sensor NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 120 of 1833

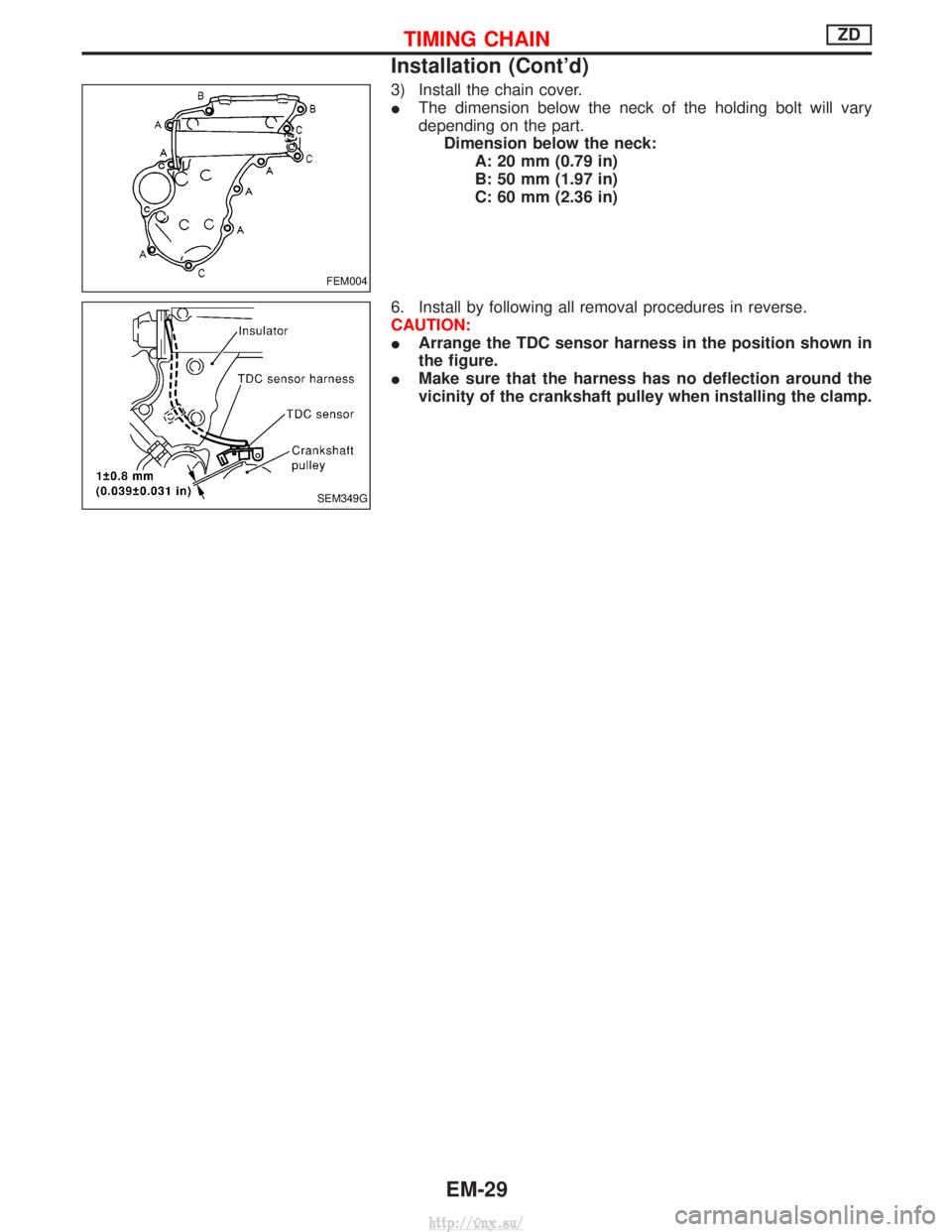

3) Install the chain cover.

IThe dimension below the neck of the holding bolt will vary

depending on the part.

Dimension below the neck: A: 20 mm (0.79 in)

B: 50 mm (1.97 in)

C: 60 mm (2.36 in)

6. Install by following all removal procedures in reverse.

CAUTION:

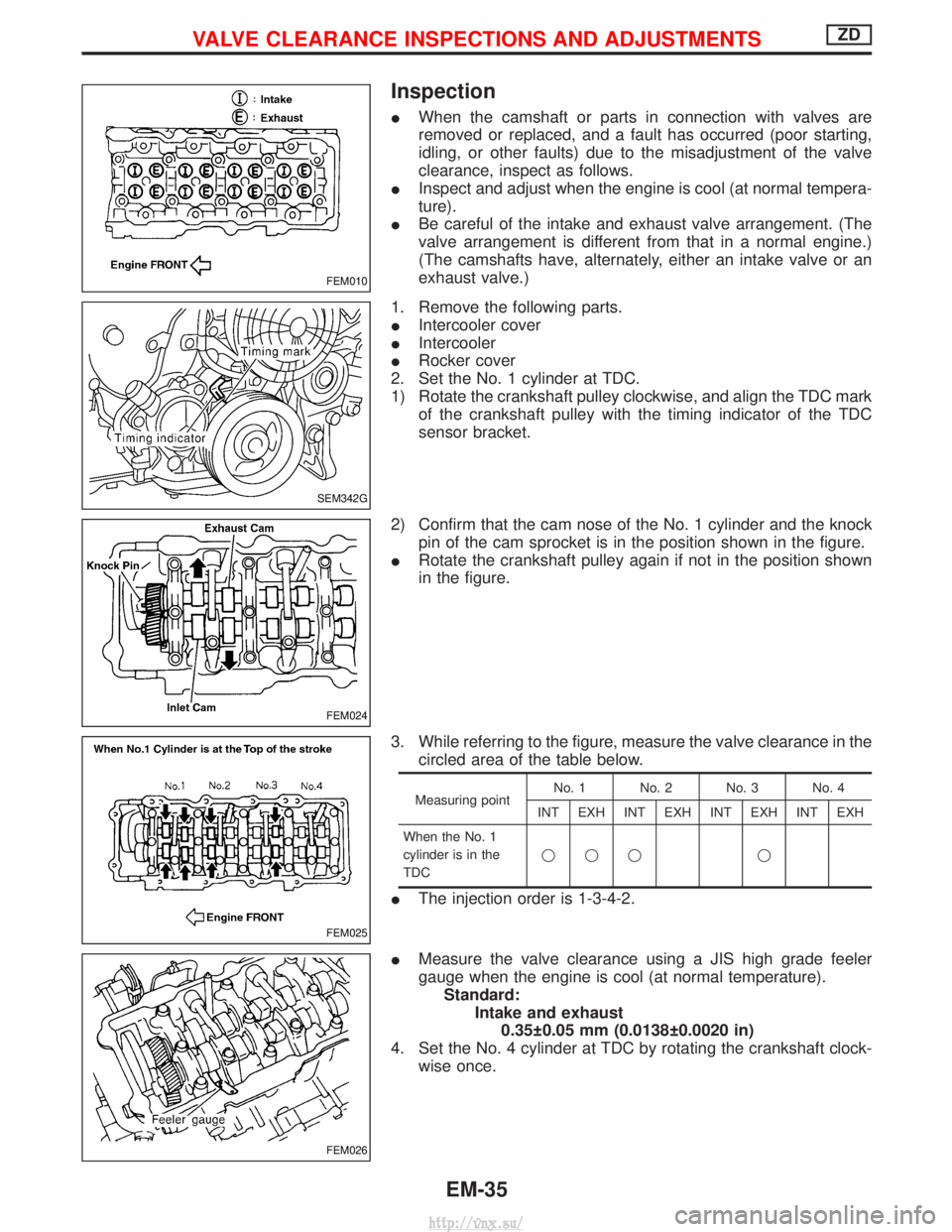

I Arrange the TDC sensor harness in the position shown in

the figure.

I Make sure that the harness has no deflection around the

vicinity of the crankshaft pulley when installing the clamp.

FEM004

SEM349G

TIMING CHAINZD

Installation (Cont'd)

EM-29

http://vnx.su/

Page 126 of 1833

Inspection

IWhen the camshaft or parts in connection with valves are

removed or replaced, and a fault has occurred (poor starting,

idling, or other faults) due to the misadjustment of the valve

clearance, inspect as follows.

I Inspect and adjust when the engine is cool (at normal tempera-

ture).

I Be careful of the intake and exhaust valve arrangement. (The

valve arrangement is different from that in a normal engine.)

(The camshafts have, alternately, either an intake valve or an

exhaust valve.)

1. Remove the following parts.

I Intercooler cover

I Intercooler

I Rocker cover

2. Set the No. 1 cylinder at TDC.

1) Rotate the crankshaft pulley clockwise, and align the TDC mark of the crankshaft pulley with the timing indicator of the TDC

sensor bracket.

2) Confirm that the cam nose of the No. 1 cylinder and the knock pin of the cam sprocket is in the position shown in the figure.

I Rotate the crankshaft pulley again if not in the position shown

in the figure.

3. While referring to the figure, measure the valve clearance in the circled area of the table below.

Measuring point No. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 1

cylinder is in the

TDC qqq q

I

The injection order is 1-3-4-2.

I Measure the valve clearance using a JIS high grade feeler

gauge when the engine is cool (at normal temperature).

Standard: Intake and exhaust0.35 0.05 mm (0.0138 0.0020 in)

4. Set the No. 4 cylinder at TDC by rotating the crankshaft clock- wise once.

FEM010

SEM342G

FEM024

FEM025

FEM026

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

EM-35

http://vnx.su/

Page 130 of 1833

Removal

1. Remove the engine assembly.Refer to ªENGINE REMOVALº, EM-63.

2. Place the engine on an engine stand (SST). Refer to ªCYLINDER BLOCKº, EM-67.

3. Remove the following.

I Auto tensioner bracket

I Air conditioner bracket

I Alternator bracket

I Oil tube

I Vacuum pump

I Rocker cover

I Oil pan (upper, lower)

I Injection tube

I Spill tube

I High pressure nozzle assembly

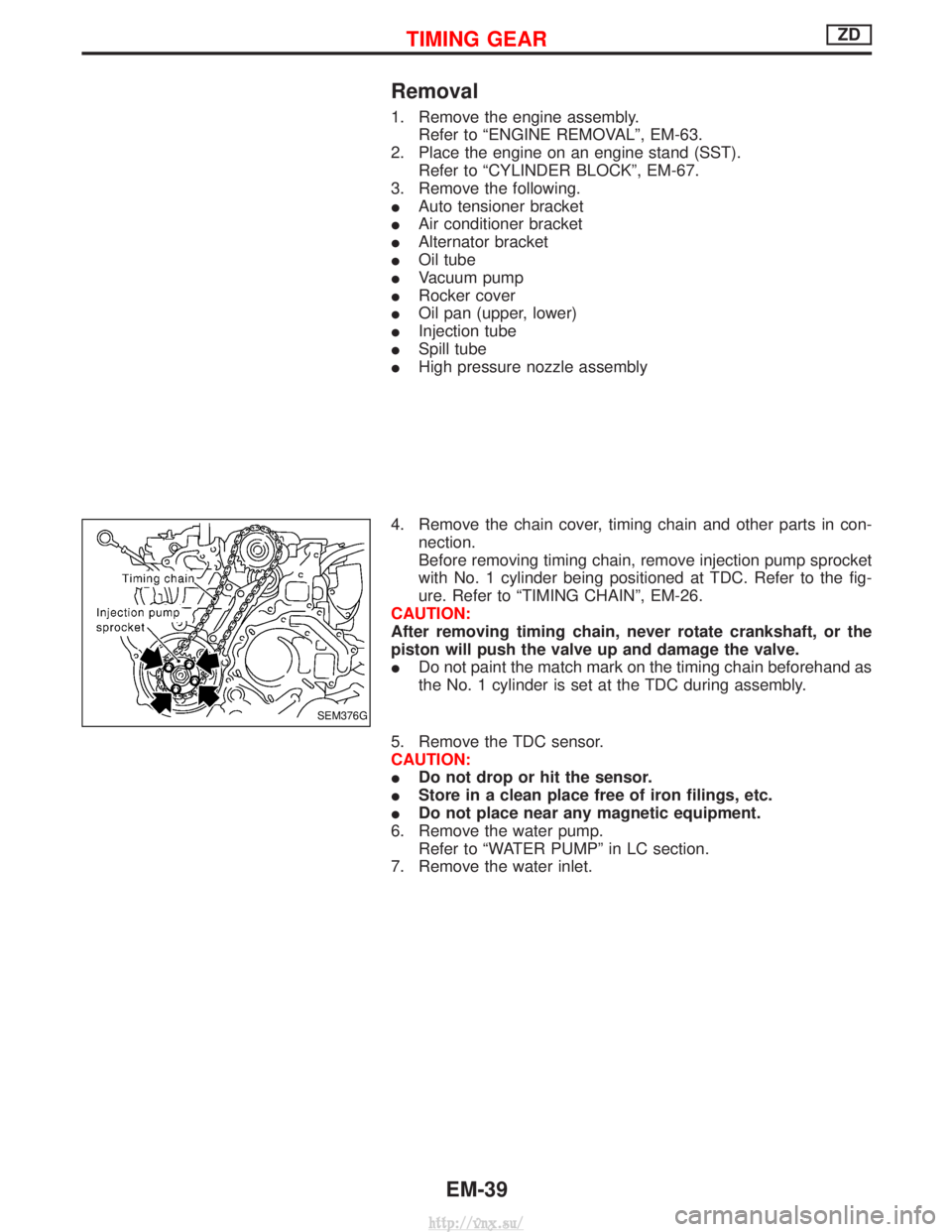

4. Remove the chain cover, timing chain and other parts in con- nection.

Before removing timing chain, remove injection pump sprocket

with No. 1 cylinder being positioned at TDC. Refer to the fig-

ure. Refer to ªTIMING CHAINº, EM-26.

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

I Do not paint the match mark on the timing chain beforehand as

the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

I Do not drop or hit the sensor.

I Store in a clean place free of iron filings, etc.

I Do not place near any magnetic equipment.

6. Remove the water pump. Refer to ªWATER PUMPº in LC section.

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-39

http://vnx.su/

Page 139 of 1833

CAUTION:

Apply the liquid gasket around the bolt holes shown by the

arrows in the figure.

4) Install the gear case.

ITap the area around the dowel pin with a plastic hammer if it

cannot be inserted easily.

CAUTION:

Do not pop out the O-rings.

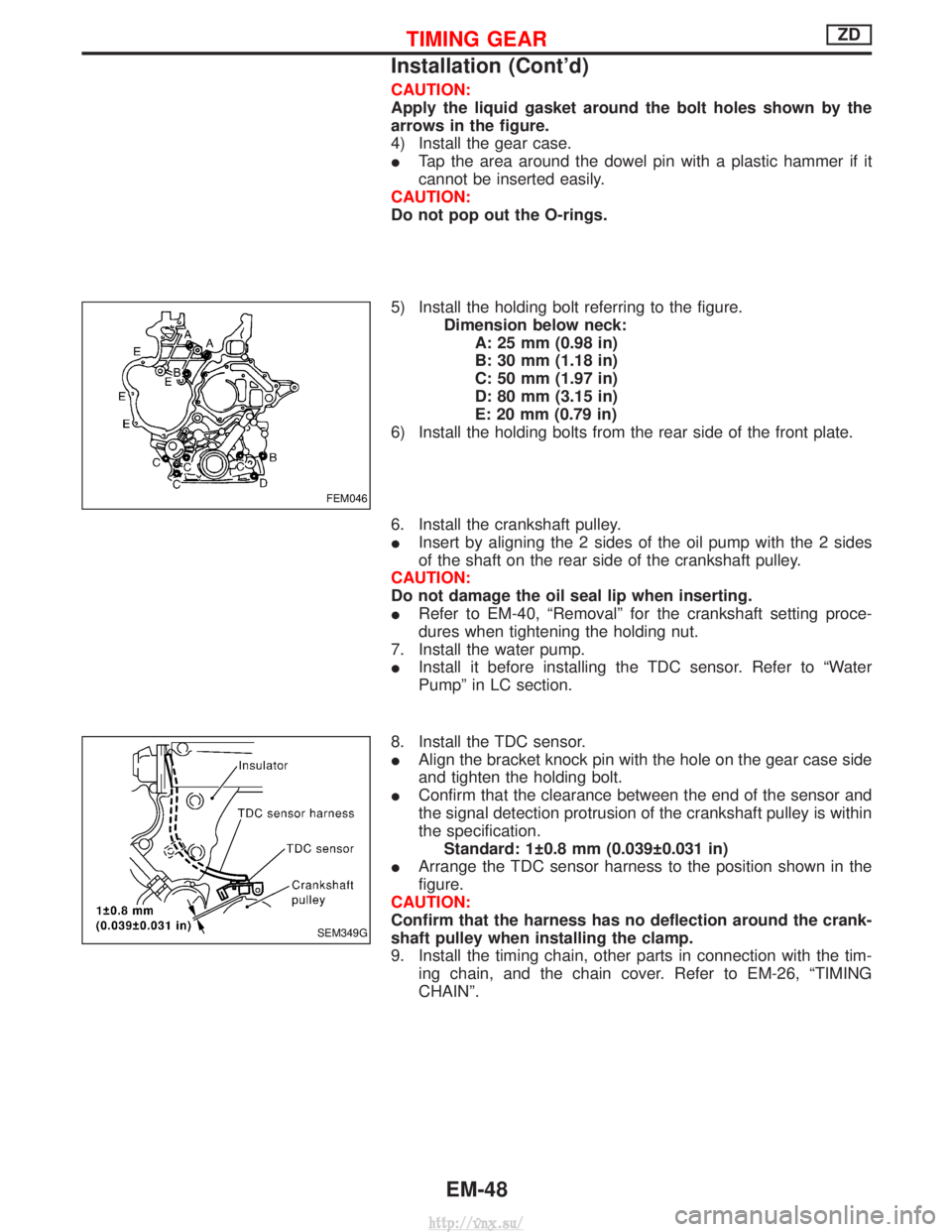

5) Install the holding bolt referring to the figure. Dimension below neck:A: 25 mm (0.98 in)

B: 30 mm (1.18 in)

C: 50 mm (1.97 in)

D: 80 mm (3.15 in)

E: 20 mm (0.79 in)

6) Install the holding bolts from the rear side of the front plate.

6. Install the crankshaft pulley.

I Insert by aligning the 2 sides of the oil pump with the 2 sides

of the shaft on the rear side of the crankshaft pulley.

CAUTION:

Do not damage the oil seal lip when inserting.

I Refer to EM-40, ªRemovalº for the crankshaft setting proce-

dures when tightening the holding nut.

7. Install the water pump.

I Install it before installing the TDC sensor. Refer to ªWater

Pumpº in LC section.

8. Install the TDC sensor.

I Align the bracket knock pin with the hole on the gear case side

and tighten the holding bolt.

I Confirm that the clearance between the end of the sensor and

the signal detection protrusion of the crankshaft pulley is within

the specification.

Standard: 1 0.8 mm (0.039 0.031 in)

I Arrange the TDC sensor harness to the position shown in the

figure.

CAUTION:

Confirm that the harness has no deflection around the crank-

shaft pulley when installing the clamp.

9. Install the timing chain, other parts in connection with the tim- ing chain, and the chain cover. Refer to EM-26, ªTIMING

CHAINº.

FEM046

SEM349G

TIMING GEARZD

Installation (Cont'd)

EM-48

http://vnx.su/

Page 191 of 1833

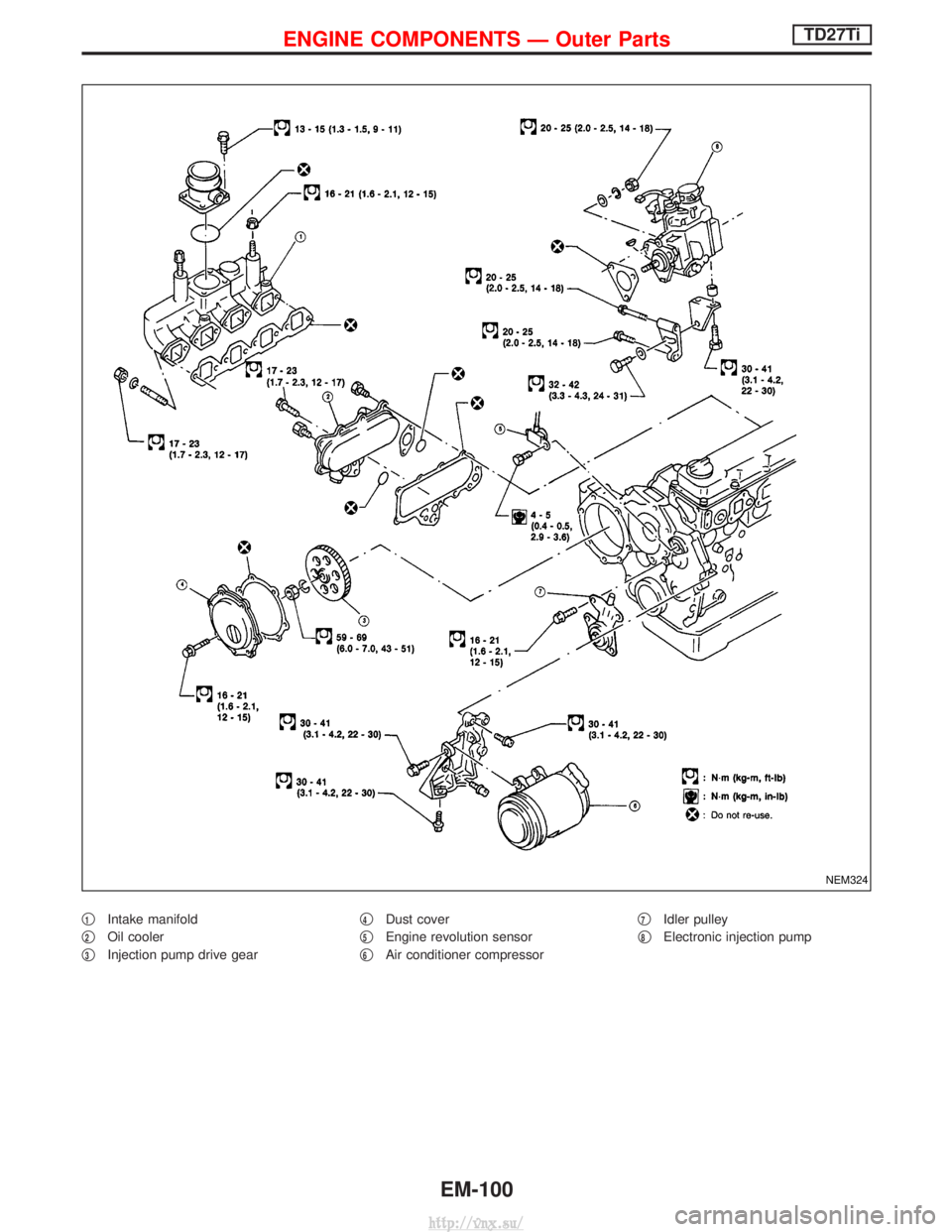

q1Intake manifold

q

2Oil cooler

q

3Injection pump drive gear q

4Dust cover

q

5Engine revolution sensor

q

6Air conditioner compressor q

7Idler pulley

q

8Electronic injection pump

NEM324

ENGINE COMPONENTS Ð Outer PartsTD27Ti

EM-100

http://vnx.su/

Page 252 of 1833

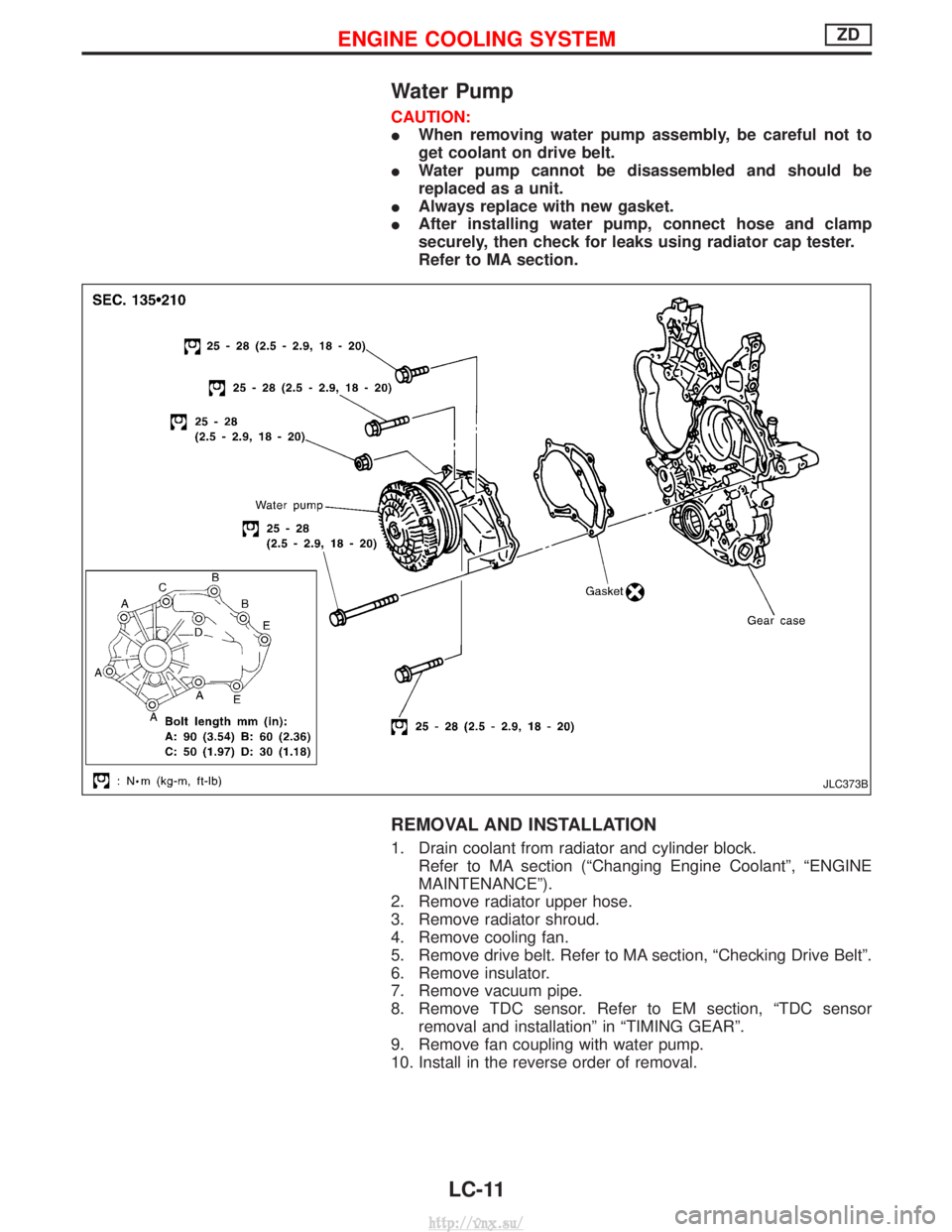

Water Pump

CAUTION:

IWhen removing water pump assembly, be careful not to

get coolant on drive belt.

I Water pump cannot be disassembled and should be

replaced as a unit.

I Always replace with new gasket.

I After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

Refer to MA section.

REMOVAL AND INSTALLATION

1. Drain coolant from radiator and cylinder block.

Refer to MA section (ªChanging Engine Coolantº, ªENGINE

MAINTENANCEº).

2. Remove radiator upper hose.

3. Remove radiator shroud.

4. Remove cooling fan.

5. Remove drive belt. Refer to MA section, ªChecking Drive Beltº.

6. Remove insulator.

7. Remove vacuum pipe.

8. Remove TDC sensor. Refer to EM section, ªTDC sensor removal and installationº in ªTIMING GEARº.

9. Remove fan coupling with water pump.

10. Install in the reverse order of removal.

JLC373B

ENGINE COOLING SYSTEMZD

LC-11

http://vnx.su/

Page 276 of 1833

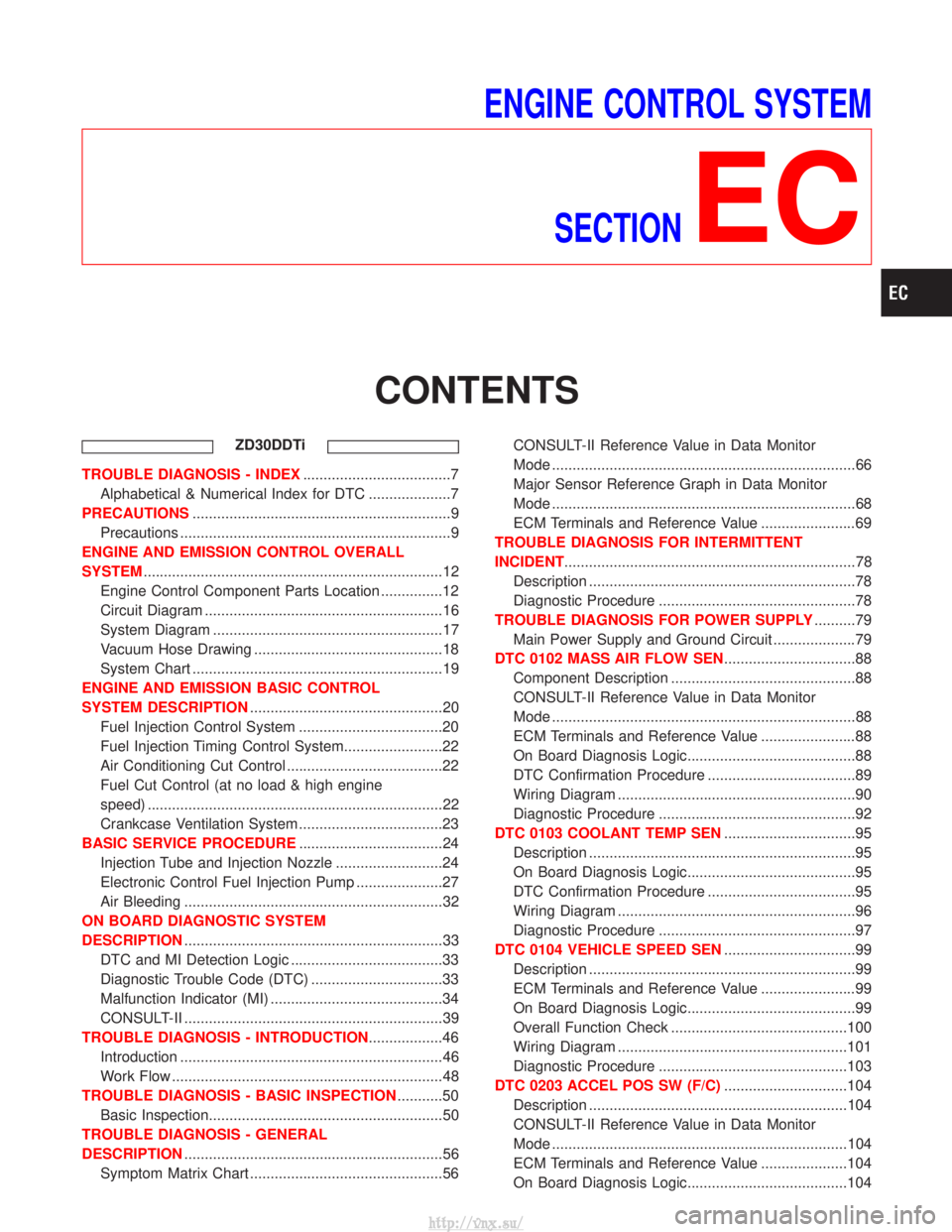

ENGINE CONTROL SYSTEMSECTION

EC

CONTENTS

ZD30DDTi

TROUBLE DIAGNOSIS - INDEX ....................................7

Alphabetical & Numerical Index for DTC ....................7

PRECAUTIONS ...............................................................9

Precautions ..................................................................9

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM ........................................................................\

.12

Engine Control Component Parts Location ...............12

Circuit Diagram ..........................................................16

System Diagram ........................................................17

Vacuum Hose Drawing ..............................................18

System Chart .............................................................19

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION ...............................................20

Fuel Injection Control System ...................................20

Fuel Injection Timing Control System........................22

Air Conditioning Cut Control ......................................22

Fuel Cut Control (at no load & high engine

speed) ........................................................................\

22

Crankcase Ventilation System ...................................23

BASIC SERVICE PROCEDURE ...................................24

Injection Tube and Injection Nozzle ..........................24

Electronic Control Fuel Injection Pump .....................27

Air Bleeding ...............................................................32

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION ...............................................................33

DTC and MI Detection Logic .....................................33

Diagnostic Trouble Code (DTC) ................................33

Malfunction Indicator (MI) ..........................................34

CONSULT-II ...............................................................39

TROUBLE DIAGNOSIS - INTRODUCTION ..................46

Introduction ................................................................46

Work Flow ..................................................................48

TROUBLE DIAGNOSIS - BASIC INSPECTION ...........50

Basic Inspection.........................................................50

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION ...............................................................56

Symptom Matrix Chart ...............................................56 CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

..66

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................\

..68

ECM Terminals and Reference Value .......................69

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT .......................................................................78

Description .................................................................78

Diagnostic Procedure ................................................78

TROUBLE DIAGNOSIS FOR POWER SUPPLY ..........79

Main Power Supply and Ground Circuit ....................79

DTC 0102 MASS AIR FLOW SEN ................................88

Component Description .............................................88

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

..88

ECM Terminals and Reference Value .......................88

On Board Diagnosis Logic.........................................88

DTC Confirmation Procedure ....................................89

Wiring Diagram ..........................................................90

Diagnostic Procedure ................................................92

DTC 0103 COOLANT TEMP SEN ................................95

Description .................................................................95

On Board Diagnosis Logic.........................................95

DTC Confirmation Procedure ....................................95

Wiring Diagram ..........................................................96

Diagnostic Procedure ................................................97

DTC 0104 VEHICLE SPEED SEN ................................99

Description .................................................................99

ECM Terminals and Reference Value .......................99

On Board Diagnosis Logic.........................................99

Overall Function Check ...........................................100

Wiring Diagram ........................................................101

Diagnostic Procedure ..............................................103

DTC 0203 ACCEL POS SW (F/C) ..............................104

Description ...............................................................104

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

104

ECM Terminals and Reference Value .....................104

On Board Diagnosis Logic.......................................104

http://vnx.su/

Page 277 of 1833

DTC Confirmation Procedure ..................................105

Wiring Diagram ........................................................106

Diagnostic Procedure ..............................................107

DTC 0208 OVER HEAT ...............................................109

Description ...............................................................109

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

109

ECM Terminals and Reference Value ..................... 110

On Board Diagnosis Logic....................................... 110

Overall Function Check ........................................... 111

Wiring Diagram ........................................................ 112

Diagnostic Procedure .............................................. 114

Main 12 Causes of Overheating..............................120

DTC 0301 ECM 2.........................................................121 Description ...............................................................121

On Board Diagnosis Logic.......................................121

DTC Confirmation Procedure ..................................121

Diagnostic Procedure ..............................................122

DTC 0402 P9×FUEL TEMP SEN .................................123

Description ...............................................................123

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

124

ECM Terminals and Reference Value .....................124

On Board Diagnosis Logic.......................................124

DTC Confirmation Procedure ..................................125

Wiring Diagram ........................................................126

Diagnostic Procedure ..............................................128

DTC 0403 ACCEL POS SENSOR ..............................130

Description ...............................................................130

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

131

ECM Terminals and Reference Value .....................131

On Board Diagnosis Logic.......................................132

DTC Confirmation Procedure ..................................132

Wiring Diagram ........................................................133

Diagnostic Procedure ..............................................137

DTC 0406 INT AIR VOL ..............................................150

On Board Diagnosis Logic.......................................150

DTC Confirmation Procedure ..................................150

Diagnostic Procedure ..............................................151

DTC 0407 CRANK POS SEN (TDC) ..........................152

Description ...............................................................152

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

152

ECM Terminals and Reference Value .....................152

On Board Diagnosis Logic.......................................153

DTC Confirmation Procedure ..................................153

Wiring Diagram ........................................................154

Diagnostic Procedure ..............................................156

DTC 0504 A/T COMM LINE ........................................160

System Description ..................................................160

ECM Terminals and Reference Value .....................160 On Board Diagnosis Logic.......................................160

DTC Confirmation Procedure ..................................161

Overall Function Check ...........................................161

Wiring Diagram ........................................................162

Diagnostic Procedure ..............................................164

DTC 0701 P1×CAM POS SEN .....................................166

Description ...............................................................166

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

167

ECM Terminals and Reference Value .....................167

On Board Diagnosis Logic.......................................167

DTC Confirmation Procedure ..................................168

Wiring Diagram ........................................................169

Diagnostic Procedure ..............................................171

DTC 0702 P2×TDC PULSE SIG ..................................173

Description ...............................................................173

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

174

ECM Terminals and Reference Value .....................174

On Board Diagnosis Logic.......................................174

DTC Confirmation Procedure ..................................175

Wiring Diagram ........................................................176

Diagnostic Procedure ..............................................178

DTC 0703 P3×PUMP COMM LINE ..............................180

Description ...............................................................180

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

181

ECM Terminals and Reference Value .....................181

On Board Diagnosis Logic.......................................181

DTC Confirmation Procedure ..................................182

Wiring Diagram ........................................................183

Diagnostic Procedure ..............................................185

DTC 0704 P4×SPILL/V CIRC, DTC 0706 P6×SPILL

VA LV E ........................................................................\

..187

Description ...............................................................187

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

188

ECM Terminals and Reference Value .....................188

On Board Diagnosis Logic.......................................188

DTC Confirmation Procedure ..................................189

Wiring Diagram ........................................................190

Diagnostic Procedure ..............................................192

DTC 0705 P5×PUMP C/MODULE ................................194

Description ...............................................................194

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

195

ECM Terminals and Reference Value .....................195

On Board Diagnosis Logic.......................................195

DTC Confirmation Procedure ..................................196

Diagnostic Procedure ..............................................196

DTC 0707 P7×F/INJ TIMG FB .....................................197

Description ...............................................................197

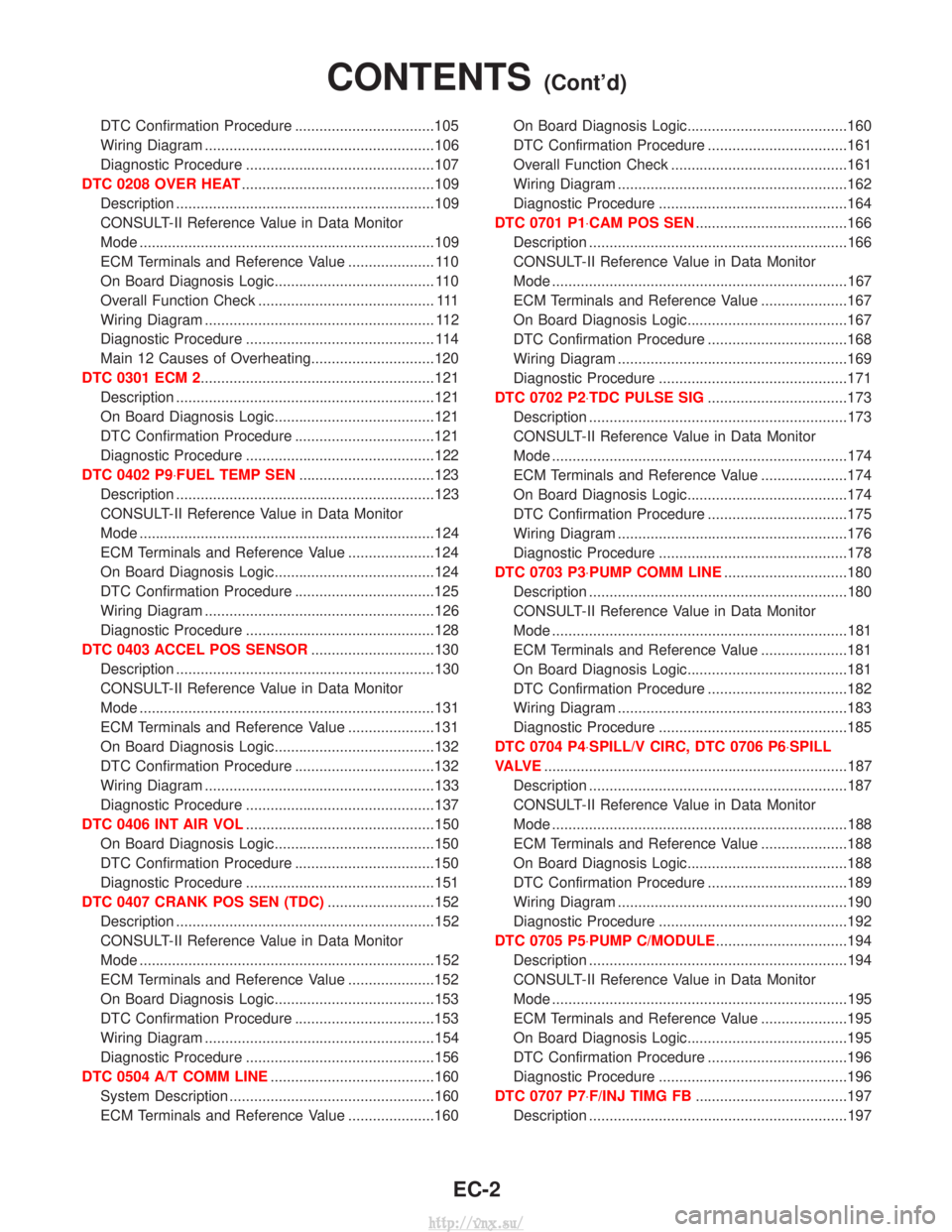

CONTENTS(Cont'd)

EC-2

http://vnx.su/

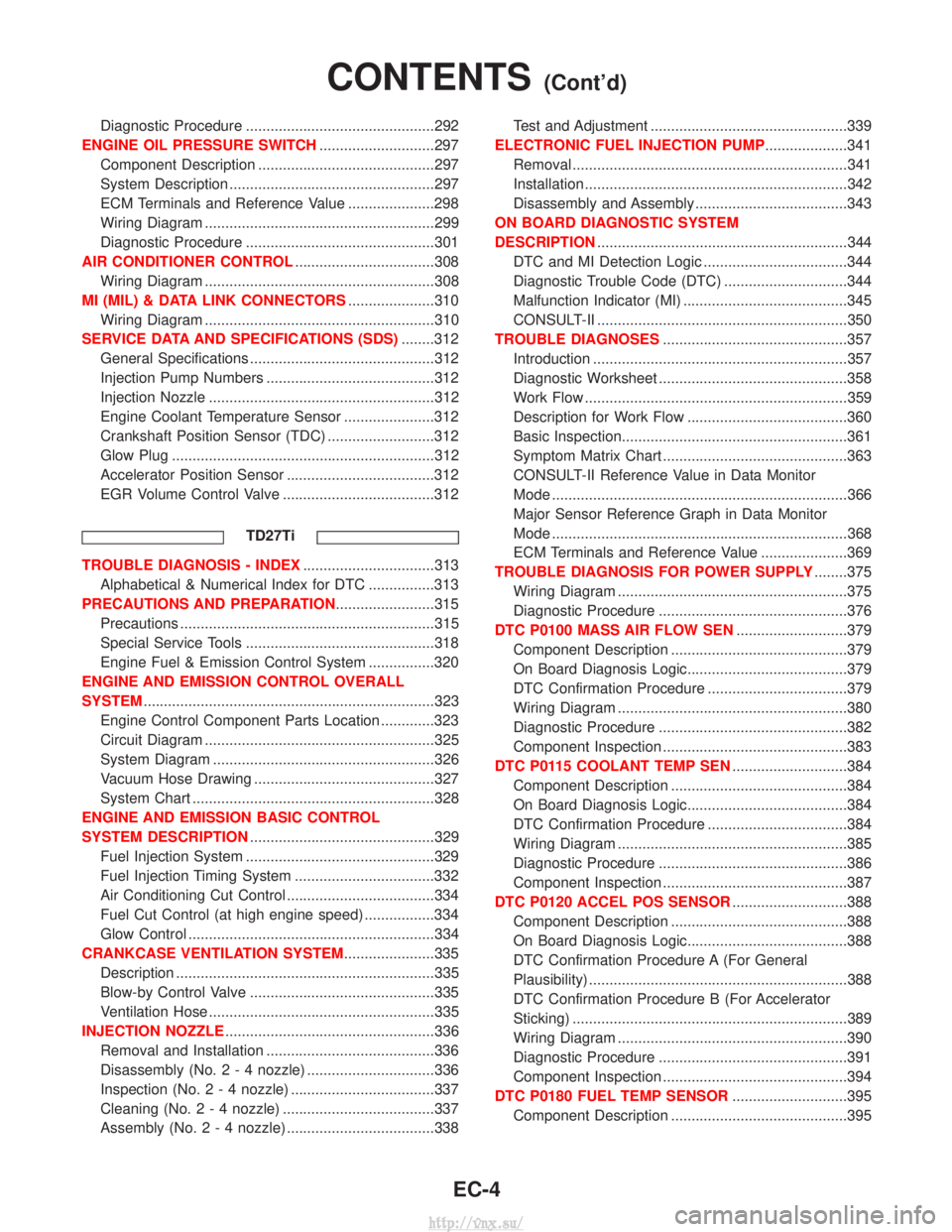

Page 279 of 1833

Diagnostic Procedure ..............................................292

ENGINE OIL PRESSURE SWITCH ............................297

Component Description ...........................................297

System Description ..................................................297

ECM Terminals and Reference Value .....................298

Wiring Diagram ........................................................299

Diagnostic Procedure ..............................................301

AIR CONDITIONER CONTROL ..................................308

Wiring Diagram ........................................................308

MI (MIL) & DATA LINK CONNECTORS .....................310

Wiring Diagram ........................................................310

SERVICE DATA AND SPECIFICATIONS (SDS) ........312

General Specifications .............................................312

Injection Pump Numbers .........................................312

Injection Nozzle .......................................................312

Engine Coolant Temperature Sensor ......................312

Crankshaft Position Sensor (TDC) ..........................312

Glow Plug ................................................................312

Accelerator Position Sensor ....................................312

EGR Volume Control Valve .....................................312

TD27Ti

TROUBLE DIAGNOSIS - INDEX ................................313

Alphabetical & Numerical Index for DTC ................313

PRECAUTIONS AND PREPARATION ........................315

Precautions ..............................................................315

Special Service Tools ..............................................318

Engine Fuel & Emission Control System ................320

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM .......................................................................323

Engine Control Component Parts Location .............323

Circuit Diagram ........................................................325

System Diagram ......................................................326

Vacuum Hose Drawing ............................................327

System Chart ...........................................................328

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION .............................................329

Fuel Injection System ..............................................329

Fuel Injection Timing System ..................................332

Air Conditioning Cut Control ....................................334

Fuel Cut Control (at high engine speed) .................334

Glow Control ............................................................334

CRANKCASE VENTILATION SYSTEM ......................335

Description ...............................................................335

Blow-by Control Valve .............................................335

Ventilation Hose .......................................................335

INJECTION NOZZLE ...................................................336

Removal and Installation .........................................336

Disassembly (No.2-4 nozzle) ...............................336

Inspection (No.2-4 nozzle) ...................................337

Cleaning (No.2-4 nozzle) .....................................337

Assembly (No.2-4 nozzle) ....................................338 Test and Adjustment ................................................339

ELECTRONIC FUEL INJECTION PUMP ....................341

Removal ...................................................................341

Installation ................................................................342

Disassembly and Assembly .....................................343

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION .............................................................344

DTC and MI Detection Logic ...................................344

Diagnostic Trouble Code (DTC) ..............................344

Malfunction Indicator (MI) ........................................345

CONSULT-II .............................................................350

TROUBLE DIAGNOSES .............................................357

Introduction ..............................................................357

Diagnostic Worksheet ..............................................358

Work Flow ................................................................359

Description for Work Flow .......................................360

Basic Inspection.......................................................361

Symptom Matrix Chart .............................................363

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

366

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................\

368

ECM Terminals and Reference Value .....................369

TROUBLE DIAGNOSIS FOR POWER SUPPLY ........375

Wiring Diagram ........................................................375

Diagnostic Procedure ..............................................376

DTC P0100 MASS AIR FLOW SEN ...........................379

Component Description ...........................................379

On Board Diagnosis Logic.......................................379

DTC Confirmation Procedure ..................................379

Wiring Diagram ........................................................380

Diagnostic Procedure ..............................................382

Component Inspection .............................................383

DTC P0115 COOLANT TEMP SEN ............................384

Component Description ...........................................384

On Board Diagnosis Logic.......................................384

DTC Confirmation Procedure ..................................384

Wiring Diagram ........................................................385

Diagnostic Procedure ..............................................386

Component Inspection .............................................387

DTC P0120 ACCEL POS SENSOR ............................388

Component Description ...........................................388

On Board Diagnosis Logic.......................................388

DTC Confirmation Procedure A (For General

Plausibility) ...............................................................388

DTC Confirmation Procedure B (For Accelerator

Sticking) ...................................................................389

Wiring Diagram ........................................................390

Diagnostic Procedure ..............................................391

Component Inspection .............................................394

DTC P0180 FUEL TEMP SENSOR ............................395

Component Description ...........................................395

CONTENTS(Cont'd)

EC-4

http://vnx.su/

Page 282 of 1833

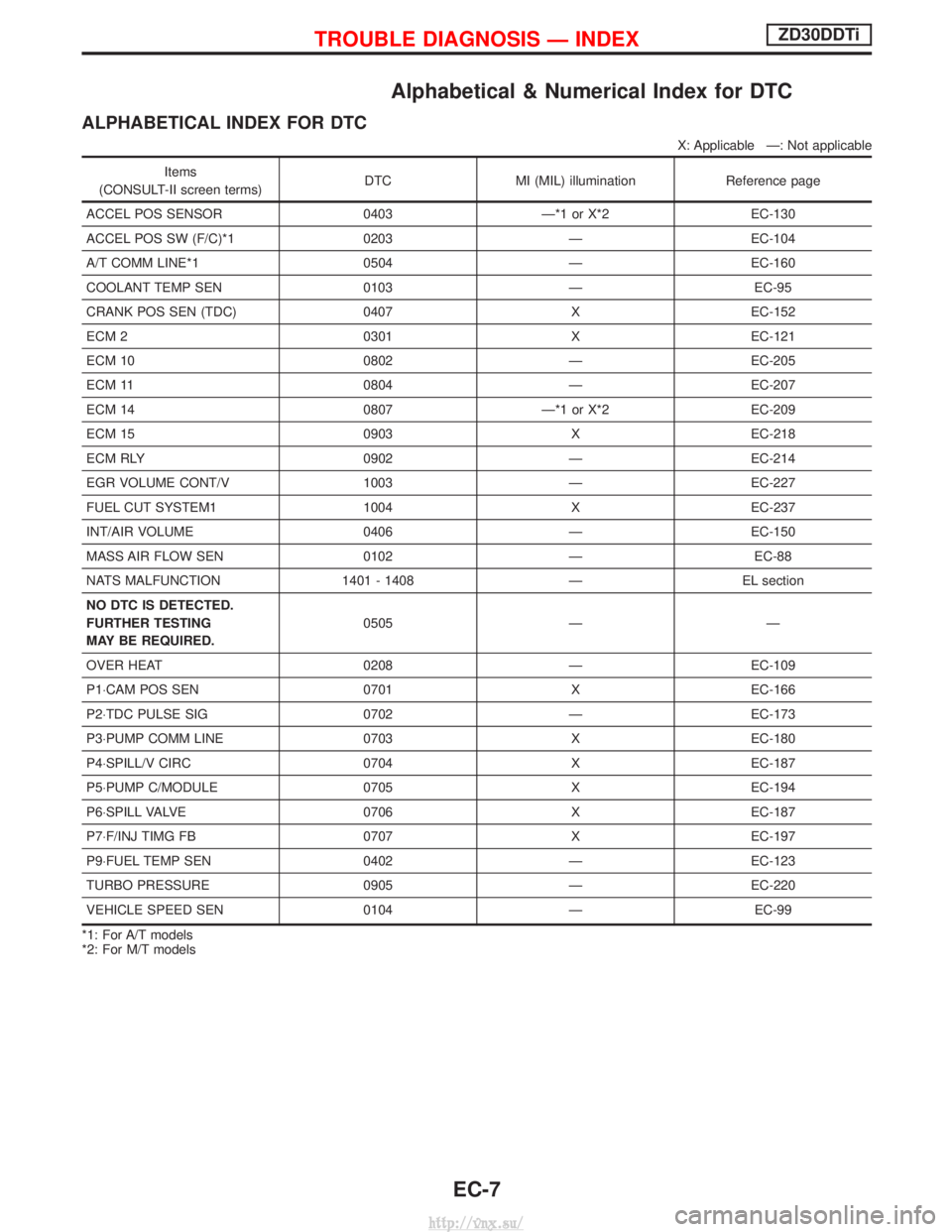

Alphabetical & Numerical Index for DTC

ALPHABETICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms) DTC MI (MIL) illumination Reference page

ACCEL POS SENSOR 0403 Ð*1 or X*2 EC-130

ACCEL POS SW (F/C)*1 0203 Ð EC-104

A/T COMM LINE*1 0504 Ð EC-160

COOLANT TEMP SEN 0103 Ð EC-95

CRANK POS SEN (TDC) 0407 X EC-152

ECM 2 0301 X EC-121

ECM 10 0802 Ð EC-205

ECM 11 0804 Ð EC-207

ECM 14 0807 Ð*1 or X*2 EC-209

ECM 15 0903 X EC-218

ECM RLY 0902 Ð EC-214

EGR VOLUME CONT/V 1003 Ð EC-227

FUEL CUT SYSTEM1 1004 X EC-237

INT/AIR VOLUME 0406 Ð EC-150

MASS AIR FLOW SEN 0102 Ð EC-88

NATS MALFUNCTION 1401 - 1408 Ð EL section

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. 0505 Ð Ð

OVER HEAT 0208 Ð EC-109

P1×CAM POS SEN 0701XEC-166

P2×TDC PULSE SIG 0702ÐEC-173

P3×PUMP COMM LINE 0703XEC-180

P4×SPILL/V CIRC 0704XEC-187

P5×PUMP C/MODULE 0705XEC-194

P6×SPILL VALVE 0706XEC-187

P7×F/INJ TIMG FB 0707XEC-197

P9×FUEL TEMP SEN 0402ÐEC-123

TURBO PRESSURE 0905ÐEC-220

VEHICLE SPEED SEN 0104ÐEC-99

*1: For A/T models

*2: For M/T models

TROUBLE DIAGNOSIS Ð INDEXZD30DDTi

EC-7

http://vnx.su/