Ignition NISSAN TERRANO 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 390 of 1833

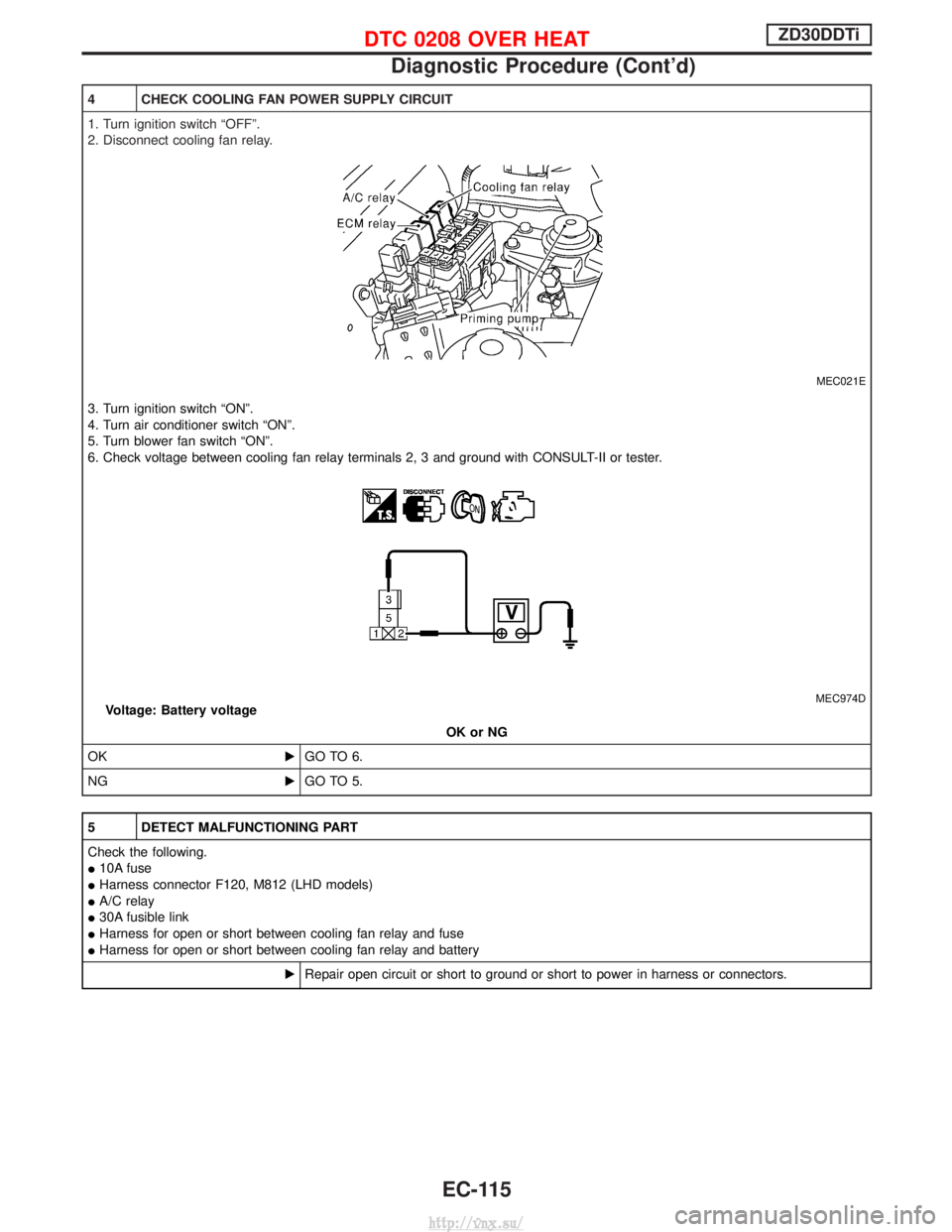

4 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay.

MEC021E

3. Turn ignition switch ªONº.

4. Turn air conditioner switch ªONº.

5. Turn blower fan switch ªONº.

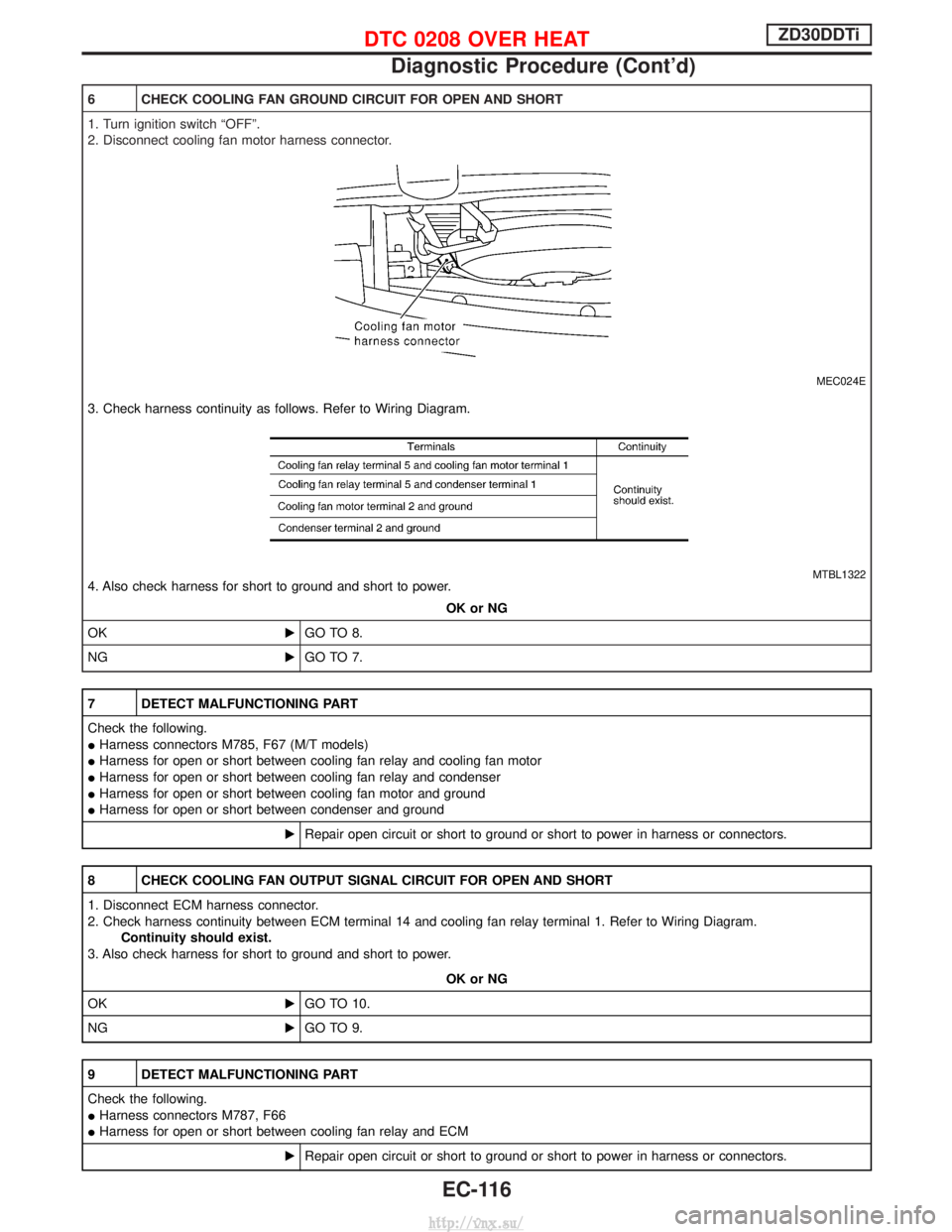

6. Check voltage between cooling fan relay terminals 2, 3 and ground with CONSULT-II or tester.

MEC974DVoltage: Battery voltageOK or NG

OK EGO TO 6.

NG EGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

I10A fuse

I Harness connector F120, M812 (LHD models)

I A/C relay

I 30A fusible link

I Harness for open or short between cooling fan relay and fuse

I Harness for open or short between cooling fan relay and battery

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-115

http://vnx.su/

Page 391 of 1833

6 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor harness connector.

MEC024E

3. Check harness continuity as follows. Refer to Wiring Diagram.

MTBL13224. Also check harness for short to ground and short to power.OK or NG

OK EGO TO 8.

NG EGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M785, F67 (M/T models)

I Harness for open or short between cooling fan relay and cooling fan motor

I Harness for open or short between cooling fan relay and condenser

I Harness for open or short between cooling fan motor and ground

I Harness for open or short between condenser and ground

ERepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 14 and cooling fan relay terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 10.

NG EGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66

I Harness for open or short between cooling fan relay and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-116

http://vnx.su/

Page 396 of 1833

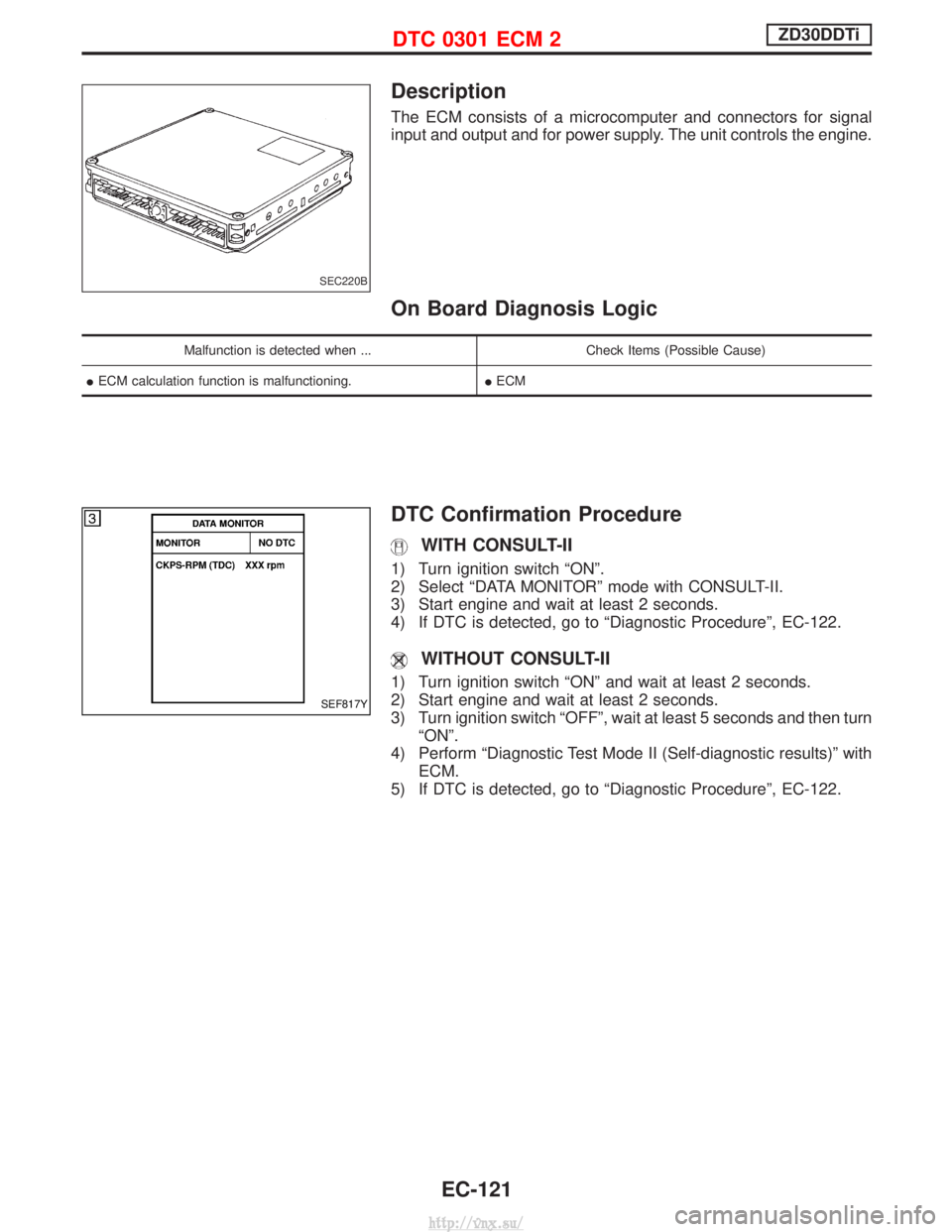

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

Malfunction is detected when ...Check Items (Possible Cause)

I ECM calculation function is malfunctioning. IECM

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-122.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-122.

SEC220B

SEF817Y

DTC 0301 ECM 2ZD30DDTi

EC-121

http://vnx.su/

Page 397 of 1833

Diagnostic Procedure

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-121, again.

5. Is the malfunction displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-121, again.

4. Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

5. Is the DTC 0301 displayed again?

YesorNo

Ye s EReplace ECM.

No EINSPECTION END

DTC 0301 ECM 2ZD30DDTi

EC-122

http://vnx.su/

Page 399 of 1833

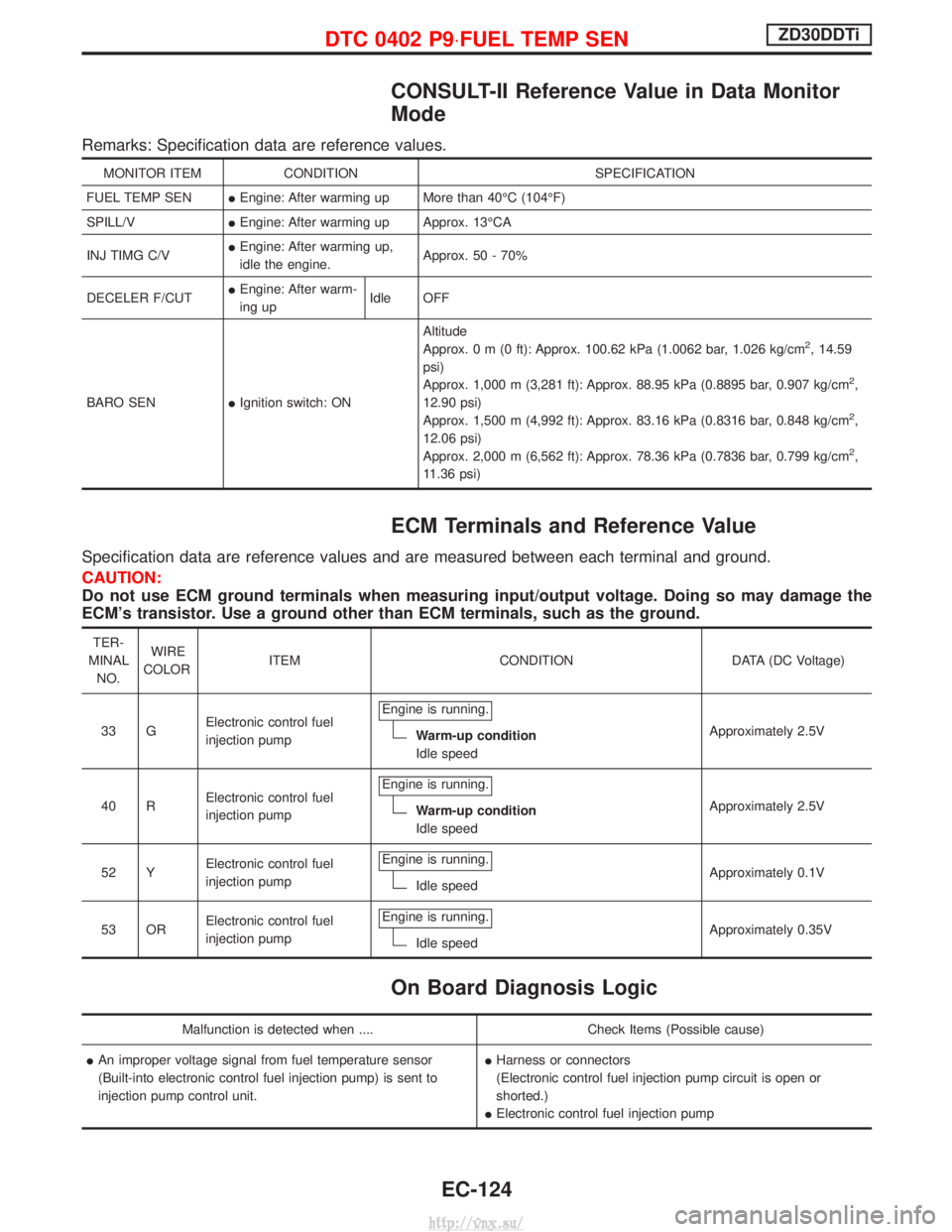

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

FUEL TEMP SEN IEngine: After warming up More than 40ÉC (104ÉF)

SPILL/V IEngine: After warming up Approx. 13ÉCA

INJ TIMG C/V I

Engine: After warming up,

idle the engine. Approx. 50 - 70%

DECELER F/CUT I

Engine: After warm-

ing up Idle OFF

BARO SEN IIgnition switch: ON Altitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

33 G Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

40 R Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

52 Y Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.1V

53 OR Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.35V

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible cause)

I An improper voltage signal from fuel temperature sensor

(Built-into electronic control fuel injection pump) is sent to

injection pump control unit. I

Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

I Electronic control fuel injection pump

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-124

http://vnx.su/

Page 400 of 1833

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-128.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed. (If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-128.SEF817Y

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-125

http://vnx.su/

Page 403 of 1833

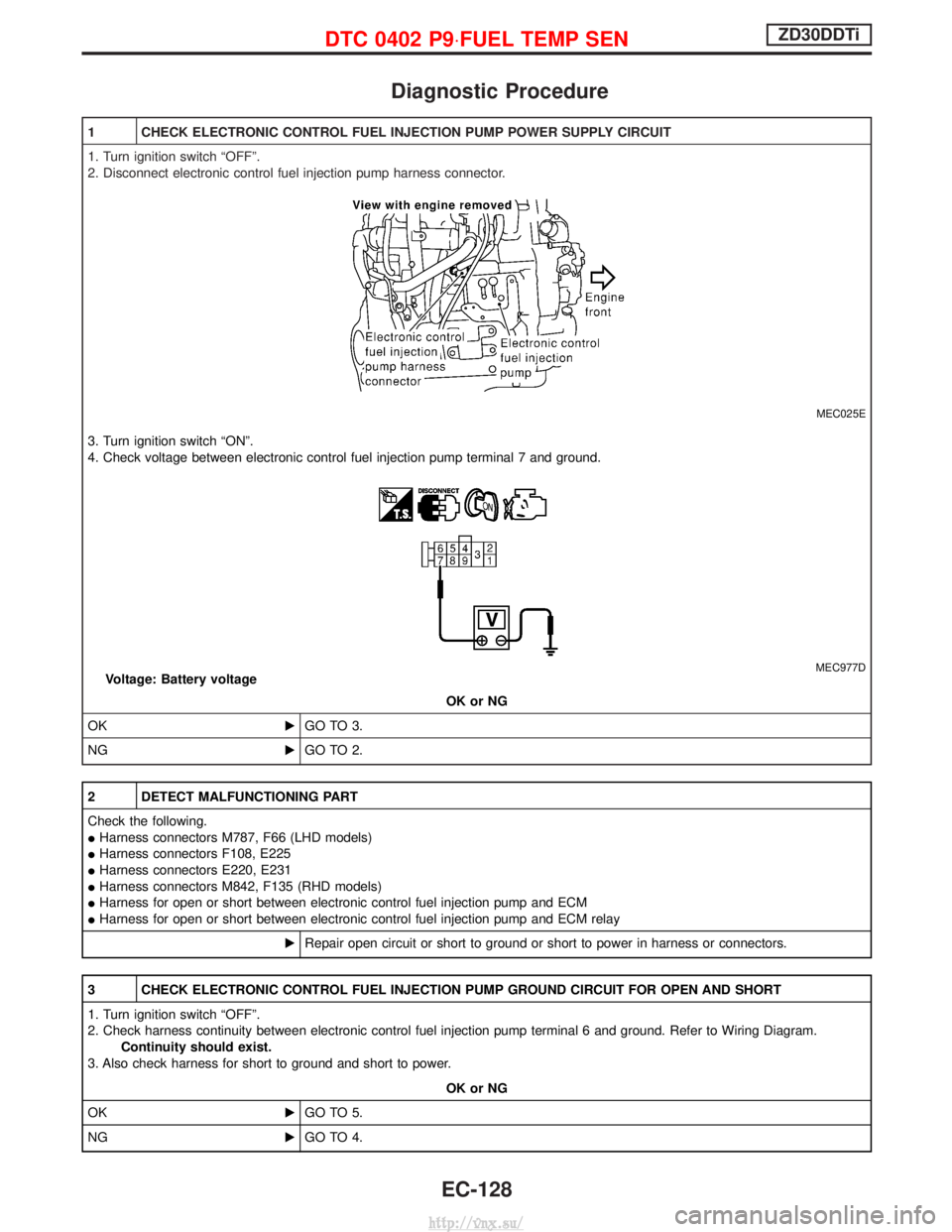

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltageOK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

I Harness connectors F108, E225

I Harness connectors E220, E231

I Harness connectors M842, F135 (RHD models)

I Harness for open or short between electronic control fuel injection pump and ECM

I Harness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0402 P9×FUEL TEMP SENZD30DDTi

EC-128

http://vnx.su/

Page 406 of 1833

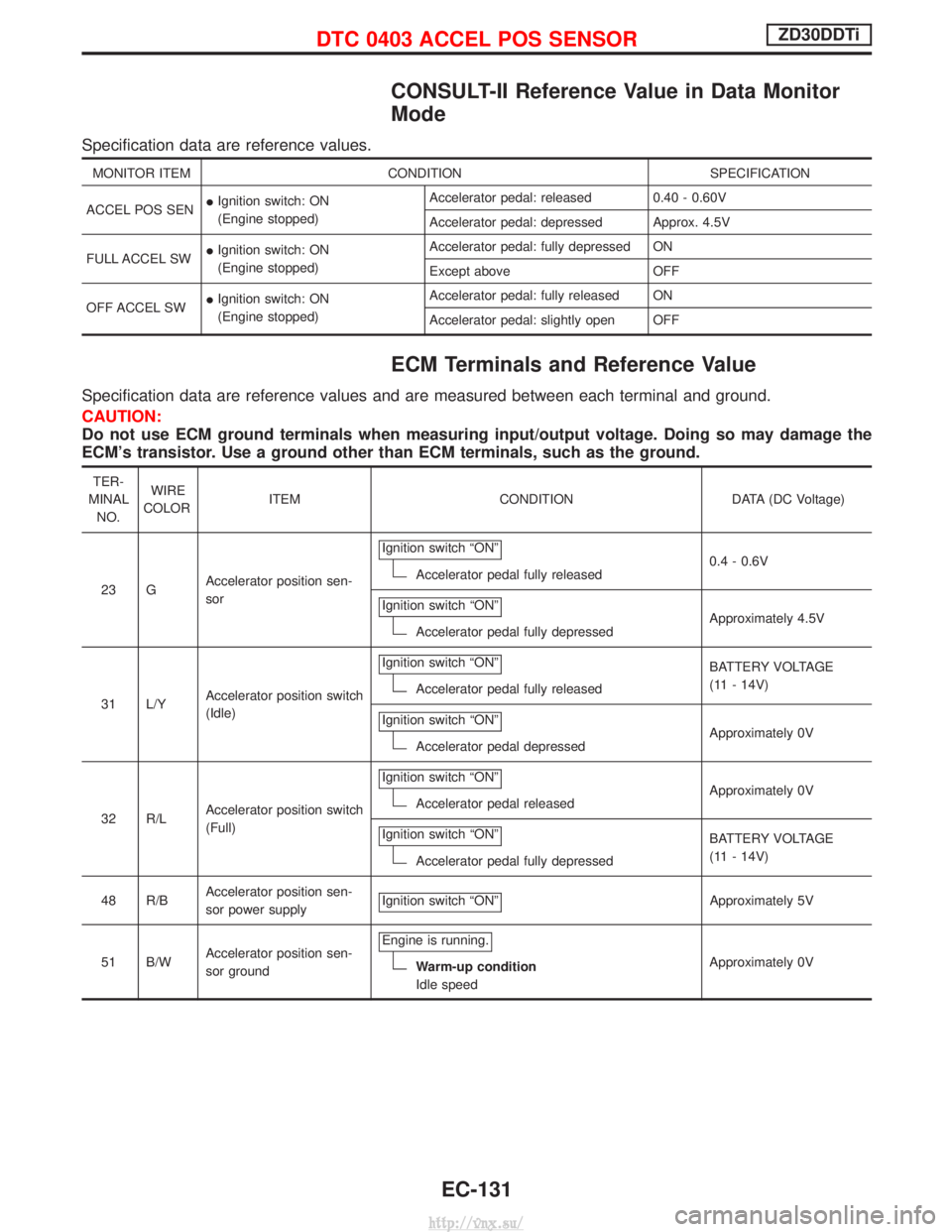

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

ACCEL POS SEN I

Ignition switch: ON

(Engine stopped) Accelerator pedal: released 0.40 - 0.60V

Accelerator pedal: depressed Approx. 4.5V

FULL ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully depressed ON

Except above OFF

OFF ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

23 G Accelerator position sen-

sor Ignition switch ªONº

Accelerator pedal fully released

0.4 - 0.6V

Ignition switch ªONº

Accelerator pedal fully depressed Approximately 4.5V

31 L/Y Accelerator position switch

(Idle) Ignition switch ªONº

Accelerator pedal fully released

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressed Approximately 0V

32 R/L Accelerator position switch

(Full) Ignition switch ªONº

Accelerator pedal released

Approximately 0V

Ignition switch ªONº

Accelerator pedal fully depressed BATTERY VOLTAGE

(11 - 14V)

48 R/B Accelerator position sen-

sor power supply Ignition switch ªONº

Approximately 5V

51 B/W Accelerator position sen-

sor ground Engine is running.

Warm-up condition

Idle speed

Approximately 0V

DTC 0403 ACCEL POS SENSORZD30DDTi

EC-131

http://vnx.su/

Page 407 of 1833

On Board Diagnosis Logic

Malfunction is detected when ...Check Items (Possible Cause)

I The relation between sensor and switch signal is not in the

normal range during the specified accelerator position. I

Harness or connectors

(The sensor circuit is open or shorted.)

I Accelerator position sensor

I Accelerator position switch

I Accelerator switch (F/C)

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress and release fully accelerator pedal slowly.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-144.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº.

2) Depress and release fully accelerator pedal slowly.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-144.

SEF817Y

DTC 0403 ACCEL POS SENSORZD30DDTi

EC-132

http://vnx.su/

Page 412 of 1833

Diagnostic Procedure

A/T MODELS

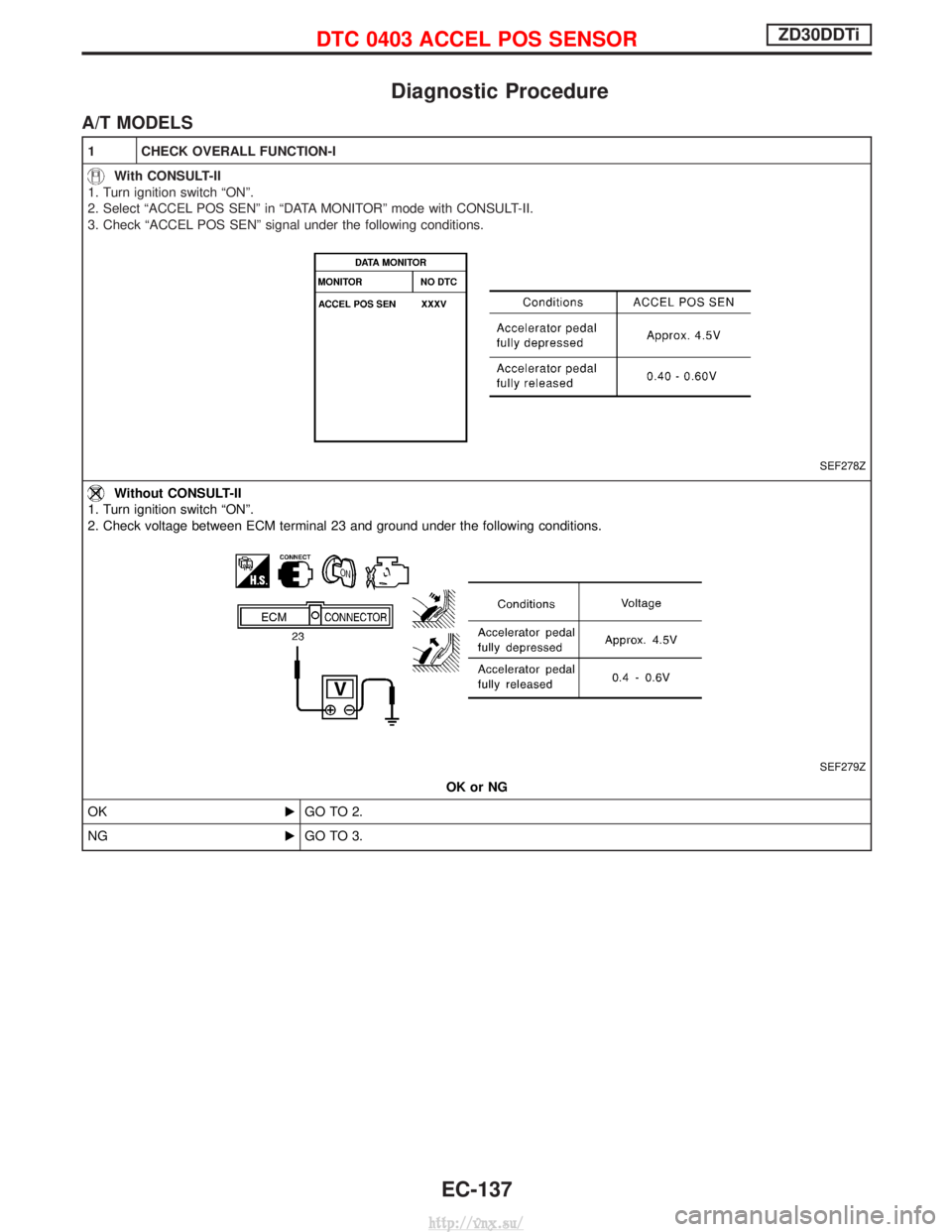

1 CHECK OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªACCEL POS SENº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªACCEL POS SENº signal under the following conditions.

SEF278Z

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 23 and ground under the following conditions.

SEF279Z

OK or NG

OK EGO TO 2.

NG EGO TO 3.

DTC 0403 ACCEL POS SENSORZD30DDTi

EC-137

http://vnx.su/