overheating NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 277 of 1833

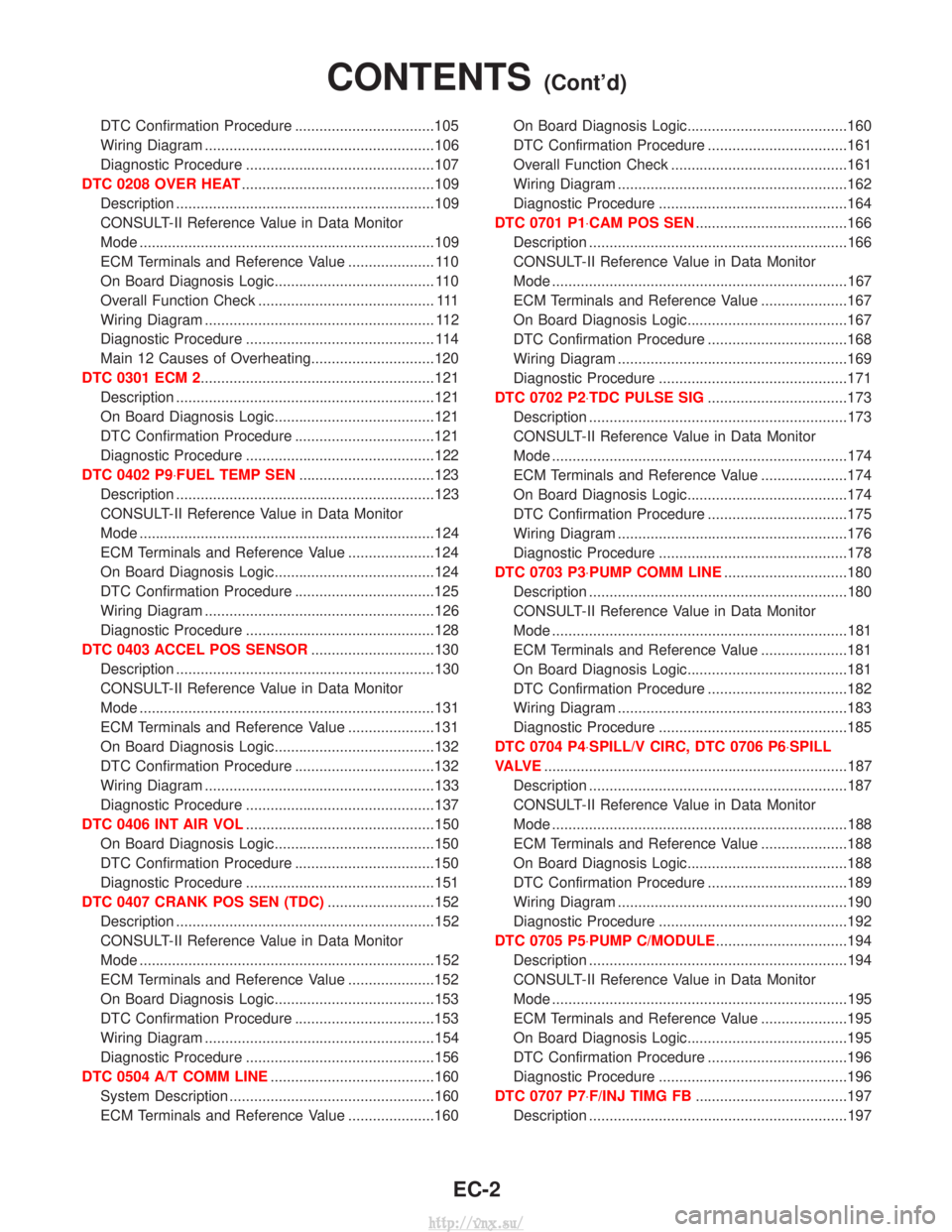

DTC Confirmation Procedure ..................................105

Wiring Diagram ........................................................106

Diagnostic Procedure ..............................................107

DTC 0208 OVER HEAT ...............................................109

Description ...............................................................109

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

109

ECM Terminals and Reference Value ..................... 110

On Board Diagnosis Logic....................................... 110

Overall Function Check ........................................... 111

Wiring Diagram ........................................................ 112

Diagnostic Procedure .............................................. 114

Main 12 Causes of Overheating..............................120

DTC 0301 ECM 2.........................................................121 Description ...............................................................121

On Board Diagnosis Logic.......................................121

DTC Confirmation Procedure ..................................121

Diagnostic Procedure ..............................................122

DTC 0402 P9×FUEL TEMP SEN .................................123

Description ...............................................................123

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

124

ECM Terminals and Reference Value .....................124

On Board Diagnosis Logic.......................................124

DTC Confirmation Procedure ..................................125

Wiring Diagram ........................................................126

Diagnostic Procedure ..............................................128

DTC 0403 ACCEL POS SENSOR ..............................130

Description ...............................................................130

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

131

ECM Terminals and Reference Value .....................131

On Board Diagnosis Logic.......................................132

DTC Confirmation Procedure ..................................132

Wiring Diagram ........................................................133

Diagnostic Procedure ..............................................137

DTC 0406 INT AIR VOL ..............................................150

On Board Diagnosis Logic.......................................150

DTC Confirmation Procedure ..................................150

Diagnostic Procedure ..............................................151

DTC 0407 CRANK POS SEN (TDC) ..........................152

Description ...............................................................152

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

152

ECM Terminals and Reference Value .....................152

On Board Diagnosis Logic.......................................153

DTC Confirmation Procedure ..................................153

Wiring Diagram ........................................................154

Diagnostic Procedure ..............................................156

DTC 0504 A/T COMM LINE ........................................160

System Description ..................................................160

ECM Terminals and Reference Value .....................160 On Board Diagnosis Logic.......................................160

DTC Confirmation Procedure ..................................161

Overall Function Check ...........................................161

Wiring Diagram ........................................................162

Diagnostic Procedure ..............................................164

DTC 0701 P1×CAM POS SEN .....................................166

Description ...............................................................166

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

167

ECM Terminals and Reference Value .....................167

On Board Diagnosis Logic.......................................167

DTC Confirmation Procedure ..................................168

Wiring Diagram ........................................................169

Diagnostic Procedure ..............................................171

DTC 0702 P2×TDC PULSE SIG ..................................173

Description ...............................................................173

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

174

ECM Terminals and Reference Value .....................174

On Board Diagnosis Logic.......................................174

DTC Confirmation Procedure ..................................175

Wiring Diagram ........................................................176

Diagnostic Procedure ..............................................178

DTC 0703 P3×PUMP COMM LINE ..............................180

Description ...............................................................180

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

181

ECM Terminals and Reference Value .....................181

On Board Diagnosis Logic.......................................181

DTC Confirmation Procedure ..................................182

Wiring Diagram ........................................................183

Diagnostic Procedure ..............................................185

DTC 0704 P4×SPILL/V CIRC, DTC 0706 P6×SPILL

VA LV E ........................................................................\

..187

Description ...............................................................187

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

188

ECM Terminals and Reference Value .....................188

On Board Diagnosis Logic.......................................188

DTC Confirmation Procedure ..................................189

Wiring Diagram ........................................................190

Diagnostic Procedure ..............................................192

DTC 0705 P5×PUMP C/MODULE ................................194

Description ...............................................................194

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

195

ECM Terminals and Reference Value .....................195

On Board Diagnosis Logic.......................................195

DTC Confirmation Procedure ..................................196

Diagnostic Procedure ..............................................196

DTC 0707 P7×F/INJ TIMG FB .....................................197

Description ...............................................................197

CONTENTS(Cont'd)

EC-2

http://vnx.su/

Page 280 of 1833

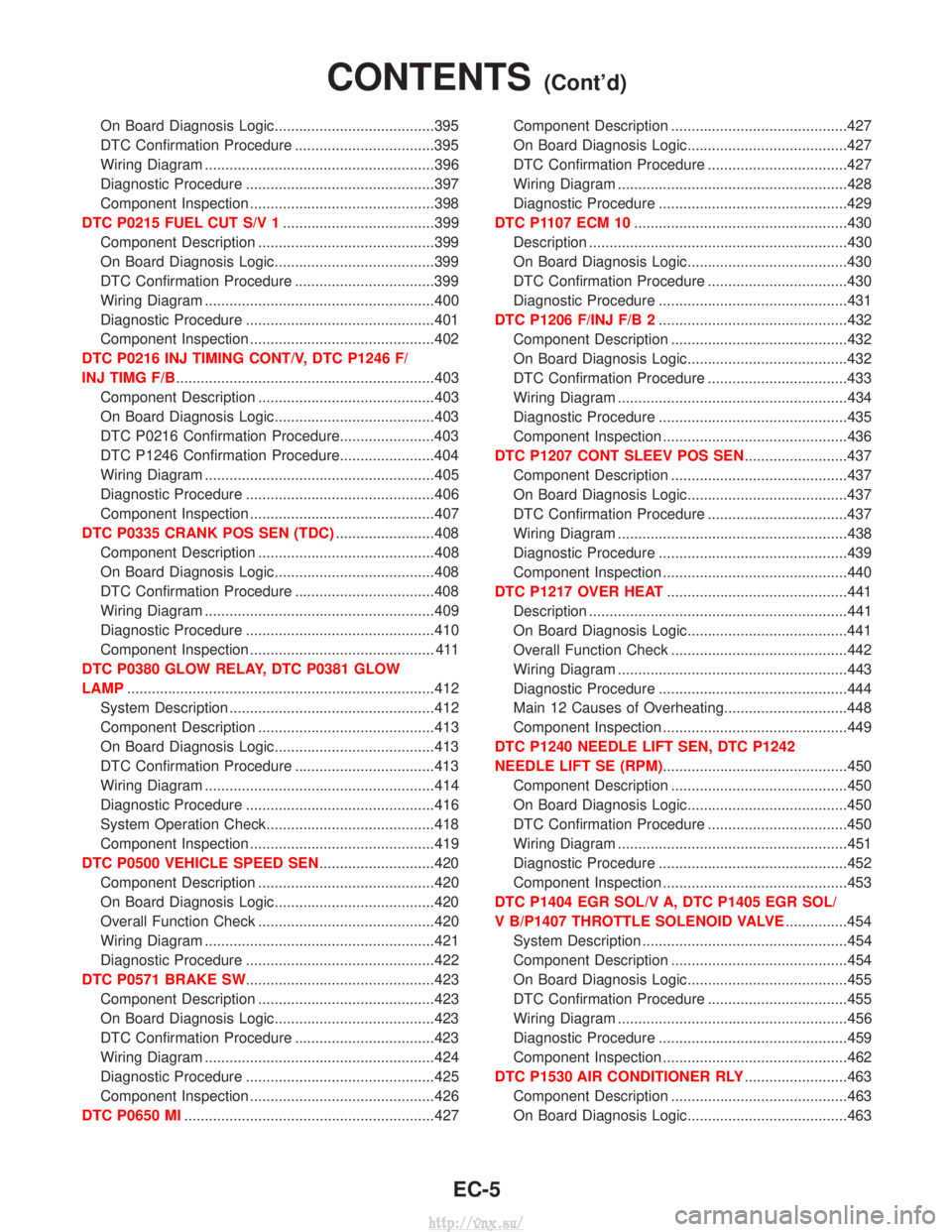

On Board Diagnosis Logic.......................................395

DTC Confirmation Procedure ..................................395

Wiring Diagram ........................................................396

Diagnostic Procedure ..............................................397

Component Inspection .............................................398

DTC P0215 FUEL CUT S/V 1 .....................................399

Component Description ...........................................399

On Board Diagnosis Logic.......................................399

DTC Confirmation Procedure ..................................399

Wiring Diagram ........................................................400

Diagnostic Procedure ..............................................401

Component Inspection .............................................402

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/

INJ TIMG F/B ...............................................................403

Component Description ...........................................403

On Board Diagnosis Logic.......................................403

DTC P0216 Confirmation Procedure.......................403

DTC P1246 Confirmation Procedure.......................404

Wiring Diagram ........................................................405

Diagnostic Procedure ..............................................406

Component Inspection .............................................407

DTC P0335 CRANK POS SEN (TDC) ........................408

Component Description ...........................................408

On Board Diagnosis Logic.......................................408

DTC Confirmation Procedure ..................................408

Wiring Diagram ........................................................409

Diagnostic Procedure ..............................................410

Component Inspection ............................................. 411

DTC P0380 GLOW RELAY, DTC P0381 GLOW

LAMP ........................................................................\

...412

System Description ..................................................412

Component Description ...........................................413

On Board Diagnosis Logic.......................................413

DTC Confirmation Procedure ..................................413

Wiring Diagram ........................................................414

Diagnostic Procedure ..............................................416

System Operation Check.........................................418

Component Inspection .............................................419

DTC P0500 VEHICLE SPEED SEN ............................420

Component Description ...........................................420

On Board Diagnosis Logic.......................................420

Overall Function Check ...........................................420

Wiring Diagram ........................................................421

Diagnostic Procedure ..............................................422

DTC P0571 BRAKE SW ..............................................423

Component Description ...........................................423

On Board Diagnosis Logic.......................................423

DTC Confirmation Procedure ..................................423

Wiring Diagram ........................................................424

Diagnostic Procedure ..............................................425

Component Inspection .............................................426

DTC P0650 MI .............................................................427 Component Description ...........................................427

On Board Diagnosis Logic.......................................427

DTC Confirmation Procedure ..................................427

Wiring Diagram ........................................................428

Diagnostic Procedure ..............................................429

DTC P1107 ECM 10 ....................................................430

Description ...............................................................430

On Board Diagnosis Logic.......................................430

DTC Confirmation Procedure ..................................430

Diagnostic Procedure ..............................................431

DTC P1206 F/INJ F/B 2 ..............................................432

Component Description ...........................................432

On Board Diagnosis Logic.......................................432

DTC Confirmation Procedure ..................................433

Wiring Diagram ........................................................434

Diagnostic Procedure ..............................................435

Component Inspection .............................................436

DTC P1207 CONT SLEEV POS SEN .........................437

Component Description ...........................................437

On Board Diagnosis Logic.......................................437

DTC Confirmation Procedure ..................................437

Wiring Diagram ........................................................438

Diagnostic Procedure ..............................................439

Component Inspection .............................................440

DTC P1217 OVER HEAT ............................................441

Description ...............................................................441

On Board Diagnosis Logic.......................................441

Overall Function Check ...........................................442

Wiring Diagram ........................................................443

Diagnostic Procedure ..............................................444

Main 12 Causes of Overheating..............................448

Component Inspection .............................................449

DTC P1240 NEEDLE LIFT SEN, DTC P1242

NEEDLE LIFT SE (RPM) .............................................450

Component Description ...........................................450

On Board Diagnosis Logic.......................................450

DTC Confirmation Procedure ..................................450

Wiring Diagram ........................................................451

Diagnostic Procedure ..............................................452

Component Inspection .............................................453

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/

V B/P1407 THROTTLE SOLENOID VALVE ...............454

System Description ..................................................454

Component Description ...........................................454

On Board Diagnosis Logic.......................................455

DTC Confirmation Procedure ..................................455

Wiring Diagram ........................................................456

Diagnostic Procedure ..............................................459

Component Inspection .............................................462

DTC P1530 AIR CONDITIONER RLY .........................463

Component Description ...........................................463

On Board Diagnosis Logic.......................................463

CONTENTS(Cont'd)

EC-5

http://vnx.su/

Page 385 of 1833

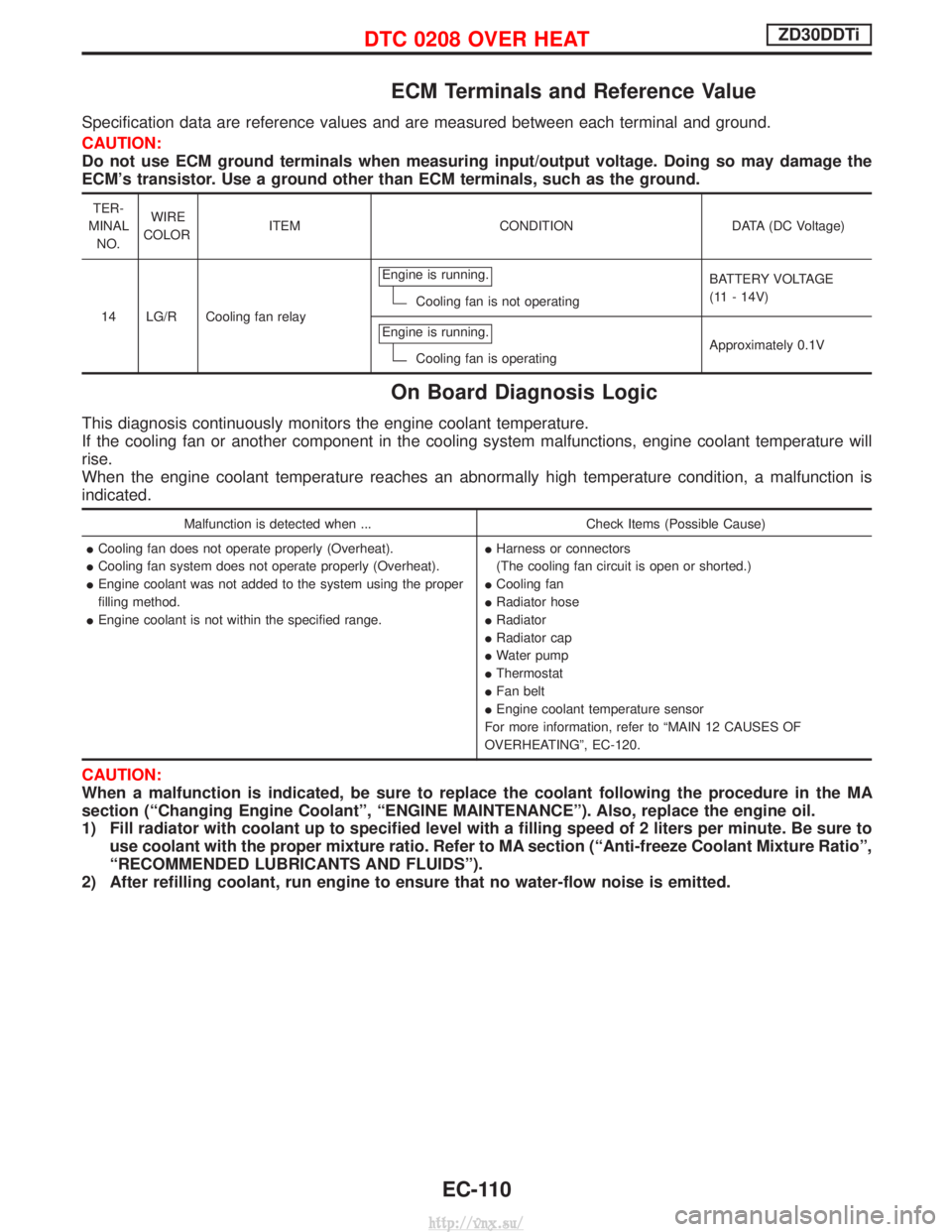

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

14 LG/R Cooling fan relay Engine is running.

Cooling fan is not operating

BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operating Approximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ...

Check Items (Possible Cause)

I Cooling fan does not operate properly (Overheat).

I Cooling fan system does not operate properly (Overheat).

I Engine coolant was not added to the system using the proper

filling method.

I Engine coolant is not within the specified range. I

Harness or connectors

(The cooling fan circuit is open or shorted.)

I Cooling fan

I Radiator hose

I Radiator

I Radiator cap

I Water pump

I Thermostat

I Fan belt

I Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-120.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture Ratioº,

ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATZD30DDTi

EC-110

http://vnx.su/

Page 395 of 1833

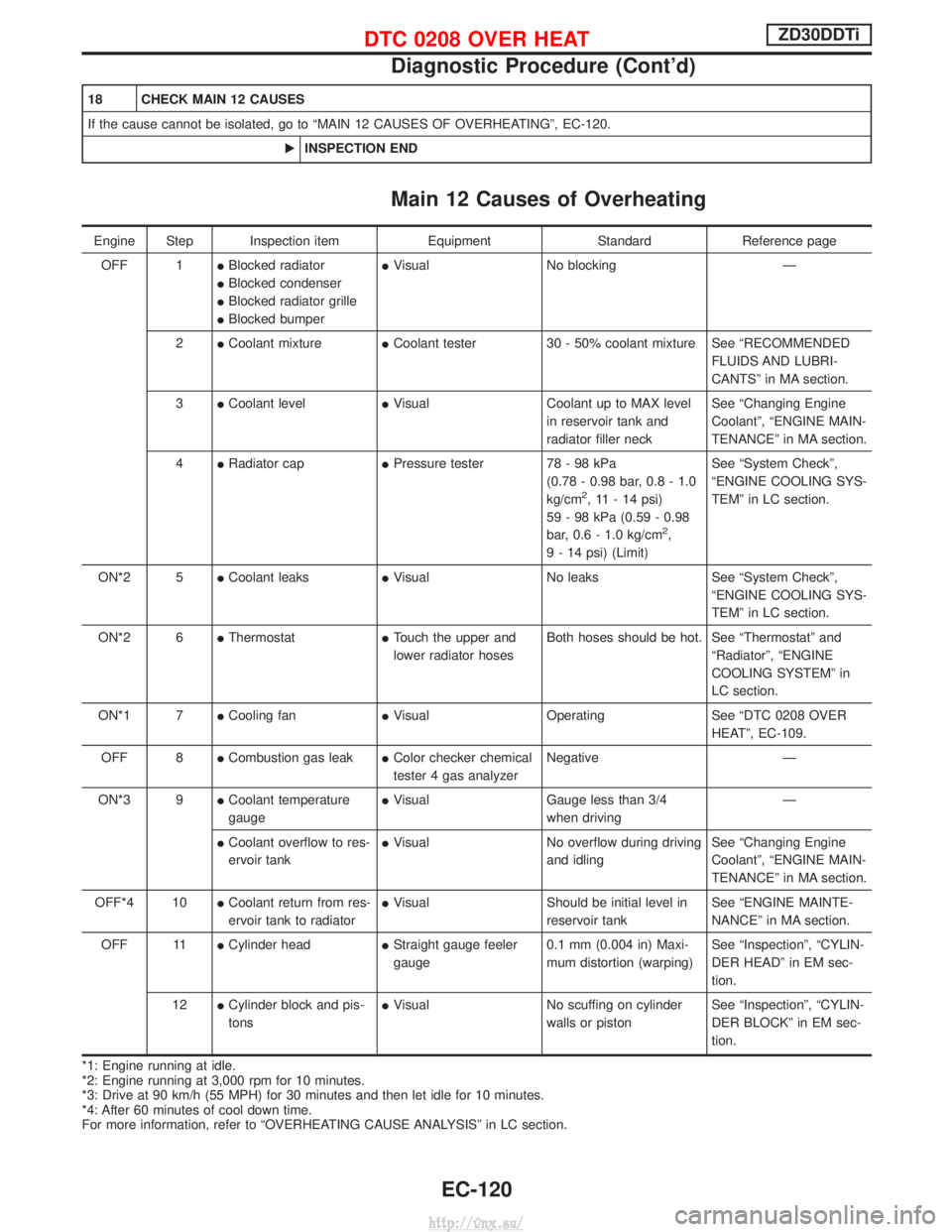

18 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-120.EINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item EquipmentStandardReference page

OFF 1 IBlocked radiator

I Blocked condenser

I Blocked radiator grille

I Blocked bumper I

Visual No blocking Ð

2 ICoolant mixture ICoolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3 ICoolant level IVisual Coolant up to MAX level

in reservoir tank and

radiator filler neck See ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA section.

4 IRadiator cap IPressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit) See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5 ICoolant leaks IVisual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6 IThermostat ITouch the upper and

lower radiator hoses Both hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7 ICooling fan IVisual Operating See ªDTC 0208 OVER

HEATº, EC-109.

OFF 8 ICombustion gas leak IColor checker chemical

tester 4 gas analyzer Negative Ð

ON*3 9 ICoolant temperature

gauge I

Visual Gauge less than 3/4

when driving Ð

I Coolant overflow to res-

ervoir tank I

Visual No overflow during driving

and idling See ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA section.

OFF*4 10 ICoolant return from res-

ervoir tank to radiator I

Visual Should be initial level in

reservoir tank See ªENGINE MAINTE-

NANCEº in MA section.

OFF 11 ICylinder head IStraight gauge feeler

gauge 0.1 mm (0.004 in) Maxi-

mum distortion (warping) See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12 ICylinder block and pis-

tons I

Visual No scuffing on cylinder

walls or piston See ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-120

http://vnx.su/

Page 716 of 1833

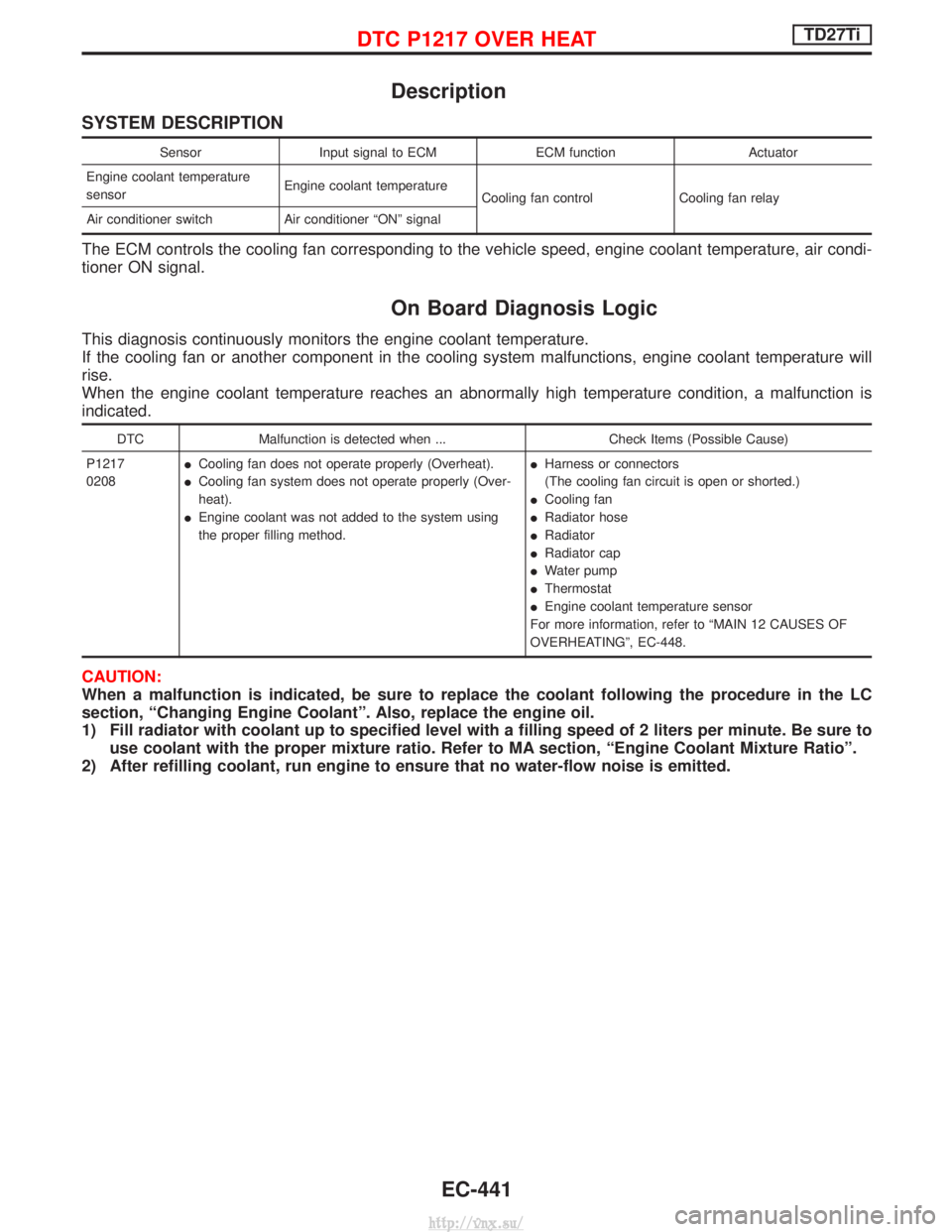

Description

SYSTEM DESCRIPTION

SensorInput signal to ECM ECM functionActuator

Engine coolant temperature

sensor Engine coolant temperature

Cooling fan control Cooling fan relay

Air conditioner switch Air conditioner ªONº signal

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, air condi-

tioner ON signal.

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1217

0208 I

Cooling fan does not operate properly (Overheat).

I Cooling fan system does not operate properly (Over-

heat).

I Engine coolant was not added to the system using

the proper filling method. I

Harness or connectors

(The cooling fan circuit is open or shorted.)

I Cooling fan

I Radiator hose

I Radiator

I Radiator cap

I Water pump

I Thermostat

I Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-448.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the LC

section, ªChanging Engine Coolantº. Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use coolant with the proper mixture ratio. Refer to MA section, ªEngine Coolant Mixture Ratioº.

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVER HEATTD27Ti

EC-441

http://vnx.su/

Page 722 of 1833

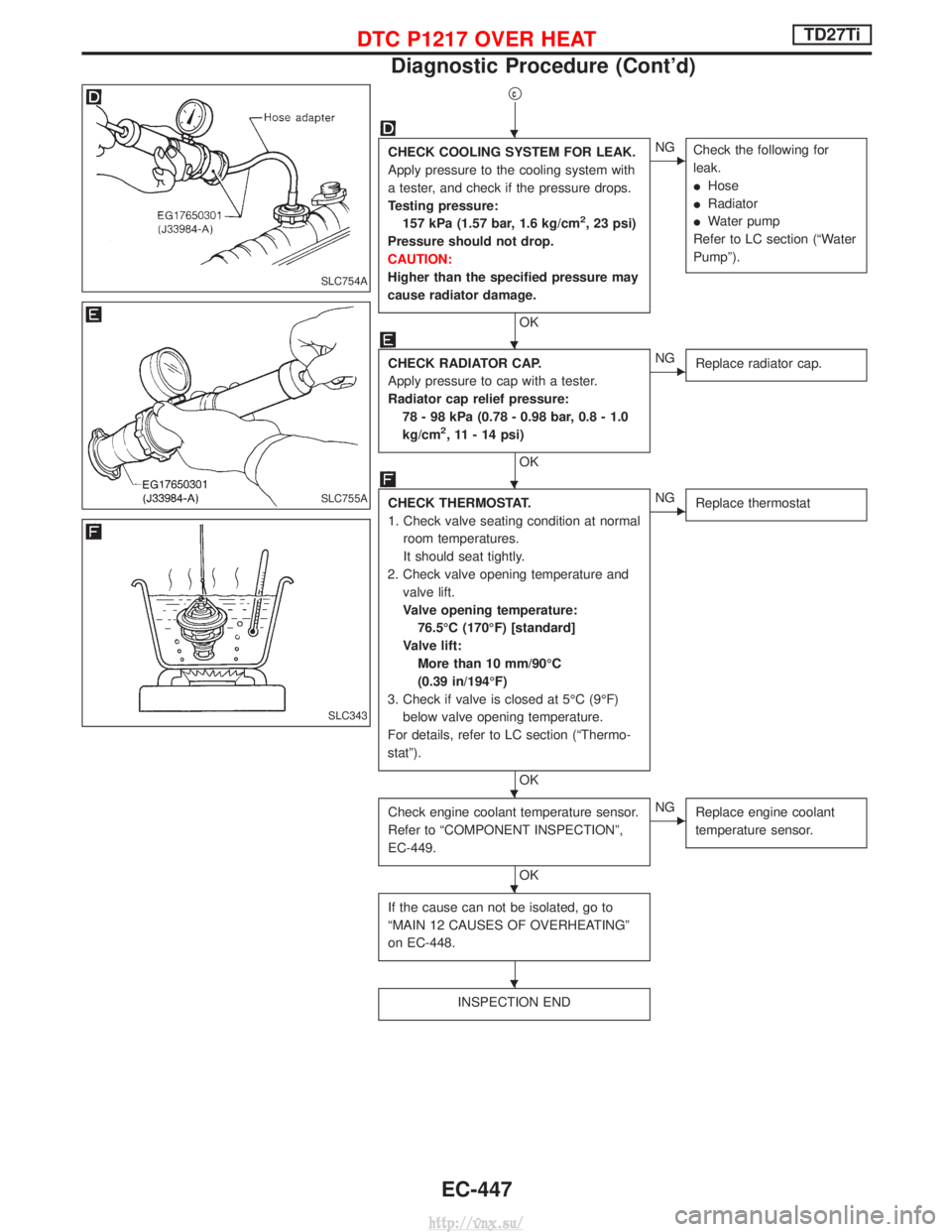

qc

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with

a tester, and check if the pressure drops.

Testing pressure:157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

ENG Check the following for

leak.

IHose

I Radiator

I Water pump

Refer to LC section (ªWater

Pumpº).

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure: 78 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

OK

ENG Replace radiator cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and valve lift.

Valve opening temperature:76.5ÉC (170ÉF) [standard]

Valve lift: More than 10 mm/90ÉC

(0.39 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature.

For details, refer to LC section (ªThermo-

statº).

OK

ENG Replace thermostat

Check engine coolant temperature sensor.

Refer to ªCOMPONENT INSPECTIONº,

EC-449.

OK

ENGReplace engine coolant

temperature sensor.

If the cause can not be isolated, go to

ªMAIN 12 CAUSES OF OVERHEATINGº

on EC-448.

INSPECTION END

SLC754A

SLC755A

SLC343

H

H

H

H

H

H

DTC P1217 OVER HEATTD27Ti

Diagnostic Procedure (Cont'd)

EC-447

http://vnx.su/

Page 723 of 1833

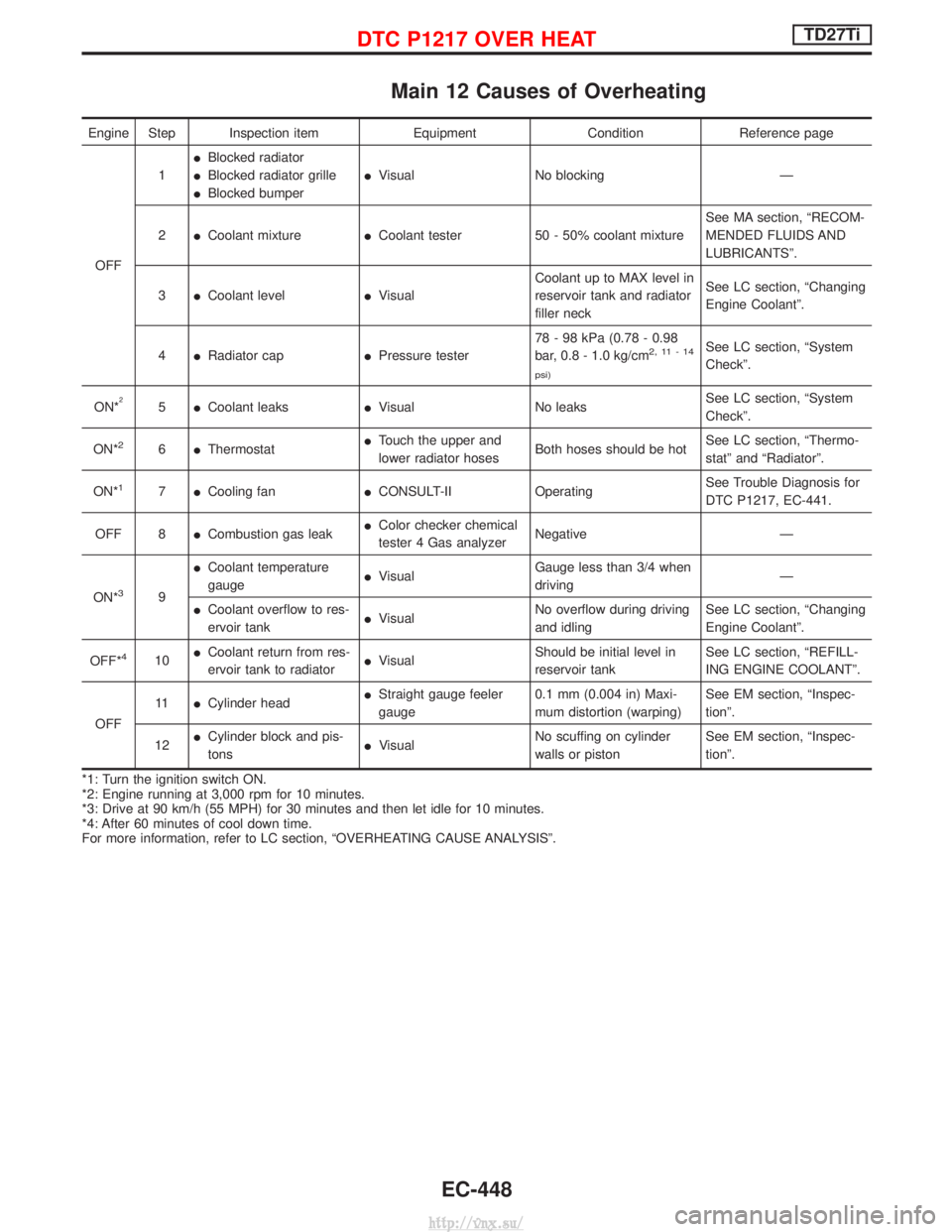

Main 12 Causes of Overheating

Engine Step Inspection itemEquipmentConditionReference page

OFF 1

I

Blocked radiator

I Blocked radiator grille

I Blocked bumper I

Visual No blocking Ð

2 ICoolant mixture ICoolant tester 50 - 50% coolant mixture See MA section, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3 ICoolant level IVisual Coolant up to MAX level in

reservoir tank and radiator

filler neck See LC section, ªChanging

Engine Coolantº.

4 IRadiator cap IPressure tester 78 - 98 kPa (0.78 - 0.98

bar, 0.8 - 1.0 kg/cm

2,11-14

psi)See LC section, ªSystem

Checkº.

ON*

25 ICoolant leaks IVisual No leaks See LC section, ªSystem

Checkº.

ON*

26 IThermostat I

Touch the upper and

lower radiator hoses Both hoses should be hot See LC section, ªThermo-

statº and ªRadiatorº.

ON*

17 ICooling fan ICONSULT-II Operating See Trouble Diagnosis for

DTC P1217, EC-441.

OFF 8 ICombustion gas leak I

Color checker chemical

tester 4 Gas analyzer Negative Ð

ON*

39 I

Coolant temperature

gauge I

Visual Gauge less than 3/4 when

driving Ð

I Coolant overflow to res-

ervoir tank I

Visual No overflow during driving

and idling See LC section, ªChanging

Engine Coolantº.

OFF*

410 I

Coolant return from res-

ervoir tank to radiator I

Visual Should be initial level in

reservoir tank See LC section, ªREFILL-

ING ENGINE COOLANTº.

OFF 11

ICylinder head I

Straight gauge feeler

gauge 0.1 mm (0.004 in) Maxi-

mum distortion (warping) See EM section, ªInspec-

tionº.

12 I

Cylinder block and pis-

tons I

Visual No scuffing on cylinder

walls or piston See EM section, ªInspec-

tionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC section, ªOVERHEATING CAUSE ANALYSISº.

DTC P1217 OVER HEATTD27Ti

EC-448

http://vnx.su/