height adjustment NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 217 of 1767

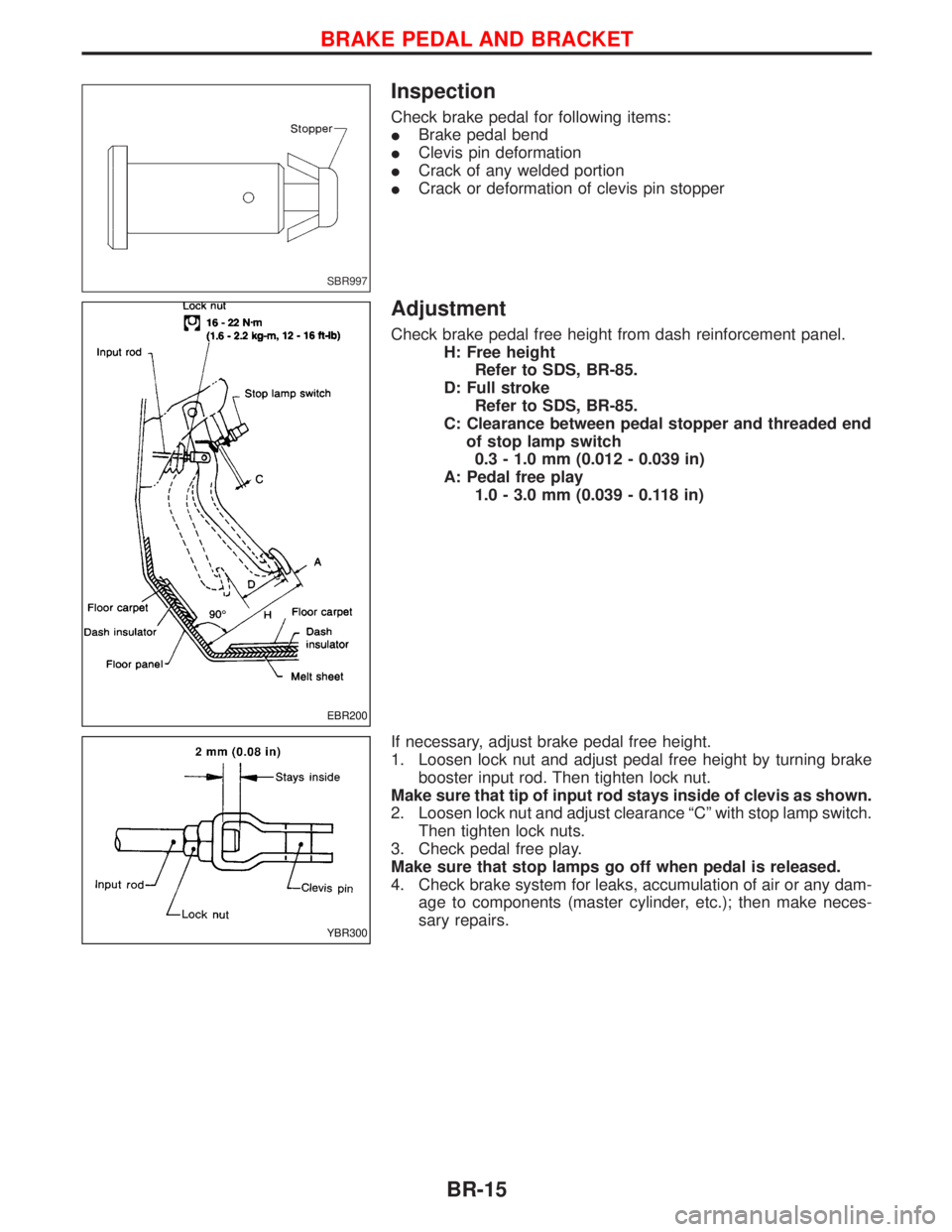

Inspection

Check brake pedal for following items:

IBrake pedal bend

IClevis pin deformation

ICrack of any welded portion

ICrack or deformation of clevis pin stopper

Adjustment

Check brake pedal free height from dash reinforcement panel.

H: Free height

Refer to SDS, BR-85.

D: Full stroke

Refer to SDS, BR-85.

C: Clearance between pedal stopper and threaded end

of stop lamp switch

0.3 - 1.0 mm (0.012 - 0.039 in)

A: Pedal free play

1.0 - 3.0 mm (0.039 - 0.118 in)

If necessary, adjust brake pedal free height.

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

Make sure that tip of input rod stays inside of clevis as shown.

2. Loosen lock nut and adjust clearance ªCº with stop lamp switch.

Then tighten lock nuts.

3. Check pedal free play.

Make sure that stop lamps go off when pedal is released.

4. Check brake system for leaks, accumulation of air or any dam-

age to components (master cylinder, etc.); then make neces-

sary repairs.

SBR997

EBR200

YBR300

BRAKE PEDAL AND BRACKET

BR-15

Page 287 of 1767

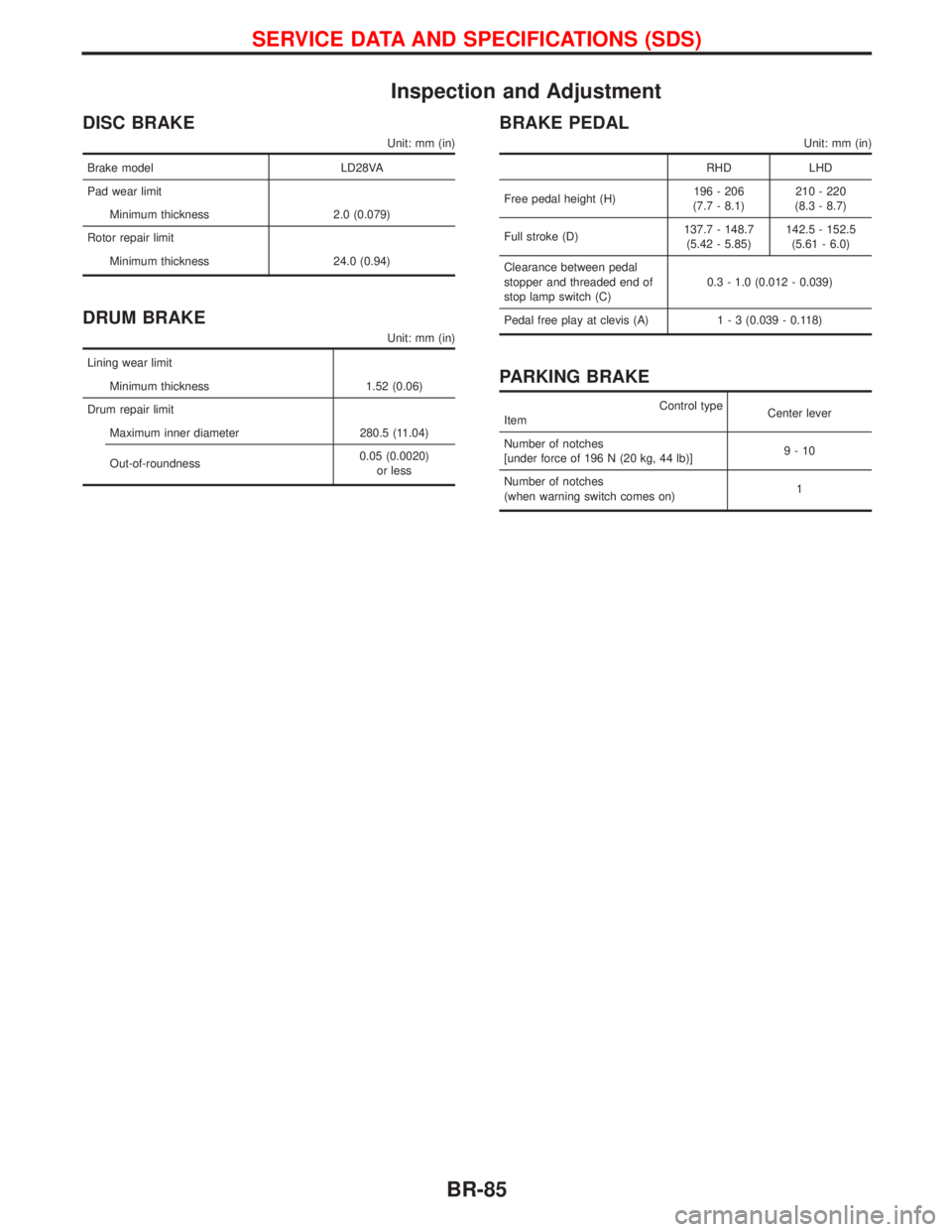

Inspection and Adjustment

DISC BRAKE

Unit: mm (in)

Brake model LD28VA

Pad wear limit

Minimum thickness 2.0 (0.079)

Rotor repair limit

Minimum thickness 24.0 (0.94)

DRUM BRAKE

Unit: mm (in)

Lining wear limit

Minimum thickness 1.52 (0.06)

Drum repair limit

Maximum inner diameter 280.5 (11.04)

Out-of-roundness0.05 (0.0020)

or less

BRAKE PEDAL

Unit: mm (in)

RHD LHD

Free pedal height (H)196 - 206

(7.7 - 8.1)210 - 220

(8.3 - 8.7)

Full stroke (D)137.7 - 148.7

(5.42 - 5.85)142.5 - 152.5

(5.61 - 6.0)

Clearance between pedal

stopper and threaded end of

stop lamp switch (C)0.3 - 1.0 (0.012 - 0.039)

Pedal free play at clevis (A)1 - 3 (0.039 - 0.118)

PARKING BRAKE

Control type

ItemCenter lever

Number of notches

[under force of 196 N (20 kg, 44 lb)]9-10

Number of notches

(when warning switch comes on)1

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-85

Page 353 of 1767

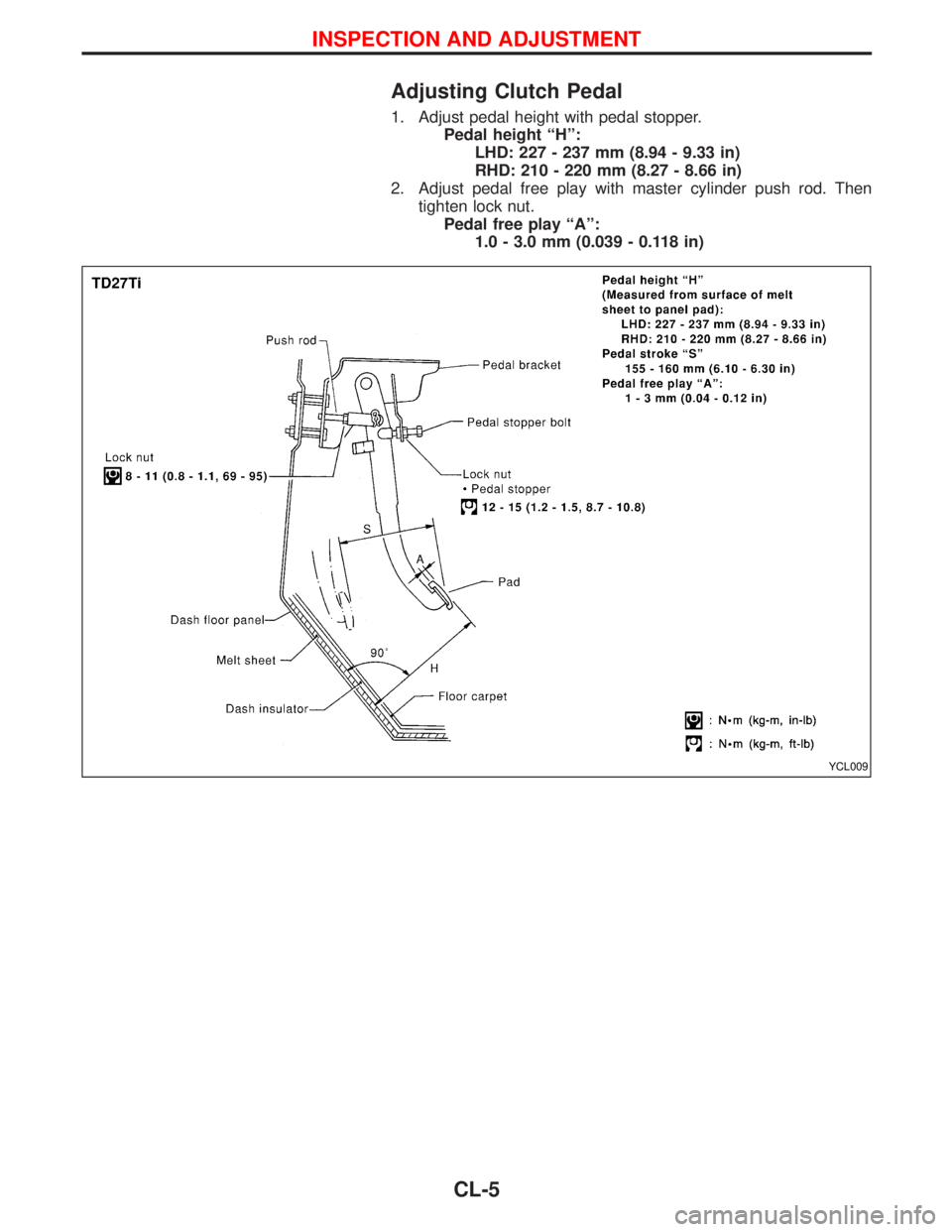

Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper.

Pedal height ªHº:

LHD: 227 - 237 mm (8.94 - 9.33 in)

RHD: 210 - 220 mm (8.27 - 8.66 in)

2. Adjust pedal free play with master cylinder push rod. Then

tighten lock nut.

Pedal free play ªAº:

1.0 - 3.0 mm (0.039 - 0.118 in)

YCL009

INSPECTION AND ADJUSTMENT

CL-5

Page 360 of 1767

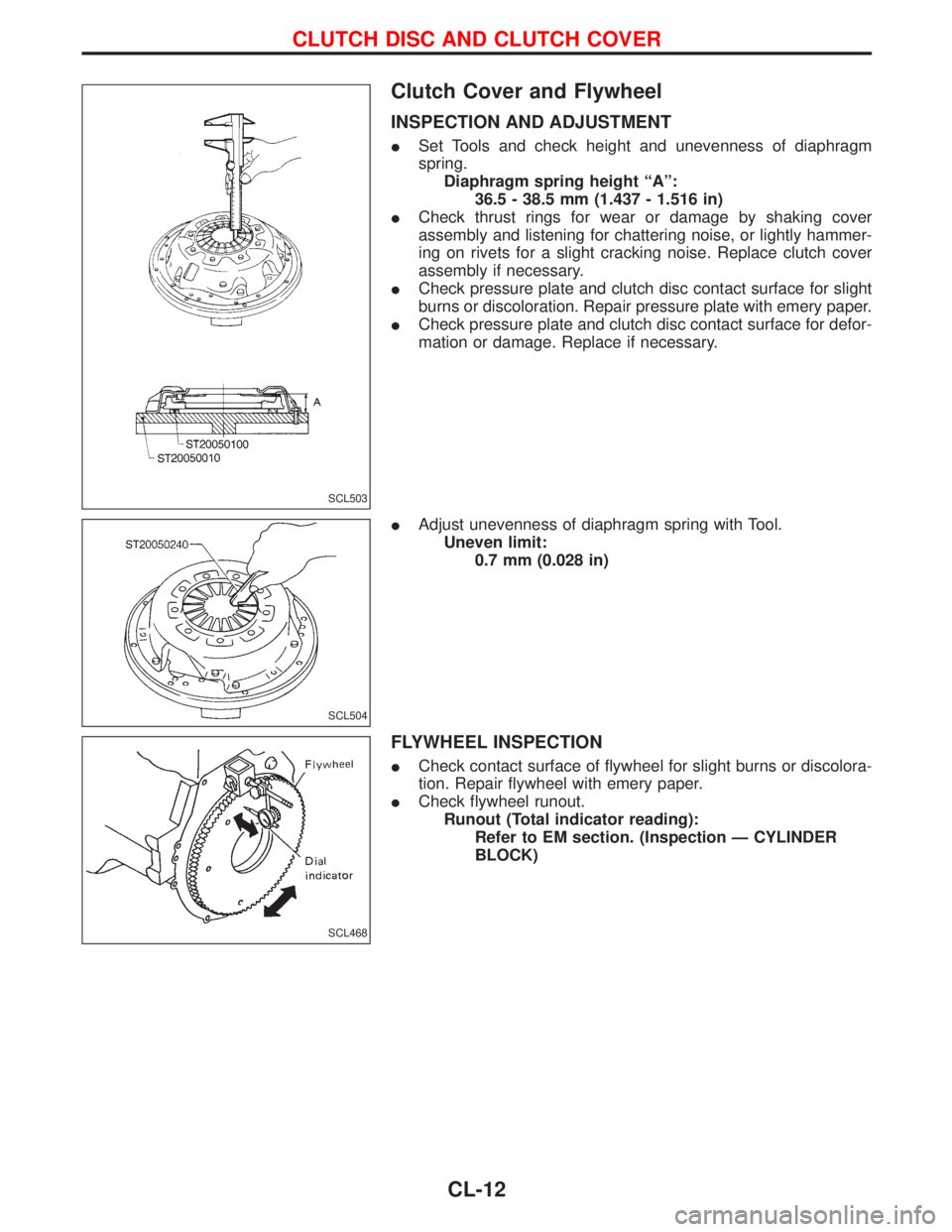

Clutch Cover and Flywheel

INSPECTION AND ADJUSTMENT

ISet Tools and check height and unevenness of diaphragm

spring.

Diaphragm spring height ªAº:

36.5 - 38.5 mm (1.437 - 1.516 in)

ICheck thrust rings for wear or damage by shaking cover

assembly and listening for chattering noise, or lightly hammer-

ing on rivets for a slight cracking noise. Replace clutch cover

assembly if necessary.

ICheck pressure plate and clutch disc contact surface for slight

burns or discoloration. Repair pressure plate with emery paper.

ICheck pressure plate and clutch disc contact surface for defor-

mation or damage. Replace if necessary.

IAdjust unevenness of diaphragm spring with Tool.

Uneven limit:

0.7 mm (0.028 in)

FLYWHEEL INSPECTION

ICheck contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

ICheck flywheel runout.

Runout (Total indicator reading):

Refer to EM section. (Inspection Ð CYLINDER

BLOCK)

SCL503

SCL504

SCL468

CLUTCH DISC AND CLUTCH COVER

CL-12

Page 362 of 1767

General Specifications

CLUTCH CONTROL SYSTEM

Type of clutch control Hydraulic

CLUTCH MASTER CYLINDER

Inner diameter mm (in) 15.87 (5/8)

CLUTCH OPERATING CYLINDER

Inner diameter mm (in)

LHD 17.46 (11/16)

RHD 19.05 (3/4)

CLUTCH DISC

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Model 250 260

Facing size

(Outer dia. x inner dia. x

thickness)250 x 160 x 3.7

(9.84 x 6.30 x 0.1457)

Thickness of disc assembly

under load7.9 - 8.3 (0.311 - 0.327)

Under a load of 5,884 N

(600 kg, 1,323 lb)

CLUTCH COVER

Engine TD27Ti ZD30DDTi

Model 250 260

Full load N (kg, lb) 5,884 (600, 1,323) 6,760 (689, 1,520)

Inspection and Adjustment

CLUTCH PEDAL

Unit: mm (in)

Handle LHD RHD

Pedal height*227 - 237

(8.94 - 9.33)210 - 220

(8.27 - 8.66)

Pedal stroke 155 - 160 (6.10 - 6.30)

Pedal free play

(Backlash at clevis)1.0 - 3.0 (0.039 - 0.118)

*: Measured from surface of melt sheet to surface of pedal

pad

CLUTCH DISC

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Disc model 250 260

Rear limit of facing

surface to rivet head0.3 (0.012)

Runout limit of facing 1 (0.04)

Distance of runout

check point (from the

hub center)120 (4.72)

Maximum of spline

backlash of spline (at

outer edge of disc)1.0 (0.039)

CLUTCH COVER

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Cover model 250 260

Diaphragm spring height 36.5 - 38.5 (1.437 - 1.516)

Uneven limit of dia-

phragm spring toe height

ªAº0.7 (0.028)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-14

Page 1252 of 1767

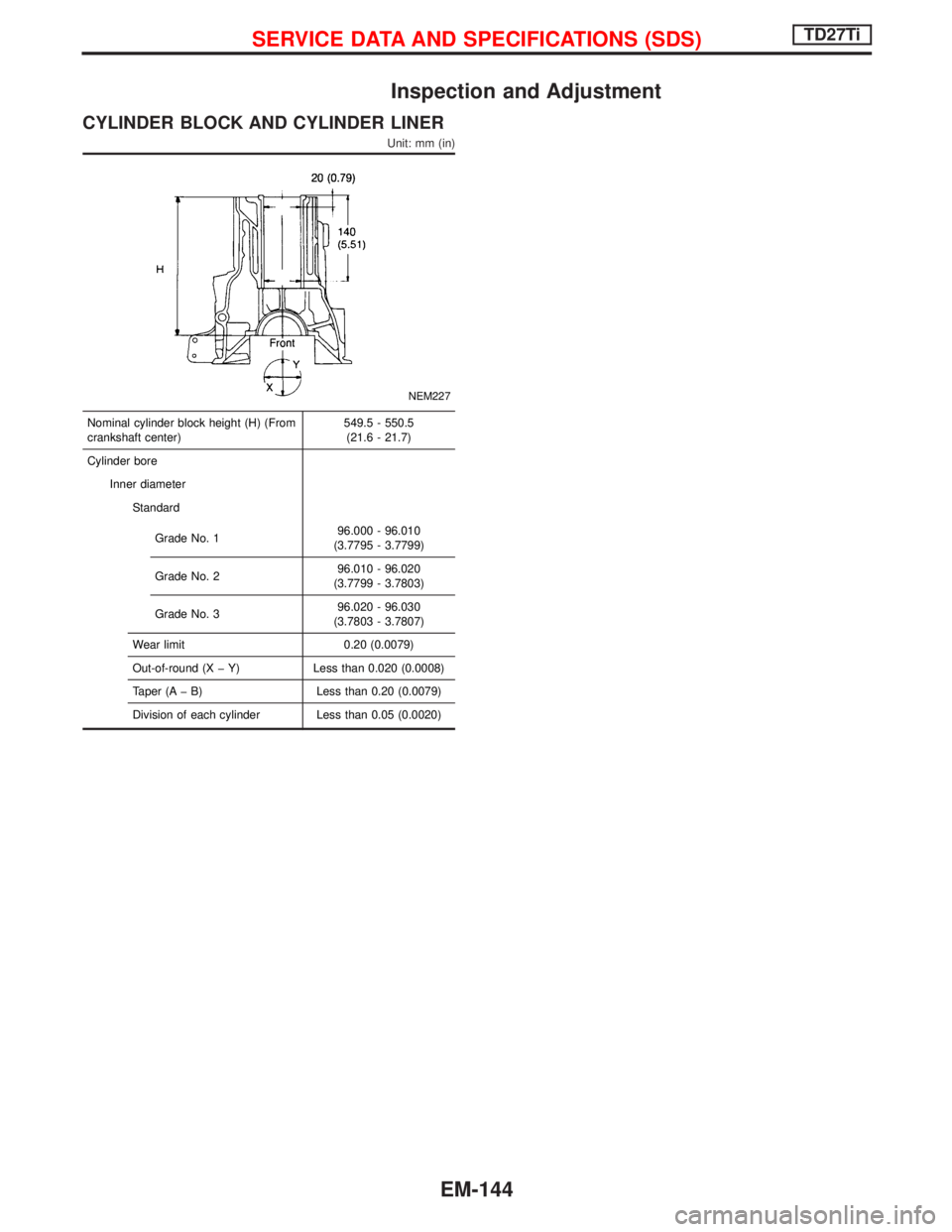

Inspection and Adjustment

CYLINDER BLOCK AND CYLINDER LINER

Unit: mm (in)

NEM227

Nominal cylinder block height (H) (From

crankshaft center)549.5 - 550.5

(21.6 - 21.7)

Cylinder bore

Inner diameter

Standard

Grade No. 196.000 - 96.010

(3.7795 - 3.7799)

Grade No. 296.010 - 96.020

(3.7799 - 3.7803)

Grade No. 396.020 - 96.030

(3.7803 - 3.7807)

Wear limit 0.20 (0.0079)

Out-of-round (X þ Y) Less than 0.020 (0.0008)

Taper (A þ B) Less than 0.20 (0.0079)

Division of each cylinder Less than 0.05 (0.0020)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-144

Page 1254 of 1767

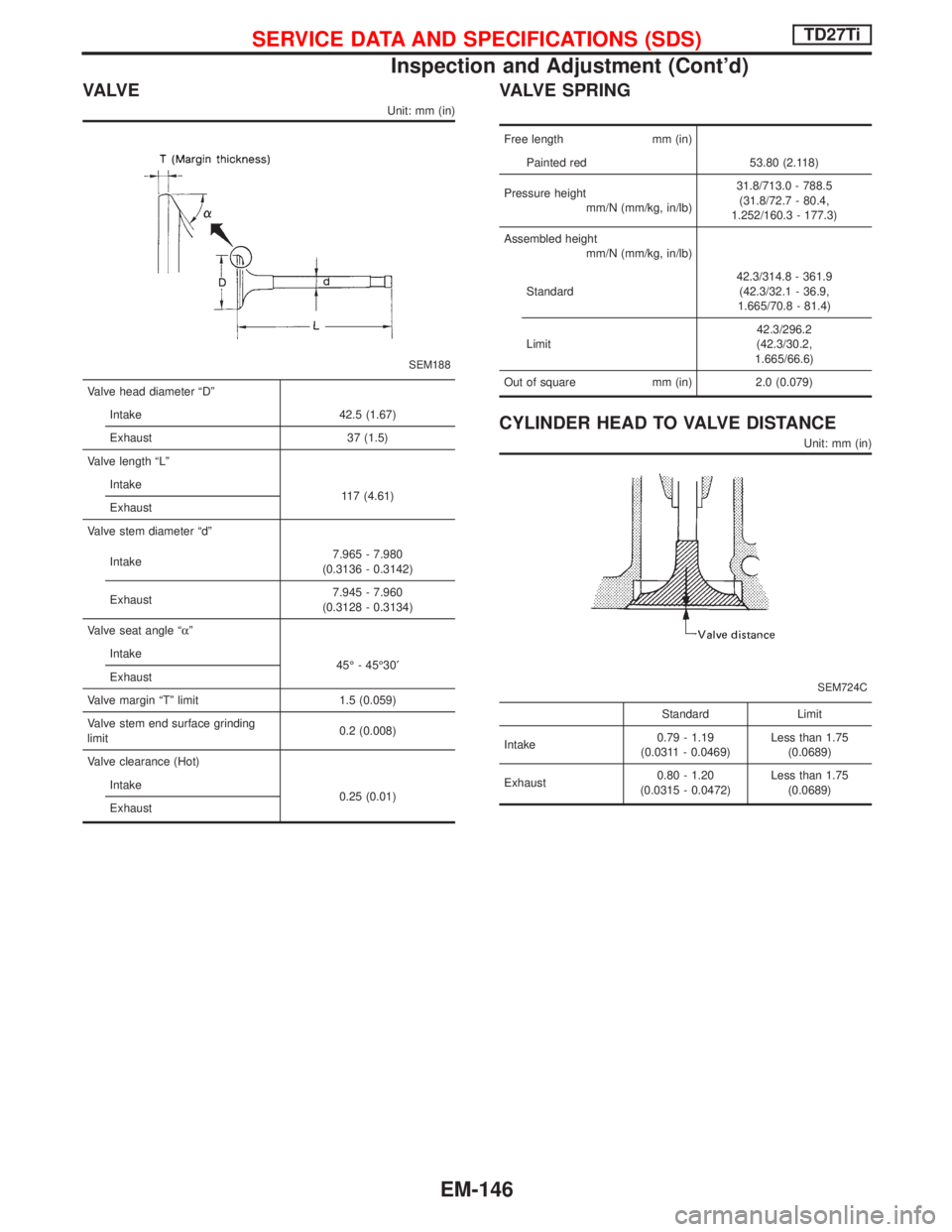

VA LV E

Unit: mm (in)

SEM188

Valve head diameter ªDº

Intake 42.5 (1.67)

Exhaust 37 (1.5)

Valve length ªLº

Intake

117 (4.61)

Exhaust

Valve stem diameter ªdº

Intake7.965 - 7.980

(0.3136 - 0.3142)

Exhaust7.945 - 7.960

(0.3128 - 0.3134)

Valve seat angle ªaº

Intake

45É - 45É30¢

Exhaust

Valve margin ªTº limit 1.5 (0.059)

Valve stem end surface grinding

limit0.2 (0.008)

Valve clearance (Hot)

Intake

0.25 (0.01)

Exhaust

VALVE SPRING

Free length mm (in)

Painted red 53.80 (2.118)

Pressure height

mm/N (mm/kg, in/lb)31.8/713.0 - 788.5

(31.8/72.7 - 80.4,

1.252/160.3 - 177.3)

Assembled height

mm/N (mm/kg, in/lb)

Standard42.3/314.8 - 361.9

(42.3/32.1 - 36.9,

1.665/70.8 - 81.4)

Limit42.3/296.2

(42.3/30.2,

1.665/66.6)

Out of square mm (in) 2.0 (0.079)

CYLINDER HEAD TO VALVE DISTANCE

Unit: mm (in)

SEM724C

Standard Limit

Intake0.79 - 1.19

(0.0311 - 0.0469)Less than 1.75

(0.0689)

Exhaust0.80 - 1.20

(0.0315 - 0.0472)Less than 1.75

(0.0689)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-146

Page 1255 of 1767

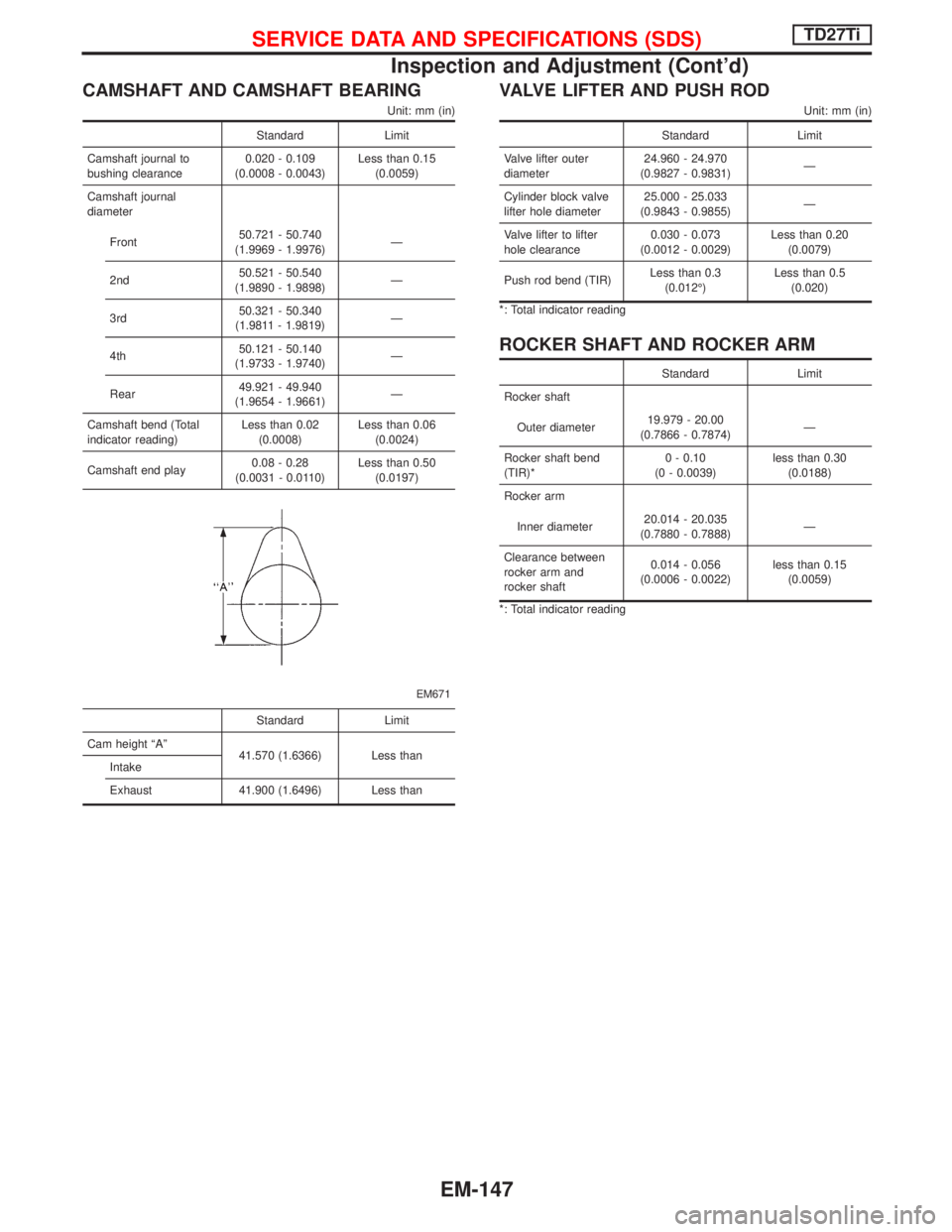

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

Standard Limit

Camshaft journal to

bushing clearance0.020 - 0.109

(0.0008 - 0.0043)Less than 0.15

(0.0059)

Camshaft journal

diameter

Front50.721 - 50.740

(1.9969 - 1.9976)Ð

2nd50.521 - 50.540

(1.9890 - 1.9898)Ð

3rd50.321 - 50.340

(1.9811 - 1.9819)Ð

4th50.121 - 50.140

(1.9733 - 1.9740)Ð

Rear49.921 - 49.940

(1.9654 - 1.9661)Ð

Camshaft bend (Total

indicator reading)Less than 0.02

(0.0008)Less than 0.06

(0.0024)

Camshaft end play0.08 - 0.28

(0.0031 - 0.0110)Less than 0.50

(0.0197)

EM671

Standard Limit

Cam height ªAº

41.570 (1.6366) Less than

Intake

Exhaust 41.900 (1.6496) Less than

VALVE LIFTER AND PUSH ROD

Unit: mm (in)

Standard Limit

Valve lifter outer

diameter24.960 - 24.970

(0.9827 - 0.9831)Ð

Cylinder block valve

lifter hole diameter25.000 - 25.033

(0.9843 - 0.9855)Ð

Valve lifter to lifter

hole clearance0.030 - 0.073

(0.0012 - 0.0029)Less than 0.20

(0.0079)

Push rod bend (TIR)Less than 0.3

(0.012É)Less than 0.5

(0.020)

*: Total indicator reading

ROCKER SHAFT AND ROCKER ARM

Standard Limit

Rocker shaft

Outer diameter19.979 - 20.00

(0.7866 - 0.7874)Ð

Rocker shaft bend

(TIR)*0 - 0.10

(0 - 0.0039)less than 0.30

(0.0188)

Rocker arm

Inner diameter20.014 - 20.035

(0.7880 - 0.7888)Ð

Clearance between

rocker arm and

rocker shaft0.014 - 0.056

(0.0006 - 0.0022)less than 0.15

(0.0059)

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-147

Page 1258 of 1767

AVAILABLE THRUST WASHER

Unit: mm (in)

Thrust washer thickness

Standard 2.275 - 2.325 (0.0896 - 0.0915)

Oversize

0.20 (0.0079) 2.475 - 2.525 (0.0974 - 0.0994)

0.40 (0.0157) 2.675 - 2.725 (0.1053 - 0.1073)

MISCELLANEOUS COMPONENTS

Unit: mm (in)

Gear train

Backlash of each gear

Standard 0.07 - 0.11 (0.0028 - 0.0043)

Limit 0.20 (0.0079)

Flywheel

Runout (Total indicator

reading)Less than 0.15 (0.0059)

Front plate

Warpage limit 0.2 (0.008)

Cylinder head

Head surface distorsion

Standard Less than 0.07 (0.0028)

Limit 0.2 (0.008)

Minimum height 89.7 (3.532)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-150

Page 1266 of 1767

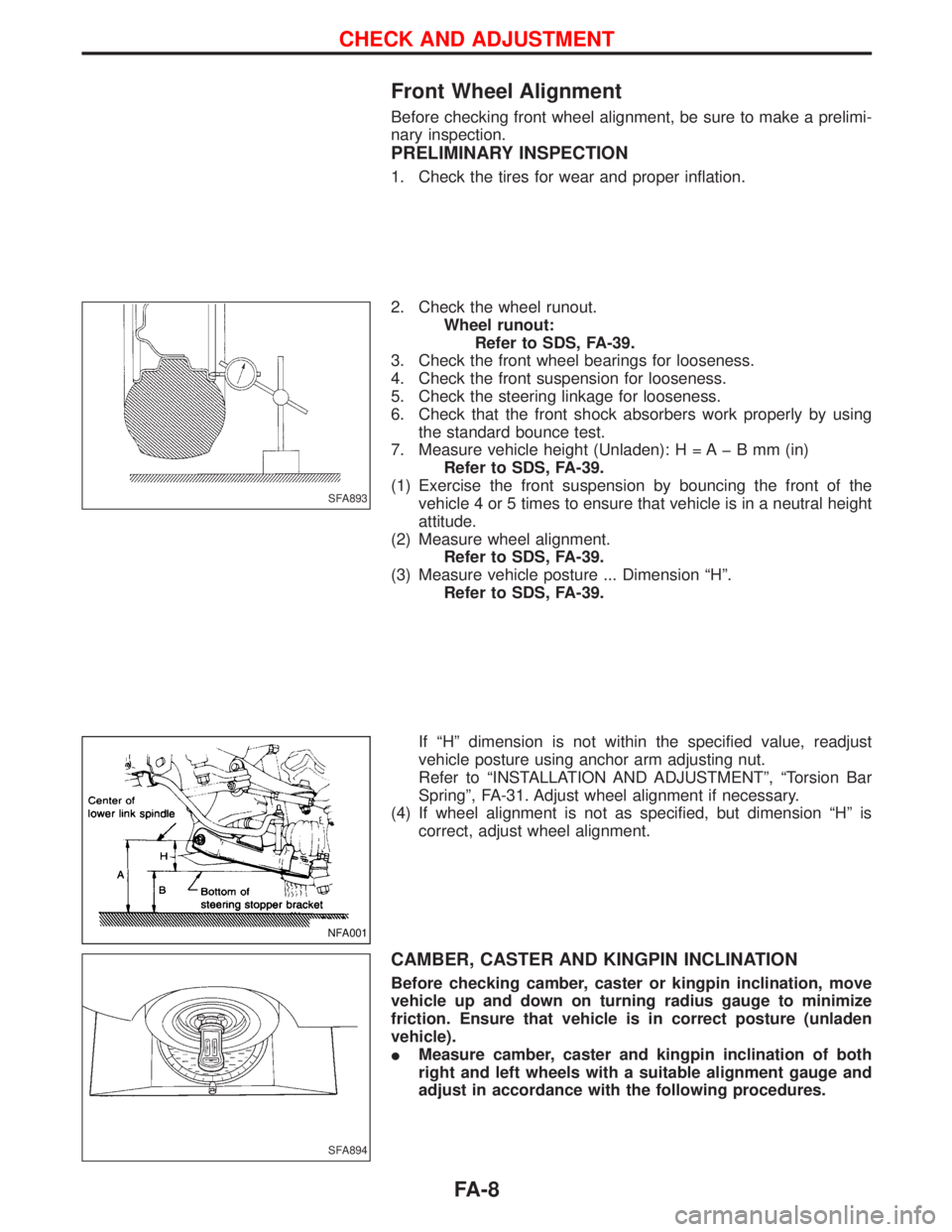

Front Wheel Alignment

Before checking front wheel alignment, be sure to make a prelimi-

nary inspection.

PRELIMINARY INSPECTION

1. Check the tires for wear and proper inflation.

2. Check the wheel runout.

Wheel runout:

Refer to SDS, FA-39.

3. Check the front wheel bearings for looseness.

4. Check the front suspension for looseness.

5. Check the steering linkage for looseness.

6. Check that the front shock absorbers work properly by using

the standard bounce test.

7. Measure vehicle height (Unladen): H = A þ B mm (in)

Refer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the

vehicle 4 or 5 times to ensure that vehicle is in a neutral height

attitude.

(2) Measure wheel alignment.

Refer to SDS, FA-39.

(3) Measure vehicle posture ... Dimension ªHº.

Refer to SDS, FA-39.

If ªHº dimension is not within the specified value, readjust

vehicle posture using anchor arm adjusting nut.

Refer to ªINSTALLATION AND ADJUSTMENTº, ªTorsion Bar

Springº, FA-31. Adjust wheel alignment if necessary.

(4) If wheel alignment is not as specified, but dimension ªHº is

correct, adjust wheel alignment.

CAMBER, CASTER AND KINGPIN INCLINATION

Before checking camber, caster or kingpin inclination, move

vehicle up and down on turning radius gauge to minimize

friction. Ensure that vehicle is in correct posture (unladen

vehicle).

IMeasure camber, caster and kingpin inclination of both

right and left wheels with a suitable alignment gauge and

adjust in accordance with the following procedures.

SFA893

NFA001

SFA894

CHECK AND ADJUSTMENT

FA-8