flat tire NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 817 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

I Disassembly should be done in a clean work area.

I Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

I Place disassembled parts in order for easier and proper assembly.

I All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

I Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

I It is very important to perform functional tests whenever they are indicated.

I The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

I Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

PREPARATION AND PRECAUTIONS

AT- 4

http://vnx.su/

Page 1119 of 1833

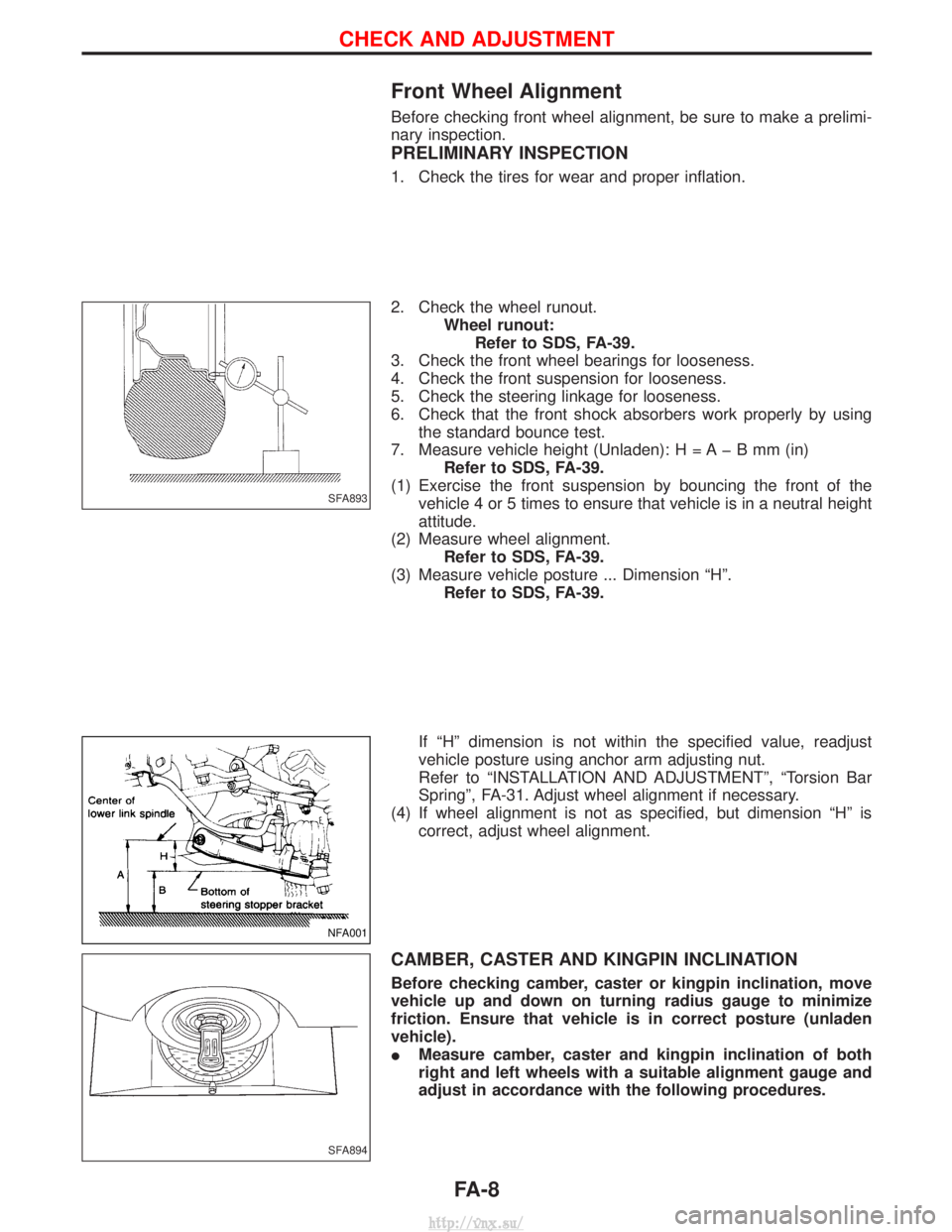

Front Wheel Alignment

Before checking front wheel alignment, be sure to make a prelimi-

nary inspection.

PRELIMINARY INSPECTION

1. Check the tires for wear and proper inflation.

2. Check the wheel runout.Wheel runout:Refer to SDS, FA-39.

3. Check the front wheel bearings for looseness.

4. Check the front suspension for looseness.

5. Check the steering linkage for looseness.

6. Check that the front shock absorbers work properly by using the standard bounce test.

7. Measure vehicle height (Unladen): H = A þ B mm (in) Refer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the vehicle 4 or 5 times to ensure that vehicle is in a neutral height

attitude.

(2) Measure wheel alignment. Refer to SDS, FA-39.

(3) Measure vehicle posture ... Dimension ªHº. Refer to SDS, FA-39.

If ªHº dimension is not within the specified value, readjust

vehicle posture using anchor arm adjusting nut.

Refer to ªINSTALLATION AND ADJUSTMENTº, ªTorsion Bar

Springº, FA-31. Adjust wheel alignment if necessary.

(4) If wheel alignment is not as specified, but dimension ªHº is correct, adjust wheel alignment.

CAMBER, CASTER AND KINGPIN INCLINATION

Before checking camber, caster or kingpin inclination, move

vehicle up and down on turning radius gauge to minimize

friction. Ensure that vehicle is in correct posture (unladen

vehicle).

IMeasure camber, caster and kingpin inclination of both

right and left wheels with a suitable alignment gauge and

adjust in accordance with the following procedures.

SFA893

NFA001

SFA894

CHECK AND ADJUSTMENT

FA-8

http://vnx.su/

Page 1242 of 1833

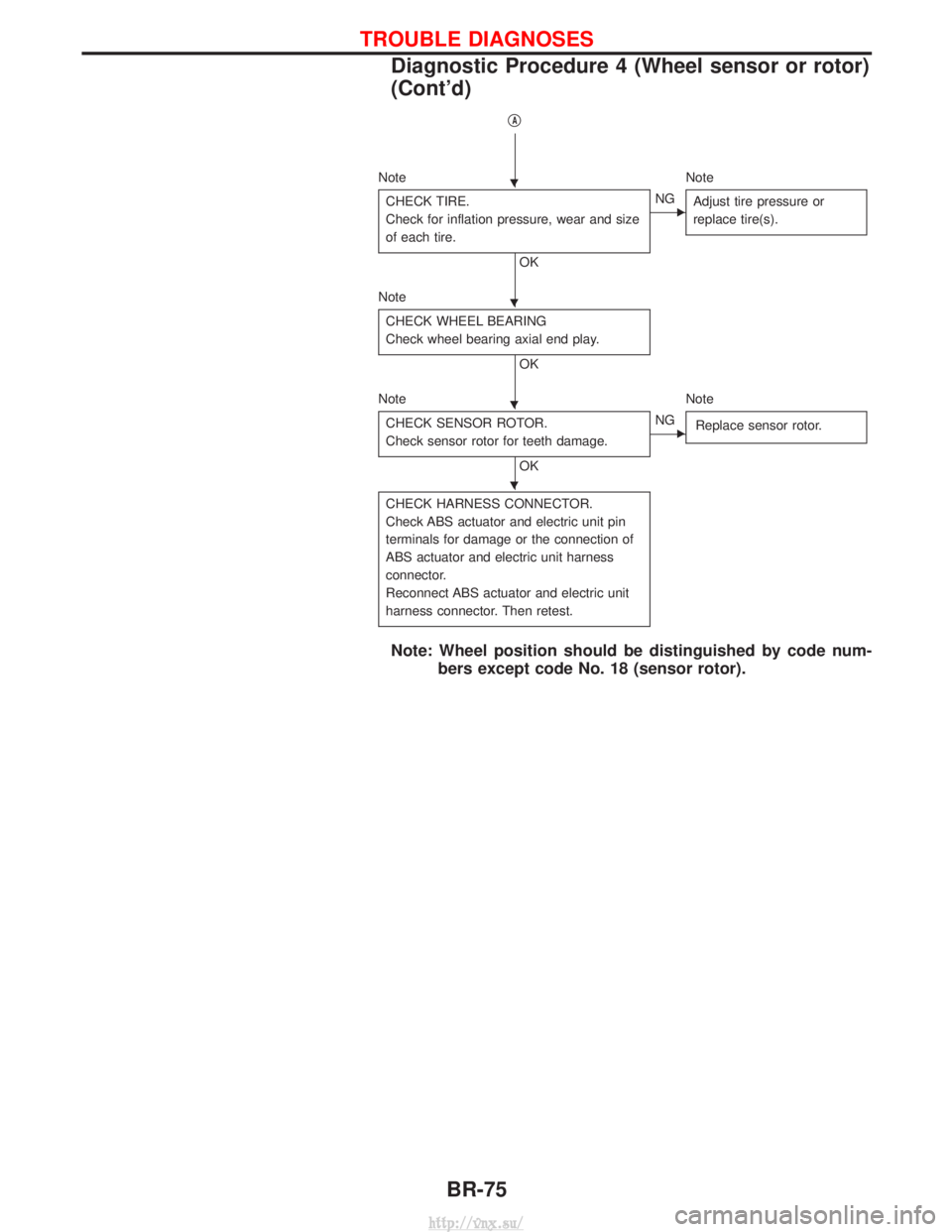

qA

NoteNote

CHECK TIRE.

Check for inflation pressure, wear and size

of each tire.

OK

ENG Adjust tire pressure or

replace tire(s).

Note

CHECK WHEEL BEARING

Check wheel bearing axial end play.

OK

Note Note CHECK SENSOR ROTOR.

Check sensor rotor for teeth damage.

OK

ENG Replace sensor rotor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

Note: Wheel position should be distinguished by code num-

bers except code No. 18 (sensor rotor).

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 4 (Wheel sensor or rotor)

(Cont'd)

BR-75

http://vnx.su/

Page 1255 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Precautions for Steering System

IBefore disassembly, thoroughly clean the outside of the unit.

I Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

I When disassembling parts, be sure to place them in order on a part rack so they can be reinstalled

in their proper positions.

I Use nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

I Before inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

I Before assembly, apply a coat of recommended ATF* to hydraulic parts. Vaseline may be applied

to O-rings and seals. Do not use any grease.

I Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Automatic transmission fluid

PRECAUTIONS

ST-2

http://vnx.su/

Page 1259 of 1833

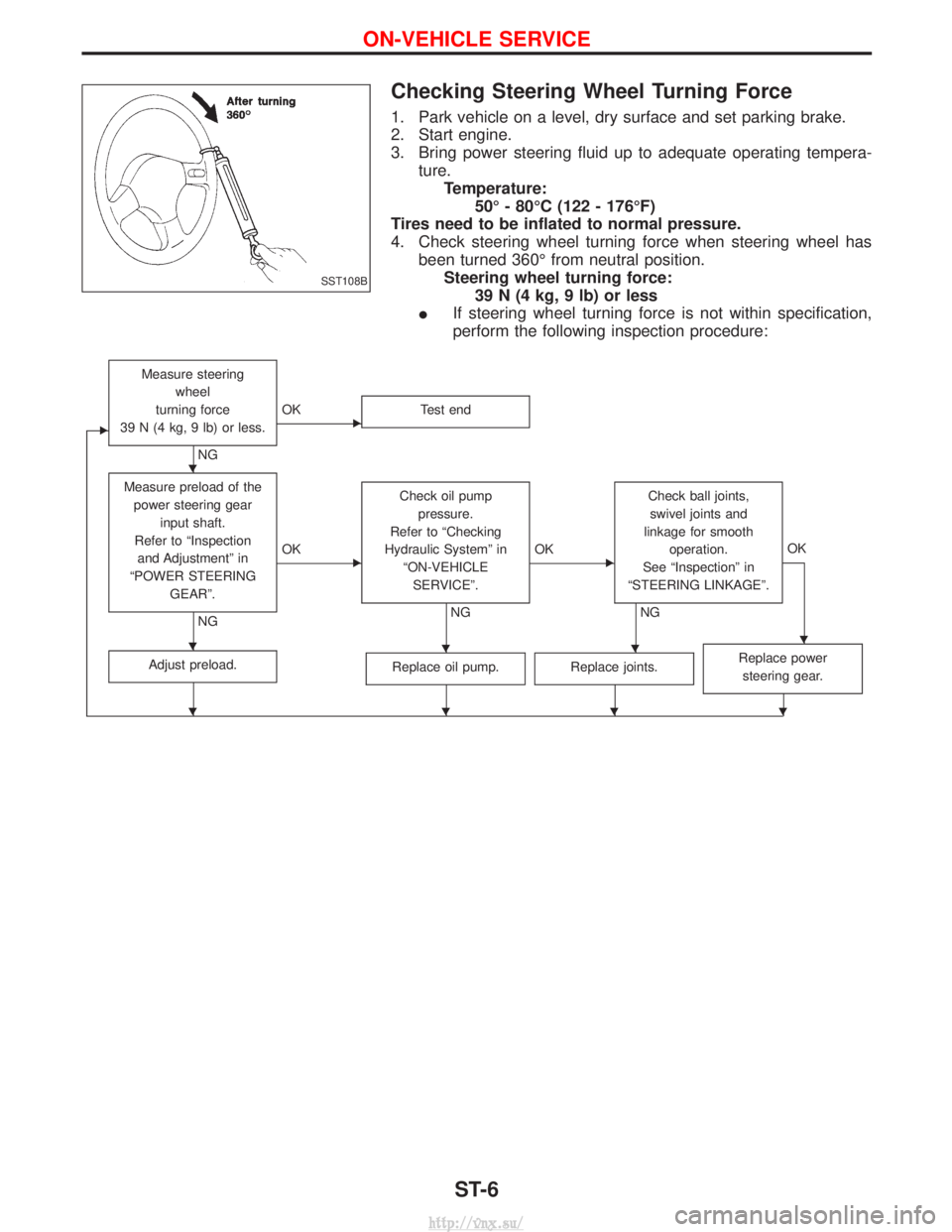

Checking Steering Wheel Turning Force

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-ture.Temperature: 50É - 80ÉC (122 - 176ÉF)

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has been turned 360É from neutral position.Steering wheel turning force: 39 N (4 kg, 9 lb) or less

I If steering wheel turning force is not within specification,

perform the following inspection procedure:

E

Measure steering

wheel

turning force

39 N (4 kg, 9 lb) or less.

NG

EOK Test end

Measure preload of the

power steering gear input shaft.

Refer to ªInspection and Adjustmentº in

ªPOWER STEERING GEARº.

NG

EOK Check oil pump

pressure.

Refer to ªChecking

Hydraulic Systemº in ªON-VEHICLESERVICEº.

NG

EOK Check ball joints,

swivel joints and

linkage for smooth operation.

See ªInspectionº in

ªSTEERING LINKAGEº.

NG OK

Adjust preload.Replace oil pump.Replace joints.Replace power

steering gear.

SST108B

H

HHHH

HHHH

ON-VEHICLE SERVICE

ST-6

http://vnx.su/

Page 1283 of 1833

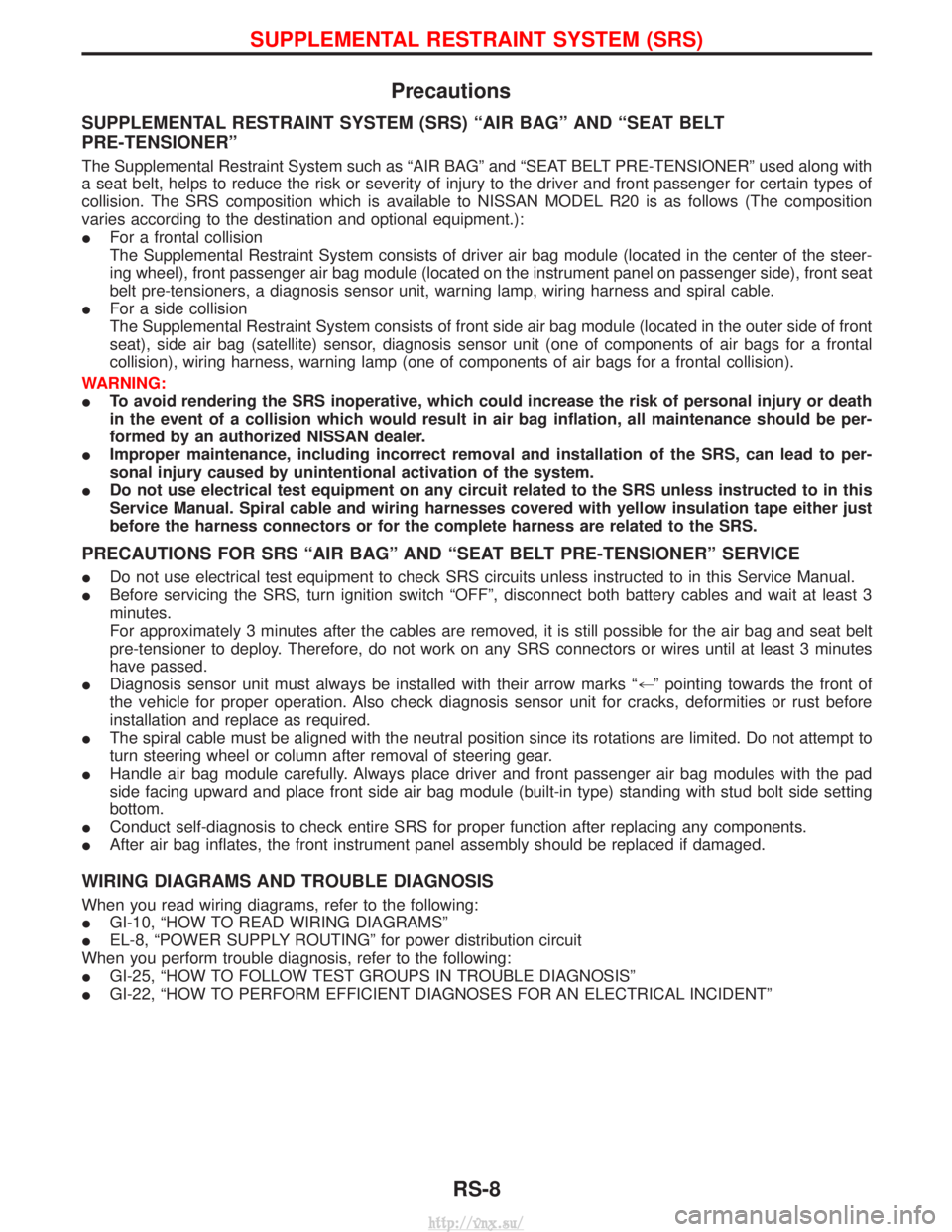

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS FOR SRS ªAIR BAGº AND ªSEAT BELT PRE-TENSIONERº SERVICE

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

WIRING DIAGRAMS AND TROUBLE DIAGNOSIS

When you read wiring diagrams, refer to the following:

IGI-10, ªHOW TO READ WIRING DIAGRAMSº

I EL-8, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

I GI-25, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSISº

I GI-22, ªHOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENTº

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-8

http://vnx.su/

Page 1294 of 1833

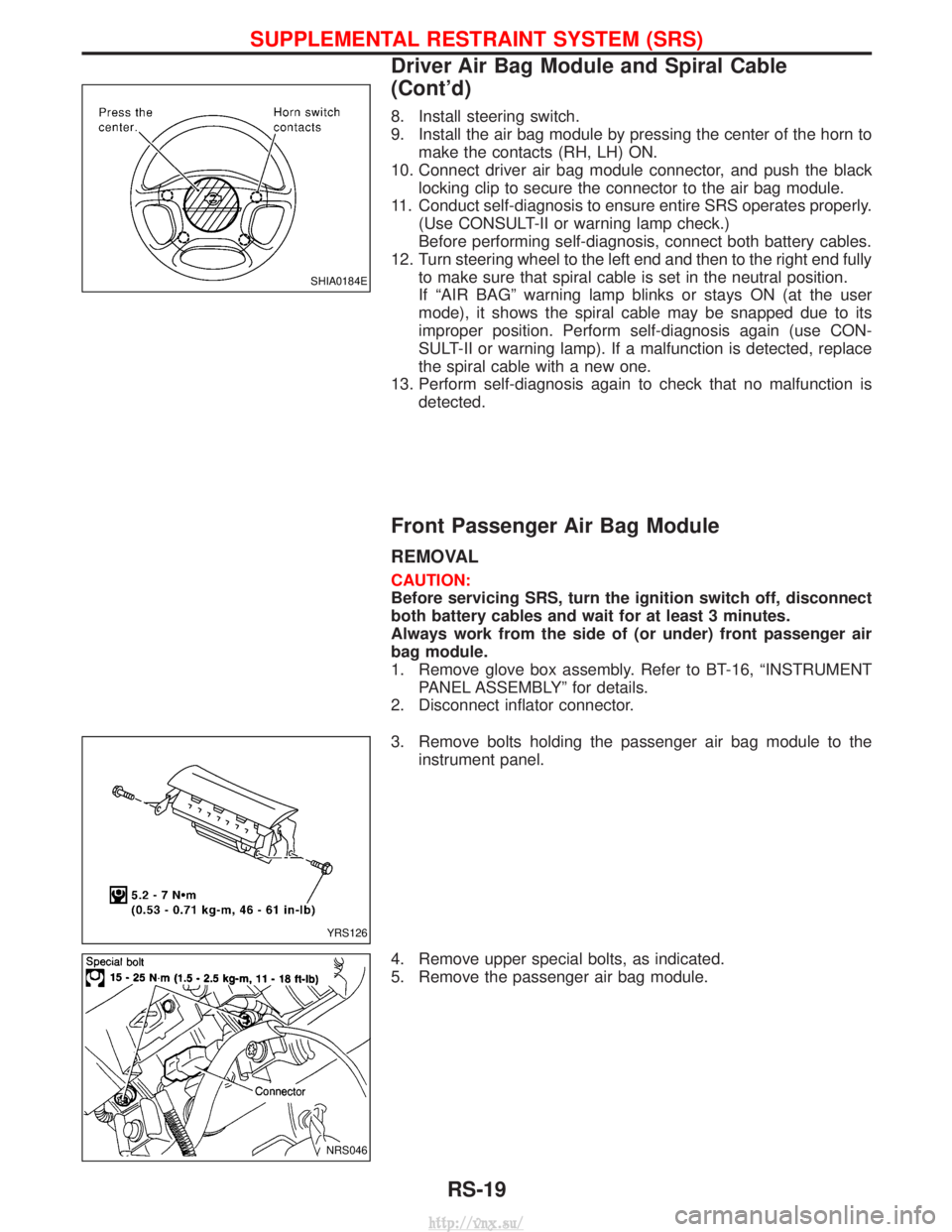

8. Install steering switch.

9. Install the air bag module by pressing the center of the horn tomake the contacts (RH, LH) ON.

10. Connect driver air bag module connector, and push the black locking clip to secure the connector to the air bag module.

11. Conduct self-diagnosis to ensure entire SRS operates properly. (Use CONSULT-II or warning lamp check.)

Before performing self-diagnosis, connect both battery cables.

12. Turn steering wheel to the left end and then to the right end fully to make sure that spiral cable is set in the neutral position.

If ªAIR BAGº warning lamp blinks or stays ON (at the user

mode), it shows the spiral cable may be snapped due to its

improper position. Perform self-diagnosis again (use CON-

SULT-II or warning lamp). If a malfunction is detected, replace

the spiral cable with a new one.

13. Perform self-diagnosis again to check that no malfunction is detected.

Front Passenger Air Bag Module

REMOVAL

CAUTION:

Before servicing SRS, turn the ignition switch off, disconnect

both battery cables and wait for at least 3 minutes.

Always work from the side of (or under) front passenger air

bag module.

1. Remove glove box assembly. Refer to BT-16, ªINSTRUMENTPANEL ASSEMBLYº for details.

2. Disconnect inflator connector.

3. Remove bolts holding the passenger air bag module to the instrument panel.

4. Remove upper special bolts, as indicated.

5. Remove the passenger air bag module.

SHIA0184E

YRS126

NRS046

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Driver Air Bag Module and Spiral Cable

(Cont'd)

RS-19

http://vnx.su/

Page 1295 of 1833

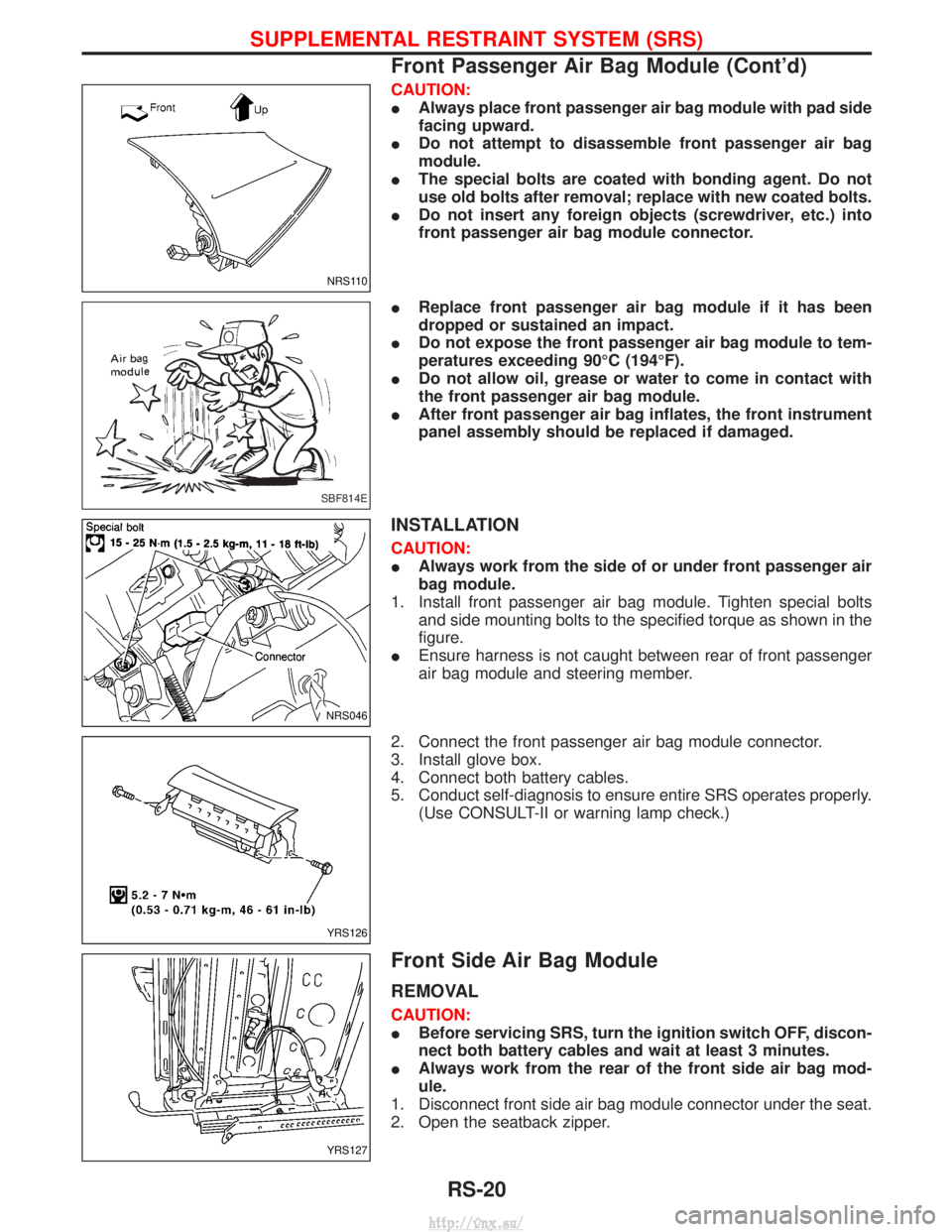

CAUTION:

IAlways place front passenger air bag module with pad side

facing upward.

I Do not attempt to disassemble front passenger air bag

module.

I The special bolts are coated with bonding agent. Do not

use old bolts after removal; replace with new coated bolts.

I Do not insert any foreign objects (screwdriver, etc.) into

front passenger air bag module connector.

I Replace front passenger air bag module if it has been

dropped or sustained an impact.

I Do not expose the front passenger air bag module to tem-

peratures exceeding 90ÉC (194ÉF).

I Do not allow oil, grease or water to come in contact with

the front passenger air bag module.

I After front passenger air bag inflates, the front instrument

panel assembly should be replaced if damaged.

INSTALLATION

CAUTION:

IAlways work from the side of or under front passenger air

bag module.

1. Install front passenger air bag module. Tighten special bolts and side mounting bolts to the specified torque as shown in the

figure.

I Ensure harness is not caught between rear of front passenger

air bag module and steering member.

2. Connect the front passenger air bag module connector.

3. Install glove box.

4. Connect both battery cables.

5. Conduct self-diagnosis to ensure entire SRS operates properly. (Use CONSULT-II or warning lamp check.)

Front Side Air Bag Module

REMOVAL

CAUTION:

IBefore servicing SRS, turn the ignition switch OFF, discon-

nect both battery cables and wait at least 3 minutes.

I Always work from the rear of the front side air bag mod-

ule.

1. Disconnect front side air bag module connector under the seat.

2. Open the seatback zipper.

NRS110

SBF814E

NRS046

YRS126

YRS127

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Front Passenger Air Bag Module (Cont'd)

RS-20

http://vnx.su/

Page 1540 of 1833

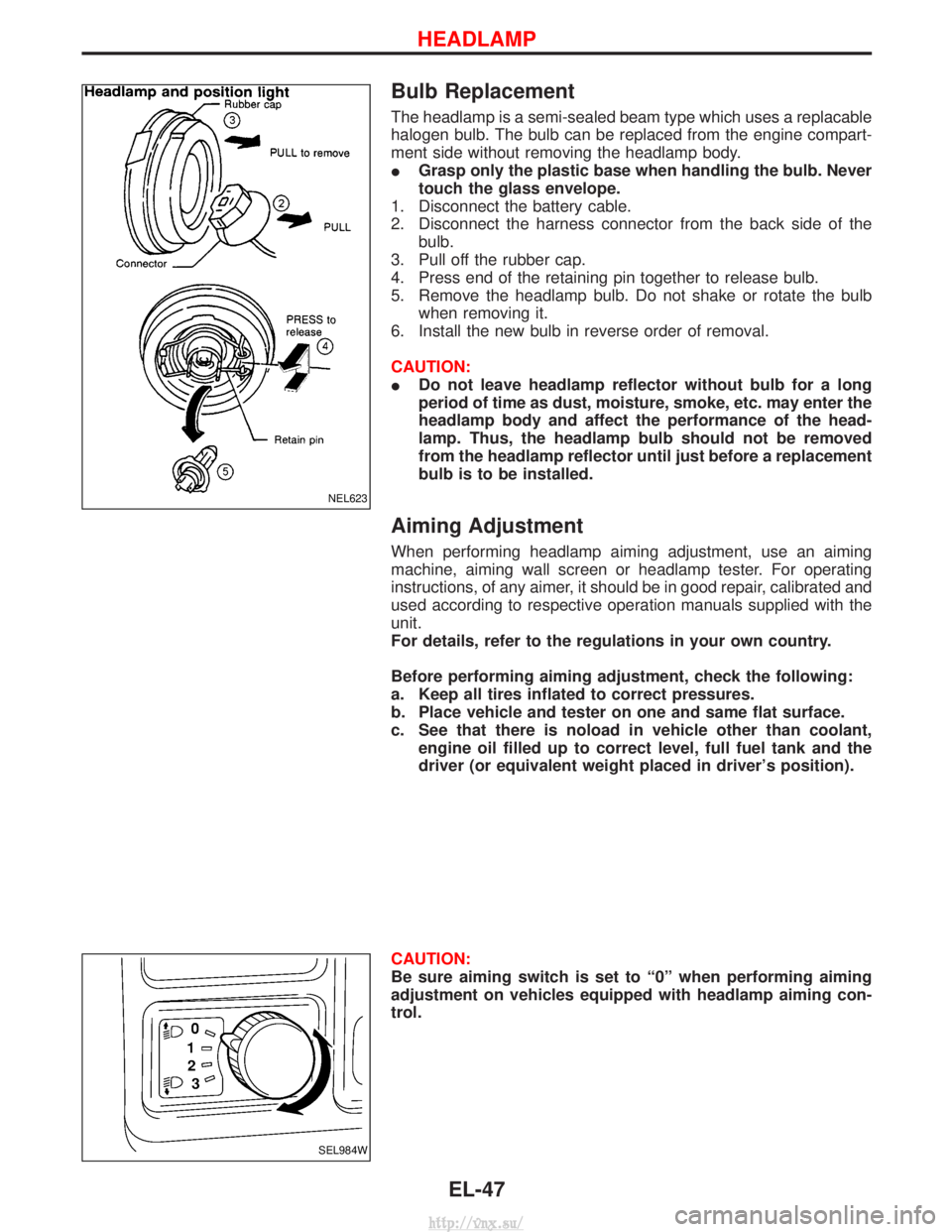

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

I Do not leave headlamp reflector without bulb for a long

period of time as dust, moisture, smoke, etc. may enter the

headlamp body and affect the performance of the head-

lamp. Thus, the headlamp bulb should not be removed

from the headlamp reflector until just before a replacement

bulb is to be installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

SEL984W

HEADLAMP

EL-47

http://vnx.su/

Page 1550 of 1833

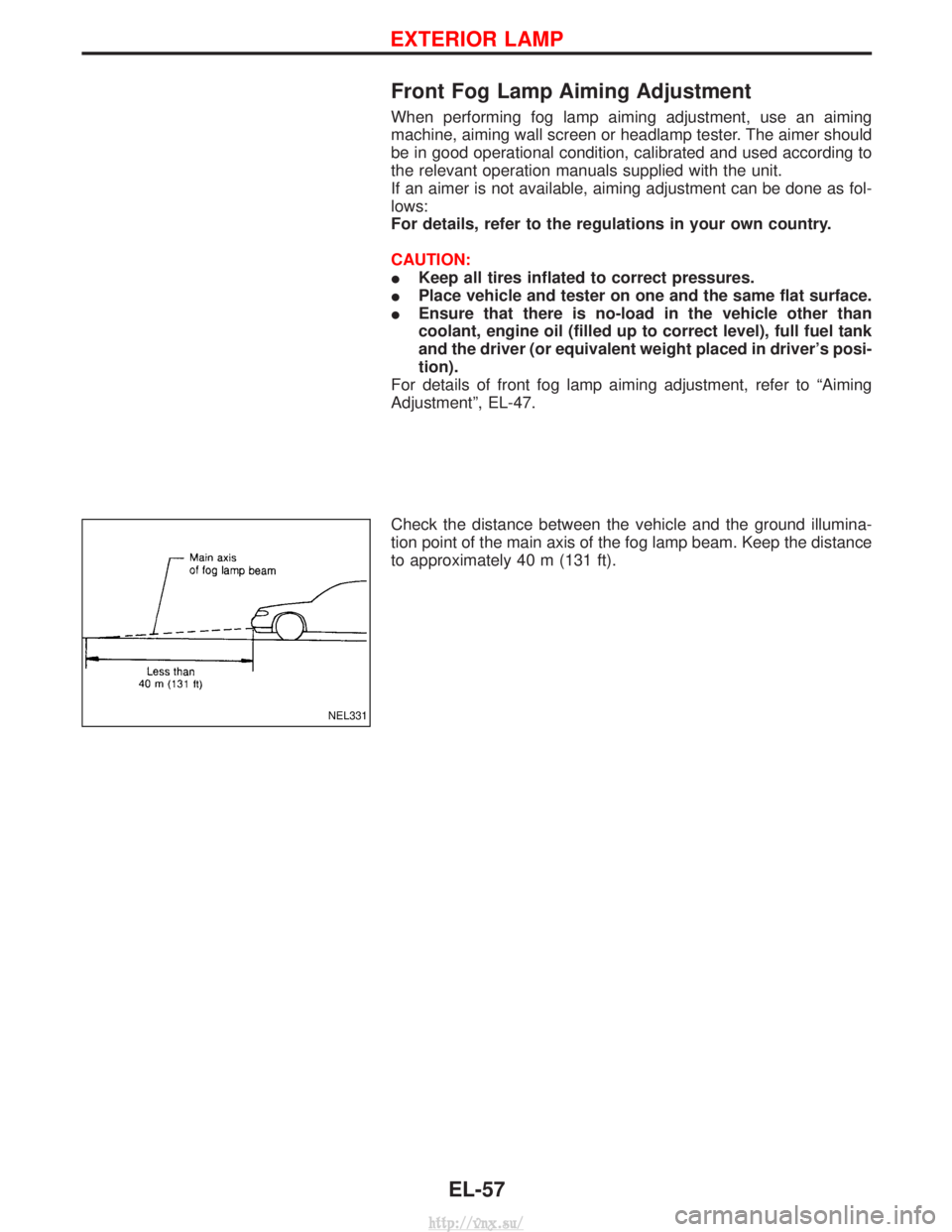

Front Fog Lamp Aiming Adjustment

When performing fog lamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. The aimer should

be in good operational condition, calibrated and used according to

the relevant operation manuals supplied with the unit.

If an aimer is not available, aiming adjustment can be done as fol-

lows:

For details, refer to the regulations in your own country.

CAUTION:

IKeep all tires inflated to correct pressures.

I Place vehicle and tester on one and the same flat surface.

I Ensure that there is no-load in the vehicle other than

coolant, engine oil (filled up to correct level), full fuel tank

and the driver (or equivalent weight placed in driver's posi-

tion).

For details of front fog lamp aiming adjustment, refer to ªAiming

Adjustmentº, EL-47.

Check the distance between the vehicle and the ground illumina-

tion point of the main axis of the fog lamp beam. Keep the distance

to approximately 40 m (131 ft).

NEL331

EXTERIOR LAMP

EL-57

http://vnx.su/