light NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 137 of 1833

Installation

1. Install the front plate.

1) Install the O-ring and gasket to the cylinder block.

2) Install the front plate.

ILightly tap with a hammer if the dowel pin cannot be inserted

easily.

CAUTION:

Make sure that the O-ring does not pop out.

3) Apply Three Bond 1207C (KP510 00150) with a spreader between the cylinder block plate under the cylinder block (oil

pan side) and the front plate (shown by the arrows in the fig-

ure).

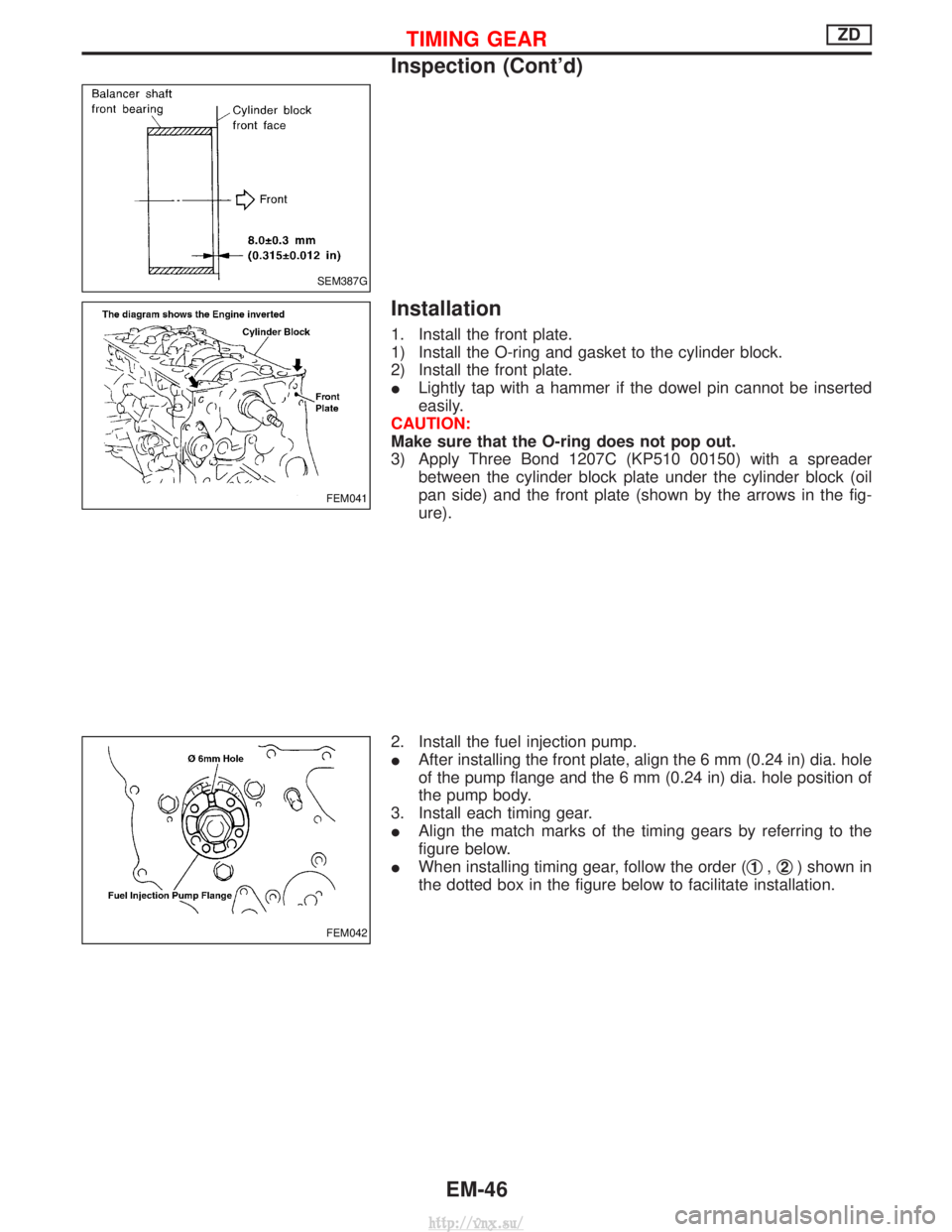

2. Install the fuel injection pump.

I After installing the front plate, align the 6 mm (0.24 in) dia. hole

of the pump flange and the 6 mm (0.24 in) dia. hole position of

the pump body.

3. Install each timing gear.

I Align the match marks of the timing gears by referring to the

figure below.

I When installing timing gear, follow the order ( q

1,q2) shown in

the dotted box in the figure below to facilitate installation.

SEM387G

FEM041

FEM042

TIMING GEARZD

Inspection (Cont'd)

EM-46

http://vnx.su/

Page 168 of 1833

CONNECTING ROD BEARING OIL CLEARANCE

Method by measurement

IInstall connecting rod bearings to connecting rods and caps,

and tighten connecting nuts to the specified torque. Use inside

micrometer to measure connecting rod bearing inner diameter.

Bearing clearance = Connecting rod bearing inner diameter þ

Crankshaft pin outer diameter

Standard: 0.035 - 0.077 mm (0.0014 - 0.0030 in)

I If out of specifications, check connecting rod big end inner

diameter and crankshaft pin outer diameter, and select appro-

priate connecting rod bearing to adjust clearance to specifica-

tions.

Refer to ªConnecting rod bearing undersize listº on the next

page.

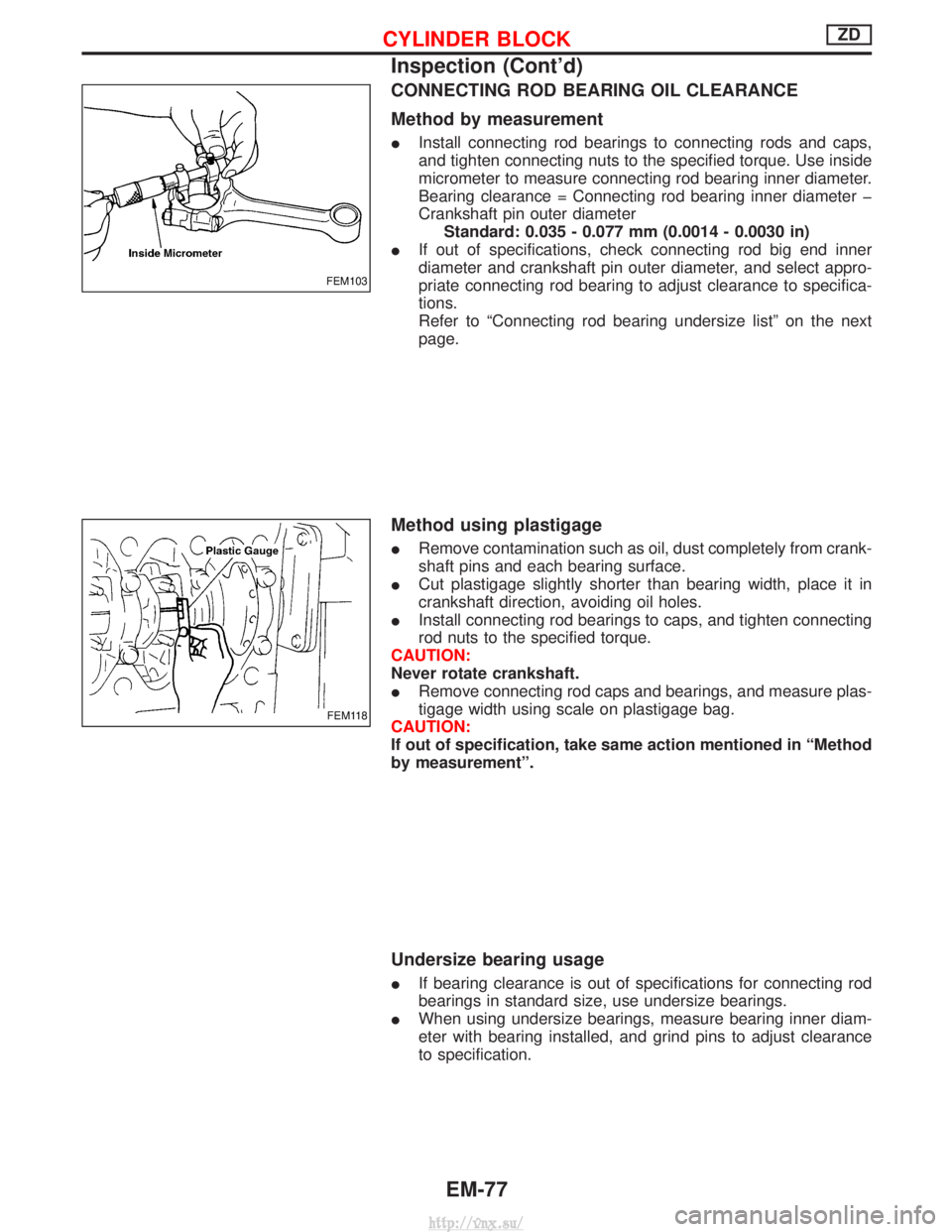

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft pins and each bearing surface.

I Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

I Install connecting rod bearings to caps, and tighten connecting

rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

I Remove connecting rod caps and bearings, and measure plas-

tigage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

I If bearing clearance is out of specifications for connecting rod

bearings in standard size, use undersize bearings.

I When using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind pins to adjust clearance

to specification.

FEM103

FEM118

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-77

http://vnx.su/

Page 169 of 1833

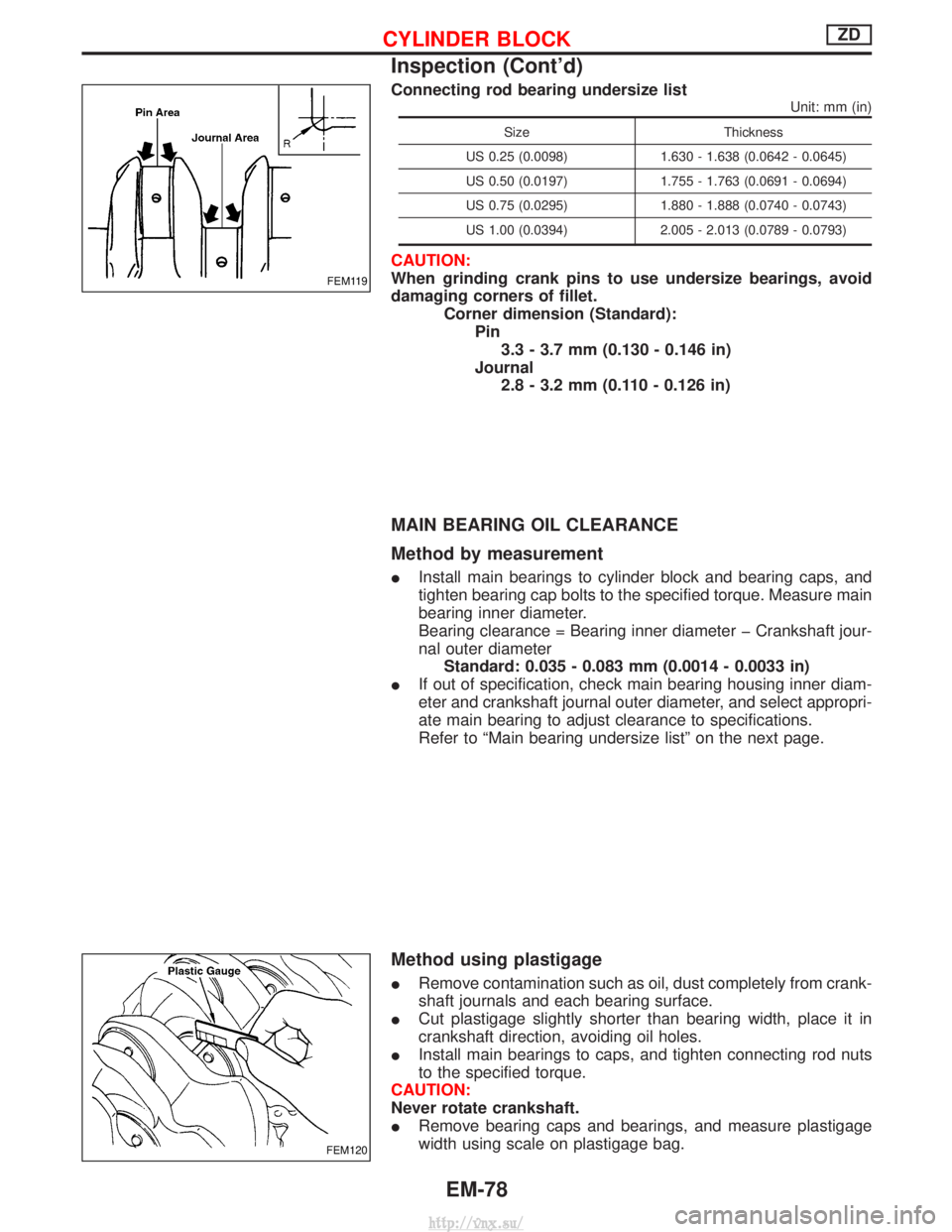

Connecting rod bearing undersize list

Unit: mm (in)

SizeThickness

US 0.25 (0.0098) 1.630 - 1.638 (0.0642 - 0.0645)

US 0.50 (0.0197) 1.755 - 1.763 (0.0691 - 0.0694)

US 0.75 (0.0295) 1.880 - 1.888 (0.0740 - 0.0743)

US 1.00 (0.0394) 2.005 - 2.013 (0.0789 - 0.0793)

CAUTION:

When grinding crank pins to use undersize bearings, avoid

damaging corners of fillet.

Corner dimension (Standard):Pin3.3 - 3.7 mm (0.130 - 0.146 in)

Journal 2.8 - 3.2 mm (0.110 - 0.126 in)

MAIN BEARING OIL CLEARANCE

Method by measurement

I Install main bearings to cylinder block and bearing caps, and

tighten bearing cap bolts to the specified torque. Measure main

bearing inner diameter.

Bearing clearance = Bearing inner diameter þ Crankshaft jour-

nal outer diameter

Standard: 0.035 - 0.083 mm (0.0014 - 0.0033 in)

I If out of specification, check main bearing housing inner diam-

eter and crankshaft journal outer diameter, and select appropri-

ate main bearing to adjust clearance to specifications.

Refer to ªMain bearing undersize listº on the next page.

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft journals and each bearing surface.

I Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

I Install main bearings to caps, and tighten connecting rod nuts

to the specified torque.

CAUTION:

Never rotate crankshaft.

I Remove bearing caps and bearings, and measure plastigage

width using scale on plastigage bag.

FEM119

FEM120

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-78

http://vnx.su/

Page 284 of 1833

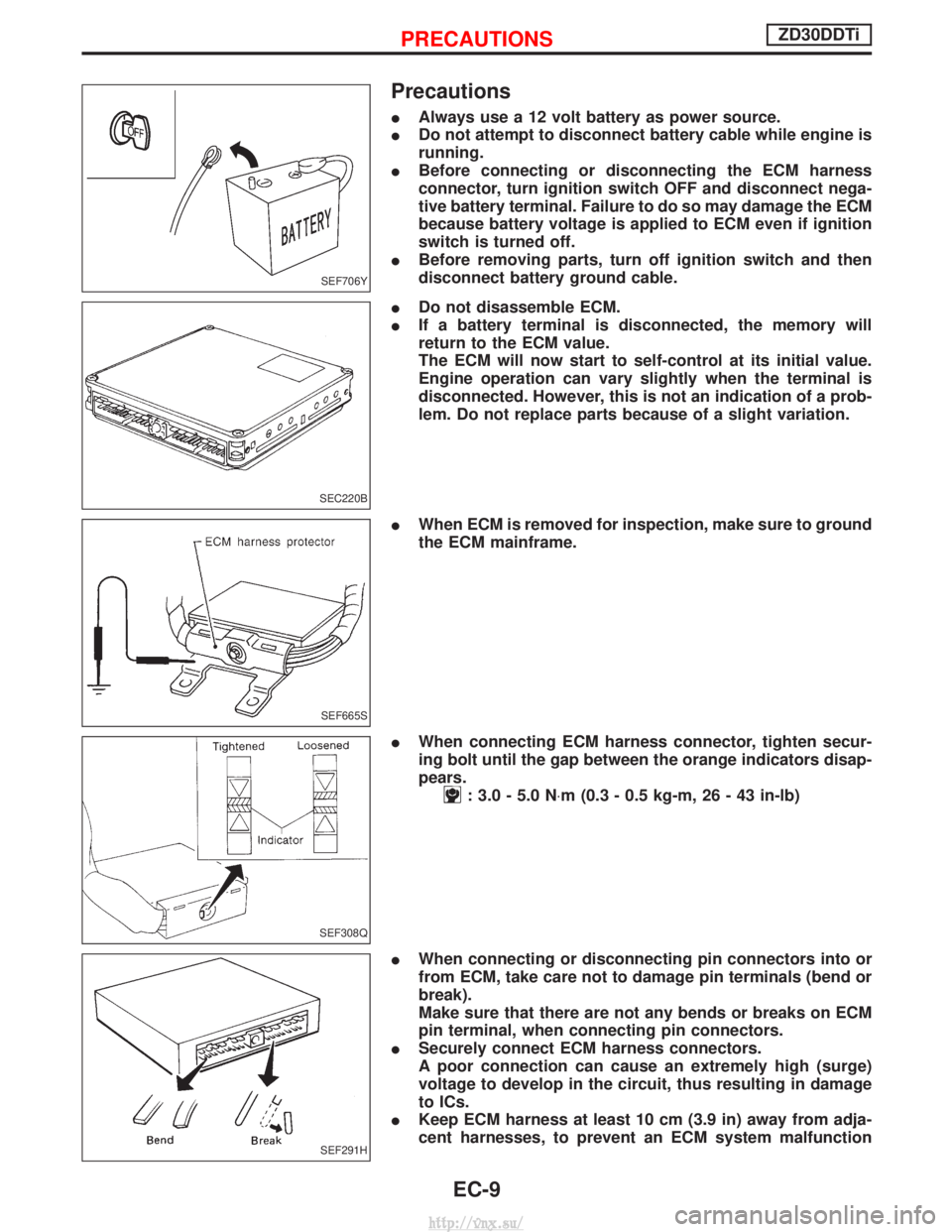

Precautions

IAlways use a 12 volt battery as power source.

I Do not attempt to disconnect battery cable while engine is

running.

I Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

I Before removing parts, turn off ignition switch and then

disconnect battery ground cable.

I Do not disassemble ECM.

I If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

I When ECM is removed for inspection, make sure to ground

the ECM mainframe.

I When connecting ECM harness connector, tighten secur-

ing bolt until the gap between the orange indicators disap-

pears.

: 3.0 - 5.0 N ×m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

I When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

I Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in damage

to ICs.

I Keep ECM harness at least 10 cm (3.9 in) away from adja-

cent harnesses, to prevent an ECM system malfunction

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-9

http://vnx.su/

Page 286 of 1833

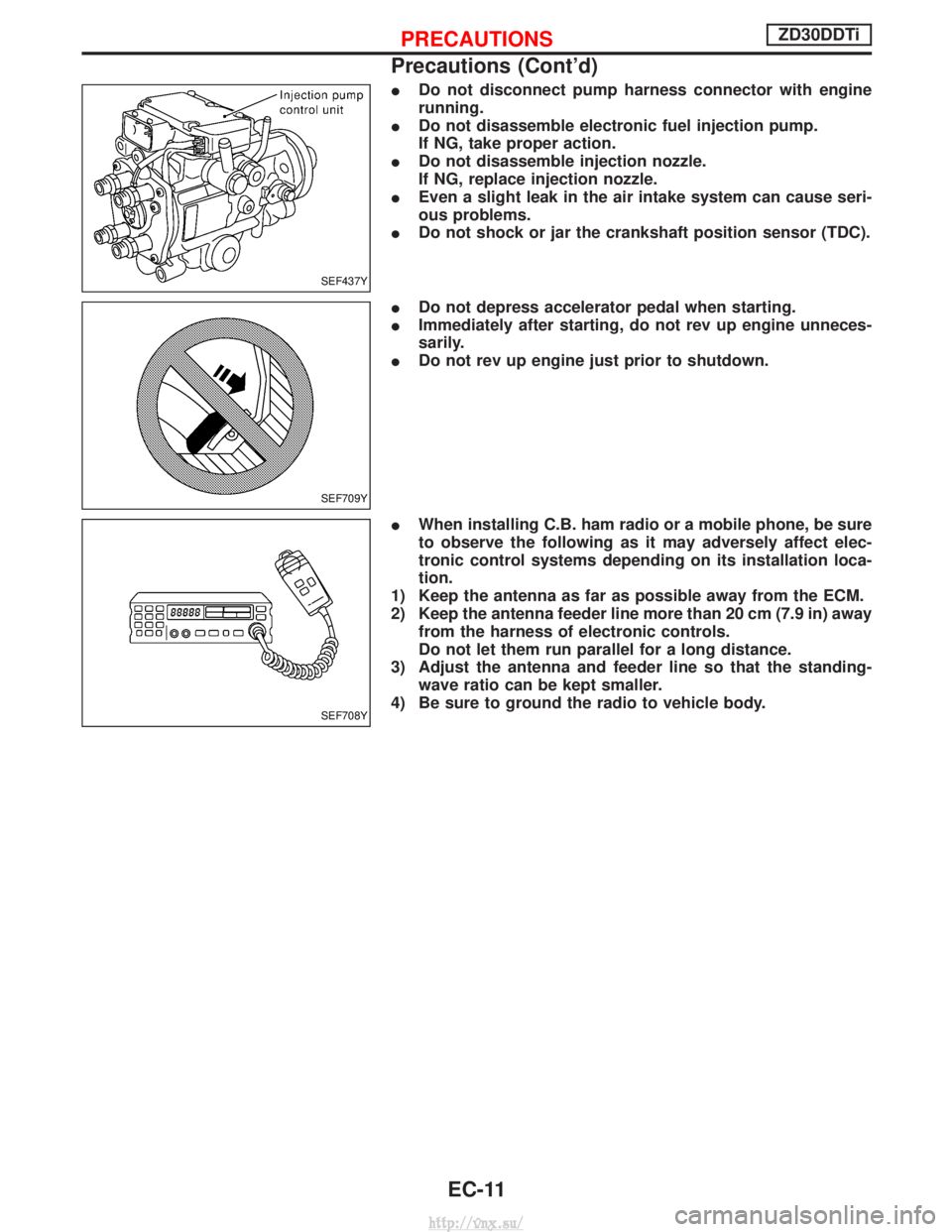

IDo not disconnect pump harness connector with engine

running.

I Do not disassemble electronic fuel injection pump.

If NG, take proper action.

I Do not disassemble injection nozzle.

If NG, replace injection nozzle.

I Even a slight leak in the air intake system can cause seri-

ous problems.

I Do not shock or jar the crankshaft position sensor (TDC).

I Do not depress accelerator pedal when starting.

I Immediately after starting, do not rev up engine unneces-

sarily.

I Do not rev up engine just prior to shutdown.

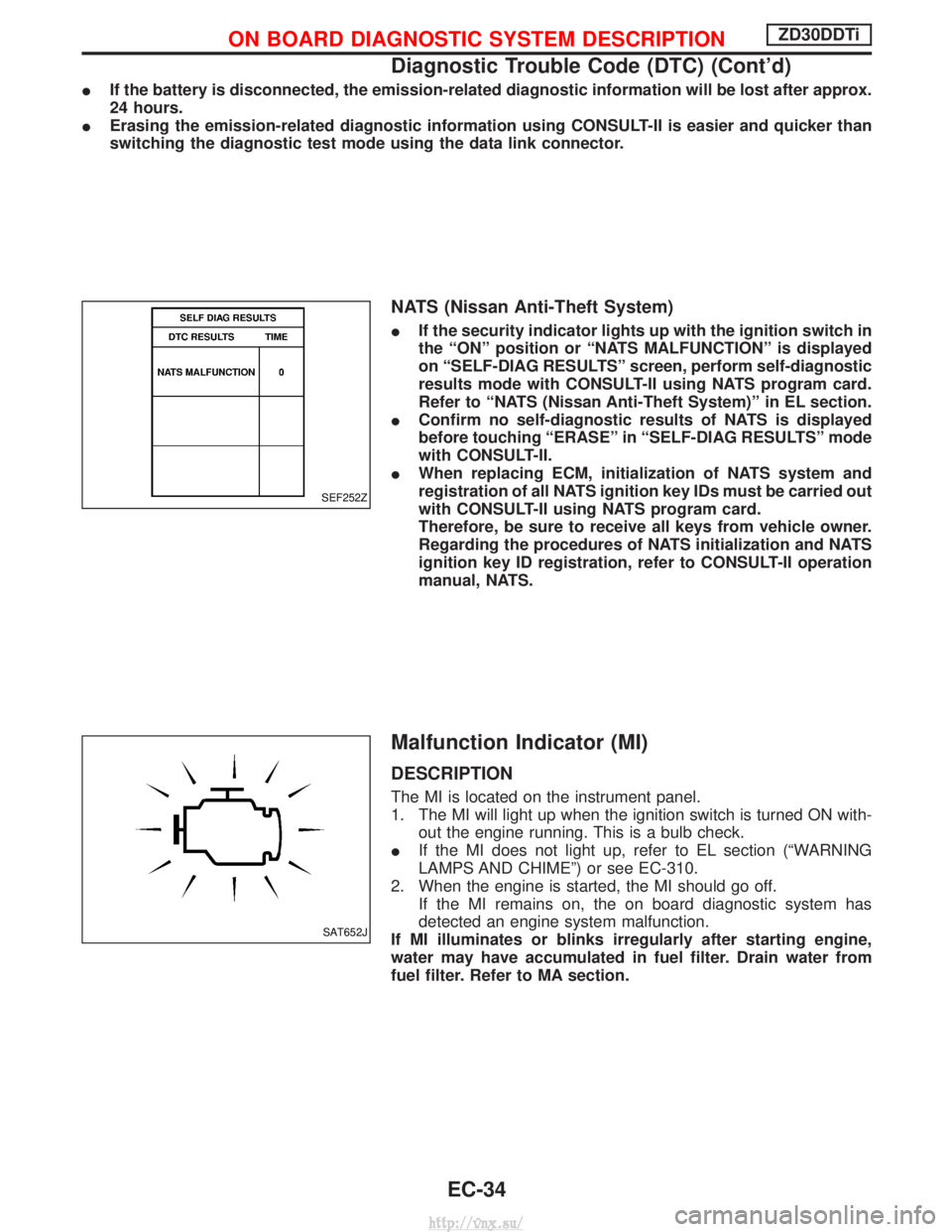

I When installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on its installation loca-

tion.

1) Keep the antenna as far as possible away from the ECM.

2) Keep the antenna feeder line more than 20 cm (7.9 in) away from the harness of electronic controls.

Do not let them run parallel for a long distance.

3) Adjust the antenna and feeder line so that the standing- wave ratio can be kept smaller.

4) Be sure to ground the radio to vehicle body.

SEF437Y

SEF709Y

SEF708Y

PRECAUTIONSZD30DDTi

Precautions (Cont'd)

EC-11

http://vnx.su/

Page 308 of 1833

DTC and MI Detection Logic

When a malfunction is detected, the malfunction (DTC) is stored in the ECM memory.

The MI will light up each time the ECM detects malfunction. For diagnostic items causing the MI to light up,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-7.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MI illumination in the diagnostic test mode II (Self-

diagnostic results). Example: 0102, 0407, 1004, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: ªCRANK POS SEN (TDC)º, etc.

I Output of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT-II can identify them. Therefore, using CONSULT-II (if available) is recommended.

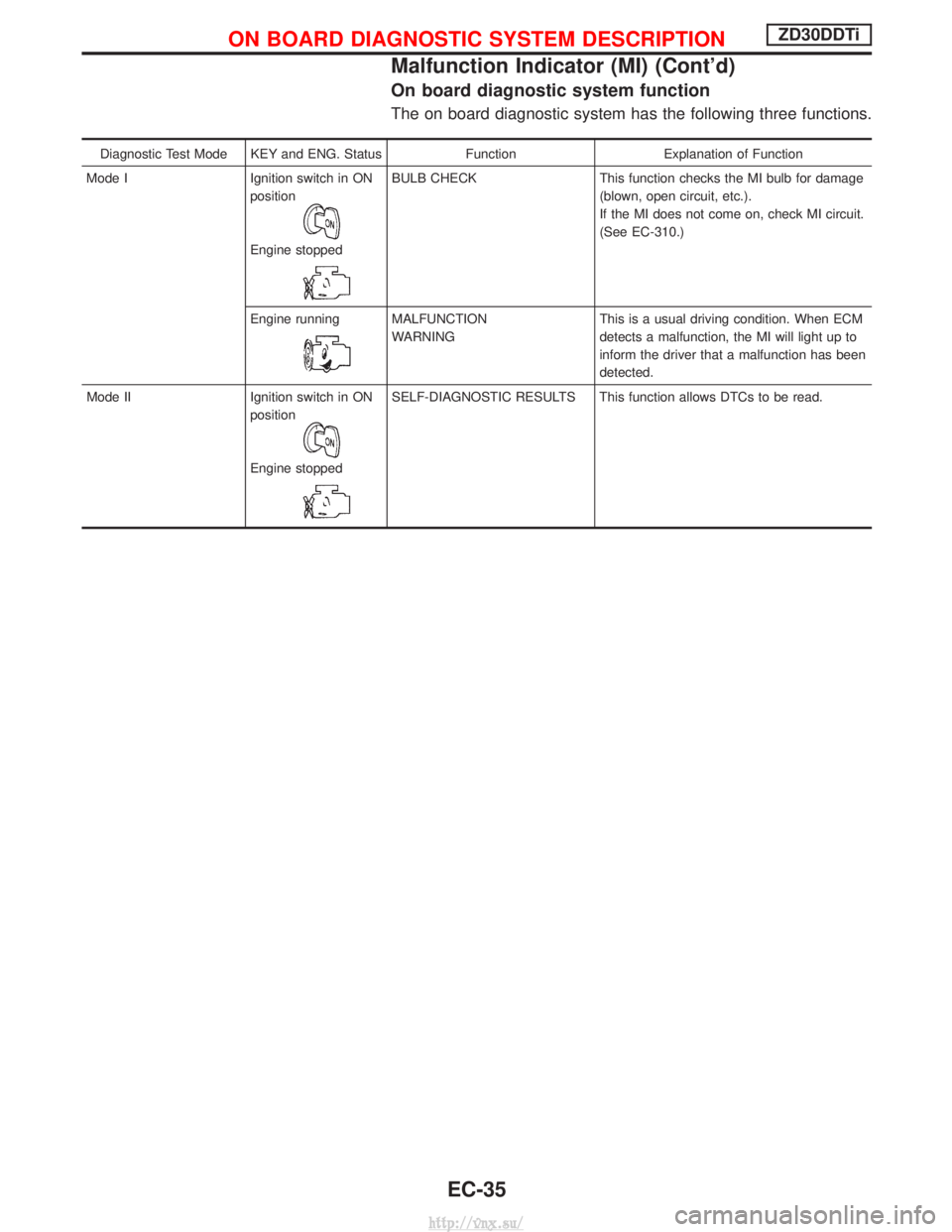

HOW TO ERASE DTC

How to erase DTC (

With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

How to erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least 5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-36.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

SEF371Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

EC-33

http://vnx.su/

Page 309 of 1833

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

I Erasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

I Confirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

I When replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

I If the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-310.

2. When the engine is started, the MI should go off. If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34

http://vnx.su/

Page 310 of 1833

On board diagnostic system function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode KEY and ENG. StatusFunctionExplanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-310.)

Engine running

MALFUNCTION

WARNING This is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-35

http://vnx.su/

Page 313 of 1833

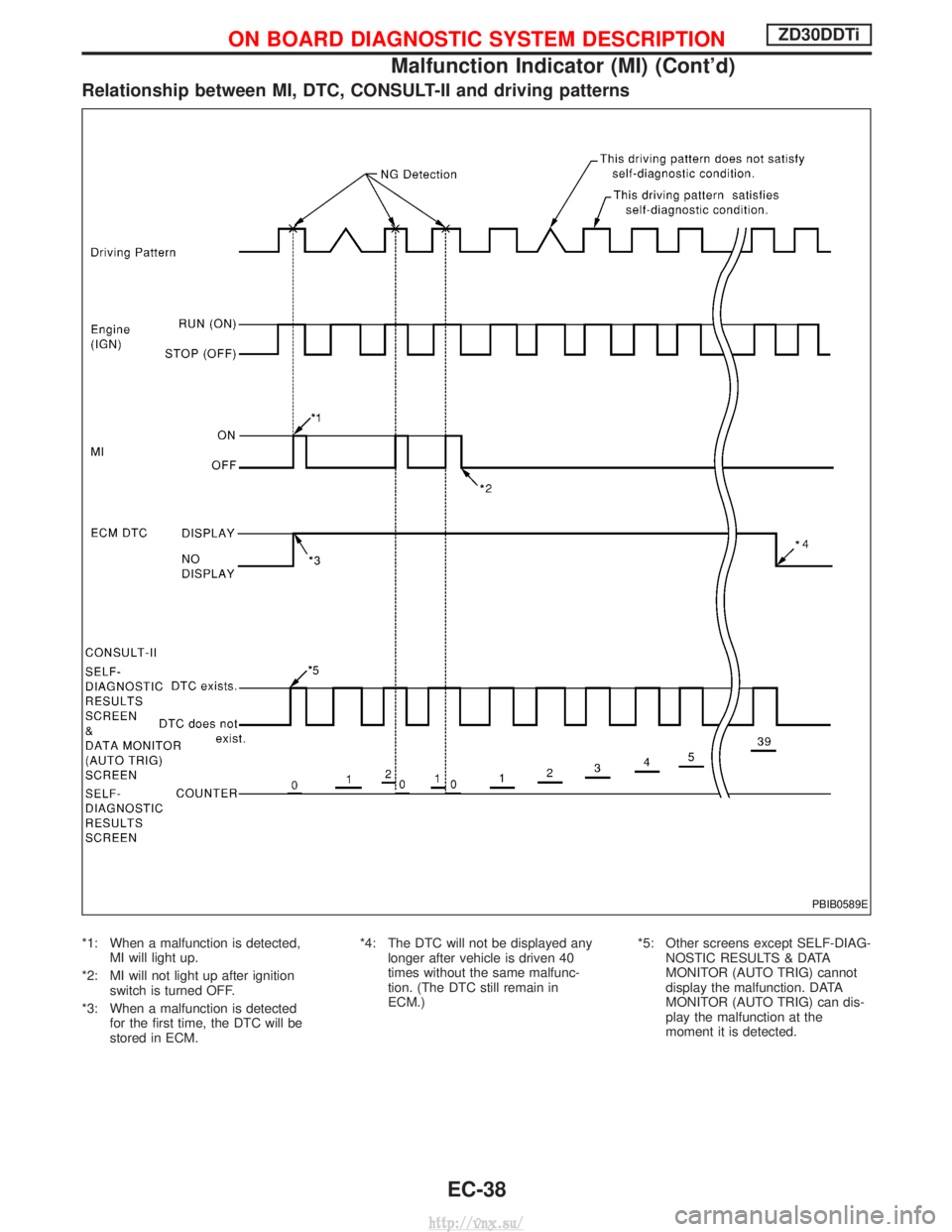

Relationship between MI, DTC, CONSULT-II and driving patterns

*1: When a malfunction is detected,MI will light up.

*2: MI will not light up after ignition switch is turned OFF.

*3: When a malfunction is detected for the first time, the DTC will be

stored in ECM. *4: The DTC will not be displayed any

longer after vehicle is driven 40

times without the same malfunc-

tion. (The DTC still remain in

ECM.) *5: Other screens except SELF-DIAG-

NOSTIC RESULTS & DATA

MONITOR (AUTO TRIG) cannot

display the malfunction. DATA

MONITOR (AUTO TRIG) can dis-

play the malfunction at the

moment it is detected.

PBIB0589E

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-38

http://vnx.su/

Page 341 of 1833

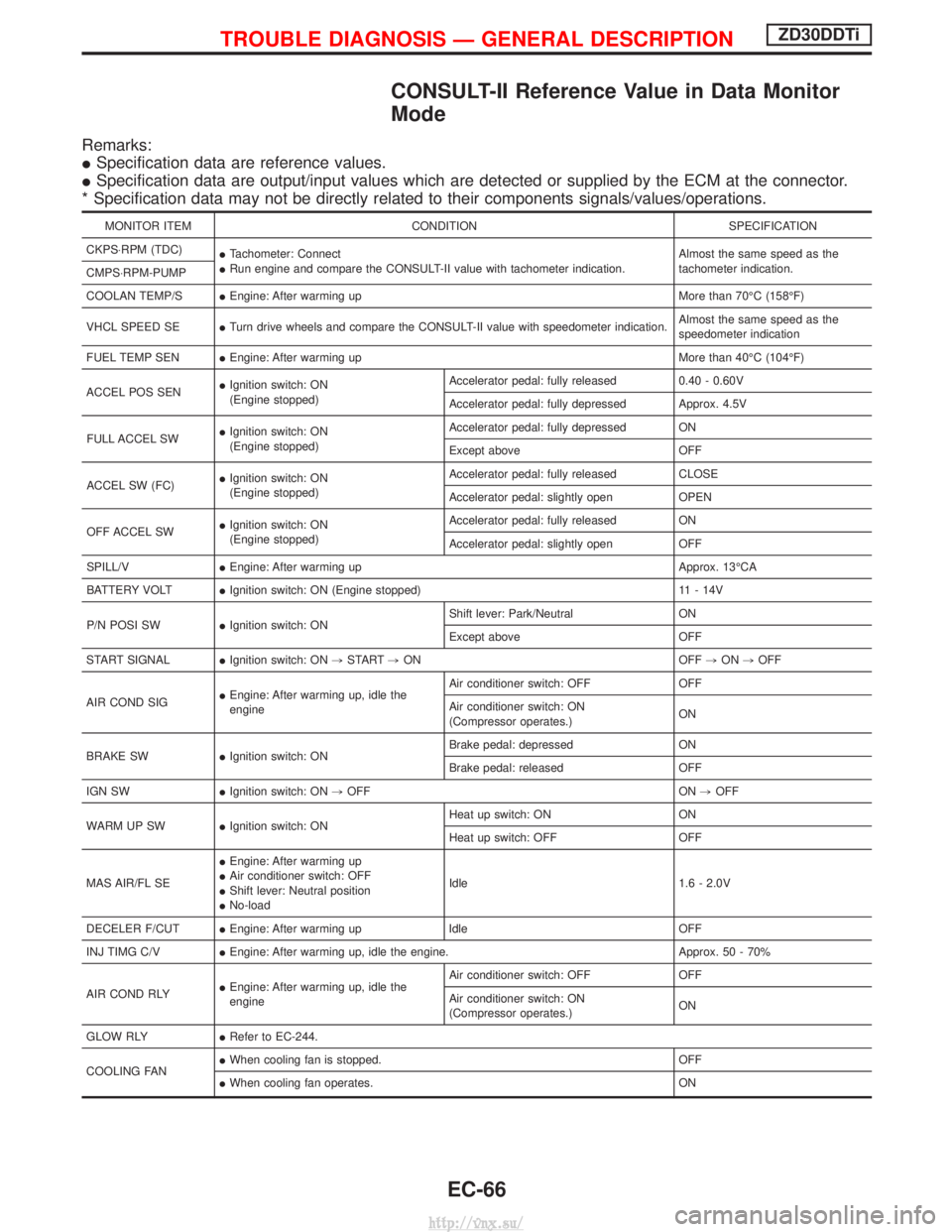

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

ISpecification data are reference values.

I Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPS×RPM (TDC) ITachometer: Connect

I Run engine and compare the CONSULT-II value with tachometer indication. Almost the same speed as the

tachometer indication.

CMPS×RPM-PUMP

COOLAN TEMP/S IEngine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE ITurn drive wheels and compare the CONSULT-II value with speedometer indication. Almost the same speed as the

speedometer indication

FUEL TEMP SEN IEngine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released

0.40 - 0.60V

Accelerator pedal: fully depressed Approx. 4.5V

FULL ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully depressed ON

Except above

OFF

ACCEL SW (FC) I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released

CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released

ON

Accelerator pedal: slightly open OFF

SPILL/V IEngine: After warming up Approx. 13ÉCA

BATTERY VOLT IIgnition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW IIgnition switch: ON Shift lever: Park/Neutral

ON

Except above OFF

START SIGNAL IIgnition switch: ON ,START ,ON OFF ,ON ,OFF

AIR COND SIG I

Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)

ON

BRAKE SW IIgnition switch: ON Brake pedal: depressed ON

Brake pedal: released OFF

IGN SW IIgnition switch: ON ,OFF ON ,OFF

WARM UP SW IIgnition switch: ON Heat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SE I

Engine: After warming up

I Air conditioner switch: OFF

I Shift lever: Neutral position

I No-load Idle 1.6 - 2.0V

DECELER F/CUT IEngine: After warming up Idle OFF

INJ TIMG C/V IEngine: After warming up, idle the engine. Approx. 50 - 70%

AIR COND RLY I

Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)

ON

GLOW RLY IRefer to EC-244.

COOLING FAN I

When cooling fan is stopped. OFF

I When cooling fan operates. ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-66

http://vnx.su/