towing NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 4 of 1833

GENERAL INFORMATIONSECTION

GI

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL ........................................8

HOW TO READ WIRING DIAGRAMS ..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL .......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT ........................................22 Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES ..................................................................25

CONSULT-II CHECKING SYSTEM ...............................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............26

Checking Equipment..................................................26

IDENTIFICATION INFORMATION .................................27

Model Variation ..........................................................27

Identification Number .................................................28

Dimensions ................................................................30

Wheels and Tires .......................................................30

LIFTING POINTS AND TOW TRUCK TOWING ...........31

Garage Jack and Safety Stand .................................31

Screw Jack ................................................................31

4-pole Lift ...................................................................32

Tow Truck Towing ......................................................32

ISO 15031-2 TERMINOLOGY LIST ..............................34

ISO 15031-2 Terminology List ...................................34

TIGHTENING TORQUE OF STANDARD BOLTS ........37

http://vnx.su/

Page 5 of 1833

Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

1. Do not operate the engine for an extended period of time with-out proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

2. Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting and towing

before working on the vehicle.

These operations should be done on a level surface.

3. When removing a heavy component such as the engine or transaxle/transmission, take care not to lose your balance and

drop it. Also, do not allow it to strike adjacent parts, especially

the brake tubes and master cylinder.

4. Before starting repairs which do not require battery power, always turn off the ignition switch, then disconnect the ground

cable from the battery to prevent accidental short circuit.

5. To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust manifold, tail pipe and muffler. Do

not remove the radiator cap when the engine is hot.

SGI285

SGI231

SGI232

SGI233

PRECAUTIONS

GI-2

http://vnx.su/

Page 34 of 1833

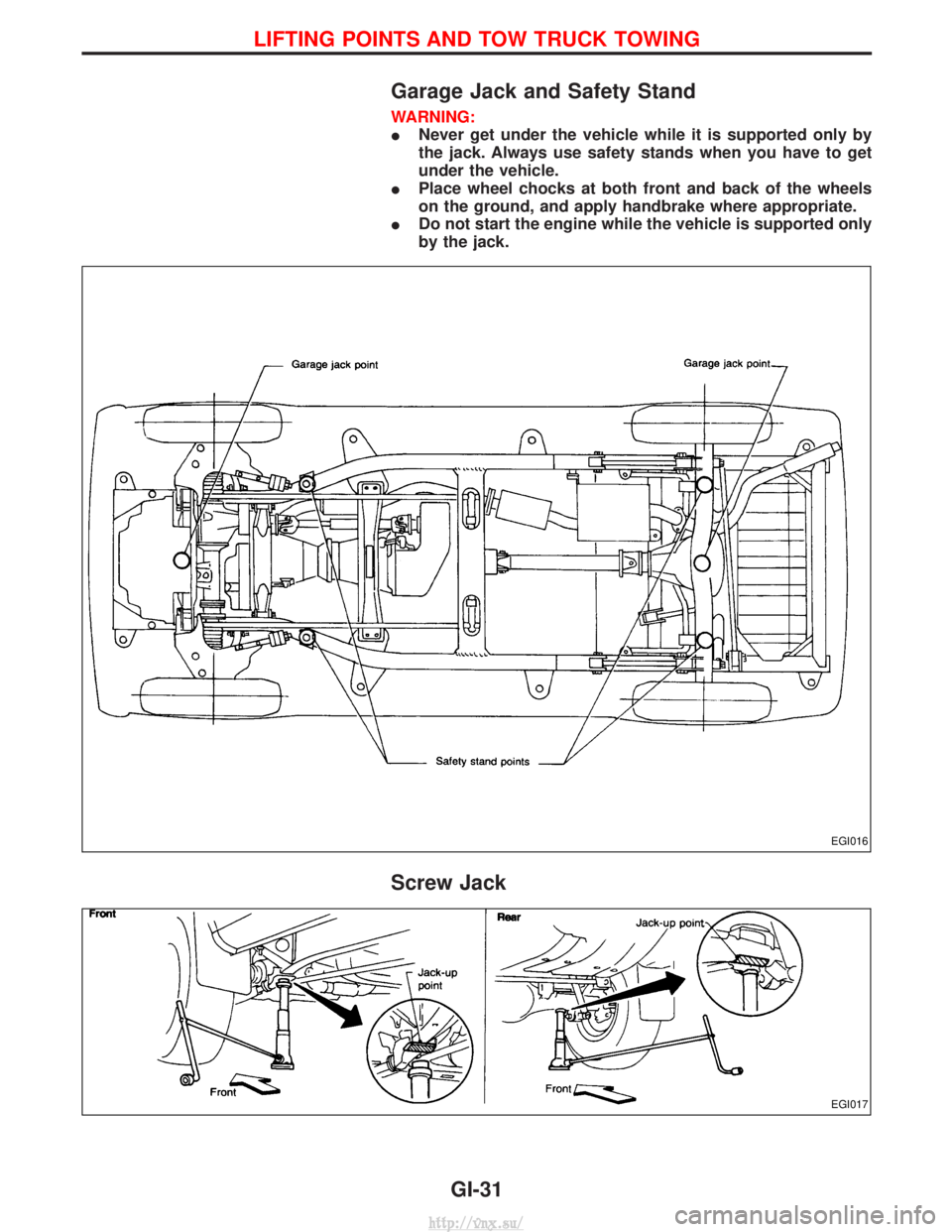

Garage Jack and Safety Stand

WARNING:

INever get under the vehicle while it is supported only by

the jack. Always use safety stands when you have to get

under the vehicle.

I Place wheel chocks at both front and back of the wheels

on the ground, and apply handbrake where appropriate.

I Do not start the engine while the vehicle is supported only

by the jack.

Screw Jack

EGI016

EGI017

LIFTING POINTS AND TOW TRUCK TOWING

GI-31

http://vnx.su/

Page 35 of 1833

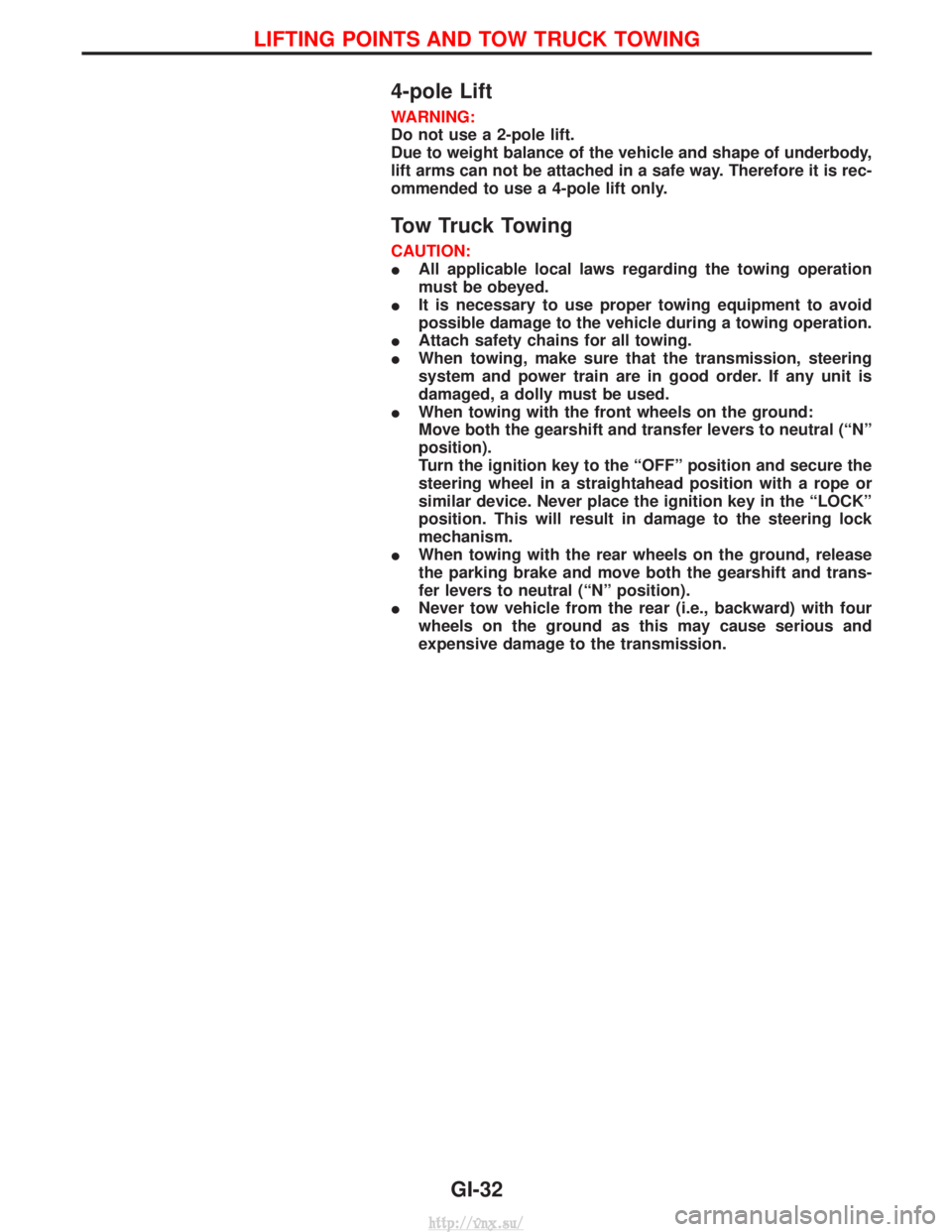

4-pole Lift

WARNING:

Do not use a 2-pole lift.

Due to weight balance of the vehicle and shape of underbody,

lift arms can not be attached in a safe way. Therefore it is rec-

ommended to use a 4-pole lift only.

Tow Truck Towing

CAUTION:

IAll applicable local laws regarding the towing operation

must be obeyed.

I It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during a towing operation.

I Attach safety chains for all towing.

I When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, a dolly must be used.

I When towing with the front wheels on the ground:

Move both the gearshift and transfer levers to neutral (ªNº

position).

Turn the ignition key to the ªOFFº position and secure the

steering wheel in a straightahead position with a rope or

similar device. Never place the ignition key in the ªLOCKº

position. This will result in damage to the steering lock

mechanism.

I When towing with the rear wheels on the ground, release

the parking brake and move both the gearshift and trans-

fer levers to neutral (ªNº position).

I Never tow vehicle from the rear (i.e., backward) with four

wheels on the ground as this may cause serious and

expensive damage to the transmission.

LIFTING POINTS AND TOW TRUCK TOWING

GI-32

http://vnx.su/

Page 36 of 1833

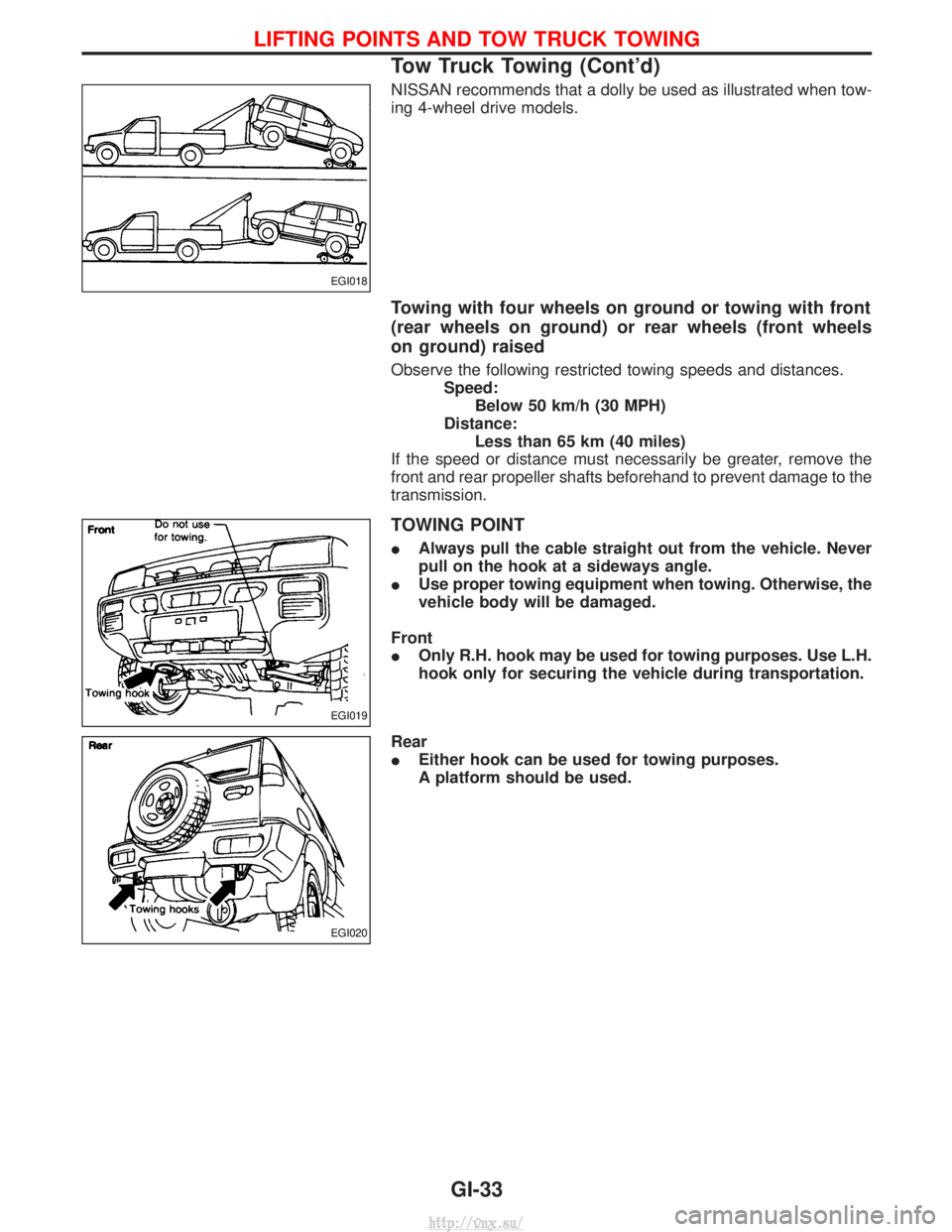

NISSAN recommends that a dolly be used as illustrated when tow-

ing 4-wheel drive models.

Towing with four wheels on ground or towing with front

(rear wheels on ground) or rear wheels (front wheels

on ground) raised

Observe the following restricted towing speeds and distances.Speed:Below 50 km/h (30 MPH)

Distance: Less than 65 km (40 miles)

If the speed or distance must necessarily be greater, remove the

front and rear propeller shafts beforehand to prevent damage to the

transmission.

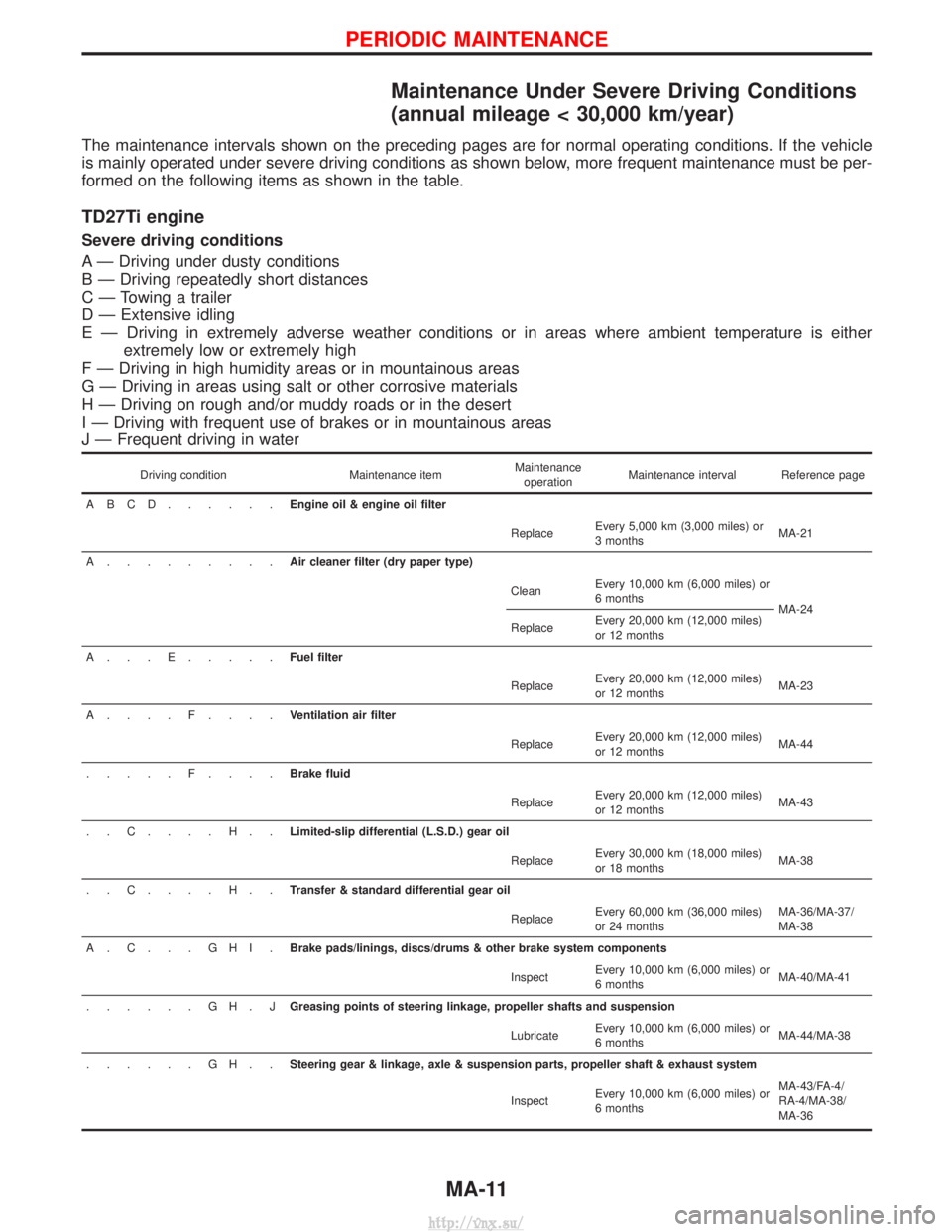

TOWING POINT

I Always pull the cable straight out from the vehicle. Never

pull on the hook at a sideways angle.

I Use proper towing equipment when towing. Otherwise, the

vehicle body will be damaged.

Front

I Only R.H. hook may be used for towing purposes. Use L.H.

hook only for securing the vehicle during transportation.

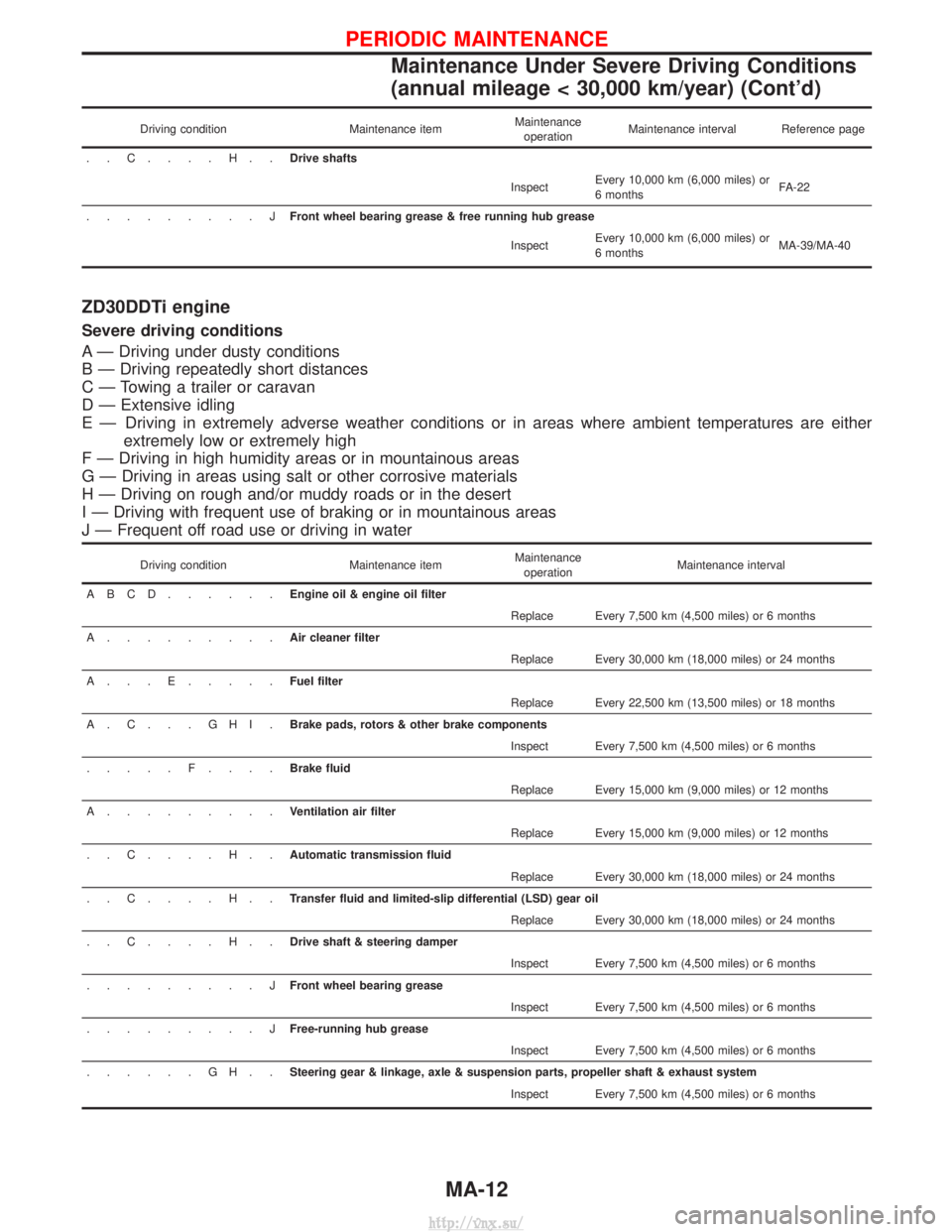

Rear

I Either hook can be used for towing purposes.

A platform should be used.

EGI018

EGI019

EGI020

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing (Cont'd)

GI-33

http://vnx.su/

Page 52 of 1833

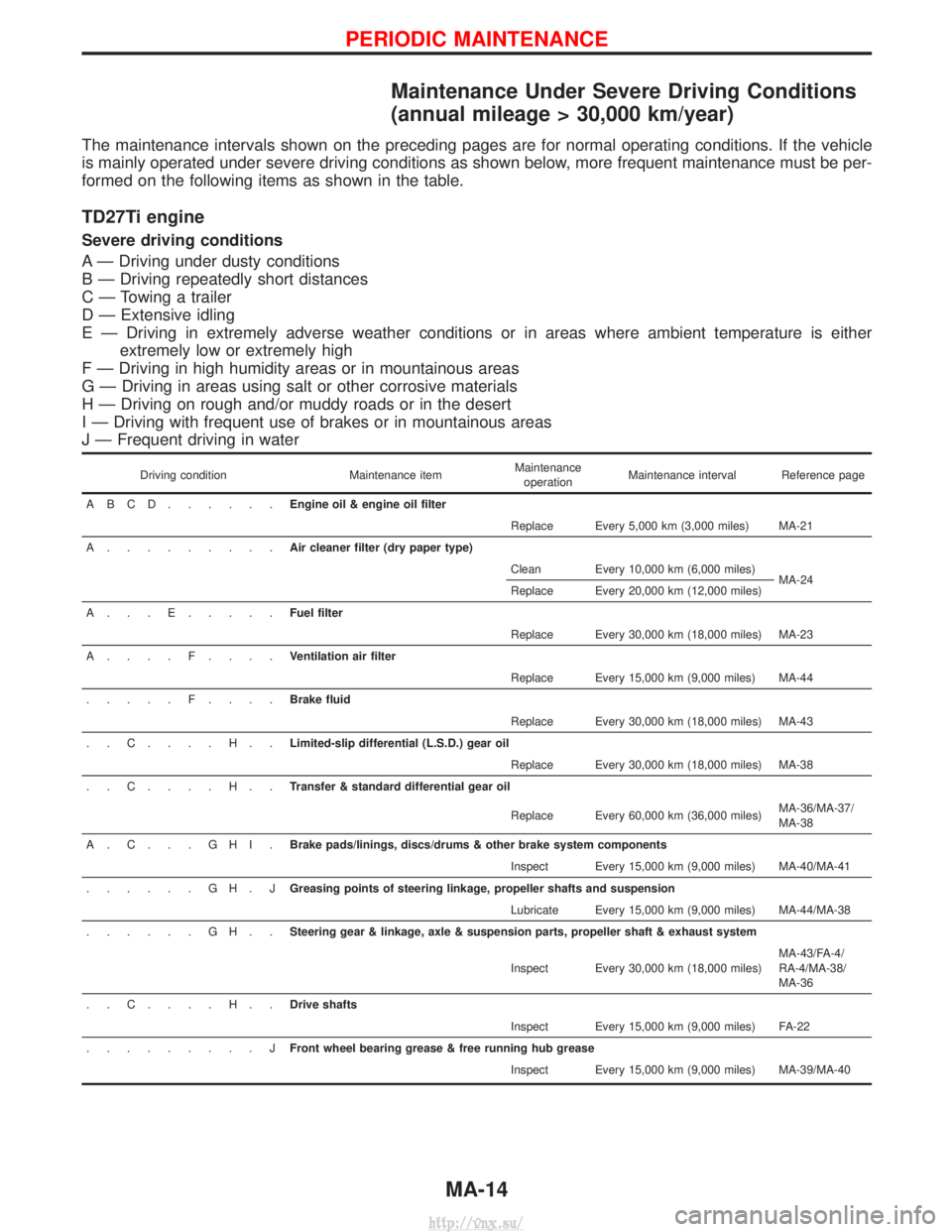

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

TD27Ti engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperature is eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of brakes or in mountainous areas

J Ð Frequent driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval Reference page

ABCD......Engine oil & engine oil filter ReplaceEvery 5,000 km (3,000 miles) or

3 months MA-21

A.........Air cleaner filter (dry paper type) CleanEvery 10,000 km (6,000 miles) or

6 months

MA-24

Replace Every 20,000 km (12,000 miles)

or 12 months

A...E.....Fuel filter

ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-23

A....F....Ventilation air filter ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-44

.....F....Brake fluid ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-43

..C....H..Limited-slip differential (L.S.D.) gear oil ReplaceEvery 30,000 km (18,000 miles)

or 18 months MA-38

..C....H..Transfer & standard differential gear oil ReplaceEvery 60,000 km (36,000 miles)

or 24 months MA-36/MA-37/

MA-38

A.C...GHI.Brake pads/linings, discs/drums & other brake system components

InspectEvery 10,000 km (6,000 miles) or

6 months MA-40/MA-41

......GH.J Greasing points of steering linkage, propeller shafts and suspension

LubricateEvery 10,000 km (6,000 miles) or

6 months MA-44/MA-38

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

InspectEvery 10,000 km (6,000 miles) or

6 months MA-43/FA-4/

RA-4/MA-38/

MA-36

PERIODIC MAINTENANCE

MA-11

http://vnx.su/

Page 53 of 1833

Driving conditionMaintenance itemMaintenance

operation Maintenance interval Reference page

..C....H..Drive shafts InspectEvery 10,000 km (6,000 miles) or

6 months FA-22

.........J Front wheel bearing grease & free running hub grease

InspectEvery 10,000 km (6,000 miles) or

6 months MA-39/MA-40

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles) or 6 months

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles) or 24 months

A...E.....Fuel filter Replace Every 22,500 km (13,500 miles) or 18 months

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 7,500 km (4,500 miles) or 6 months

.....F....Brake fluid Replace Every 15,000 km (9,000 miles) or 12 months

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles) or 12 months

..C....H..Automatic transmission fluid Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Drive shaft & steering damper Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Front wheel bearing grease

Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Free-running hub grease

Inspect Every 7,500 km (4,500 miles) or 6 months

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 7,500 km (4,500 miles) or 6 months

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) (Cont'd)

MA-12

http://vnx.su/

Page 55 of 1833

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

TD27Ti engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperature is eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of brakes or in mountainous areas

J Ð Frequent driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval Reference page

ABCD......Engine oil & engine oil filter Replace Every 5,000 km (3,000 miles) MA-21

A.........Air cleaner filter (dry paper type) Clean Every 10,000 km (6,000 miles)MA-24

Replace Every 20,000 km (12,000 miles)

A...E.....Fuel filter Replace Every 30,000 km (18,000 miles) MA-23

A....F....Ventilation air filter Replace Every 15,000 km (9,000 miles) MA-44

.....F....Brake fluid Replace Every 30,000 km (18,000 miles) MA-43

..C....H..Limited-slip differential (L.S.D.) gear oil Replace Every 30,000 km (18,000 miles) MA-38

..C....H..Transfer & standard differential gear oil

Replace Every 60,000 km (36,000 miles)MA-36/MA-37/

MA-38

A.C...GHI.Brake pads/linings, discs/drums & other brake system components Inspect Every 15,000 km (9,000 miles) MA-40/MA-41

......GH.J Greasing points of steering linkage, propeller shafts and suspension

Lubricate Every 15,000 km (9,000 miles) MA-44/MA-38

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

Inspect Every 30,000 km (18,000 miles)MA-43/FA-4/

RA-4/MA-38/

MA-36

..C....H..Drive shafts Inspect Every 15,000 km (9,000 miles) FA-22

.........J Front wheel bearing grease & free running hub grease

Inspect Every 15,000 km (9,000 miles) MA-39/MA-40

PERIODIC MAINTENANCE

MA-14

http://vnx.su/

Page 56 of 1833

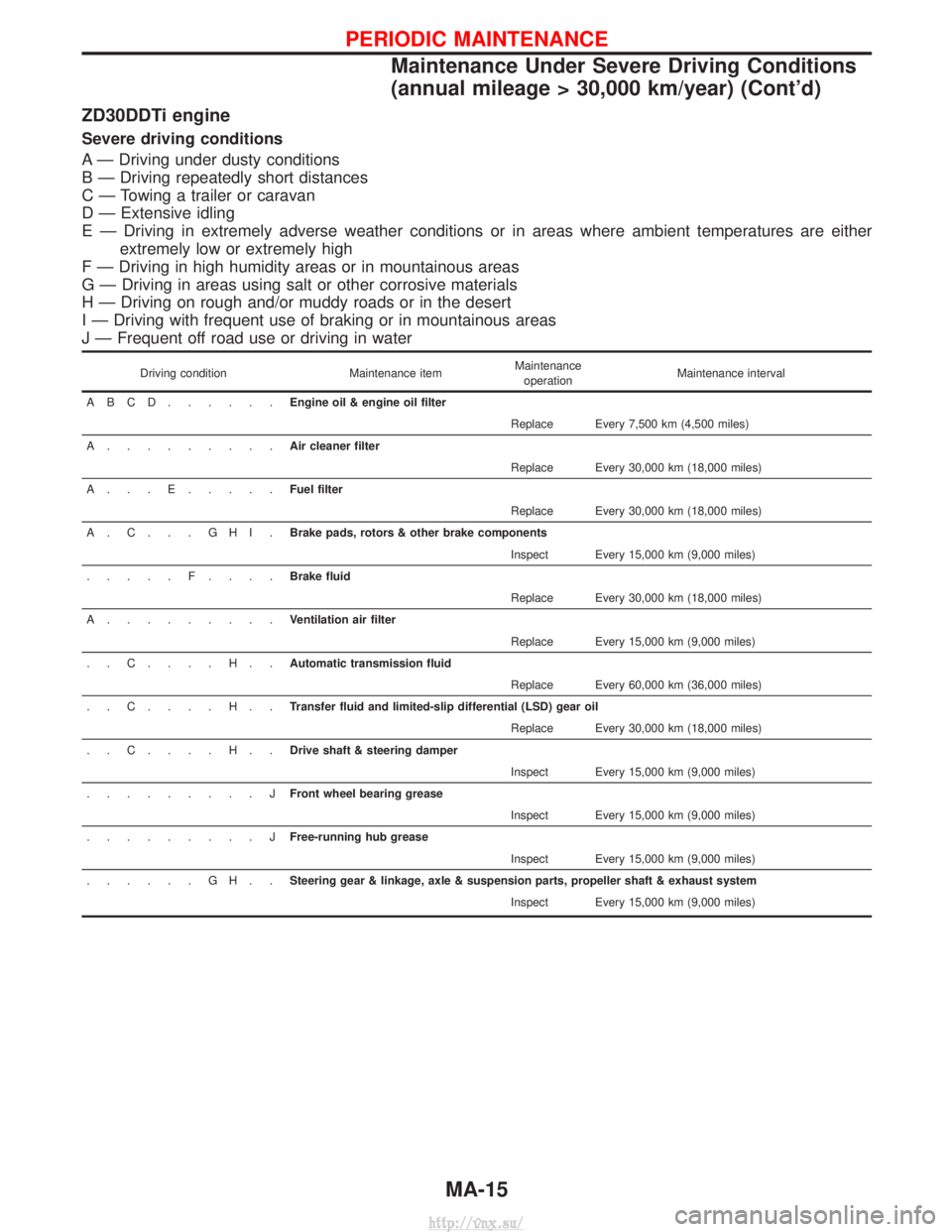

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles)

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles)

A...E.....Fuel filter Replace Every 30,000 km (18,000 miles)

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 15,000 km (9,000 miles)

.....F....Brake fluid Replace Every 30,000 km (18,000 miles)

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles)

..C....H..Automatic transmission fluid Replace Every 60,000 km (36,000 miles)

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles)

..C....H..Drive shaft & steering damper Inspect Every 15,000 km (9,000 miles)

.........J Front wheel bearing grease

Inspect Every 15,000 km (9,000 miles)

.........J Free-running hub grease

Inspect Every 15,000 km (9,000 miles)

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 15,000 km (9,000 miles)

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) (Cont'd)

MA-15

http://vnx.su/

Page 1832 of 1833

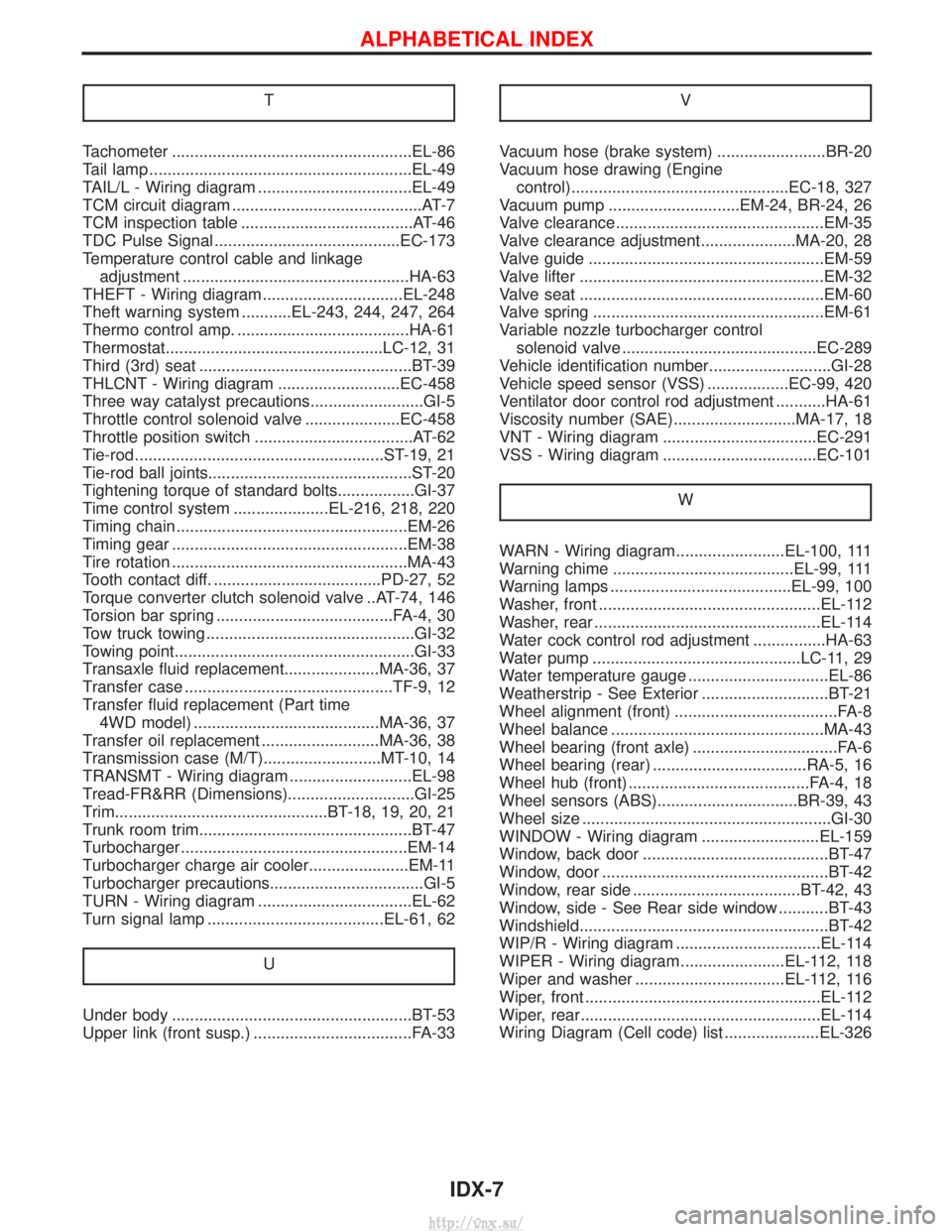

T

Tachometer .....................................................EL-86

Tail lamp ..........................................................EL-49

TAIL/L - Wiring diagram ..................................EL-49

TCM circuit diagram ..........................................AT-7

TCM inspection table ......................................AT-46

TDC Pulse Signal .........................................EC-173

Temperature control cable and linkageadjustment ..................................................HA-63

THEFT - Wiring diagram...............................EL-248

Theft warning system ...........EL-243, 244, 247, 264

Thermo control amp. ......................................HA-61

Thermostat................................................LC-12, 31

Third (3rd) seat ...............................................BT-39

THLCNT - Wiring diagram ...........................EC-458

Three way catalyst precautions.........................GI-5

Throttle control solenoid valve .....................EC-458

Throttle position switch ...................................AT-62

Tie-rod .......................................................ST-19, 21

Tie-rod ball joints.............................................ST-20

Tightening torque of standard bolts.................GI-37

Time control system .....................EL-216, 218, 220

Timing chain ...................................................EM-26

Timing gear ....................................................EM-38

Tire rotation ....................................................MA-43

Tooth contact diff. .....................................PD-27, 52

Torque converter clutch solenoid valve ..AT-74, 146

Torsion bar spring .......................................FA-4, 30

Tow truck towing ..............................................GI-32

Towing point.....................................................GI-33

Transaxle fluid replacement.....................MA-36, 37

Transfer case ..............................................TF-9, 12

Transfer fluid replacement (Part time 4WD model) .........................................MA-36, 37

Transfer oil replacement ..........................MA-36, 38

Transmission case (M/T)..........................MT-10, 14

TRANSMT - Wiring diagram ...........................EL-98

Tread-FR&RR (Dimensions)............................GI-25

Trim...............................................BT-18, 19, 20, 21

Trunk room trim...............................................BT-47

Turbocharger ..................................................EM-14

Turbocharger charge air cooler......................EM-11

Turbocharger precautions..................................GI-5

TURN - Wiring diagram ..................................EL-62

Turn signal lamp .......................................EL-61, 62

U

Under body .....................................................BT-53

Upper link (front susp.) ...................................FA-33 V

Vacuum hose (brake system) ........................BR-20

Vacuum hose drawing (Engine

control)................................................EC-18, 327

Vacuum pump .............................EM-24, BR-24, 26

Valve clearance..............................................EM-35

Valve clearance adjustment.....................MA-20, 28

Valve guide ....................................................EM-59

Valve lifter ......................................................EM-32

Valve seat ......................................................EM-60

Valve spring ...................................................EM-61

Variable nozzle turbocharger control solenoid valve ...........................................EC-289

Vehicle identification number...........................GI-28

Vehicle speed sensor (VSS) ..................EC-99, 420

Ventilator door control rod adjustment ...........HA-61

Viscosity number (SAE)...........................MA-17, 18

VNT - Wiring diagram ..................................EC-291

VSS - Wiring diagram ..................................EC-101

W

WARN - Wiring diagram........................EL-100, 111

Warning chime ........................................EL-99, 111

Warning lamps ........................................EL-99, 100

Washer, front .................................................EL-112

Washer, rear ..................................................EL-114

Water cock control rod adjustment ................HA-63

Water pump ..............................................LC-11, 29

Water temperature gauge ...............................EL-86

Weatherstrip - See Exterior ............................BT-21

Wheel alignment (front) ....................................FA-8

Wheel balance ...............................................MA-43

Wheel bearing (front axle) ................................FA-6

Wheel bearing (rear) ..................................RA-5, 16

Wheel hub (front) ........................................FA-4, 18

Wheel sensors (ABS)...............................BR-39, 43

Wheel size .......................................................GI-30

WINDOW - Wiring diagram ..........................EL-159

Window, back door .........................................BT-47

Window, door ..................................................BT-42

Window, rear side .....................................BT-42, 43

Window, side - See Rear side window ...........BT-43

Windshield.......................................................BT-42

WIP/R - Wiring diagram ................................EL-114

WIPER - Wiring diagram .......................EL-112, 118

Wiper and washer .................................EL-112, 116

Wiper, front ....................................................EL-112

Wiper, rear.....................................................EL-114

Wiring Diagram (Cell code) list .....................EL-326

ALPHABETICAL INDEX

IDX-7

http://vnx.su/