time control NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 16 of 1767

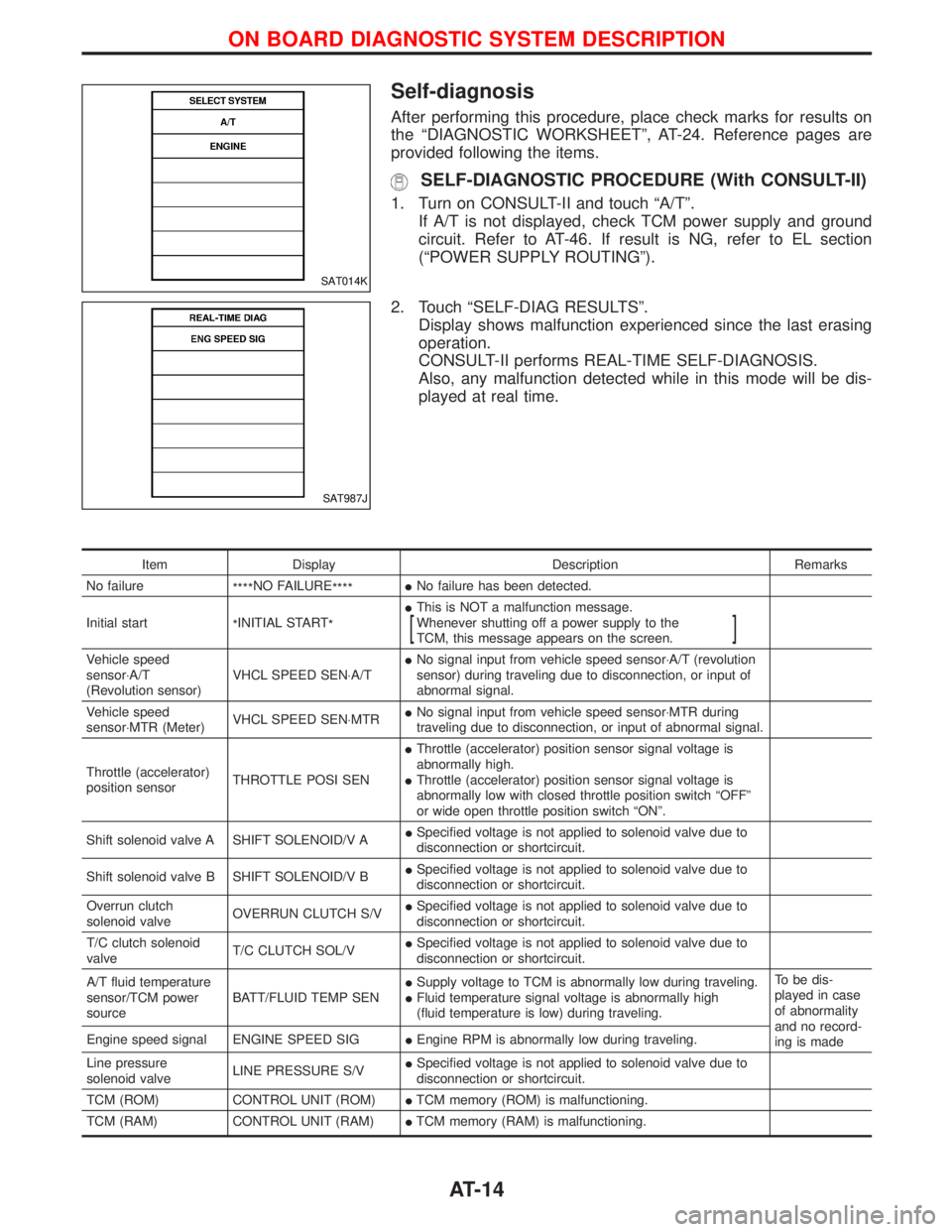

Self-diagnosis

After performing this procedure, place check marks for results on

the ªDIAGNOSTIC WORKSHEETº, AT-24. Reference pages are

provided following the items.

SELF-DIAGNOSTIC PROCEDURE (With CONSULT-II)

1. Turn on CONSULT-II and touch ªA/Tº.

If A/T is not displayed, check TCM power supply and ground

circuit. Refer to AT-46. If result is NG, refer to EL section

(ªPOWER SUPPLY ROUTINGº).

2. Touch ªSELF-DIAG RESULTSº.

Display shows malfunction experienced since the last erasing

operation.

CONSULT-II performs REAL-TIME SELF-DIAGNOSIS.

Also, any malfunction detected while in this mode will be dis-

played at real time.

Item Display Description Remarks

No failure

****NO FAILURE

****INo failure has been detected.

Initial start

*INITIAL START

*IThis is NOT a malfunction message.

Whenever shutting off a power supply to the

TCM, this message appears on the screen.

[]

Vehicle speed

sensor×A/T

(Revolution sensor)VHCL SPEED SEN×A/TINo signal input from vehicle speed sensor×A/T (revolution

sensor) during traveling due to disconnection, or input of

abnormal signal.

Vehicle speed

sensor×MTR (Meter)VHCL SPEED SEN×MTRINo signal input from vehicle speed sensor×MTR during

traveling due to disconnection, or input of abnormal signal.

Throttle (accelerator)

position sensorTHROTTLE POSI SENIThrottle (accelerator) position sensor signal voltage is

abnormally high.

IThrottle (accelerator) position sensor signal voltage is

abnormally low with closed throttle position switch ªOFFº

or wide open throttle position switch ªONº.

Shift solenoid valve A SHIFT SOLENOID/V AISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

Shift solenoid valve B SHIFT SOLENOID/V BISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

Overrun clutch

solenoid valveOVERRUN CLUTCH S/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

T/C clutch solenoid

valveT/C CLUTCH SOL/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

A/T fluid temperature

sensor/TCM power

sourceBATT/FLUID TEMP SENISupply voltage to TCM is abnormally low during traveling.

IFluid temperature signal voltage is abnormally high

(fluid temperature is low) during traveling.To be dis-

played in case

of abnormality

and no record-

ing is made Engine speed signal ENGINE SPEED SIGIEngine RPM is abnormally low during traveling.

Line pressure

solenoid valveLINE PRESSURE S/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

TCM (ROM) CONTROL UNIT (ROM)ITCM memory (ROM) is malfunctioning.

TCM (RAM) CONTROL UNIT (RAM)ITCM memory (RAM) is malfunctioning.

SAT014K

SAT987J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-14

Page 20 of 1767

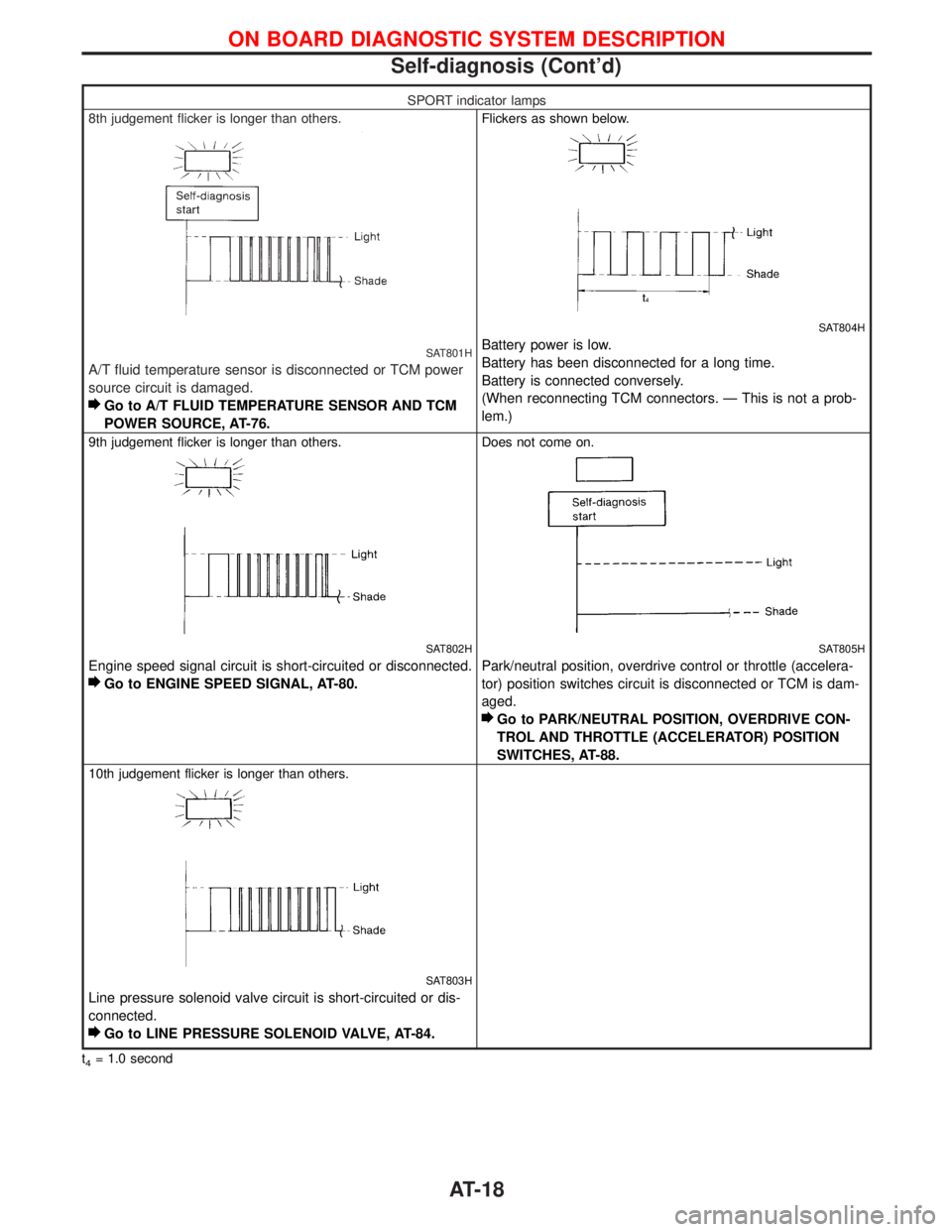

SPORT indicator lamps

8th judgement flicker is longer than others.

SAT801H

A/T fluid temperature sensor is disconnected or TCM power

source circuit is damaged.

Go to A/T FLUID TEMPERATURE SENSOR AND TCM

POWER SOURCE, AT-76.

Flickers as shown below.

SAT804H

Battery power is low.

Battery has been disconnected for a long time.

Battery is connected conversely.

(When reconnecting TCM connectors. Ð This is not a prob-

lem.)

9th judgement flicker is longer than others.

SAT802H

Engine speed signal circuit is short-circuited or disconnected.

Go to ENGINE SPEED SIGNAL, AT-80.

Does not come on.

SAT805H

Park/neutral position, overdrive control or throttle (accelera-

tor) position switches circuit is disconnected or TCM is dam-

aged.

Go to PARK/NEUTRAL POSITION, OVERDRIVE CON-

TROL AND THROTTLE (ACCELERATOR) POSITION

SWITCHES, AT-88.

10th judgement flicker is longer than others.

SAT803H

Line pressure solenoid valve circuit is short-circuited or dis-

connected.

Go to LINE PRESSURE SOLENOID VALVE, AT-84.

t4= 1.0 second

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Self-diagnosis (Cont'd)

AT-18

Page 22 of 1767

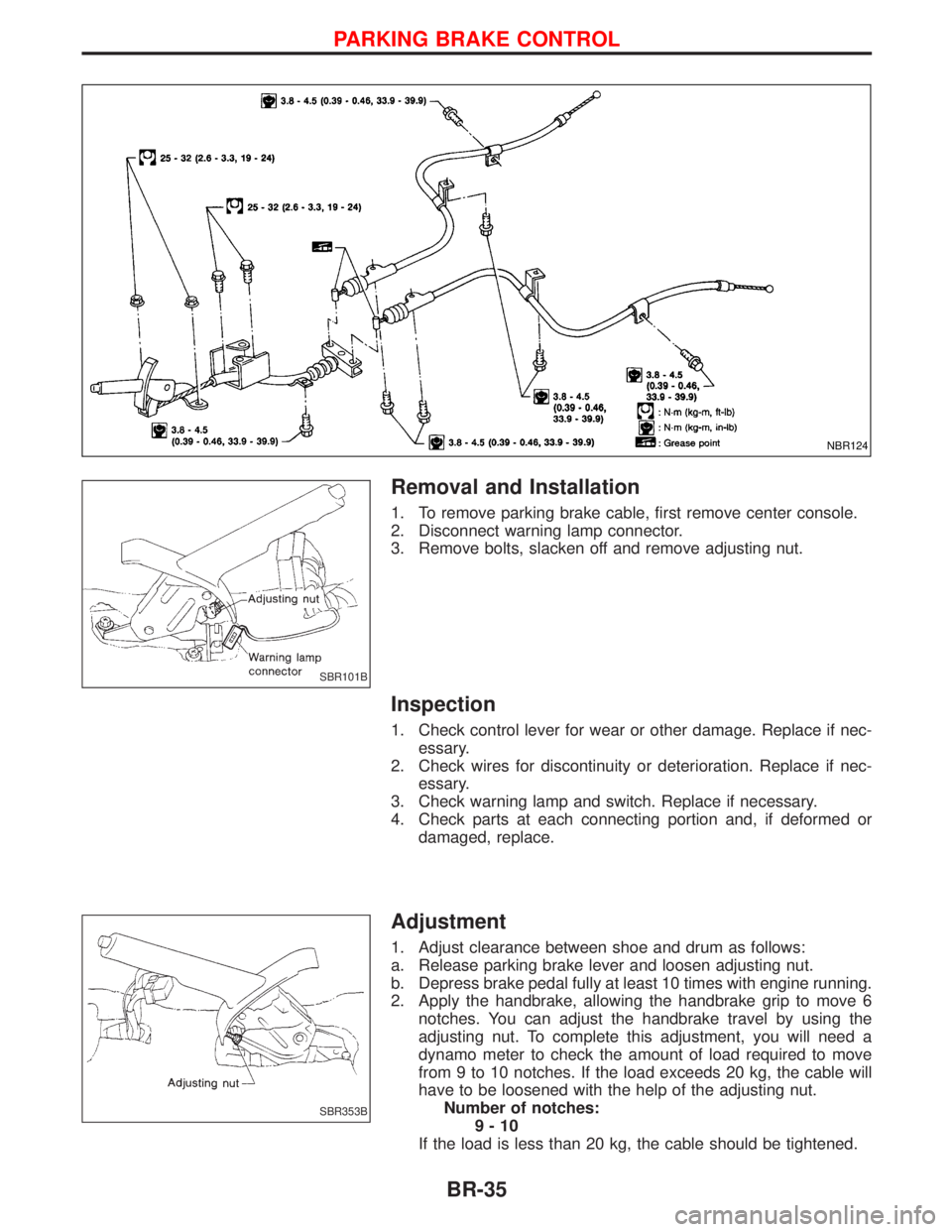

Diagnosis by CONSULT-II

NOTICE

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

IShift schedule indicated in Service Manual refers to the point where shifts start. Gear position displayed

on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is displayed

upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-14.

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

Vehicle speed sensor 1

(A/T)

(Revolution sensor)VHCL/S SE×A/T

[km/h] or [mph]

XÐIVehicle speed computed from signal

of revolution sensor is displayed.When racing engine in ªNº or ªPº posi-

tion with vehicle stationary, CON-

SULT-II data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter)VHCL/S SE×MTR

[km/h] or [mph]

XÐIVehicle speed computed from signal

of vehicle speed sensor is dis-

played.Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0 km/h (0

MPH) when vehicle is stationary.

Throttle (accelerator)

position sensorTHRTL POS SEN

[V]XÐIThrottle (accelerator) position sen-

sor signal voltage is displayed.

A/T fluid temperature

sensorFLUID TEMP SE

[V]

XÐIA/T fluid temperature sensor signal

voltage is displayed.

ISignal voltage lowers as fluid tem-

perature rises.

Battery voltage BATTERY VOLT

[V]XÐISource voltage of TCM is displayed.

Engine speed ENGINE SPEED

[rpm]

XXIEngine speed, computed from

engine speed signal, is displayed.Engine speed display may not be

accurate under approx. 800 rpm. It

may not indicate 0 rpm even when

engine is not running.

Overdrive control switch OVERDRIVE SW

[ON/OFF]XÐION/OFF state computed from signal

of overdrive control SW is displayed.

P/N position switch P/N POSI SW

[ON/OFF]XÐION/OFF state computed from signal

of P/N position SW is displayed.

R position switch R POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of R position SW is displayed.

D position switch D POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of D position SW is displayed.

2 position switch 2 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 2 position SW, is displayed.

1 position switch 1 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 1 position SW, is displayed.

ASCD-cruise signal ASCD×CRUISE

[ON/OFF]

XÐIStatus of ASCD cruise signal is dis-

played.

ON ... Cruising state

OFF ... Normal running stateIThis is displayed even when no

ASCD is mounted.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-20

Page 237 of 1767

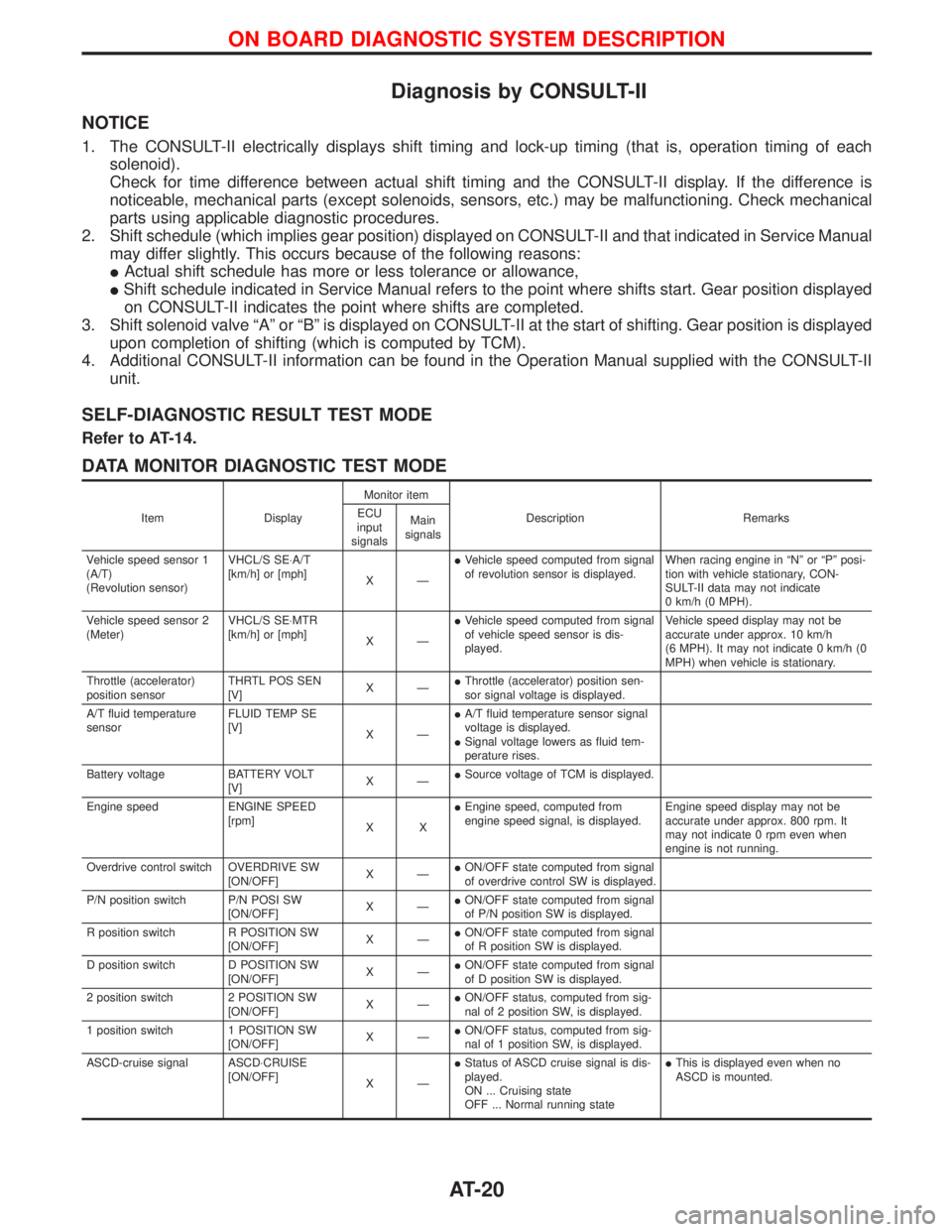

Removal and Installation

1. To remove parking brake cable, first remove center console.

2. Disconnect warning lamp connector.

3. Remove bolts, slacken off and remove adjusting nut.

Inspection

1. Check control lever for wear or other damage. Replace if nec-

essary.

2. Check wires for discontinuity or deterioration. Replace if nec-

essary.

3. Check warning lamp and switch. Replace if necessary.

4. Check parts at each connecting portion and, if deformed or

damaged, replace.

Adjustment

1. Adjust clearance between shoe and drum as follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine running.

2. Apply the handbrake, allowing the handbrake grip to move 6

notches. You can adjust the handbrake travel by using the

adjusting nut. To complete this adjustment, you will need a

dynamo meter to check the amount of load required to move

from 9 to 10 notches. If the load exceeds 20 kg, the cable will

have to be loosened with the help of the adjusting nut.

Number of notches:

9-10

If the load is less than 20 kg, the cable should be tightened.

NBR124

SBR101B

SBR353B

PARKING BRAKE CONTROL

BR-35

Page 239 of 1767

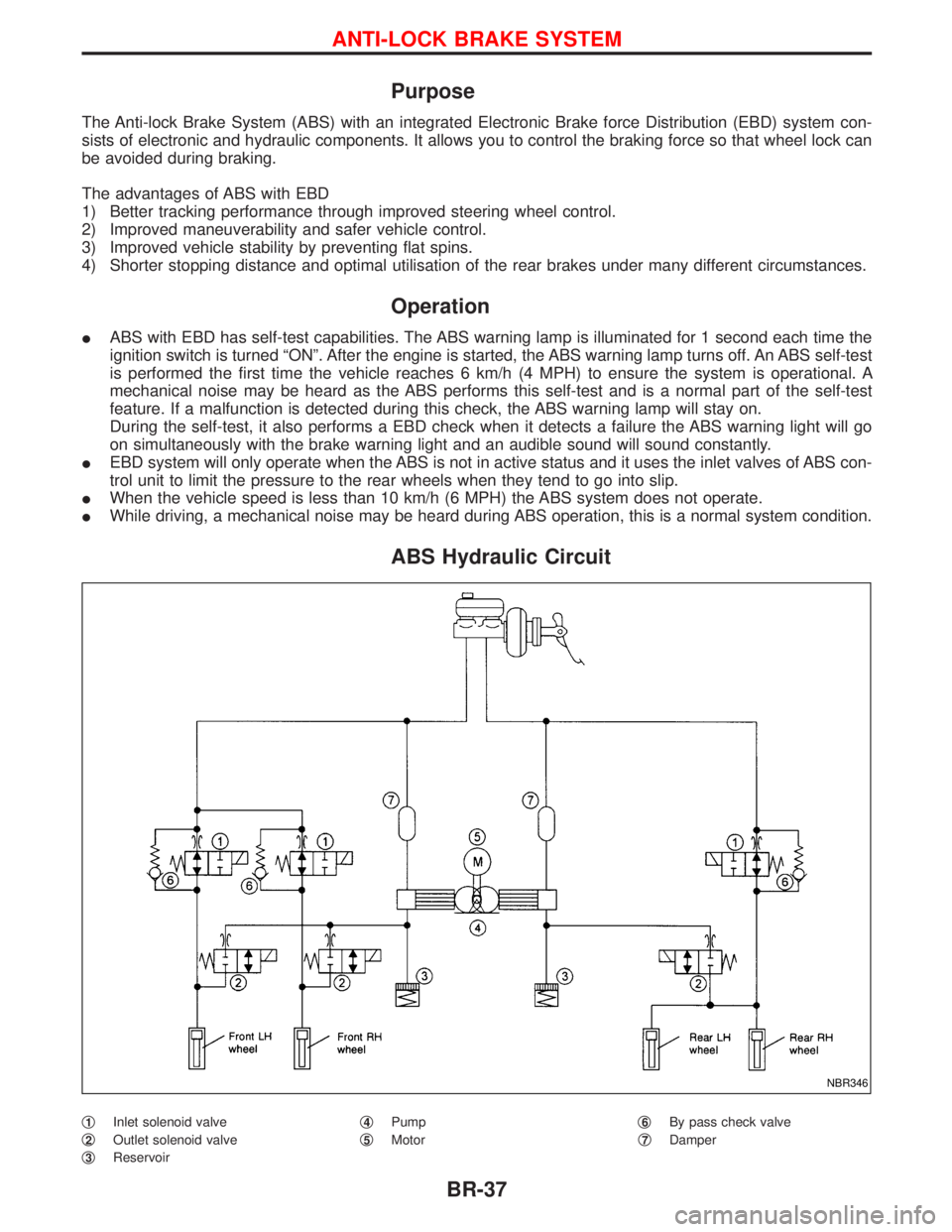

Purpose

The Anti-lock Brake System (ABS) with an integrated Electronic Brake force Distribution (EBD) system con-

sists of electronic and hydraulic components. It allows you to control the braking force so that wheel lock can

be avoided during braking.

The advantages of ABS with EBD

1) Better tracking performance through improved steering wheel control.

2) Improved maneuverability and safer vehicle control.

3) Improved vehicle stability by preventing flat spins.

4) Shorter stopping distance and optimal utilisation of the rear brakes under many different circumstances.

Operation

IABS with EBD has self-test capabilities. The ABS warning lamp is illuminated for 1 second each time the

ignition switch is turned ªONº. After the engine is started, the ABS warning lamp turns off. An ABS self-test

is performed the first time the vehicle reaches 6 km/h (4 MPH) to ensure the system is operational. A

mechanical noise may be heard as the ABS performs this self-test and is a normal part of the self-test

feature. If a malfunction is detected during this check, the ABS warning lamp will stay on.

During the self-test, it also performs a EBD check when it detects a failure the ABS warning light will go

on simultaneously with the brake warning light and an audible sound will sound constantly.

IEBD system will only operate when the ABS is not in active status and it uses the inlet valves of ABS con-

trol unit to limit the pressure to the rear wheels when they tend to go into slip.

IWhen the vehicle speed is less than 10 km/h (6 MPH) the ABS system does not operate.

IWhile driving, a mechanical noise may be heard during ABS operation, this is a normal system condition.

ABS Hydraulic Circuit

q1Inlet solenoid valve

q

2Outlet solenoid valve

q

3Reservoirq

4Pump

q

5Motorq

6By pass check valve

q

7Damper

NBR346

ANTI-LOCK BRAKE SYSTEM

BR-37

Page 261 of 1767

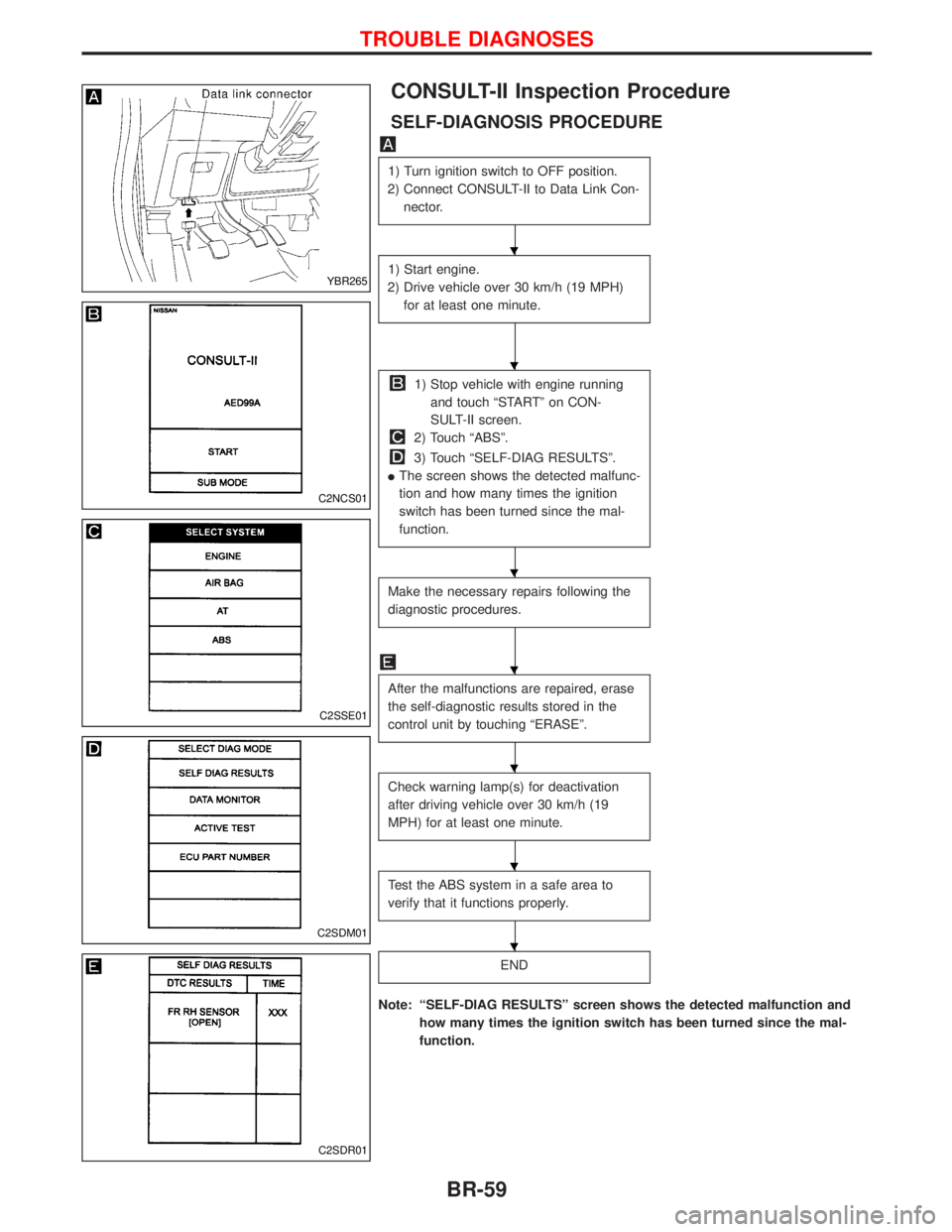

CONSULT-II Inspection Procedure

SELF-DIAGNOSIS PROCEDURE

1) Turn ignition switch to OFF position.

2) Connect CONSULT-II to Data Link Con-

nector.

1) Start engine.

2) Drive vehicle over 30 km/h (19 MPH)

for at least one minute.

1) Stop vehicle with engine running

and touch ªSTARTº on CON-

SULT-II screen.

2) Touch ªABSº.

3) Touch ªSELF-DIAG RESULTSº.

IThe screen shows the detected malfunc-

tion and how many times the ignition

switch has been turned since the mal-

function.

Make the necessary repairs following the

diagnostic procedures.

After the malfunctions are repaired, erase

the self-diagnostic results stored in the

control unit by touching ªERASEº.

Check warning lamp(s) for deactivation

after driving vehicle over 30 km/h (19

MPH) for at least one minute.

Test the ABS system in a safe area to

verify that it functions properly.

END

Note: ªSELF-DIAG RESULTSº screen shows the detected malfunction and

how many times the ignition switch has been turned since the mal-

function.

YBR265

C2NCS01

C2SSE01

C2SDM01

C2SDR01

H

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-59

Page 383 of 1767

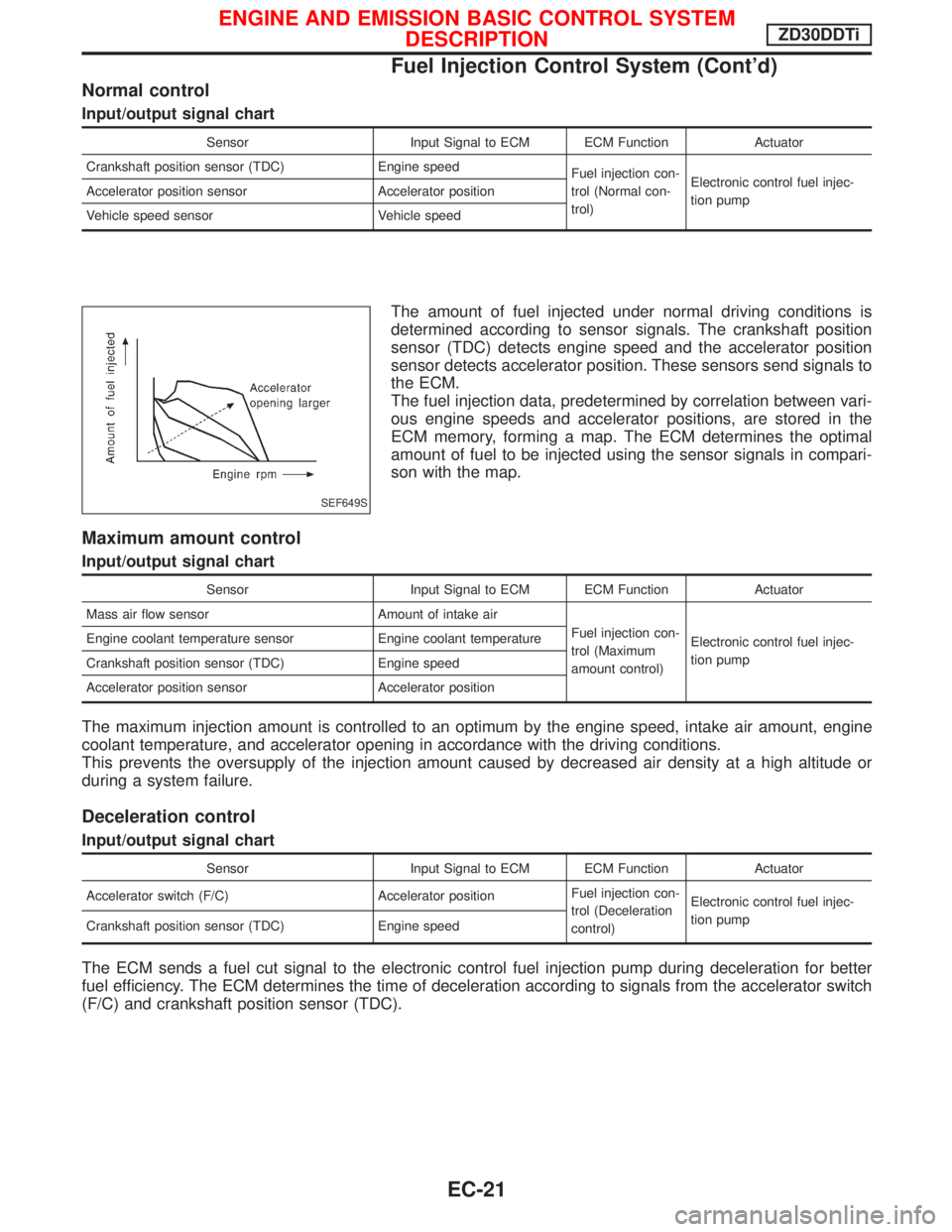

Normal control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (TDC) Engine speed

Fuel injection con-

trol (Normal con-

trol)Electronic control fuel injec-

tion pump Accelerator position sensor Accelerator position

Vehicle speed sensor Vehicle speed

The amount of fuel injected under normal driving conditions is

determined according to sensor signals. The crankshaft position

sensor (TDC) detects engine speed and the accelerator position

sensor detects accelerator position. These sensors send signals to

the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds and accelerator positions, are stored in the

ECM memory, forming a map. The ECM determines the optimal

amount of fuel to be injected using the sensor signals in compari-

son with the map.

Maximum amount control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Mass air flow sensor Amount of intake air

Fuel injection con-

trol (Maximum

amount control)Electronic control fuel injec-

tion pump Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

Accelerator position sensor Accelerator position

The maximum injection amount is controlled to an optimum by the engine speed, intake air amount, engine

coolant temperature, and accelerator opening in accordance with the driving conditions.

This prevents the oversupply of the injection amount caused by decreased air density at a high altitude or

during a system failure.

Deceleration control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Accelerator switch (F/C) Accelerator positionFuel injection con-

trol (Deceleration

control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC) Engine speed

The ECM sends a fuel cut signal to the electronic control fuel injection pump during deceleration for better

fuel efficiency. The ECM determines the time of deceleration according to signals from the accelerator switch

(F/C) and crankshaft position sensor (TDC).

SEF649S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

Fuel Injection Control System (Cont'd)

EC-21

Page 384 of 1767

Fuel Injection Timing Control System

DESCRIPTION

The target fuel injection timing in accordance with the engine speed and the fuel injection amount are recorded

as a map in the ECM beforehand. The ECM and the injection pump control unit exchange signals and per-

form feedback control for optimum injection timing in accordance with the map.

Air Conditioning Cut Control

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner cut

controlAir conditioner relay Accelerator position sensorAccelerator valve opening

angle

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System description

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This continues

until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel injec-

tion pump Park/Neutral position (PNP) switch Neutral position

Accelerator position switch or Accelerator

switch (F/C)Accelerator position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,700 rpm with no load (for example, in neutral and engine speed over 2,700

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº, EC-20.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-22

Page 391 of 1767

![NISSAN TERRANO 2002 Service Repair Manual c. Install the tightening bolt [Part No.: 81-20620-28, thread diam-

eter: M6, under head: 20 mm (0.79 in), pitch: 1.0 mm (0.039 in)]

to the idler gear tightening bolt hole, and tighten to the speci-

f NISSAN TERRANO 2002 Service Repair Manual c. Install the tightening bolt [Part No.: 81-20620-28, thread diam-

eter: M6, under head: 20 mm (0.79 in), pitch: 1.0 mm (0.039 in)]

to the idler gear tightening bolt hole, and tighten to the speci-

f](/img/5/57393/w960_57393-390.png)

c. Install the tightening bolt [Part No.: 81-20620-28, thread diam-

eter: M6, under head: 20 mm (0.79 in), pitch: 1.0 mm (0.039 in)]

to the idler gear tightening bolt hole, and tighten to the speci-

fied torque:

: 2.5 - 3.4 N×m (0.25 - 0.35 kg-m, 22 - 30 in-lb)

CAUTION:

ITo protect the idler gear from damage, do not use the sub-

stitute part for the tightening bolt.

IHereafter, do not turn the crankshaft to avoid hitting tight-

ening bolt head against the gear case.

IDo not remove the idler gear tightening bolt before instal-

lations of the timing chain and related parts are completed.

7. Make mating marks on the cam sprocket, fuel injection pump

sprocket, and timing chain with paint.

8. Make mating marks on the fuel injection pump gear and idler

gear with paint.

9. Remove the chain tensioner.

(1) Loosen the upper and lower installation bolts.

(2) While holding the chain tensioner by hand, remove the upper

installation bolt to release the spring tension.

(3) Remove the lower installation bolt first, and then the chain ten-

sioner.

ISince the chain tensioner does not have a mechanism to pre-

vent the plunger pop-out, watch out for the fall of the plunger

and spring. (Return prevention mechanism is available.)

10. Remove the timing chain slack guide.

11. Remove the cam sprocket and timing chain at the same time.

IMake mating marks on each sprocket and timing chain.

IHold the hexagon head of the camshaft on the exhaust mani-

fold side, and loosen the cam sprocket installation bolt.

CAUTION:

Do not loosen the installation bolt using a chain tension.

12. Remove the fuel injection pump sprocket and gear as an

assembly.

IFix the fuel injection pump gear with the pulley holder (SST),

and loosen the installation bolt for removal.

ITry not to move the pump shaft when removing.

IConnect the sprocket and gear with a dowel pin, and tighten

them together with the installation bolt.

JEF263Z

JEF264Z

JEF265Z

JEF266Z

JEF267Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-29

Page 393 of 1767

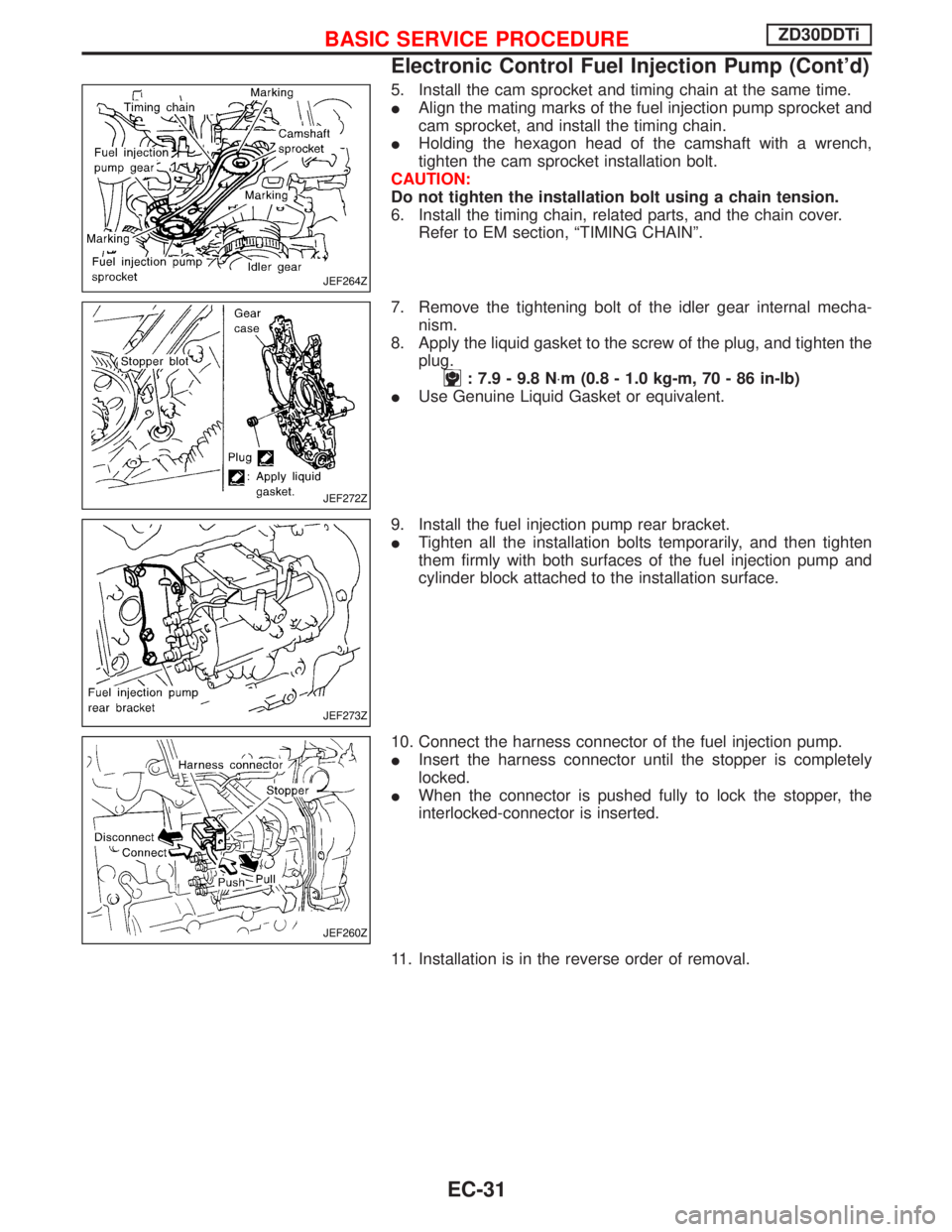

5. Install the cam sprocket and timing chain at the same time.

IAlign the mating marks of the fuel injection pump sprocket and

cam sprocket, and install the timing chain.

IHolding the hexagon head of the camshaft with a wrench,

tighten the cam sprocket installation bolt.

CAUTION:

Do not tighten the installation bolt using a chain tension.

6. Install the timing chain, related parts, and the chain cover.

Refer to EM section, ªTIMING CHAINº.

7. Remove the tightening bolt of the idler gear internal mecha-

nism.

8. Apply the liquid gasket to the screw of the plug, and tighten the

plug.

: 7.9 - 9.8 N×m (0.8 - 1.0 kg-m, 70 - 86 in-lb)

IUse Genuine Liquid Gasket or equivalent.

9. Install the fuel injection pump rear bracket.

ITighten all the installation bolts temporarily, and then tighten

them firmly with both surfaces of the fuel injection pump and

cylinder block attached to the installation surface.

10. Connect the harness connector of the fuel injection pump.

IInsert the harness connector until the stopper is completely

locked.

IWhen the connector is pushed fully to lock the stopper, the

interlocked-connector is inserted.

11. Installation is in the reverse order of removal.

JEF264Z

JEF272Z

JEF273Z

JEF260Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-31