sensor NISSAN TERRANO 2004 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 347 of 1833

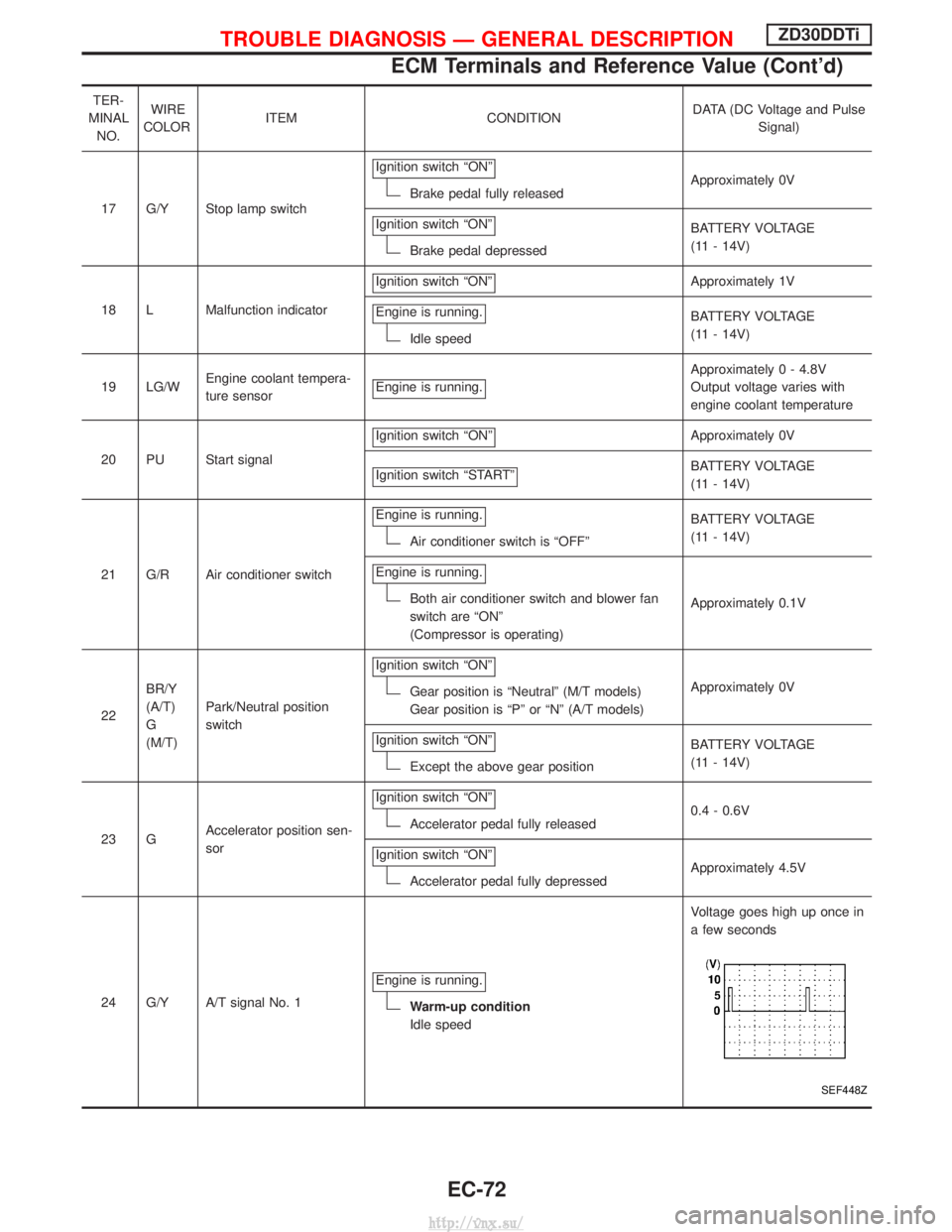

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

17 G/Y Stop lamp switch Ignition switch ªONº

Brake pedal fully released

Approximately 0V

Ignition switch ªONº

Brake pedal depressed BATTERY VOLTAGE

(11 - 14V)

18 L Malfunction indicator Ignition switch ªONº

Approximately 1V

Engine is running.

Idle speed BATTERY VOLTAGE

(11 - 14V)

19 LG/W Engine coolant tempera-

ture sensor Engine is running.

Approximately 0 - 4.8V

Output voltage varies with

engine coolant temperature

20 PU Start signal Ignition switch ªONº

Approximately 0V

Ignition switch ªSTARTº

BATTERY VOLTAGE

(11 - 14V)

21 G/R Air conditioner switch Engine is running.

Air conditioner switch is ªOFFº

BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Both air conditioner switch and blower fan

switch are ªONº

(Compressor is operating) Approximately 0.1V

22 BR/Y

(A/T)

G

(M/T) Park/Neutral position

switch Ignition switch ªONº

Gear position is ªNeutralº (M/T models)

Gear position is ªPº or ªNº (A/T models)

Approximately 0V

Ignition switch ªONº

Except the above gear position BATTERY VOLTAGE

(11 - 14V)

23 G Accelerator position sen-

sor Ignition switch ªONº

Accelerator pedal fully released

0.4 - 0.6V

Ignition switch ªONº

Accelerator pedal fully depressed Approximately 4.5V

24 G/Y A/T signal No. 1 Engine is running.

Warm-up condition

Idle speed Voltage goes high up once in

a few seconds

SEF448Z

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-72

http://vnx.su/

Page 348 of 1833

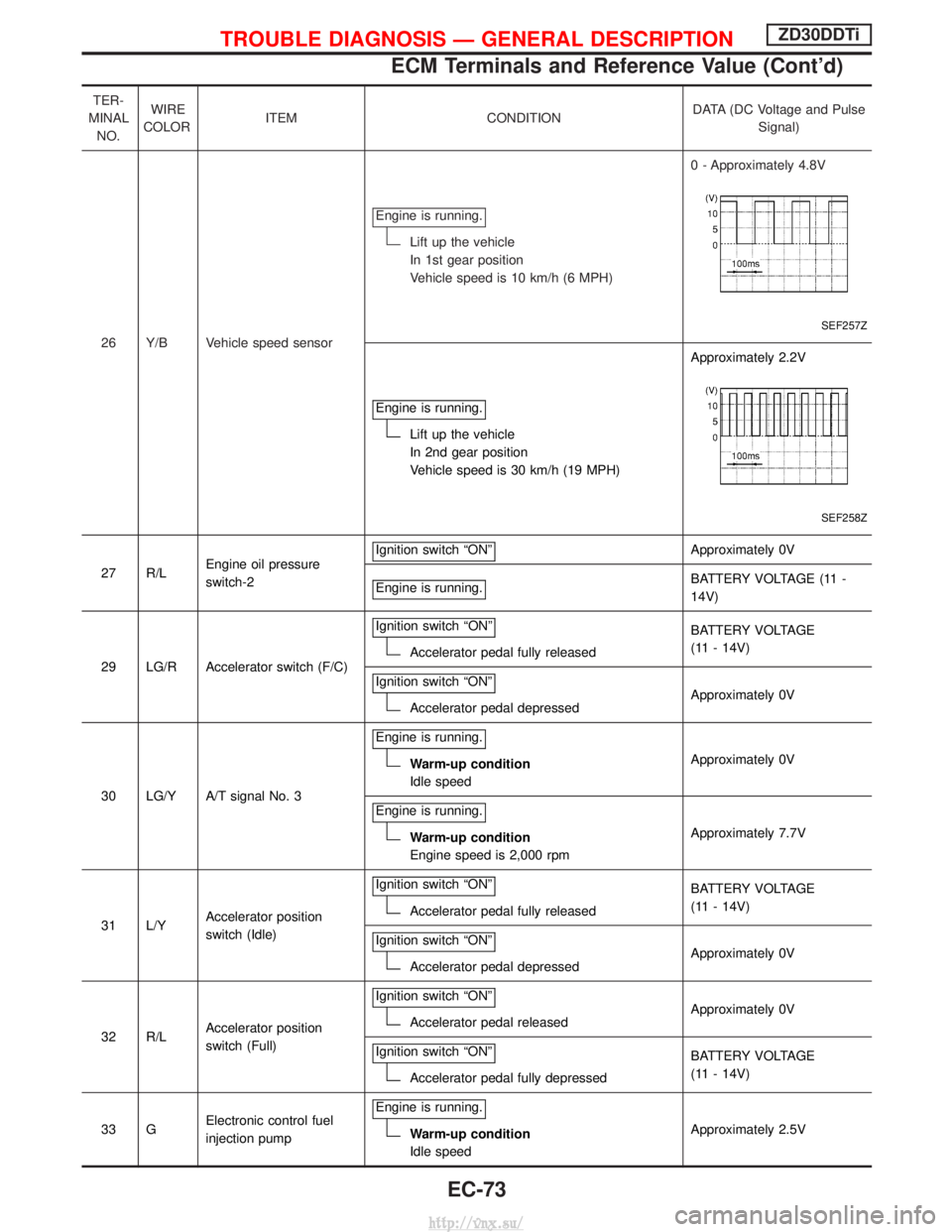

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

26 Y/B Vehicle speed sensor Engine is running.

Lift up the vehicle

In 1st gear position

Vehicle speed is 10 km/h (6 MPH)

0 - Approximately 4.8V

SEF257Z

Engine is running.

Lift up the vehicle

In 2nd gear position

Vehicle speed is 30 km/h (19 MPH)Approximately 2.2V

SEF258Z

27 R/L

Engine oil pressure

switch-2 Ignition switch ªONº

Approximately 0V

Engine is running.

BATTERY VOLTAGE (11 -

14V)

29 LG/R Accelerator switch (F/C) Ignition switch ªONº

Accelerator pedal fully released

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressed Approximately 0V

30 LG/Y A/T signal No. 3 Engine is running.

Warm-up condition

Idle speed

Approximately 0V

Engine is running.

Warm-up condition

Engine speed is 2,000 rpm Approximately 7.7V

31 L/Y Accelerator position

switch (Idle) Ignition switch ªONº

Accelerator pedal fully released

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressed Approximately 0V

32 R/L Accelerator position

switch (Full) Ignition switch ªONº

Accelerator pedal released

Approximately 0V

Ignition switch ªONº

Accelerator pedal fully depressed BATTERY VOLTAGE

(11 - 14V)

33 G Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-73

http://vnx.su/

Page 349 of 1833

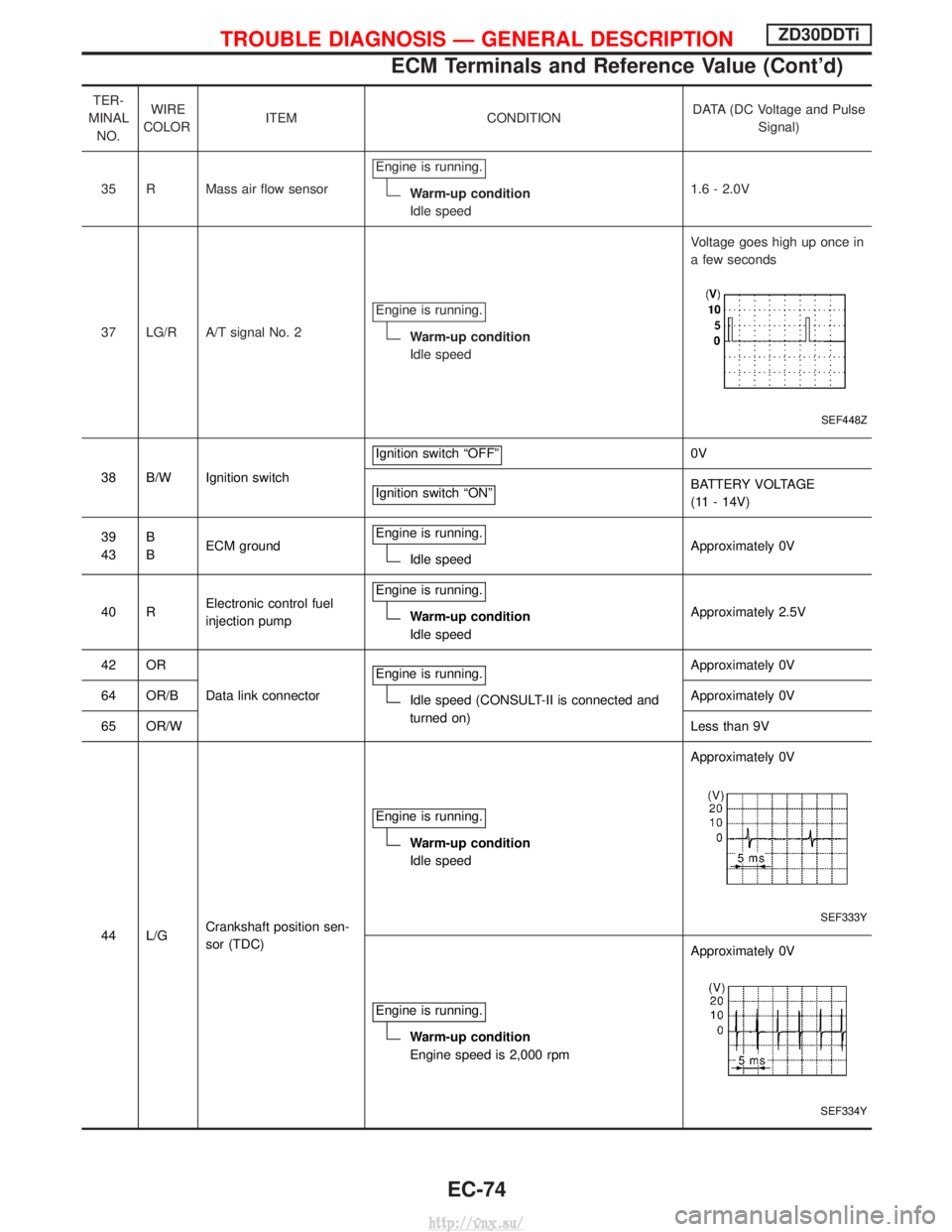

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

35 R Mass air flow sensor Engine is running.

Warm-up condition

Idle speed 1.6 - 2.0V

37 LG/R A/T signal No. 2 Engine is running.

Warm-up condition

Idle speed Voltage goes high up once in

a few seconds

SEF448Z

38 B/W Ignition switch

Ignition switch ªOFFº

0V

Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

39

43 B

B

ECM ground Engine is running.

Idle speed Approximately 0V

40 R Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

42 OR Data link connector Engine is running.

Idle speed (CONSULT-II is connected and

turned on) Approximately 0V

64 OR/B Approximately 0V

65 OR/W Less than 9V

44 L/G Crankshaft position sen-

sor (TDC) Engine is running.

Warm-up condition

Idle speed

Approximately 0V

SEF333Y

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 0V

SEF334Y

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-74

http://vnx.su/

Page 350 of 1833

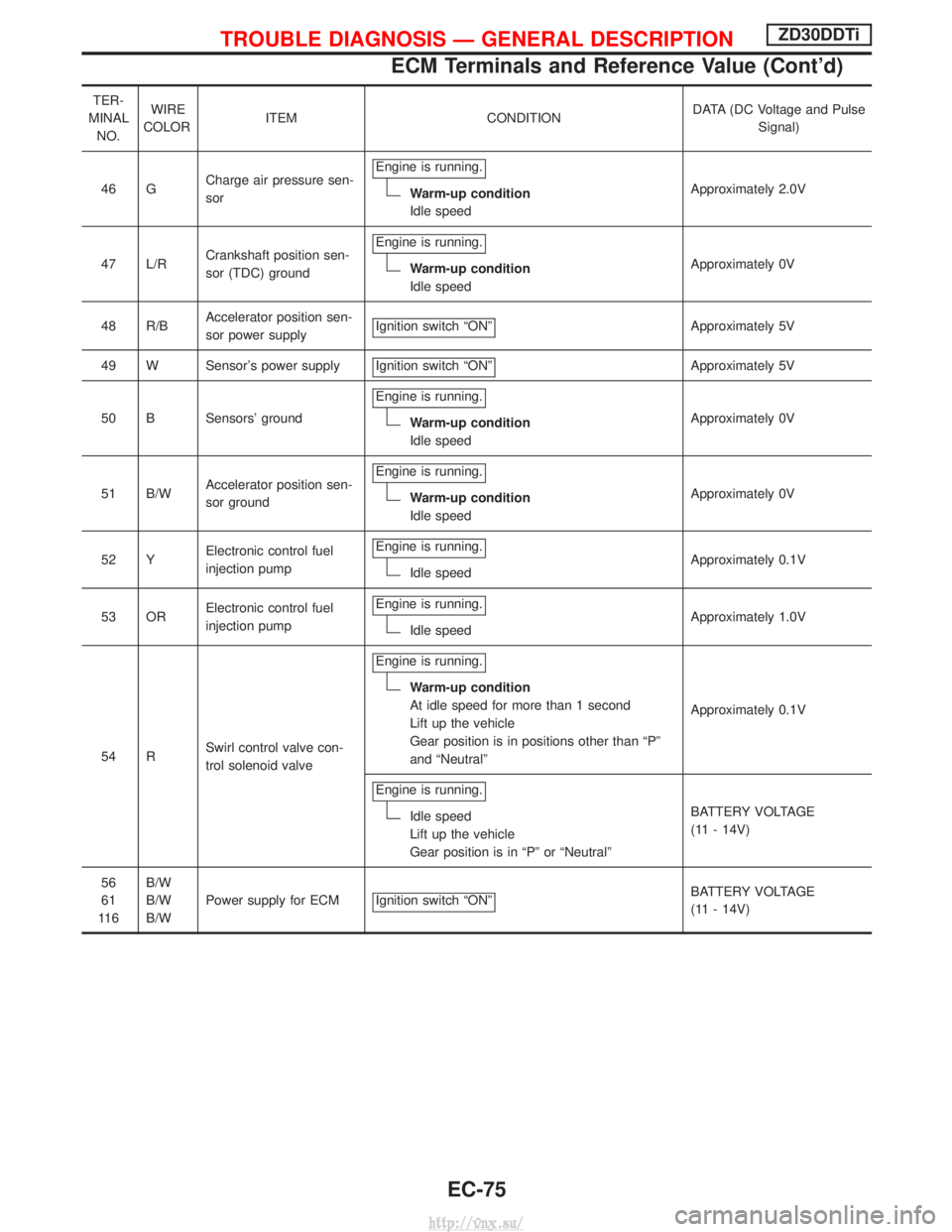

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

46 G Charge air pressure sen-

sor Engine is running.

Warm-up condition

Idle speed

Approximately 2.0V

47 L/R Crankshaft position sen-

sor (TDC) ground Engine is running.

Warm-up condition

Idle speed

Approximately 0V

48 R/B Accelerator position sen-

sor power supply Ignition switch ªONº

Approximately 5V

49 W Sensor's power supply Ignition switch ªONº

Approximately 5V

50 B Sensors' ground Engine is running.

Warm-up condition

Idle speed Approximately 0V

51 B/W Accelerator position sen-

sor ground Engine is running.

Warm-up condition

Idle speed

Approximately 0V

52 Y Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.1V

53 OR Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 1.0V

54 R Swirl control valve con-

trol solenoid valve Engine is running.

Warm-up condition

At idle speed for more than 1 second

Lift up the vehicle

Gear position is in positions other than ªPº

and ªNeutralº

Approximately 0.1V

Engine is running.

Idle speed

Lift up the vehicle

Gear position is in ªPº or ªNeutralº BATTERY VOLTAGE

(11 - 14V)

56

61

11 6 B/W

B/W

B/W

Power supply for ECM Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-75

http://vnx.su/

Page 363 of 1833

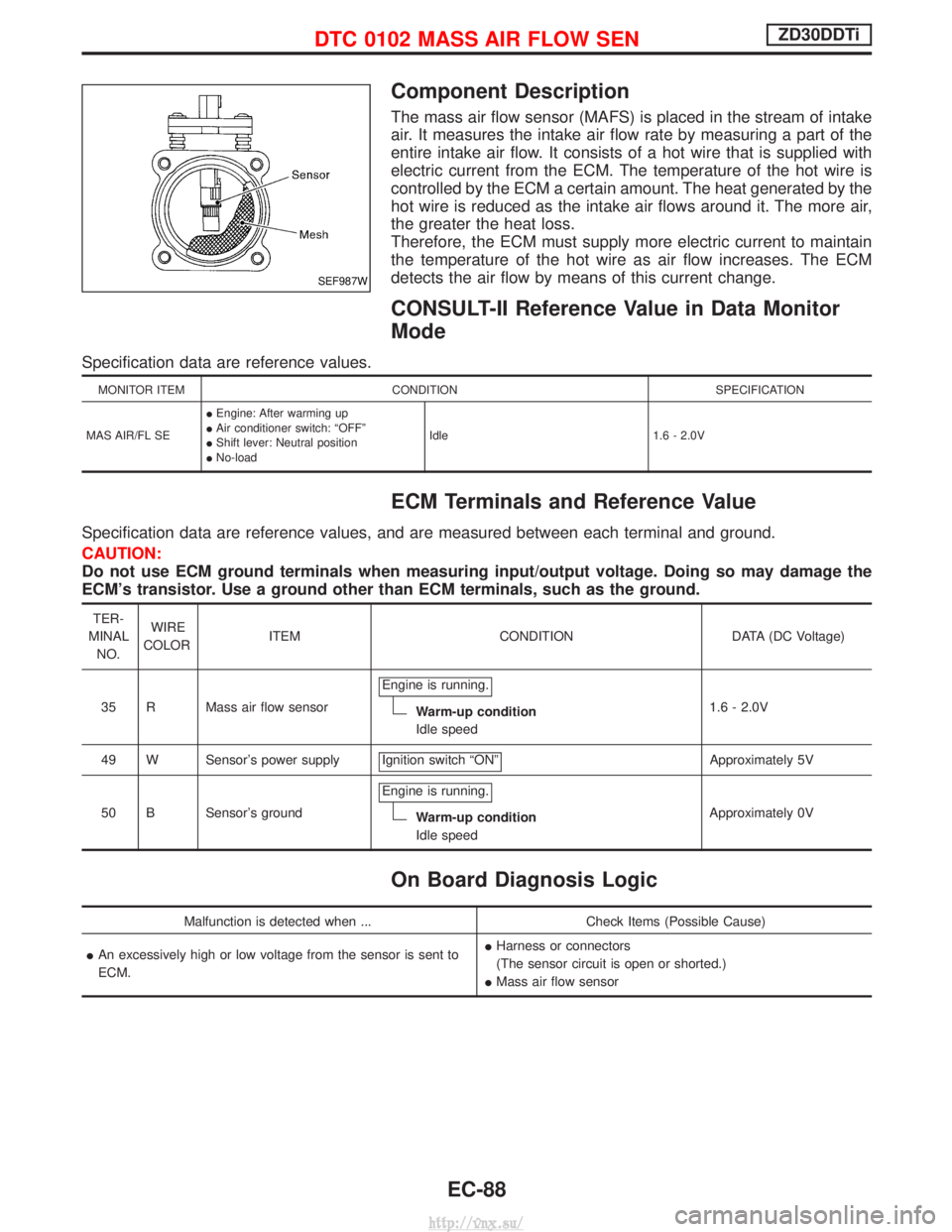

Component Description

The mass air flow sensor (MAFS) is placed in the stream of intake

air. It measures the intake air flow rate by measuring a part of the

entire intake air flow. It consists of a hot wire that is supplied with

electric current from the ECM. The temperature of the hot wire is

controlled by the ECM a certain amount. The heat generated by the

hot wire is reduced as the intake air flows around it. The more air,

the greater the heat loss.

Therefore, the ECM must supply more electric current to maintain

the temperature of the hot wire as air flow increases. The ECM

detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

MAS AIR/FL SE I

Engine: After warming up

I Air conditioner switch: ªOFFº

I Shift lever: Neutral position

I No-load Idle

1.6 - 2.0V

ECM Terminals and Reference Value

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

35 R Mass air flow sensor Engine is running.

Warm-up condition

Idle speed 1.6 - 2.0V

49 W Sensor's power supply Ignition switch ªONº

Approximately 5V

50 B Sensor's ground Engine is running.

Warm-up condition

Idle speed Approximately 0V

On Board Diagnosis Logic

Malfunction is detected when ...

Check Items (Possible Cause)

I An excessively high or low voltage from the sensor is sent to

ECM. I

Harness or connectors

(The sensor circuit is open or shorted.)

I Mass air flow sensor

SEF987W

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-88

http://vnx.su/

Page 367 of 1833

Diagnostic Procedure

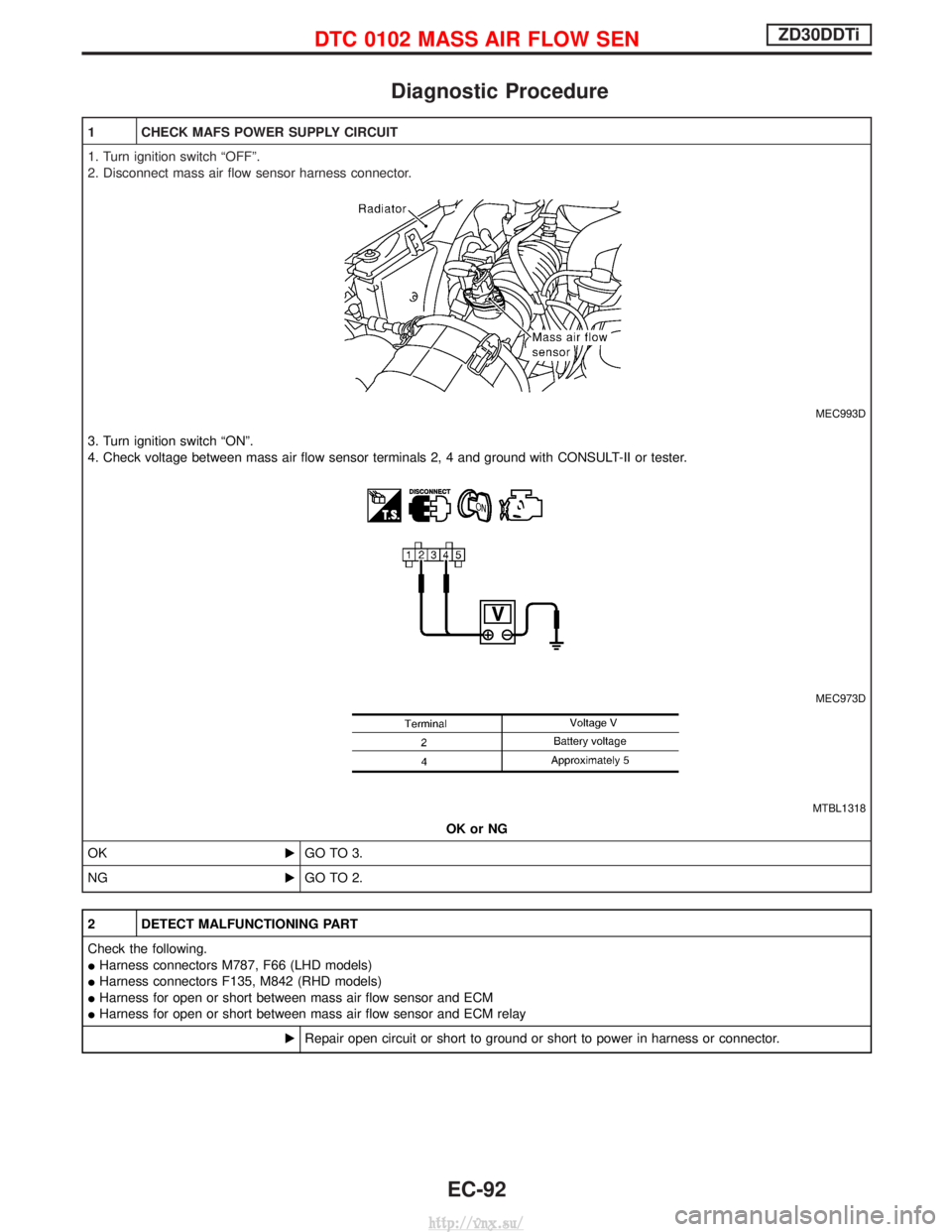

1 CHECK MAFS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect mass air flow sensor harness connector.

MEC993D

3. Turn ignition switch ªONº.

4. Check voltage between mass air flow sensor terminals 2, 4 and ground with CONSULT-II or tester.

MEC973D

MTBL1318

OK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between mass air flow sensor and ECM

I Harness for open or short between mass air flow sensor and ECM relay

ERepair open circuit or short to ground or short to power in harness or connector.

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-92

http://vnx.su/

Page 368 of 1833

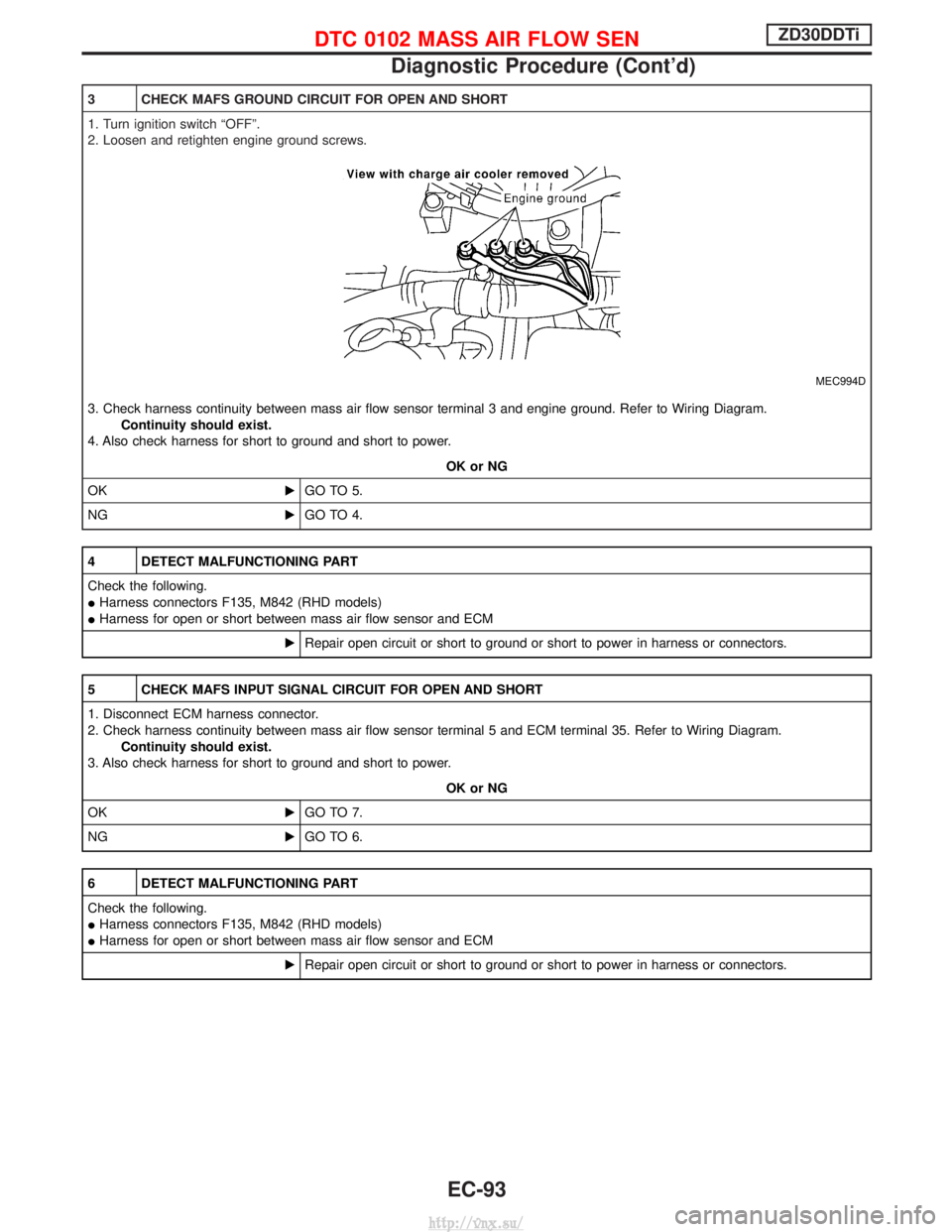

3 CHECK MAFS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

MEC994D

3. Check harness continuity between mass air flow sensor terminal 3 and engine ground. Refer to Wiring Diagram.Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F135, M842 (RHD models)

I Harness for open or short between mass air flow sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK MAFS INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between mass air flow sensor terminal 5 and ECM terminal 35. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 7.

NG EGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F135, M842 (RHD models)

I Harness for open or short between mass air flow sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0102 MASS AIR FLOW SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-93

http://vnx.su/

Page 369 of 1833

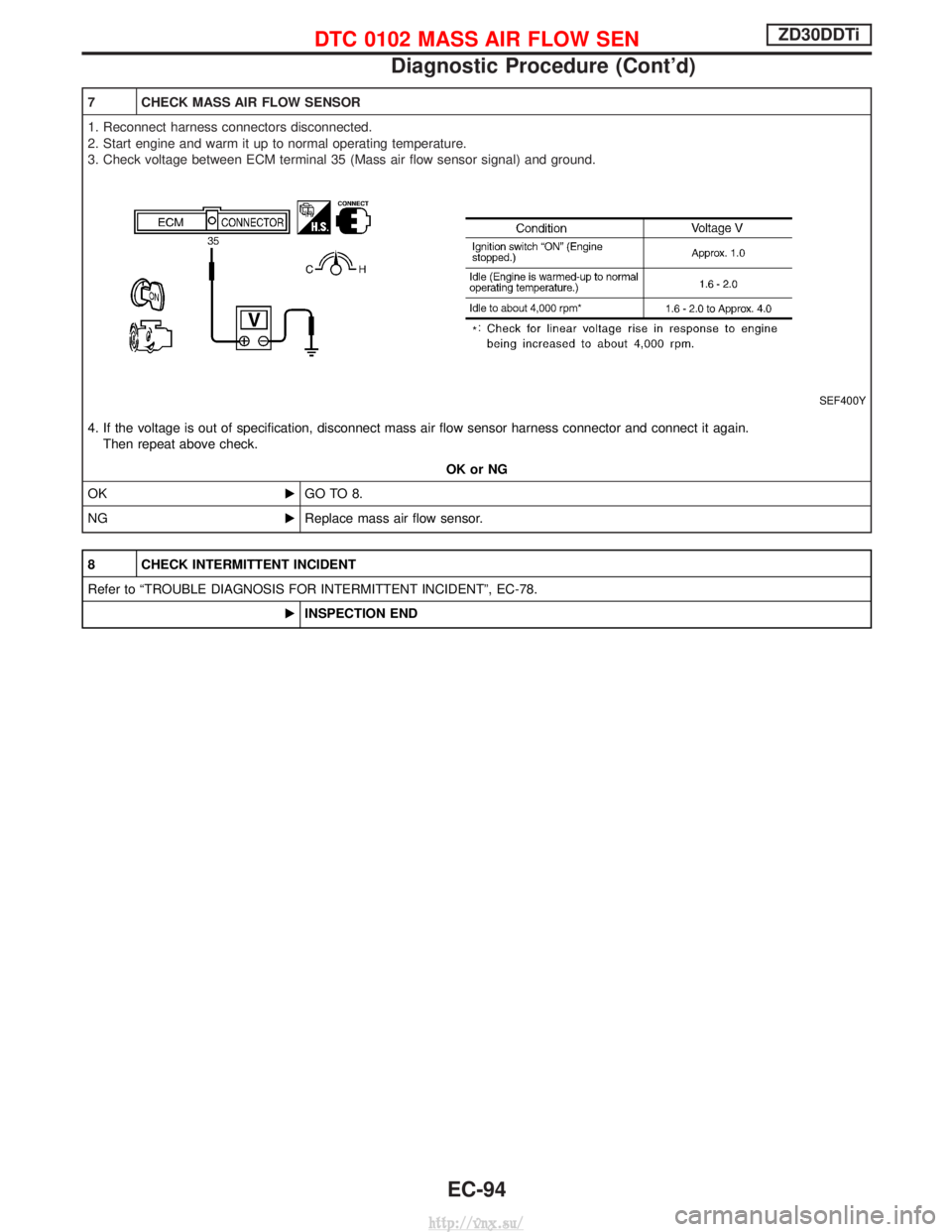

7 CHECK MASS AIR FLOW SENSOR

1. Reconnect harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 35 (Mass air flow sensor signal) and ground.

SEF400Y

4. If the voltage is out of specification, disconnect mass air flow sensor harness connector and connect it again.Then repeat above check.

OK or NG

OK EGO TO 8.

NG EReplace mass air flow sensor.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0102 MASS AIR FLOW SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-94

http://vnx.su/

Page 370 of 1833

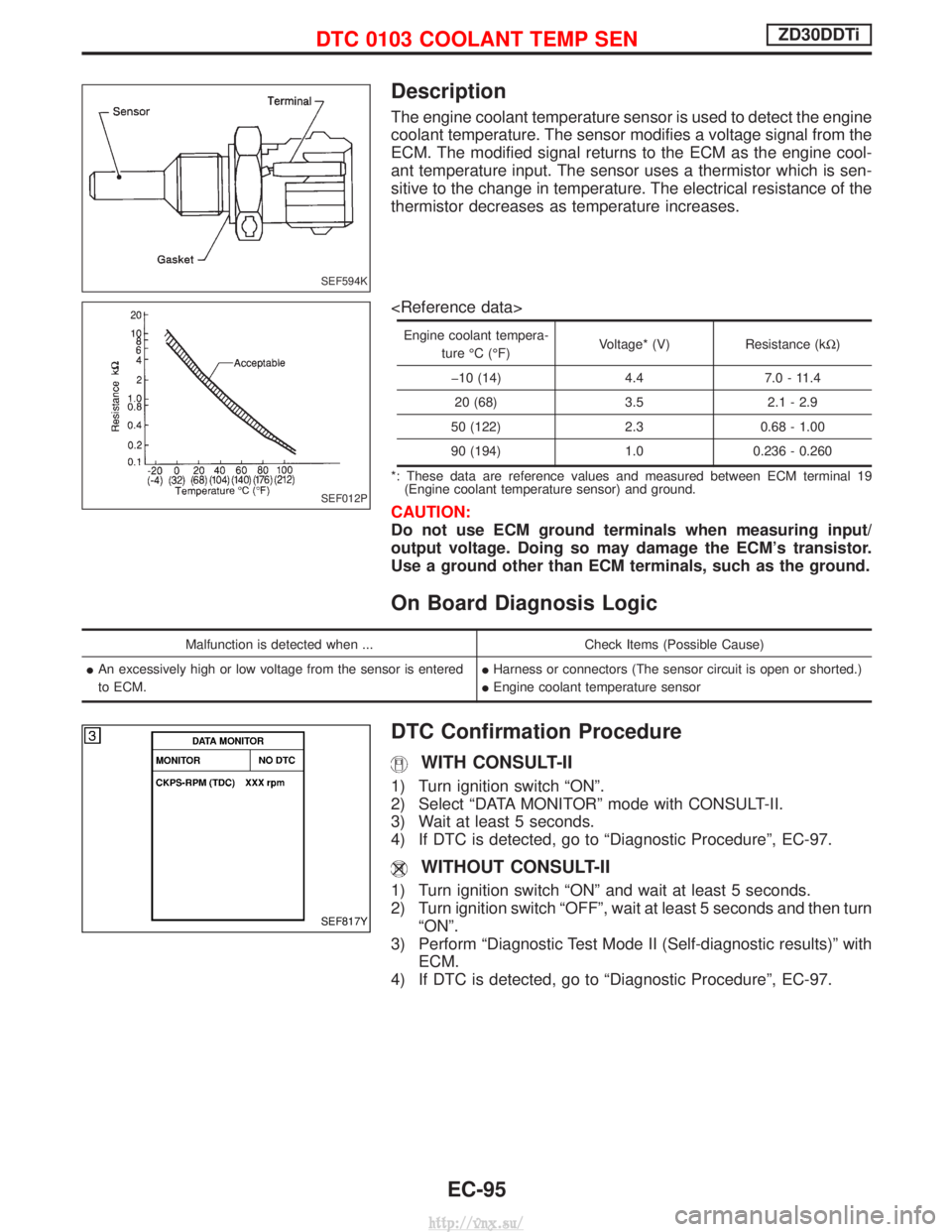

Description

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine cool-

ant temperature input. The sensor uses a thermistor which is sen-

sitive to the change in temperature. The electrical resistance of the

thermistor decreases as temperature increases.

Engine coolant tempera-ture ÉC (ÉF) Voltage* (V) Resistance (kW

)

þ10 (14) 4.4 7.0 - 11.4 20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

*: These data are reference values and measured between ECM terminal 19 (Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may damage the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

I An excessively high or low voltage from the sensor is entered

to ECM. I

Harness or connectors (The sensor circuit is open or shorted.)

I Engine coolant temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-97.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 5 seconds.

2) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-97.

SEF594K

SEF012P

SEF817Y

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-95

http://vnx.su/

Page 372 of 1833

Diagnostic Procedure

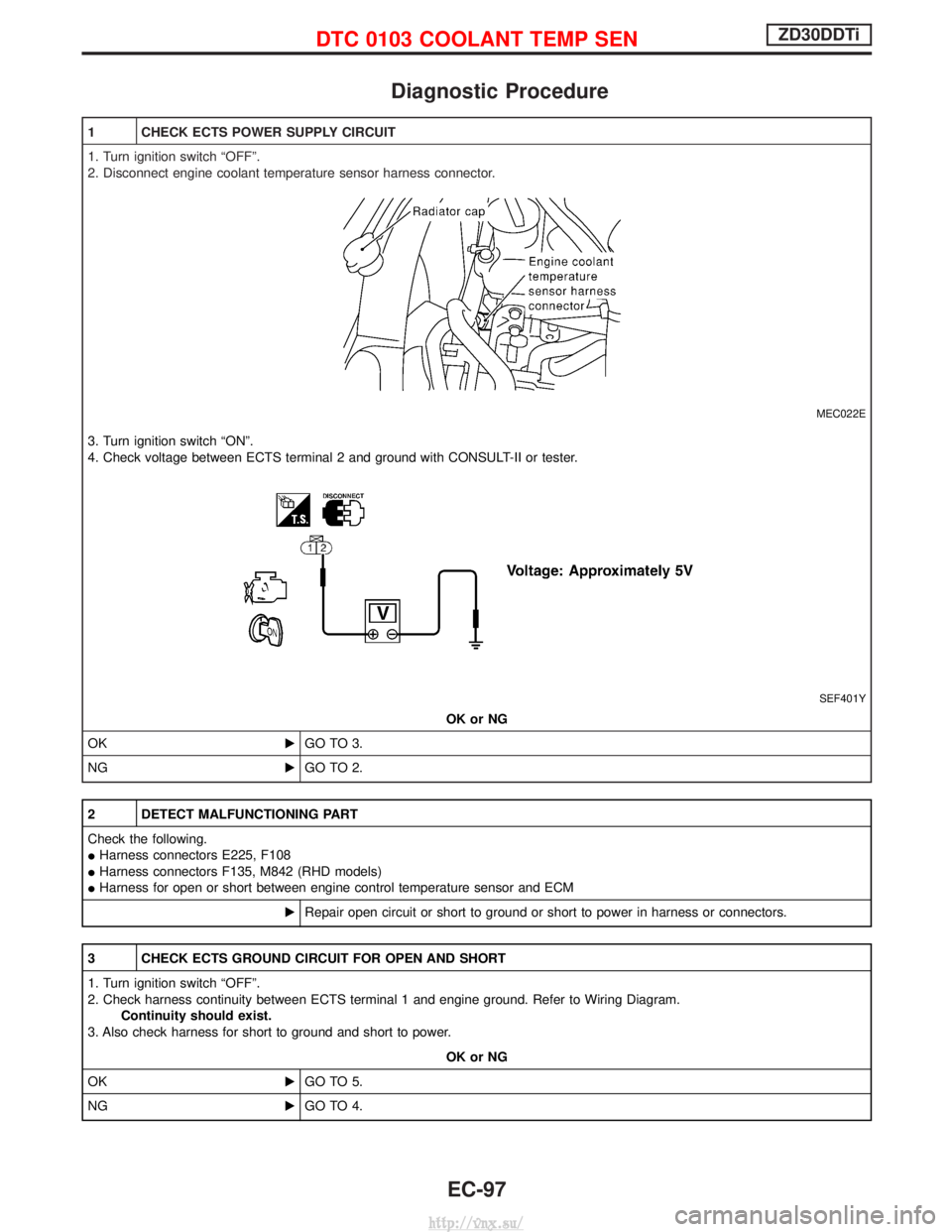

1 CHECK ECTS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

MEC022E

3. Turn ignition switch ªONº.

4. Check voltage between ECTS terminal 2 and ground with CONSULT-II or tester.

SEF401Y

OK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between engine control temperature sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECTS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between ECTS terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-97

http://vnx.su/