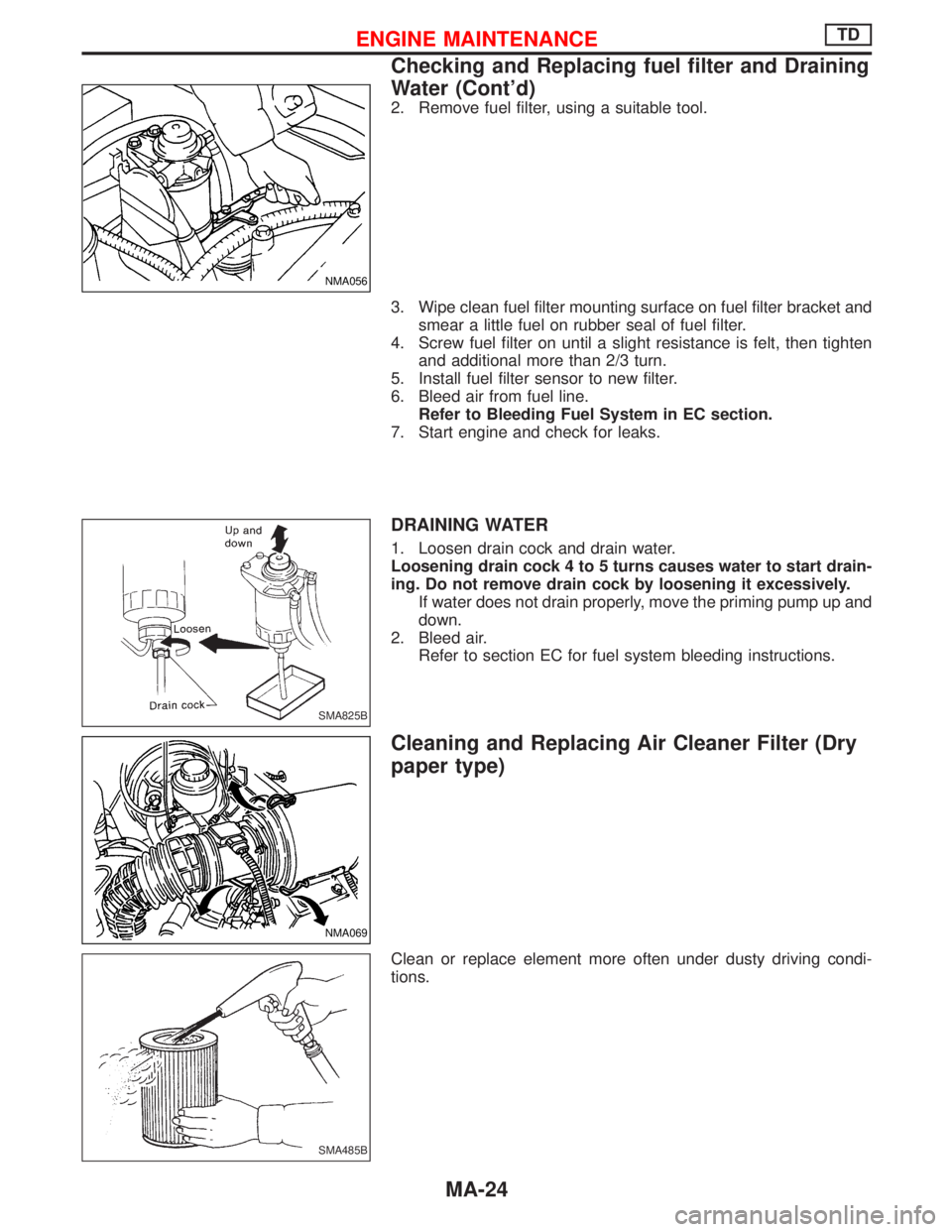

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see if it

is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 1.0 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to check

for leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Higher than the specified pressure may cause radiator dam-

age.

Checking and Replacing fuel filter and Draining

Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

REPLACING FUEL FILTER

1. Remove fuel filter sensor and drain fuel.

YMA008

SLC613

SMA990A

NMA009

ENGINE MAINTENANCETD

Changing Engine Coolant (Cont'd)

MA-23

Page 1483 of 1767

2. Remove fuel filter, using a suitable tool.

3. Wipe clean fuel filter mounting surface on fuel filter bracket and

smear a little fuel on rubber seal of fuel filter.

4. Screw fuel filter on until a slight resistance is felt, then tighten

and additional more than 2/3 turn.

5. Install fuel filter sensor to new filter.

6. Bleed air from fuel line.

Refer to Bleeding Fuel System in EC section.

7. Start engine and check for leaks.

DRAINING WATER

1. Loosen drain cock and drain water.

Loosening drain cock 4 to 5 turns causes water to start drain-

ing. Do not remove drain cock by loosening it excessively.

If water does not drain properly, move the priming pump up and

down.

2. Bleed air.

Refer to section EC for fuel system bleeding instructions.

Cleaning and Replacing Air Cleaner Filter (Dry

paper type)

Clean or replace element more often under dusty driving condi-

tions.

NMA056

SMA825B

NMA069

SMA485B

ENGINE MAINTENANCETD

Checking and Replacing fuel filter and Draining

Water (Cont'd)

MA-24

Page 1485 of 1767

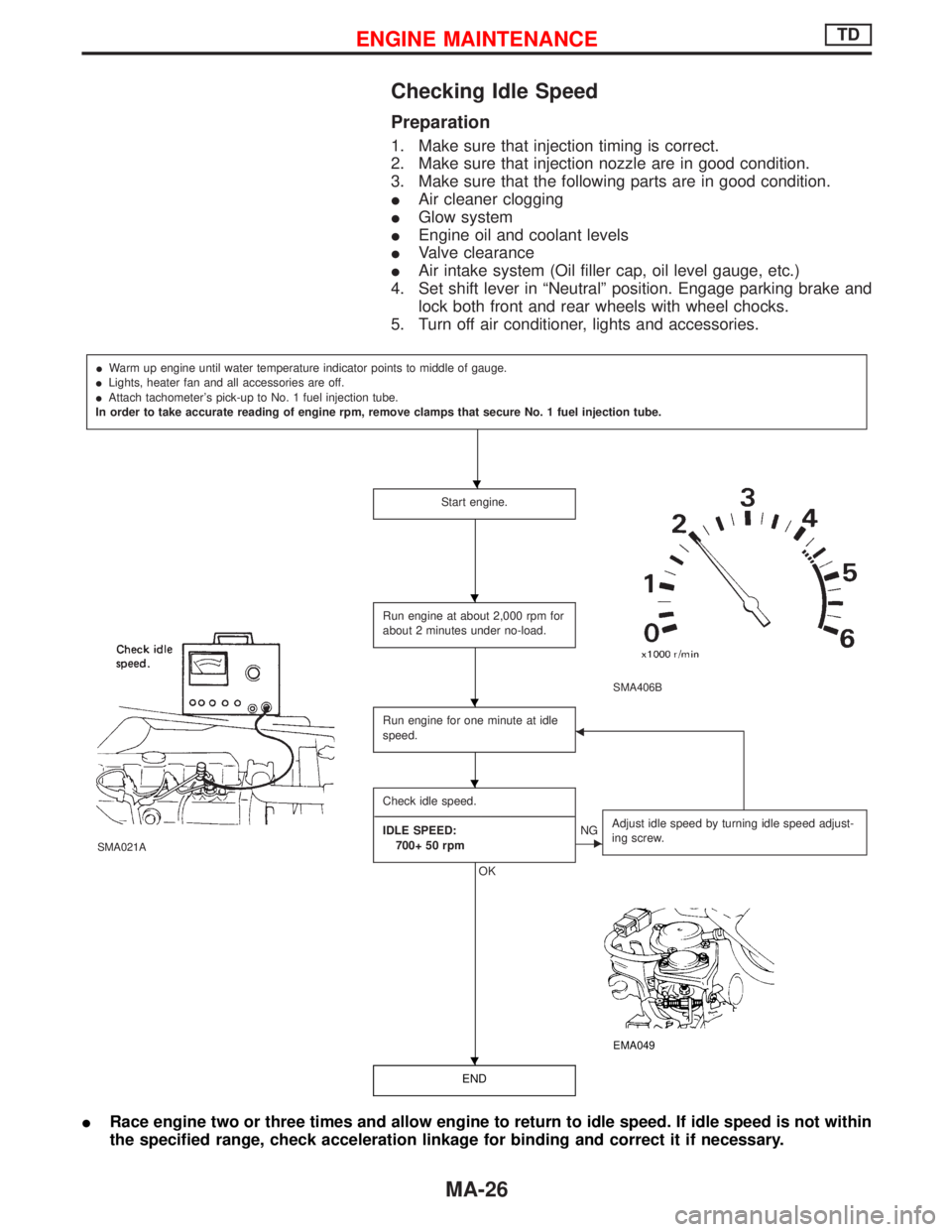

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

IGlow system

IEngine oil and coolant levels

IValve clearance

IAir intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and

lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

IWarm up engine until water temperature indicator points to middle of gauge.

ILights, heater fan and all accessories are off.

IAttach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

IDLE SPEED:

700+ 50 rpm

OK

ENGAdjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

IRace engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

Page 1491 of 1767

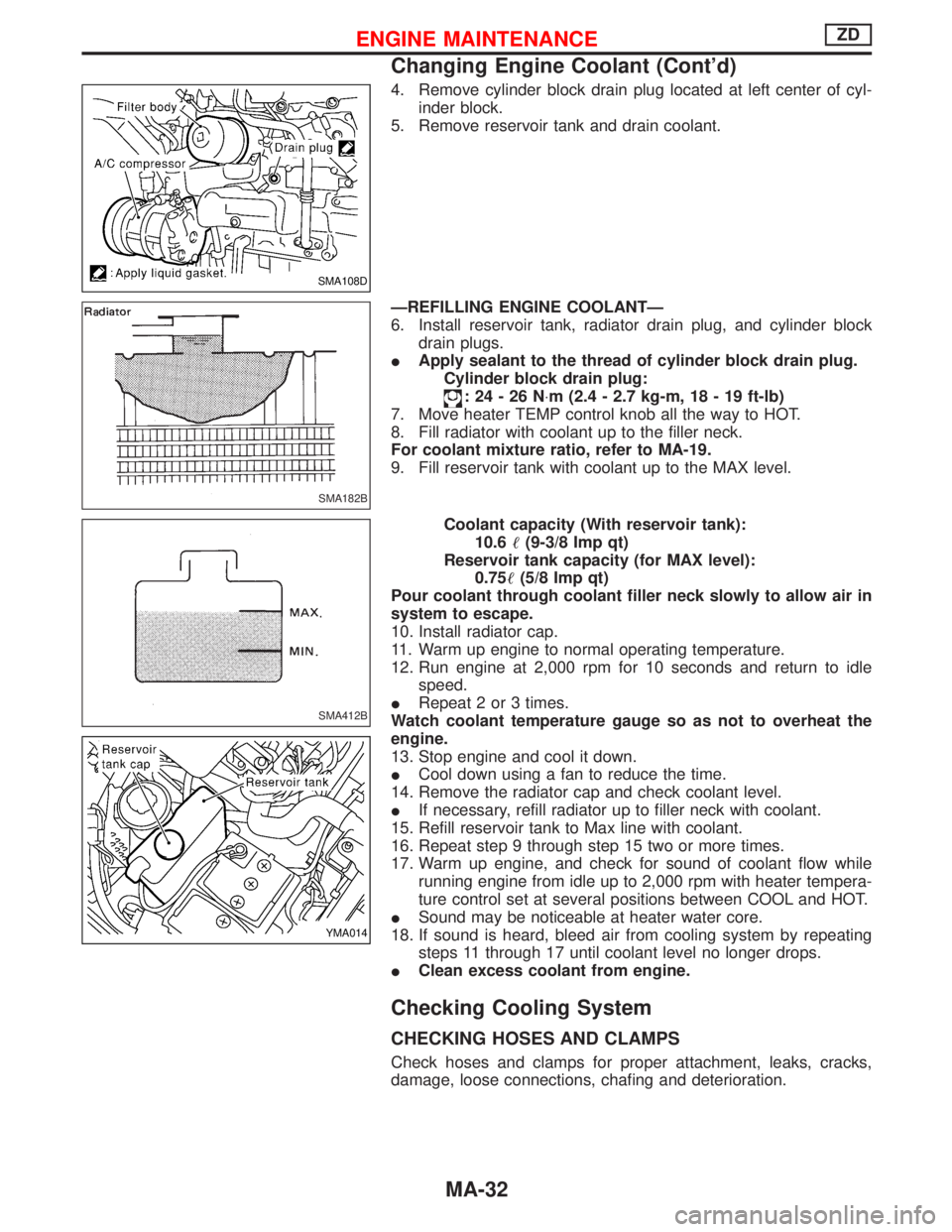

4. Remove cylinder block drain plug located at left center of cyl-

inder block.

5. Remove reservoir tank and drain coolant.

ÐREFILLING ENGINE COOLANTÐ

6. Install reservoir tank, radiator drain plug, and cylinder block

drain plugs.

IApply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:24-26N×m (2.4 - 2.7 kg-m, 18 - 19 ft-lb)

7. Move heater TEMP control knob all the way to HOT.

8. Fill radiator with coolant up to the filler neck.

For coolant mixture ratio, refer to MA-19.

9. Fill reservoir tank with coolant up to the MAX level.

Coolant capacity (With reservoir tank):

10.6(9-3/8 Imp qt)

Reservoir tank capacity (for MAX level):

0.75(5/8 Imp qt)

Pour coolant through coolant filler neck slowly to allow air in

system to escape.

10. Install radiator cap.

11. Warm up engine to normal operating temperature.

12. Run engine at 2,000 rpm for 10 seconds and return to idle

speed.

IRepeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

13. Stop engine and cool it down.

ICool down using a fan to reduce the time.

14. Remove the radiator cap and check coolant level.

IIf necessary, refill radiator up to filler neck with coolant.

15. Refill reservoir tank to Max line with coolant.

16. Repeat step 9 through step 15 two or more times.

17. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

ISound may be noticeable at heater water core.

18. If sound is heard, bleed air from cooling system by repeating

steps 11 through 17 until coolant level no longer drops.

IClean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

SMA108D

SMA182B

SMA412B

YMA014

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-32

Page 1492 of 1767

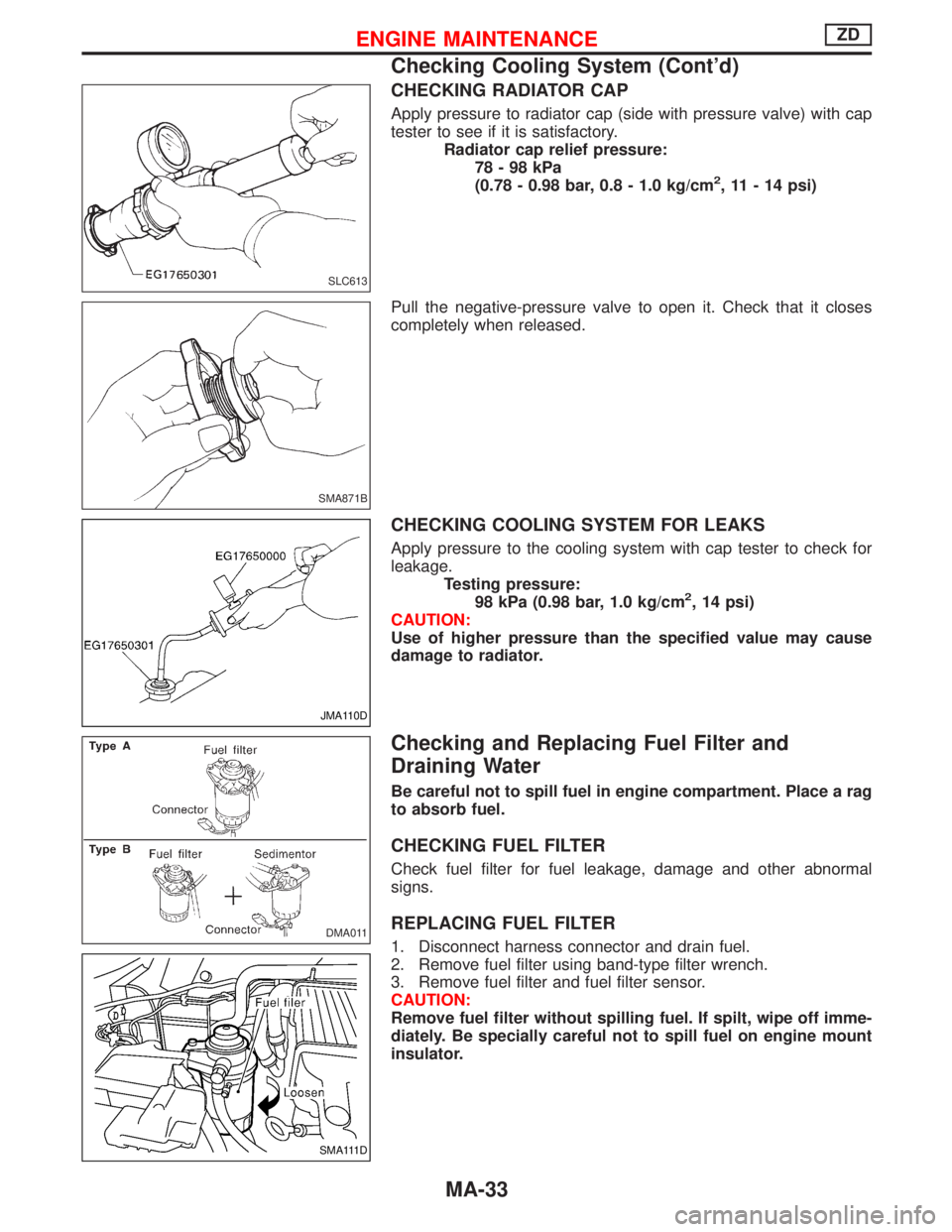

CHECKING RADIATOR CAP

Apply pressure to radiator cap (side with pressure valve) with cap

tester to see if it is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off imme-

diately. Be specially careful not to spill fuel on engine mount

insulator.

SLC613

SMA871B

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-33