check transmission fluid NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 12 of 1833

7. The followingSYMBOLS AND ABBREVIATIONS are used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disassem- bly.

L.H., R.H.: Left-Hand, Right-Hand

FR, RR : Front, Rear

2WD : 2-Wheel Drive

4WD : 4-Wheel Drive

qP: Apply petroleum jelly.

: Apply A.T.F.

A.T.F. : Automatic Transmission Fluid

H : Select with proper thickness.

I : Adjustment is required.

M/T : Manual Transaxle/Transmission

A/C : Air Conditioner

P/S : Power Steering

S.S.T. : Special Service Tools

S.D.S. : Service Data and Specifications

SAE : Society of Automotive Engineers, Inc.

L.H.D. : Left-Hand Drive

R.H.D. : Right-Hand Drive

8. The UNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system. ªExampleºTightening torque:59-78N ×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

9. TROUBLE DIAGNOSES are included in sections dealing with complicated components.

10. SERVICE DATA AND SPECIFICATIONS are contained at the end of each section for quick reference of

data.

11. The captions WARNINGandCAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

I WARNING indicates the possibility of personal injury if instructions are not followed.

I CAUTION indicates the possibility of component damage if instructions are not followed.

I BOLD TYPED STATEMENTS exceptWARNING andCAUTION give you helpful information.

HOW TO USE THIS MANUAL

GI-9

http://vnx.su/

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 48 of 1833

![NISSAN TERRANO 2004 Service Repair Manual Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten[ ] = At the specified mileage only

MAINTENANCE OPERATION MAINTENANCE INTE NISSAN TERRANO 2004 Service Repair Manual Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten[ ] = At the specified mileage only

MAINTENANCE OPERATION MAINTENANCE INTE](/img/5/57394/w960_57394-47.png)

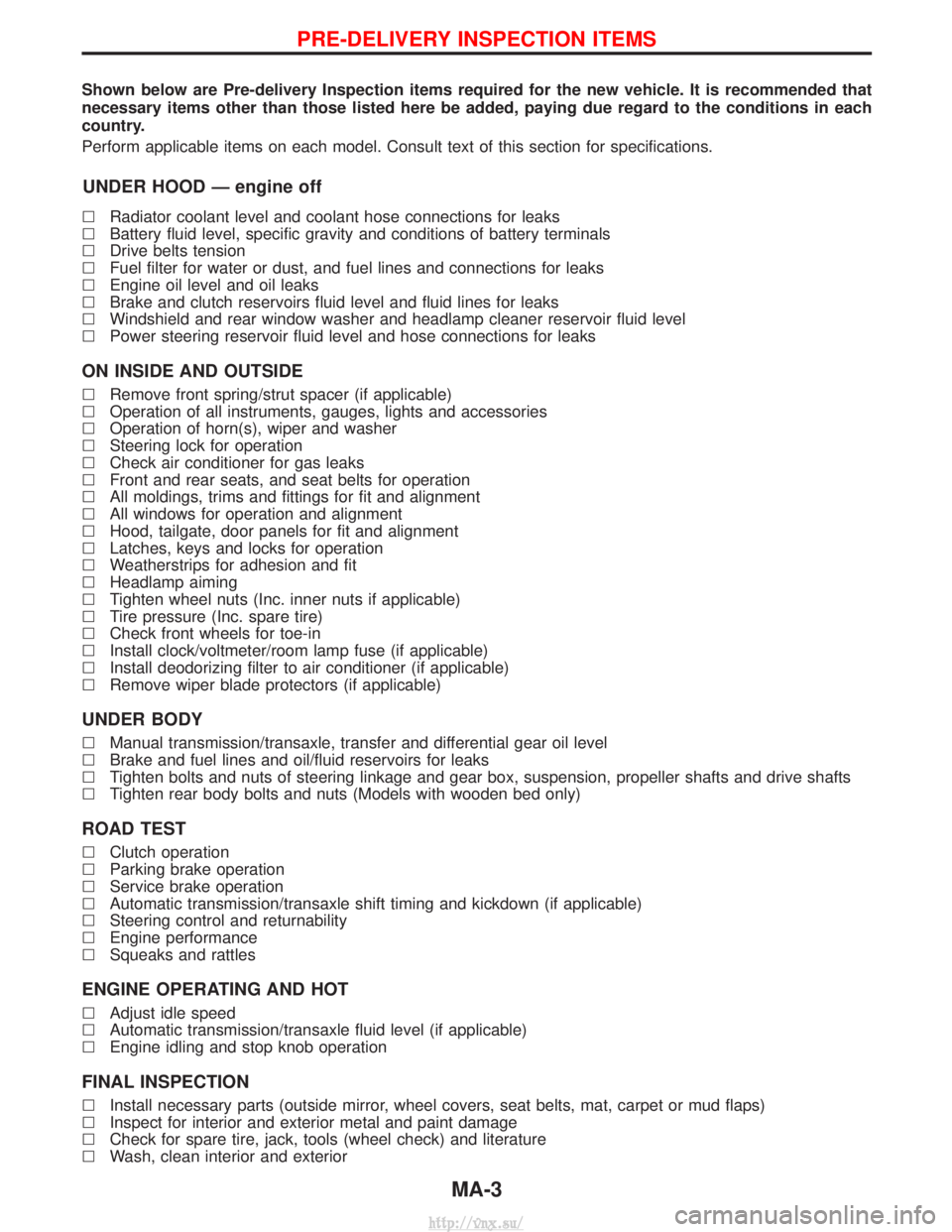

Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten[ ] = At the specified mileage only

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Refer-ence

page

Perform on a kilometer basis, but on

a semi-annual basis when driving

less than 20,000 km (12,000 miles)

per year. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Months 6 12 18 24 30 36 42 48 54 50 66 72

Underhood and under vehicle

Headlamp aiming

IIIIII EL-41

Wheel alignment (if necessary, rotate & balance wheels) IIIIII MA-43

Brake pads, discs & other components* IIIIII MA-40

Brake linings, drums & other components* IIIIII MA-41

Foot brake, parking brake & clutch (for free play, stroke &

operation) IIIIII

MA-42

Brake booster vacuum hoses, connections, check valve I I I MA-40

Brake & clutch, systems and fluid (for level and leaks) IIIIII MA-36/

MA-40

Brake fluid* R R R MA-43

Power steering fluid and lines (for level and leaks) IIIIII MA-44

Air bag system See NOTE (1) RS-17

Ventilation air filter* RRRRMA-44

Transfer and standard differential gear oil* I I R I I R MA-37/

MA-38

Manual transmission oil I I I [R] I I MA-36

LSD gear oil (for level and leaks)* I I R I I R MA-38

Steering gear & linkage, axle & suspension parts, propeller

shaft and exhaust system* IIIIII MA-43/

FA-4/

RA-4/

MA-38/ MA-36

Greasing points of steering gear linkage,

propeller shaft and suspension* See NOTE (2)

LLLLLL MA-44/

MA-38

Drive shafts* IIIIIIF A-13

Front wheel bearing grease* IRIRIR MA-39

Free running hub grease* IIIIII MA-40

Body mounting bolts and nuts TTTTTTBT-48

Body corrosion See NOTE (3) MA-47

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased daily if it is immersed in water.

(3) Inspect once per year.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe drivingconditionsº.

PERIODIC MAINTENANCE

Maintenance Schedule for Diesel Engine

Models (annual mileage < 30,000 km/year)

(Cont'd)

MA-7

http://vnx.su/

Page 51 of 1833

Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page

Perform on a kilometer basis only. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Underhood and under vehicle

Headlamp aiming

IIIIEL-41

Wheel alignment (it necessary, rotate & balance wheels) IIIIMA-43

Brake pads, discs & other components* IIIIMA-40

Brake linings, drums & other components* IIIIMA-41

Foot brake, parking brake & clutch (for free play, stroke &

operation) IIII

MA-42

Brake booster vacuum hoses, connections, check valve I I MA-40

Brake & clutch, systems and fluid (for level and leaks) IIIIMA-36/

MA-40

Brake fluid* R R MA-43

Power steering fluid and lines (for level and leaks) IIIIMA-44

Air bag system See NOTE (1) RS-17

Ventilation air filter* RRRRMA-44

Transfer and standard differential gear oil* IRIRMA-37/

MA-38

Manual transmission oil I I R I MA-36

LSD gear oil* IRIRMA-38

Steering gar & linkage, axle & suspension parts, propeller shaft

and exhaust system* IIIIMA-43/

FA-4/

RA-4/

MA-38/ MA-36

Greasing points of steering gear linkage,

propeller shaft and suspension* See NOTE (2)

LLLL MA-44/

MA-38

Drive shafts* IIIIFA-13

Front wheel bearing grease* IRIRMA-39

Free running hub grease* IIIIMA-40

Body mounting bolts and nuts TTTTBT-48

Body corrosion See NOTE (3) MA-47

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased daily if it is immersed in water.

(3) Inspect once per year.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe drivingconditionsº.

PERIODIC MAINTENANCE

Maintenance Schedule for Diesel Engine

Models (annual mileage > 30,000 km/year)

(Cont'd)

MA-10

http://vnx.su/

Page 78 of 1833

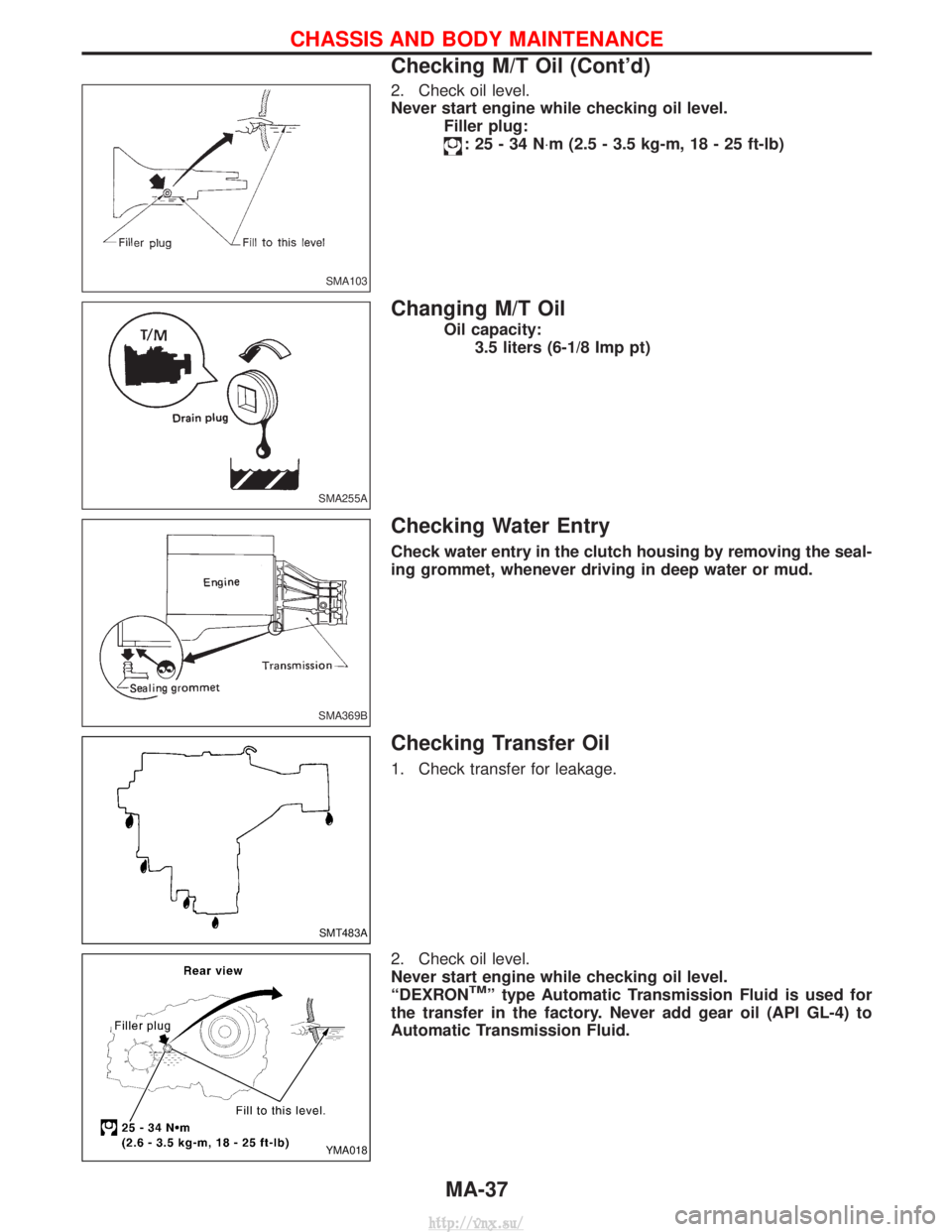

2. Check oil level.

Never start engine while checking oil level.Filler plug:

:25-34N ×m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing M/T Oil

Oil capacity:

3.5 liters (6-1/8 Imp pt)

Checking Water Entry

Check water entry in the clutch housing by removing the seal-

ing grommet, whenever driving in deep water or mud.

Checking Transfer Oil

1. Check transfer for leakage.

2. Check oil level.

Never start engine while checking oil level.

ªDEXRON

TMº type Automatic Transmission Fluid is used for

the transfer in the factory. Never add gear oil (API GL-4) to

Automatic Transmission Fluid.

SMA103

SMA255A

SMA369B

SMT483A

YMA018

CHASSIS AND BODY MAINTENANCE

Checking M/T Oil (Cont'd)

MA-37

http://vnx.su/

Page 79 of 1833

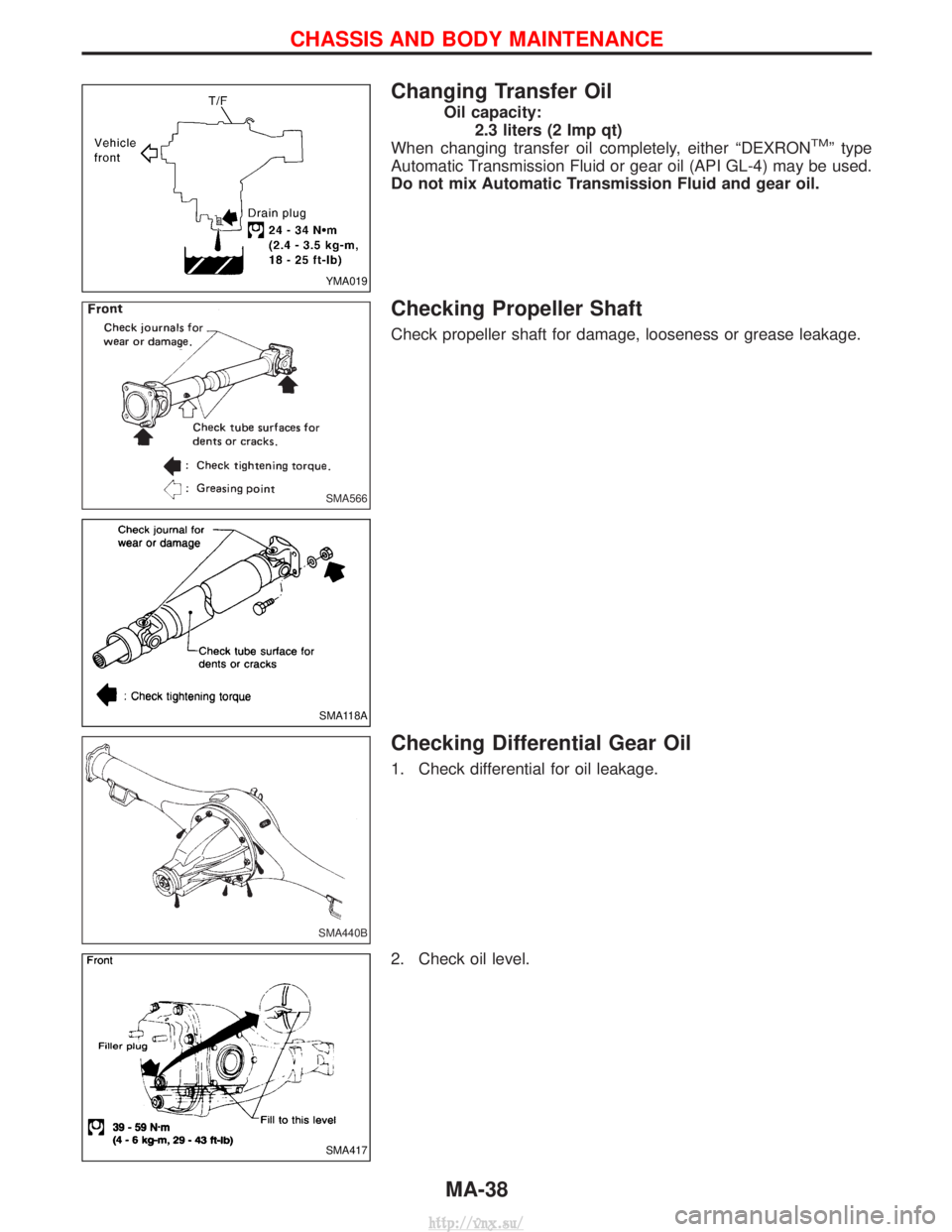

Changing Transfer Oil

Oil capacity:2.3 liters (2 Imp qt)

When changing transfer oil completely, either ªDEXRON

TMº type

Automatic Transmission Fluid or gear oil (API GL-4) may be used.

Do not mix Automatic Transmission Fluid and gear oil.

Checking Propeller Shaft

Check propeller shaft for damage, looseness or grease leakage.

Checking Differential Gear Oil

1. Check differential for oil leakage.

2. Check oil level.

YMA019

SMA566

SMA118A

SMA440B

SMA417

CHASSIS AND BODY MAINTENANCE

MA-38

http://vnx.su/

Page 85 of 1833

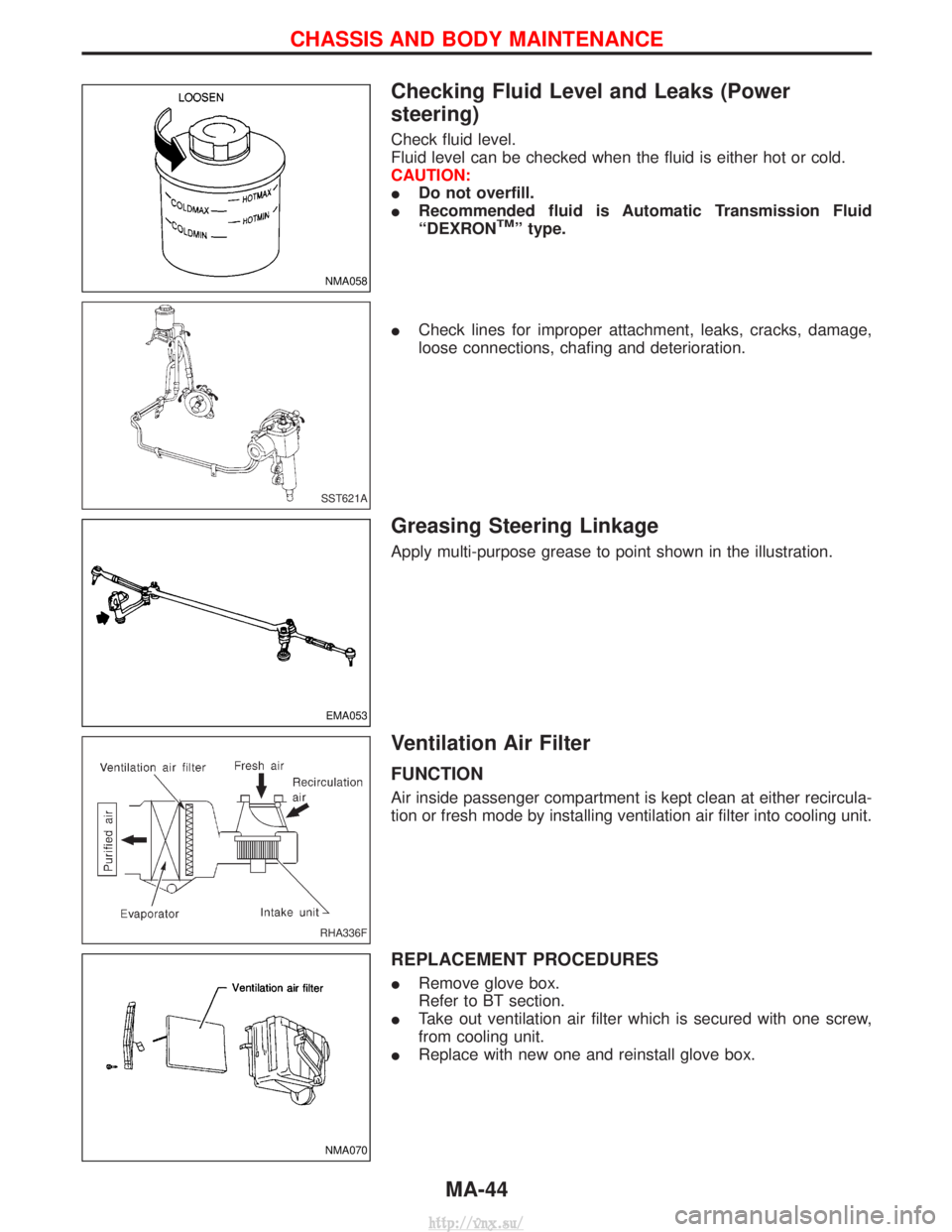

Checking Fluid Level and Leaks (Power

steering)

Check fluid level.

Fluid level can be checked when the fluid is either hot or cold.

CAUTION:

IDo not overfill.

I Recommended fluid is Automatic Transmission Fluid

ªDEXRON

TMº type.

I Check lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

Greasing Steering Linkage

Apply multi-purpose grease to point shown in the illustration.

Ventilation Air Filter

FUNCTION

Air inside passenger compartment is kept clean at either recircula-

tion or fresh mode by installing ventilation air filter into cooling unit.

REPLACEMENT PROCEDURES

IRemove glove box.

Refer to BT section.

I Take out ventilation air filter which is secured with one screw,

from cooling unit.

I Replace with new one and reinstall glove box.

NMA058

SST621A

EMA053

RHA336F

NMA070

CHASSIS AND BODY MAINTENANCE

MA-44

http://vnx.su/

Page 814 of 1833

AUTOMATIC TRANSMISSIONSECTION

AT

CONTENTS

PREPARATION AND PRECAUTIONS ............................3

Special Service Tools ..................................................3

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............4

Precautions for SRS ²AIR BAG² and²SEAT

BELT PRE-TENSIONER² Service ...............................4

Precautions ..................................................................4

Service Notice or Precautions .....................................5

OVERALL SYSTEM ........................................................6

A/T Electrical Parts Location .......................................6

Wiring Diagram - A/T -.................................................7

Cross-sectional View ...................................................8

Hydraulic Control Circuits ............................................9

Shift Mechanism ........................................................10

Control System ..........................................................12

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION ...............................................................14

Self-diagnosis ............................................................14

Diagnosis by CONSULT-II .........................................20

TROUBLE DIAGNOSIS - Introduction ........................22

Introduction ................................................................22

Diagnostic Worksheet ................................................23

Work Flow ..................................................................26

TROUBLE DIAGNOSIS - Basic Inspection ................27

A/T Fluid Check .........................................................27

Stall Test ....................................................................27

Line Pressure Test .....................................................30

Road Test...................................................................32

TROUBLE DIAGNOSIS - General Description ...........43

Symptom Chart ..........................................................43

TCM Terminals and Reference Value........................46

TROUBLE DIAGNOSIS FOR POWER SUPPLY ..........49

Wiring Diagram - AT - MAIN ......................................49

TCM Power Supply Circuit ........................................50

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×A/T ........................................................................\

.51

Wiring Diagram - AT - VSSA/T ..................................51

Vehicle Speed Sensor×A/T (Revolution sensor) ........52 TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×MTR

.......................................................................54

Wiring Diagram - AT - VSSMTR ................................54

Vehicle Speed Sensor×MTR ......................................56

TROUBLE DIAGNOSIS FOR THROTTLE POSI

SEN ........................................................................\

........58

Wiring Diagram - AT - TPS ........................................58

Throttle (Accelerator) Position Sensor ......................62

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

A ........................................................................\

.............64

Wiring Diagram - AT - SSV/A ....................................64

Shift Solenoid Valve A ...............................................65

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

B ........................................................................\

.............67

Wiring Diagram - AT - SSV/B ....................................67

Shift Solenoid Valve B ...............................................68

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH

S/V ........................................................................\

..........70

Wiring Diagram - AT - OVRCSV................................70

Overrun Clutch Solenoid Valve .................................71

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V .....73

Wiring Diagram - AT - TCV........................................73

Torque Converter Clutch Solenoid Valve ..................74

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP

SEN ........................................................................\

........77

Wiring Diagram - AT - BA/FTS ..................................77

A/T Fluid Temperature Sensor and TCM Power

Source........................................................................\

78

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG ....81

Wiring Diagram - AT - ENGSS ..................................81

Engine Speed Signal .................................................82

TROUBLE DIAGNOSIS FOR LINE PRESSURE

S/V ........................................................................\

..........84

Wiring Diagram - AT - LPSV......................................84

Line Pressure Solenoid Valve ...................................86

TROUBLE DIAGNOSIS FOR NON-DETECTABLE

ITEMS........................................................................\

.....89 Wiring Diagram - AT - PNP/SW.................................89

http://vnx.su/

Page 818 of 1833

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

I Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

I After overhaul, refill the transmission with new ATF.

I When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

Service Notice or Precautions

FAIL-SAFE

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear even with a shift lever position of ª1º, ª2º or ªDº. Cus-

tomer may complain of ªsluggish or poor accelerationº.

When the Fail-Safe operation occurs the next time the key is turned to the ªONº position, the SPORT indica-

tor lamp will blink for about 8 seconds. (For diagnosis, refer to AT-33.)

Fail-Safe may activate without electrical circuit damages if the vehicle is driven under extreme conditions (such

as excessive wheel spins and emergency braking immediately afterwards). In this case, turn the ignition key

ªOFFº for 5 seconds and then ªONº to recover normal shift pattern.

The blinking of the SPORT indicator lamp for about 8 seconds will appear only once and be cleared. The cus-

tomer may resume normal driving conditions by chance.

Always follow the ªWORK FLOWº (Refer to AT-26).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate the damage of the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS performed after checking the sensor, no damages will be indicated.

PREPARATION AND PRECAUTIONS

Precautions (Cont'd)

AT- 5

http://vnx.su/

Page 840 of 1833

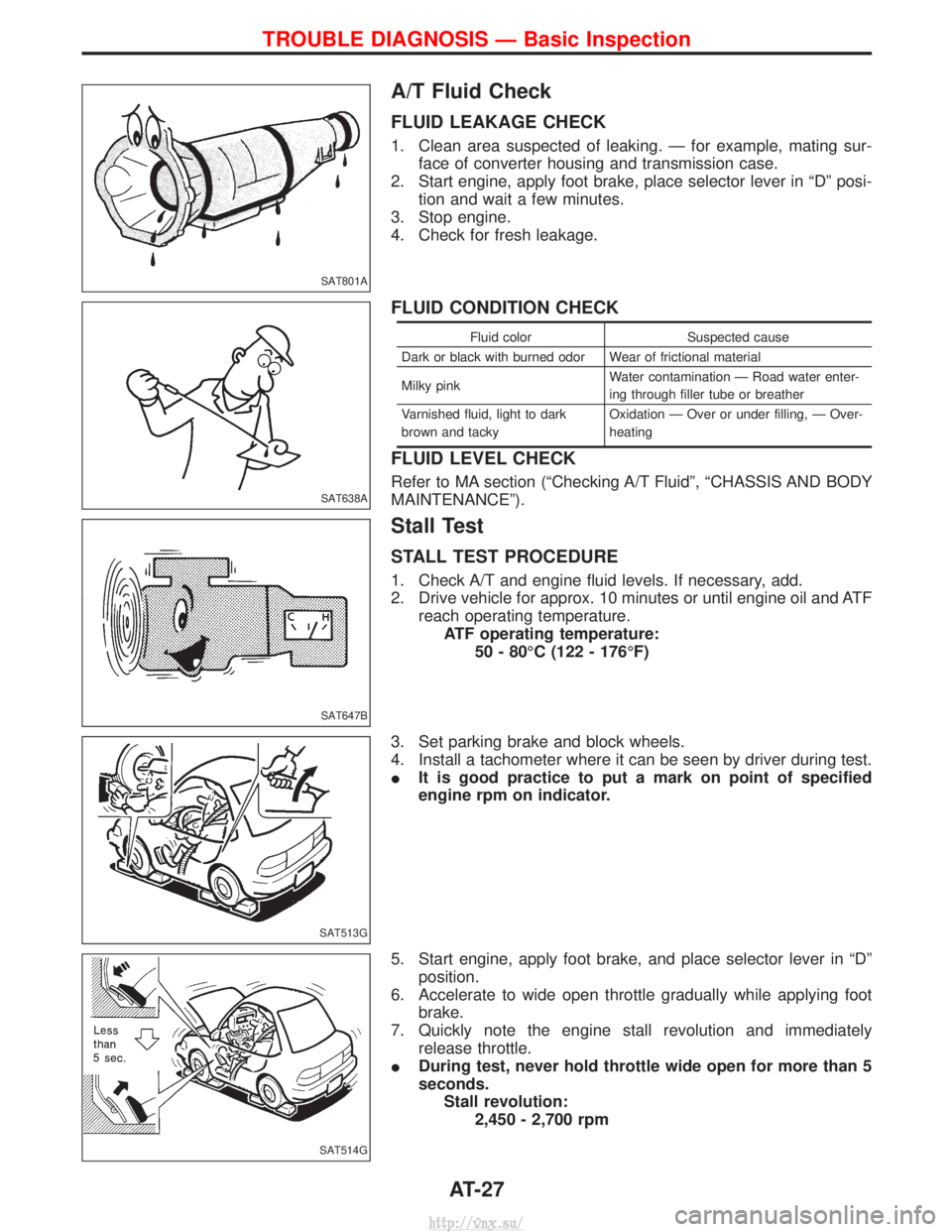

A/T Fluid Check

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. Ð for example, mating sur-face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi- tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

Fluid color Suspected cause

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water enter-

ing through filler tube or breather

Varnished fluid, light to dark

brown and tacky Oxidation Ð Over or under filling, Ð Over-

heating

FLUID LEVEL CHECK

Refer to MA section (ªChecking A/T Fluidº, ªCHASSIS AND BODY

MAINTENANCEº).

Stall Test

STALL TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.ATF operating temperature: 50 - 80ÉC (122 - 176ÉF)

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

I It is good practice to put a mark on point of specified

engine rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in ªDº position.

6. Accelerate to wide open throttle gradually while applying foot brake.

7. Quickly note the engine stall revolution and immediately release throttle.

I During test, never hold throttle wide open for more than 5

seconds.

Stall revolution: 2,450 - 2,700 rpm

SAT801A

SAT638A

SAT647B

SAT513G

SAT514G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-27

http://vnx.su/