Ignition NISSAN TERRANO 2002 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 469 of 1767

Diagnostic Procedure

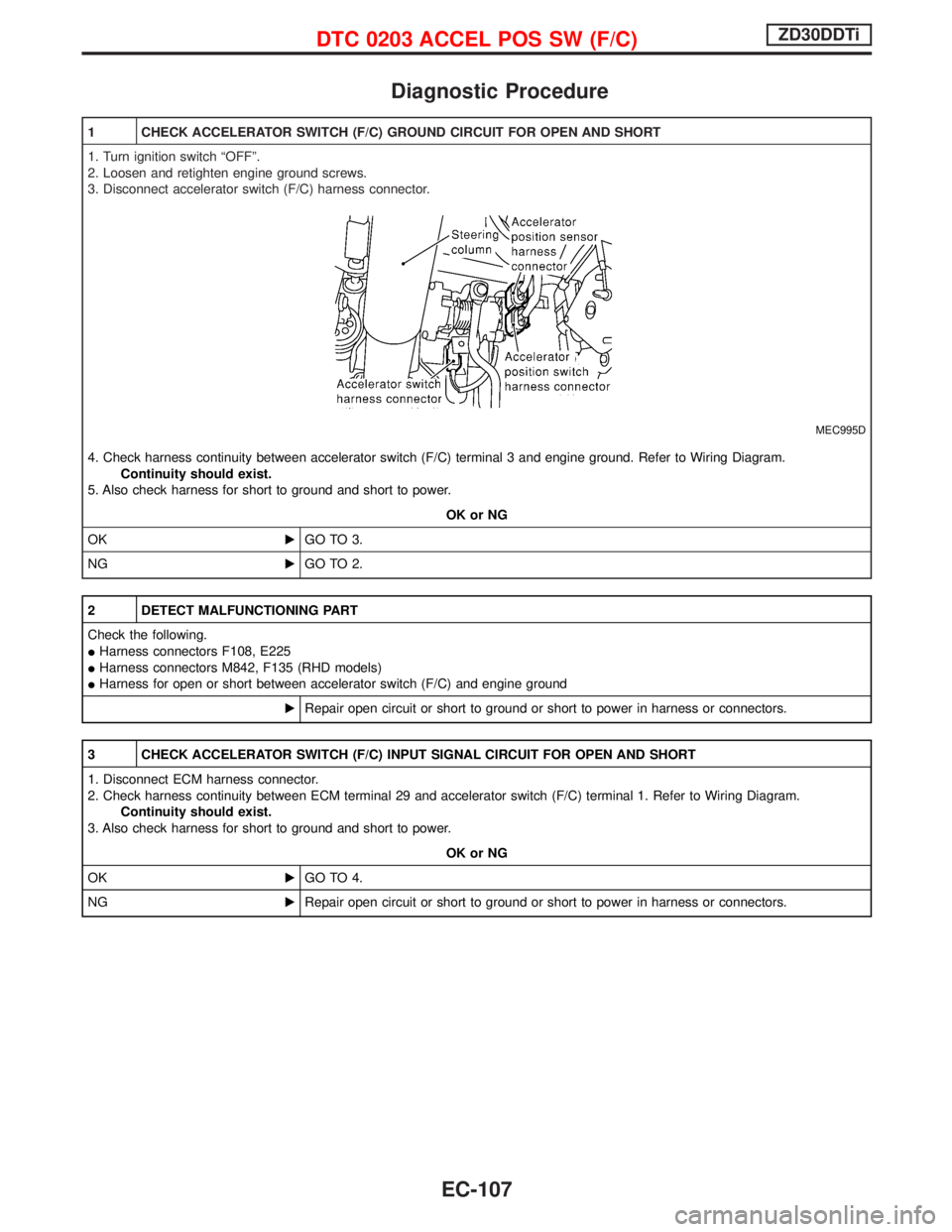

1 CHECK ACCELERATOR SWITCH (F/C) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

3. Disconnect accelerator switch (F/C) harness connector.

MEC995D

4. Check harness continuity between accelerator switch (F/C) terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F108, E225

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between accelerator switch (F/C) and engine ground

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ACCELERATOR SWITCH (F/C) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 29 and accelerator switch (F/C) terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 4.

NGERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0203 ACCEL POS SW (F/C)ZD30DDTi

EC-107

Page 473 of 1767

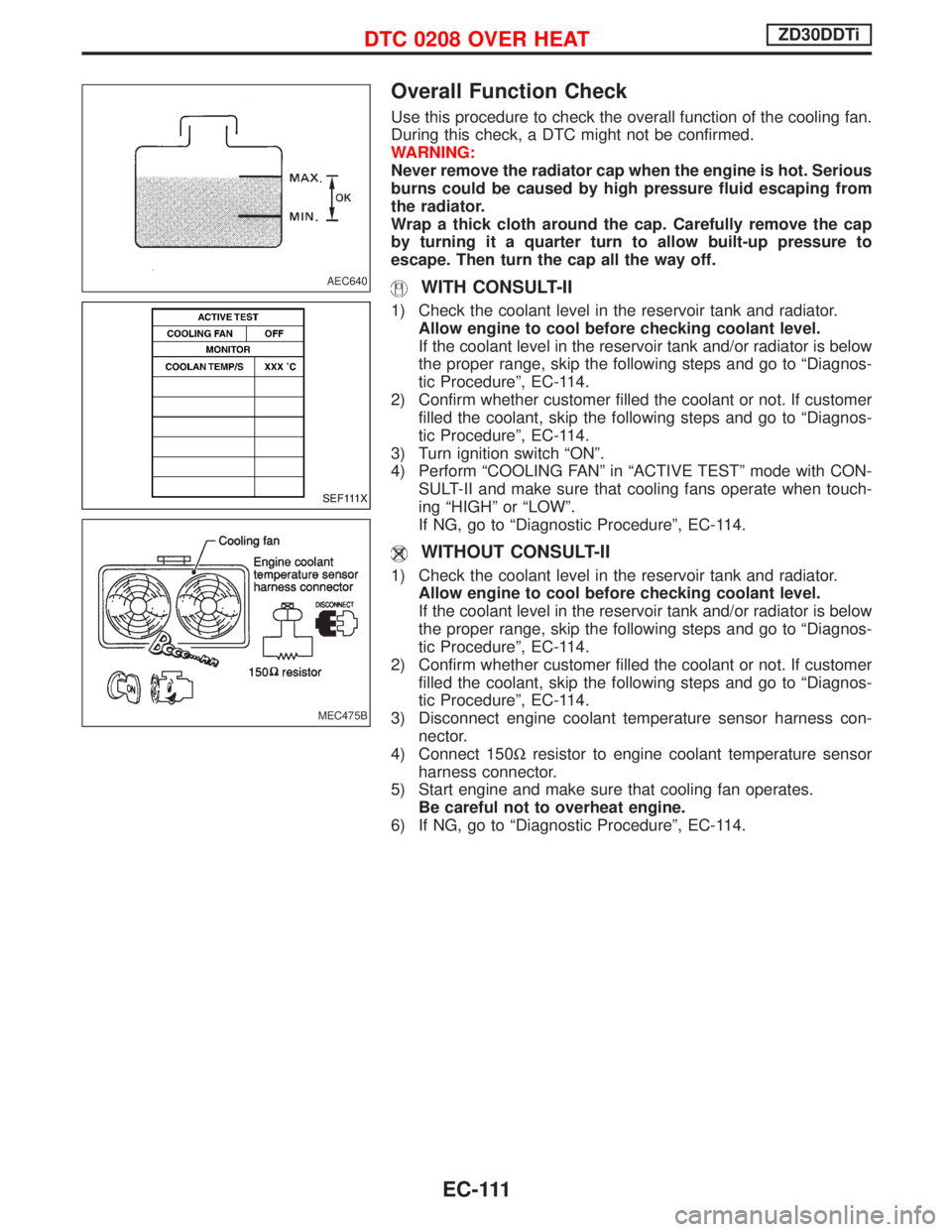

Overall Function Check

Use this procedure to check the overall function of the cooling fan.

During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

WITH CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

3) Turn ignition switch ªONº.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode with CON-

SULT-II and make sure that cooling fans operate when touch-

ing ªHIGHº or ªLOWº.

If NG, go to ªDiagnostic Procedureº, EC-114.

WITHOUT CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

3) Disconnect engine coolant temperature sensor harness con-

nector.

4) Connect 150Wresistor to engine coolant temperature sensor

harness connector.

5) Start engine and make sure that cooling fan operates.

Be careful not to overheat engine.

6) If NG, go to ªDiagnostic Procedureº, EC-114.

AEC640

SEF111X

MEC475B

DTC 0208 OVER HEATZD30DDTi

EC-111

Page 476 of 1767

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye sEGO TO 2.

NoEGO TO 3.

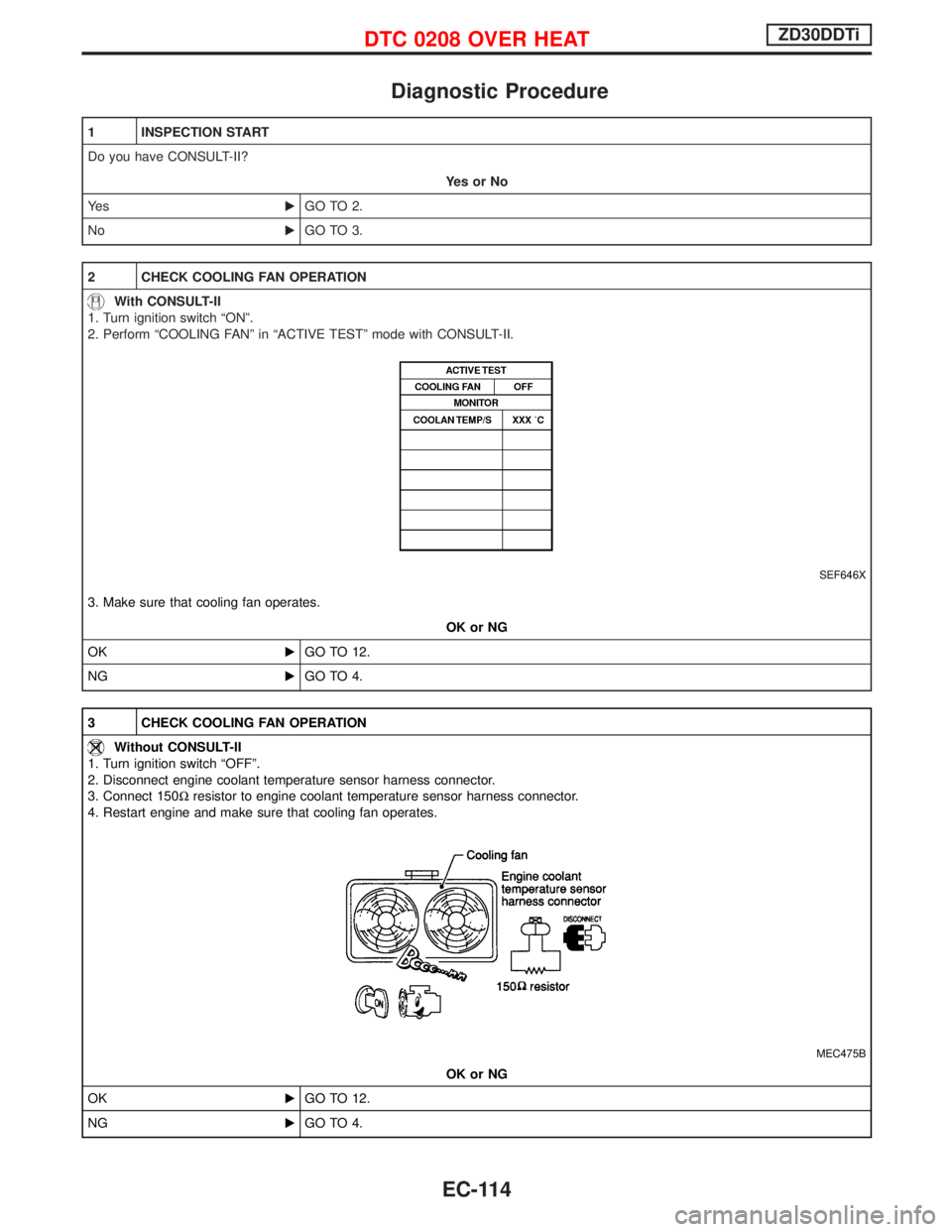

2 CHECK COOLING FAN OPERATION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF646X

3. Make sure that cooling fan operates.

OK or NG

OKEGO TO 12.

NGEGO TO 4.

3 CHECK COOLING FAN OPERATION

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect 150Wresistor to engine coolant temperature sensor harness connector.

4. Restart engine and make sure that cooling fan operates.

MEC475B

OK or NG

OKEGO TO 12.

NGEGO TO 4.

DTC 0208 OVER HEATZD30DDTi

EC-114

Page 477 of 1767

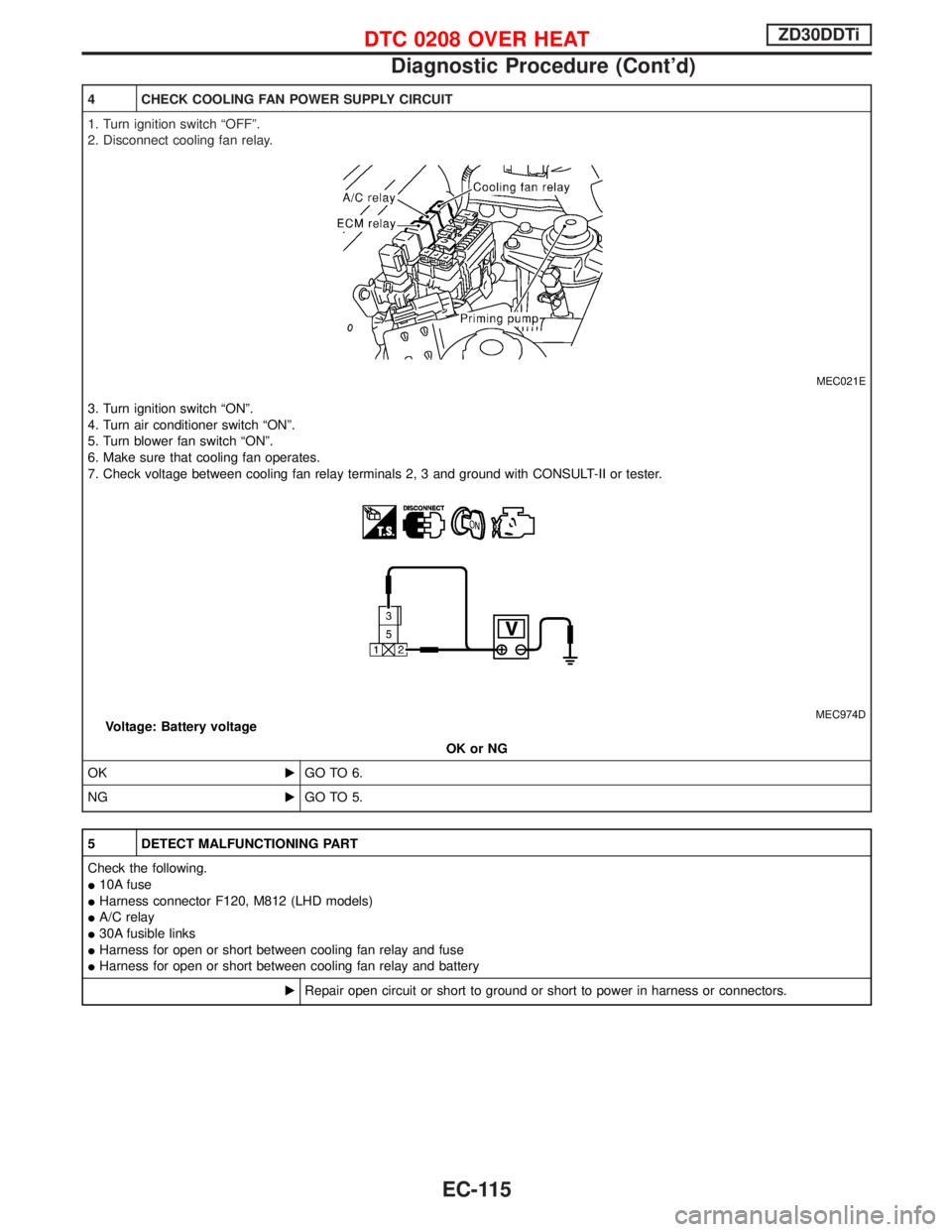

4 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay.

MEC021E

3. Turn ignition switch ªONº.

4. Turn air conditioner switch ªONº.

5. Turn blower fan switch ªONº.

6. Make sure that cooling fan operates.

7. Check voltage between cooling fan relay terminals 2, 3 and ground with CONSULT-II or tester.

MEC974DVoltage: Battery voltage

OK or NG

OKEGO TO 6.

NGEGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

I10A fuse

IHarness connector F120, M812 (LHD models)

IA/C relay

I30A fusible links

IHarness for open or short between cooling fan relay and fuse

IHarness for open or short between cooling fan relay and battery

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-115

Page 478 of 1767

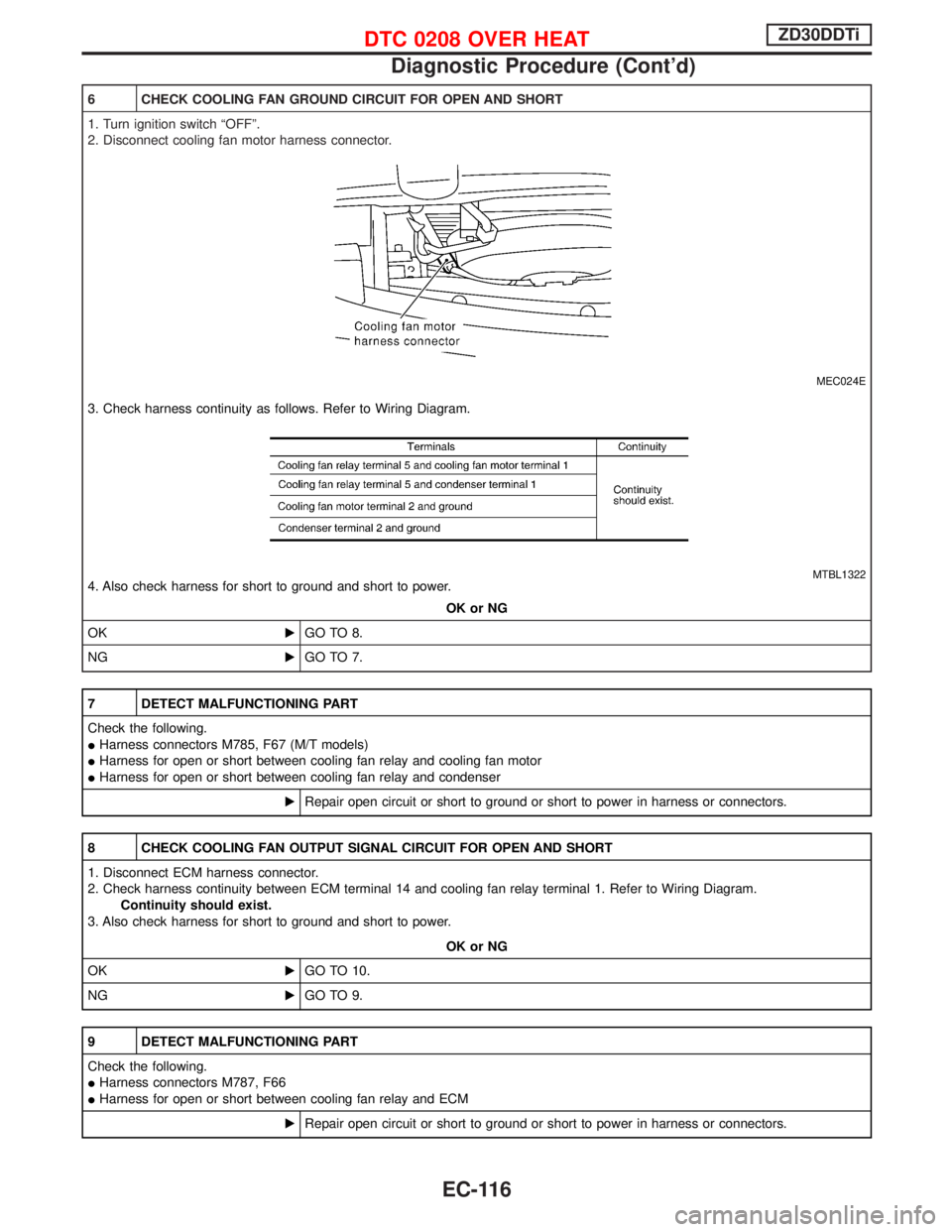

6 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor harness connector.

MEC024E

3. Check harness continuity as follows. Refer to Wiring Diagram.

MTBL13224. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 8.

NGEGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M785, F67 (M/T models)

IHarness for open or short between cooling fan relay and cooling fan motor

IHarness for open or short between cooling fan relay and condenser

ERepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 14 and cooling fan relay terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 10.

NGEGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66

IHarness for open or short between cooling fan relay and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-116

Page 483 of 1767

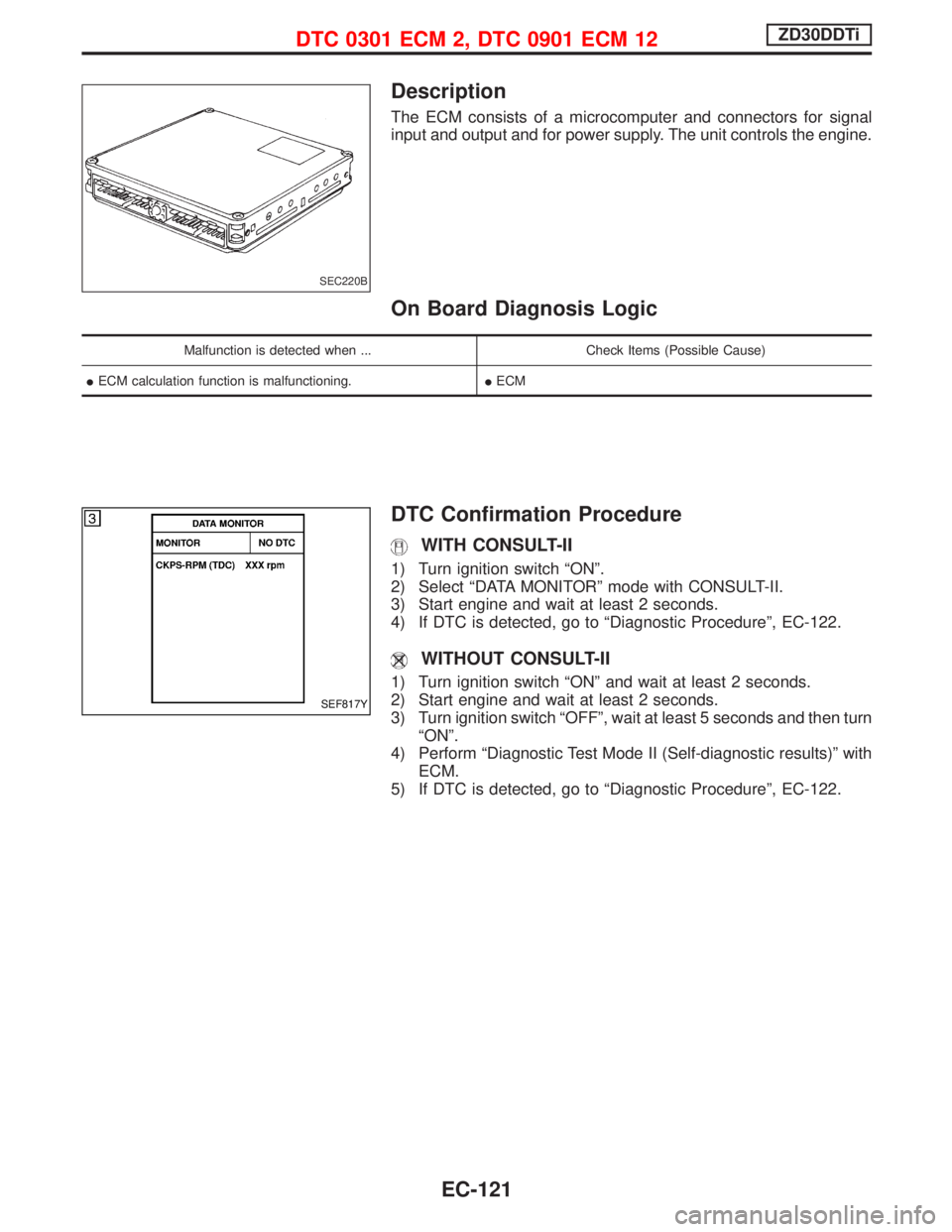

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

IECM calculation function is malfunctioning.IECM

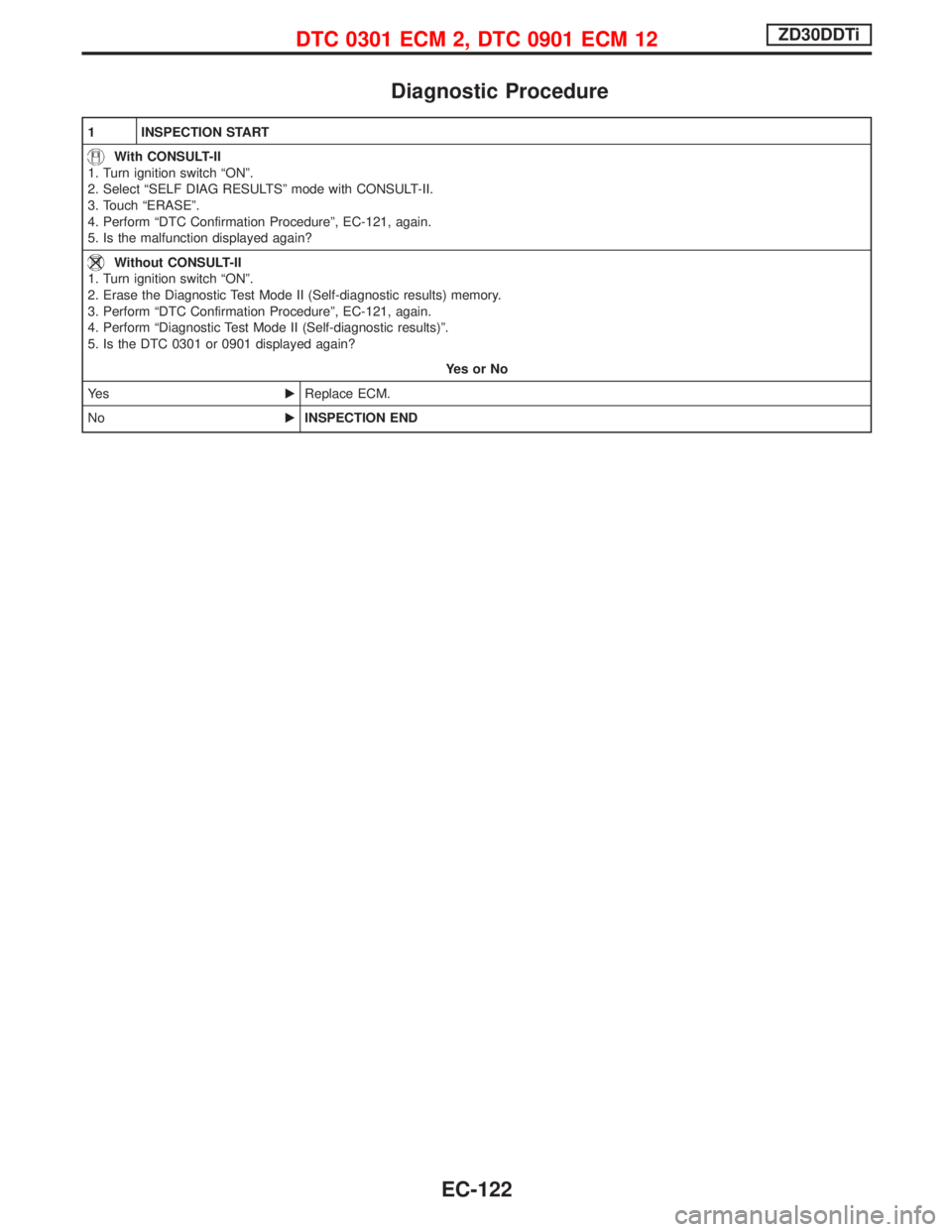

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-122.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-122.

SEC220B

SEF817Y

DTC 0301 ECM 2, DTC 0901 ECM 12ZD30DDTi

EC-121

Page 484 of 1767

Diagnostic Procedure

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-121, again.

5. Is the malfunction displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-121, again.

4. Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

5. Is the DTC 0301 or 0901 displayed again?

YesorNo

Ye sEReplace ECM.

NoEINSPECTION END

DTC 0301 ECM 2, DTC 0901 ECM 12ZD30DDTi

EC-122

Page 486 of 1767

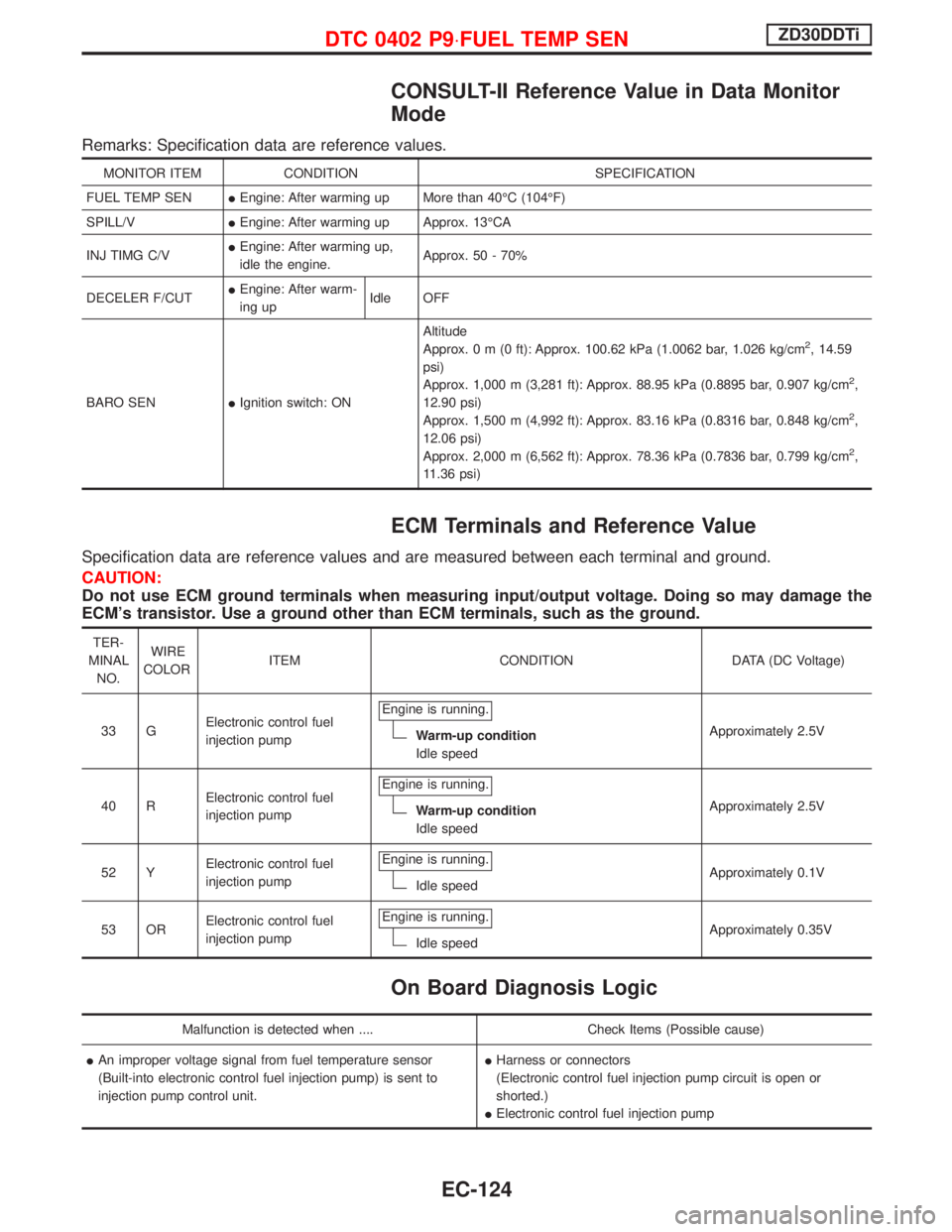

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SENIEngine: After warming up More than 40ÉC (104ÉF)

SPILL/VIEngine: After warming up Approx. 13ÉCA

INJ TIMG C/VIEngine: After warming up,

idle the engine.Approx. 50 - 70%

DECELER F/CUTIEngine: After warm-

ing upIdle OFF

BARO SENIIgnition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

33 GElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.5V

40 RElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.5V

52 YElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.1V

53 ORElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.35V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible cause)

IAn improper voltage signal from fuel temperature sensor

(Built-into electronic control fuel injection pump) is sent to

injection pump control unit.IHarness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

IElectronic control fuel injection pump

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-124

Page 487 of 1767

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-128.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-128.SEF817Y

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-125

Page 490 of 1767

Diagnostic Procedure

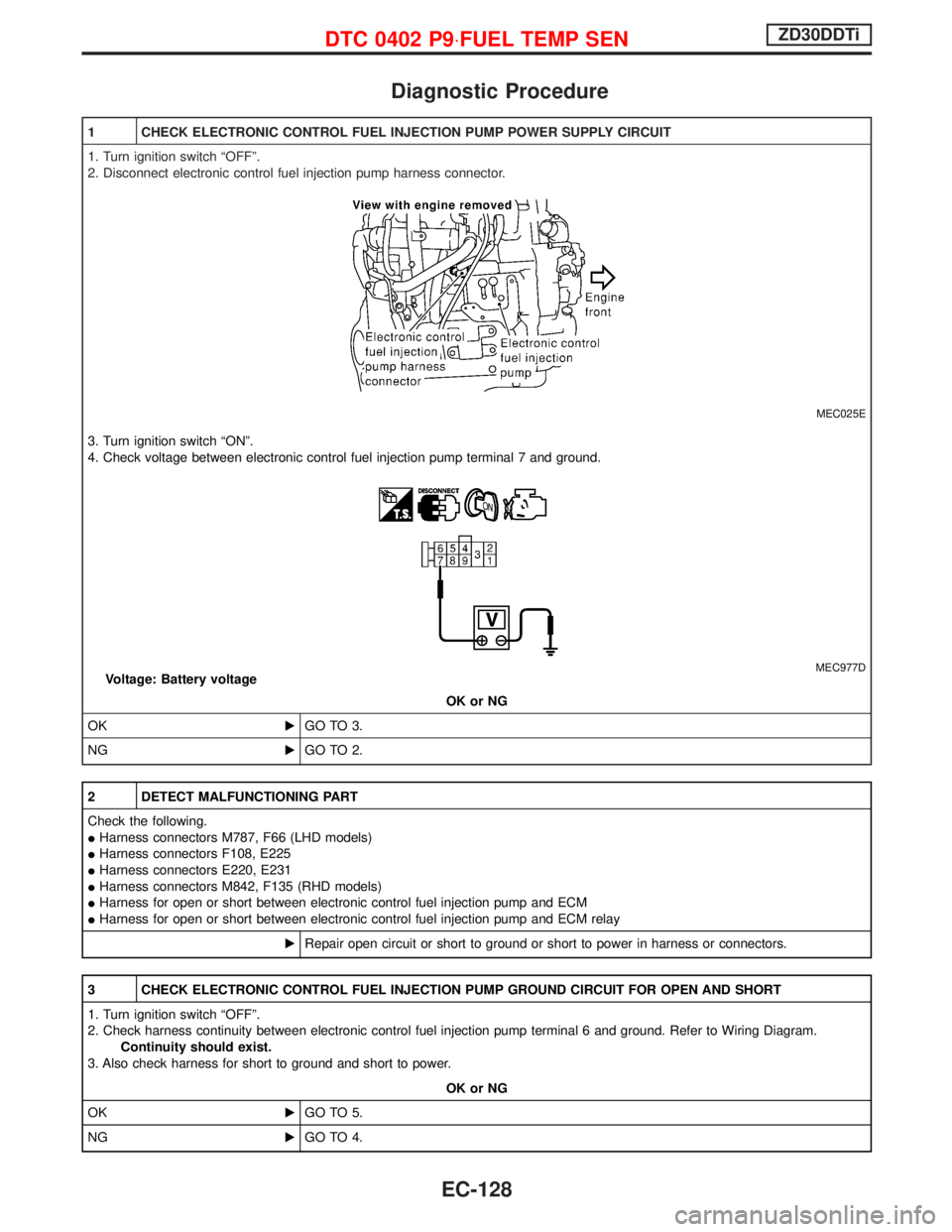

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltage

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F108, E225

IHarness connectors E220, E231

IHarness connectors M842, F135 (RHD models)

IHarness for open or short between electronic control fuel injection pump and ECM

IHarness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-128