brake light NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 45 of 1833

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 67 of 1833

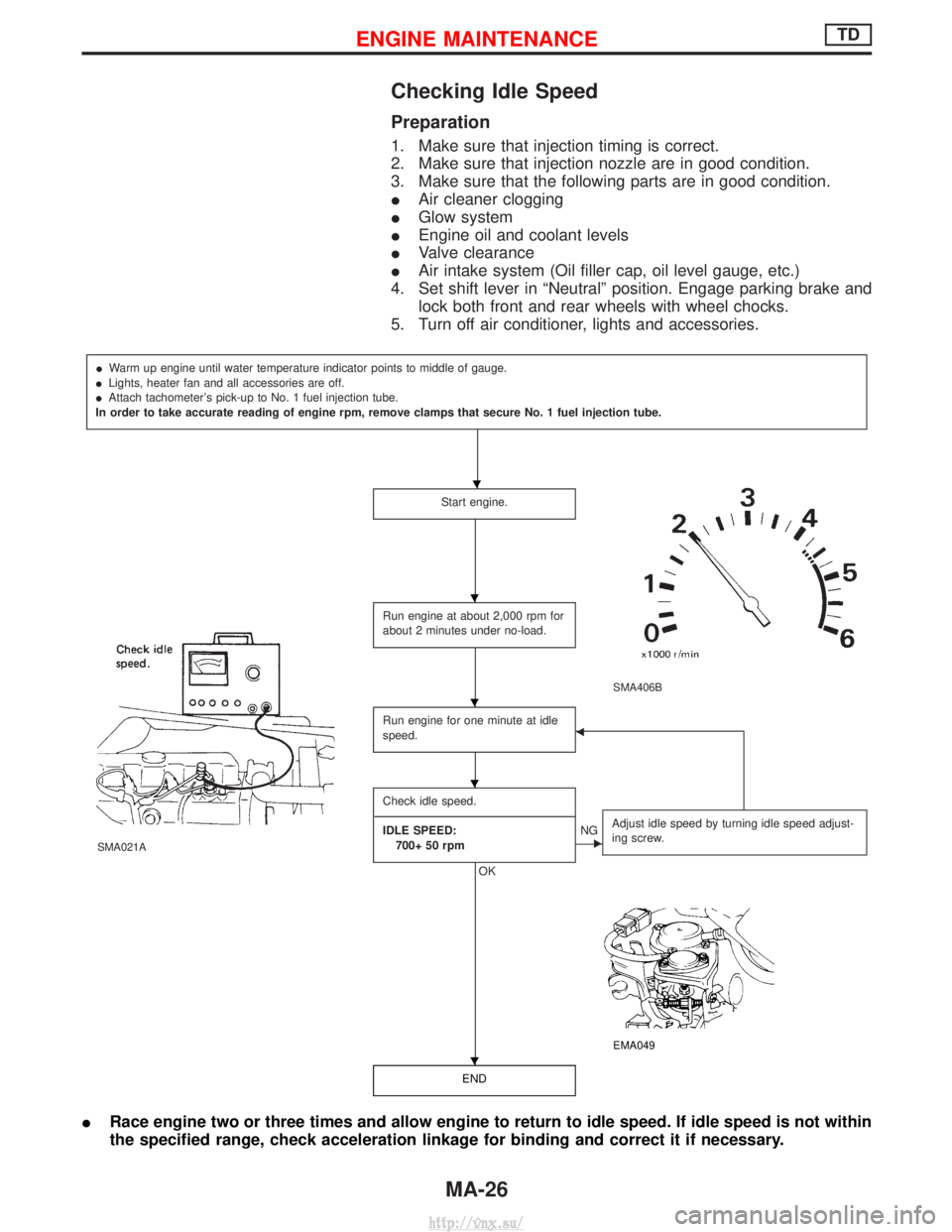

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

I Glow system

I Engine oil and coolant levels

I Valve clearance

I Air intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

I Warm up engine until water temperature indicator points to middle of gauge.

I Lights, heater fan and all accessories are off.

I Attach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- IDLE SPEED: 700+ 50 rpm

OK

ENG Adjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

I

Race engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

http://vnx.su/

Page 341 of 1833

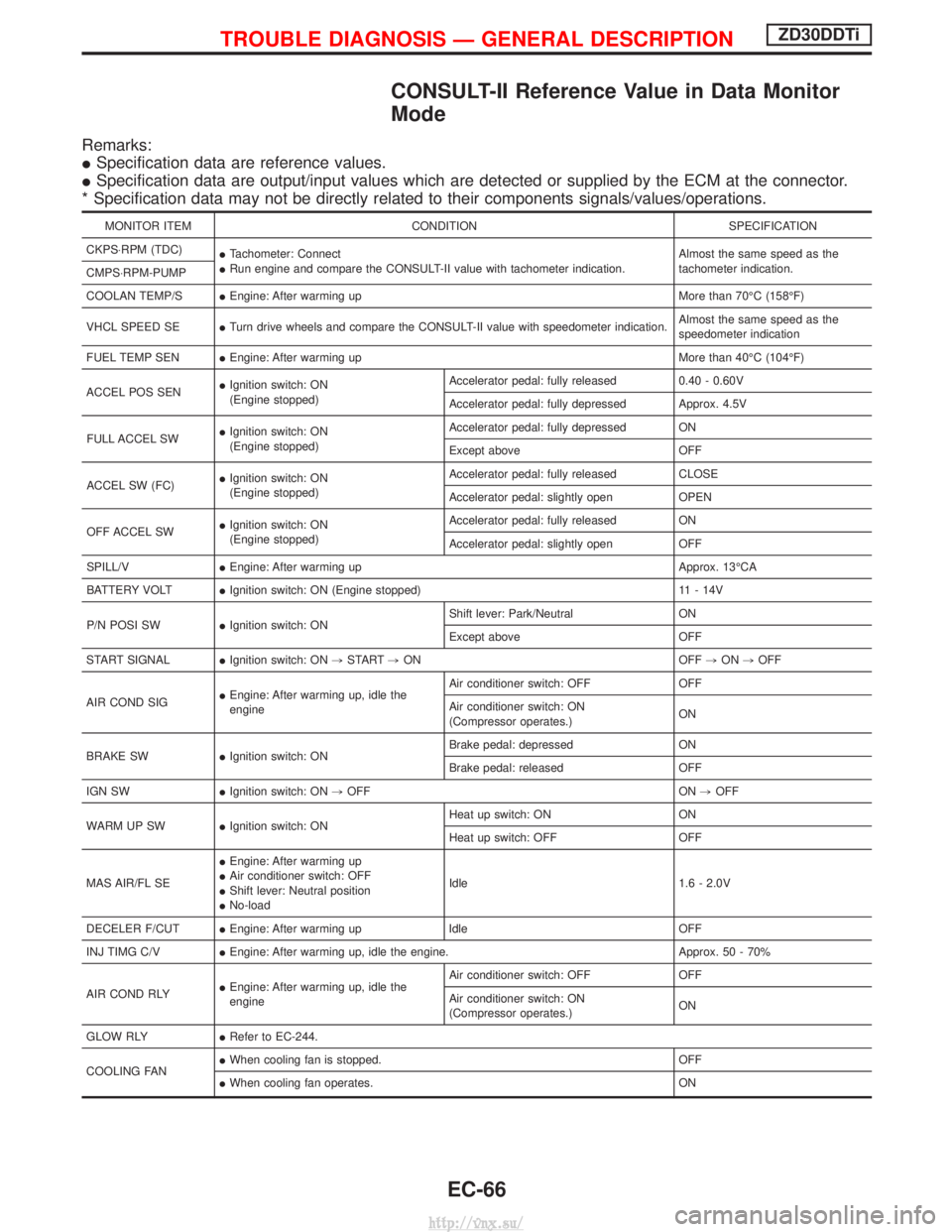

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

ISpecification data are reference values.

I Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPS×RPM (TDC) ITachometer: Connect

I Run engine and compare the CONSULT-II value with tachometer indication. Almost the same speed as the

tachometer indication.

CMPS×RPM-PUMP

COOLAN TEMP/S IEngine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE ITurn drive wheels and compare the CONSULT-II value with speedometer indication. Almost the same speed as the

speedometer indication

FUEL TEMP SEN IEngine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released

0.40 - 0.60V

Accelerator pedal: fully depressed Approx. 4.5V

FULL ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully depressed ON

Except above

OFF

ACCEL SW (FC) I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released

CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released

ON

Accelerator pedal: slightly open OFF

SPILL/V IEngine: After warming up Approx. 13ÉCA

BATTERY VOLT IIgnition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW IIgnition switch: ON Shift lever: Park/Neutral

ON

Except above OFF

START SIGNAL IIgnition switch: ON ,START ,ON OFF ,ON ,OFF

AIR COND SIG I

Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)

ON

BRAKE SW IIgnition switch: ON Brake pedal: depressed ON

Brake pedal: released OFF

IGN SW IIgnition switch: ON ,OFF ON ,OFF

WARM UP SW IIgnition switch: ON Heat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SE I

Engine: After warming up

I Air conditioner switch: OFF

I Shift lever: Neutral position

I No-load Idle 1.6 - 2.0V

DECELER F/CUT IEngine: After warming up Idle OFF

INJ TIMG C/V IEngine: After warming up, idle the engine. Approx. 50 - 70%

AIR COND RLY I

Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)

ON

GLOW RLY IRefer to EC-244.

COOLING FAN I

When cooling fan is stopped. OFF

I When cooling fan operates. ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-66

http://vnx.su/

Page 815 of 1833

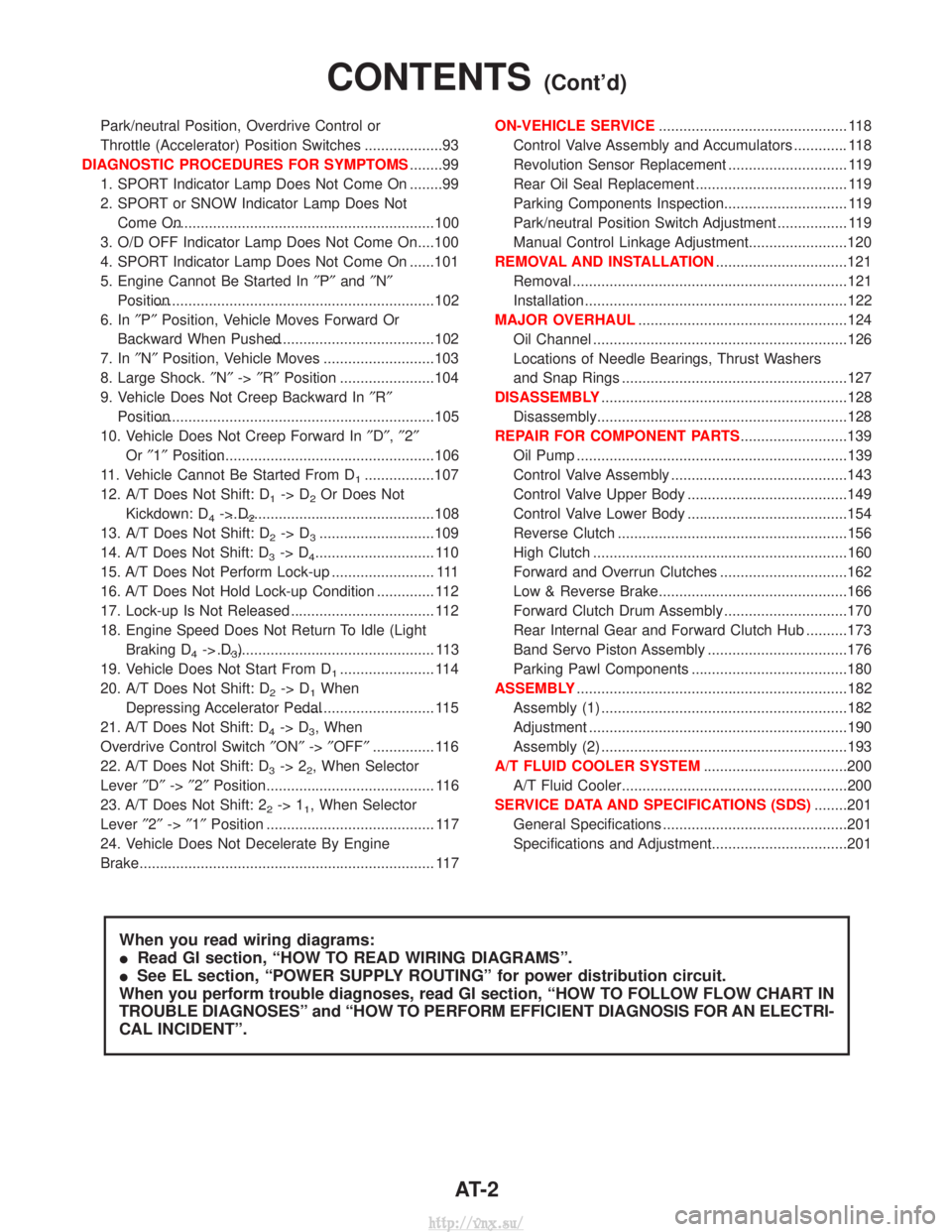

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches ...................93

DIAGNOSTIC PROCEDURES FOR SYMPTOMS ........99

1. SPORT Indicator Lamp Does Not Come On ........99

2. SPORT or SNOW Indicator Lamp Does Not Come On.................................................................100

3. O/D OFF Indicator Lamp Does Not Come On....100

4. SPORT Indicator Lamp Does Not Come On ......101

5. Engine Cannot Be Started In ²P² and ²N²

Position....................................................................102

6. In ²P² Position, Vehicle Moves Forward Or

Backward When Pushed.........................................102

7. In ²N² Position, Vehicle Moves ...........................103

8. Large Shock. ²N² ->²R² Position .......................104

9. Vehicle Does Not Creep Backward In ²R²

Position....................................................................105

10. Vehicle Does Not Creep Forward In ²D² ,²2²

Or ²1² Position.........................................................106

11. Vehicle Cannot Be Started From D

1.................107

12. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................108

13. A/T Does Not Shift: D

2-> D3............................109

14. A/T Does Not Shift: D

3-> D4............................. 110

15. A/T Does Not Perform Lock-up ......................... 111

16. A/T Does Not Hold Lock-up Condition .............. 112

17. Lock-up Is Not Released ................................... 112

18. Engine Speed Does Not Return To Idle (Light Braking D

4-> D3)..................................................... 113

19. Vehicle Does Not Start From D

1....................... 114

20. A/T Does Not Shift: D

2-> D1When

Depressing Accelerator Pedal................................. 115

21. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch ²ON² ->²OFF² ............... 116

22. A/T Does Not Shift: D

3-> 22, When Selector

Lever ²D² ->²2² Position......................................... 116

23. A/T Does Not Shift: 2

2-> 11, When Selector

Lever ²2² ->²1² Position ......................................... 117

24. Vehicle Does Not Decelerate By Engine

Brake........................................................................\

117 ON-VEHICLE SERVICE

.............................................. 118

Control Valve Assembly and Accumulators ............. 118

Revolution Sensor Replacement ............................. 119

Rear Oil Seal Replacement ..................................... 119

Parking Components Inspection.............................. 119

Park/neutral Position Switch Adjustment ................. 119

Manual Control Linkage Adjustment........................120

REMOVAL AND INSTALLATION ................................121

Removal ...................................................................121

Installation ................................................................122

MAJOR OVERHAUL ...................................................124

Oil Channel ..............................................................126

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................127

DISASSEMBLY ............................................................128

Disassembly.............................................................128

REPAIR FOR COMPONENT PARTS ..........................139

Oil Pump ..................................................................139

Control Valve Assembly ...........................................143

Control Valve Upper Body .......................................149

Control Valve Lower Body .......................................154

Reverse Clutch ........................................................156

High Clutch ..............................................................160

Forward and Overrun Clutches ...............................162

Low & Reverse Brake..............................................166

Forward Clutch Drum Assembly ..............................170

Rear Internal Gear and Forward Clutch Hub ..........173

Band Servo Piston Assembly ..................................176

Parking Pawl Components ......................................180

ASSEMBLY ..................................................................182

Assembly (1) ............................................................182

Adjustment ...............................................................190

Assembly (2) ............................................................193

A/T FLUID COOLER SYSTEM ...................................200

A/T Fluid Cooler.......................................................200

SERVICE DATA AND SPECIFICATIONS (SDS) ........201

General Specifications .............................................201

Specifications and Adjustment.................................201

When you read wiring diagrams:

I Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

I See EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENTº.

CONTENTS(Cont'd)

AT- 2

http://vnx.su/

Page 837 of 1833

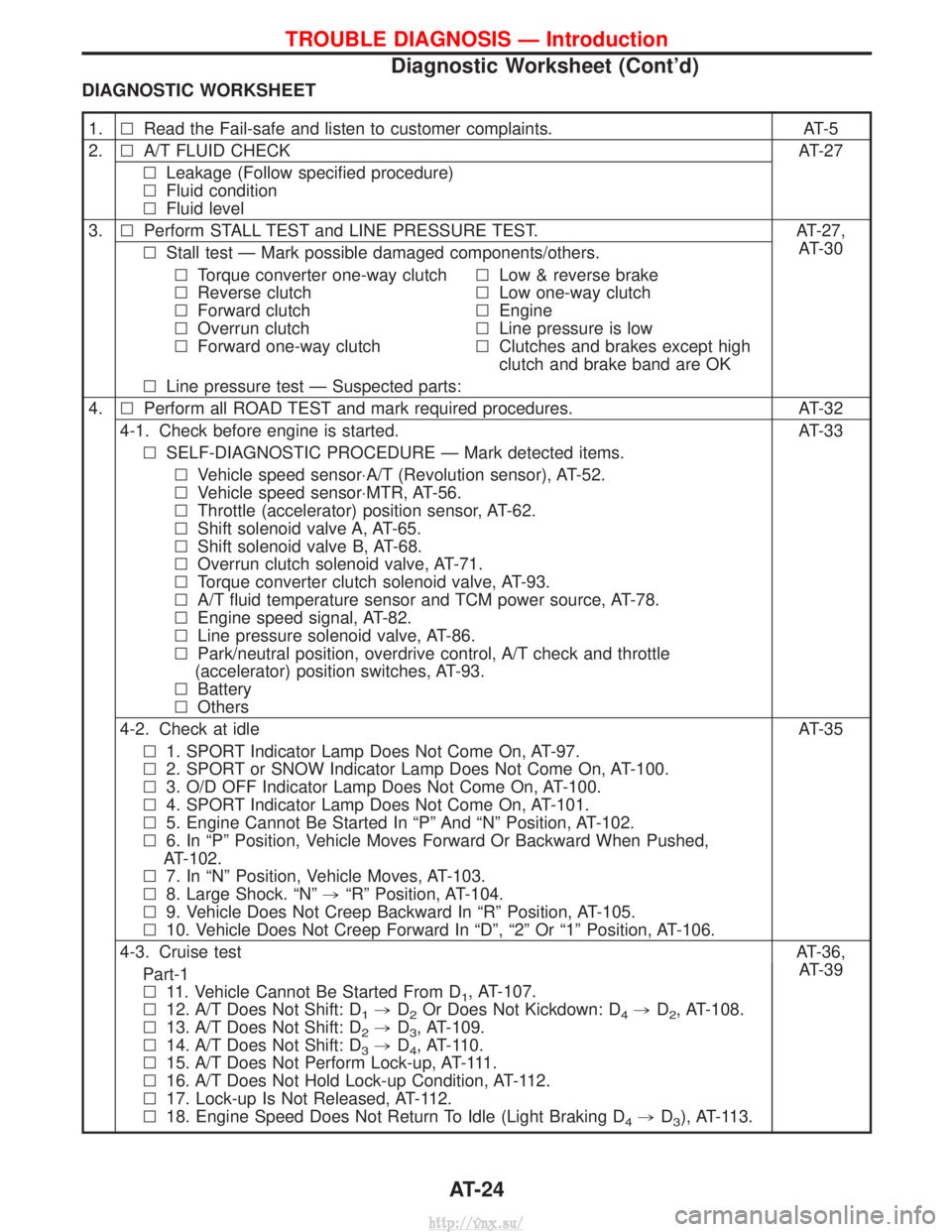

DIAGNOSTIC WORKSHEET

1.lRead the Fail-safe and listen to customer complaints. AT-5

2. lA/T FLUID CHECK AT-27

l Leakage (Follow specified procedure)

l Fluid condition

l Fluid level

3. lPerform STALL TEST and LINE PRESSURE TEST. AT-27,

AT-30

l Stall test Ð Mark possible damaged components/others.

l Torque converter one-way clutch

l Reverse clutch

l Forward clutch

l Overrun clutch

l Forward one-way clutch l

Low & reverse brake

l Low one-way clutch

l Engine

l Line pressure is low

l Clutches and brakes except high

clutch and brake band are OK

l Line pressure test Ð Suspected parts:

4. lPerform all ROAD TEST and mark required procedures. AT-32

4-1. Check before engine is started. AT-33 l SELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

l Vehicle speed sensor×A/T (Revolution sensor), AT-52.

l Vehicle speed sensor×MTR, AT-56.

l Throttle (accelerator) position sensor, AT-62.

l Shift solenoid valve A, AT-65.

l Shift solenoid valve B, AT-68.

l Overrun clutch solenoid valve, AT-71.

l Torque converter clutch solenoid valve, AT-93.

l A/T fluid temperature sensor and TCM power source, AT-78.

l Engine speed signal, AT-82.

l Line pressure solenoid valve, AT-86.

l Park/neutral position, overdrive control, A/T check and throttle

(accelerator) position switches, AT-93.

l Battery

l Others

4-2. Check at idle AT-35 l 1. SPORT Indicator Lamp Does Not Come On, AT-97.

l 2. SPORT or SNOW Indicator Lamp Does Not Come On, AT-100.

l 3. O/D OFF Indicator Lamp Does Not Come On, AT-100.

l 4. SPORT Indicator Lamp Does Not Come On, AT-101.

l 5. Engine Cannot Be Started In ªPº And ªNº Position, AT-102.

l 6. In ªPº Position, Vehicle Moves Forward Or Backward When Pushed,

AT-102.

l 7. In ªNº Position, Vehicle Moves, AT-103.

l 8. Large Shock. ªNº ,ªRº Position, AT-104.

l 9. Vehicle Does Not Creep Backward In ªRº Position, AT-105.

l 10. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position, AT-106.

4-3. Cruise test AT-36,

AT-39

Part-1

l 11. Vehicle Cannot Be Started From D

1, AT-107.

l 12. A/T Does Not Shift: D

1,D2Or Does Not Kickdown: D4,D2, AT-108.

l 13. A/T Does Not Shift: D

2,D3, AT-109.

l 14. A/T Does Not Shift: D

3,D4, AT-110.

l 15. A/T Does Not Perform Lock-up, AT-111.

l 16. A/T Does Not Hold Lock-up Condition, AT-112.

l 17. Lock-up Is Not Released, AT-112.

l 18. Engine Speed Does Not Return To Idle (Light Braking D

4,D3), AT-113.

TROUBLE DIAGNOSIS Ð Introduction

Diagnostic Worksheet (Cont'd)

AT-24

http://vnx.su/

Page 840 of 1833

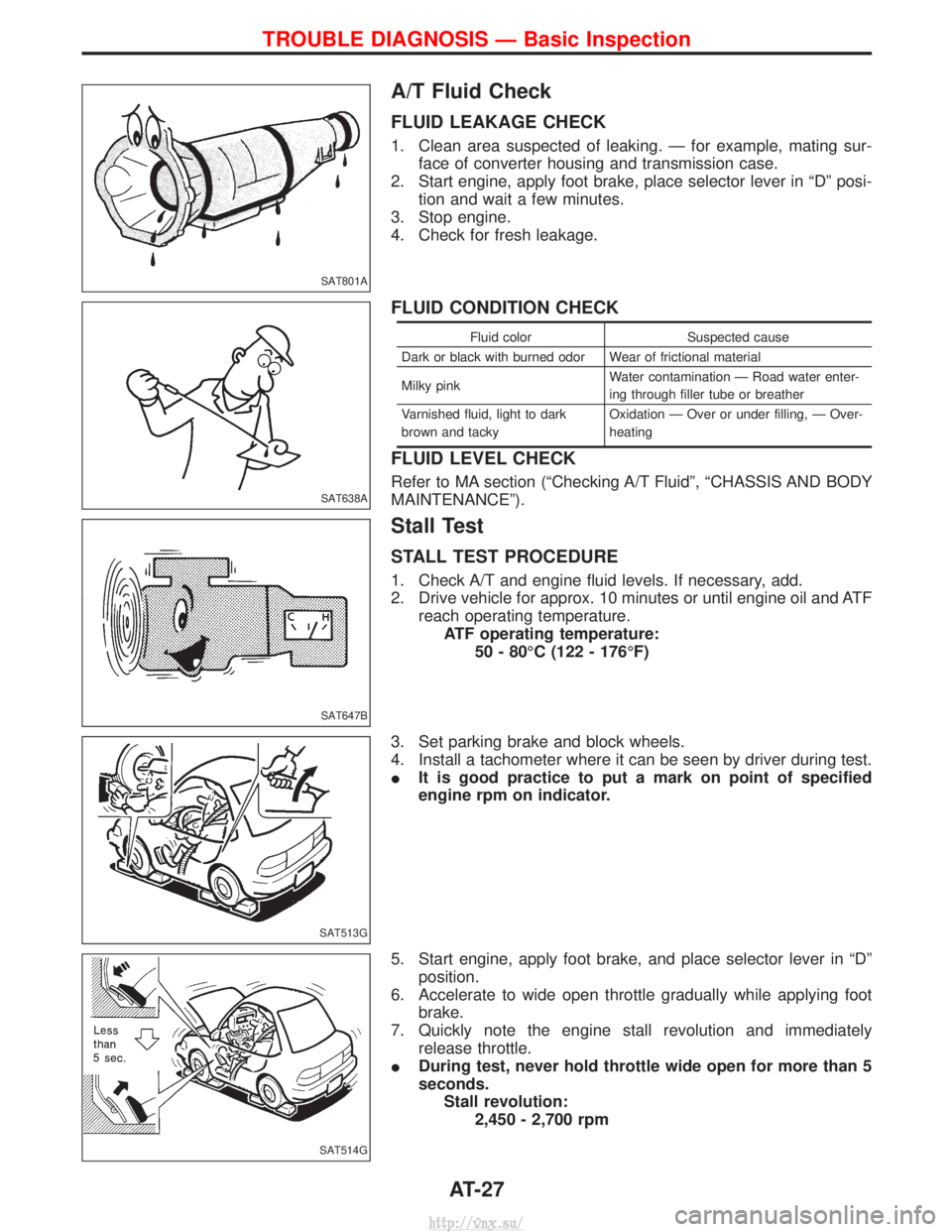

A/T Fluid Check

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. Ð for example, mating sur-face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi- tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

Fluid color Suspected cause

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water enter-

ing through filler tube or breather

Varnished fluid, light to dark

brown and tacky Oxidation Ð Over or under filling, Ð Over-

heating

FLUID LEVEL CHECK

Refer to MA section (ªChecking A/T Fluidº, ªCHASSIS AND BODY

MAINTENANCEº).

Stall Test

STALL TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.ATF operating temperature: 50 - 80ÉC (122 - 176ÉF)

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

I It is good practice to put a mark on point of specified

engine rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in ªDº position.

6. Accelerate to wide open throttle gradually while applying foot brake.

7. Quickly note the engine stall revolution and immediately release throttle.

I During test, never hold throttle wide open for more than 5

seconds.

Stall revolution: 2,450 - 2,700 rpm

SAT801A

SAT638A

SAT647B

SAT513G

SAT514G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-27

http://vnx.su/

Page 853 of 1833

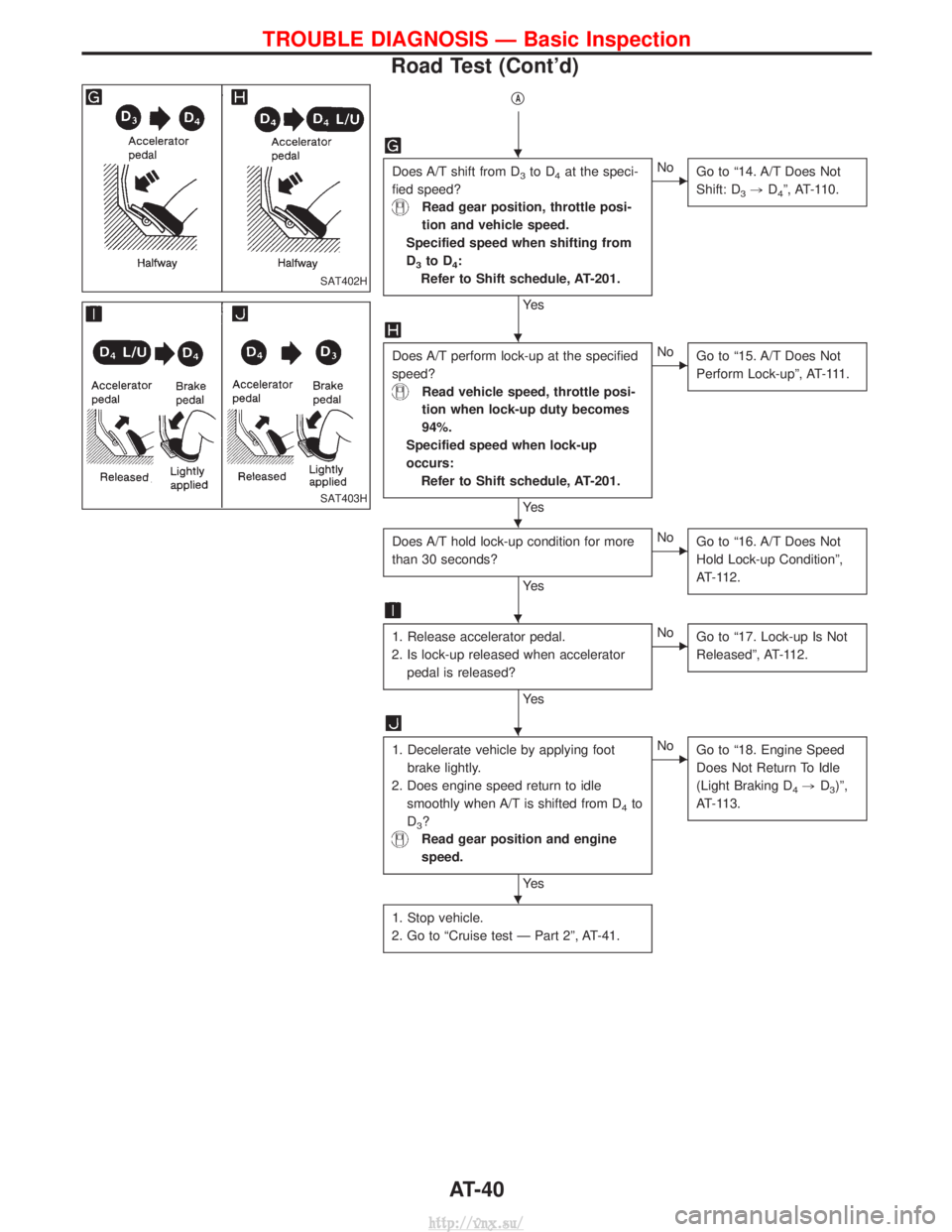

qA

Does A/T shift from D3to D4at the speci-

fied speed?

Read gear position, throttle posi-

tion and vehicle speed.

Specified speed when shifting from

D

3to D4:

Refer to Shift schedule, AT-201.

Ye s

ENo Go to ª14. A/T Does Not

Shift: D

3,D4º, AT-110.

Does A/T perform lock-up at the specified

speed?

Read vehicle speed, throttle posi-

tion when lock-up duty becomes

94%.

Specified speed when lock-up

occurs: Refer to Shift schedule, AT-201.

Ye s

ENo Go to ª15. A/T Does Not

Perform Lock-upº, AT-111.

Does A/T hold lock-up condition for more

than 30 seconds?

Ye s

ENoGo to ª16. A/T Does Not

Hold Lock-up Conditionº,

AT-112.

1. Release accelerator pedal.

2. Is lock-up released when accelerator pedal is released?

Ye s

ENo Go to ª17. Lock-up Is Not

Releasedº, AT-112.

1. Decelerate vehicle by applying foot

brake lightly.

2. Does engine speed return to idle smoothly when A/T is shifted from D

4to

D

3?

Read gear position and engine

speed.

Ye s

ENo Go to ª18. Engine Speed

Does Not Return To Idle

(Light Braking D

4,D3)º,

AT-113.

1. Stop vehicle.

2. Go to ªCruise test Ð Part 2º, AT-41.

SAT402H

SAT403H

H

H

H

H

H

H

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-40

http://vnx.su/

Page 855 of 1833

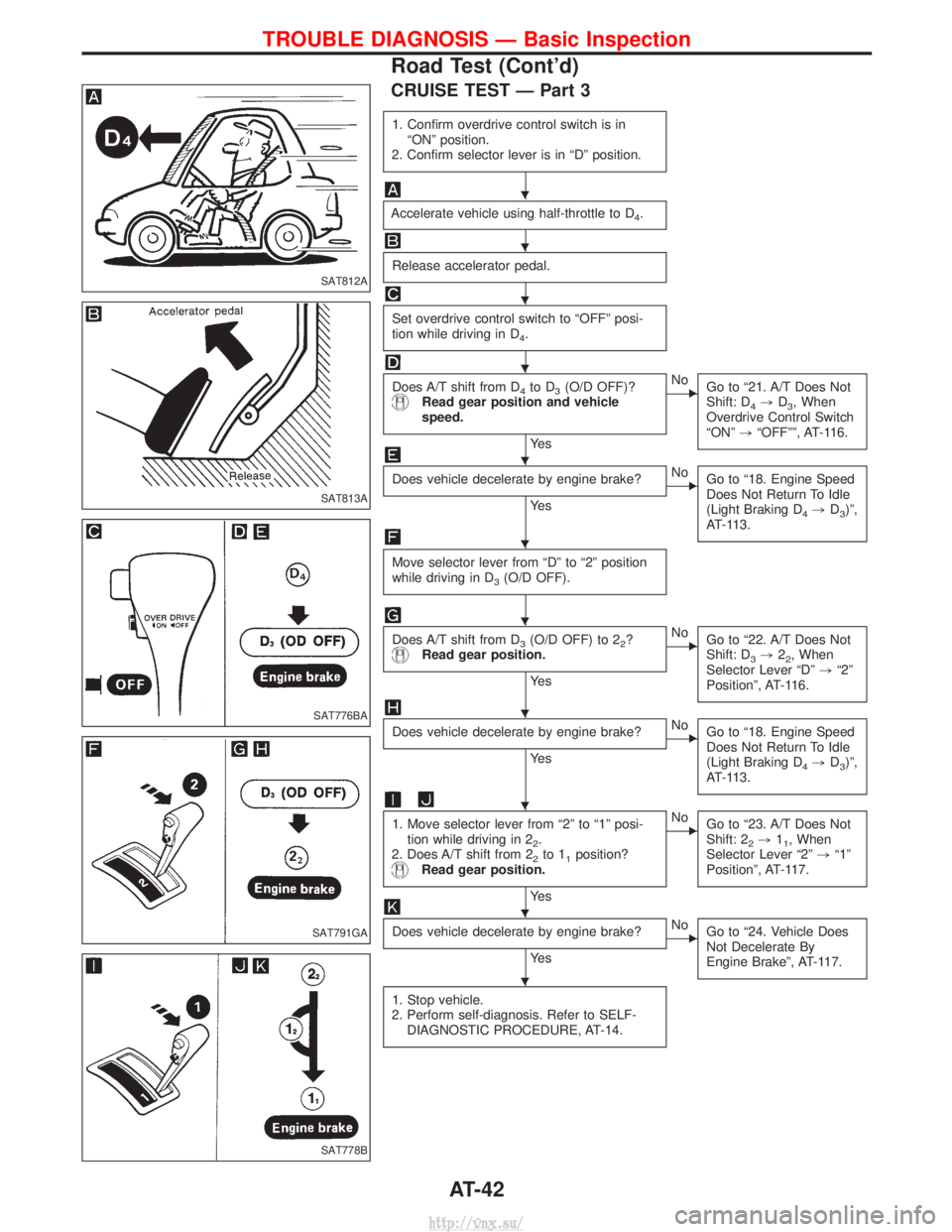

CRUISE TEST Ð Part 3

1. Confirm overdrive control switch is inªONº position.

2. Confirm selector lever is in ªDº position.

Accelerate vehicle using half-throttle to D4.

Release accelerator pedal.

Set overdrive control switch to ªOFFº posi-

tion while driving in D

4.

Does A/T shift from D4to D3(O/D OFF)?Read gear position and vehicle

speed.

Ye s

ENo Go to ª21. A/T Does Not

Shift: D

4,D3, When

Overdrive Control Switch

ªONº ,ªOFFºº, AT-116.

Does vehicle decelerate by engine brake?

Ye s

ENo

Go to ª18. Engine Speed

Does Not Return To Idle

(Light Braking D

4,D3)º,

AT-113.

Move selector lever from ªDº to ª2º position

while driving in D

3(O/D OFF).

Does A/T shift from D3(O/D OFF) to 22?Read gear position.

Ye s

ENo Go to ª22. A/T Does Not

Shift: D

3,22, When

Selector Lever ªDº ,ª2º

Positionº, AT-116.

Does vehicle decelerate by engine brake?

Ye s

ENo Go to ª18. Engine Speed

Does Not Return To Idle

(Light Braking D

4,D3)º,

AT-113.

1. Move selector lever from ª2º to ª1º posi- tion while driving in 2

2.

2. Does A/T shift from 2

2to 11position?Read gear position.

Ye s

ENo Go to ª23. A/T Does Not

Shift: 2

2,11, When

Selector Lever ª2º ,ª1º

Positionº, AT-117.

Does vehicle decelerate by engine brake?

Ye s

ENo Go to ª24. Vehicle Does

Not Decelerate By

Engine Brakeº, AT-117.

1. Stop vehicle.

2. Perform self-diagnosis. Refer to SELF- DIAGNOSTIC PROCEDURE, AT-14.

SAT812A

SAT813A

SAT776BA

SAT791GA

SAT778B

H

H

H

H

H

H

H

H

H

H

H

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-42

http://vnx.su/

Page 926 of 1833

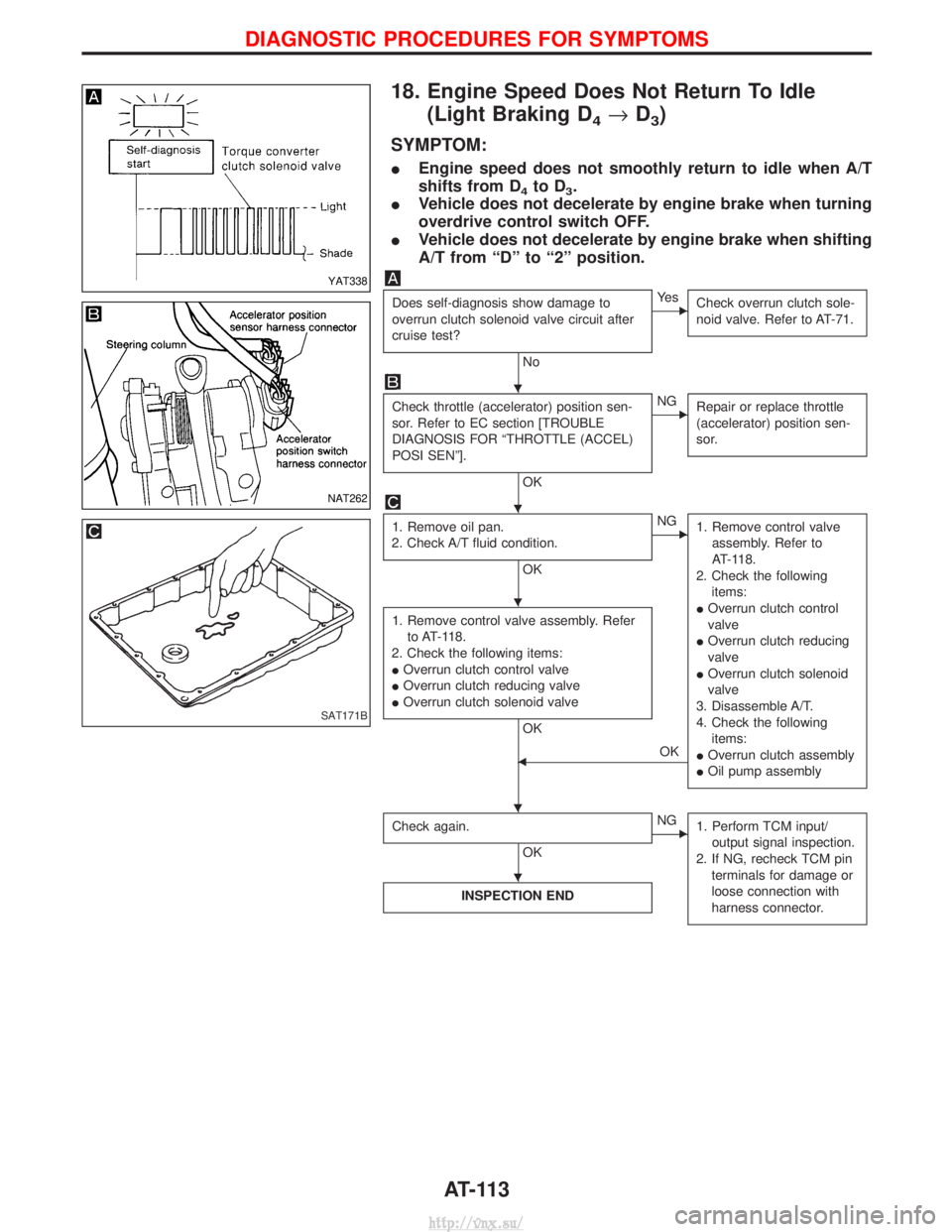

18. Engine Speed Does Not Return To Idle(Light Braking D

4®D3)

SYMPTOM:

I Engine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

I Vehicle does not decelerate by engine brake when turning

overdrive control switch OFF.

I Vehicle does not decelerate by engine brake when shifting

A/T from ªDº to ª2º position.

Does self-diagnosis show damage to

overrun clutch solenoid valve circuit after

cruise test?

No

EYe s

Check overrun clutch sole-

noid valve. Refer to AT-71.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENGRepair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG 1. Remove control valve

assembly. Refer to

AT-118.

2. Check the following items:

I Overrun clutch control

valve

I Overrun clutch reducing

valve

I Overrun clutch solenoid

valve

3. Disassemble A/T.

4. Check the following items:

I Overrun clutch assembly

I Oil pump assembly

1. Remove control valve assembly. Refer

to AT-118.

2. Check the following items:

I Overrun clutch control valve

I Overrun clutch reducing valve

I Overrun clutch solenoid valve

OK

FOK

Check again.

OK

ENG 1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT338

NAT262

SAT171B

H

H

H

HH

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-113

http://vnx.su/