engine overheat NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 73 of 1833

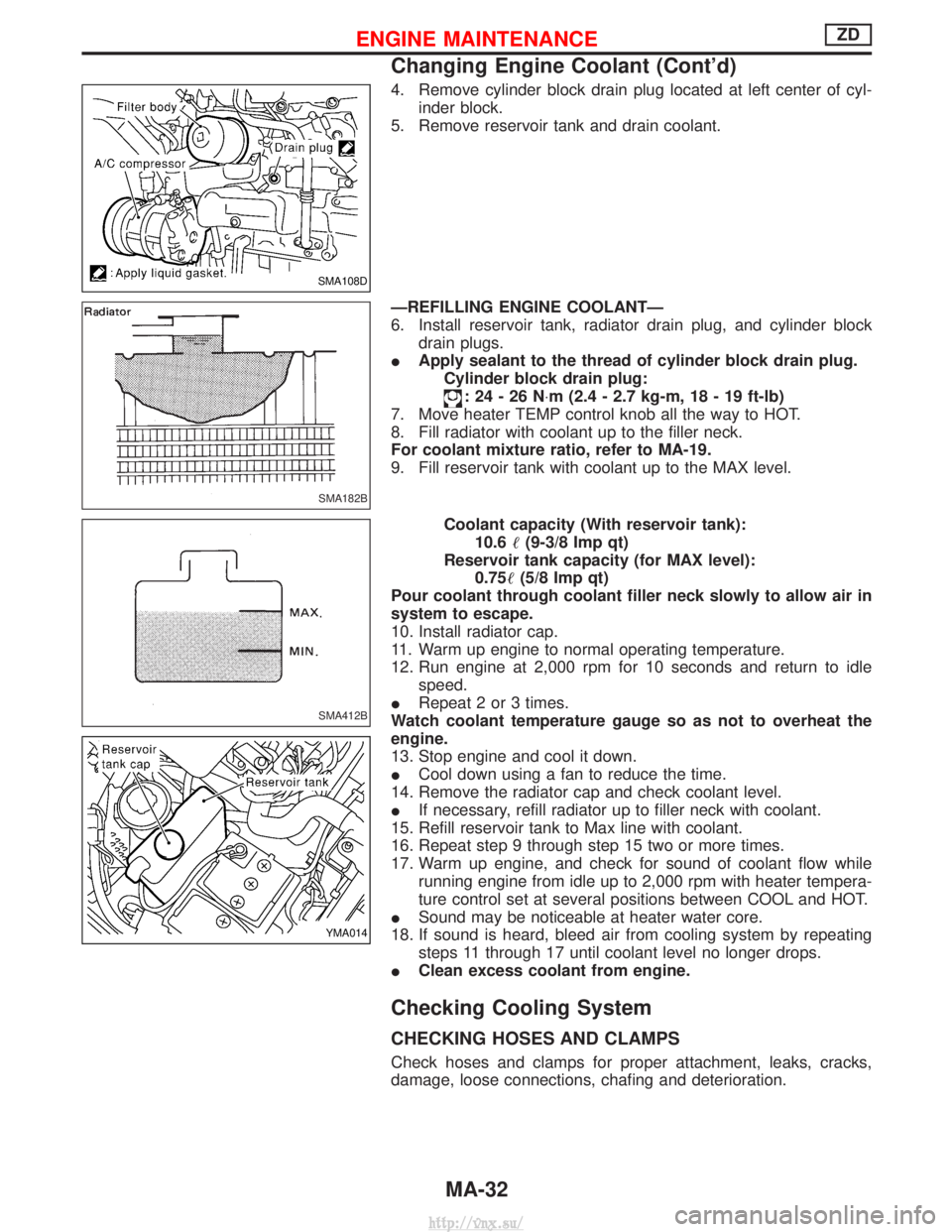

4. Remove cylinder block drain plug located at left center of cyl-inder block.

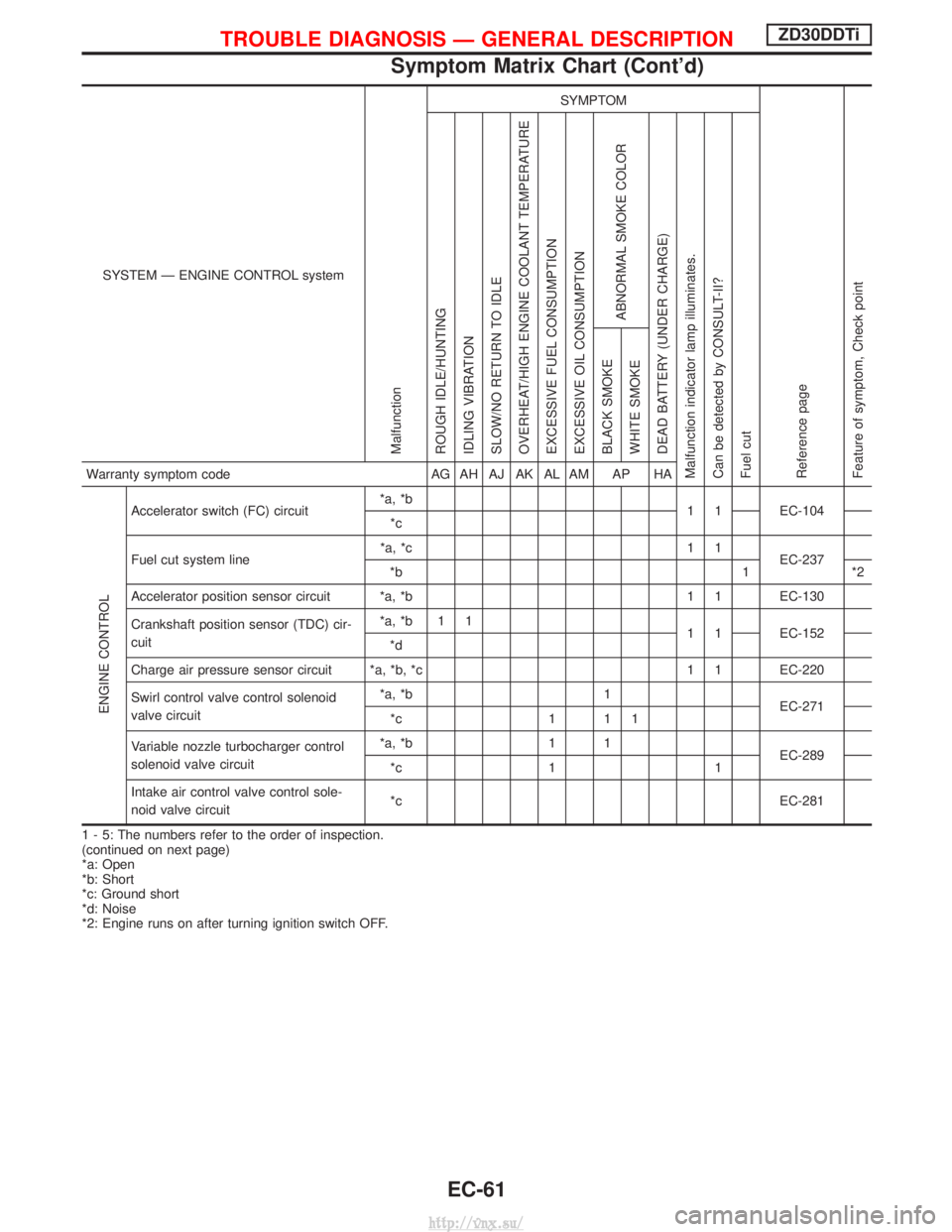

5. Remove reservoir tank and drain coolant.

ÐREFILLING ENGINE COOLANTÐ

6. Install reservoir tank, radiator drain plug, and cylinder block drain plugs.

I Apply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:24-26N ×m (2.4 - 2.7 kg-m, 18 - 19 ft-lb)

7. Move heater TEMP control knob all the way to HOT.

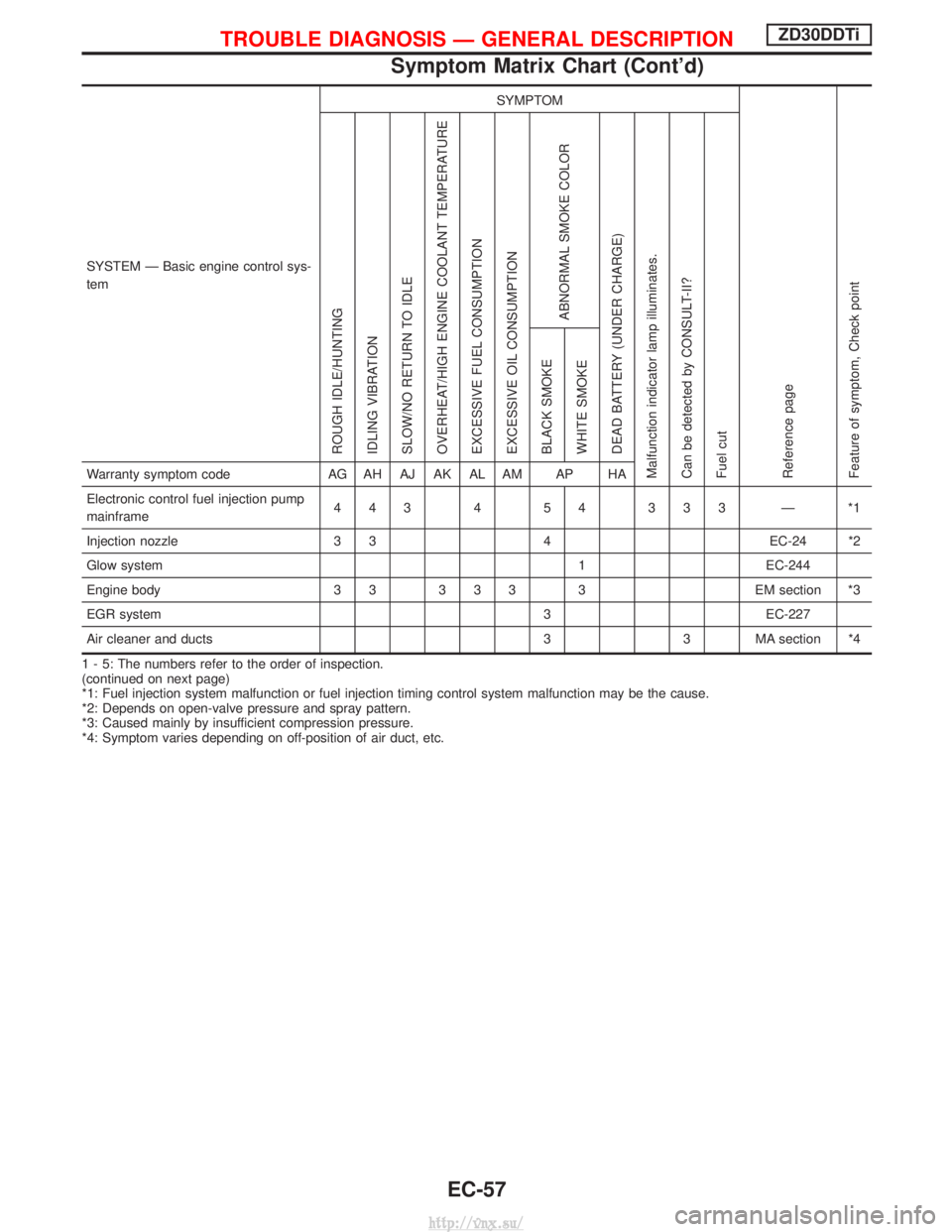

8. Fill radiator with coolant up to the filler neck.

For coolant mixture ratio, refer to MA-19.

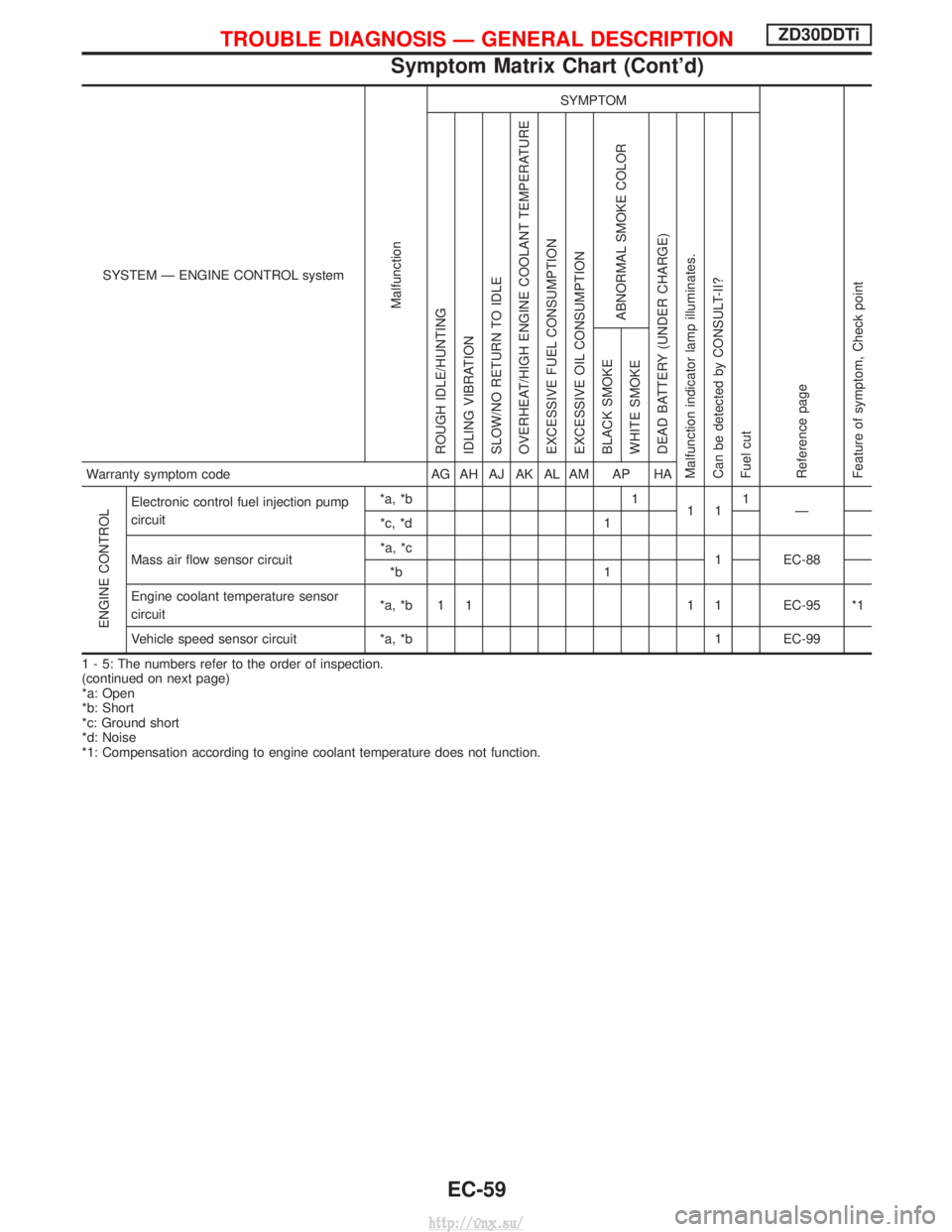

9. Fill reservoir tank with coolant up to the MAX level.

Coolant capacity (With reservoir tank):10.6 (9-3/8 Imp qt)

Reservoir tank capacity (for MAX level): 0.75 (5/8 Imp qt)

Pour coolant through coolant filler neck slowly to allow air in

system to escape.

10. Install radiator cap.

11. Warm up engine to normal operating temperature.

12. Run engine at 2,000 rpm for 10 seconds and return to idle speed.

I Repeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

13. Stop engine and cool it down.

I Cool down using a fan to reduce the time.

14. Remove the radiator cap and check coolant level.

I If necessary, refill radiator up to filler neck with coolant.

15. Refill reservoir tank to Max line with coolant.

16. Repeat step 9 through step 15 two or more times.

17. Warm up engine, and check for sound of coolant flow while running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

I Sound may be noticeable at heater water core.

18. If sound is heard, bleed air from cooling system by repeating steps 11 through 17 until coolant level no longer drops.

I Clean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

SMA108D

SMA182B

SMA412B

YMA014

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-32

http://vnx.su/

Page 332 of 1833

SYSTEM Ð Basic engine control sys-

temSYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut BLACK SMOKE

WHITE SMOKEWarranty symptom code

AG AH AJ AK AL AM AP HA

Electronic control fuel injection pump

mainframe 443 4 54 333 Ð *1

Injection nozzle 3 34 EC-24 *2

Glow system 1 EC-244

Engine body 3 3 3 3 3 3 EM section *3

EGR system 3 EC-227

Air cleaner and ducts 3 3 MA section *4

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*1: Fuel injection system malfunction or fuel injection timing control system malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-57

http://vnx.su/

Page 334 of 1833

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut BLACK SMOKE

WHITE SMOKEWarranty symptom code

AG AH AJ AK AL AM AP HA

ENGINE CONTROL

Electronic control fuel injection pump

circuit*a, *b 1

111

Ð

*c, *d 1

Mass air flow sensor circuit *a, *c

1 EC-88

*b 1

Engine coolant temperature sensor

circuit *a, *b 1 1 1 1 EC-95 *1

Vehicle speed sensor circuit *a, *b 1 EC-99

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*1: Compensation according to engine coolant temperature does not function.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-59

http://vnx.su/

Page 336 of 1833

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut BLACK SMOKE

WHITE SMOKEWarranty symptom code

AG AH AJ AK AL AM AP HA

ENGINE CONTROL

Accelerator switch (FC) circuit*a, *b

1 1 EC-104

*c

Fuel cut system line *a, *c 1 1

EC-237

*b 1 *2

Accelerator position sensor circuit *a, *b 1 1 EC-130

Crankshaft position sensor (TDC) cir-

cuit *a, *b 1 1

1 1 EC-152

*d

Charge air pressure sensor circuit *a, *b, *c 1 1 EC-220

Swirl control valve control solenoid

valve circuit *a, *b 1

EC-271

*c 1 1 1

Variable nozzle turbocharger control

solenoid valve circuit *a, *b 1 1

EC-289

*c 1 1

Intake air control valve control sole-

noid valve circuit *c EC-281

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*2: Engine runs on after turning ignition switch OFF.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-61

http://vnx.su/

Page 338 of 1833

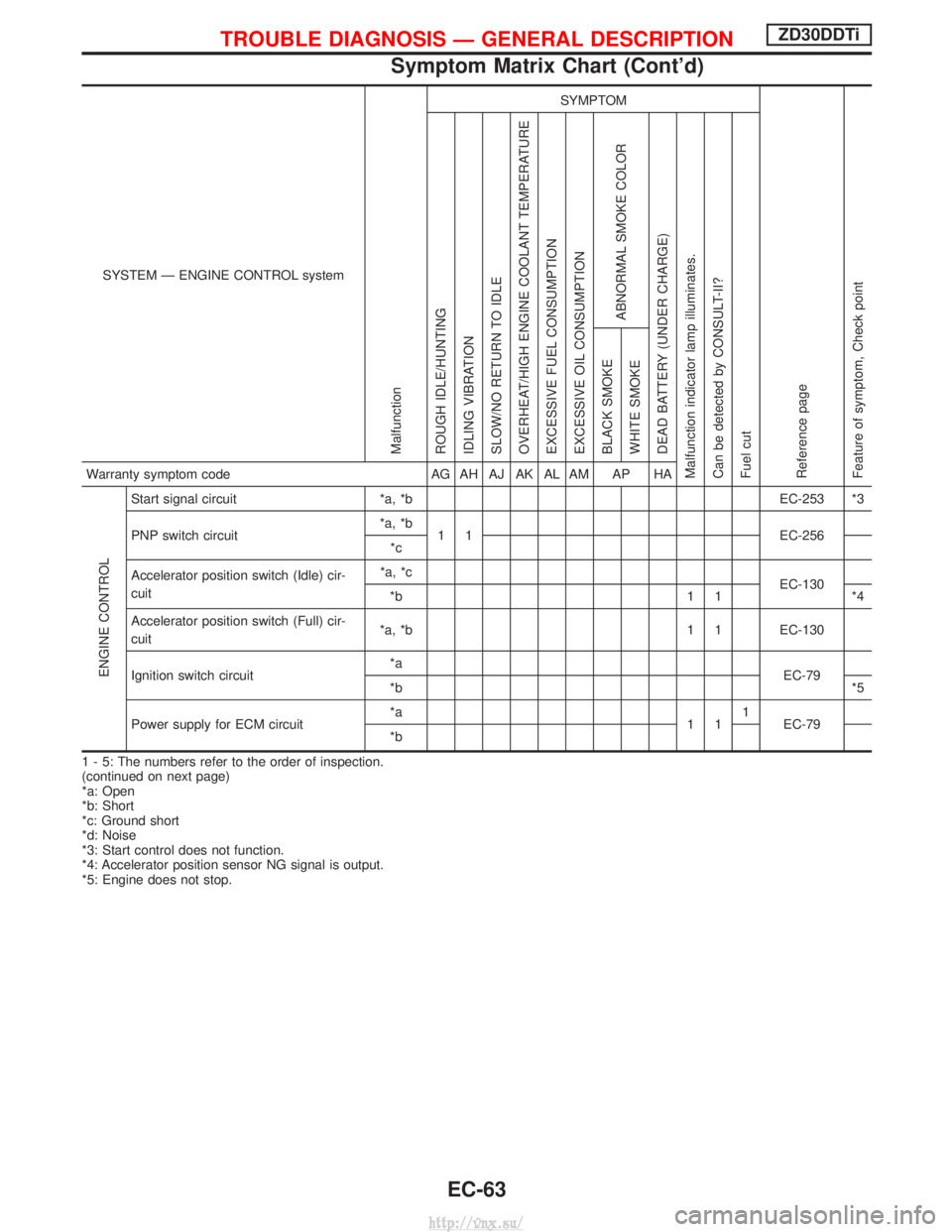

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut BLACK SMOKE

WHITE SMOKEWarranty symptom code

AG AH AJ AK AL AM AP HA

ENGINE CONTROL

Start signal circuit*a, *b EC-253 *3

PNP switch circuit *a, *b

1 1 EC-256

*c

Accelerator position switch (Idle) cir-

cuit *a, *c

EC-130

*b 1 1 *4

Accelerator position switch (Full) cir-

cuit *a, *b 1 1 EC-130

Ignition switch circuit *a

EC-79

*b *5

Power supply for ECM circuit *a

111

EC-79

*b

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*3: Start control does not function.

*4: Accelerator position sensor NG signal is output.

*5: Engine does not stop.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-63

http://vnx.su/

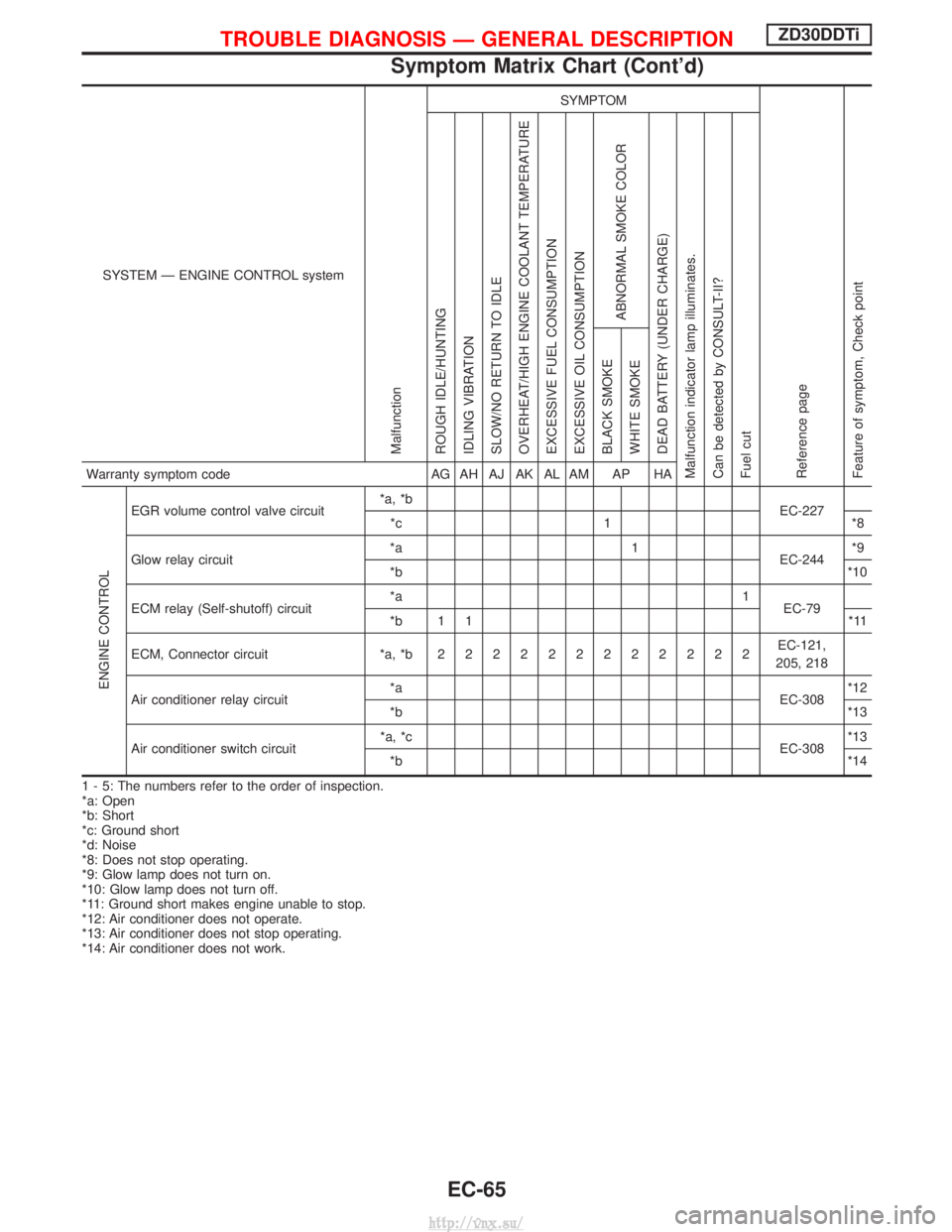

Page 340 of 1833

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut BLACK SMOKE

WHITE SMOKEWarranty symptom code

AG AH AJ AK AL AM AP HA

ENGINE CONTROL

EGR volume control valve circuit*a, *b

EC-227

*c 1 *8

Glow relay circuit *a 1

EC-244*9

*b *10

ECM relay (Self-shutoff) circuit *a 1

EC-79

*b 1 1 *11

ECM, Connector circuit *a, *b 222222222222 EC-121,

205, 218

Air conditioner relay circuit *a

EC-308*12

*b *13

Air conditioner switch circuit *a, *c

EC-308*13

*b *14

1 - 5: The numbers refer to the order of inspection.

*a: Open

*b: Short

*c: Ground short

*d: Noise

*8: Does not stop operating.

*9: Glow lamp does not turn on.

*10: Glow lamp does not turn off.

*11: Ground short makes engine unable to stop.

*12: Air conditioner does not operate.

*13: Air conditioner does not stop operating.

*14: Air conditioner does not work.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

Symptom Matrix Chart (Cont'd)

EC-65

http://vnx.su/

Page 385 of 1833

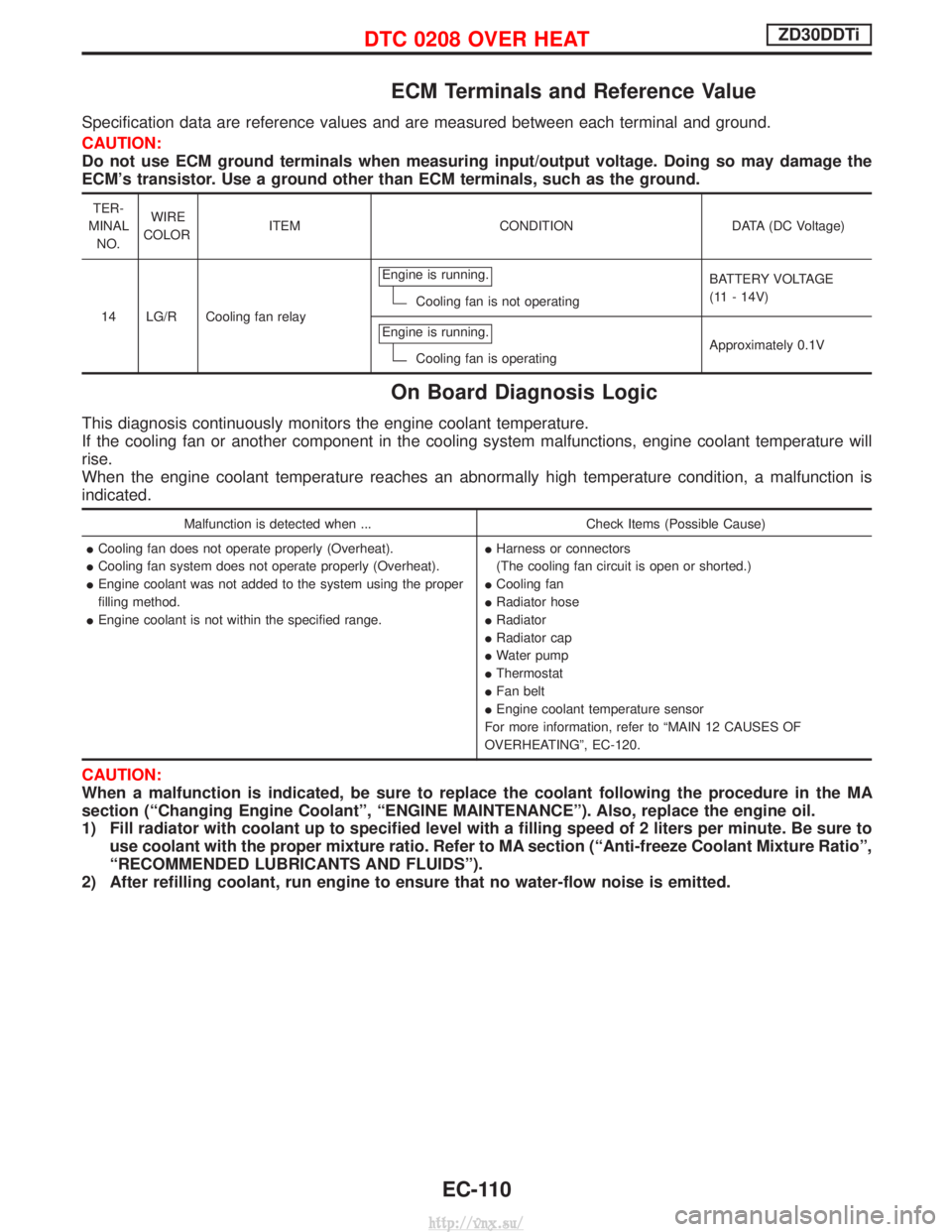

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

14 LG/R Cooling fan relay Engine is running.

Cooling fan is not operating

BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operating Approximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ...

Check Items (Possible Cause)

I Cooling fan does not operate properly (Overheat).

I Cooling fan system does not operate properly (Overheat).

I Engine coolant was not added to the system using the proper

filling method.

I Engine coolant is not within the specified range. I

Harness or connectors

(The cooling fan circuit is open or shorted.)

I Cooling fan

I Radiator hose

I Radiator

I Radiator cap

I Water pump

I Thermostat

I Fan belt

I Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-120.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture Ratioº,

ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATZD30DDTi

EC-110

http://vnx.su/

Page 386 of 1833

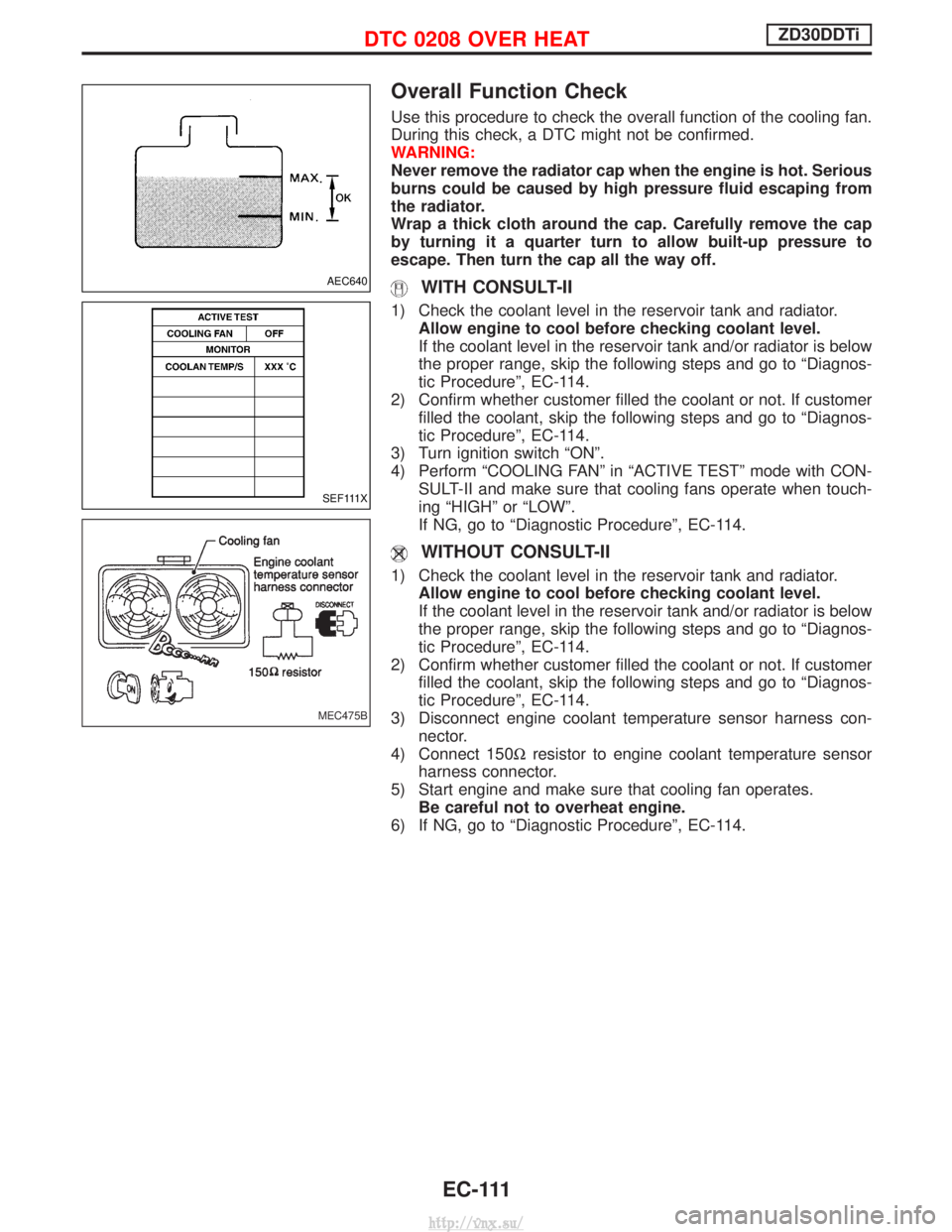

Overall Function Check

Use this procedure to check the overall function of the cooling fan.

During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

WITH CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

2) Confirm whether customer filled the coolant or not. If customer filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

3) Turn ignition switch ªONº.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode with CON- SULT-II and make sure that cooling fans operate when touch-

ing ªHIGHº or ªLOWº.

If NG, go to ªDiagnostic Procedureº, EC-114.

WITHOUT CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

2) Confirm whether customer filled the coolant or not. If customer filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-114.

3) Disconnect engine coolant temperature sensor harness con- nector.

4) Connect 150W resistor to engine coolant temperature sensor

harness connector.

5) Start engine and make sure that cooling fan operates. Be careful not to overheat engine.

6) If NG, go to ªDiagnostic Procedureº, EC-114.

AEC640

SEF111X

MEC475B

DTC 0208 OVER HEATZD30DDTi

EC-111

http://vnx.su/

Page 395 of 1833

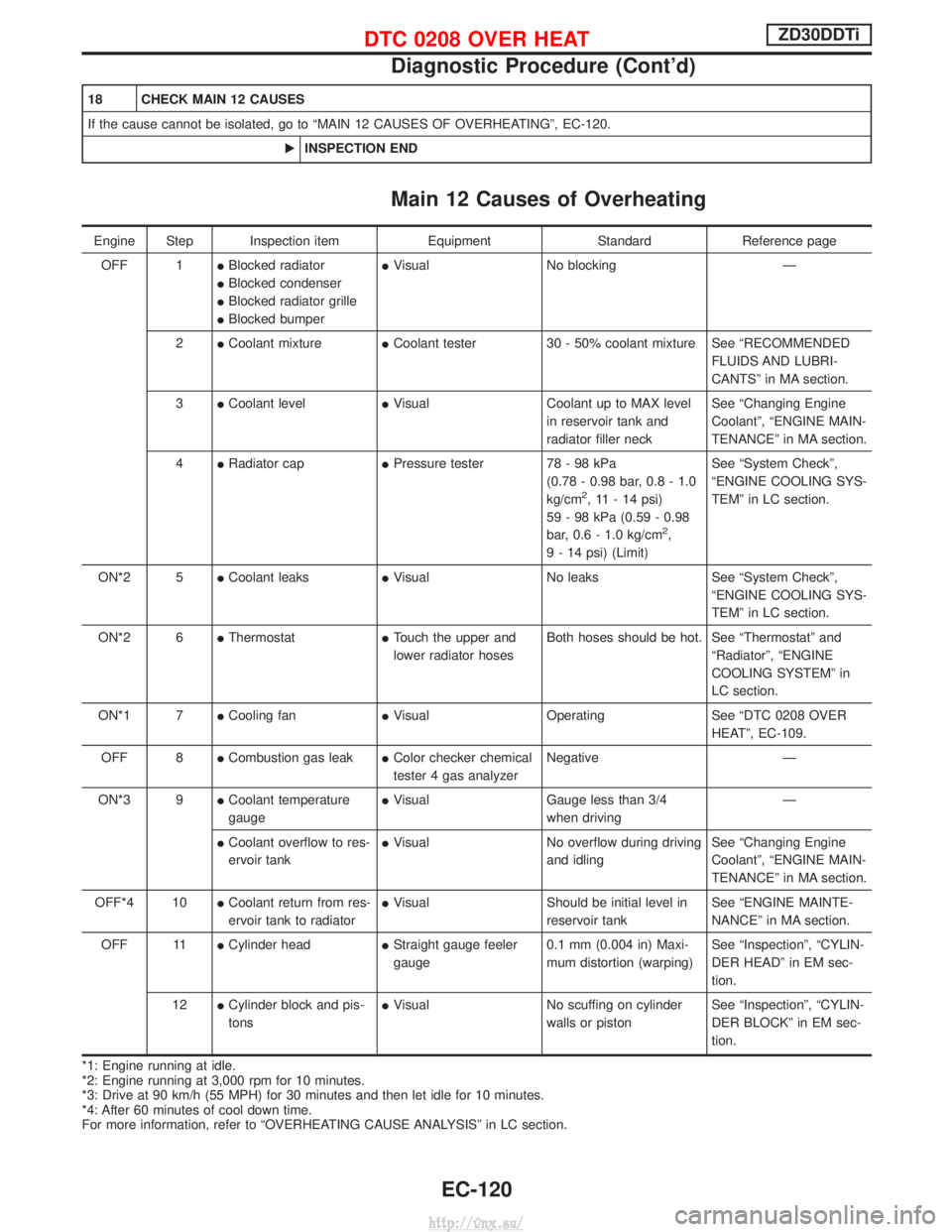

18 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-120.EINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item EquipmentStandardReference page

OFF 1 IBlocked radiator

I Blocked condenser

I Blocked radiator grille

I Blocked bumper I

Visual No blocking Ð

2 ICoolant mixture ICoolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3 ICoolant level IVisual Coolant up to MAX level

in reservoir tank and

radiator filler neck See ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA section.

4 IRadiator cap IPressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit) See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5 ICoolant leaks IVisual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6 IThermostat ITouch the upper and

lower radiator hoses Both hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7 ICooling fan IVisual Operating See ªDTC 0208 OVER

HEATº, EC-109.

OFF 8 ICombustion gas leak IColor checker chemical

tester 4 gas analyzer Negative Ð

ON*3 9 ICoolant temperature

gauge I

Visual Gauge less than 3/4

when driving Ð

I Coolant overflow to res-

ervoir tank I

Visual No overflow during driving

and idling See ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA section.

OFF*4 10 ICoolant return from res-

ervoir tank to radiator I

Visual Should be initial level in

reservoir tank See ªENGINE MAINTE-

NANCEº in MA section.

OFF 11 ICylinder head IStraight gauge feeler

gauge 0.1 mm (0.004 in) Maxi-

mum distortion (warping) See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12 ICylinder block and pis-

tons I

Visual No scuffing on cylinder

walls or piston See ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-120

http://vnx.su/

Page 638 of 1833

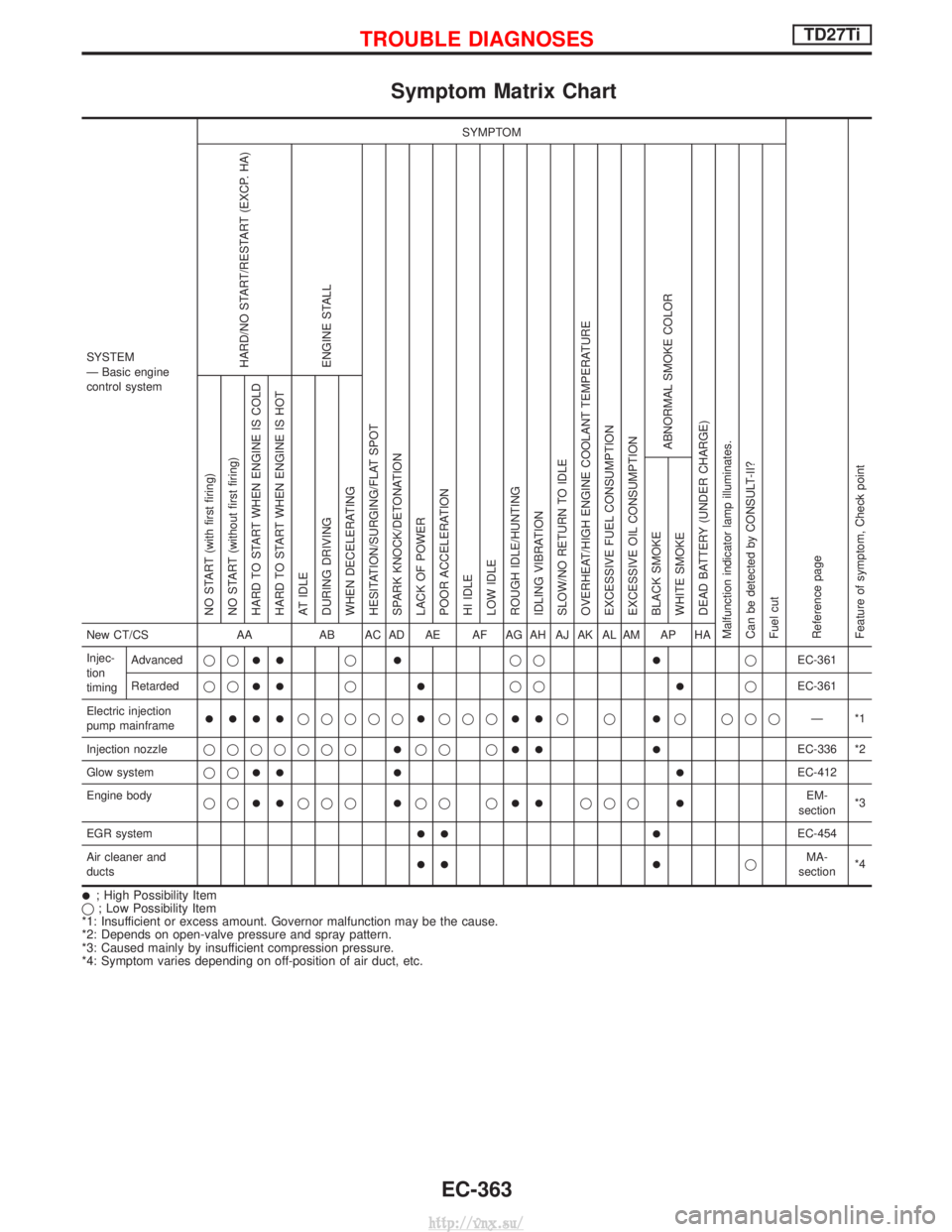

Symptom Matrix Chart

SYSTEM

Ð Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATING

BLACK SMOKE

WHITE SMOKENew CT/CS

AAAB AC AD AE AF AG AH AJ AK AL AM AP HA

Injec-

tion

timing Advanced

qq

IIqIqqIqEC-361

Retarded qq

IIqIqqIqEC-361

Electric injection

pump mainframe

IIIIqqqqqIqqqIIqqIq qqq Ð*1

Injection nozzle qqqqqqq

Iqq qIIIEC-336 *2

Glow system qq

III IEC-412

Engine body qq

IIqqqIqq qIIqqqIEM-

section *3

EGR system

II IEC-454

Air cleaner and

ducts

II IqMA-

section *4

I; High Possibility Item

q ; Low Possibility Item

*1: Insufficient or excess amount. Governor malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSESTD27Ti

EC-363

http://vnx.su/