Ignition NISSAN TERRANO 2004 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 423 of 1833

8 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªCLEARº.

EGO TO 10.

9 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

EGO TO 10.

10 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

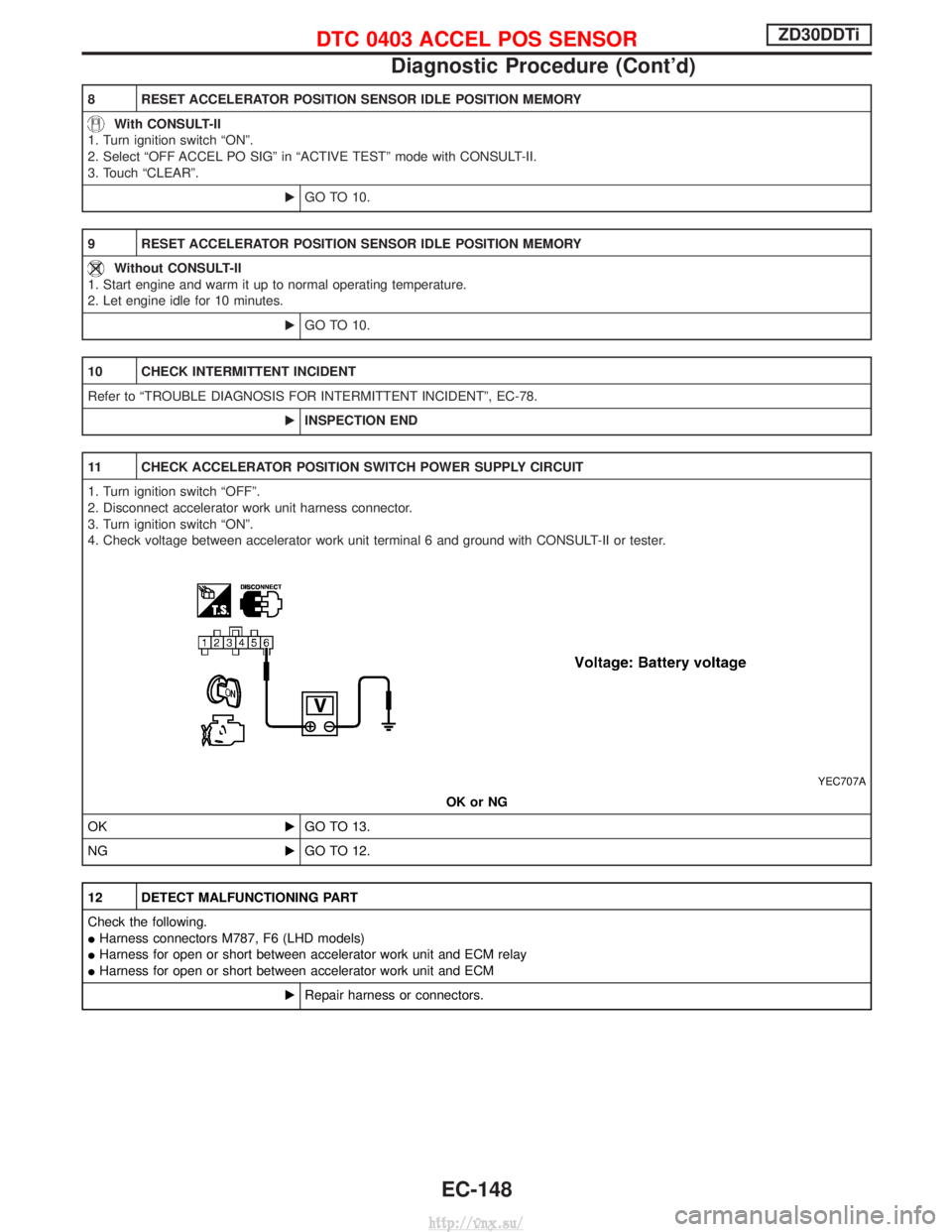

11 CHECK ACCELERATOR POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator work unit harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between accelerator work unit terminal 6 and ground with CONSULT-II or tester.

YEC707A

OK or NG

OK EGO TO 13.

NG EGO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F6 (LHD models)

I Harness for open or short between accelerator work unit and ECM relay

I Harness for open or short between accelerator work unit and ECM

ERepair harness or connectors.

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-148

http://vnx.su/

Page 424 of 1833

13 CHECK ACCELERATOR POSITION SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between accelerator work unit terminal 5 and ECM terminal 31. Refer to Wiring Diagram.Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 14.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

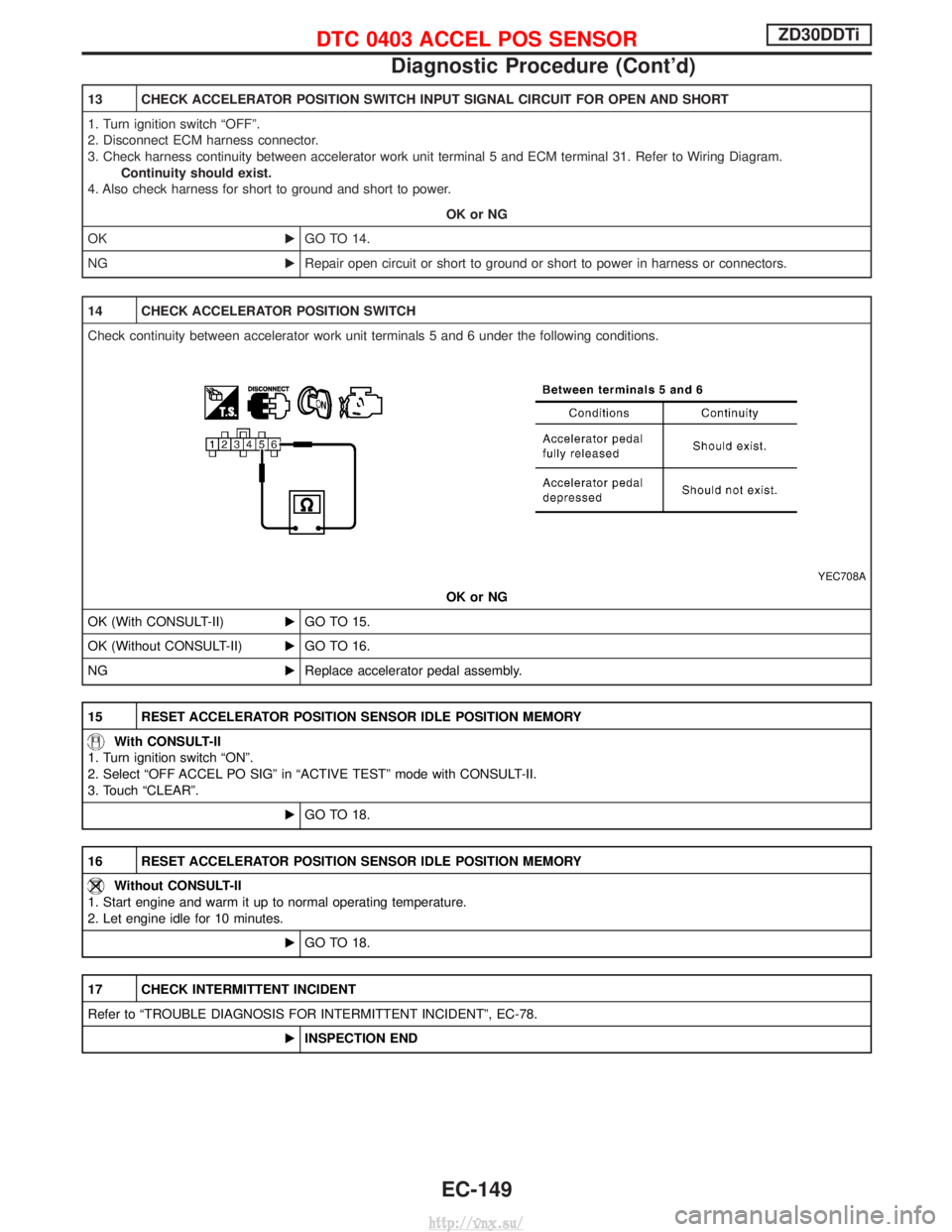

14 CHECK ACCELERATOR POSITION SWITCH

Check continuity between accelerator work unit terminals 5 and 6 under the following conditions.

YEC708A

OK or NG

OK (With CONSULT-II) EGO TO 15.

OK (Without CONSULT-II) EGO TO 16.

NG EReplace accelerator pedal assembly.

15 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªCLEARº.

EGO TO 18.

16 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

EGO TO 18.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-149

http://vnx.su/

Page 425 of 1833

On Board Diagnosis Logic

Malfunction is detected when ...Check Items (Possible Cause)

I An excessively high voltage from the mass air flow sensor is

sent to ECM when engine is running. I

Air duct

I Charge air cooler

I Variable nozzle turbocharger control system

I Variable nozzle turbocharger

I Mass air flow sensor

I Harness or connectors

(The mass air flow sensor circuit is shorted.)

DTC Confirmation Procedure

NOTE:

If DTC 0406 ªINT AIR VOLº displayed with DTC 0102 ªMASS

AIR FLOW SENº, perform trouble diagnosis for DTC 0102

ªMASS AIR FLOW SENº first. (See EC-88.)

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle.

5) Maintain the engine speed more than 4,000 rpm for at least 10

seconds.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-151.

WITHOUT CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Drive vehicle.

3) Maintain the engine speed more than 4,000 rpm for at least 10 seconds.

4) Stop vehicle.

5) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-151.SEF817Y

DTC 0406 INT AIR VOLZD30DDTi

EC-150

http://vnx.su/

Page 428 of 1833

On Board Diagnosis Logic

Malfunction is detected when ...Check Items (Possible Cause)

I An improper signal from the sensor is sent to ECM during

engine running and cranking. I

Harness or connectors

(The sensor circuit is open.)

I Crankshaft position sensor (TDC)

DTC Confirmation Procedure

Before performing the following procedure, confirm that bat-

tery voltage is more than 10V.

WITH CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-156.

WITHOUT CONSULT-II

1) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle speed.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-156.

SEF817Y

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-153

http://vnx.su/

Page 431 of 1833

Diagnostic Procedure

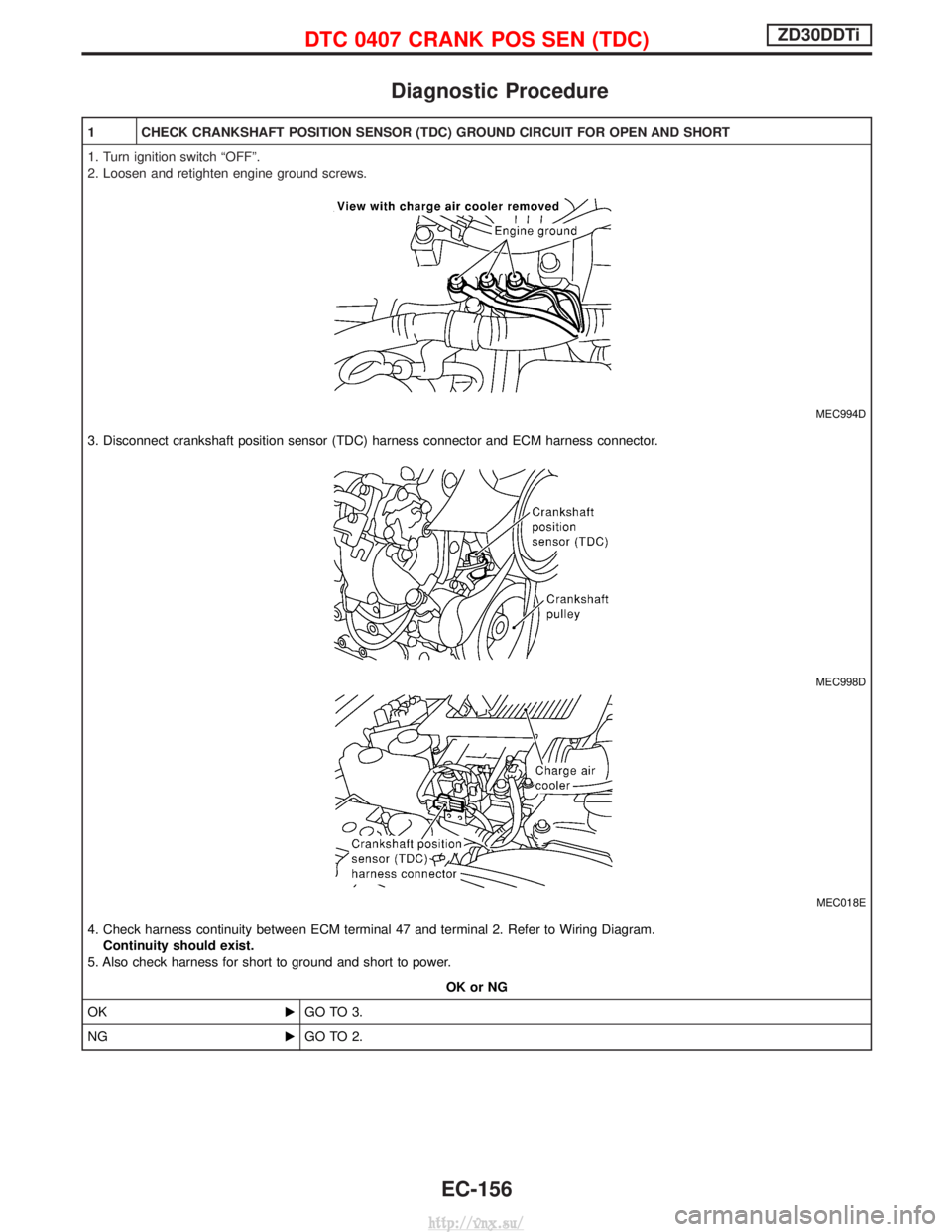

1 CHECK CRANKSHAFT POSITION SENSOR (TDC) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

MEC994D

3. Disconnect crankshaft position sensor (TDC) harness connector and ECM harness connector.

MEC998D

MEC018E

4. Check harness continuity between ECM terminal 47 and terminal 2. Refer to Wiring Diagram.Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 3.

NG EGO TO 2.

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-156

http://vnx.su/

Page 436 of 1833

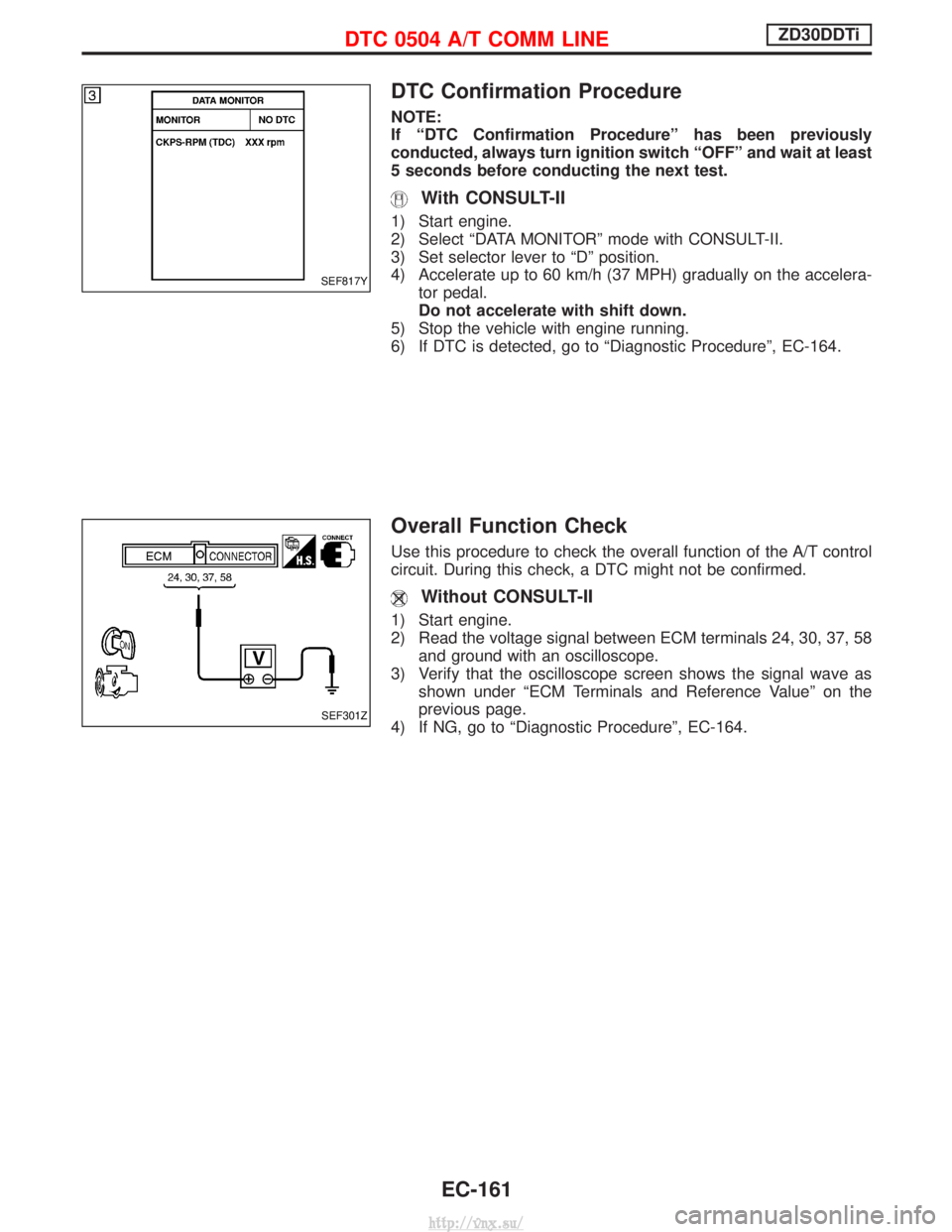

DTC Confirmation Procedure

NOTE:

If ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

5 seconds before conducting the next test.

With CONSULT-II

1) Start engine.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Set selector lever to ªDº position.

4) Accelerate up to 60 km/h (37 MPH) gradually on the accelera-tor pedal.

Do not accelerate with shift down.

5) Stop the vehicle with engine running.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-164.

Overall Function Check

Use this procedure to check the overall function of the A/T control

circuit. During this check, a DTC might not be confirmed.

Without CONSULT-II

1) Start engine.

2) Read the voltage signal between ECM terminals 24, 30, 37, 58 and ground with an oscilloscope.

3) Verify that the oscilloscope screen shows the signal wave as shown under ªECM Terminals and Reference Valueº on the

previous page.

4) If NG, go to ªDiagnostic Procedureº, EC-164.

SEF817Y

SEF301Z

DTC 0504 A/T COMM LINEZD30DDTi

EC-161

http://vnx.su/

Page 439 of 1833

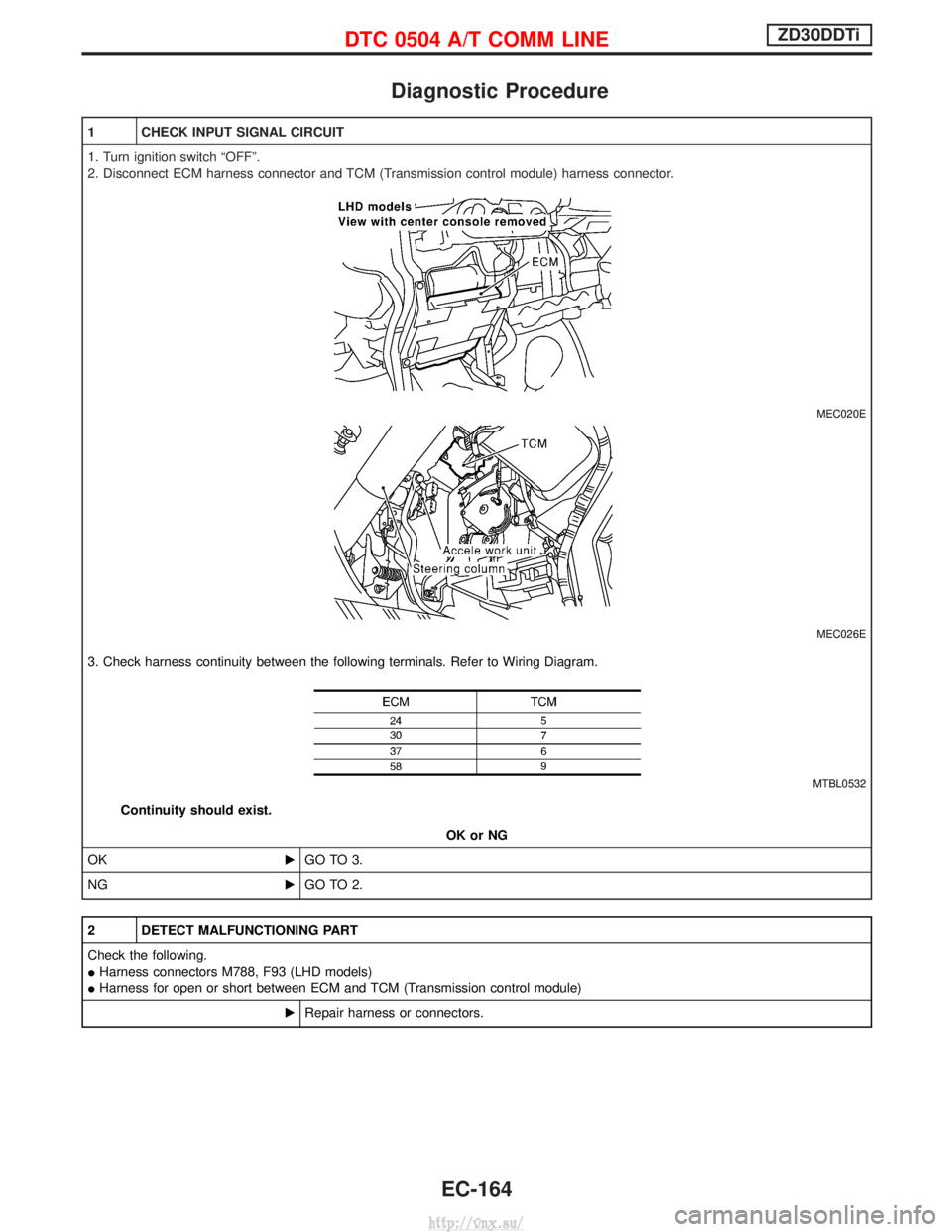

Diagnostic Procedure

1 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and TCM (Transmission control module) harness connector.

MEC020E

MEC026E

3. Check harness continuity between the following terminals. Refer to Wiring Diagram.

MTBL0532

Continuity should exist.OK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M788, F93 (LHD models)

I Harness for open or short between ECM and TCM (Transmission control module)

ERepair harness or connectors.

DTC 0504 A/T COMM LINEZD30DDTi

EC-164

http://vnx.su/

Page 442 of 1833

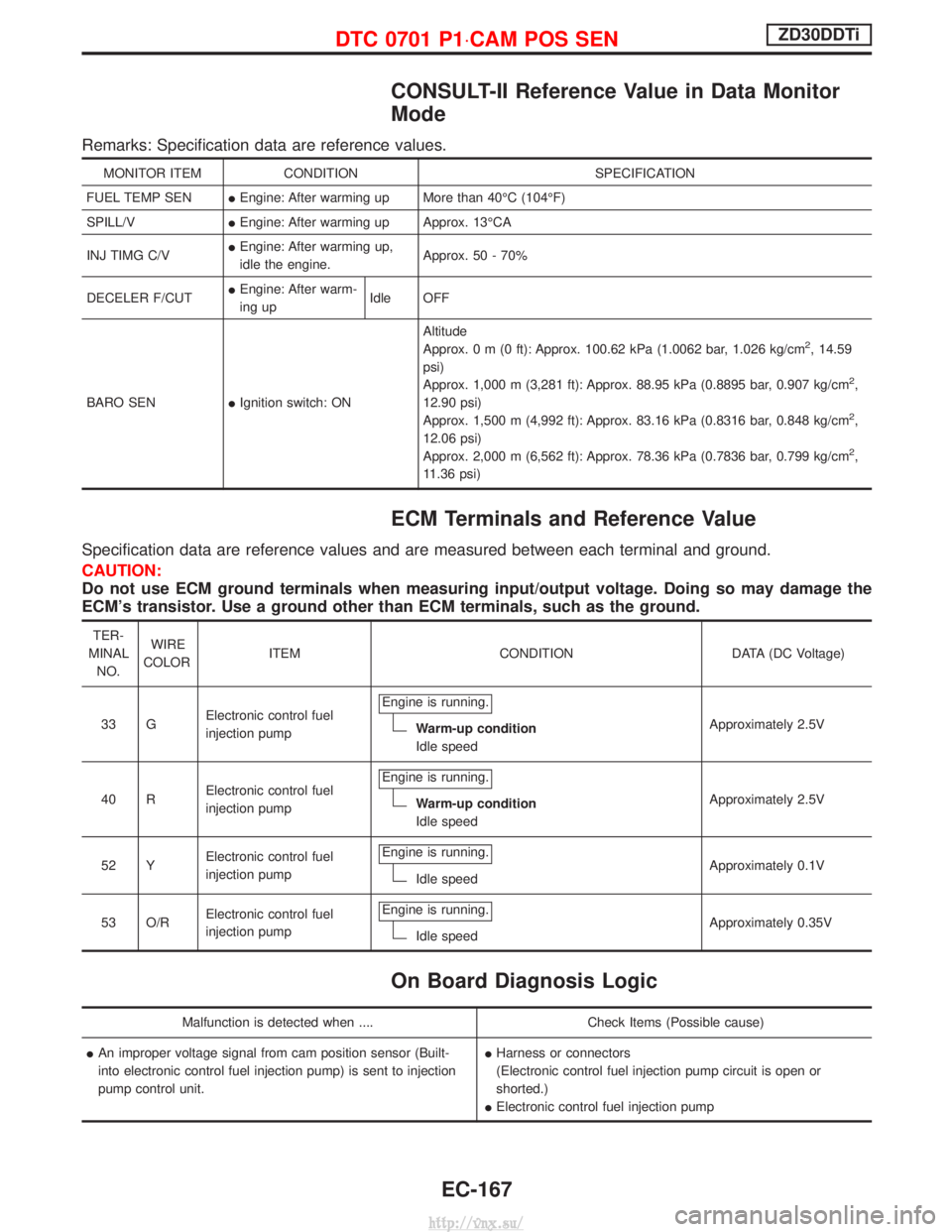

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

FUEL TEMP SEN IEngine: After warming up More than 40ÉC (104ÉF)

SPILL/V IEngine: After warming up Approx. 13ÉCA

INJ TIMG C/V I

Engine: After warming up,

idle the engine. Approx. 50 - 70%

DECELER F/CUT I

Engine: After warm-

ing up Idle OFF

BARO SEN IIgnition switch: ON Altitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

33 G Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

40 R Electronic control fuel

injection pump Engine is running.

Warm-up condition

Idle speed

Approximately 2.5V

52 Y Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.1V

53 O/R Electronic control fuel

injection pump Engine is running.

Idle speed

Approximately 0.35V

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible cause)

I An improper voltage signal from cam position sensor (Built-

into electronic control fuel injection pump) is sent to injection

pump control unit. I

Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

I Electronic control fuel injection pump

DTC 0701 P1×CAM POS SENZD30DDTi

EC-167

http://vnx.su/

Page 443 of 1833

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-171.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed. (If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-171.SEF817Y

DTC 0701 P1×CAM POS SENZD30DDTi

EC-168

http://vnx.su/

Page 446 of 1833

Diagnostic Procedure

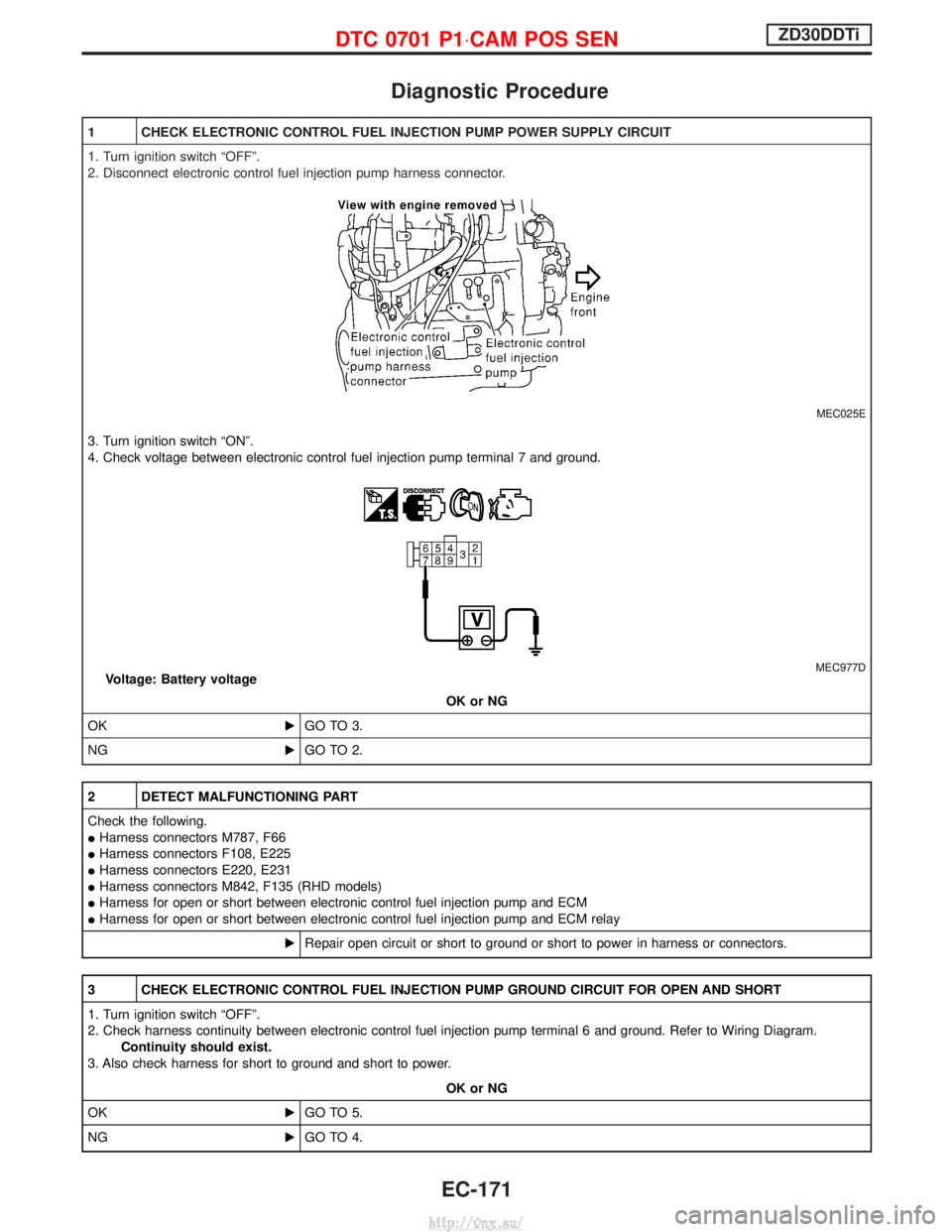

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

MEC025E

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

MEC977DVoltage: Battery voltageOK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66

I Harness connectors F108, E225

I Harness connectors E220, E231

I Harness connectors M842, F135 (RHD models)

I Harness for open or short between electronic control fuel injection pump and ECM

I Harness for open or short between electronic control fuel injection pump and ECM relay

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0701 P1×CAM POS SENZD30DDTi

EC-171

http://vnx.su/