fuel pump NISSAN TERRANO 2004 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 348 of 1833

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

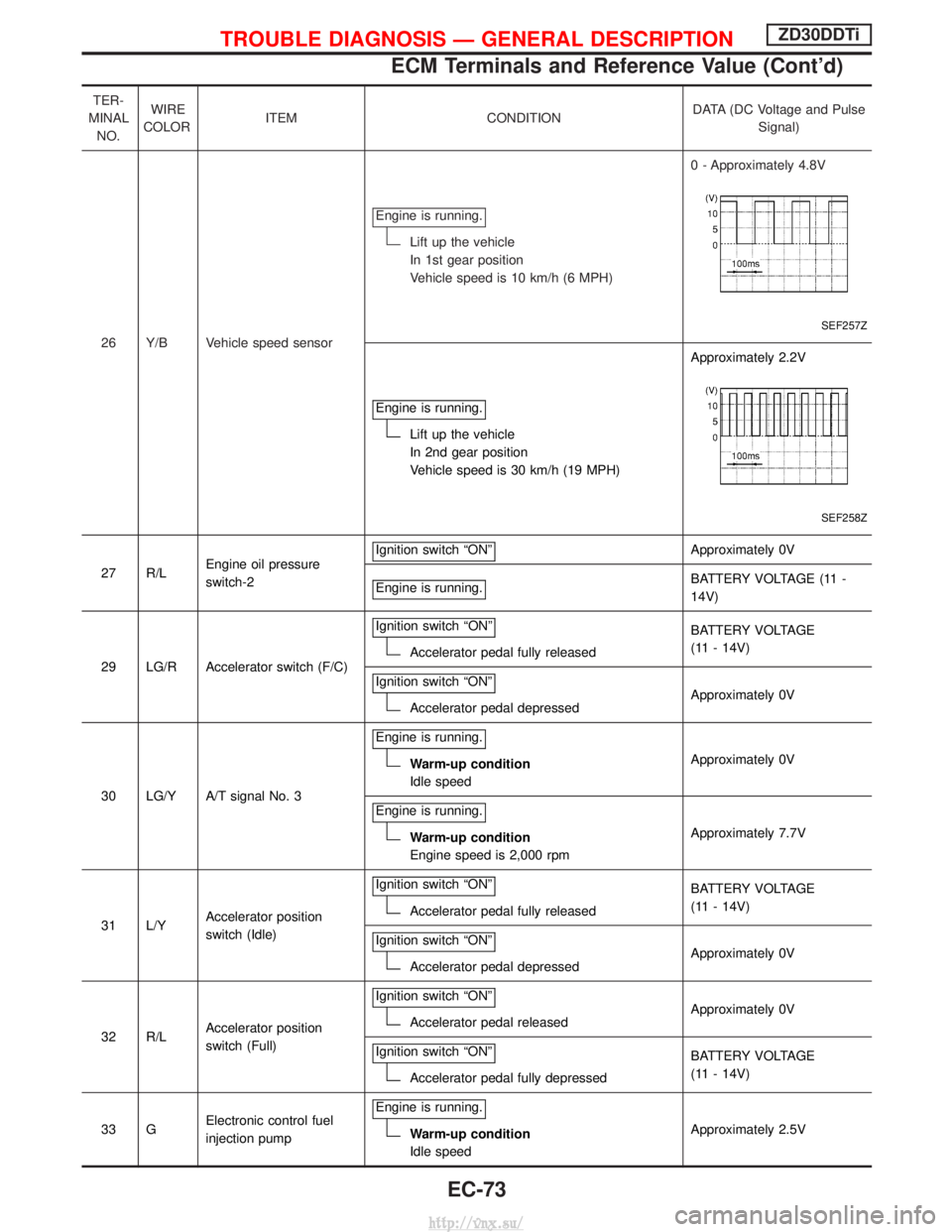

26 Y/B Vehicle speed sensor Engine is running.

Lift up the vehicle

In 1st gear position

Vehicle speed is 10 km/h (6 MPH)

0 - Approximately 4.8V

SEF257Z

Engine is running.

Lift up the vehicle

In 2nd gear position

Vehicle speed is 30 km/h (19 MPH)Approximately 2.2V

SEF258Z

27 R/L

Engine oil pressure

switch-2 Ignition switch ªONº

Approximately 0V

Engine is running.

BATTERY VOLTAGE (11 -

14V)

29 LG/R Accelerator switch (F/C) Ignition switch ªONº

Accelerator pedal fully released

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressed Approximately 0V

30 LG/Y A/T signal No. 3 Engine is running.

Warm-up condition

Idle speed

Approximately 0V

Engine is running.

Warm-up condition

Engine speed is 2,000 rpm Approximately 7.7V

31 L/Y Accelerator position

switch (Idle) Ignition switch ªONº

Accelerator pedal fully released

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressed Approximately 0V

32 R/L Accelerator position

switch (Full) Ignition switch ªONº

Accelerator pedal released

Approximately 0V

Ignition switch ªONº

Accelerator pedal fully depressed BATTERY VOLTAGE

(11 - 14V)

33 G Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-73

http://vnx.su/

Page 349 of 1833

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

35 R Mass air flow sensor Engine is running.

Warm-up condition

Idle speed 1.6 - 2.0V

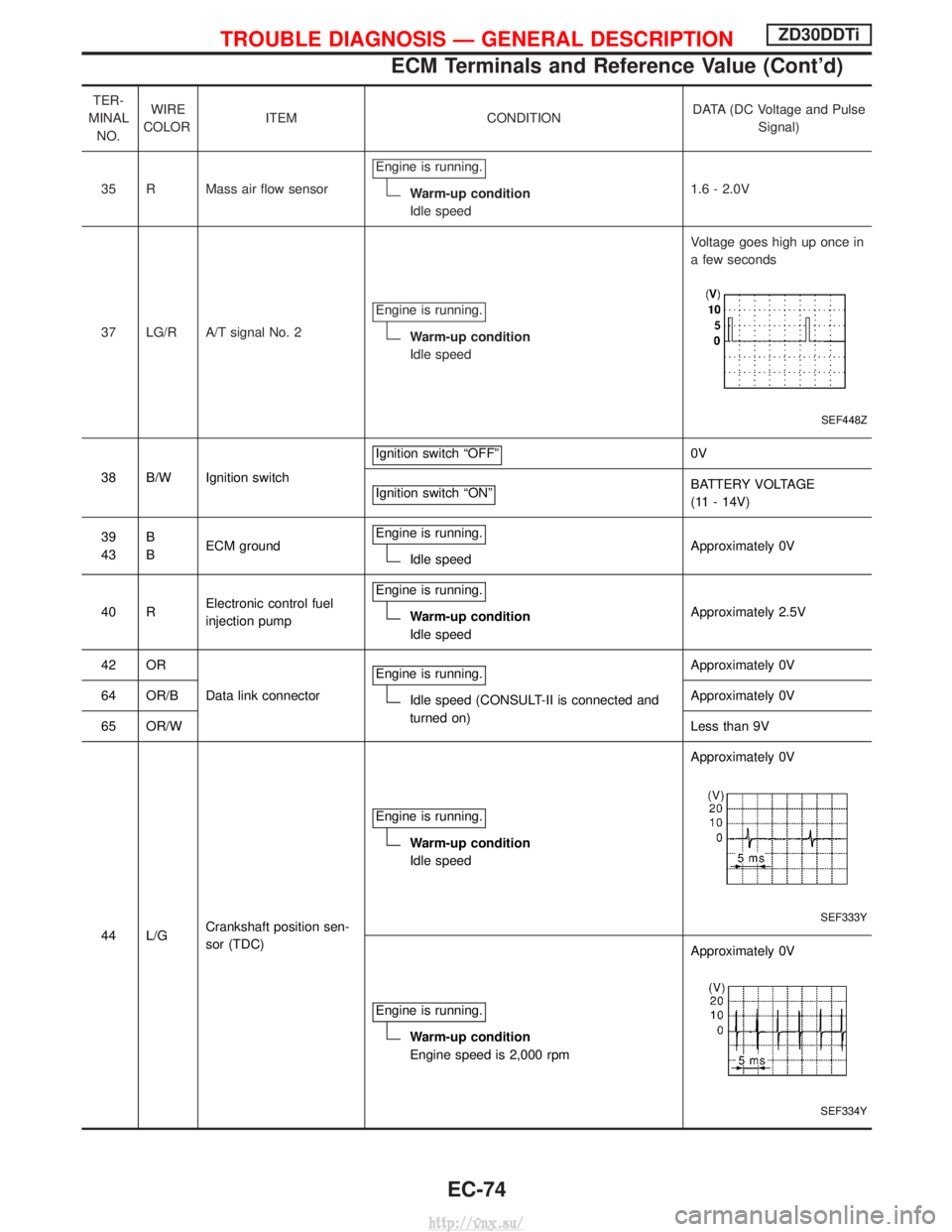

37 LG/R A/T signal No. 2 Engine is running.

Warm-up condition

Idle speed Voltage goes high up once in

a few seconds

SEF448Z

38 B/W Ignition switch

Ignition switch ªOFFº

0V

Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

39

43 B

B

ECM ground Engine is running.

Idle speed Approximately 0V

40 R Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

42 OR Data link connector Engine is running.

Idle speed (CONSULT-II is connected and

turned on) Approximately 0V

64 OR/B Approximately 0V

65 OR/W Less than 9V

44 L/G Crankshaft position sen-

sor (TDC) Engine is running.

Warm-up condition

Idle speed

Approximately 0V

SEF333Y

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 0V

SEF334Y

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-74

http://vnx.su/

Page 350 of 1833

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

46 G Charge air pressure sen-

sor Engine is running.

Warm-up condition

Idle speed

Approximately 2.0V

47 L/R Crankshaft position sen-

sor (TDC) ground Engine is running.

Warm-up condition

Idle speed

Approximately 0V

48 R/B Accelerator position sen-

sor power supply Ignition switch ªONº

Approximately 5V

49 W Sensor's power supply Ignition switch ªONº

Approximately 5V

50 B Sensors' ground Engine is running.

Warm-up condition

Idle speed Approximately 0V

51 B/W Accelerator position sen-

sor ground Engine is running.

Warm-up condition

Idle speed

Approximately 0V

52 Y Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.1V

53 OR Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 1.0V

54 R Swirl control valve con-

trol solenoid valve Engine is running.

Warm-up condition

At idle speed for more than 1 second

Lift up the vehicle

Gear position is in positions other than ªPº

and ªNeutralº

Approximately 0.1V

Engine is running.

Idle speed

Lift up the vehicle

Gear position is in ªPº or ªNeutralº BATTERY VOLTAGE

(11 - 14V)

56

61

11 6 B/W

B/W

B/W

Power supply for ECM Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-75

http://vnx.su/

Page 358 of 1833

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F108, E225

I Harness connectors M842, F135 (RHD models)

I Harness for open or short between ECM and engine ground

ERepair open circuit or short to ground or short to power in harness or connectors.

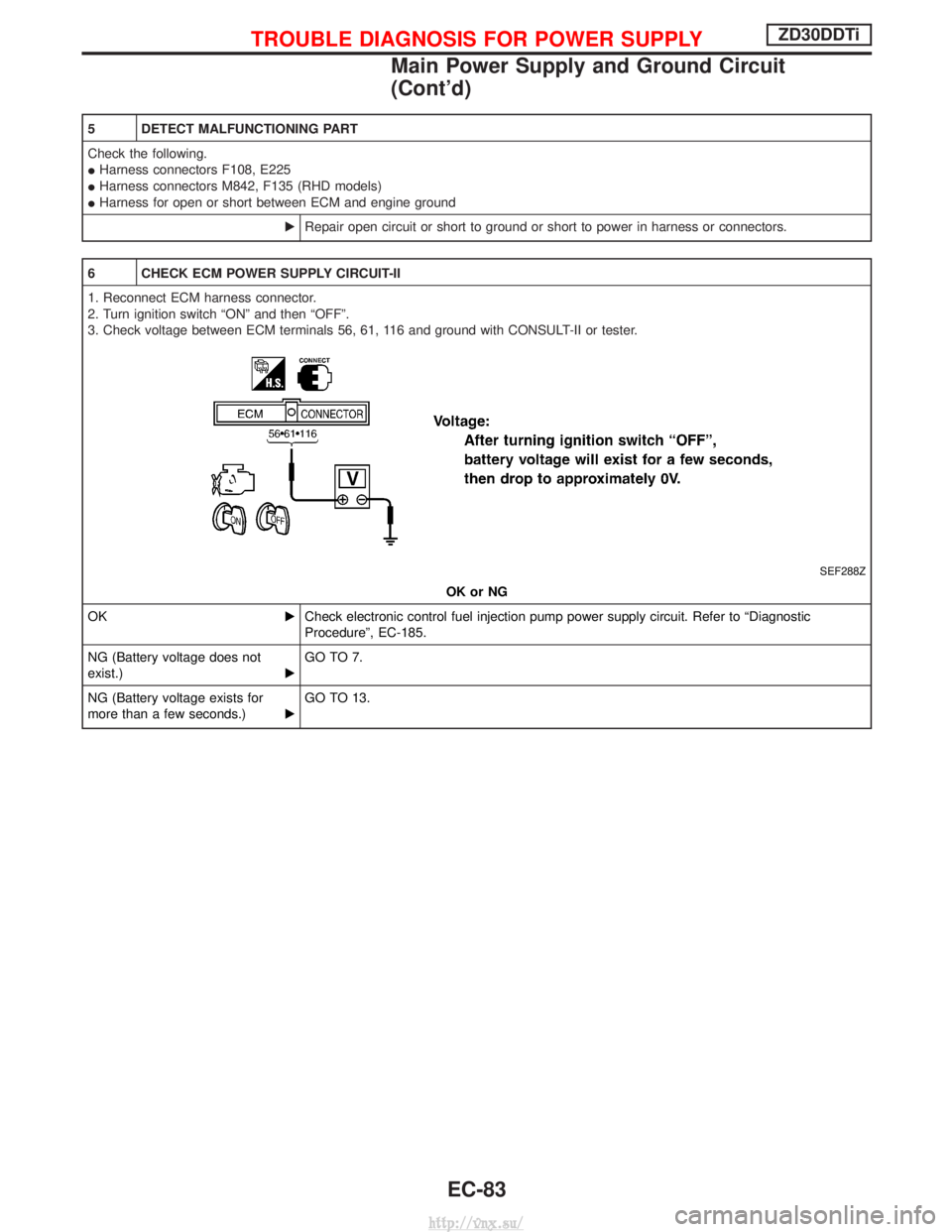

6 CHECK ECM POWER SUPPLY CIRCUIT-II

1. Reconnect ECM harness connector.

2. Turn ignition switch ªONº and then ªOFFº.

3. Check voltage between ECM terminals 56, 61, 116 and ground with CONSULT-II or tester.

SEF288Z

OK or NG

OK ECheck electronic control fuel injection pump power supply circuit. Refer to ªDiagnostic

Procedureº, EC-185.

NG (Battery voltage does not

exist.) EGO TO 7.

NG (Battery voltage exists for

more than a few seconds.) EGO TO 13.

TROUBLE DIAGNOSIS FOR POWER SUPPLYZD30DDTi

Main Power Supply and Ground Circuit

(Cont'd)

EC-83

http://vnx.su/

Page 398 of 1833

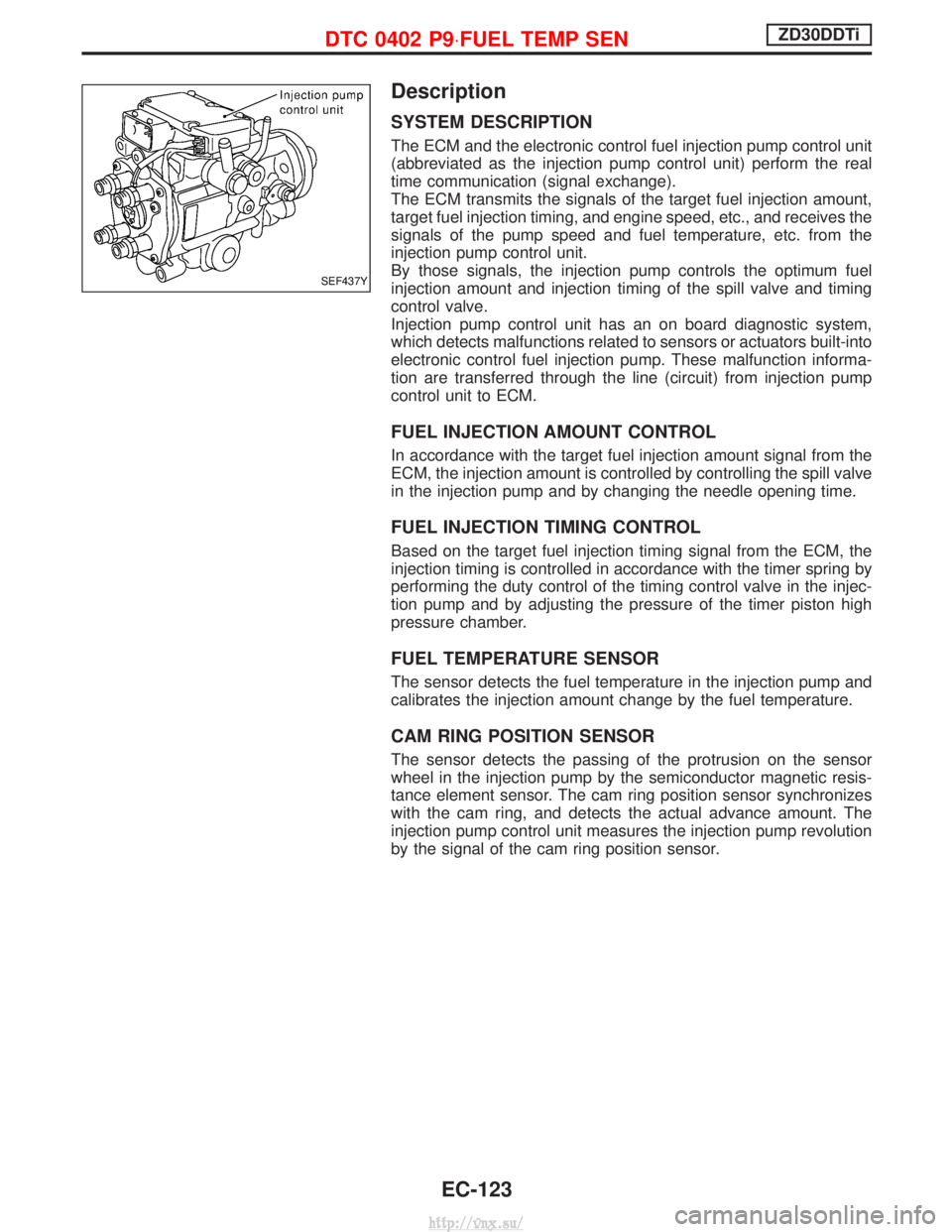

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives the

signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

SEF437Y

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-123

http://vnx.su/

Page 399 of 1833

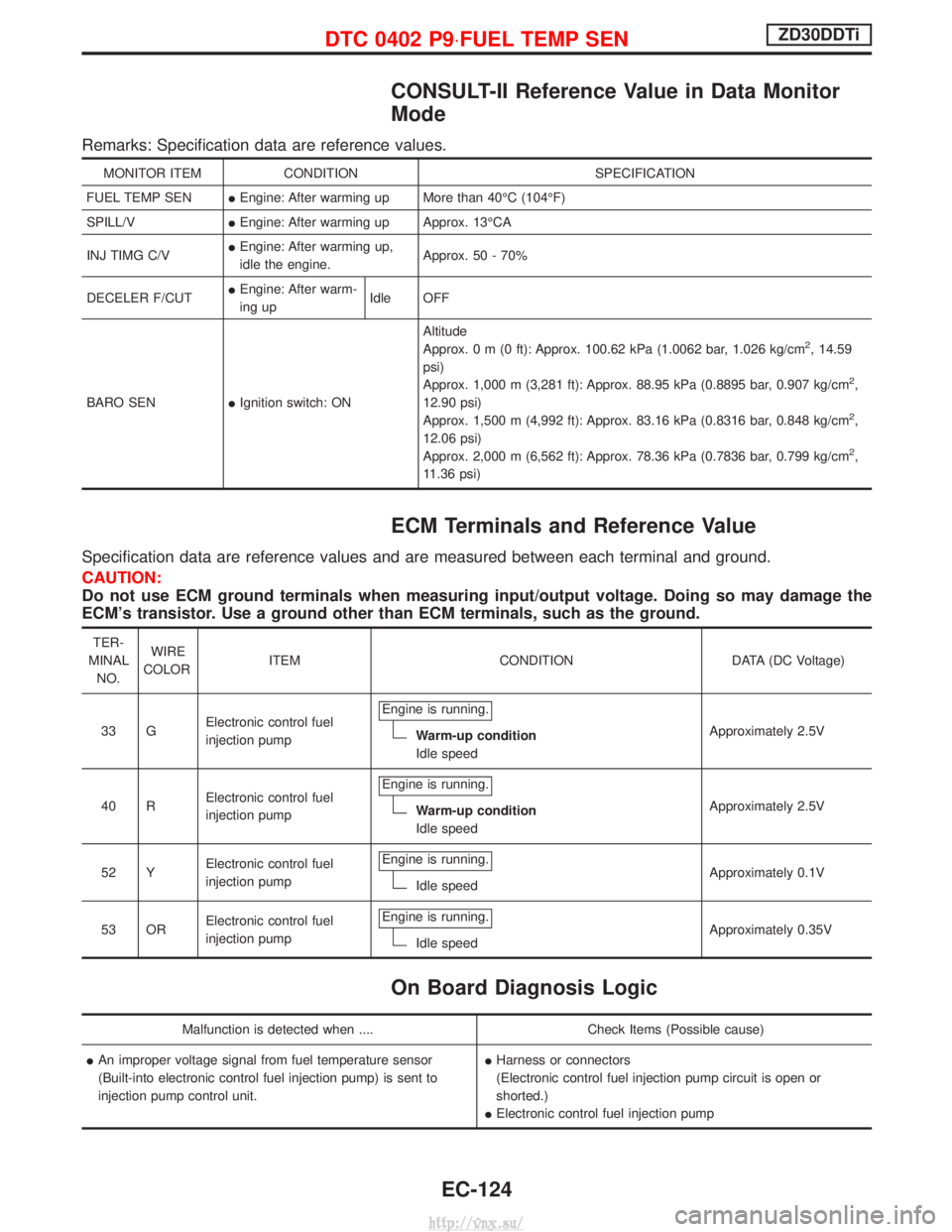

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

FUEL TEMP SEN IEngine: After warming up More than 40ÉC (104ÉF)

SPILL/V IEngine: After warming up Approx. 13ÉCA

INJ TIMG C/V I

Engine: After warming up,

idle the engine. Approx. 50 - 70%

DECELER F/CUT I

Engine: After warm-

ing up Idle OFF

BARO SEN IIgnition switch: ON Altitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

33 G Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

40 R Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

52 Y Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.1V

53 OR Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.35V

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible cause)

I An improper voltage signal from fuel temperature sensor

(Built-into electronic control fuel injection pump) is sent to

injection pump control unit. I

Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

I Electronic control fuel injection pump

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-124

http://vnx.su/

Page 403 of 1833

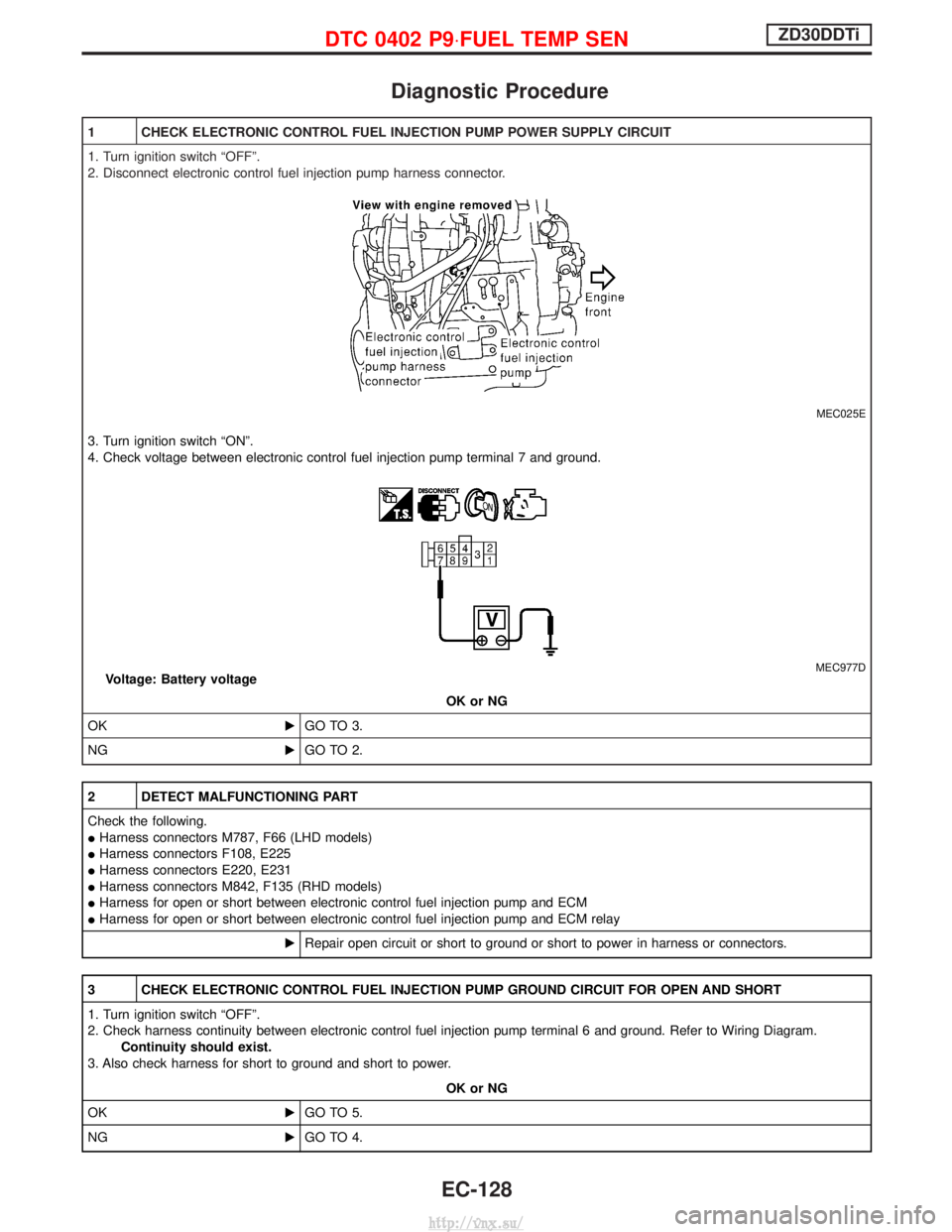

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltageOK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

I Harness connectors F108, E225

I Harness connectors E220, E231

I Harness connectors M842, F135 (RHD models)

I Harness for open or short between electronic control fuel injection pump and ECM

I Harness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-128

http://vnx.su/

Page 404 of 1833

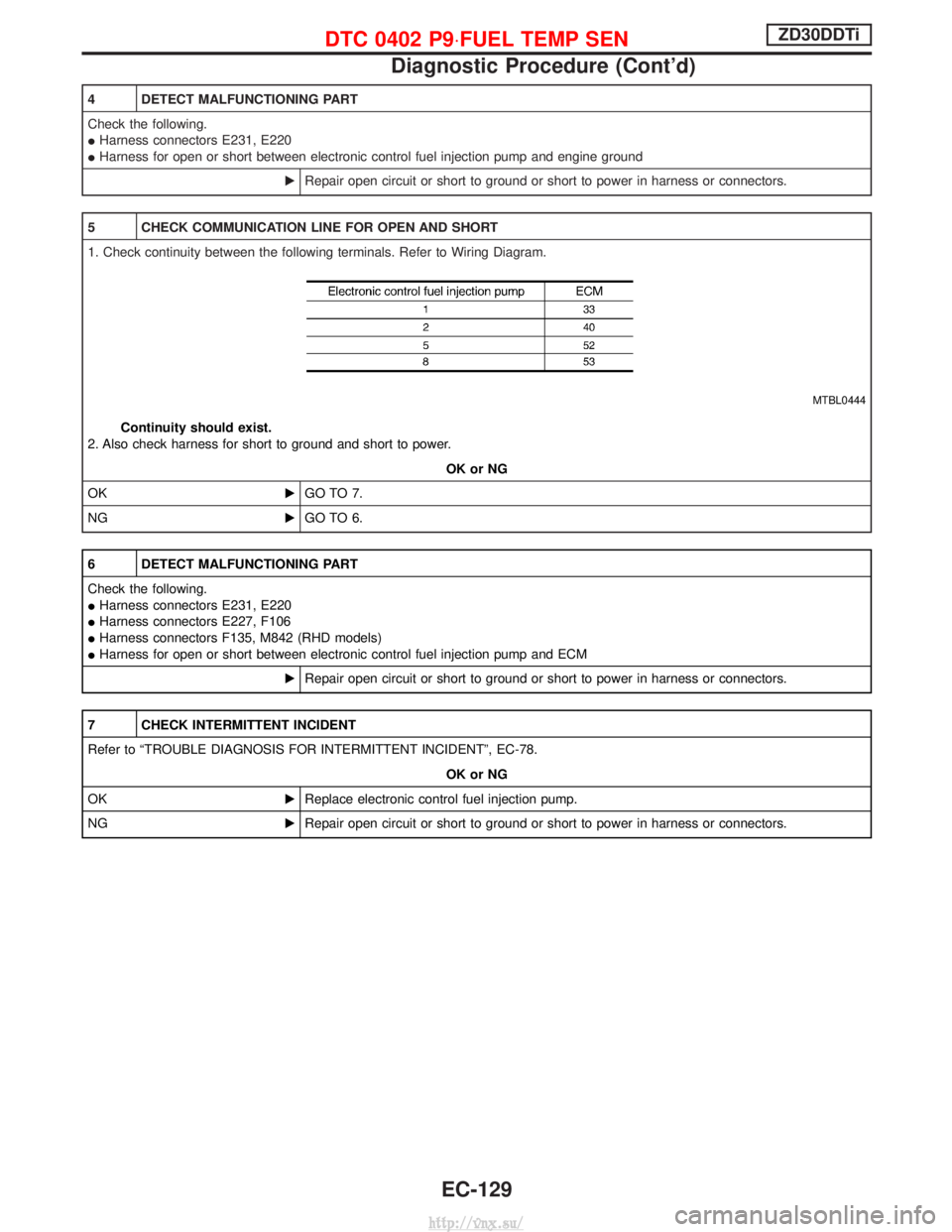

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E231, E220

I Harness for open or short between electronic control fuel injection pump and engine ground

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 7.

NG EGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E231, E220

I Harness connectors E227, F106

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between electronic control fuel injection pump and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

OK or NG

OK EReplace electronic control fuel injection pump.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0402 P9×FUEL TEMP SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-129

http://vnx.su/

Page 441 of 1833

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives the

signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

SEF437Y

DTC 0701 P1×CAM POS SENZD30DDTi

EC-166

http://vnx.su/

Page 442 of 1833

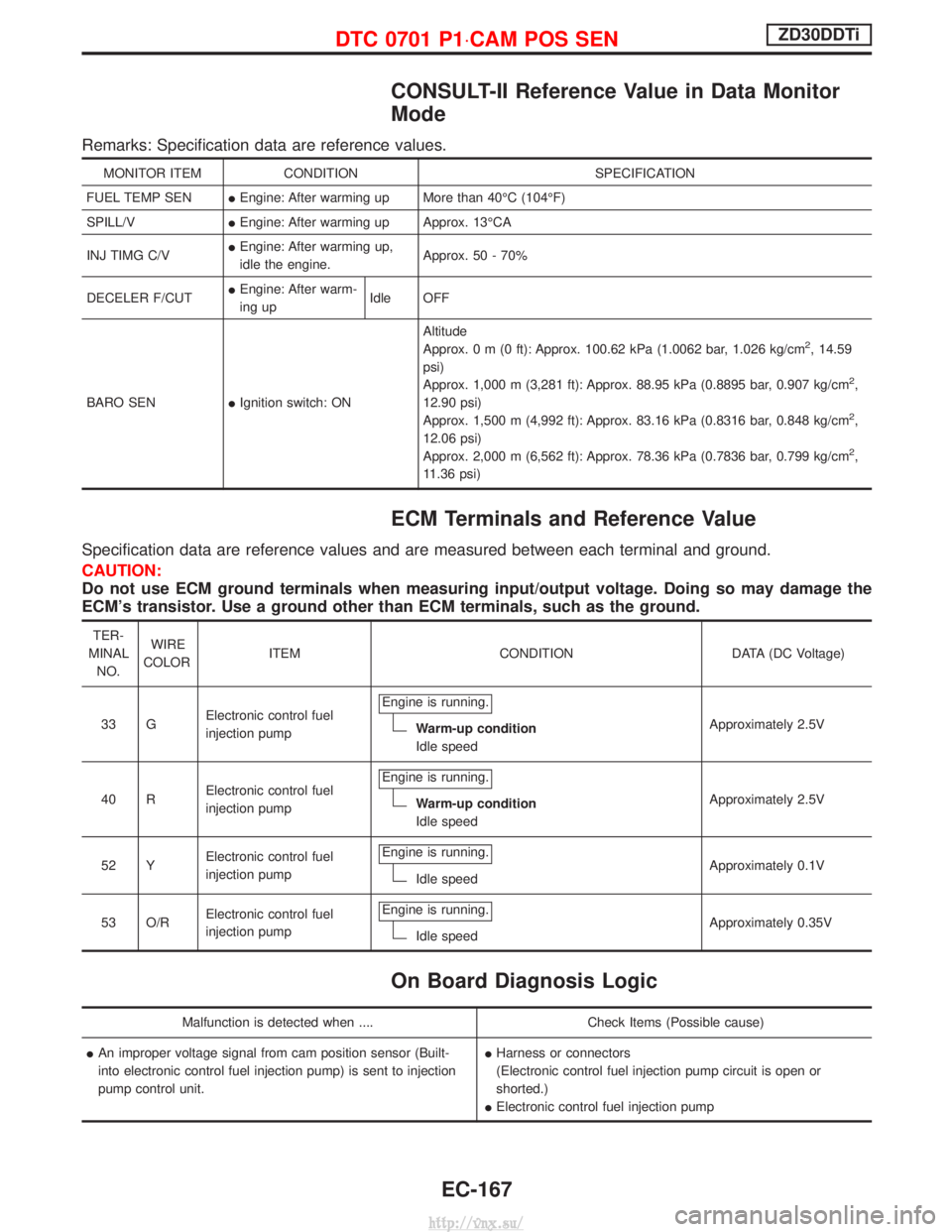

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

FUEL TEMP SEN IEngine: After warming up More than 40ÉC (104ÉF)

SPILL/V IEngine: After warming up Approx. 13ÉCA

INJ TIMG C/V I

Engine: After warming up,

idle the engine. Approx. 50 - 70%

DECELER F/CUT I

Engine: After warm-

ing up Idle OFF

BARO SEN IIgnition switch: ON Altitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

33 G Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

40 R Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

52 Y Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.1V

53 O/R Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.35V

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible cause)

I An improper voltage signal from cam position sensor (Built-

into electronic control fuel injection pump) is sent to injection

pump control unit. I

Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

I Electronic control fuel injection pump

DTC 0701 P1×CAM POS SENZD30DDTi

EC-167

http://vnx.su/