height NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 33 of 1833

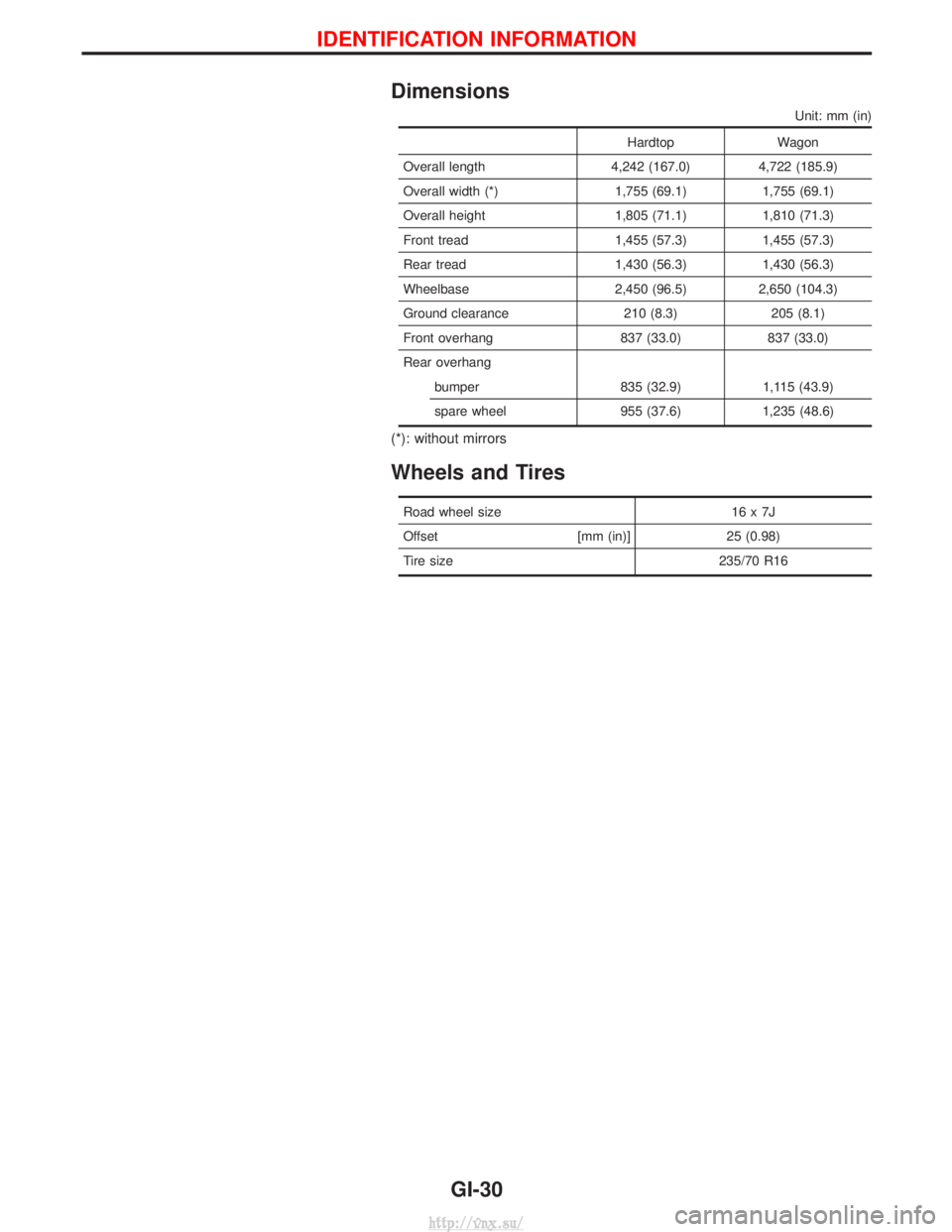

Dimensions

Unit: mm (in)

HardtopWagon

Overall length 4,242 (167.0) 4,722 (185.9)

Overall width (*) 1,755 (69.1) 1,755 (69.1)

Overall height 1,805 (71.1) 1,810 (71.3)

Front tread 1,455 (57.3) 1,455 (57.3)

Rear tread 1,430 (56.3) 1,430 (56.3)

Wheelbase 2,450 (96.5) 2,650 (104.3)

Ground clearance 210 (8.3) 205 (8.1)

Front overhang 837 (33.0) 837 (33.0)

Rear overhang bumper 835 (32.9) 1,115 (43.9)

spare wheel 955 (37.6) 1,235 (48.6)

(*): without mirrors

Wheels and Tires

Road wheel size 16 x 7J

Offset [mm (in)]25 (0.98)

Tire size 235/70 R16

IDENTIFICATION INFORMATION

GI-30

http://vnx.su/

Page 77 of 1833

Checking Exhaust System

Check exhaust pipes, muffler and mounting for proper attachment,

leaks, cracks, damage, loose connections, chafing and deteriora-

tion. Replace all defective parts.

Checking Clutch Operation

Check clutch pedal height, free play and smooth operation.Pedal height ªHº:RHD:210 - 220 mm (8.27 - 8.66 in)

LHD: 227 - 237 mm (8.94 - 9.33 in)

Pedal free play ªAº: 1.0 - 3.0 mm (0.039 - 0.118 in)

If necessary, adjust clutch pedal height and pedal free play. Refer

to Section CL.

Checking Clutch Fluid Level and Leaks

I If fluid level is extremely low, check clutch system for leaks.

Checking Clutch System

Check fluid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, chafing and deterioration.

Checking M/T Oil

1. Check for oil leakage.

SMA211A

SMA438A

SMA941B

SMA741A

SMA429A

CHASSIS AND BODY MAINTENANCE

MA-36

http://vnx.su/

Page 83 of 1833

TEMPORARY METHOD FOR CHECKING LINING WEAR

Remove inspection hole plug and check for lining wear.

Checking Foot Brake Pedal Operation

Check brake pedal free height, depressed height and for smooth

operation.H: Free height:RHD: 196 - 206 mm (7.72 - 8.11 in)

LHD: 210 - 220 mm (8.27 - 8.66 in)

D: Depressed height: Under force of 490 N (50 kg, 110 lb)

with engine running

RHD: 137.7 - 147.7 mm (5.42 - 5.81 in)

LHD: 142.5 - 152.5 mm (5.61 - 6.00 in)

A: Pedal free play 1.0 - 3.0 mm (0.039 - 0.118 in)

Checking Parking Brake

1. Pull lever with specified amount of force.Check lever stroke and for smooth operation.Number of notches

[At pulling force of 196 N (20 kg, 44 lb)]: 9-10

2. Use adjuster to adjust lever stroke.

(1) Loosen lock nut q

A, rotate adjusterqB.

(2) Tighten lock nut q

A.

SBR461A

SMA441B

EMA050

SBR032A

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake (Cont'd)

MA-42

http://vnx.su/

Page 90 of 1833

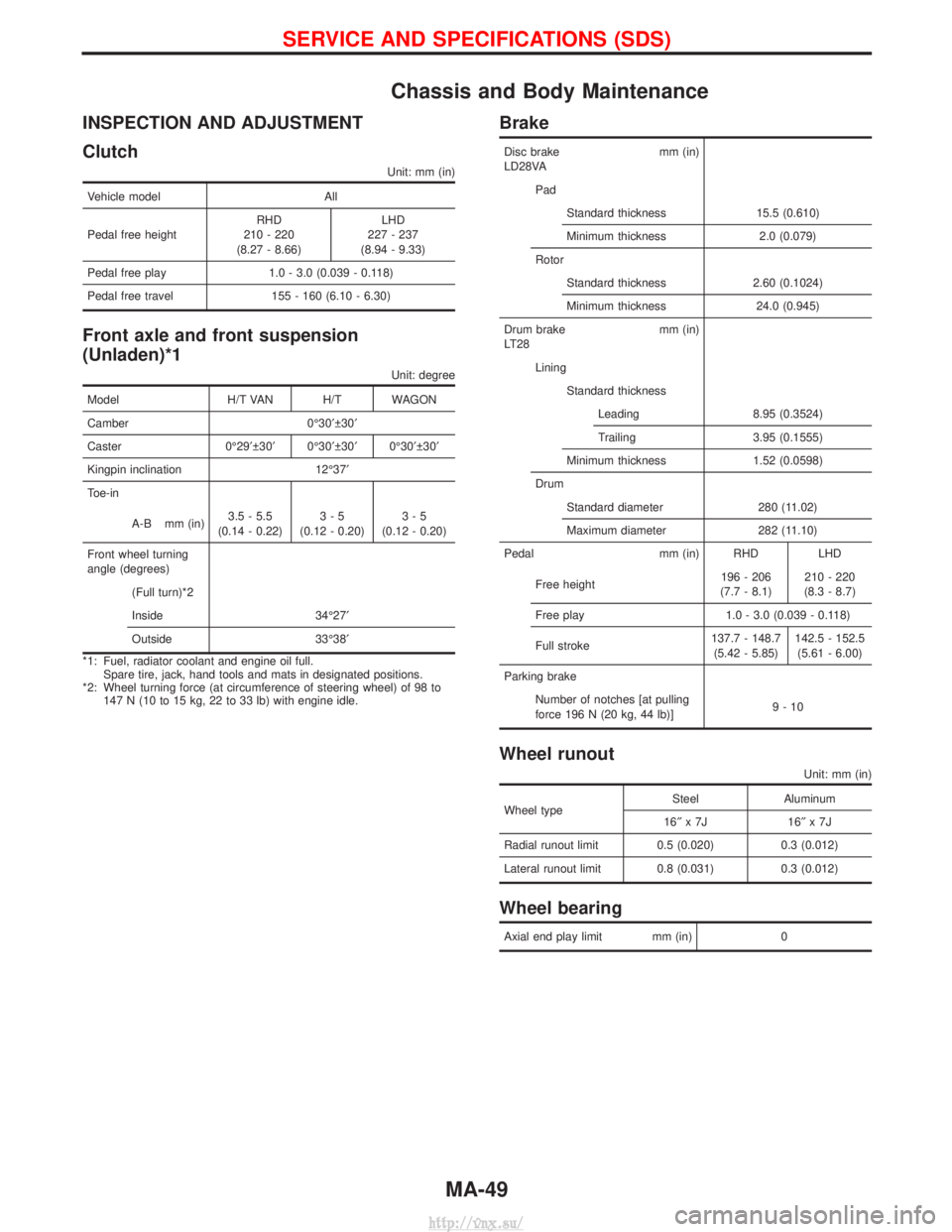

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Clutch

Unit: mm (in)

Vehicle modelAll

Pedal free height RHD

210 - 220

(8.27 - 8.66) LHD

227 - 237

(8.94 - 9.33)

Pedal free play 1.0 - 3.0 (0.039 - 0.118)

Pedal free travel 155 - 160 (6.10 - 6.30)

Front axle and front suspension

(Unladen)*1

Unit: degree

Model H/T VAN H/T WAGON

Camber 0É30¢ 30¢

Caster 0É29¢ 30¢ 0É30¢ 30¢ 0É30¢ 30¢

Kingpin inclination 12É37¢

Toe-in

A-B mm (in) 3.5 - 5.5

(0.14 - 0.22) 3-5

(0.12 - 0.20) 3-5

(0.12 - 0.20)

Front wheel turning

angle (degrees) (Full turn)*2

Inside 34É27¢

Outside 33É38¢

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

Brake

Disc brake mm (in)

LD28VA

PadStandard thickness 15.5 (0.610)

Minimum thickness 2.0 (0.079)

Rotor Standard thickness 2.60 (0.1024)

Minimum thickness 24.0 (0.945)

Drum brake mm (in)

LT28 LiningStandard thicknessLeading 8.95 (0.3524)

Trailing 3.95 (0.1555)

Minimum thickness 1.52 (0.0598)

Drum Standard diameter 280 (11.02)

Maximum diameter 282 (11.10)

Pedal mm (in) RHD LHD

Free height 196 - 206

(7.7 - 8.1) 210 - 220

(8.3 - 8.7)

Free play 1.0 - 3.0 (0.039 - 0.118)

Full stroke 137.7 - 148.7

(5.42 - 5.85) 142.5 - 152.5

(5.61 - 6.00)

Parking brake Number of notches [at pulling

force 196 N (20 kg, 44 lb)] 9-10

Wheel runout

Unit: mm (in)

Wheel typeSteel Aluminum

16² x7J 16 ²x7J

Radial runout limit 0.5 (0.020) 0.3 (0.012)

Lateral runout limit 0.8 (0.031) 0.3 (0.012)

Wheel bearing

Axial end play limit mm (in) 0

SERVICE AND SPECIFICATIONS (SDS)

MA-49

http://vnx.su/

Page 122 of 1833

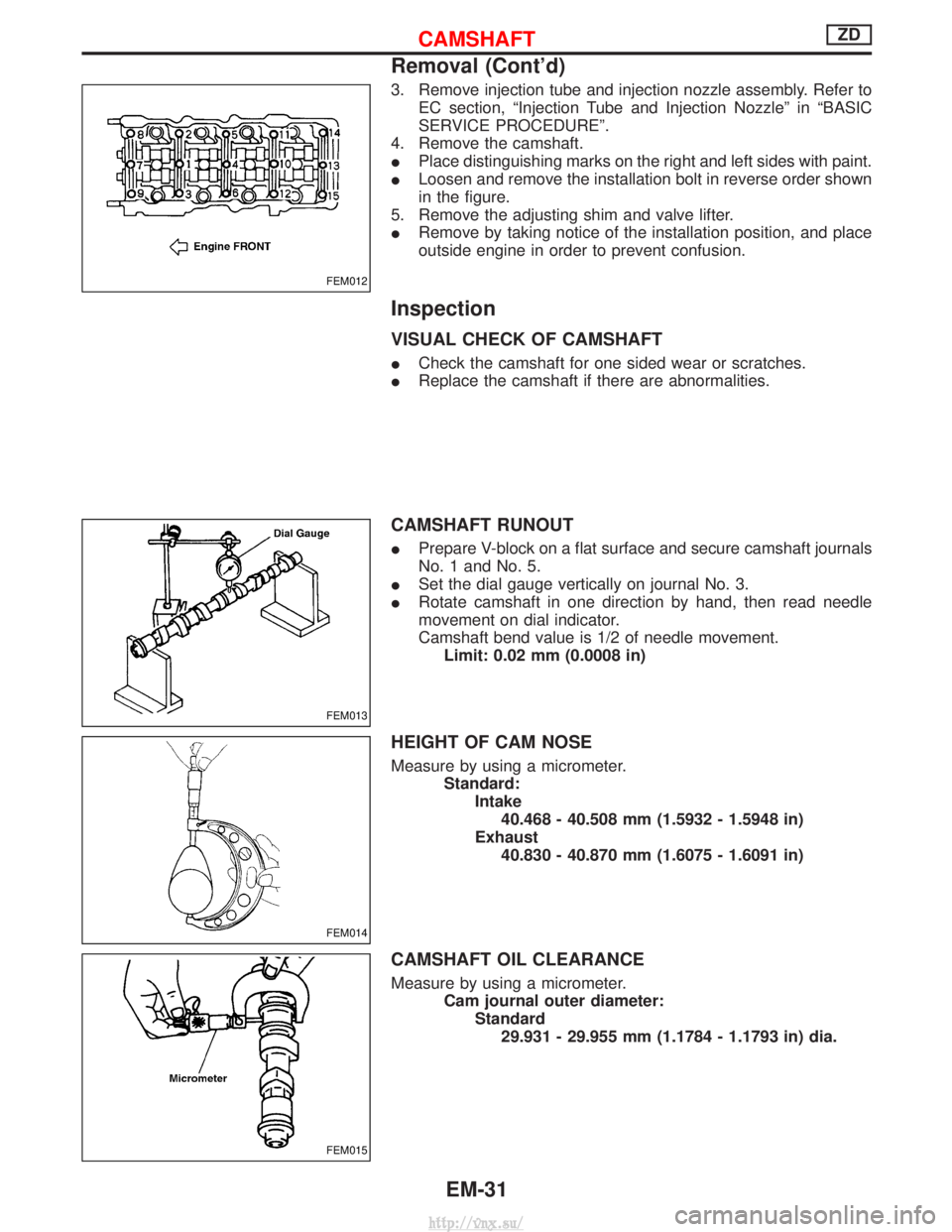

3. Remove injection tube and injection nozzle assembly. Refer toEC section, ªInjection Tube and Injection Nozzleº in ªBASIC

SERVICE PROCEDUREº.

4. Remove the camshaft.

I Place distinguishing marks on the right and left sides with paint.

I Loosen and remove the installation bolt in reverse order shown

in the figure.

5. Remove the adjusting shim and valve lifter.

I Remove by taking notice of the installation position, and place

outside engine in order to prevent confusion.

Inspection

VISUAL CHECK OF CAMSHAFT

ICheck the camshaft for one sided wear or scratches.

I Replace the camshaft if there are abnormalities.

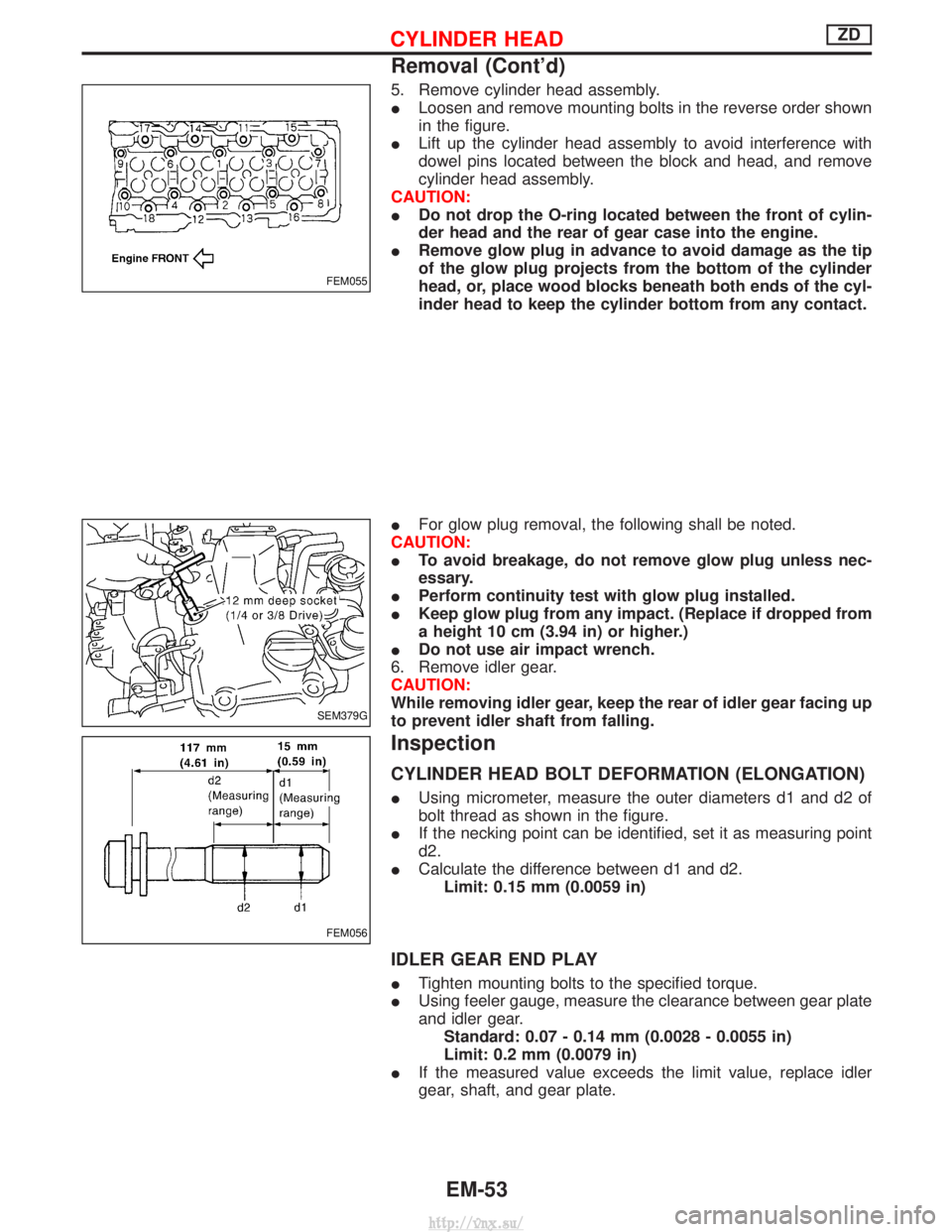

CAMSHAFT RUNOUT

IPrepare V-block on a flat surface and secure camshaft journals

No. 1 and No. 5.

I Set the dial gauge vertically on journal No. 3.

I Rotate camshaft in one direction by hand, then read needle

movement on dial indicator.

Camshaft bend value is 1/2 of needle movement.

Limit: 0.02 mm (0.0008 in)

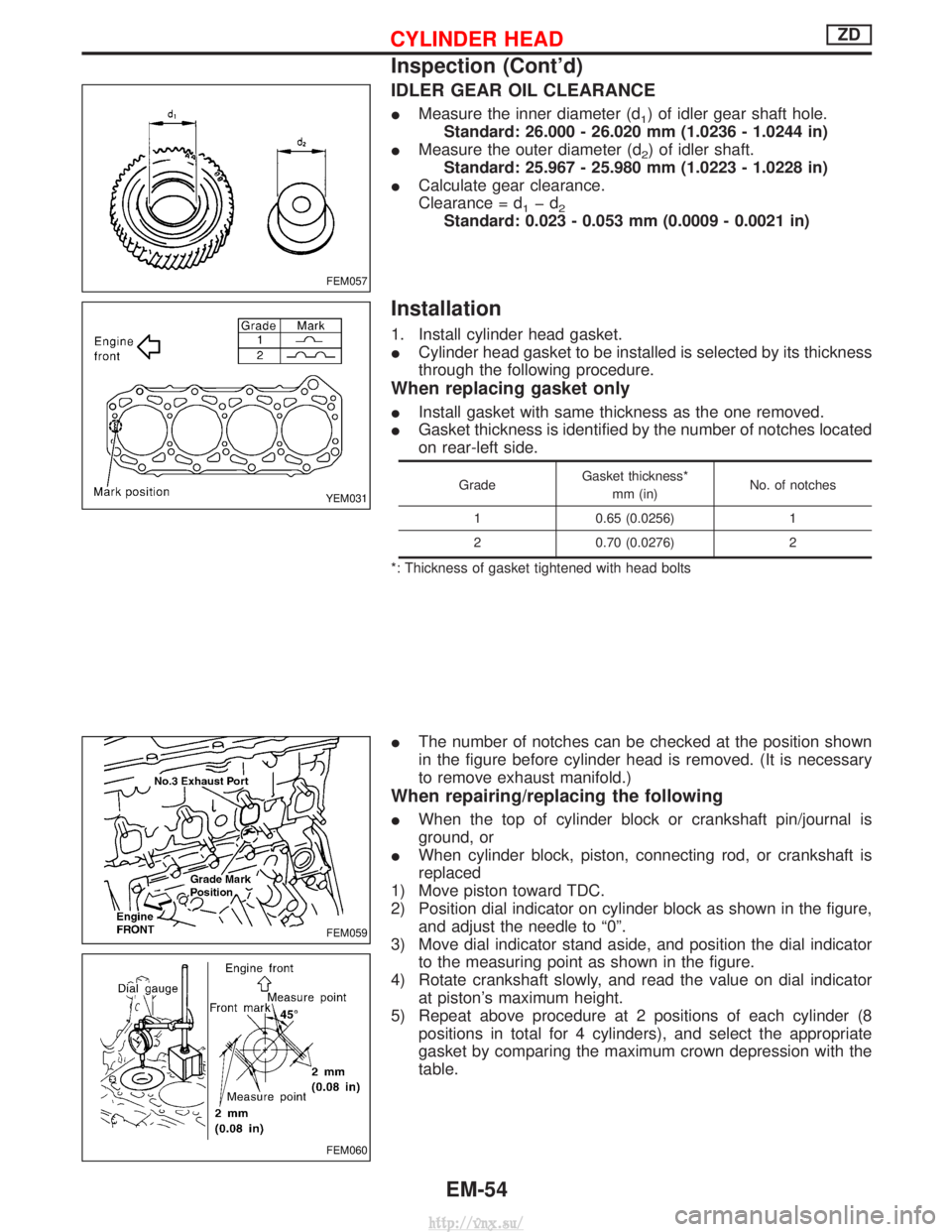

HEIGHT OF CAM NOSE

Measure by using a micrometer. Standard:Intake40.468 - 40.508 mm (1.5932 - 1.5948 in)

Exhaust 40.830 - 40.870 mm (1.6075 - 1.6091 in)

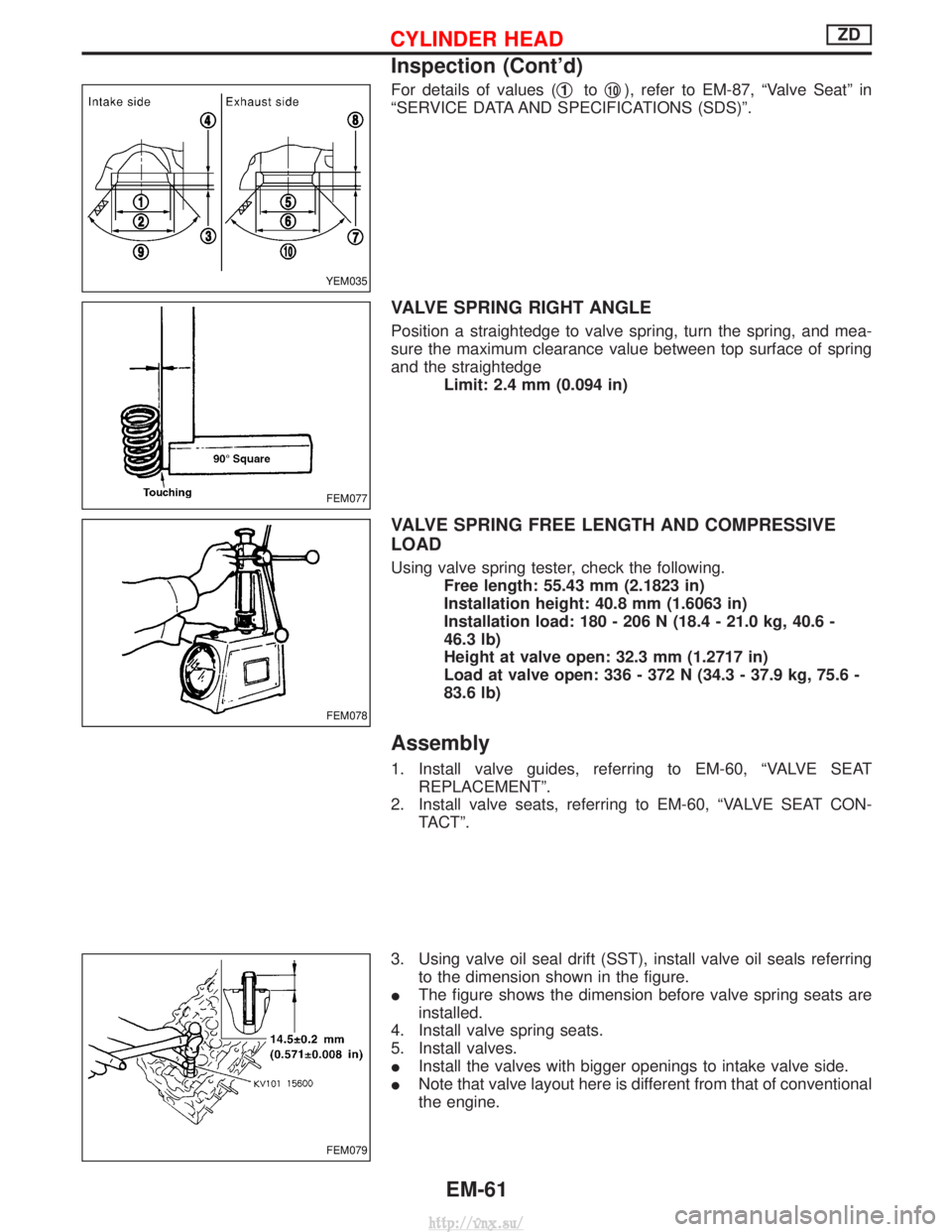

CAMSHAFT OIL CLEARANCE

Measure by using a micrometer. Cam journal outer diameter:Standard29.931 - 29.955 mm (1.1784 - 1.1793 in) dia.

FEM012

FEM013

FEM014

FEM015

CAMSHAFTZD

Removal (Cont'd)

EM-31

http://vnx.su/

Page 144 of 1833

5. Remove cylinder head assembly.

ILoosen and remove mounting bolts in the reverse order shown

in the figure.

I Lift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

I Do not drop the O-ring located between the front of cylin-

der head and the rear of gear case into the engine.

I Remove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylinder

head, or, place wood blocks beneath both ends of the cyl-

inder head to keep the cylinder bottom from any contact.

I For glow plug removal, the following shall be noted.

CAUTION:

I To avoid breakage, do not remove glow plug unless nec-

essary.

I Perform continuity test with glow plug installed.

I Keep glow plug from any impact. (Replace if dropped from

a height 10 cm (3.94 in) or higher.)

I Do not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing up

to prevent idler shaft from falling.

Inspection

CYLINDER HEAD BOLT DEFORMATION (ELONGATION)

I Using micrometer, measure the outer diameters d1 and d2 of

bolt thread as shown in the figure.

I If the necking point can be identified, set it as measuring point

d2.

I Calculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

I Tighten mounting bolts to the specified torque.

I Using feeler gauge, measure the clearance between gear plate

and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

I If the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-53

http://vnx.su/

Page 145 of 1833

IDLER GEAR OIL CLEARANCE

IMeasure the inner diameter (d1) of idler gear shaft hole.

Standard: 26.000 - 26.020 mm (1.0236 - 1.0244 in)

I Measure the outer diameter (d

2) of idler shaft.

Standard: 25.967 - 25.980 mm (1.0223 - 1.0228 in)

I Calculate gear clearance.

Clearance = d

1þd2Standard: 0.023 - 0.053 mm (0.0009 - 0.0021 in)

Installation

1. Install cylinder head gasket.

ICylinder head gasket to be installed is selected by its thickness

through the following procedure.

When replacing gasket only

IInstall gasket with same thickness as the one removed.

I Gasket thickness is identified by the number of notches located

on rear-left side.

Grade Gasket thickness*

mm (in) No. of notches

1 0.65 (0.0256) 1

2 0.70 (0.0276) 2

*: Thickness of gasket tightened with head bolts

I The number of notches can be checked at the position shown

in the figure before cylinder head is removed. (It is necessary

to remove exhaust manifold.)

When repairing/replacing the following

IWhen the top of cylinder block or crankshaft pin/journal is

ground, or

I When cylinder block, piston, connecting rod, or crankshaft is

replaced

1) Move piston toward TDC.

2) Position dial indicator on cylinder block as shown in the figure, and adjust the needle to ª0º.

3) Move dial indicator stand aside, and position the dial indicator to the measuring point as shown in the figure.

4) Rotate crankshaft slowly, and read the value on dial indicator at piston's maximum height.

5) Repeat above procedure at 2 positions of each cylinder (8 positions in total for 4 cylinders), and select the appropriate

gasket by comparing the maximum crown depression with the

table.

FEM057

YEM031

FEM059

FEM060

CYLINDER HEADZD

Inspection (Cont'd)

EM-54

http://vnx.su/

Page 152 of 1833

For details of values (q1toq10), refer to EM-87, ªValve Seatº in

ªSERVICE DATA AND SPECIFICATIONS (SDS)º.

VALVE SPRING RIGHT ANGLE

Position a straightedge to valve spring, turn the spring, and mea-

sure the maximum clearance value between top surface of spring

and the straightedge Limit: 2.4 mm (0.094 in)

VALVE SPRING FREE LENGTH AND COMPRESSIVE

LOAD

Using valve spring tester, check the following.Free length: 55.43 mm (2.1823 in)

Installation height: 40.8 mm (1.6063 in)

Installation load: 180 - 206 N (18.4 - 21.0 kg, 40.6 -

46.3 lb)

Height at valve open: 32.3 mm (1.2717 in)

Load at valve open: 336 - 372 N (34.3 - 37.9 kg, 75.6 -

83.6 lb)

Assembly

1. Install valve guides, referring to EM-60, ªVALVE SEATREPLACEMENTº.

2. Install valve seats, referring to EM-60, ªVALVE SEAT CON- TACTº.

3. Using valve oil seal drift (SST), install valve oil seals referring to the dimension shown in the figure.

I The figure shows the dimension before valve spring seats are

installed.

4. Install valve spring seats.

5. Install valves.

I Install the valves with bigger openings to intake valve side.

I Note that valve layout here is different from that of conventional

the engine.

YEM035

FEM077

FEM078

FEM079

CYLINDER HEADZD

Inspection (Cont'd)

EM-61

http://vnx.su/

Page 170 of 1833

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

IIf bearing clearance is out of specifications for main bearings

in standard size, use undersize bearings.

I When using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind crank journals to adjust

clearance to specification.

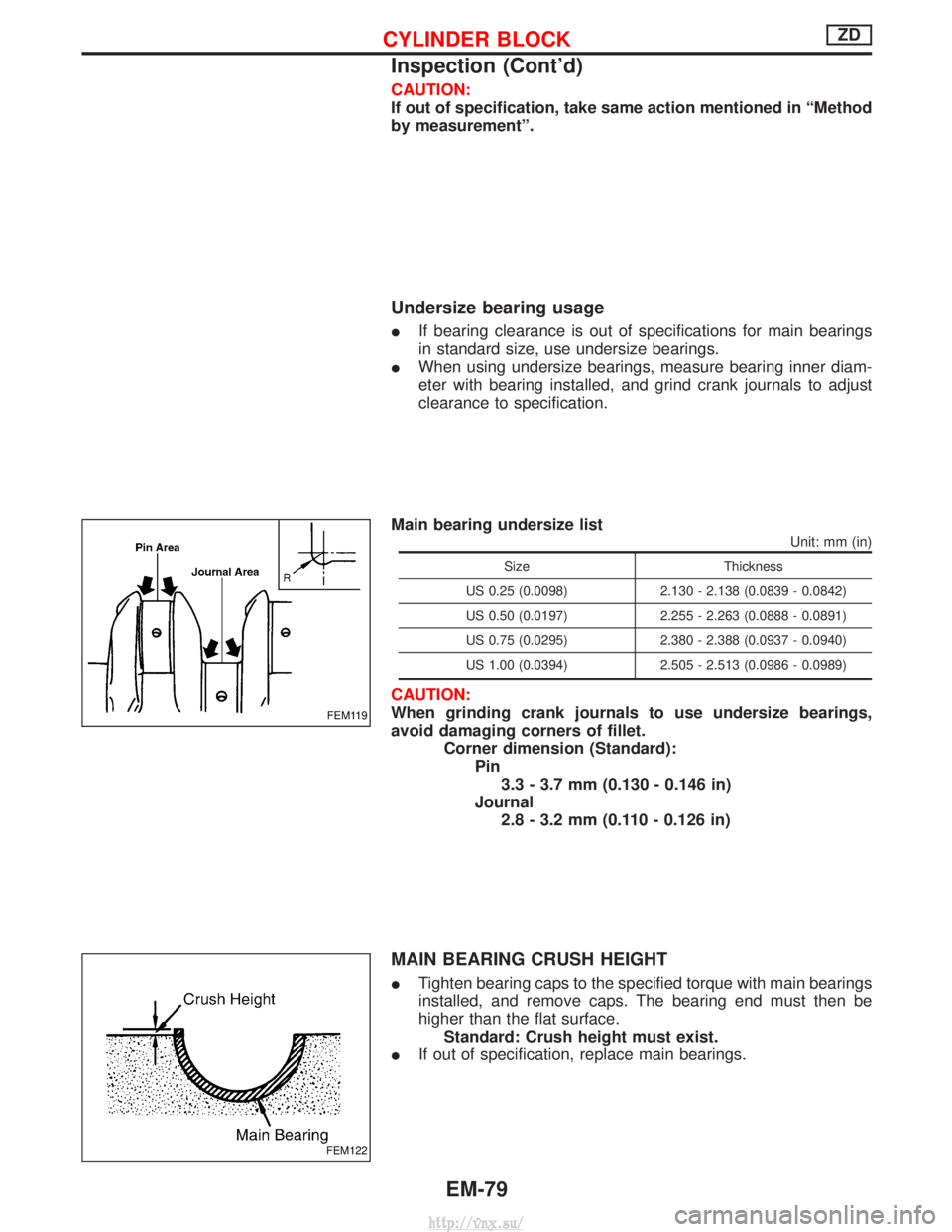

Main bearing undersize list

Unit: mm (in)

Size Thickness

US 0.25 (0.0098) 2.130 - 2.138 (0.0839 - 0.0842)

US 0.50 (0.0197) 2.255 - 2.263 (0.0888 - 0.0891)

US 0.75 (0.0295) 2.380 - 2.388 (0.0937 - 0.0940)

US 1.00 (0.0394) 2.505 - 2.513 (0.0986 - 0.0989)

CAUTION:

When grinding crank journals to use undersize bearings,

avoid damaging corners of fillet.

Corner dimension (Standard):Pin3.3 - 3.7 mm (0.130 - 0.146 in)

Journal 2.8 - 3.2 mm (0.110 - 0.126 in)

MAIN BEARING CRUSH HEIGHT

I Tighten bearing caps to the specified torque with main bearings

installed, and remove caps. The bearing end must then be

higher than the flat surface.

Standard: Crush height must exist.

I If out of specification, replace main bearings.

FEM119

FEM122

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-79

http://vnx.su/

Page 177 of 1833

VALVE SPRING

Free heightmm (in)55.43 (2.1823)

Pressure N (kg, lb) at height mm (in) 354 (36.1, 79.6) at 32.3 (1.2717)

Out-of-square mm (in) 2.4 (0.094)

VALVE LIFTER

Unit: mm (in)

Valve lifter outer diameter 34.455 - 34.465 (1.3565 - 1.3569)

Lifter guide inner diameter 34.495 - 34.515 (1.3581 - 1.3589)

Clearance between lifter and lifter guide 0.030 - 0.060 (0.0012 - 0.0024)

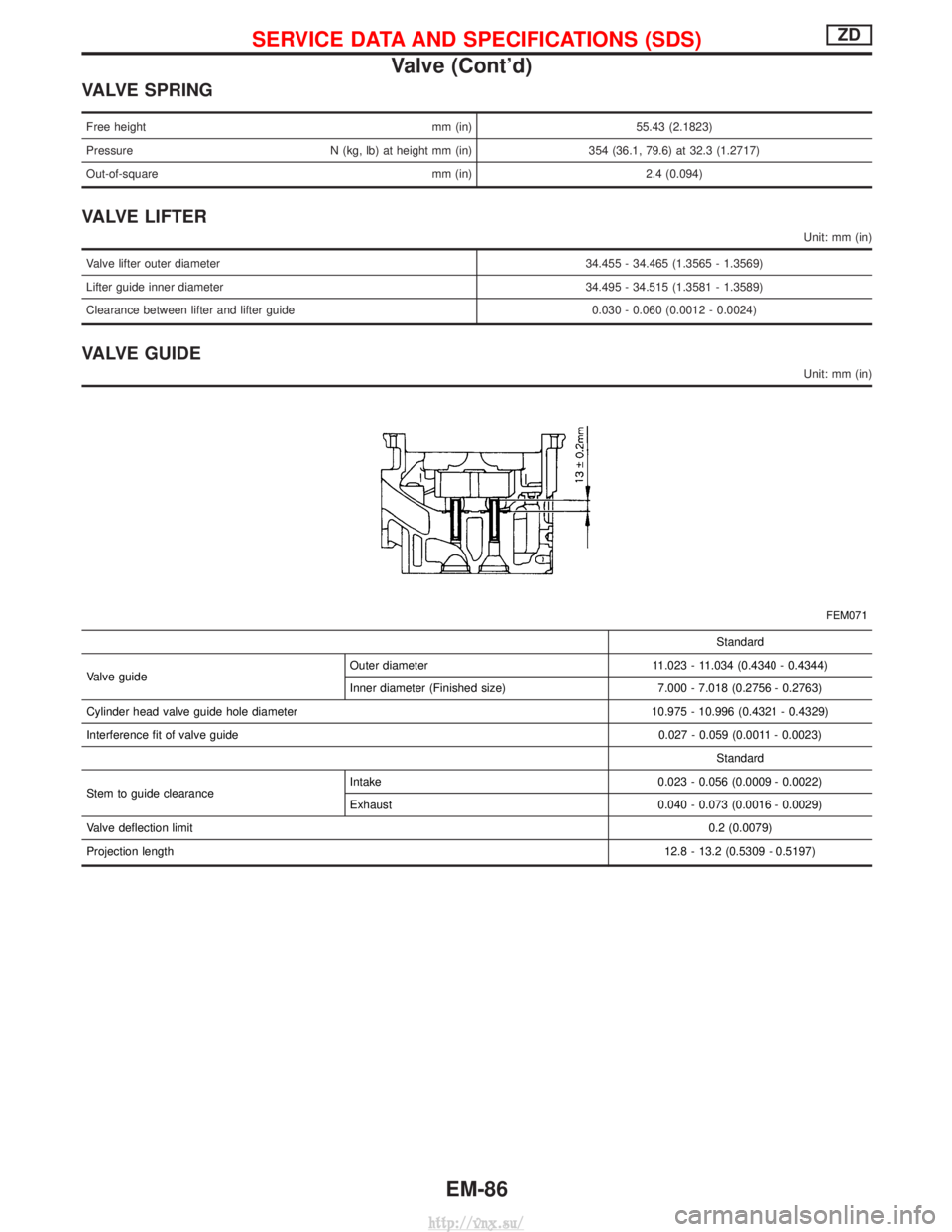

VALVE GUIDE

Unit: mm (in)

FEM071

Standard

Valve guide Outer diameter 11.023 - 11.034 (0.4340 - 0.4344)

Inner diameter (Finished size) 7.000 - 7.018 (0.2756 - 0.2763)

Cylinder head valve guide hole diameter 10.975 - 10.996 (0.4321 - 0.4329)

Interference fit of valve guide 0.027 - 0.059 (0.0011 - 0.0023)

Standard

Stem to guide clearance Intake 0.023 - 0.056 (0.0009 - 0.0022)

Exhaust 0.040 - 0.073 (0.0016 - 0.0029)

Valve deflection limit 0.2 (0.0079)

Projection length 12.8 - 13.2 (0.5309 - 0.5197)

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

Valve (Cont'd)

EM-86

http://vnx.su/