oil pressure NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 8 of 1833

Precautions for Multiport Fuel Injection System

or Engine Control System

1. Before connecting or disconnecting any harness connector forthe multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ªOFFº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

2. Before disconnecting pressurized fuel line from fuel pump to injectors, be sure to release fuel pressure to eliminate danger.

3. Be careful not to jar components such as control unit and air flow meter.

Precautions for Catalyst

If a large amount of unburned fuel enters the converter, the con-

verter temperature will rise to excessively high values. To prevent

this, follow the procedure below:

1. Use unleaded gasoline only. Leaded gasoline will seriouslydamage the catalytic converter.

2. When checking for ignition spark or measuring engine compression, perform tests quickly and only when necessary.

3. Do not run engine when the fuel tank level is low, as a result the engine may misfire causing damage to the converter.

4. Do not place the vehicle on inflammable material. Keep inflam- mable material off the exhaust pipe.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

For proper operation of the system, follow the procedure below:

1. Always use the recommended oil. Follow the instructions forproper time to change the oil and proper oil level.

2. Avoid accelerating engine to a high rpm immediately after start- ing.

3. If engine had been operating at high rpm for an extended period of time, let it idle for a few minutes prior to shutting it off.

SGI787

SGI290

SGI292

PRECAUTIONS

GI-5

http://vnx.su/

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 45 of 1833

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 46 of 1833

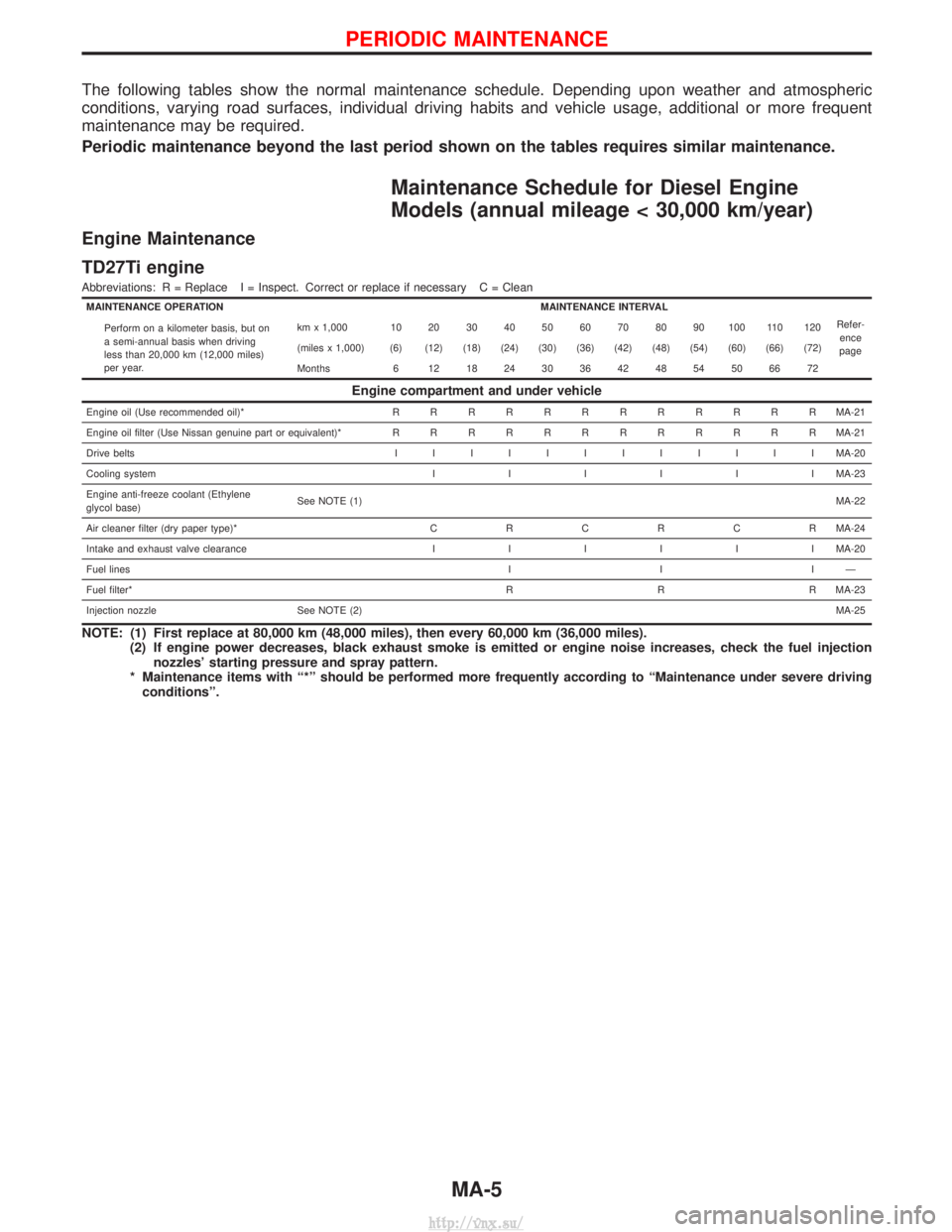

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric

conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent

maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

Maintenance Schedule for Diesel Engine

Models (annual mileage < 30,000 km/year)

Engine Maintenance

TD27Ti engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary C = Clean

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-ence

page

Perform on a kilometer basis, but on

a semi-annual basis when driving

less than 20,000 km (12,000 miles)

per year. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Months 6 12 18 24 30 36 42 48 54 50 66 72

Engine compartment and under vehicle

Engine oil (Use recommended oil)*

RRRRRRRRRRRR MA-21

Engine oil filter (Use Nissan genuine part or equivalent)* RRRRRRRRRRRR MA-21

Drive belts IIIIIIIIIIII MA-20

Cooling system IIIIII MA-23

Engine anti-freeze coolant (Ethylene

glycol base) See NOTE (1)

MA-22

Air cleaner filter (dry paper type)* CRCRCR MA-24

Intake and exhaust valve clearance IIIIII MA-20

Fuel lines IIIÐ

Fuel filter* R R R MA-23

Injection nozzle See NOTE (2) MA-25

NOTE: (1) First replace at 80,000 km (48,000 miles), then every 60,000 km (36,000 miles).

(2) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check the fuel injectionnozzles' starting pressure and spray pattern.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving conditionsº.

PERIODIC MAINTENANCE

MA-5

http://vnx.su/

Page 49 of 1833

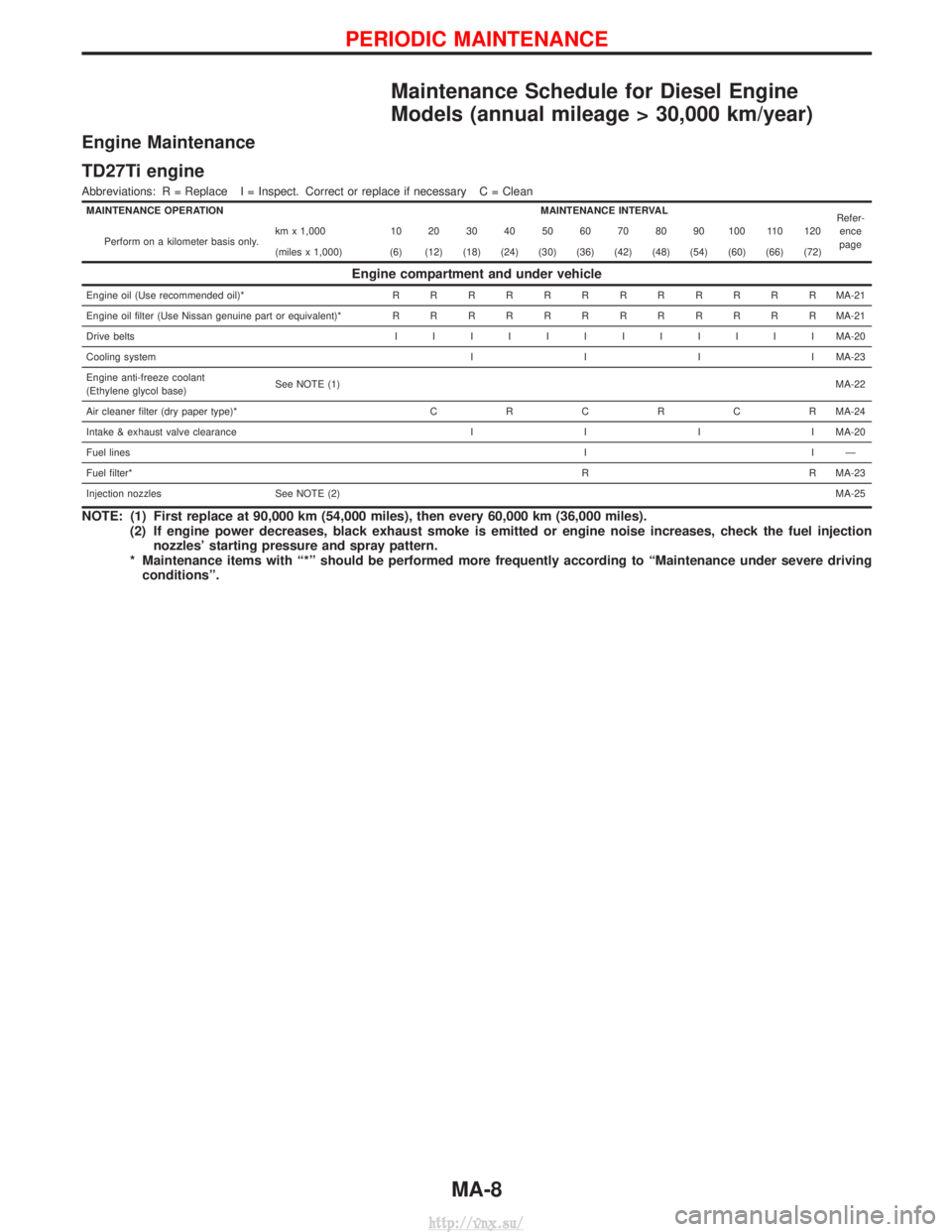

Maintenance Schedule for Diesel Engine

Models (annual mileage > 30,000 km/year)

Engine Maintenance

TD27Ti engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary C = Clean

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page

Perform on a kilometer basis only. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Engine compartment and under vehicle

Engine oil (Use recommended oil)*

RRRRRRRRRRRR MA-21

Engine oil filter (Use Nissan genuine part or equivalent)* RRRRRRRRRRRR MA-21

Drive belts IIIIIIIIIIII MA-20

Cooling system IIIIMA-23

Engine anti-freeze coolant

(Ethylene glycol base) See NOTE (1)

MA-22

Air cleaner filter (dry paper type)* CRCRCR MA-24

Intake & exhaust valve clearance IIIIMA-20

Fuel lines IIÐ

Fuel filter* R R MA-23

Injection nozzles See NOTE (2) MA-25

NOTE: (1) First replace at 90,000 km (54,000 miles), then every 60,000 km (36,000 miles).

(2) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check the fuel injectionnozzles' starting pressure and spray pattern.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving conditionsº.

PERIODIC MAINTENANCE

MA-8

http://vnx.su/

Page 89 of 1833

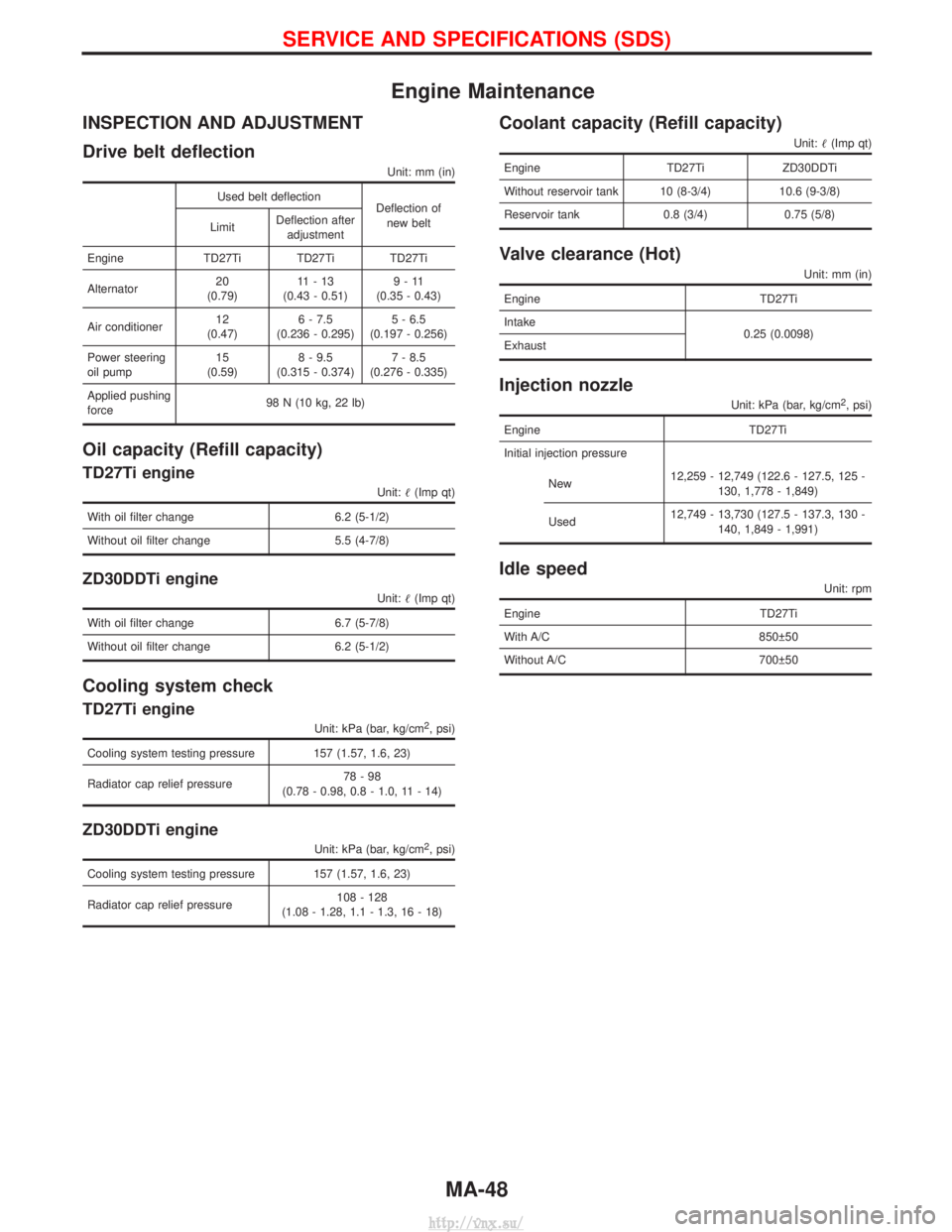

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflectionDeflection of

new belt

Limit Deflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator 20

(0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner 12

(0.47) 6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering

oil pump 15

(0.59) 8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:

(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit: (Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

TD27Ti engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

ZD30DDTi engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 108 - 128

(1.08 - 1.28, 1.1 - 1.3, 16 - 18)

Coolant capacity (Refill capacity)

Unit: (Imp qt)

Engine TD27TiZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake 0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New 12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used 12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

http://vnx.su/

Page 92 of 1833

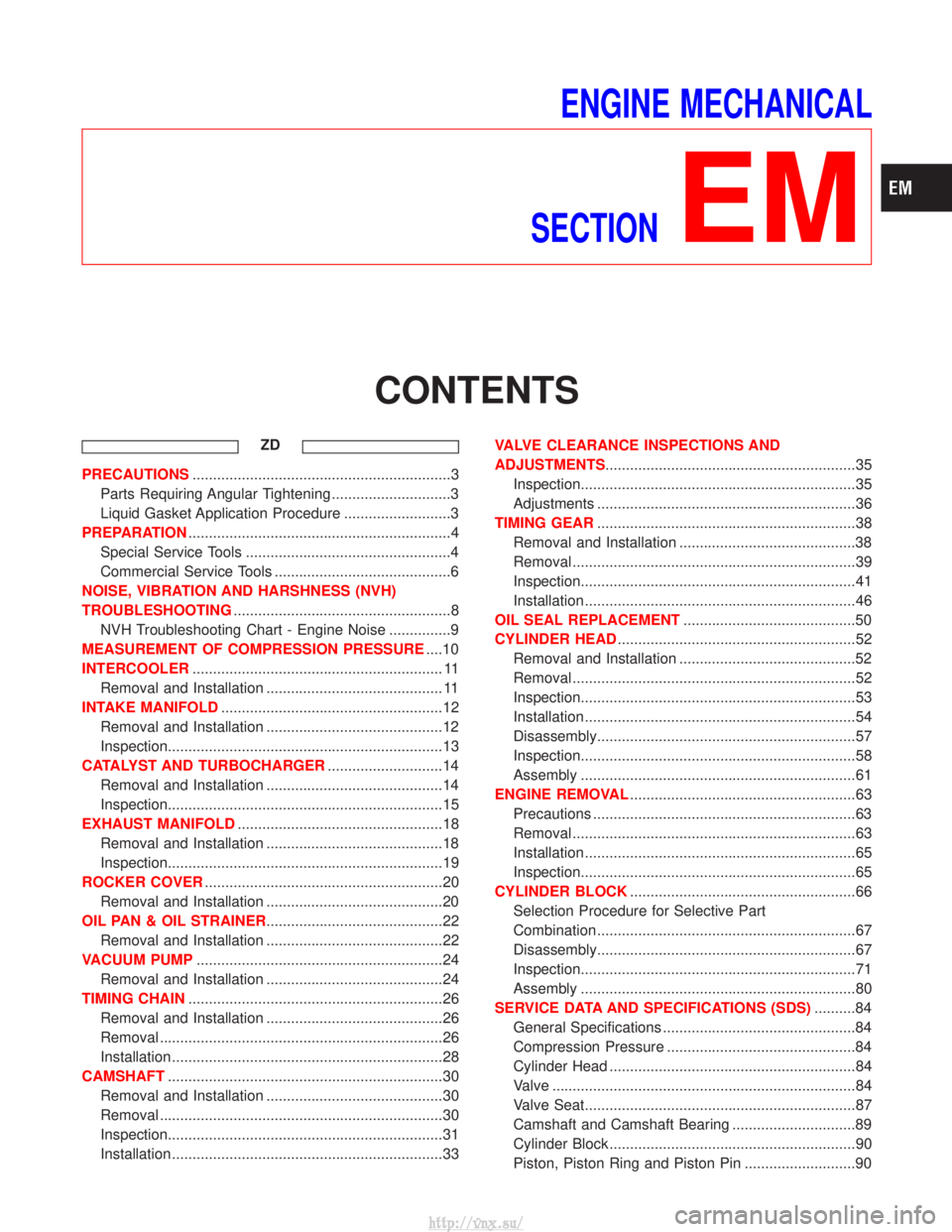

ENGINE MECHANICAL

SECTION

EM

CONTENTS

ZD

PRECAUTIONS ...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION ................................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .....................................................8

NVH Troubleshooting Chart - Engine Noise ...............9

MEASUREMENT OF COMPRESSION PRESSURE ....10

INTERCOOLER ............................................................. 11

Removal and Installation ........................................... 11

INTAKE MANIFOLD ......................................................12

Removal and Installation ...........................................12

Inspection...................................................................13

CATALYST AND TURBOCHARGER ............................14

Removal and Installation ...........................................14

Inspection...................................................................15

EXHAUST MANIFOLD ..................................................18

Removal and Installation ...........................................18

Inspection...................................................................19

ROCKER COVER ..........................................................20

Removal and Installation ...........................................20

OIL PAN & OIL STRAINER ...........................................22

Removal and Installation ...........................................22

VACUUM PUMP ............................................................24

Removal and Installation ...........................................24

TIMING CHAIN ..............................................................26

Removal and Installation ...........................................26

Removal .....................................................................26

Installation ..................................................................28

CAMSHAFT ...................................................................30

Removal and Installation ...........................................30

Removal .....................................................................30

Inspection...................................................................31

Installation ..................................................................33 VALVE CLEARANCE INSPECTIONS AND

ADJUSTMENTS

.............................................................35

Inspection...................................................................35

Adjustments ...............................................................36

TIMING GEAR ...............................................................38

Removal and Installation ...........................................38

Removal .....................................................................39

Inspection...................................................................41

Installation ..................................................................46

OIL SEAL REPLACEMENT ..........................................50

CYLINDER HEAD ..........................................................52

Removal and Installation ...........................................52

Removal .....................................................................52

Inspection...................................................................53

Installation ..................................................................54

Disassembly...............................................................57

Inspection...................................................................58

Assembly ...................................................................61

ENGINE REMOVAL .......................................................63

Precautions ................................................................63

Removal .....................................................................63

Installation ..................................................................65

Inspection...................................................................65

CYLINDER BLOCK .......................................................66

Selection Procedure for Selective Part

Combination ...............................................................67

Disassembly...............................................................67

Inspection...................................................................71

Assembly ...................................................................80

SERVICE DATA AND SPECIFICATIONS (SDS) ..........84

General Specifications ...............................................84

Compression Pressure ..............................................84

Cylinder Head ............................................................84

Valve ........................................................................\

..84

Valve Seat..................................................................87

Camshaft and Camshaft Bearing ..............................89

Cylinder Block ............................................................90

Piston, Piston Ring and Piston Pin ...........................90

http://vnx.su/

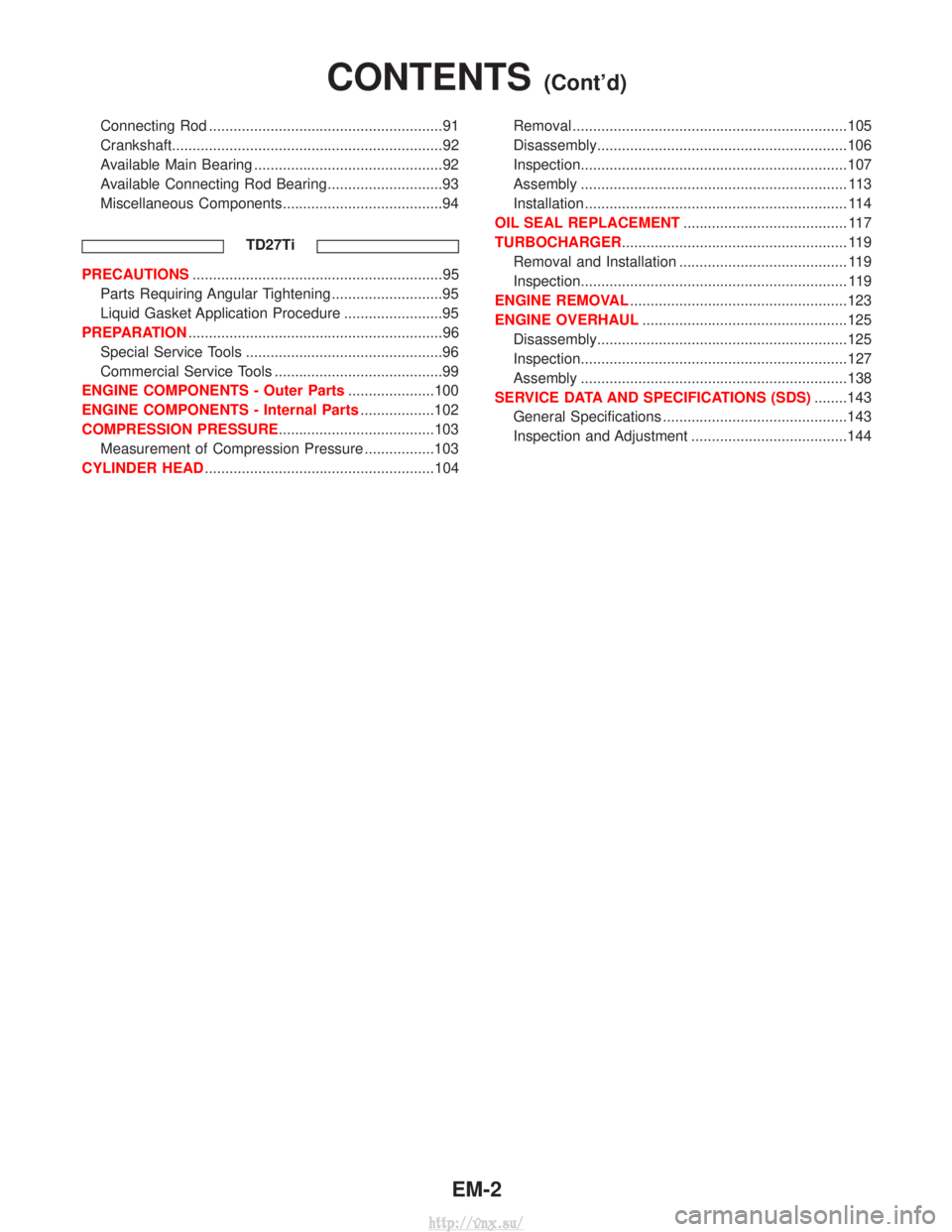

Page 93 of 1833

Connecting Rod .........................................................91

Crankshaft..................................................................92

Available Main Bearing ..............................................92

Available Connecting Rod Bearing............................93

Miscellaneous Components.......................................94TD27Ti

PRECAUTIONS.............................................................95

Parts Requiring Angular Tightening ...........................95

Liquid Gasket Application Procedure ........................95

PREPARATION ..............................................................96

Special Service Tools ................................................96

Commercial Service Tools .........................................99

ENGINE COMPONENTS - Outer Parts .....................100

ENGINE COMPONENTS - Internal Parts ..................102

COMPRESSION PRESSURE......................................103 Measurement of Compression Pressure .................103

CYLINDER HEAD ........................................................104 Removal ...................................................................105

Disassembly.............................................................106

Inspection.................................................................107

Assembly ................................................................. 113

Installation ................................................................ 114

OIL SEAL REPLACEMENT ........................................ 117

TURBOCHARGER ....................................................... 119

Removal and Installation ......................................... 119

Inspection................................................................. 119

ENGINE REMOVAL .....................................................123

ENGINE OVERHAUL ..................................................125

Disassembly.............................................................125

Inspection.................................................................127

Assembly .................................................................138

SERVICE DATA AND SPECIFICATIONS (SDS) ........143

General Specifications .............................................143

Inspection and Adjustment ......................................144

CONTENTS(Cont'd)

EM-2

http://vnx.su/

Page 96 of 1833

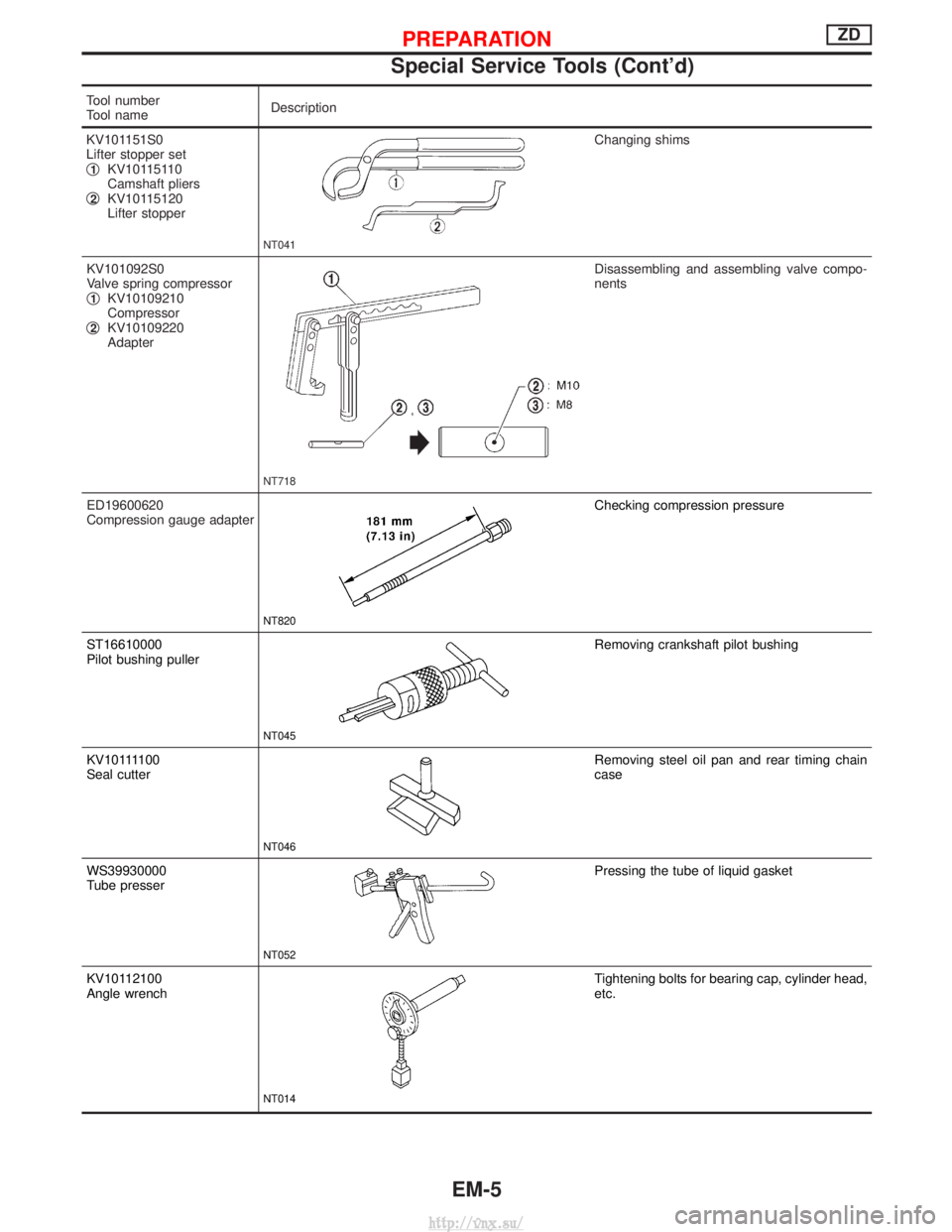

Tool number

Tool nameDescription

KV101151S0

Lifter stopper set

q

1KV10115110

Camshaft pliers

q

2KV10115120

Lifter stopper

NT041

Changing shims

KV101092S0

Valve spring compressor

q

1KV10109210

Compressor

q

2KV10109220

Adapter

NT718

Disassembling and assembling valve compo-

nents

ED19600620

Compression gauge adapter

NT820

Checking compression pressure

ST16610000

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV101111 0 0

Seal cutter

NT046

Removing steel oil pan and rear timing chain

case

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder head,

etc.

PREPARATIONZD

Special Service Tools (Cont'd)

EM-5

http://vnx.su/

Page 101 of 1833

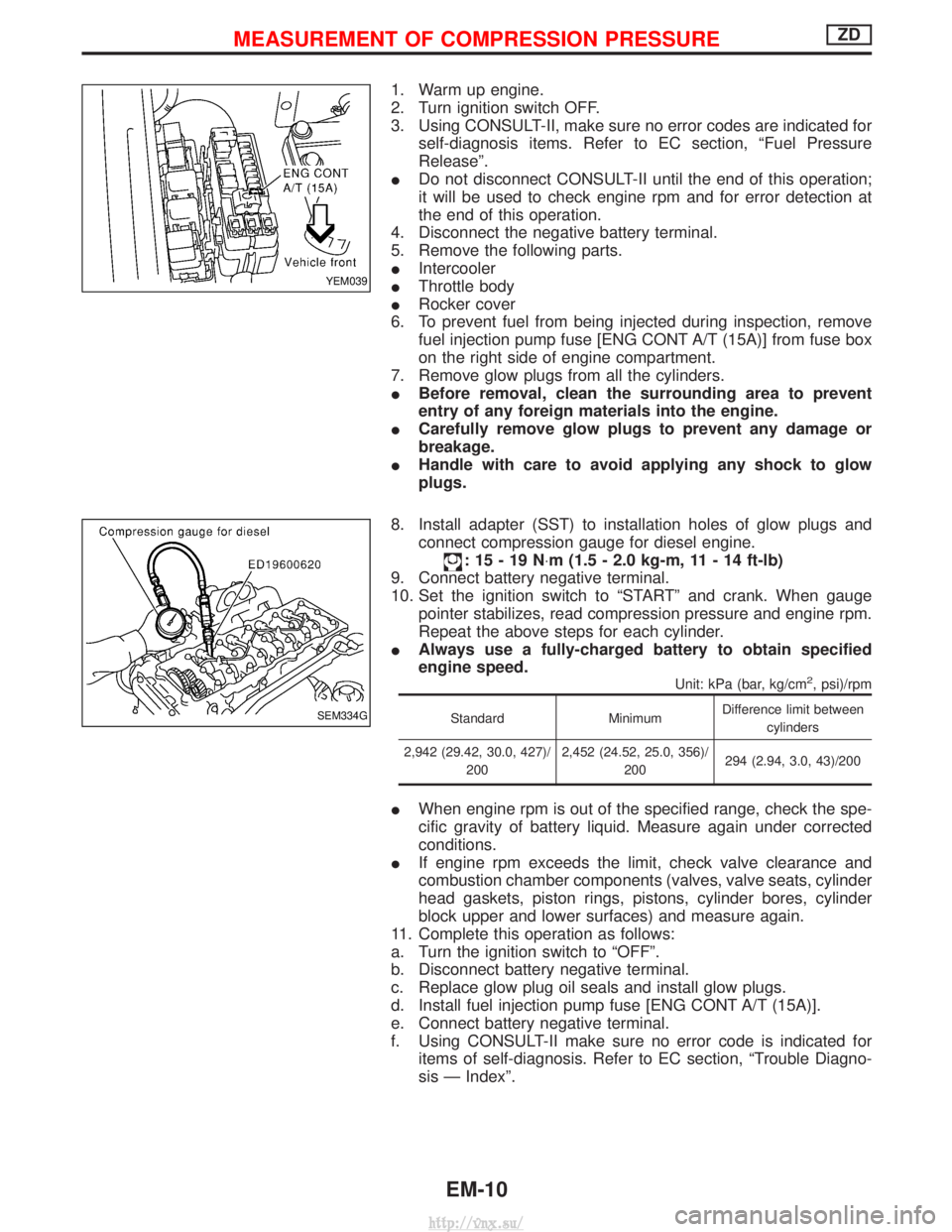

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated forself-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

I Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

I Intercooler

I Throttle body

I Rocker cover

6. To prevent fuel from being injected during inspection, remove fuel injection pump fuse [ENG CONT A/T (15A)] from fuse box

on the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

I Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

I Carefully remove glow plugs to prevent any damage or

breakage.

I Handle with care to avoid applying any shock to glow

plugs.

8. Install adapter (SST) to installation holes of glow plugs and connect compression gauge for diesel engine.

:15-19N ×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

I Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/ 200 2,452 (24.52, 25.0, 356)/

200 294 (2.94, 3.0, 43)/200

I

When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

I If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylinder

head gaskets, piston rings, pistons, cylinder bores, cylinder

block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT A/T (15A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for items of self-diagnosis. Refer to EC section, ªTrouble Diagno-

sis Ð Indexº.

YEM039

SEM334G

MEASUREMENT OF COMPRESSION PRESSUREZD

EM-10

http://vnx.su/