light NISSAN TERRANO 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1032 of 1833

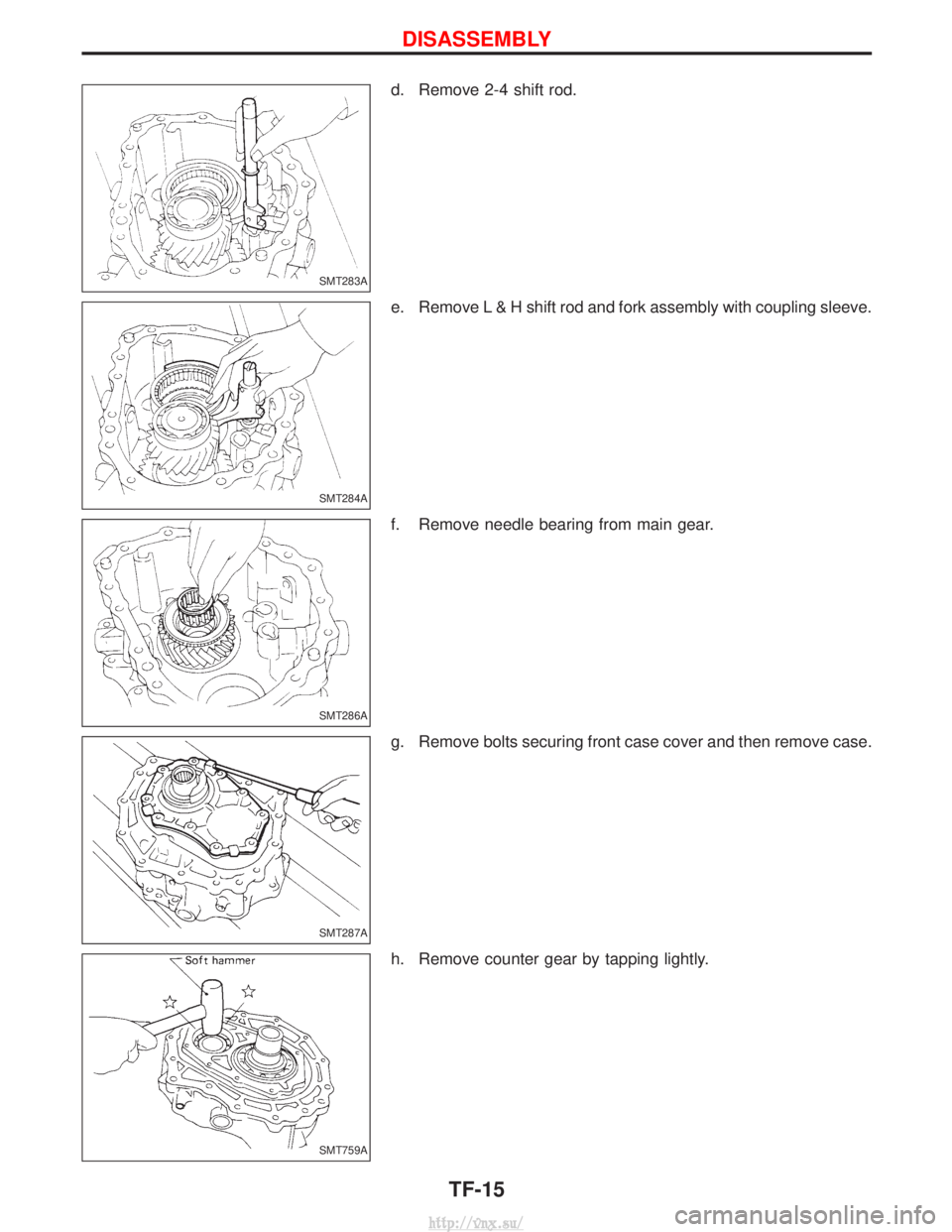

d. Remove 2-4 shift rod.

e. Remove L & H shift rod and fork assembly with coupling sleeve.

f. Remove needle bearing from main gear.

g. Remove bolts securing front case cover and then remove case.

h. Remove counter gear by tapping lightly.

SMT283A

SMT284A

SMT286A

SMT287A

SMT759A

DISASSEMBLY

TF-15

http://vnx.su/

Page 1033 of 1833

i. Remove main gear by tapping lightly.

SMT288A

DISASSEMBLY

TF-16

http://vnx.su/

Page 1043 of 1833

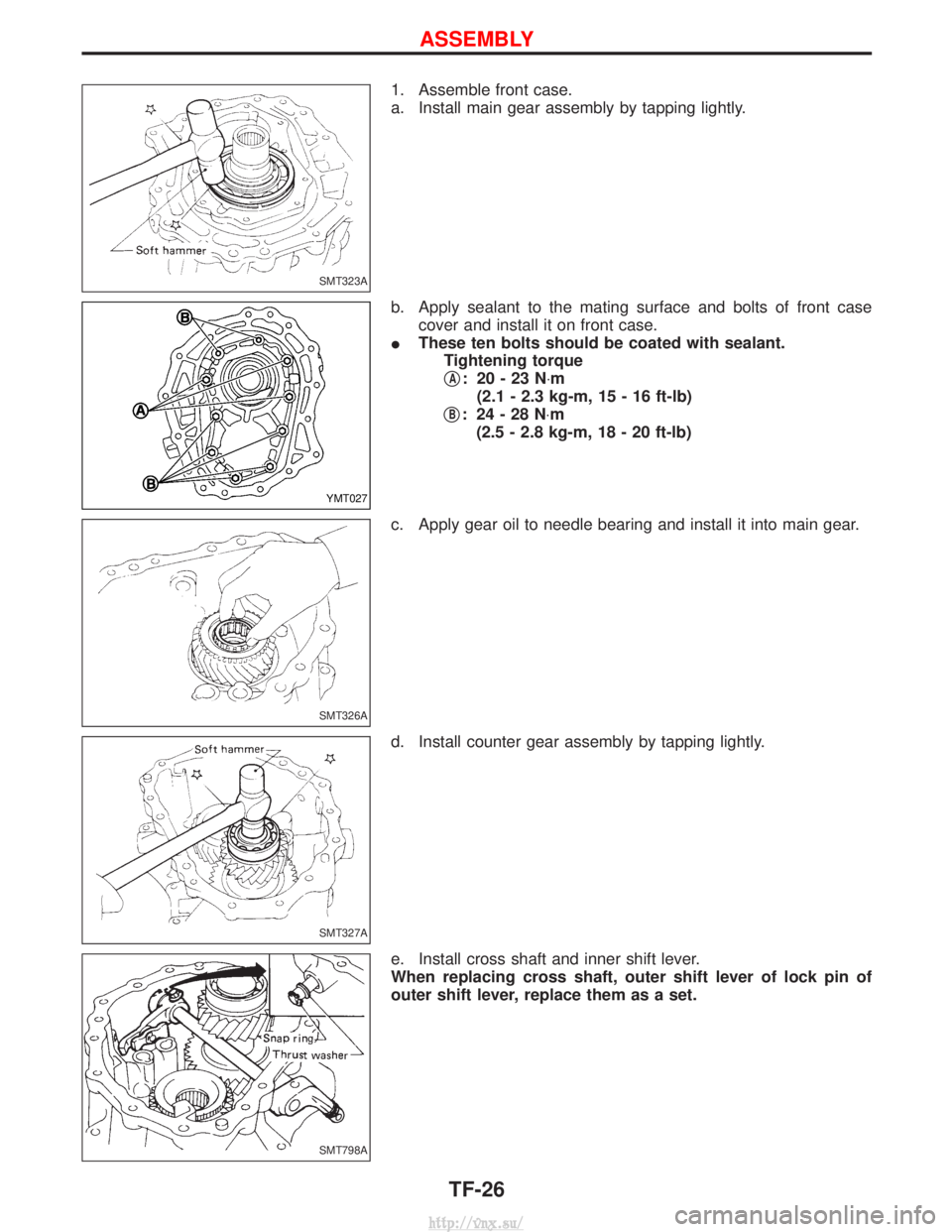

1. Assemble front case.

a. Install main gear assembly by tapping lightly.

b. Apply sealant to the mating surface and bolts of front casecover and install it on front case.

I These ten bolts should be coated with sealant.

Tightening torque

q

A: 20-23N ×m

(2.1 - 2.3 kg-m, 15 - 16 ft-lb)

q

B: 24-28N ×m

(2.5 - 2.8 kg-m, 18 - 20 ft-lb)

c. Apply gear oil to needle bearing and install it into main gear.

d. Install counter gear assembly by tapping lightly.

e. Install cross shaft and inner shift lever.

When replacing cross shaft, outer shift lever of lock pin of

outer shift lever, replace them as a set.

SMT323A

YMT027

SMT326A

SMT327A

SMT798A

ASSEMBLY

TF-26

http://vnx.su/

Page 1045 of 1833

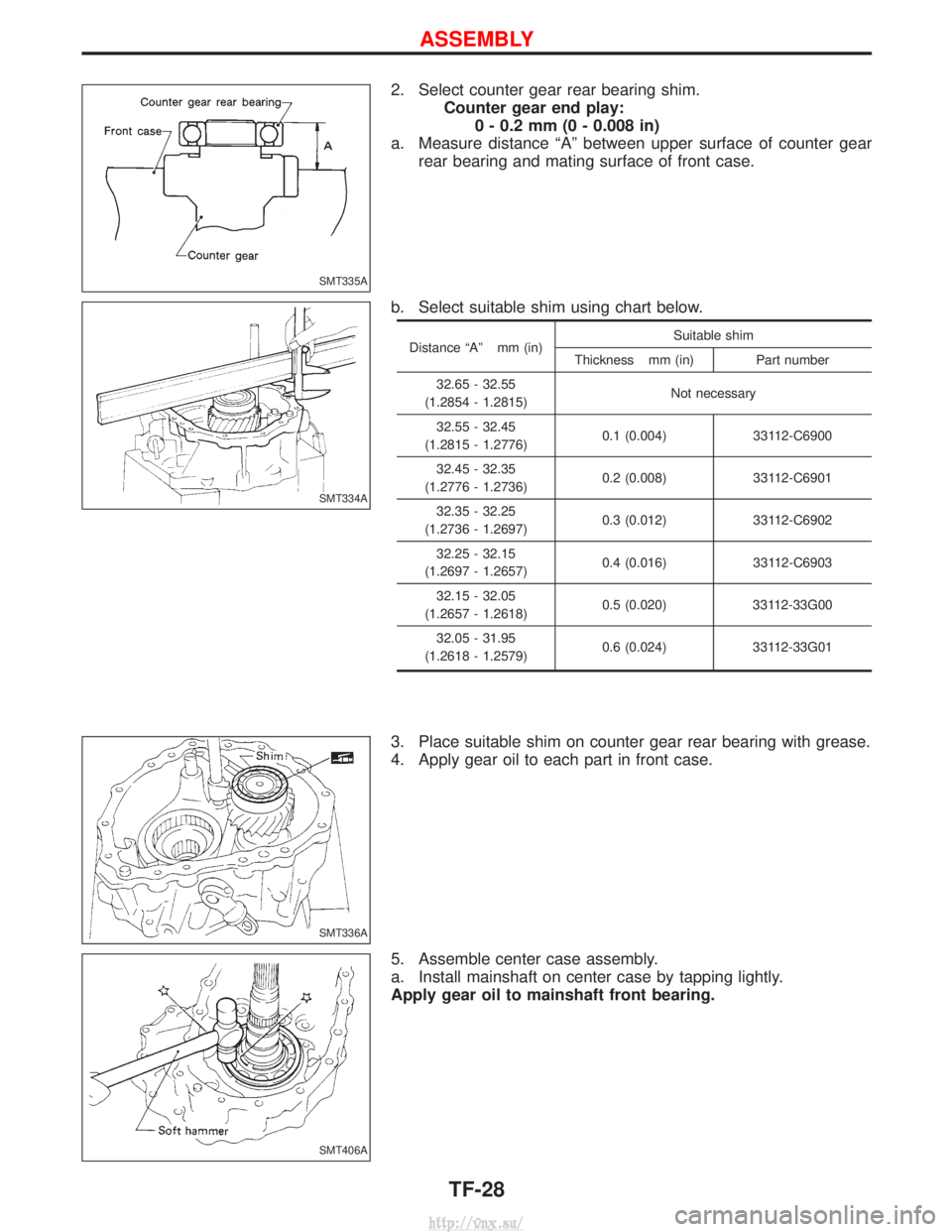

2. Select counter gear rear bearing shim.Counter gear end play:0 - 0.2 mm (0 - 0.008 in)

a. Measure distance ªAº between upper surface of counter gear rear bearing and mating surface of front case.

b. Select suitable shim using chart below.

Distance ªAº mm (in) Suitable shim

Thickness mm (in) Part number

32.65 - 32.55

(1.2854 - 1.2815) Not necessary

32.55 - 32.45

(1.2815 - 1.2776) 0.1 (0.004) 33112-C6900

32.45 - 32.35

(1.2776 - 1.2736) 0.2 (0.008) 33112-C6901

32.35 - 32.25

(1.2736 - 1.2697) 0.3 (0.012) 33112-C6902

32.25 - 32.15

(1.2697 - 1.2657) 0.4 (0.016) 33112-C6903

32.15 - 32.05

(1.2657 - 1.2618) 0.5 (0.020) 33112-33G00

32.05 - 31.95

(1.2618 - 1.2579) 0.6 (0.024) 33112-33G01

3. Place suitable shim on counter gear rear bearing with grease.

4. Apply gear oil to each part in front case.

5. Assemble center case assembly.

a. Install mainshaft on center case by tapping lightly.

Apply gear oil to mainshaft front bearing.

SMT335A

SMT334A

SMT336A

SMT406A

ASSEMBLY

TF-28

http://vnx.su/

Page 1046 of 1833

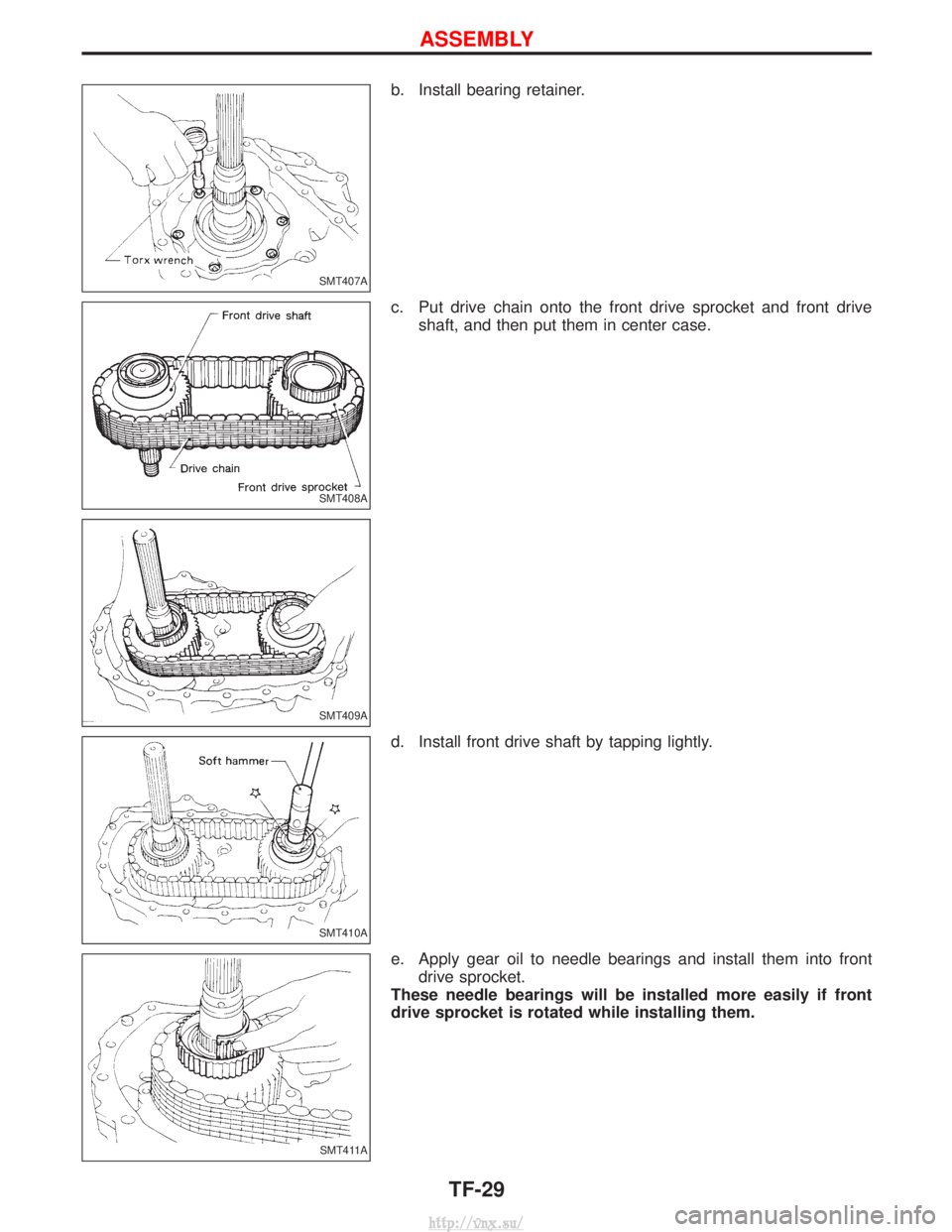

b. Install bearing retainer.

c. Put drive chain onto the front drive sprocket and front driveshaft, and then put them in center case.

d. Install front drive shaft by tapping lightly.

e. Apply gear oil to needle bearings and install them into front drive sprocket.

These needle bearings will be installed more easily if front

drive sprocket is rotated while installing them.

SMT407A

SMT408A

SMT409A

SMT410A

SMT411A

ASSEMBLY

TF-29

http://vnx.su/

Page 1059 of 1833

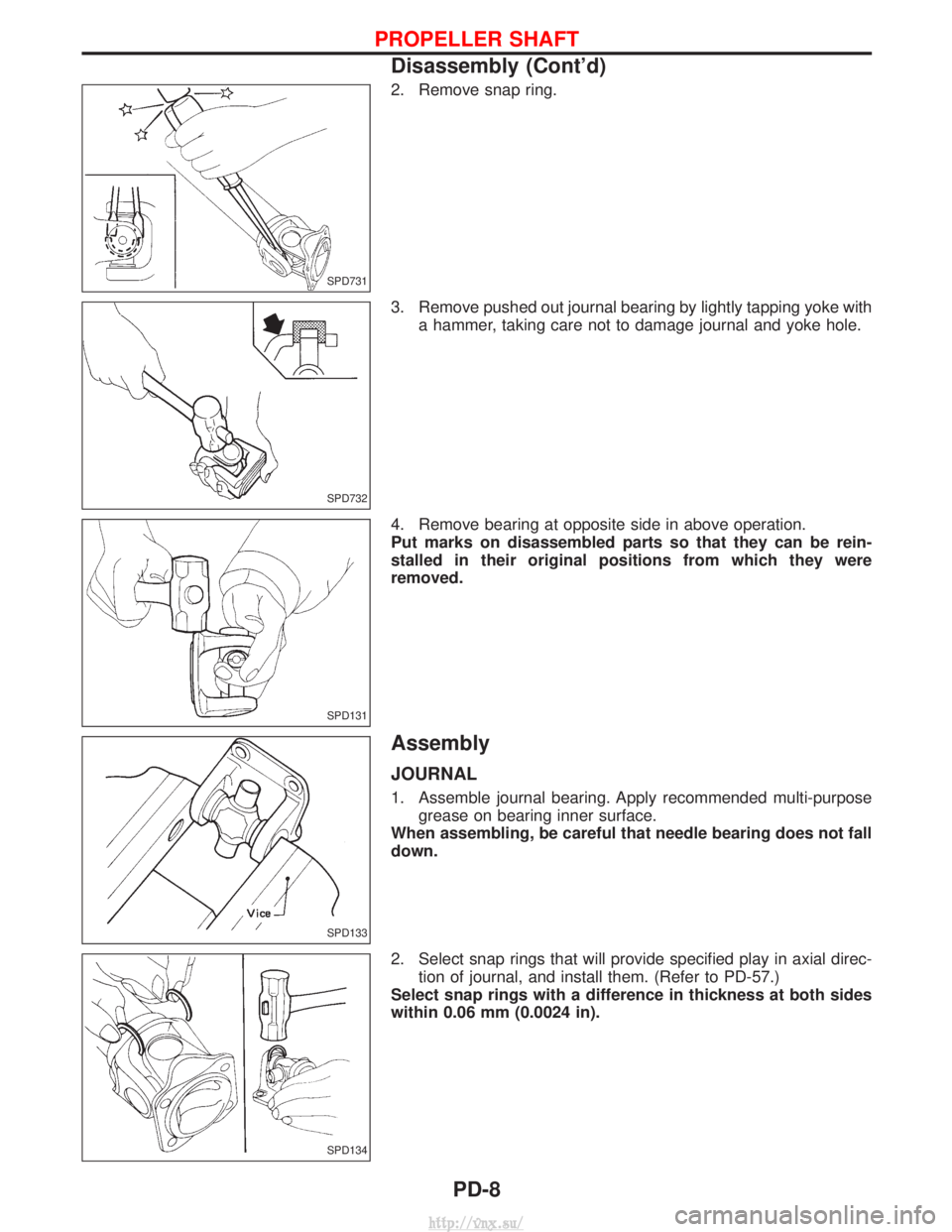

2. Remove snap ring.

3. Remove pushed out journal bearing by lightly tapping yoke witha hammer, taking care not to damage journal and yoke hole.

4. Remove bearing at opposite side in above operation.

Put marks on disassembled parts so that they can be rein-

stalled in their original positions from which they were

removed.

Assembly

JOURNAL

1. Assemble journal bearing. Apply recommended multi-purpose grease on bearing inner surface.

When assembling, be careful that needle bearing does not fall

down.

2. Select snap rings that will provide specified play in axial direc- tion of journal, and install them. (Refer to PD-57.)

Select snap rings with a difference in thickness at both sides

within 0.06 mm (0.0024 in).

SPD731

SPD732

SPD131

SPD133

SPD134

PROPELLER SHAFT

Disassembly (Cont'd)

PD-8

http://vnx.su/

Page 1080 of 1833

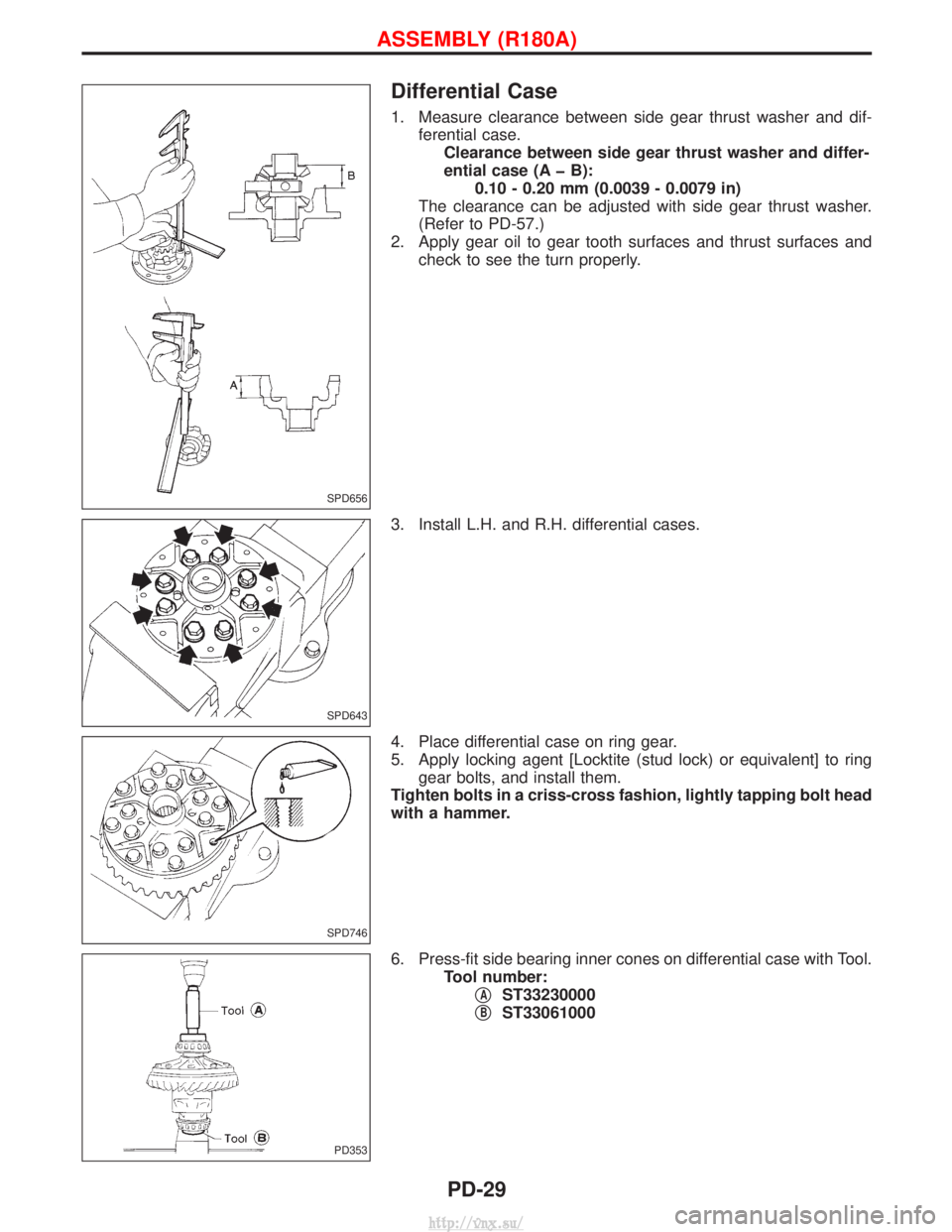

Differential Case

1. Measure clearance between side gear thrust washer and dif-ferential case.Clearance between side gear thrust washer and differ-

ential case (A þ B): 0.10 - 0.20 mm (0.0039 - 0.0079 in)

The clearance can be adjusted with side gear thrust washer.

(Refer to PD-57.)

2. Apply gear oil to gear tooth surfaces and thrust surfaces and check to see the turn properly.

3. Install L.H. and R.H. differential cases.

4. Place differential case on ring gear.

5. Apply locking agent [Locktite (stud lock) or equivalent] to ring gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

6. Press-fit side bearing inner cones on differential case with Tool. Tool number:q

AST33230000

q

BST33061000

SPD656

SPD643

SPD746

PD353

ASSEMBLY (R180A)

PD-29

http://vnx.su/

Page 1099 of 1833

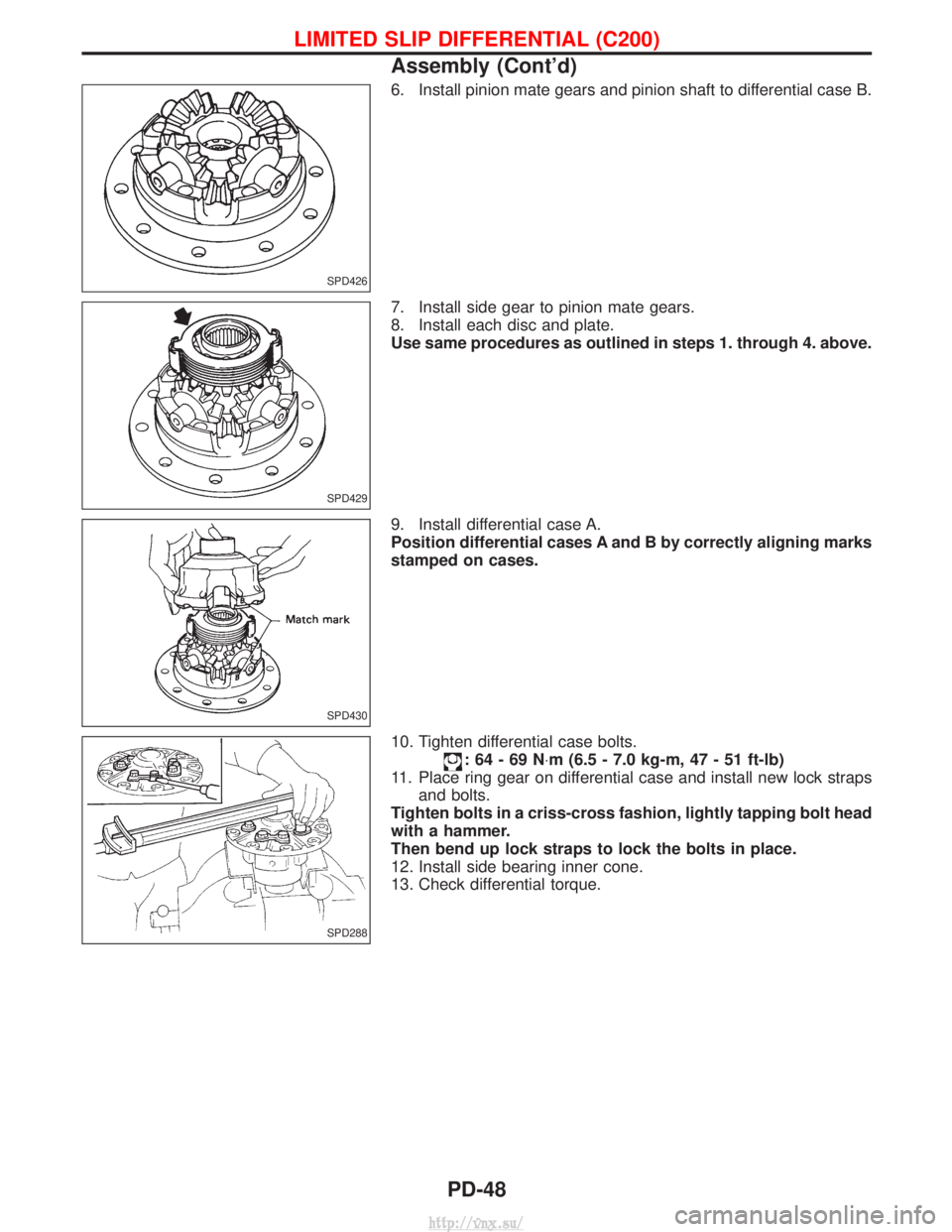

6. Install pinion mate gears and pinion shaft to differential case B.

7. Install side gear to pinion mate gears.

8. Install each disc and plate.

Use same procedures as outlined in steps 1. through 4. above.

9. Install differential case A.

Position differential cases A and B by correctly aligning marks

stamped on cases.

10. Tighten differential case bolts.

:64-69N×m (6.5 - 7.0 kg-m, 47 - 51 ft-lb)

11. Place ring gear on differential case and install new lock straps and bolts.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

Then bend up lock straps to lock the bolts in place.

12. Install side bearing inner cone.

13. Check differential torque.

SPD426

SPD429

SPD430

SPD288

LIMITED SLIP DIFFERENTIAL (C200)

Assembly (Cont'd)

PD-48

http://vnx.su/

Page 1106 of 1833

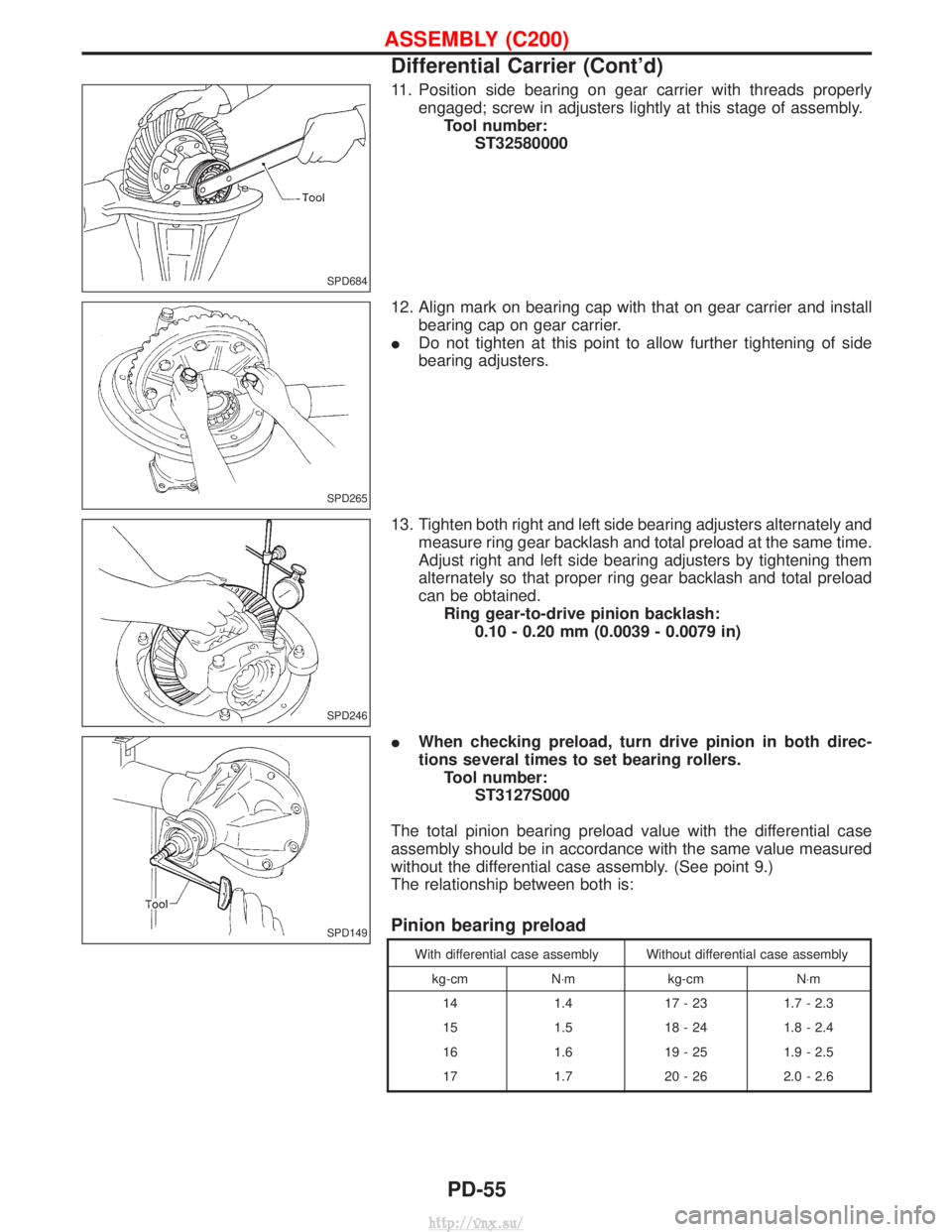

11. Position side bearing on gear carrier with threads properlyengaged; screw in adjusters lightly at this stage of assembly.Tool number: ST32580000

12. Align mark on bearing cap with that on gear carrier and install bearing cap on gear carrier.

I Do not tighten at this point to allow further tightening of side

bearing adjusters.

13. Tighten both right and left side bearing adjusters alternately and measure ring gear backlash and total preload at the same time.

Adjust right and left side bearing adjusters by tightening them

alternately so that proper ring gear backlash and total preload

can be obtained.Ring gear-to-drive pinion backlash: 0.10 - 0.20 mm (0.0039 - 0.0079 in)

I When checking preload, turn drive pinion in both direc-

tions several times to set bearing rollers.

Tool number: ST3127S000

The total pinion bearing preload value with the differential case

assembly should be in accordance with the same value measured

without the differential case assembly. (See point 9.)

The relationship between both is:

Pinion bearing preload

With differential case assembly Without differential case assembly kg-cm N×m kg-cmN×m

14 1.417 - 23 1.7 - 2.3

15 1.518 - 24 1.8 - 2.4

16 1.619 - 25 1.9 - 2.5

17 1.720 - 26 2.0 - 2.6

SPD684

SPD265

SPD246

SPD149

ASSEMBLY (C200)

Differential Carrier (Cont'd)

PD-55

http://vnx.su/

Page 1131 of 1833

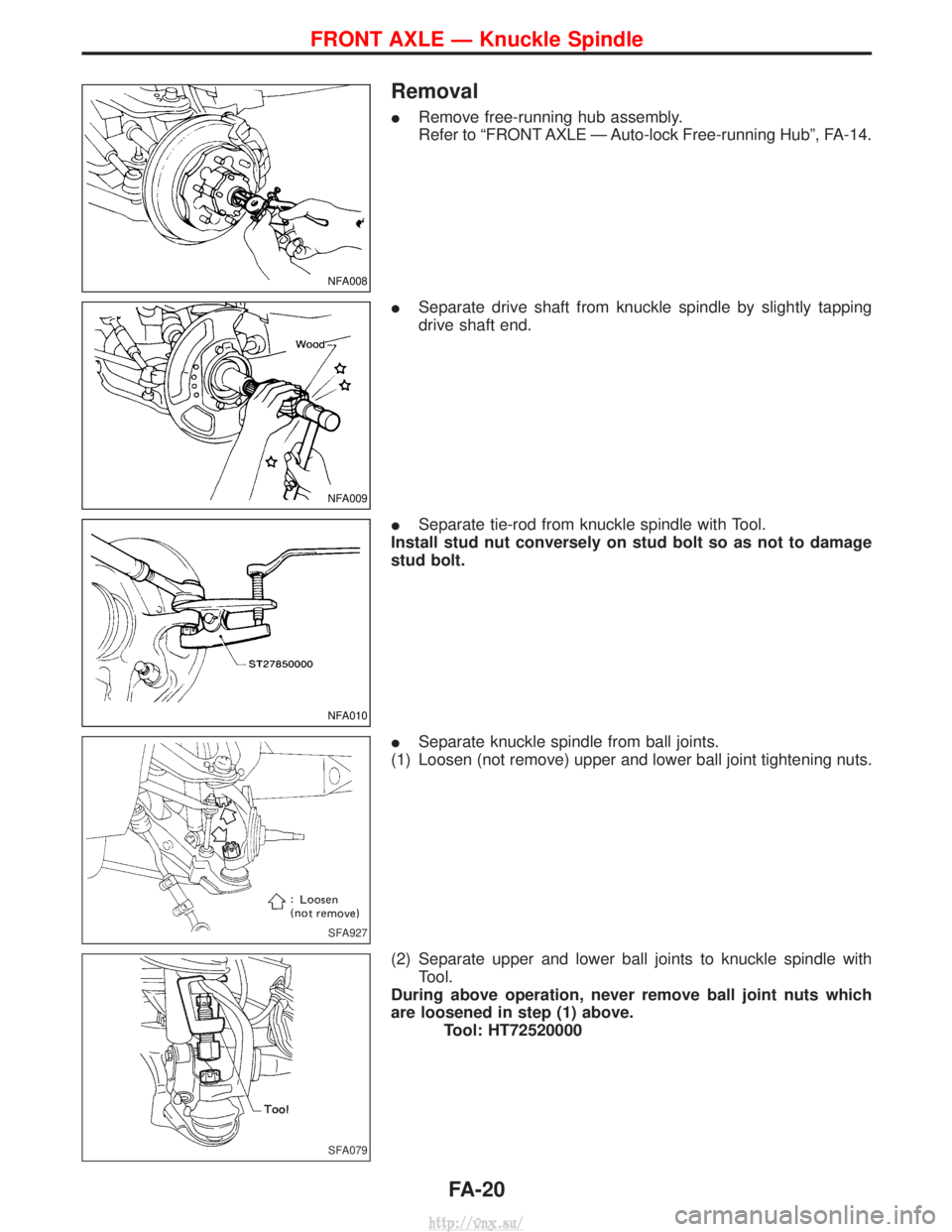

Removal

IRemove free-running hub assembly.

Refer to ªFRONT AXLE Ð Auto-lock Free-running Hubº, FA-14.

I Separate drive shaft from knuckle spindle by slightly tapping

drive shaft end.

I Separate tie-rod from knuckle spindle with Tool.

Install stud nut conversely on stud bolt so as not to damage

stud bolt.

I Separate knuckle spindle from ball joints.

(1) Loosen (not remove) upper and lower ball joint tightening nuts.

(2) Separate upper and lower ball joints to knuckle spindle with Tool.

During above operation, never remove ball joint nuts which

are loosened in step (1) above. Tool: HT72520000

NFA008

NFA009

NFA010

SFA927

SFA079

FRONT AXLE Ð Knuckle Spindle

FA-20

http://vnx.su/