speedometer NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1230 of 1833

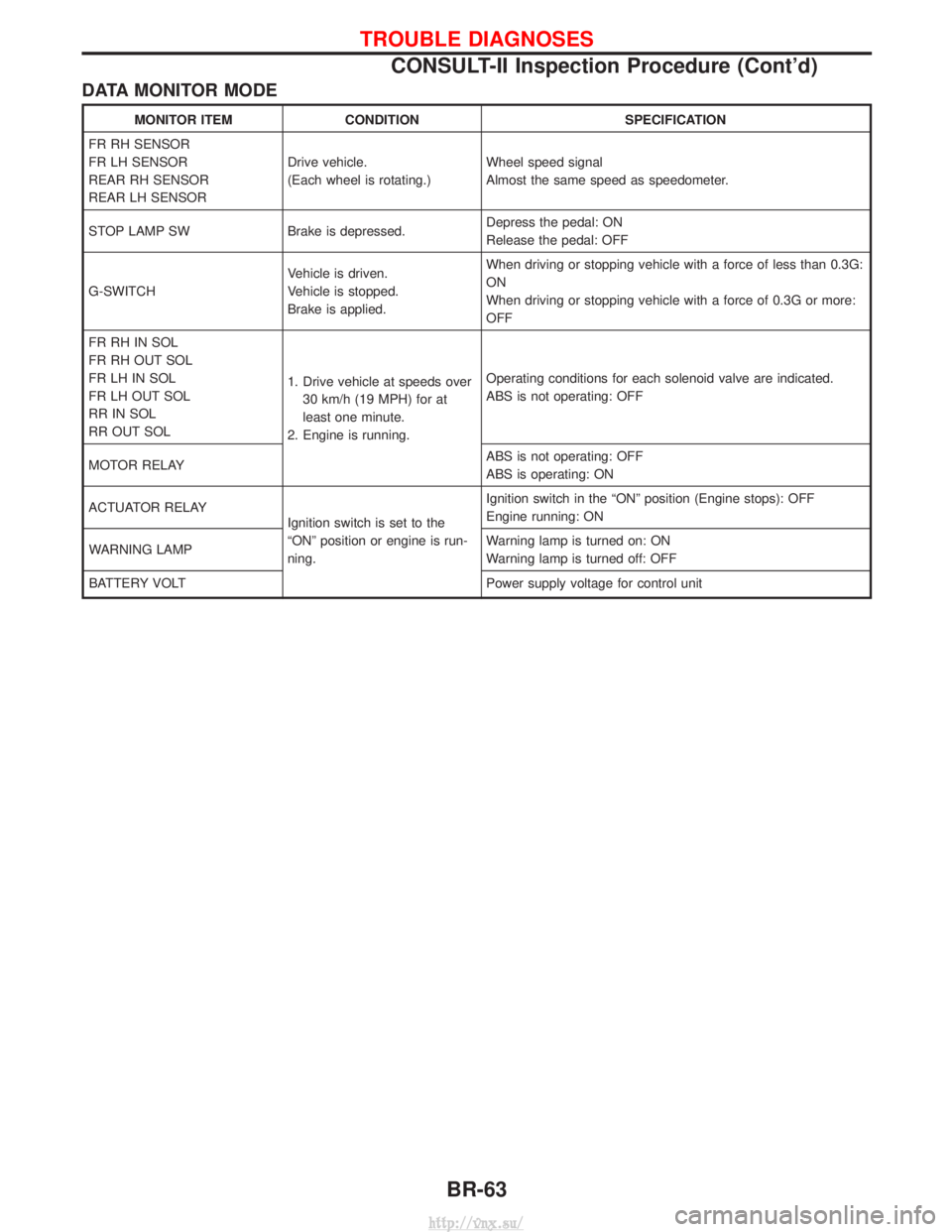

DATA MONITOR MODE

MONITOR ITEMCONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

REAR RH SENSOR

REAR LH SENSOR Drive vehicle.

(Each wheel is rotating.)

Wheel speed signal

Almost the same speed as speedometer.

STOP LAMP SW Brake is depressed. Depress the pedal: ON

Release the pedal: OFF

G-SWITCH Vehicle is driven.

Vehicle is stopped.

Brake is applied.When driving or stopping vehicle with a force of less than 0.3G:

ON

When driving or stopping vehicle with a force of 0.3G or more:

OFF

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL 1. Drive vehicle at speeds over

30 km/h (19 MPH) for at

least one minute.

2. Engine is running. Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

MOTOR RELAY ABS is not operating: OFF

ABS is operating: ON

ACTUATOR RELAY Ignition switch is set to the

ªONº position or engine is run-

ning.Ignition switch in the ªONº position (Engine stops): OFF

Engine running: ON

WARNING LAMP Warning lamp is turned on: ON

Warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

TROUBLE DIAGNOSES

CONSULT-II Inspection Procedure (Cont'd)

BR-63

http://vnx.su/

Page 1575 of 1833

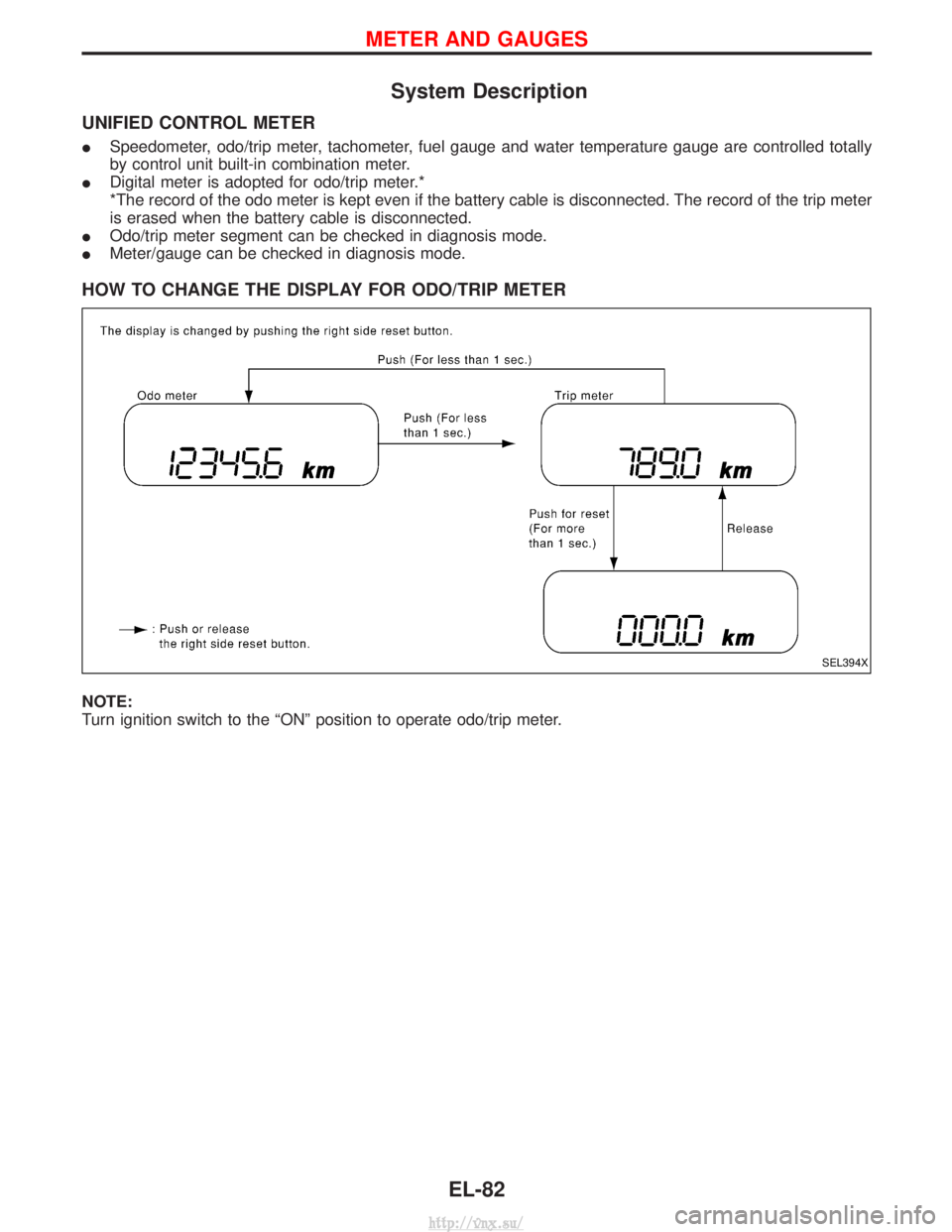

System Description

UNIFIED CONTROL METER

ISpeedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled totally

by control unit built-in combination meter.

I Digital meter is adopted for odo/trip meter.*

*The record of the odo meter is kept even if the battery cable is disconnected. The record of the trip meter

is erased when the battery cable is disconnected.

I Odo/trip meter segment can be checked in diagnosis mode.

I Meter/gauge can be checked in diagnosis mode.

HOW TO CHANGE THE DISPLAY FOR ODO/TRIP METER

NOTE:

Turn ignition switch to the ªONº position to operate odo/trip meter.

SEL394X

METER AND GAUGES

EL-82

http://vnx.su/

Page 1576 of 1833

![NISSAN TERRANO 2004 Service User Guide POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or STA NISSAN TERRANO 2004 Service User Guide POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or STA](/img/5/57394/w960_57394-1575.png)

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

I through 10A fuse [No. 12, located in the fuse block (J/B)]

I to combination meter terminal 28.

Ground is supplied

I through body grounds F36, F47 (LHD models) or M33, M754 (RHD models)

I to combination meter terminal 29.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

Thermal transmitter provides a engine coolant temperature signal to combination meter for water temperature

gauge.

TACHOMETER

The tachometer indicates engine speed in revolution per minutes (rpm). ECM provides an engine speed sig-

nal to combination meter for tachometer.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

Ifrom body grounds B10 and B18

I through terminal 3 of the fuel level sensor unit and

I through terminal 2 (TD27Ti engine) or 1 (ZD30DDTi engine) of the fuel level sensor unit

I to combination meter terminal 13 for the fuel gauge.

SPEEDOMETER

The combination meter receives a signal from vehicle speed sensor. The speedometer converts the signal into

the vehicle speed displayed.

AMBIENT TEMPERATURE GAUGE

Ambient temperature sensor provides the signal for ambient temperature to combination meter.

METER AND GAUGES

System Description (Cont'd)

EL-83

http://vnx.su/

Page 1583 of 1833

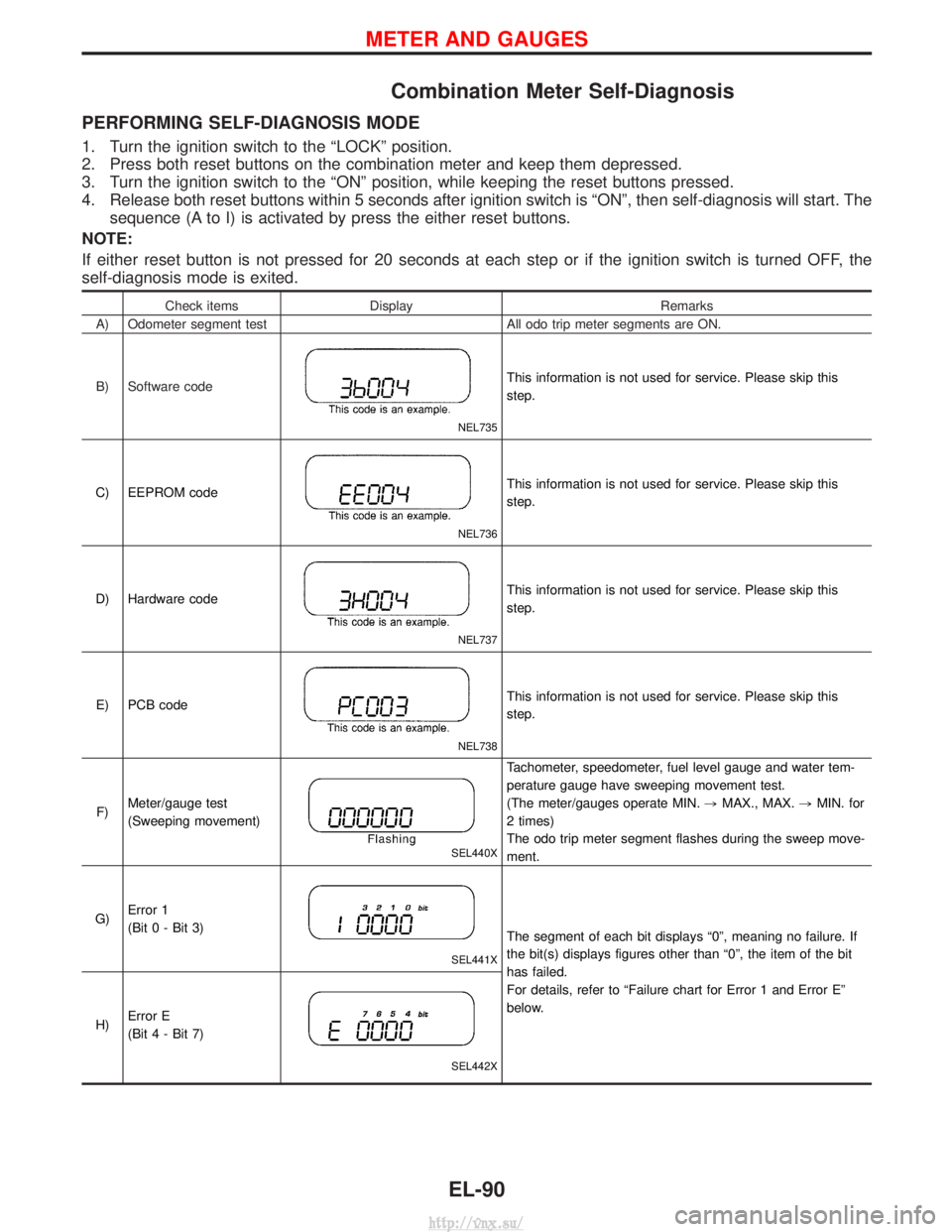

Combination Meter Self-Diagnosis

PERFORMING SELF-DIAGNOSIS MODE

1. Turn the ignition switch to the ªLOCKº position.

2. Press both reset buttons on the combination meter and keep them depressed.

3. Turn the ignition switch to the ªONº position, while keeping the reset buttons pressed.

4. Release both reset buttons within 5 seconds after ignition switch is ªONº, then self-diagnosis will start. Thesequence (A to I) is activated by press the either reset buttons.

NOTE:

If either reset button is not pressed for 20 seconds at each step or if the ignition switch is turned OFF, the

self-diagnosis mode is exited.

Check items Display Remarks

A) Odometer segment test All odo trip meter segments are ON.

B) Software code

NEL735

This information is not used for service. Please skip this

step.

C) EEPROM code

NEL736

This information is not used for service. Please skip this

step.

D) Hardware code

NEL737

This information is not used for service. Please skip this

step.

E) PCB code

NEL738

This information is not used for service. Please skip this

step.

F) Meter/gauge test

(Sweeping movement)

SEL440X

Tachometer, speedometer, fuel level gauge and water tem-

perature gauge have sweeping movement test.

(The meter/gauges operate MIN.

,MAX., MAX. ,MIN. for

2 times)

The odo trip meter segment flashes during the sweep move-

ment.

G) Error 1

(Bit 0 - Bit 3)

SEL441X

The segment of each bit displays ª0º, meaning no failure. If

the bit(s) displays figures other than ª0º, the item of the bit

has failed.

For details, refer to ªFailure chart for Error 1 and Error Eº

below.

H) Error E

(Bit 4 - Bit 7)

SEL442X

METER AND GAUGES

EL-90

http://vnx.su/

Page 1584 of 1833

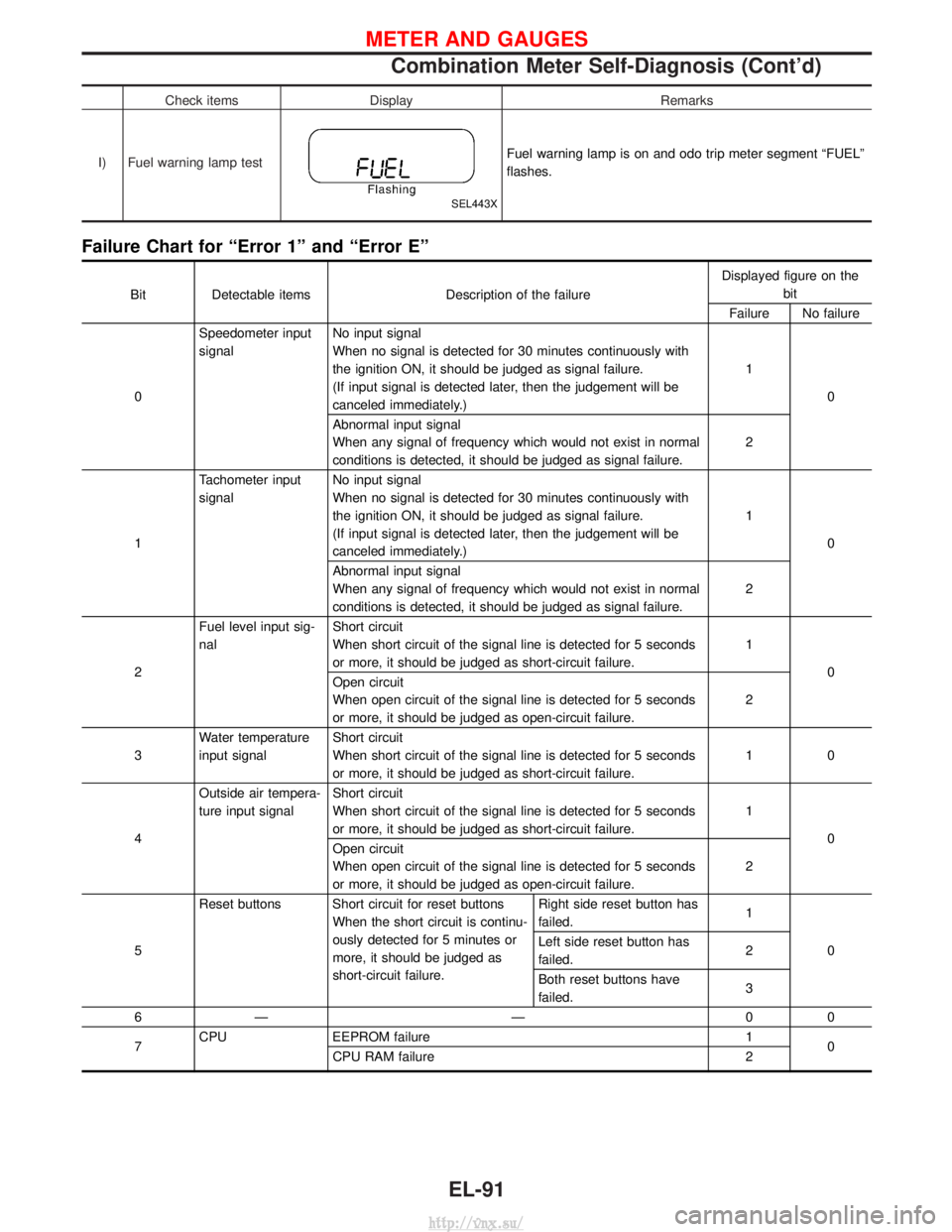

Check itemsDisplay Remarks

I) Fuel warning lamp test

SEL443X

Fuel warning lamp is on and odo trip meter segment ªFUELº

flashes.

Failure Chart for ªError 1º and ªError Eº

Bit Detectable items Description of the failureDisplayed figure on the

bit

Failure No failure

0 Speedometer input

signal

No input signal

When no signal is detected for 30 minutes continuously with

the ignition ON, it should be judged as signal failure.

(If input signal is detected later, then the judgement will be

canceled immediately.) 1

0

Abnormal input signal

When any signal of frequency which would not exist in normal

conditions is detected, it should be judged as signal failure. 2

1 Tachometer input

signal

No input signal

When no signal is detected for 30 minutes continuously with

the ignition ON, it should be judged as signal failure.

(If input signal is detected later, then the judgement will be

canceled immediately.) 1

0

Abnormal input signal

When any signal of frequency which would not exist in normal

conditions is detected, it should be judged as signal failure. 2

2 Fuel level input sig-

nal

Short circuit

When short circuit of the signal line is detected for 5 seconds

or more, it should be judged as short-circuit failure. 1

0

Open circuit

When open circuit of the signal line is detected for 5 seconds

or more, it should be judged as open-circuit failure. 2

3 Water temperature

input signal Short circuit

When short circuit of the signal line is detected for 5 seconds

or more, it should be judged as short-circuit failure. 10

4 Outside air tempera-

ture input signal

Short circuit

When short circuit of the signal line is detected for 5 seconds

or more, it should be judged as short-circuit failure. 1

0

Open circuit

When open circuit of the signal line is detected for 5 seconds

or more, it should be judged as open-circuit failure. 2

5 Reset buttons Short circuit for reset buttons

When the short circuit is continu-

ously detected for 5 minutes or

more, it should be judged as

short-circuit failure. Right side reset button has

failed.

1

0

Left side reset button has

failed. 2

Both reset buttons have

failed. 3

6Ð Ð 00

7 CPU EEPROM failure 1

0

CPU RAM failure 2

METER AND GAUGES

Combination Meter Self-Diagnosis (Cont'd)

EL-91

http://vnx.su/

Page 1586 of 1833

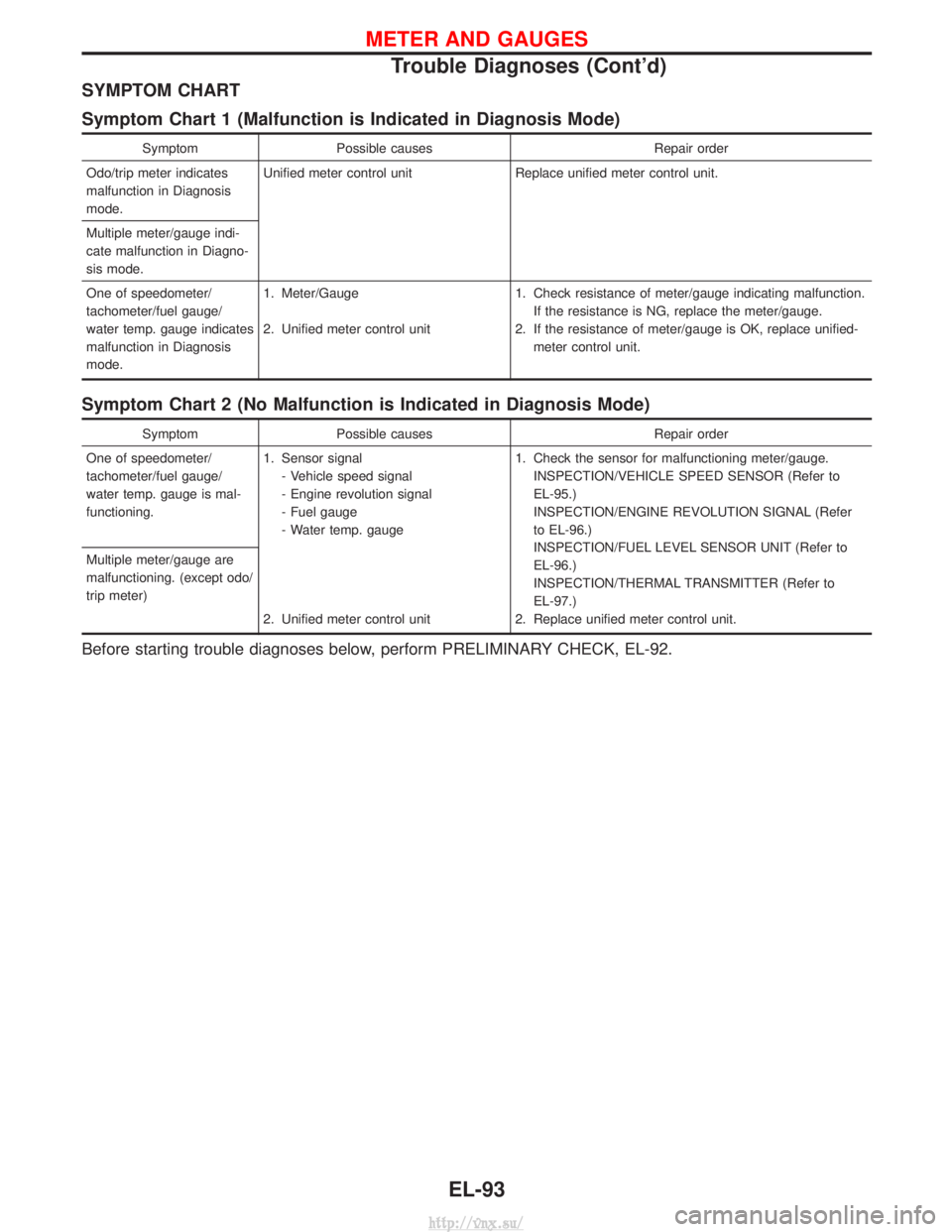

SYMPTOM CHART

Symptom Chart 1 (Malfunction is Indicated in Diagnosis Mode)

SymptomPossible causes Repair order

Odo/trip meter indicates

malfunction in Diagnosis

mode. Unified meter control unit

Replace unified meter control unit.

Multiple meter/gauge indi-

cate malfunction in Diagno-

sis mode.

One of speedometer/

tachometer/fuel gauge/

water temp. gauge indicates

malfunction in Diagnosis

mode. 1. Meter/Gauge

2. Unified meter control unit

1. Check resistance of meter/gauge indicating malfunction.

If the resistance is NG, replace the meter/gauge.

2. If the resistance of meter/gauge is OK, replace unified- meter control unit.

Symptom Chart 2 (No Malfunction is Indicated in Diagnosis Mode)

Symptom Possible causes Repair order

One of speedometer/

tachometer/fuel gauge/

water temp. gauge is mal-

functioning. 1. Sensor signal

- Vehicle speed signal

- Engine revolution signal

- Fuel gauge

- Water temp. gauge

2. Unified meter control unit 1. Check the sensor for malfunctioning meter/gauge.

INSPECTION/VEHICLE SPEED SENSOR (Refer to

EL-95.)

INSPECTION/ENGINE REVOLUTION SIGNAL (Refer

to EL-96.)

INSPECTION/FUEL LEVEL SENSOR UNIT (Refer to

EL-96.)

INSPECTION/THERMAL TRANSMITTER (Refer to

EL-97.)

2. Replace unified meter control unit.

Multiple meter/gauge are

malfunctioning. (except odo/

trip meter)

Before starting trouble diagnoses below, perform PRELIMINARY CHECK, EL-92.

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-93

http://vnx.su/

Page 1588 of 1833

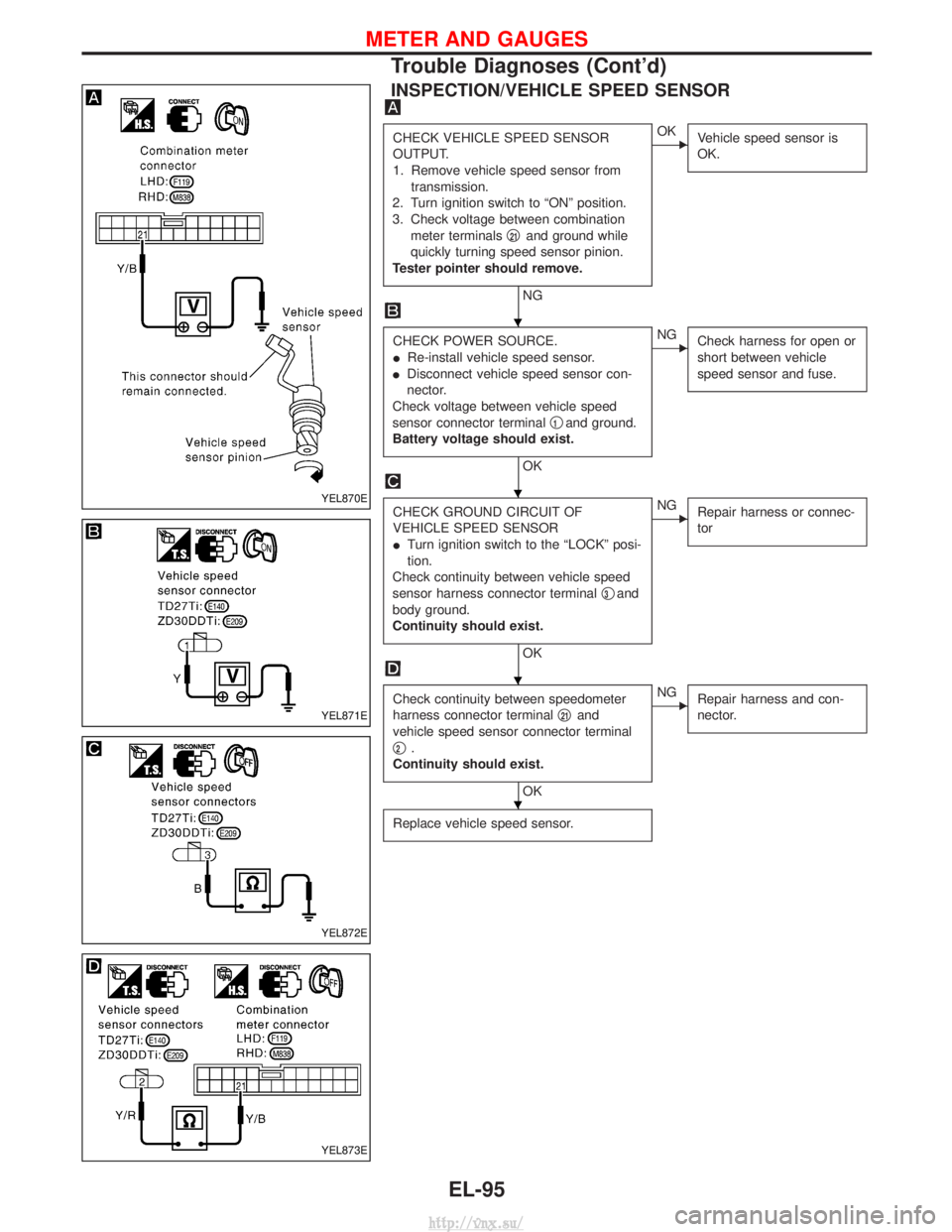

INSPECTION/VEHICLE SPEED SENSOR

CHECK VEHICLE SPEED SENSOR

OUTPUT.

1. Remove vehicle speed sensor fromtransmission.

2. Turn ignition switch to ªONº position.

3. Check voltage between combination meter terminals q

21and ground while

quickly turning speed sensor pinion.

Tester pointer should remove.

NG

EOK Vehicle speed sensor is

OK.

CHECK POWER SOURCE.

IRe-install vehicle speed sensor.

I Disconnect vehicle speed sensor con-

nector.

Check voltage between vehicle speed

sensor connector terminal q

1and ground.

Battery voltage should exist.

OK

ENG Check harness for open or

short between vehicle

speed sensor and fuse.

CHECK GROUND CIRCUIT OF

VEHICLE SPEED SENSOR

ITurn ignition switch to the ªLOCKº posi-

tion.

Check continuity between vehicle speed

sensor harness connector terminal q

3and

body ground.

Continuity should exist.

OK

ENG Repair harness or connec-

tor

Check continuity between speedometer

harness connector terminal q

21and

vehicle speed sensor connector terminal

q

2.

Continuity should exist.

OK

ENG Repair harness and con-

nector.

Replace vehicle speed sensor.

YEL870E

YEL871E

YEL872E

YEL873E

H

H

H

H

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-95

http://vnx.su/

Page 1819 of 1833

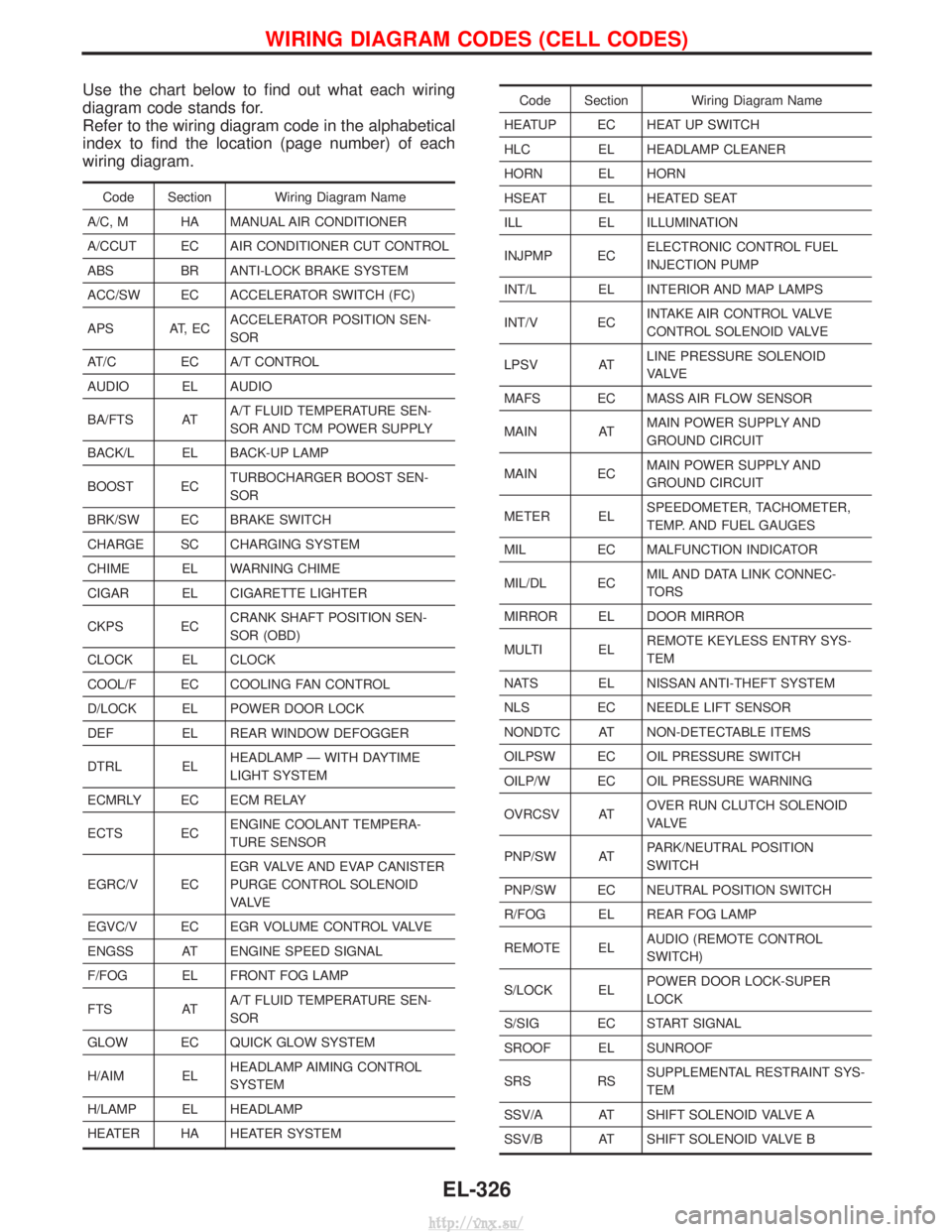

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

A/C, M HA MANUAL AIR CONDITIONER

A/CCUT EC AIR CONDITIONER CUT CONTROL

ABS BR ANTI-LOCK BRAKE SYSTEM

ACC/SW EC ACCELERATOR SWITCH (FC)

APS AT, EC ACCELERATOR POSITION SEN-

SOR

AT/C EC A/T CONTROL

AUDIO EL AUDIO

BA/FTS AT A/T FLUID TEMPERATURE SEN-

SOR AND TCM POWER SUPPLY

BACK/L EL BACK-UP LAMP

BOOST EC TURBOCHARGER BOOST SEN-

SOR

BRK/SW EC BRAKE SWITCH

CHARGE SC CHARGING SYSTEM

CHIME EL WARNING CHIME

CIGAR EL CIGARETTE LIGHTER

CKPS EC CRANK SHAFT POSITION SEN-

SOR (OBD)

CLOCK EL CLOCK

COOL/F EC COOLING FAN CONTROL

D/LOCK EL POWER DOOR LOCK

DEF EL REAR WINDOW DEFOGGER

DTRL EL HEADLAMP Ð WITH DAYTIME

LIGHT SYSTEM

ECMRLY EC ECM RELAY

ECTS EC ENGINE COOLANT TEMPERA-

TURE SENSOR

EGRC/V EC EGR VALVE AND EVAP CANISTER

PURGE CONTROL SOLENOID

VA LV E

EGVC/V EC EGR VOLUME CONTROL VALVE

ENGSS AT ENGINE SPEED SIGNAL

F/FOG EL FRONT FOG LAMP

FTS AT A/T FLUID TEMPERATURE SEN-

SOR

GLOW EC QUICK GLOW SYSTEM

H/AIM EL HEADLAMP AIMING CONTROL

SYSTEM

H/LAMP EL HEADLAMP

HEATER HA HEATER SYSTEM

Code Section Wiring Diagram Name

HEATUP EC HEAT UP SWITCH

HLC EL HEADLAMP CLEANER

HORN EL HORN

HSEAT EL HEATED SEAT

ILL EL ILLUMINATION

INJPMP EC ELECTRONIC CONTROL FUEL

INJECTION PUMP

INT/L EL INTERIOR AND MAP LAMPS

INT/V EC INTAKE AIR CONTROL VALVE

CONTROL SOLENOID VALVE

LPSV AT LINE PRESSURE SOLENOID

VA LV E

MAFS EC MASS AIR FLOW SENSOR

MAIN AT MAIN POWER SUPPLY AND

GROUND CIRCUIT

MAIN EC MAIN POWER SUPPLY AND

GROUND CIRCUIT

METER EL SPEEDOMETER, TACHOMETER,

TEMP. AND FUEL GAUGES

MIL EC MALFUNCTION INDICATOR

MIL/DL EC MIL AND DATA LINK CONNEC-

TORS

MIRROR EL DOOR MIRROR

MULTI EL REMOTE KEYLESS ENTRY SYS-

TEM

NATS EL NISSAN ANTI-THEFT SYSTEM

NLS EC NEEDLE LIFT SENSOR

NONDTC AT NON-DETECTABLE ITEMS

OILPSW EC OIL PRESSURE SWITCH

OILP/W EC OIL PRESSURE WARNING

OVRCSV AT OVER RUN CLUTCH SOLENOID

VA LV E

PNP/SW AT PARK/NEUTRAL POSITION

SWITCH

PNP/SW EC NEUTRAL POSITION SWITCH

R/FOG EL REAR FOG LAMP

REMOTE EL AUDIO (REMOTE CONTROL

SWITCH)

S/LOCK EL POWER DOOR LOCK-SUPER

LOCK

S/SIG EC START SIGNAL

SROOF EL SUNROOF

SRS RS SUPPLEMENTAL RESTRAINT SYS-

TEM

SSV/A AT SHIFT SOLENOID VALVE A

SSV/B AT SHIFT SOLENOID VALVE B

WIRING DIAGRAM CODES (CELL CODES)

EL-326

http://vnx.su/

Page 1831 of 1833

Power steering hydraulic pressure ...................ST-7

Power steering oil pump ...........................ST-16, 22

Power steering system bleeding.......................ST-5

Power supply routing ..................................EL-8, 10

Power window.......................................EL-156, 158

Pre-delivery inspection.....................................MA-3

Priming pump .................................................EC-50

Propeller shaft ............................................PD-5, 57

Propeller shaft greasing...........................MA-36, 38

Propeller shaft inspection ........................MA-36, 38

Propeller shaft on vehicle service ....................PD-6

Pump communication line (ElectronicFuel Injection Pump) ................................EC-180

Pump control module (Electronic Fuel Injection Pump).........................................EC-194

R

Radiator ....................................................LC-14, 32

Rear axle................................................RA-4, 6, 12

Rear bumper .....................................................BT-8

Rear case (Transfer)...................................TF-9, 24

Rear combination lamp removal andinstallation .....................................................BT-8

Rear door ........................................................BT-12

Rear door trim...........................................BT-18, 19

Rear drum brake ............................................BR-32

Rear fog lamp .................................................EL-58

Rear side window .....................................BT-21, 43

Rear suspension ........................................RA-4, 12

Rear window defogger .................EL-125, 132, 133

Refrigerant connection precaution ...................HA-4

Refrigerant general precaution.........................HA-3

Refrigerant lines .............................................HA-17

Refrigeration cycle............................................HA-9

REMOTE - Wiring diagram ...........................EL-145

Removal and installation (A/T)......................AT-121

Removal and installation (Transfer) ..................TF-7

Reverse clutch ..............................................AT-156

Reverse idler shaft (M/T)................................MT-11

Reverse main gear (M/T) ...............................MT-11

Revolution sensor (A/T) ..........................AT-52, 119

R/FOG - Wiring diagram .................................EL-58

Ring gear diff. inspection .........................PD-20, 42

Rocker cover ..................................................EM-20

Roof trim .........................................................BT-20

Rotor disc (front) .............................................FA-18

S

Screw jack .......................................................GI-31

Seal - See Exterior .........................................BT-21

Seat belt inspection .................................MA-36, 45

Seat belt pre-tensioner ...............................RS-2, 11

Seat belt pre-tensioner disposal ....................RS-22

Seat belt, front ..................................................RS-4

Seat, front .......................................................BT-34

Seat, second (2nd) .........................................BT-37 Seat, third (3rd) ...............................................BT-39

Second (2nd) seat ..........................................BT-37

Self-diagnostic results ............................EC-35, 347

Shift control (Transfer) ..............................TF-11, 24

Shift control components

(M/T) ............................MT-13, 14, 15, 21, 23, 31

Shift fork (M/T) ...............................................MT-13

Shift schedule................................................AT-201

Shift solenoid valve A (A/T).............................AT-65

Shift solenoid valve B (A/T) ............................AT-68

Shock absorber (front) ....................................FA-30

Shock absorber (rear) ..............................RA-14, 16

Side air bag ....................................................RS-20

Side air bag (satellite) sensor ........................RS-15

Side bearing preload diff. ...............................PD-24

Side trim....................................................BT-18, 21

Side window - See Rear side window ............BT-21

S/LOCK - Wiring diagram .............................EL-184

SMJ (super multiple junction) .......................Foldout

Speedometer...................................................EL-86

Spill valve .....................................................EC-187

Spiral cable.....................................................RS-16

SROOF - Wiring diagram .............................EL-153

SRS - See Supplemental Restraint System ..........................................................RS-8

SRS - Wiring diagram ....................................RS-34

SRS Trouble diagnoses .................................RS-28

S/SIG - Wiring diagram ................................EC-253

Stabilizer bar (front) ....................................FA-4, 33

Stabilizer bar (rear) ..................................RA-15, 16

Stall test (A/T) .........................................AT-27, 201

Standardized relay ............................................EL-6

START - Wiring diagram ................................SC-14

Start signal ...................................................EC-253

Starter .............................................................SC-17

Starting system...............................................SC-13

Steering gear and linkage inspection ......MA-36, 43

Steering gear oil level ..............................MA-36, 44

Steering gear, linkage and transfer gear inspection ..............................MA-36, 43, 44

Steering linkage ........................................ST-17, 22

Steering switch................................................EL-27

Steering wheel and column ........................ST-8, 22

Steering wheel play ..........................................ST-4

Steering wheel turning force .............................ST-6

Stop lamp ........................................................EL-52

Stop lamp switch ..................................EC-209, 426

STOP/L - Wiring diagram................................EL-52

Striking rod (M/T) ...........................................MT-13

Sub-gear (M/T) ...............................................MT-11

Sunroof............................................................BT-40

Sunroof, electric ............................................EL-153

Super lock ....................EL-171, 179, 180, 182, 192

Supplemental Restraint System .......................RS-8

Swirl control valve control solenoid valve .........................................................EC-271

SWL/V - Wiring diagram ..............................EC-273

Symptom matrix chart ............................EC-56, 363

ALPHABETICAL INDEX

IDX-6

http://vnx.su/