check engine NISSAN TERRANO 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 171 of 1833

Assembly

1. Blow air sufficiently to inside coolant passage, oil passage,crankcase, and cylinder bore to remove foreign matter.

2. Install main bearings and thrust bearings.

1) Remove contamination, dust and oil from bearing mounting positions on cylinder block and main bearing caps.

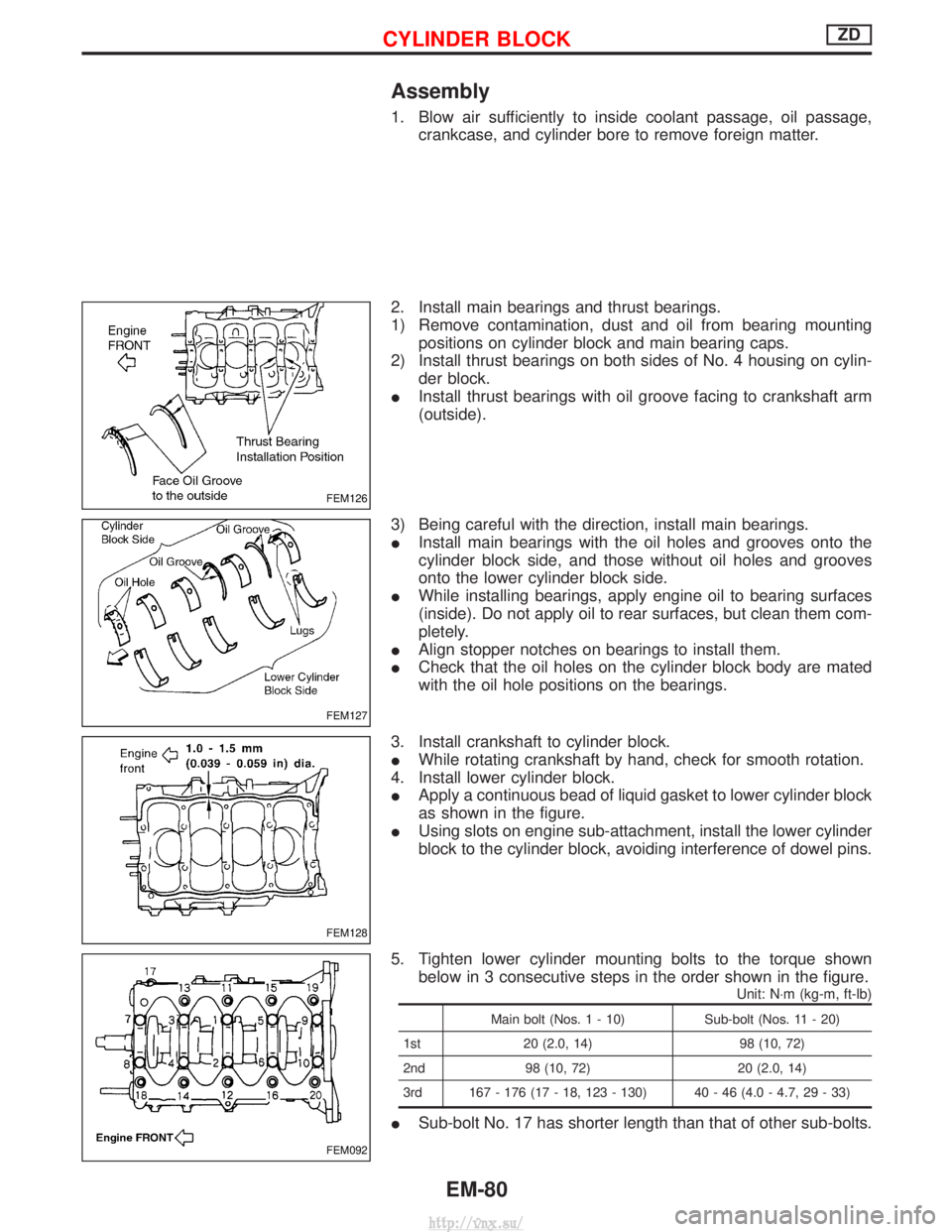

2) Install thrust bearings on both sides of No. 4 housing on cylin- der block.

I Install thrust bearings with oil groove facing to crankshaft arm

(outside).

3) Being careful with the direction, install main bearings.

I Install main bearings with the oil holes and grooves onto the

cylinder block side, and those without oil holes and grooves

onto the lower cylinder block side.

I While installing bearings, apply engine oil to bearing surfaces

(inside). Do not apply oil to rear surfaces, but clean them com-

pletely.

I Align stopper notches on bearings to install them.

I Check that the oil holes on the cylinder block body are mated

with the oil hole positions on the bearings.

3. Install crankshaft to cylinder block.

I While rotating crankshaft by hand, check for smooth rotation.

4. Install lower cylinder block.

I Apply a continuous bead of liquid gasket to lower cylinder block

as shown in the figure.

I Using slots on engine sub-attachment, install the lower cylinder

block to the cylinder block, avoiding interference of dowel pins.

5. Tighten lower cylinder mounting bolts to the torque shown below in 3 consecutive steps in the order shown in the figure.

Unit: N ×m (kg-m, ft-lb)

Main bolt (Nos. 1 - 10) Sub-bolt (Nos. 11 - 20)

1st 20 (2.0, 14) 98 (10, 72)

2nd 98 (10, 72) 20 (2.0, 14)

3rd 167 - 176 (17 - 18, 123 - 130) 40 - 46 (4.0 - 4.7, 29 - 33)

I Sub-bolt No. 17 has shorter length than that of other sub-bolts.

FEM126

FEM127

FEM128

FEM092

CYLINDER BLOCKZD

EM-80

http://vnx.su/

Page 172 of 1833

6. Install mounting bolts for engine sub-attachment shown byarrows in the figure.

I After tightening bolts to the specified torque, check crankshaft

for smooth rotation.

I Check crankshaft end play.

Refer to EM-71, ªCRANKSHAFT END PLAYº.

7. Install pistons to connecting rod.

1) Using long nose pliers, install snap rings to grooves on piston rear side.

I Fit snap rings correctly into grooves.

2) Install pistons to connecting rods.

I Using industrial dryer, heat pistons up to approx. 60 to 70ÉC

(140 to 158ÉF) until piston pin can be pressed down by finger

touch. Then insert piston pins into piston and connecting rod

from front side of piston toward rear.

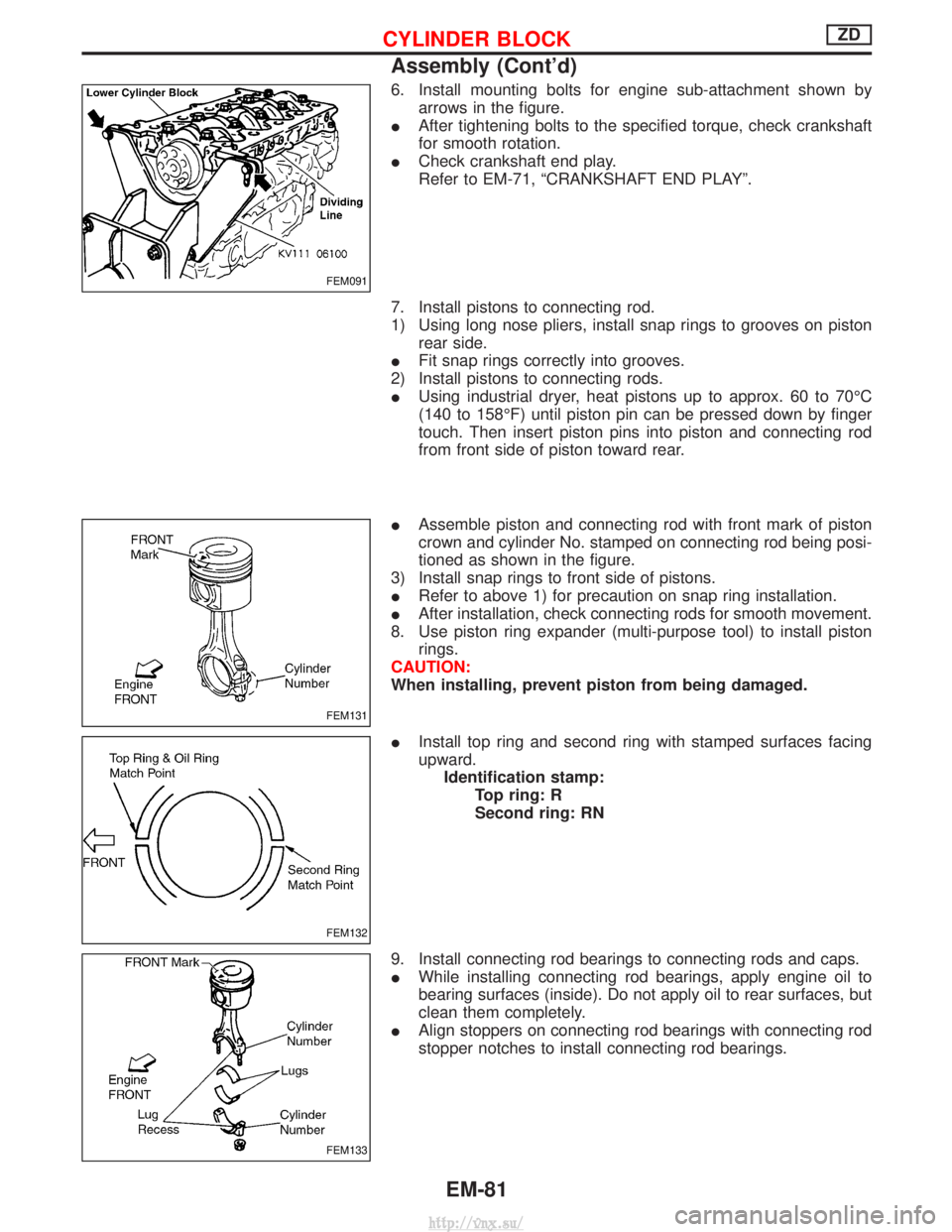

I Assemble piston and connecting rod with front mark of piston

crown and cylinder No. stamped on connecting rod being posi-

tioned as shown in the figure.

3) Install snap rings to front side of pistons.

I Refer to above 1) for precaution on snap ring installation.

I After installation, check connecting rods for smooth movement.

8. Use piston ring expander (multi-purpose tool) to install piston rings.

CAUTION:

When installing, prevent piston from being damaged.

I Install top ring and second ring with stamped surfaces facing

upward.

Identification stamp: Top ring: R

Second ring: RN

9. Install connecting rod bearings to connecting rods and caps.

I While installing connecting rod bearings, apply engine oil to

bearing surfaces (inside). Do not apply oil to rear surfaces, but

clean them completely.

I Align stoppers on connecting rod bearings with connecting rod

stopper notches to install connecting rod bearings.

FEM091

FEM131

FEM132

FEM133

CYLINDER BLOCKZD

Assembly (Cont'd)

EM-81

http://vnx.su/

Page 173 of 1833

10. Install piston and connecting rod assembly to crankshaft.

IMove crankshaft pin to be removed to BDC.

I Align cylinder position with cylinder No. on connecting rod to

install piston and connecting rod assembly.

I Using piston ring compressor (multi-purpose tool), install piston

and connecting rod assembly with front mark on piston crown

facing toward the front side of engine.

CAUTION:

When installing piston and connecting rod assembly, prevent

the big end of connecting rod from interfering with oil jet.

11. Install connecting rod caps and mounting nuts.

I Align cylinder No. stamped on connecting rod with that on cap

to install connecting rod cap.

I After tightening nuts, check crankshaft for smooth rotation.

I Check connecting rod side clearance.

Refer to EM-71, ªCONNECTING ROD SIDE CLEARANCEº.

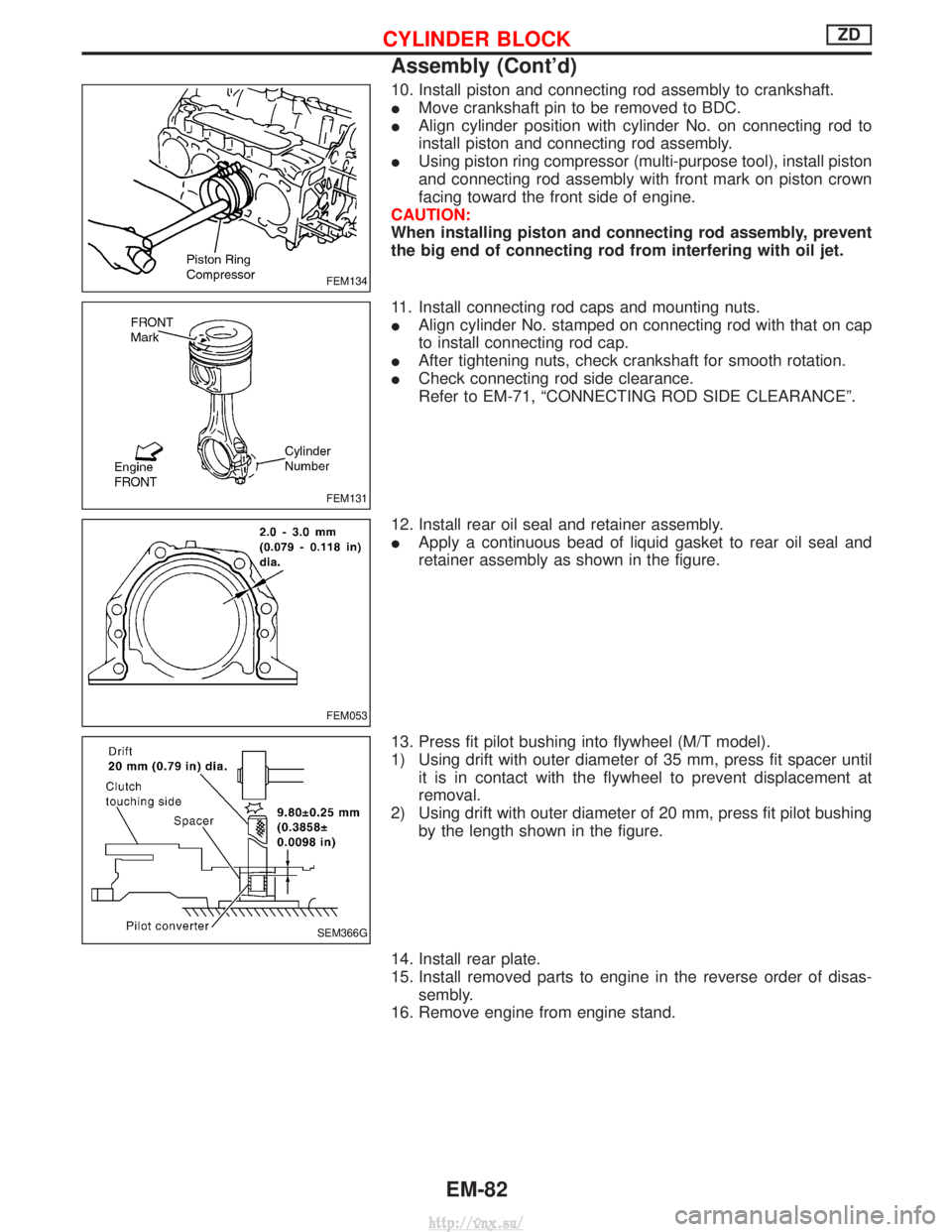

12. Install rear oil seal and retainer assembly.

I Apply a continuous bead of liquid gasket to rear oil seal and

retainer assembly as shown in the figure.

13. Press fit pilot bushing into flywheel (M/T model).

1) Using drift with outer diameter of 35 mm, press fit spacer until it is in contact with the flywheel to prevent displacement at

removal.

2) Using drift with outer diameter of 20 mm, press fit pilot bushing by the length shown in the figure.

14. Install rear plate.

15. Install removed parts to engine in the reverse order of disas- sembly.

16. Remove engine from engine stand.

FEM134

FEM131

FEM053

SEM366G

CYLINDER BLOCKZD

Assembly (Cont'd)

EM-82

http://vnx.su/

Page 206 of 1833

2. Install cylinder head.

ICylinder head identification mark

3. Apply oil to threaded portion and seat surface of bolts and tighten cylinder head bolts using Tool.

CAUTION:

I Tightening procedure

1st: Tighten bolts to 39 - 44 N×m (4.0 - 4.5 kg-m, 29 - 33 ft-lb)

2nd: Tighten bolts to 54 - 59 N ×m

(5.5 - 6.0 kg-m, 40 - 43 ft-lb)

3rd: (1) Mark exhaust side of cylinder head and cylin-der head bolts with paint as shown.

(2) Turn all bolts 90 10 degrees clockwise.

(3) Check that paint mark of each bolt is facing the front of the vehicle.

4. Apply engine oil and install push rods.

5. Install rocker shaft assembly. Adjust intake and exhaust valve clearance carefully.

Refer to MA section in order to accomplish valve adjustment.

NEM179

SEM641B

SEM580C

SEM642B

CYLINDER HEADTD27Ti

Installation (Cont'd)

EM-115

http://vnx.su/

Page 218 of 1833

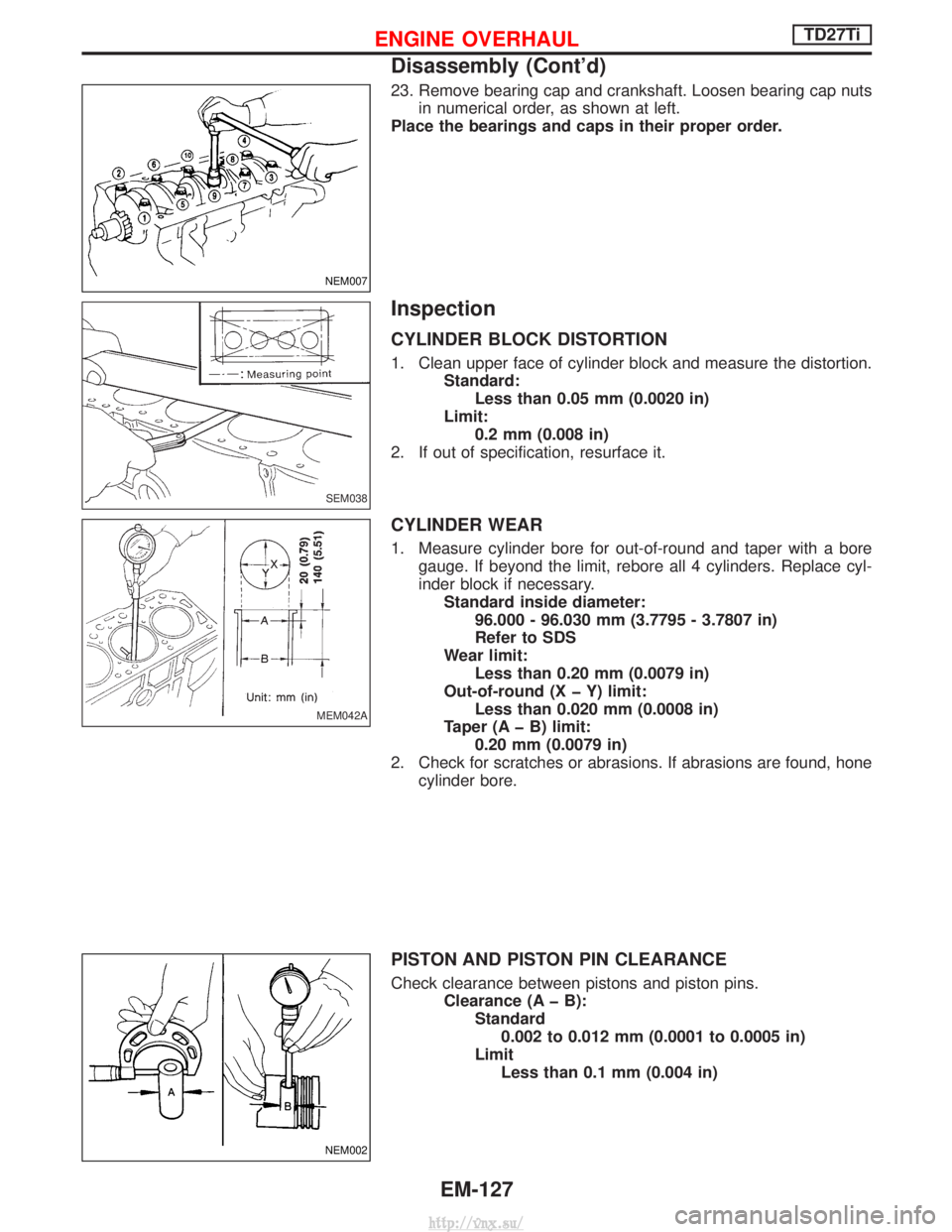

23. Remove bearing cap and crankshaft. Loosen bearing cap nutsin numerical order, as shown at left.

Place the bearings and caps in their proper order.

Inspection

CYLINDER BLOCK DISTORTION

1. Clean upper face of cylinder block and measure the distortion. Standard:Less than 0.05 mm (0.0020 in)

Limit: 0.2 mm (0.008 in)

2. If out of specification, resurface it.

CYLINDER WEAR

1. Measure cylinder bore for out-of-round and taper with a bore gauge. If beyond the limit, rebore all 4 cylinders. Replace cyl-

inder block if necessary.Standard inside diameter: 96.000 - 96.030 mm (3.7795 - 3.7807 in)

Refer to SDS

Wear limit: Less than 0.20 mm (0.0079 in)

Out-of-round (X þ Y) limit: Less than 0.020 mm (0.0008 in)

Taper (A þ B) limit: 0.20 mm (0.0079 in)

2. Check for scratches or abrasions. If abrasions are found, hone cylinder bore.

PISTON AND PISTON PIN CLEARANCE

Check clearance between pistons and piston pins. Clearance (A þ B):Standard0.002 to 0.012 mm (0.0001 to 0.0005 in)

Limit Less than 0.1 mm (0.004 in)

NEM007

SEM038

MEM042A

NEM002

ENGINE OVERHAULTD27Ti

Disassembly (Cont'd)

EM-127

http://vnx.su/

Page 221 of 1833

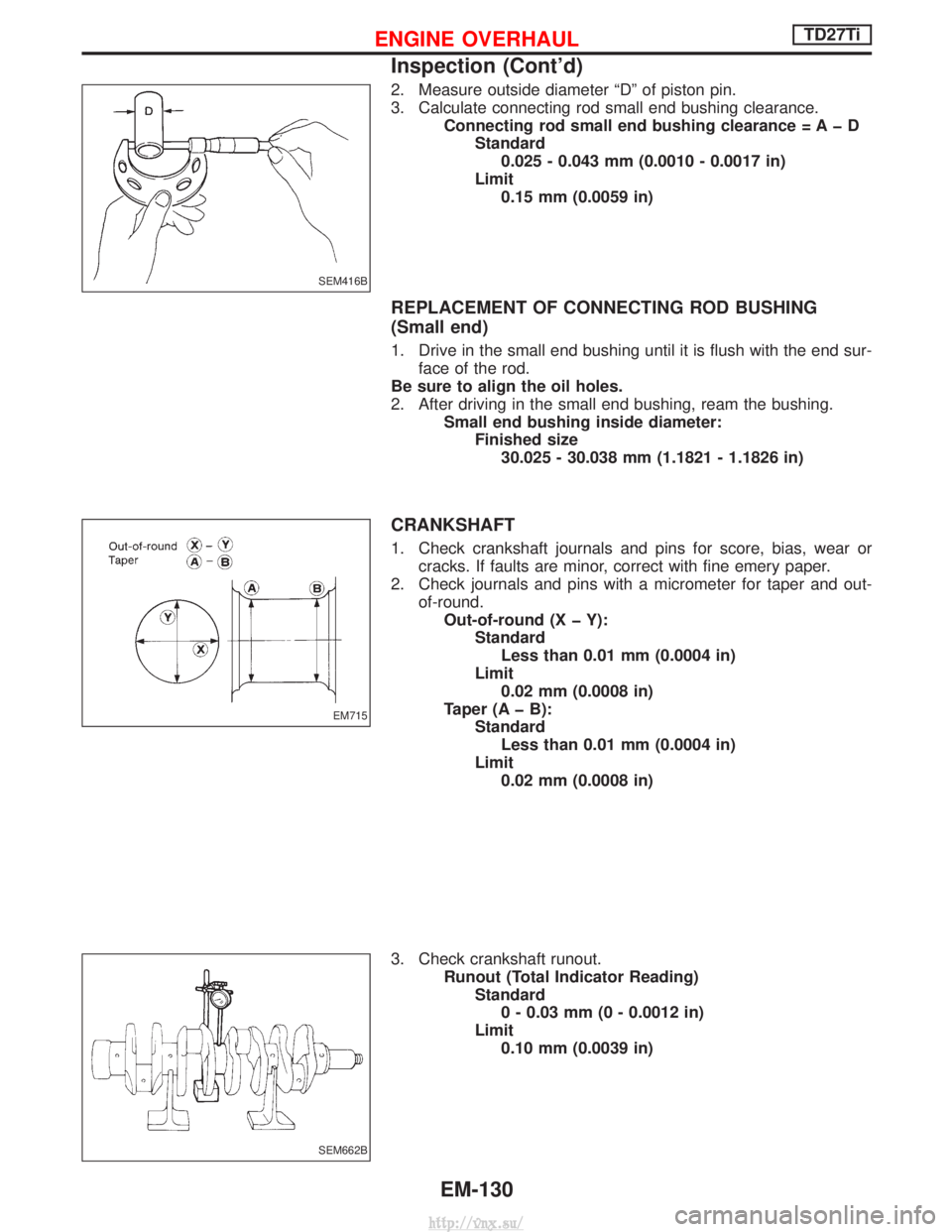

2. Measure outside diameter ªDº of piston pin.

3. Calculate connecting rod small end bushing clearance.Connecting rod small end bushing clearance = A þ DStandard0.025 - 0.043 mm (0.0010 - 0.0017 in)

Limit 0.15 mm (0.0059 in)

REPLACEMENT OF CONNECTING ROD BUSHING

(Small end)

1. Drive in the small end bushing until it is flush with the end sur- face of the rod.

Be sure to align the oil holes.

2. After driving in the small end bushing, ream the bushing. Small end bushing inside diameter:Finished size30.025 - 30.038 mm (1.1821 - 1.1826 in)

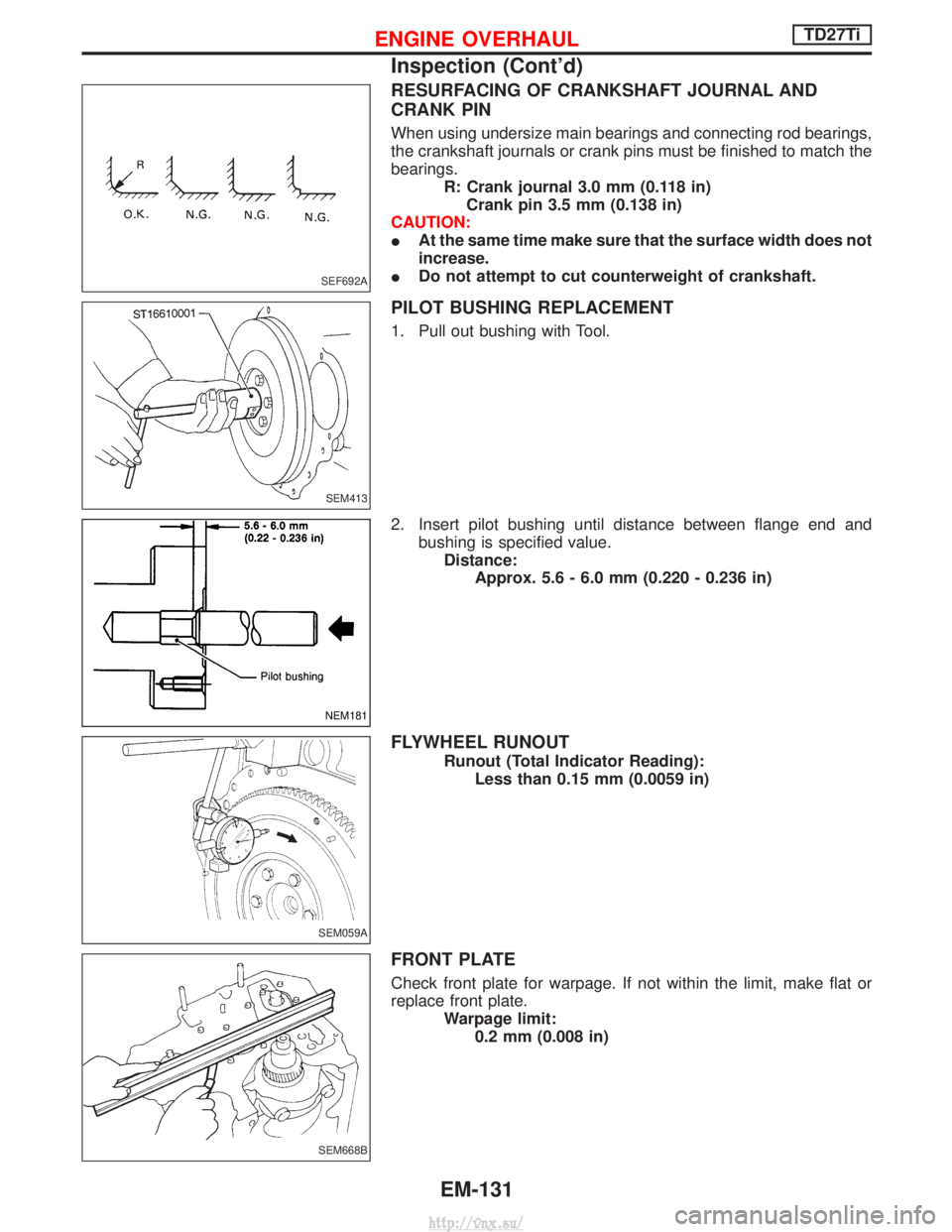

CRANKSHAFT

1. Check crankshaft journals and pins for score, bias, wear or cracks. If faults are minor, correct with fine emery paper.

2. Check journals and pins with a micrometer for taper and out- of-round.Out-of-round (X þ Y): StandardLess than 0.01 mm (0.0004 in)

Limit 0.02 mm (0.0008 in)

Taper (A þ B): StandardLess than 0.01 mm (0.0004 in)

Limit 0.02 mm (0.0008 in)

3. Check crankshaft runout. Runout (Total Indicator Reading)Standard0 - 0.03 mm (0 - 0.0012 in)

Limit 0.10 mm (0.0039 in)

SEM416B

EM715

SEM662B

ENGINE OVERHAULTD27Ti

Inspection (Cont'd)

EM-130

http://vnx.su/

Page 222 of 1833

RESURFACING OF CRANKSHAFT JOURNAL AND

CRANK PIN

When using undersize main bearings and connecting rod bearings,

the crankshaft journals or crank pins must be finished to match the

bearings.R: Crank journal 3.0 mm (0.118 in)Crank pin 3.5 mm (0.138 in)

CAUTION:

I At the same time make sure that the surface width does not

increase.

I Do not attempt to cut counterweight of crankshaft.

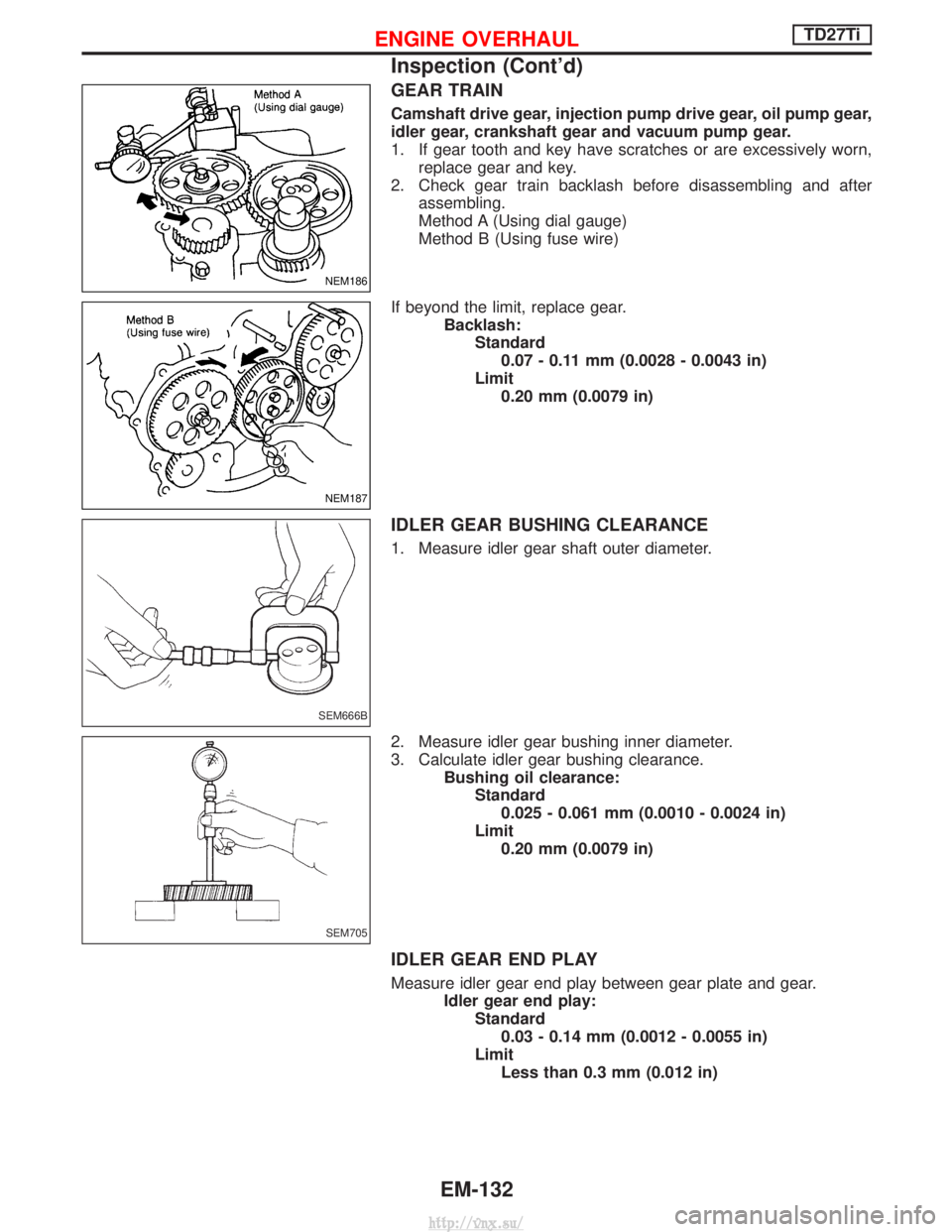

PILOT BUSHING REPLACEMENT

1. Pull out bushing with Tool.

2. Insert pilot bushing until distance between flange end and

bushing is specified value.Distance: Approx. 5.6 - 6.0 mm (0.220 - 0.236 in)

FLYWHEEL RUNOUT

Runout (Total Indicator Reading):Less than 0.15 mm (0.0059 in)

FRONT PLATE

Check front plate for warpage. If not within the limit, make flat or

replace front plate. Warpage limit:0.2 mm (0.008 in)

SEF692A

SEM413

NEM181

SEM059A

SEM668B

ENGINE OVERHAULTD27Ti

Inspection (Cont'd)

EM-131

http://vnx.su/

Page 223 of 1833

GEAR TRAIN

Camshaft drive gear, injection pump drive gear, oil pump gear,

idler gear, crankshaft gear and vacuum pump gear.

1. If gear tooth and key have scratches or are excessively worn,replace gear and key.

2. Check gear train backlash before disassembling and after assembling.

Method A (Using dial gauge)

Method B (Using fuse wire)

If beyond the limit, replace gear. Backlash:Standard0.07 - 0.11 mm (0.0028 - 0.0043 in)

Limit 0.20 mm (0.0079 in)

IDLER GEAR BUSHING CLEARANCE

1. Measure idler gear shaft outer diameter.

2. Measure idler gear bushing inner diameter.

3. Calculate idler gear bushing clearance. Bushing oil clearance:Standard0.025 - 0.061 mm (0.0010 - 0.0024 in)

Limit 0.20 mm (0.0079 in)

IDLER GEAR END PLAY

Measure idler gear end play between gear plate and gear. Idler gear end play:Standard0.03 - 0.14 mm (0.0012 - 0.0055 in)

Limit Less than 0.3 mm (0.012 in)

NEM186

NEM187

SEM666B

SEM705

ENGINE OVERHAULTD27Ti

Inspection (Cont'd)

EM-132

http://vnx.su/

Page 225 of 1833

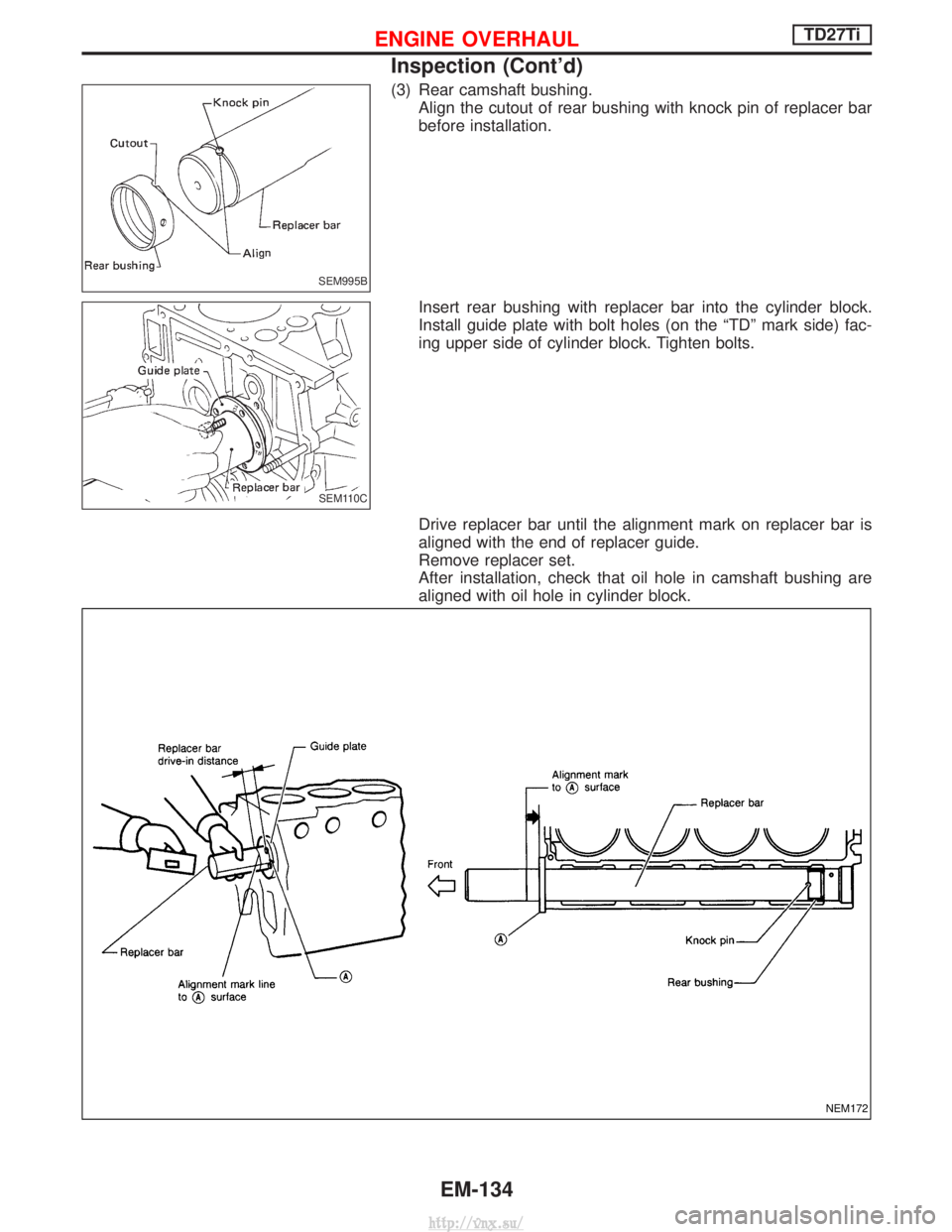

(3) Rear camshaft bushing.Align the cutout of rear bushing with knock pin of replacer bar

before installation.

Insert rear bushing with replacer bar into the cylinder block.

Install guide plate with bolt holes (on the ªTDº mark side) fac-

ing upper side of cylinder block. Tighten bolts.

Drive replacer bar until the alignment mark on replacer bar is

aligned with the end of replacer guide.

Remove replacer set.

After installation, check that oil hole in camshaft bushing are

aligned with oil hole in cylinder block.

SEM995B

SEM110C

NEM172

ENGINE OVERHAULTD27Ti

Inspection (Cont'd)

EM-134

http://vnx.su/

Page 227 of 1833

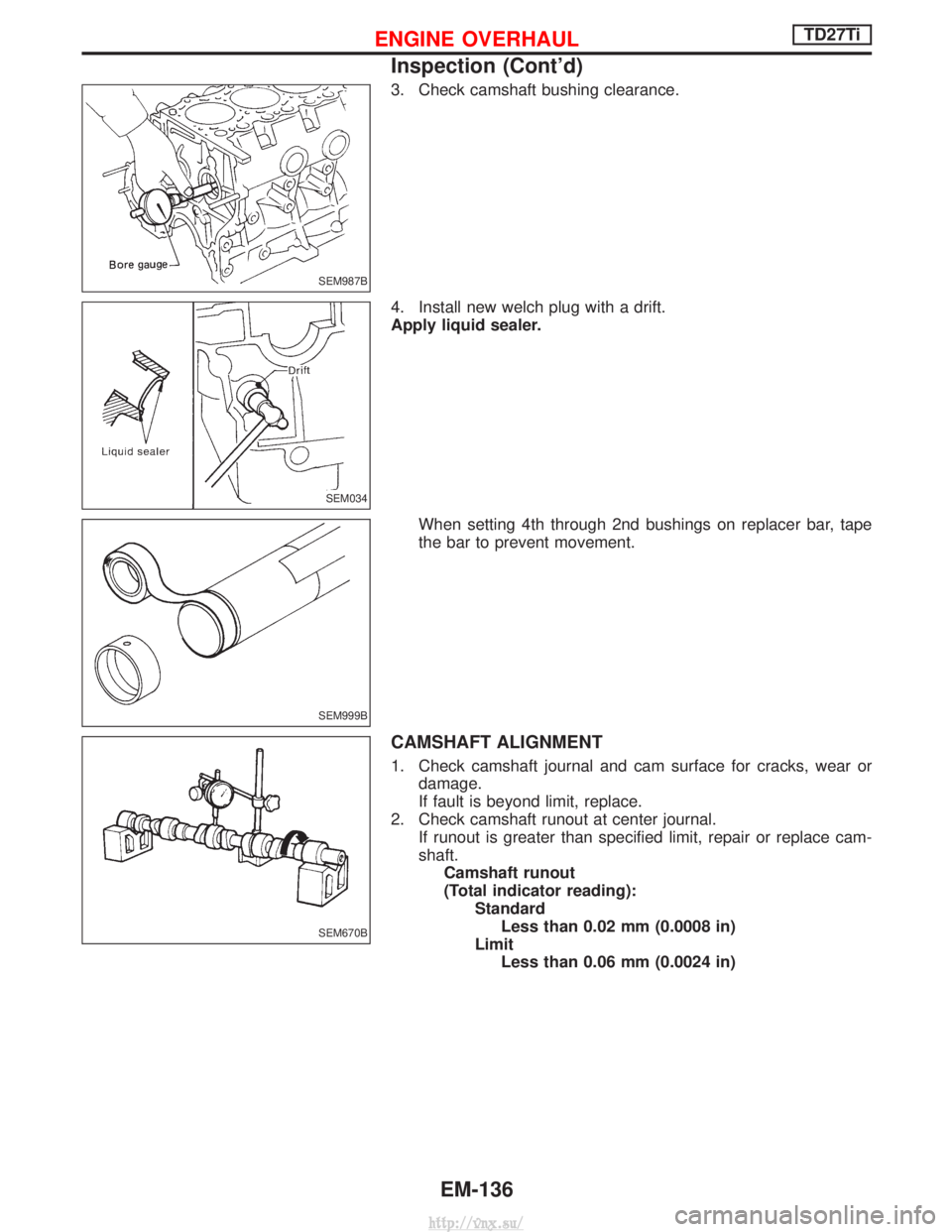

3. Check camshaft bushing clearance.

4. Install new welch plug with a drift.

Apply liquid sealer.When setting 4th through 2nd bushings on replacer bar, tape

the bar to prevent movement.

CAMSHAFT ALIGNMENT

1. Check camshaft journal and cam surface for cracks, wear ordamage.

If fault is beyond limit, replace.

2. Check camshaft runout at center journal. If runout is greater than specified limit, repair or replace cam-

shaft.Camshaft runout

(Total indicator reading): StandardLess than 0.02 mm (0.0008 in)

Limit Less than 0.06 mm (0.0024 in)

SEM987B

SEM034

SEM999B

SEM670B

ENGINE OVERHAULTD27Ti

Inspection (Cont'd)

EM-136

http://vnx.su/