check engine NISSAN TERRANO 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 71 of 1833

3. Drain oil and fill with new engine oil.Oil grade:API CF4 or ACEA B3-96.98 or ACEA B3/E3-96.98

Viscosity: See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-1009.

Refill oil capacity (approximate): Without oil filter change5.2 (4-5/8 Imp qt)

With oil filter change 5.7 (5 Imp qt)

CAUTION:

I Be sure to clean and install oil pan drain plug with washer.

Drain plug:

:54-58N ×m (5.5 - 6.0 kg-m, 40 - 43 ft-lb)

I The refill capacity changes depending on the oil tempera-

ture and drain time; use these valves as a reference and be

certain to check with the dipstick when changing the oil.

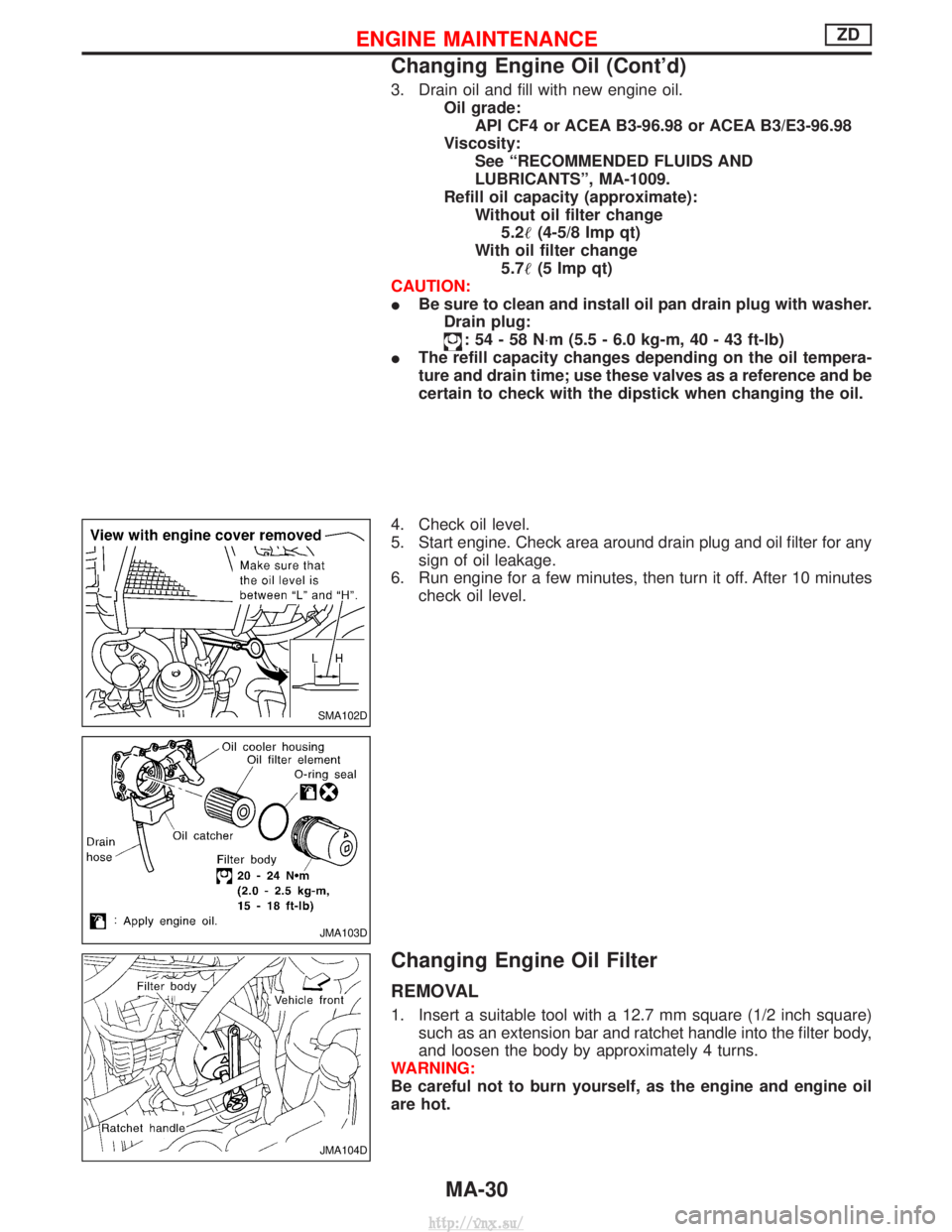

4. Check oil level.

5. Start engine. Check area around drain plug and oil filter for any sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After 10 minutes check oil level.

Changing Engine Oil Filter

REMOVAL

1. Insert a suitable tool with a 12.7 mm square (1/2 inch square)such as an extension bar and ratchet handle into the filter body,

and loosen the body by approximately 4 turns.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

SMA102D

JMA103D

JMA104D

ENGINE MAINTENANCEZD

Changing Engine Oil (Cont'd)

MA-30

http://vnx.su/

Page 72 of 1833

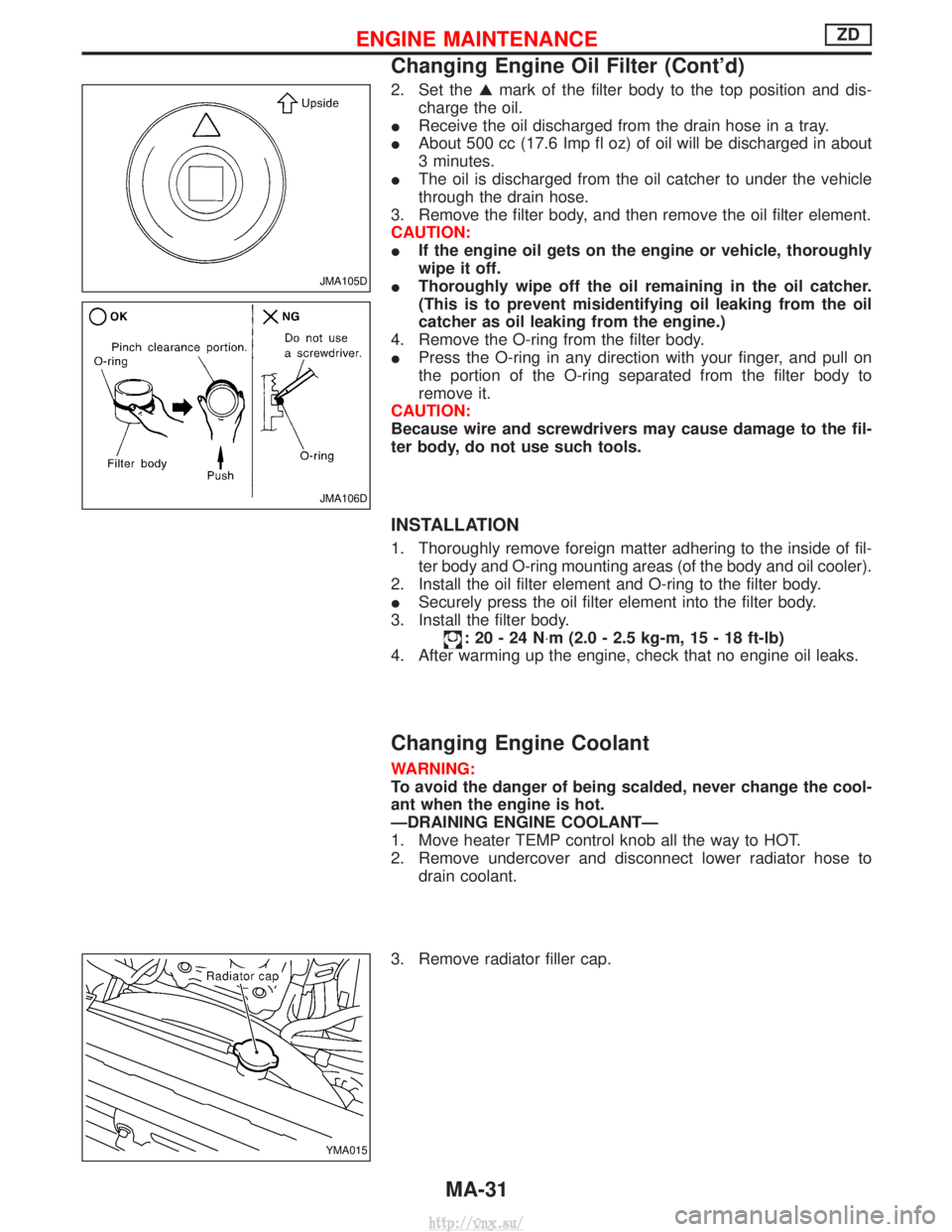

2. Set theGmark of the filter body to the top position and dis-

charge the oil.

I Receive the oil discharged from the drain hose in a tray.

I About 500 cc (17.6 Imp fl oz) of oil will be discharged in about

3 minutes.

I The oil is discharged from the oil catcher to under the vehicle

through the drain hose.

3. Remove the filter body, and then remove the oil filter element.

CAUTION:

I If the engine oil gets on the engine or vehicle, thoroughly

wipe it off.

I Thoroughly wipe off the oil remaining in the oil catcher.

(This is to prevent misidentifying oil leaking from the oil

catcher as oil leaking from the engine.)

4. Remove the O-ring from the filter body.

I Press the O-ring in any direction with your finger, and pull on

the portion of the O-ring separated from the filter body to

remove it.

CAUTION:

Because wire and screwdrivers may cause damage to the fil-

ter body, do not use such tools.

INSTALLATION

1. Thoroughly remove foreign matter adhering to the inside of fil- ter body and O-ring mounting areas (of the body and oil cooler).

2. Install the oil filter element and O-ring to the filter body.

I Securely press the oil filter element into the filter body.

3. Install the filter body.

:20-24N ×m (2.0 - 2.5 kg-m, 15 - 18 ft-lb)

4. After warming up the engine, check that no engine oil leaks.

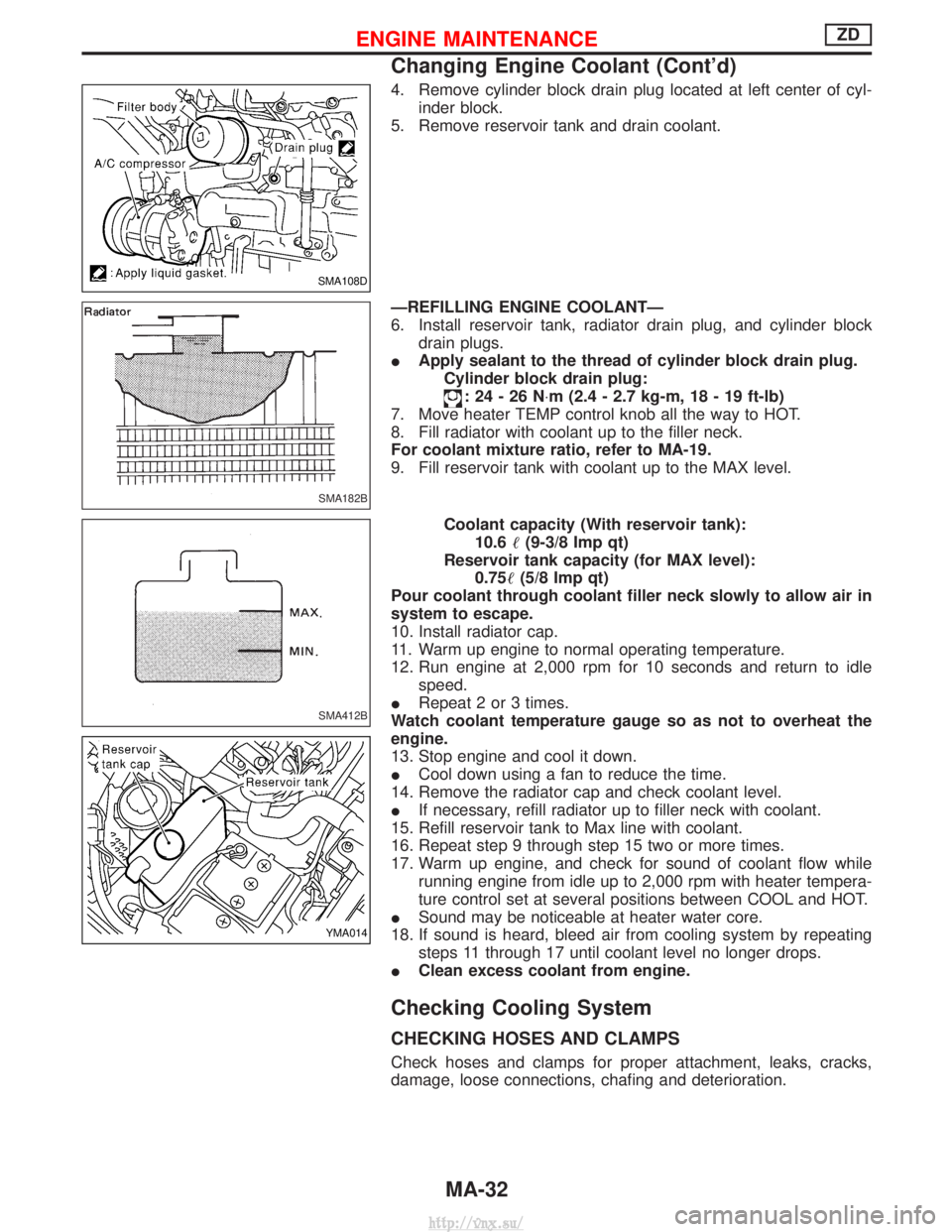

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never change the cool-

ant when the engine is hot.

ÐDRAINING ENGINE COOLANTÐ

1. Move heater TEMP control knob all the way to HOT.

2. Remove undercover and disconnect lower radiator hose to drain coolant.

3. Remove radiator filler cap.

JMA105D

JMA106D

YMA015

ENGINE MAINTENANCEZD

Changing Engine Oil Filter (Cont'd)

MA-31

http://vnx.su/

Page 73 of 1833

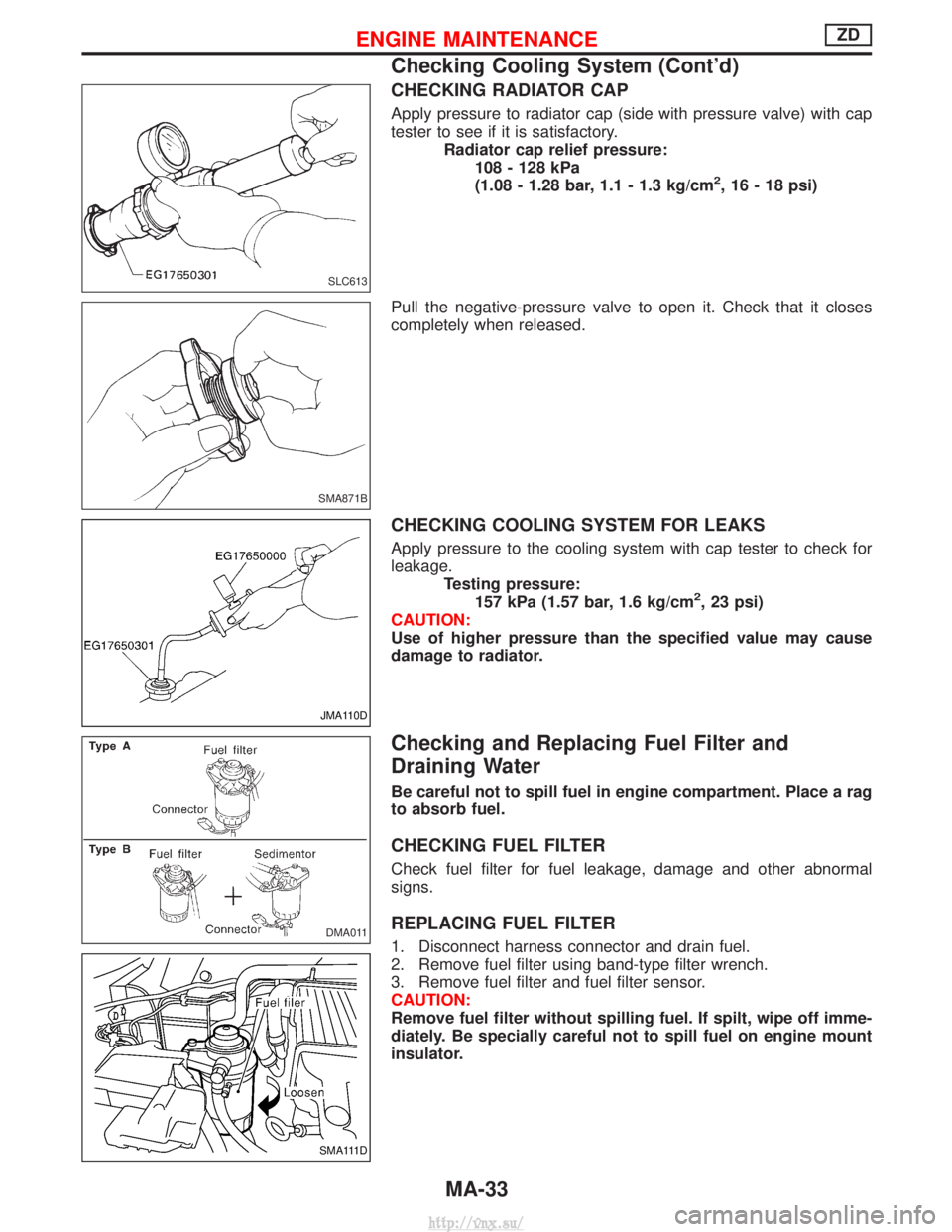

4. Remove cylinder block drain plug located at left center of cyl-inder block.

5. Remove reservoir tank and drain coolant.

ÐREFILLING ENGINE COOLANTÐ

6. Install reservoir tank, radiator drain plug, and cylinder block drain plugs.

I Apply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:24-26N ×m (2.4 - 2.7 kg-m, 18 - 19 ft-lb)

7. Move heater TEMP control knob all the way to HOT.

8. Fill radiator with coolant up to the filler neck.

For coolant mixture ratio, refer to MA-19.

9. Fill reservoir tank with coolant up to the MAX level.

Coolant capacity (With reservoir tank):10.6 (9-3/8 Imp qt)

Reservoir tank capacity (for MAX level): 0.75 (5/8 Imp qt)

Pour coolant through coolant filler neck slowly to allow air in

system to escape.

10. Install radiator cap.

11. Warm up engine to normal operating temperature.

12. Run engine at 2,000 rpm for 10 seconds and return to idle speed.

I Repeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

13. Stop engine and cool it down.

I Cool down using a fan to reduce the time.

14. Remove the radiator cap and check coolant level.

I If necessary, refill radiator up to filler neck with coolant.

15. Refill reservoir tank to Max line with coolant.

16. Repeat step 9 through step 15 two or more times.

17. Warm up engine, and check for sound of coolant flow while running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

I Sound may be noticeable at heater water core.

18. If sound is heard, bleed air from cooling system by repeating steps 11 through 17 until coolant level no longer drops.

I Clean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

SMA108D

SMA182B

SMA412B

YMA014

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-32

http://vnx.su/

Page 74 of 1833

CHECKING RADIATOR CAP

Apply pressure to radiator cap (side with pressure valve) with cap

tester to see if it is satisfactory.Radiator cap relief pressure:108 - 128 kPa

(1.08 - 1.28 bar, 1.1 - 1.3 kg/cm

2, 16 - 18 psi)

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage. Testing pressure:157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off imme-

diately. Be specially careful not to spill fuel on engine mount

insulator.

SLC613

SMA871B

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-33

http://vnx.su/

Page 75 of 1833

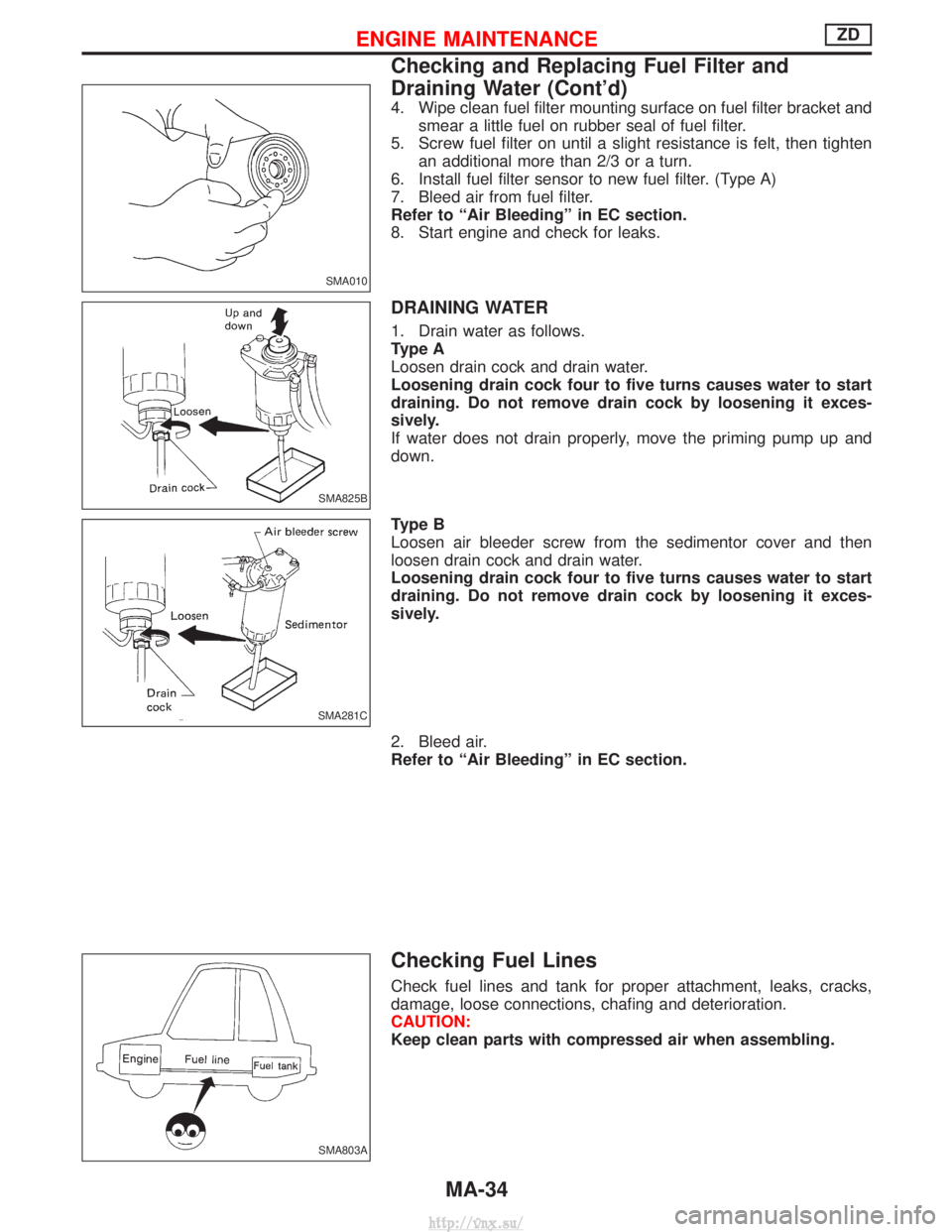

4. Wipe clean fuel filter mounting surface on fuel filter bracket andsmear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten an additional more than 2/3 or a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-34

http://vnx.su/

Page 78 of 1833

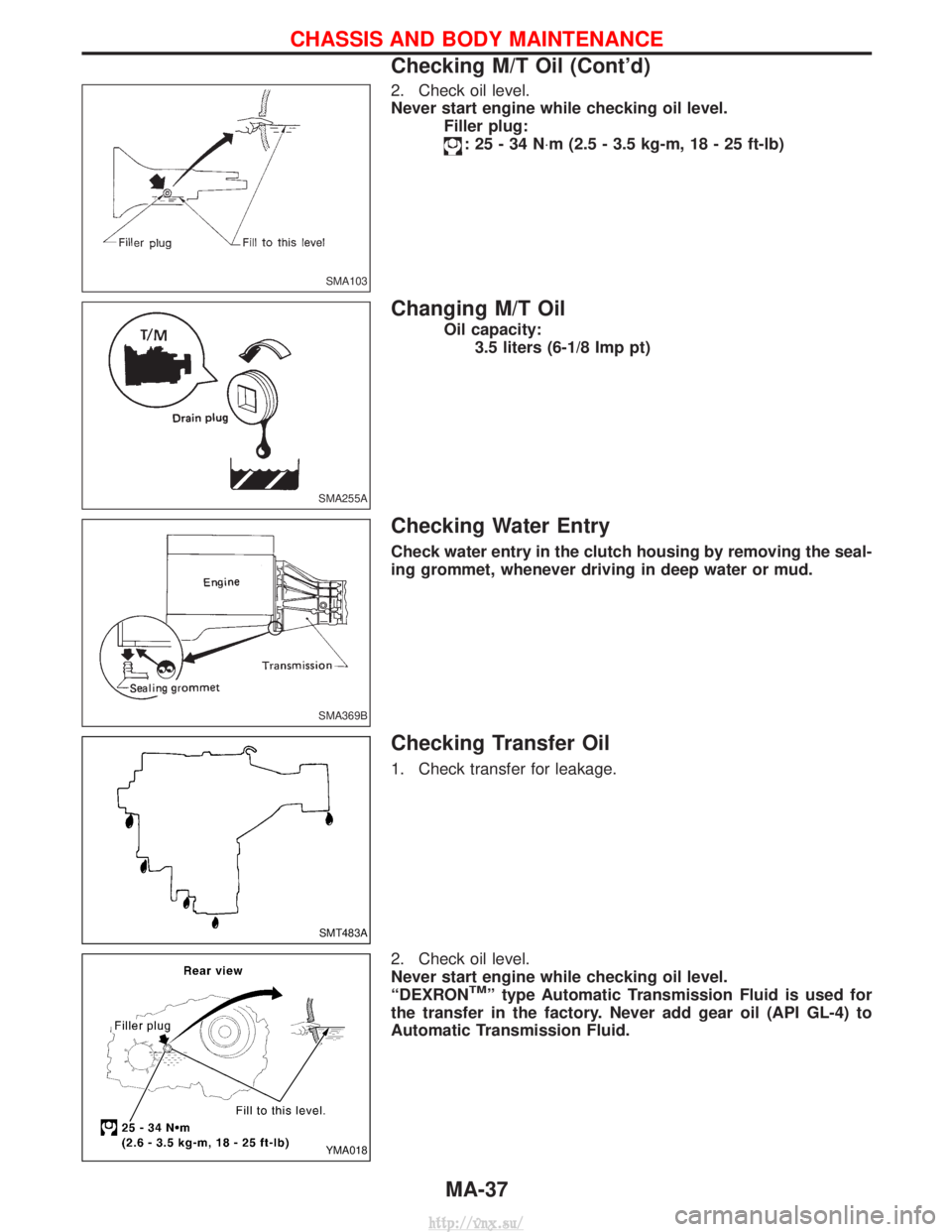

2. Check oil level.

Never start engine while checking oil level.Filler plug:

:25-34N ×m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing M/T Oil

Oil capacity:

3.5 liters (6-1/8 Imp pt)

Checking Water Entry

Check water entry in the clutch housing by removing the seal-

ing grommet, whenever driving in deep water or mud.

Checking Transfer Oil

1. Check transfer for leakage.

2. Check oil level.

Never start engine while checking oil level.

ªDEXRON

TMº type Automatic Transmission Fluid is used for

the transfer in the factory. Never add gear oil (API GL-4) to

Automatic Transmission Fluid.

SMA103

SMA255A

SMA369B

SMT483A

YMA018

CHASSIS AND BODY MAINTENANCE

Checking M/T Oil (Cont'd)

MA-37

http://vnx.su/

Page 83 of 1833

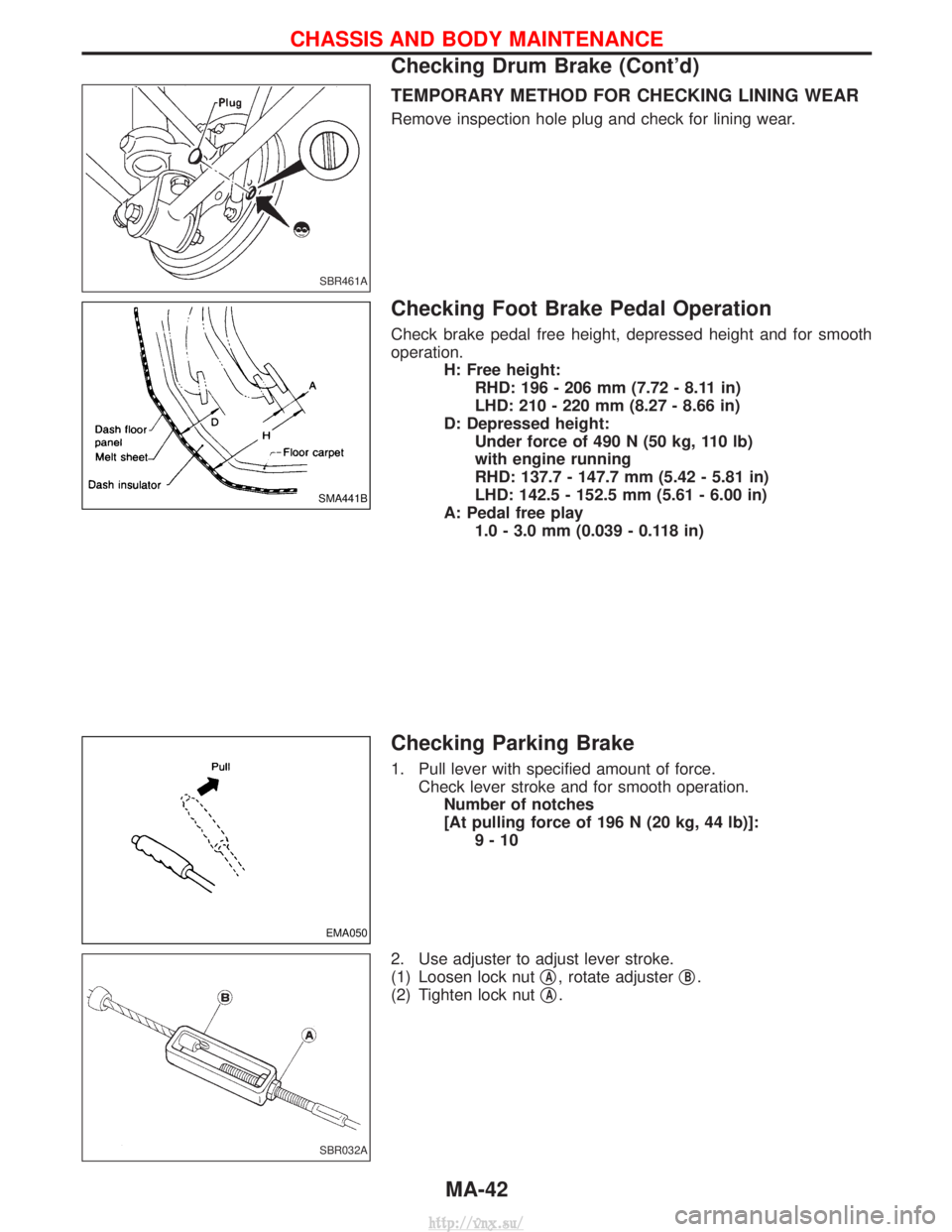

TEMPORARY METHOD FOR CHECKING LINING WEAR

Remove inspection hole plug and check for lining wear.

Checking Foot Brake Pedal Operation

Check brake pedal free height, depressed height and for smooth

operation.H: Free height:RHD: 196 - 206 mm (7.72 - 8.11 in)

LHD: 210 - 220 mm (8.27 - 8.66 in)

D: Depressed height: Under force of 490 N (50 kg, 110 lb)

with engine running

RHD: 137.7 - 147.7 mm (5.42 - 5.81 in)

LHD: 142.5 - 152.5 mm (5.61 - 6.00 in)

A: Pedal free play 1.0 - 3.0 mm (0.039 - 0.118 in)

Checking Parking Brake

1. Pull lever with specified amount of force.Check lever stroke and for smooth operation.Number of notches

[At pulling force of 196 N (20 kg, 44 lb)]: 9-10

2. Use adjuster to adjust lever stroke.

(1) Loosen lock nut q

A, rotate adjusterqB.

(2) Tighten lock nut q

A.

SBR461A

SMA441B

EMA050

SBR032A

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake (Cont'd)

MA-42

http://vnx.su/

Page 88 of 1833

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut lower in engine

compartment, etc.

Panel edge

Back door lid opening, sun roof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel,

etc.

Parts contact

Waist moulding, windshield moulding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-47

http://vnx.su/

Page 89 of 1833

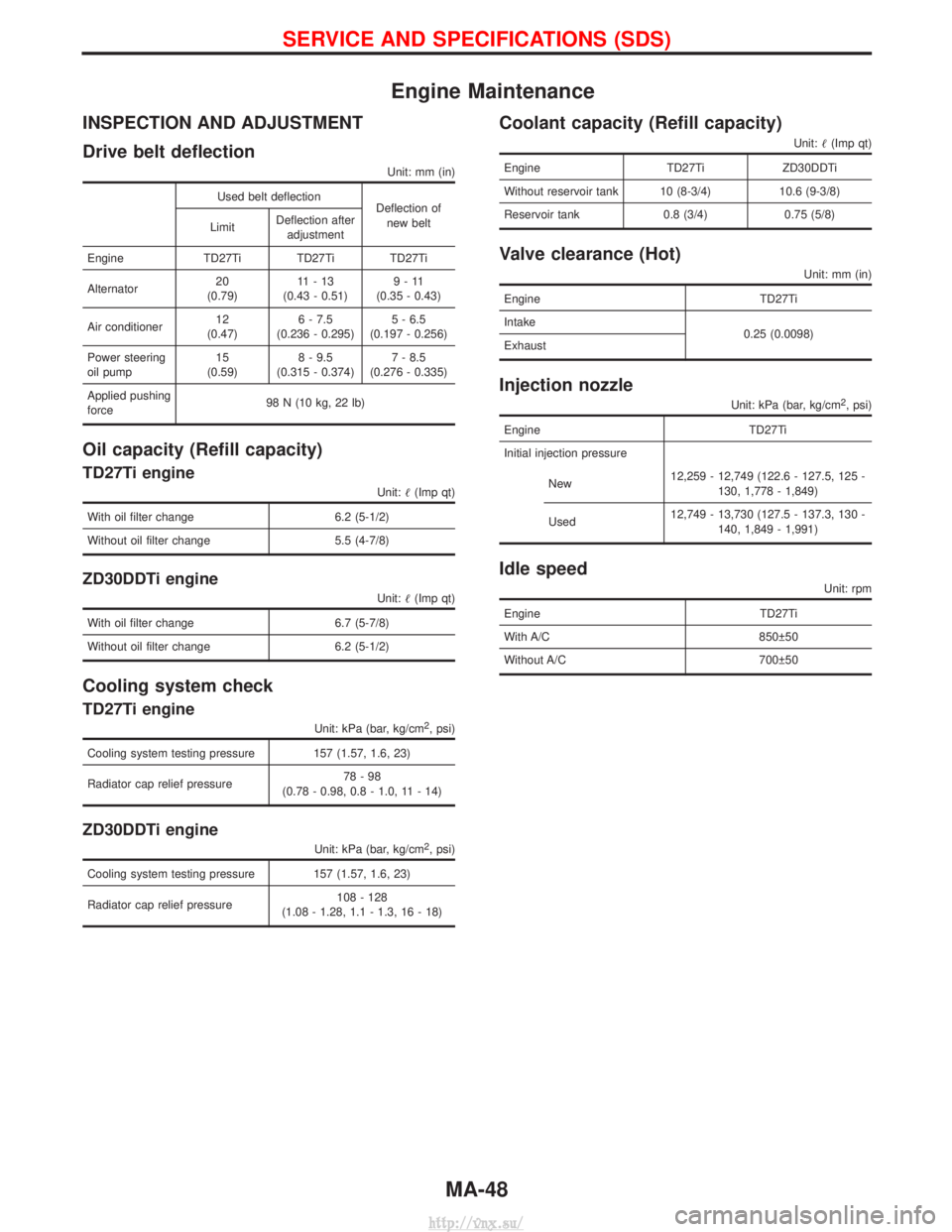

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflectionDeflection of

new belt

Limit Deflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator 20

(0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner 12

(0.47) 6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering

oil pump 15

(0.59) 8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:

(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit: (Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

TD27Ti engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

ZD30DDTi engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 108 - 128

(1.08 - 1.28, 1.1 - 1.3, 16 - 18)

Coolant capacity (Refill capacity)

Unit: (Imp qt)

Engine TD27TiZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake 0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New 12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used 12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

http://vnx.su/

Page 100 of 1833

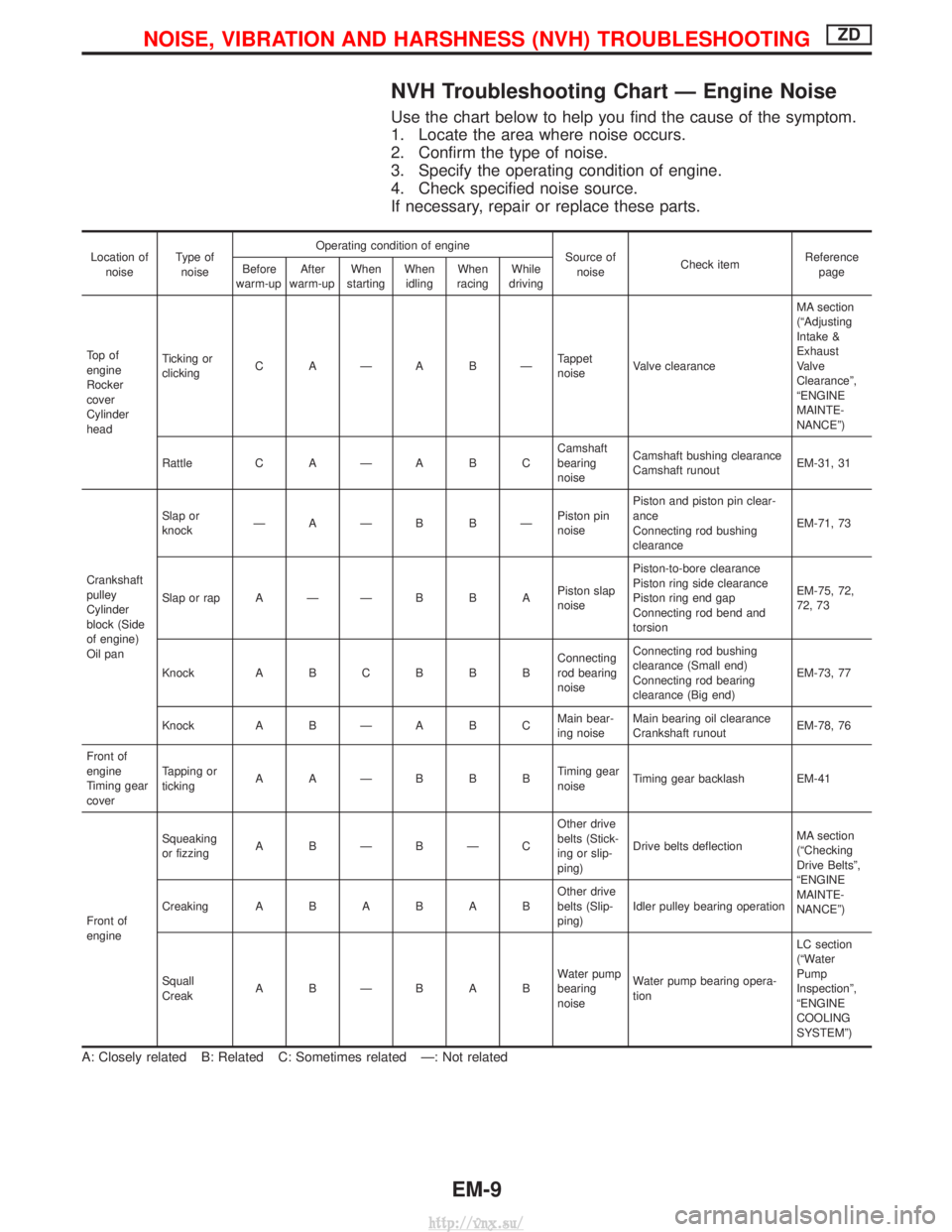

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location ofnoise Type of

noise Operating condition of engine

Source of

noise Check item Reference

page

Before

warm-up After

warm-up When

starting When

idling When

racing While

driving

To p o f

engine

Rocker

cover

Cylinder

head Ticking or

clicking

C AÐA BÐ Tappet

noiseValve clearance MA section

(ªAdjusting

Intake &

Exhaust

Valve

Clearanceº,

ªENGINE

MAINTE-

NANCEº)

Rattle C A Ð A B C Camshaft

bearing

noiseCamshaft bushing clearance

Camshaft runout

EM-31, 31

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil pan Slap or

knock

ÐAÐB BÐ Piston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearance

EM-71, 73

Slap or rap A Ð Ð B B A Piston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsion EM-75, 72,

72, 73

Knock A B C B B B Connecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)

EM-73, 77

Knock A B Ð A B C Main bear-

ing noiseMain bearing oil clearance

Crankshaft runout

EM-78, 76

Front of

engine

Timing gear

cover Tapping or

ticking

AAÐBBB Timing gear

noiseTiming gear backlash EM-41

Front of

engine Squeaking

or fizzing

A BÐBÐC Other drive

belts (Stick-

ing or slip-

ping)Drive belts deflection

MA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº)

Creaking

ABABAB Other drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

Creak ABÐBAB Water pump

bearing

noiseWater pump bearing opera-

tion LC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGZD

EM-9

http://vnx.su/