height NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 217 of 1767

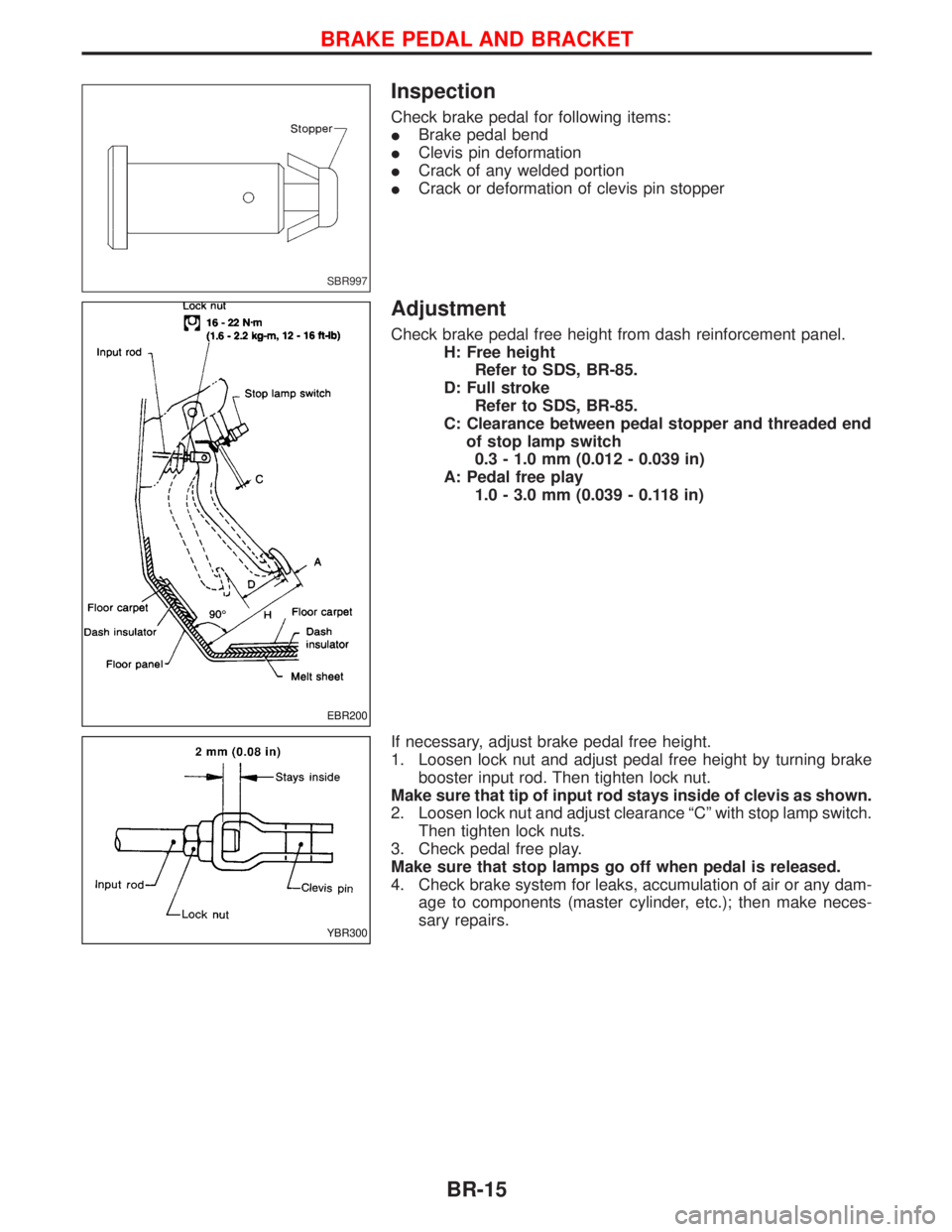

Inspection

Check brake pedal for following items:

IBrake pedal bend

IClevis pin deformation

ICrack of any welded portion

ICrack or deformation of clevis pin stopper

Adjustment

Check brake pedal free height from dash reinforcement panel.

H: Free height

Refer to SDS, BR-85.

D: Full stroke

Refer to SDS, BR-85.

C: Clearance between pedal stopper and threaded end

of stop lamp switch

0.3 - 1.0 mm (0.012 - 0.039 in)

A: Pedal free play

1.0 - 3.0 mm (0.039 - 0.118 in)

If necessary, adjust brake pedal free height.

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

Make sure that tip of input rod stays inside of clevis as shown.

2. Loosen lock nut and adjust clearance ªCº with stop lamp switch.

Then tighten lock nuts.

3. Check pedal free play.

Make sure that stop lamps go off when pedal is released.

4. Check brake system for leaks, accumulation of air or any dam-

age to components (master cylinder, etc.); then make neces-

sary repairs.

SBR997

EBR200

YBR300

BRAKE PEDAL AND BRACKET

BR-15

Page 287 of 1767

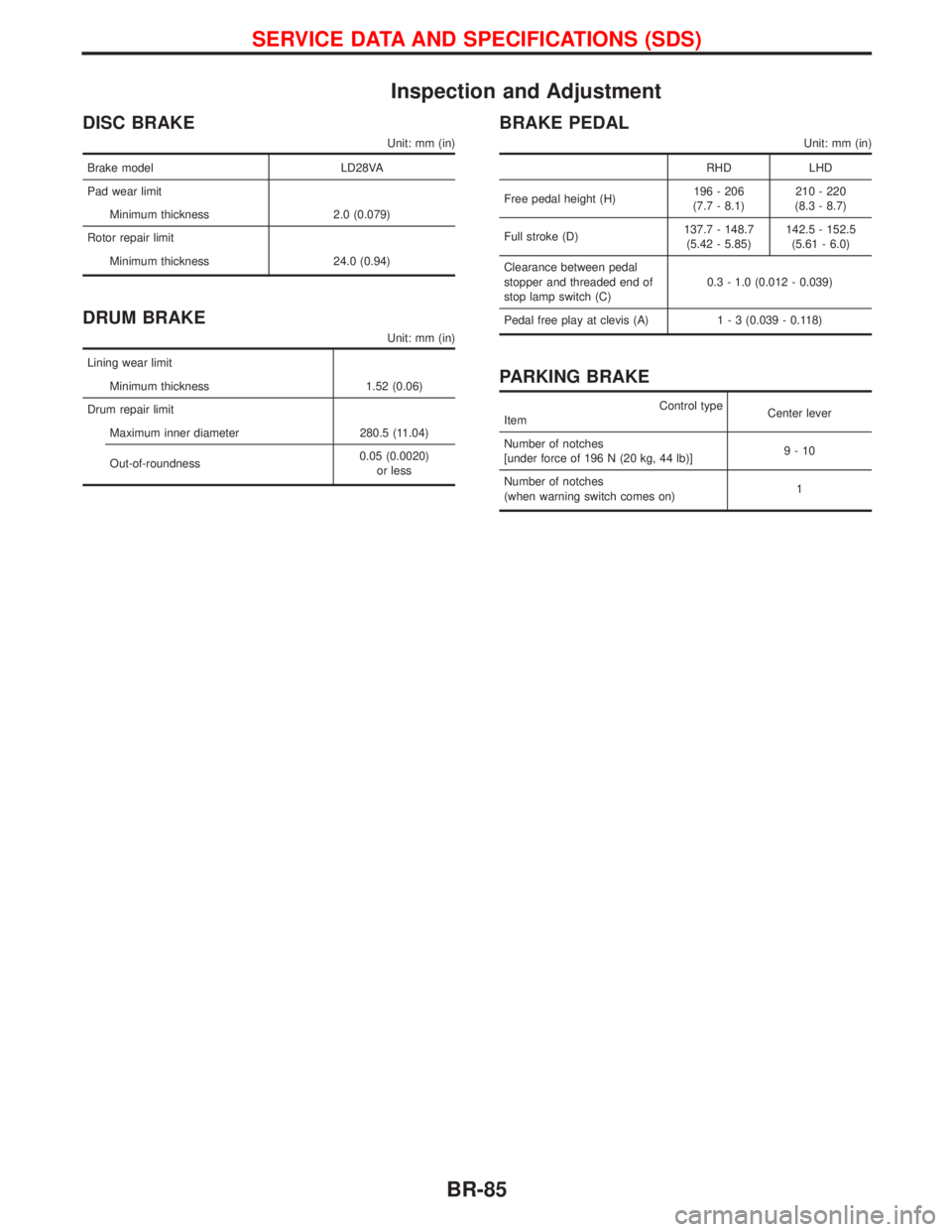

Inspection and Adjustment

DISC BRAKE

Unit: mm (in)

Brake model LD28VA

Pad wear limit

Minimum thickness 2.0 (0.079)

Rotor repair limit

Minimum thickness 24.0 (0.94)

DRUM BRAKE

Unit: mm (in)

Lining wear limit

Minimum thickness 1.52 (0.06)

Drum repair limit

Maximum inner diameter 280.5 (11.04)

Out-of-roundness0.05 (0.0020)

or less

BRAKE PEDAL

Unit: mm (in)

RHD LHD

Free pedal height (H)196 - 206

(7.7 - 8.1)210 - 220

(8.3 - 8.7)

Full stroke (D)137.7 - 148.7

(5.42 - 5.85)142.5 - 152.5

(5.61 - 6.0)

Clearance between pedal

stopper and threaded end of

stop lamp switch (C)0.3 - 1.0 (0.012 - 0.039)

Pedal free play at clevis (A)1 - 3 (0.039 - 0.118)

PARKING BRAKE

Control type

ItemCenter lever

Number of notches

[under force of 196 N (20 kg, 44 lb)]9-10

Number of notches

(when warning switch comes on)1

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-85

Page 353 of 1767

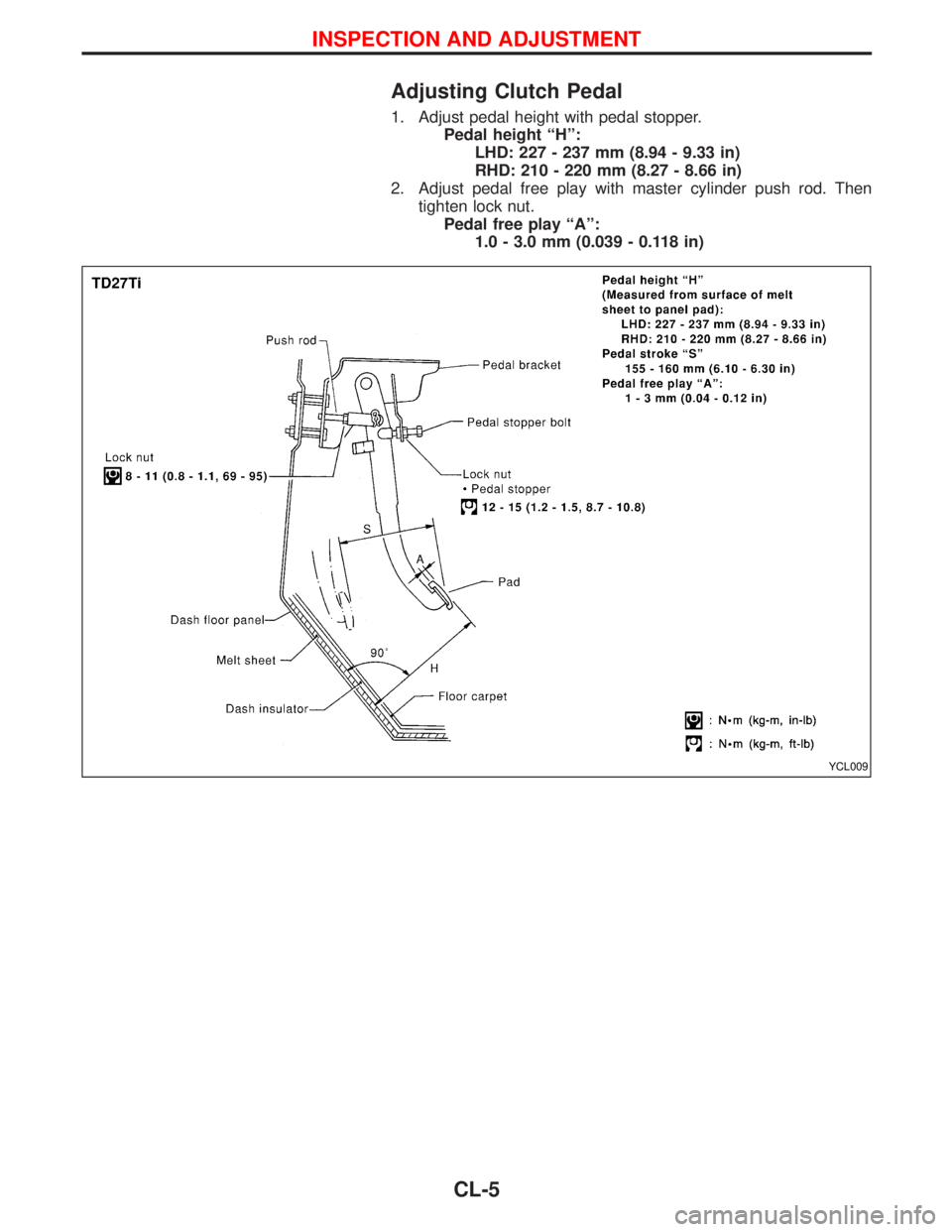

Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper.

Pedal height ªHº:

LHD: 227 - 237 mm (8.94 - 9.33 in)

RHD: 210 - 220 mm (8.27 - 8.66 in)

2. Adjust pedal free play with master cylinder push rod. Then

tighten lock nut.

Pedal free play ªAº:

1.0 - 3.0 mm (0.039 - 0.118 in)

YCL009

INSPECTION AND ADJUSTMENT

CL-5

Page 360 of 1767

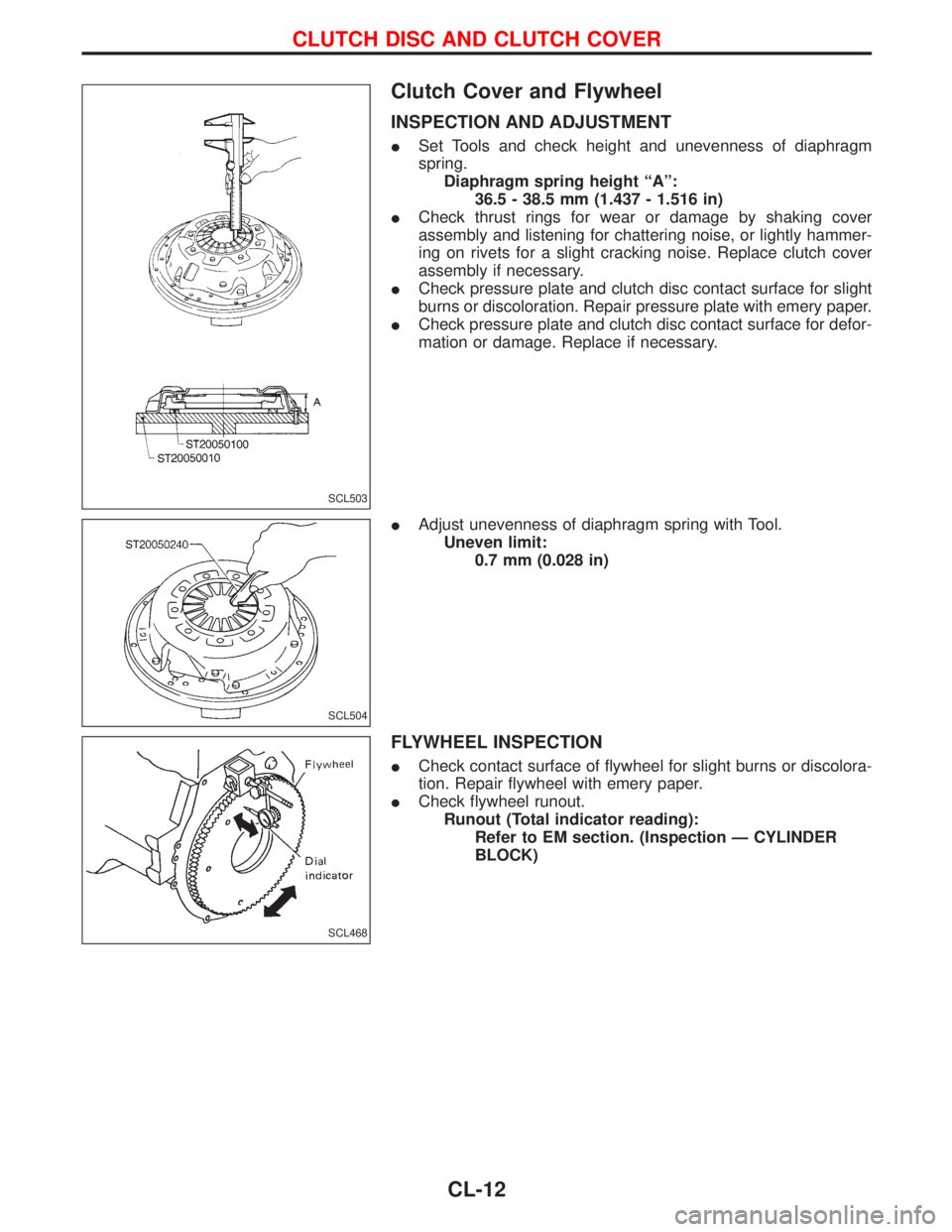

Clutch Cover and Flywheel

INSPECTION AND ADJUSTMENT

ISet Tools and check height and unevenness of diaphragm

spring.

Diaphragm spring height ªAº:

36.5 - 38.5 mm (1.437 - 1.516 in)

ICheck thrust rings for wear or damage by shaking cover

assembly and listening for chattering noise, or lightly hammer-

ing on rivets for a slight cracking noise. Replace clutch cover

assembly if necessary.

ICheck pressure plate and clutch disc contact surface for slight

burns or discoloration. Repair pressure plate with emery paper.

ICheck pressure plate and clutch disc contact surface for defor-

mation or damage. Replace if necessary.

IAdjust unevenness of diaphragm spring with Tool.

Uneven limit:

0.7 mm (0.028 in)

FLYWHEEL INSPECTION

ICheck contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

ICheck flywheel runout.

Runout (Total indicator reading):

Refer to EM section. (Inspection Ð CYLINDER

BLOCK)

SCL503

SCL504

SCL468

CLUTCH DISC AND CLUTCH COVER

CL-12

Page 362 of 1767

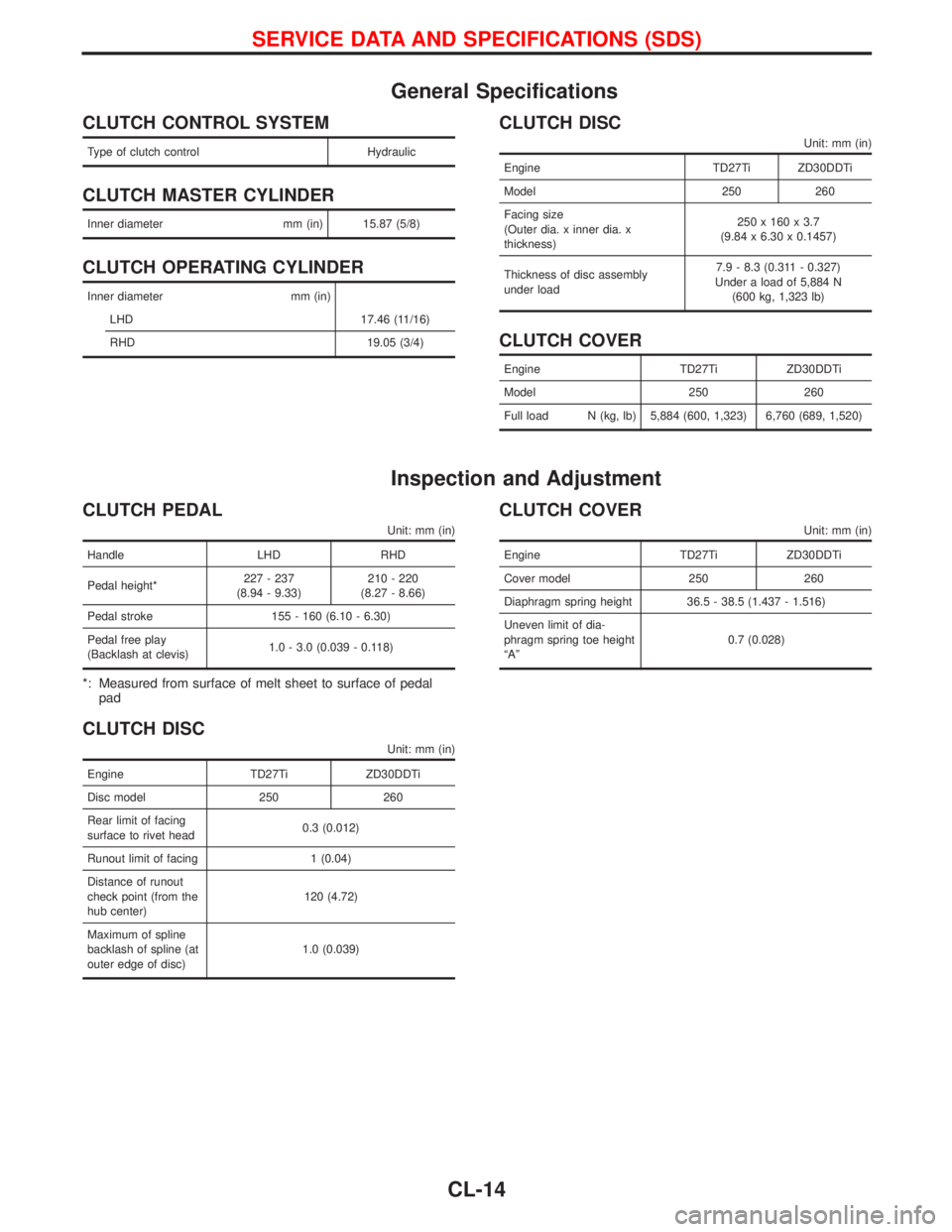

General Specifications

CLUTCH CONTROL SYSTEM

Type of clutch control Hydraulic

CLUTCH MASTER CYLINDER

Inner diameter mm (in) 15.87 (5/8)

CLUTCH OPERATING CYLINDER

Inner diameter mm (in)

LHD 17.46 (11/16)

RHD 19.05 (3/4)

CLUTCH DISC

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Model 250 260

Facing size

(Outer dia. x inner dia. x

thickness)250 x 160 x 3.7

(9.84 x 6.30 x 0.1457)

Thickness of disc assembly

under load7.9 - 8.3 (0.311 - 0.327)

Under a load of 5,884 N

(600 kg, 1,323 lb)

CLUTCH COVER

Engine TD27Ti ZD30DDTi

Model 250 260

Full load N (kg, lb) 5,884 (600, 1,323) 6,760 (689, 1,520)

Inspection and Adjustment

CLUTCH PEDAL

Unit: mm (in)

Handle LHD RHD

Pedal height*227 - 237

(8.94 - 9.33)210 - 220

(8.27 - 8.66)

Pedal stroke 155 - 160 (6.10 - 6.30)

Pedal free play

(Backlash at clevis)1.0 - 3.0 (0.039 - 0.118)

*: Measured from surface of melt sheet to surface of pedal

pad

CLUTCH DISC

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Disc model 250 260

Rear limit of facing

surface to rivet head0.3 (0.012)

Runout limit of facing 1 (0.04)

Distance of runout

check point (from the

hub center)120 (4.72)

Maximum of spline

backlash of spline (at

outer edge of disc)1.0 (0.039)

CLUTCH COVER

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Cover model 250 260

Diaphragm spring height 36.5 - 38.5 (1.437 - 1.516)

Uneven limit of dia-

phragm spring toe height

ªAº0.7 (0.028)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-14

Page 609 of 1767

![NISSAN TERRANO 2002 Service Repair Manual 17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

IDo not bump glow plug heating element. If it is bumped, NISSAN TERRANO 2002 Service Repair Manual 17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

IDo not bump glow plug heating element. If it is bumped,](/img/5/57393/w960_57393-608.png)

17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

IDo not bump glow plug heating element. If it is bumped, replace glow plug with a new one.

IIf glow plug is dropped from a height of 10 cm (3.94 in) or higher, replace with a new one.

IIf glow plug installation hole is contaminated with carbon, remove it with a reamer or suitable tool.

IHand-tighten glow plug by turning it two or three times, then tighten using a tool to specified torque.

:15-20N×m (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

OK or NG

OKEGO TO 18.

NGEReplace glow plug.

18 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-247

Page 758 of 1767

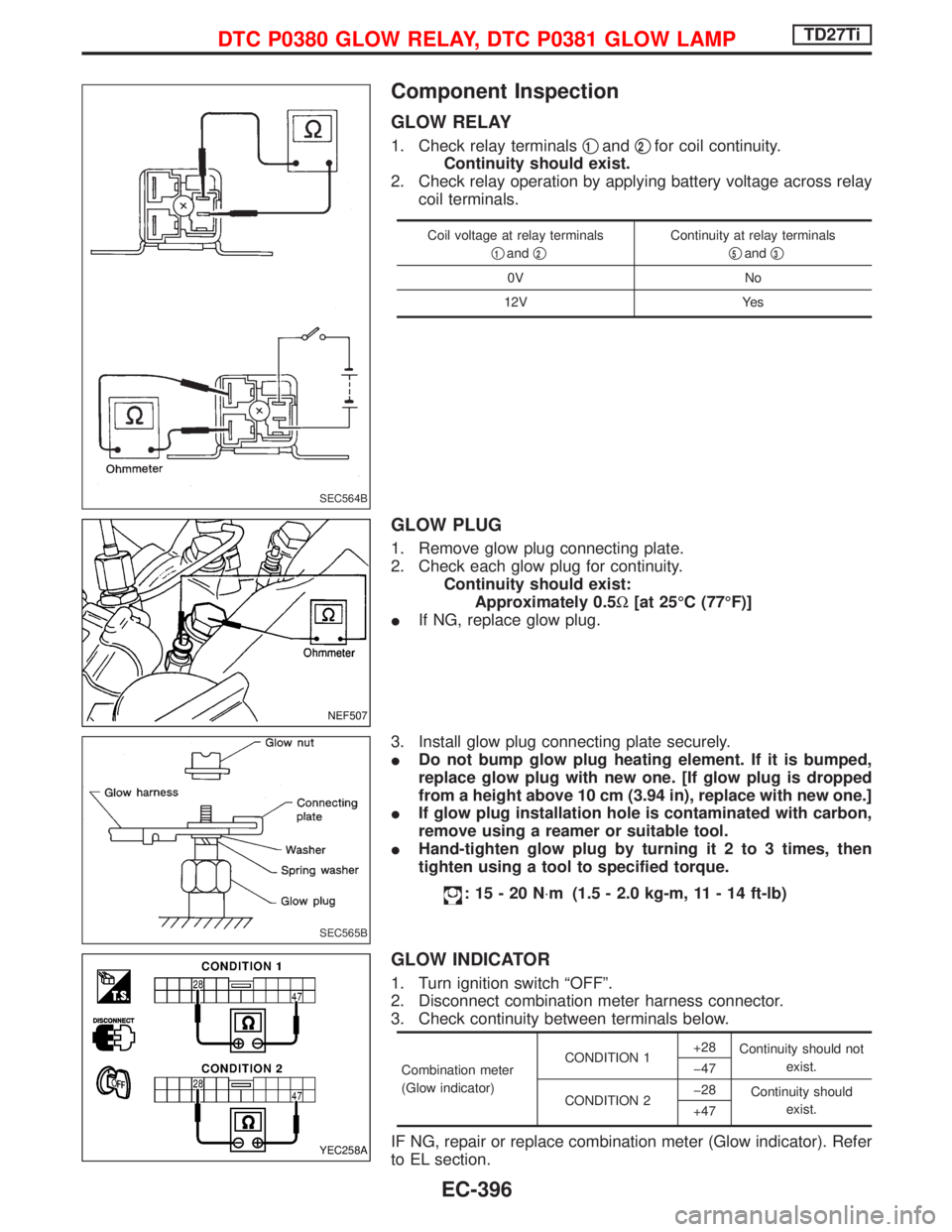

Component Inspection

GLOW RELAY

1. Check relay terminalsq1andq2for coil continuity.

Continuity should exist.

2. Check relay operation by applying battery voltage across relay

coil terminals.

Coil voltage at relay terminals

q

1andq2

Continuity at relay terminals

q

5andq3

0V No

12V Yes

GLOW PLUG

1. Remove glow plug connecting plate.

2. Check each glow plug for continuity.

Continuity should exist:

Approximately 0.5W[at 25ÉC (77ÉF)]

IIf NG, replace glow plug.

3. Install glow plug connecting plate securely.

IDo not bump glow plug heating element. If it is bumped,

replace glow plug with new one. [If glow plug is dropped

from a height above 10 cm (3.94 in), replace with new one.]

IIf glow plug installation hole is contaminated with carbon,

remove using a reamer or suitable tool.

IHand-tighten glow plug by turning it 2 to 3 times, then

tighten using a tool to specified torque.

:15-20N×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

GLOW INDICATOR

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector.

3. Check continuity between terminals below.

Combination meter

(Glow indicator)CONDITION 1+28

Continuity should not

exist.

þ47

CONDITION 2þ28

Continuity should

exist.

+47

IF NG, repair or replace combination meter (Glow indicator). Refer

to EL section.

SEC564B

NEF507

SEC565B

YEC258A

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-396

Page 1139 of 1767

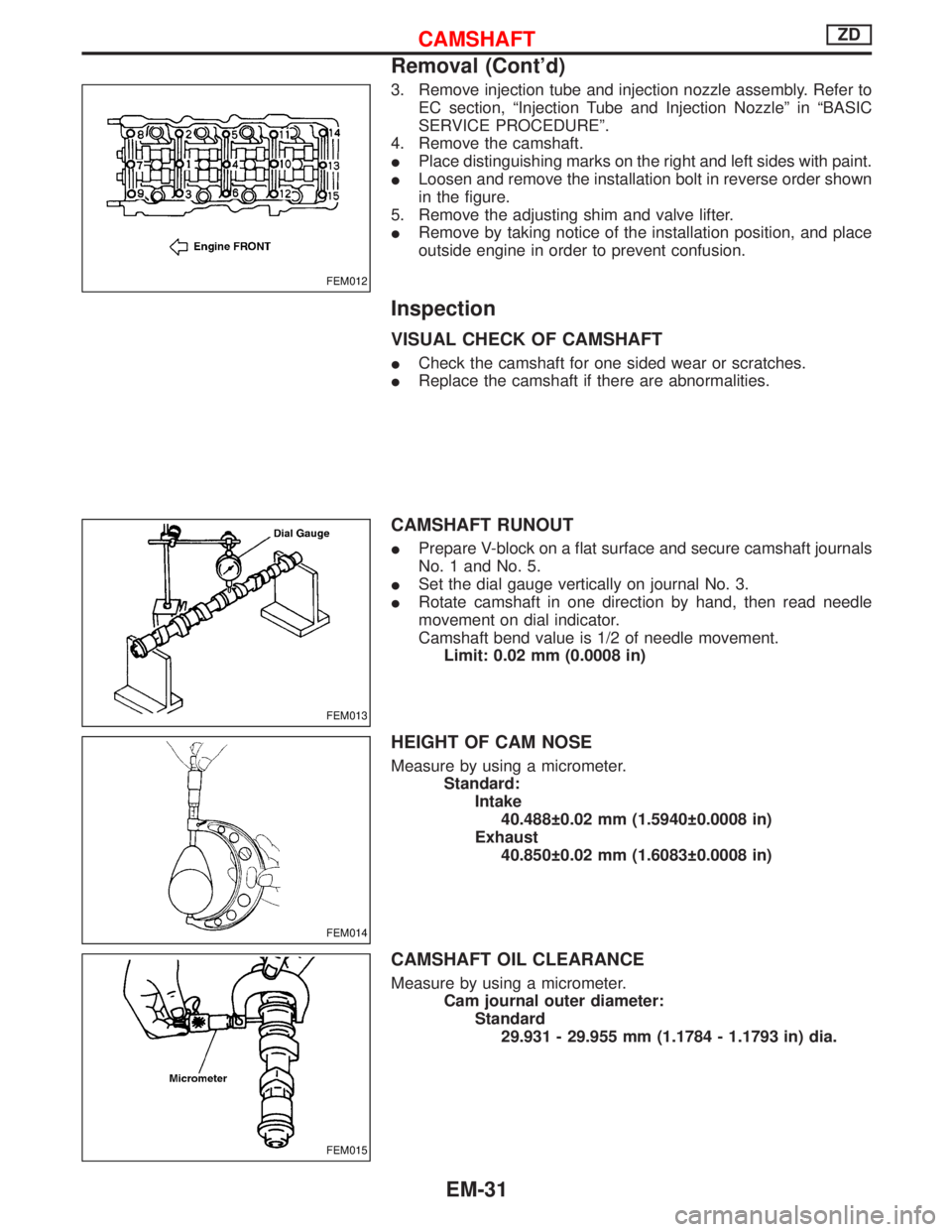

3. Remove injection tube and injection nozzle assembly. Refer to

EC section, ªInjection Tube and Injection Nozzleº in ªBASIC

SERVICE PROCEDUREº.

4. Remove the camshaft.

IPlace distinguishing marks on the right and left sides with paint.

ILoosen and remove the installation bolt in reverse order shown

in the figure.

5. Remove the adjusting shim and valve lifter.

IRemove by taking notice of the installation position, and place

outside engine in order to prevent confusion.

Inspection

VISUAL CHECK OF CAMSHAFT

ICheck the camshaft for one sided wear or scratches.

IReplace the camshaft if there are abnormalities.

CAMSHAFT RUNOUT

IPrepare V-block on a flat surface and secure camshaft journals

No. 1 and No. 5.

ISet the dial gauge vertically on journal No. 3.

IRotate camshaft in one direction by hand, then read needle

movement on dial indicator.

Camshaft bend value is 1/2 of needle movement.

Limit: 0.02 mm (0.0008 in)

HEIGHT OF CAM NOSE

Measure by using a micrometer.

Standard:

Intake

40.488 0.02 mm (1.5940 0.0008 in)

Exhaust

40.850 0.02 mm (1.6083 0.0008 in)

CAMSHAFT OIL CLEARANCE

Measure by using a micrometer.

Cam journal outer diameter:

Standard

29.931 - 29.955 mm (1.1784 - 1.1793 in) dia.

FEM012

FEM013

FEM014

FEM015

CAMSHAFTZD

Removal (Cont'd)

EM-31

Page 1161 of 1767

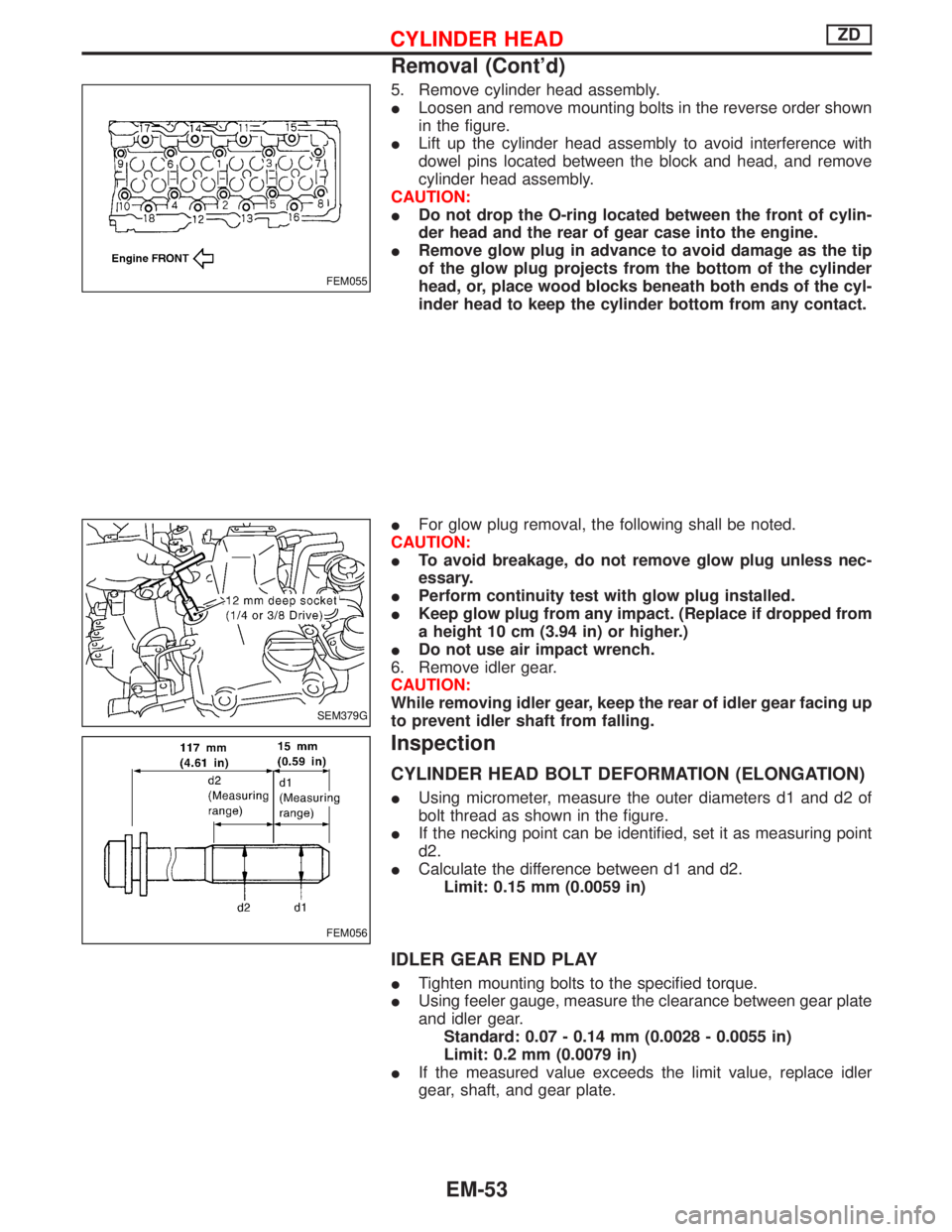

5. Remove cylinder head assembly.

ILoosen and remove mounting bolts in the reverse order shown

in the figure.

ILift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

IDo not drop the O-ring located between the front of cylin-

der head and the rear of gear case into the engine.

IRemove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylinder

head, or, place wood blocks beneath both ends of the cyl-

inder head to keep the cylinder bottom from any contact.

IFor glow plug removal, the following shall be noted.

CAUTION:

ITo avoid breakage, do not remove glow plug unless nec-

essary.

IPerform continuity test with glow plug installed.

IKeep glow plug from any impact. (Replace if dropped from

a height 10 cm (3.94 in) or higher.)

IDo not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing up

to prevent idler shaft from falling.

Inspection

CYLINDER HEAD BOLT DEFORMATION (ELONGATION)

IUsing micrometer, measure the outer diameters d1 and d2 of

bolt thread as shown in the figure.

IIf the necking point can be identified, set it as measuring point

d2.

ICalculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

ITighten mounting bolts to the specified torque.

IUsing feeler gauge, measure the clearance between gear plate

and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

IIf the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-53

Page 1162 of 1767

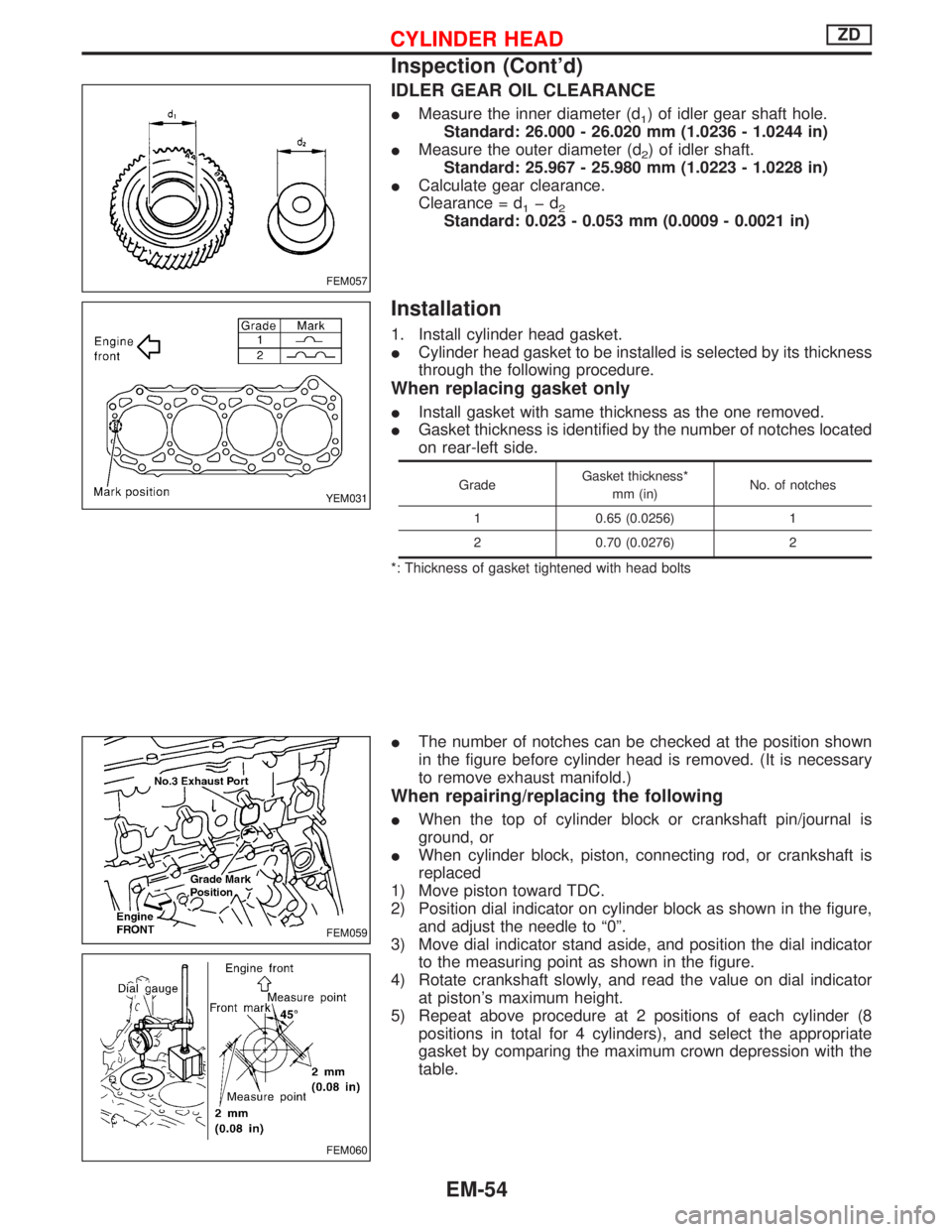

IDLER GEAR OIL CLEARANCE

IMeasure the inner diameter (d1) of idler gear shaft hole.

Standard: 26.000 - 26.020 mm (1.0236 - 1.0244 in)

IMeasure the outer diameter (d

2) of idler shaft.

Standard: 25.967 - 25.980 mm (1.0223 - 1.0228 in)

ICalculate gear clearance.

Clearance = d

1þd2Standard: 0.023 - 0.053 mm (0.0009 - 0.0021 in)

Installation

1. Install cylinder head gasket.

ICylinder head gasket to be installed is selected by its thickness

through the following procedure.

When replacing gasket only

IInstall gasket with same thickness as the one removed.

IGasket thickness is identified by the number of notches located

on rear-left side.

GradeGasket thickness*

mm (in)No. of notches

1 0.65 (0.0256) 1

2 0.70 (0.0276) 2

*: Thickness of gasket tightened with head bolts

IThe number of notches can be checked at the position shown

in the figure before cylinder head is removed. (It is necessary

to remove exhaust manifold.)

When repairing/replacing the following

IWhen the top of cylinder block or crankshaft pin/journal is

ground, or

IWhen cylinder block, piston, connecting rod, or crankshaft is

replaced

1) Move piston toward TDC.

2) Position dial indicator on cylinder block as shown in the figure,

and adjust the needle to ª0º.

3) Move dial indicator stand aside, and position the dial indicator

to the measuring point as shown in the figure.

4) Rotate crankshaft slowly, and read the value on dial indicator

at piston's maximum height.

5) Repeat above procedure at 2 positions of each cylinder (8

positions in total for 4 cylinders), and select the appropriate

gasket by comparing the maximum crown depression with the

table.

FEM057

YEM031

FEM059

FEM060

CYLINDER HEADZD

Inspection (Cont'd)

EM-54