height adjustment NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 90 of 1833

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Clutch

Unit: mm (in)

Vehicle modelAll

Pedal free height RHD

210 - 220

(8.27 - 8.66) LHD

227 - 237

(8.94 - 9.33)

Pedal free play 1.0 - 3.0 (0.039 - 0.118)

Pedal free travel 155 - 160 (6.10 - 6.30)

Front axle and front suspension

(Unladen)*1

Unit: degree

Model H/T VAN H/T WAGON

Camber 0É30¢ 30¢

Caster 0É29¢ 30¢ 0É30¢ 30¢ 0É30¢ 30¢

Kingpin inclination 12É37¢

Toe-in

A-B mm (in) 3.5 - 5.5

(0.14 - 0.22) 3-5

(0.12 - 0.20) 3-5

(0.12 - 0.20)

Front wheel turning

angle (degrees) (Full turn)*2

Inside 34É27¢

Outside 33É38¢

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

Brake

Disc brake mm (in)

LD28VA

PadStandard thickness 15.5 (0.610)

Minimum thickness 2.0 (0.079)

Rotor Standard thickness 2.60 (0.1024)

Minimum thickness 24.0 (0.945)

Drum brake mm (in)

LT28 LiningStandard thicknessLeading 8.95 (0.3524)

Trailing 3.95 (0.1555)

Minimum thickness 1.52 (0.0598)

Drum Standard diameter 280 (11.02)

Maximum diameter 282 (11.10)

Pedal mm (in) RHD LHD

Free height 196 - 206

(7.7 - 8.1) 210 - 220

(8.3 - 8.7)

Free play 1.0 - 3.0 (0.039 - 0.118)

Full stroke 137.7 - 148.7

(5.42 - 5.85) 142.5 - 152.5

(5.61 - 6.00)

Parking brake Number of notches [at pulling

force 196 N (20 kg, 44 lb)] 9-10

Wheel runout

Unit: mm (in)

Wheel typeSteel Aluminum

16² x7J 16 ²x7J

Radial runout limit 0.5 (0.020) 0.3 (0.012)

Lateral runout limit 0.8 (0.031) 0.3 (0.012)

Wheel bearing

Axial end play limit mm (in) 0

SERVICE AND SPECIFICATIONS (SDS)

MA-49

http://vnx.su/

Page 235 of 1833

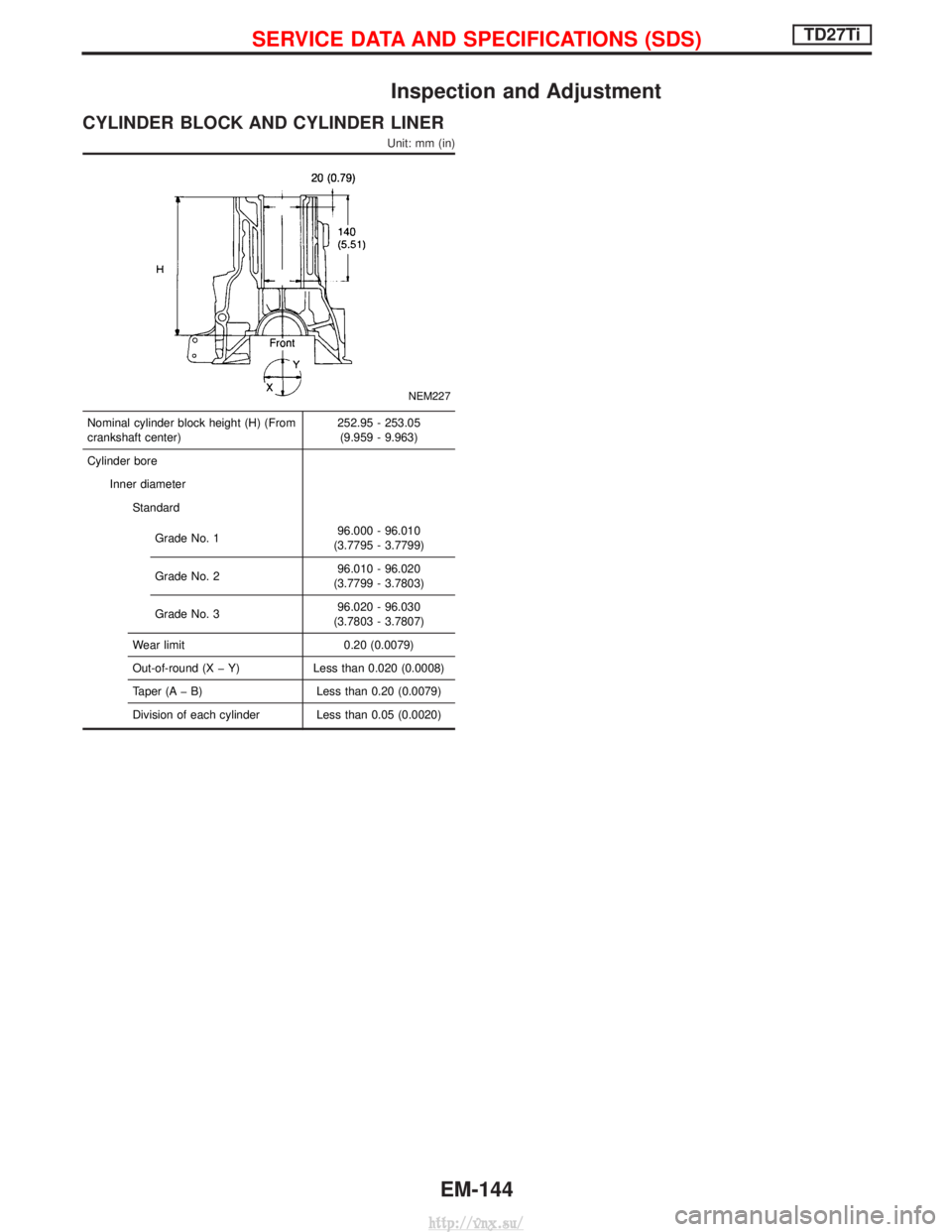

Inspection and Adjustment

CYLINDER BLOCK AND CYLINDER LINER

Unit: mm (in)

NEM227

Nominal cylinder block height (H) (From

crankshaft center)252.95 - 253.05

(9.959 - 9.963)

Cylinder bore Inner diameterStandard

Grade No. 1 96.000 - 96.010

(3.7795 - 3.7799)

Grade No. 2 96.010 - 96.020

(3.7799 - 3.7803)

Grade No. 3 96.020 - 96.030

(3.7803 - 3.7807)

Wear limit 0.20 (0.0079)

Out-of-round (X þ Y) Less than 0.020 (0.0008)

Taper (A þ B) Less than 0.20 (0.0079)

Division of each cylinder Less than 0.05 (0.0020)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-144

http://vnx.su/

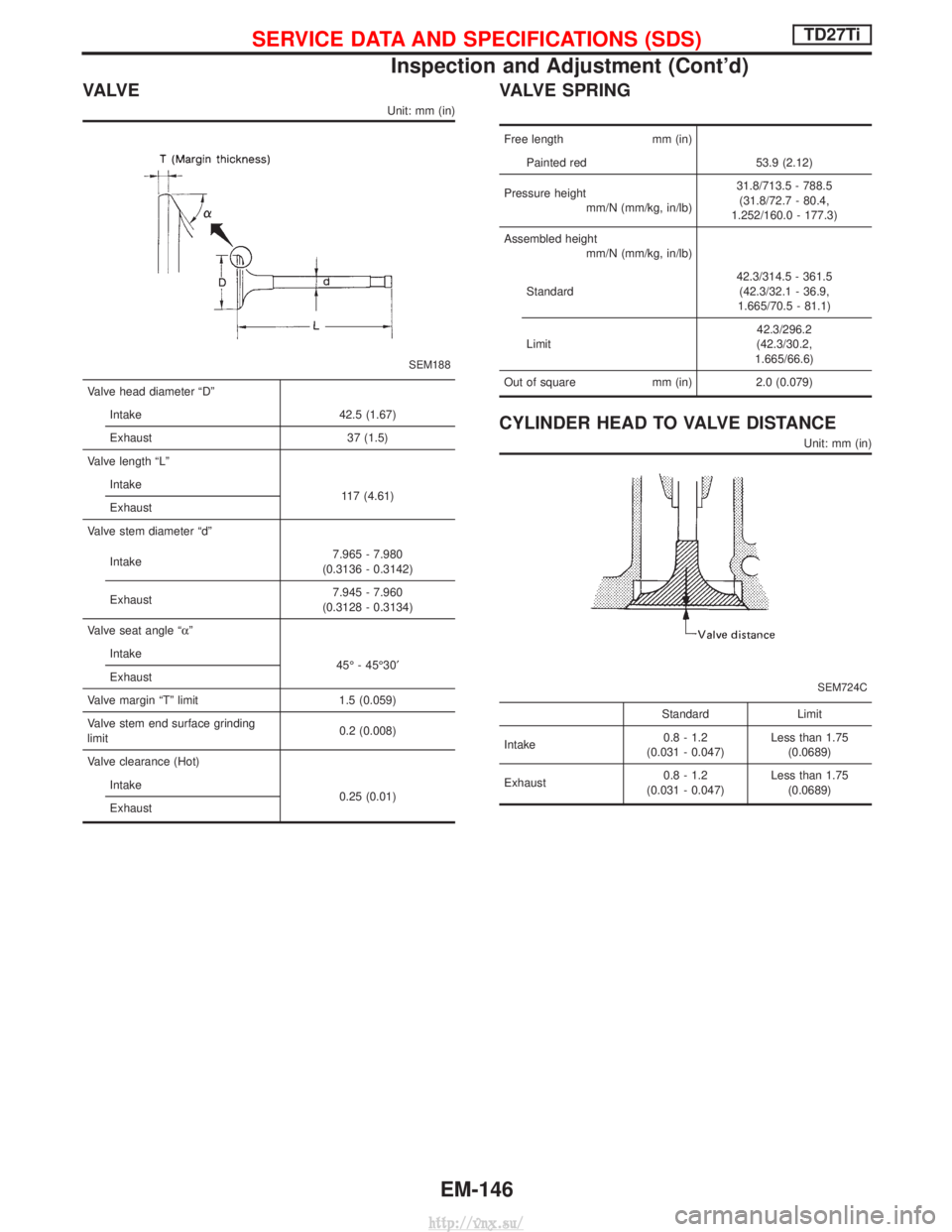

Page 237 of 1833

VA LV E

Unit: mm (in)

SEM188

Valve head diameter ªDºIntake 42.5 (1.67)

Exhaust 37 (1.5)

Valve length ªLº Intake 117 (4.61)

Exhaust

Valve stem diameter ªdº

Intake 7.965 - 7.980

(0.3136 - 0.3142)

Exhaust 7.945 - 7.960

(0.3128 - 0.3134)

Valve seat angle ªa º

Intake 45É - 45É30¢

Exhaust

Valve margin ªTº limit 1.5 (0.059)

Valve stem end surface grinding

limit 0.2 (0.008)

Valve clearance (Hot) Intake 0.25 (0.01)

Exhaust

VALVE SPRING

Free length mm (in)

Painted red 53.9 (2.12)

Pressure height mm/N (mm/kg, in/lb) 31.8/713.5 - 788.5

(31.8/72.7 - 80.4,

1.252/160.0 - 177.3)

Assembled height mm/N (mm/kg, in/lb)

Standard 42.3/314.5 - 361.5

(42.3/32.1 - 36.9,

1.665/70.5 - 81.1)

Limit 42.3/296.2

(42.3/30.2,

1.665/66.6)

Out of square mm (in)2.0 (0.079)

CYLINDER HEAD TO VALVE DISTANCE

Unit: mm (in)

SEM724C

Standard Limit

Intake 0.8 - 1.2

(0.031 - 0.047) Less than 1.75

(0.0689)

Exhaust 0.8 - 1.2

(0.031 - 0.047) Less than 1.75

(0.0689)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-146

http://vnx.su/

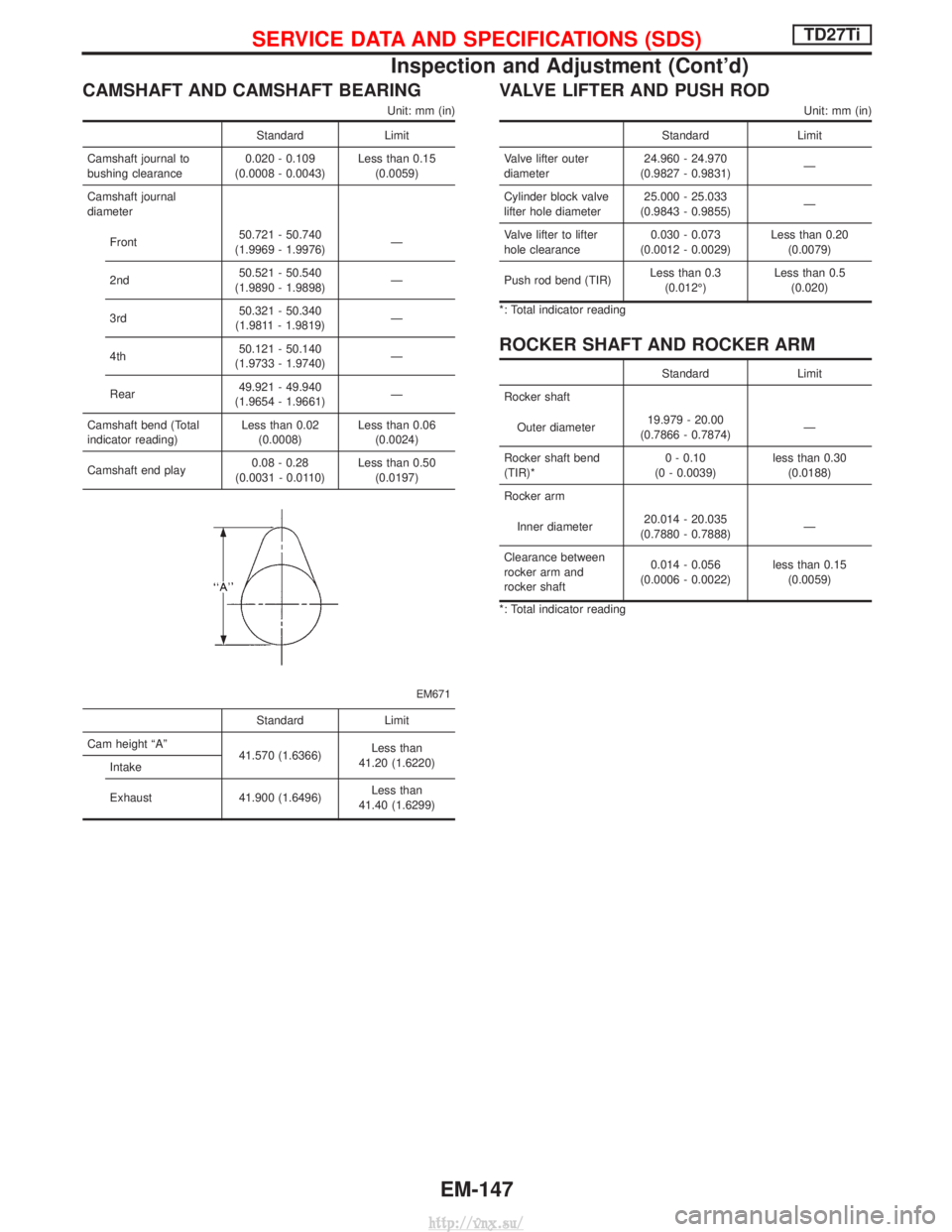

Page 238 of 1833

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

StandardLimit

Camshaft journal to

bushing clearance 0.020 - 0.109

(0.0008 - 0.0043) Less than 0.15

(0.0059)

Camshaft journal

diameter

Front 50.721 - 50.740

(1.9969 - 1.9976) Ð

2nd 50.521 - 50.540

(1.9890 - 1.9898) Ð

3rd 50.321 - 50.340

(1.9811 - 1.9819) Ð

4th 50.121 - 50.140

(1.9733 - 1.9740) Ð

Rear 49.921 - 49.940

(1.9654 - 1.9661) Ð

Camshaft bend (Total

indicator reading) Less than 0.02

(0.0008) Less than 0.06

(0.0024)

Camshaft end play 0.08 - 0.28

(0.0031 - 0.0110) Less than 0.50

(0.0197)

EM671

Standard Limit

Cam height ªAº 41.570 (1.6366)Less than

41.20 (1.6220)

Intake

Exhaust 41.900 (1.6496) Less than

41.40 (1.6299)

VALVE LIFTER AND PUSH ROD

Unit: mm (in)

Standard Limit

Valve lifter outer

diameter 24.960 - 24.970

(0.9827 - 0.9831) Ð

Cylinder block valve

lifter hole diameter 25.000 - 25.033

(0.9843 - 0.9855) Ð

Valve lifter to lifter

hole clearance 0.030 - 0.073

(0.0012 - 0.0029) Less than 0.20

(0.0079)

Push rod bend (TIR) Less than 0.3

(0.012É) Less than 0.5

(0.020)

*: Total indicator reading

ROCKER SHAFT AND ROCKER ARM

Standard Limit

Rocker shaft

Outer diameter 19.979 - 20.00

(0.7866 - 0.7874) Ð

Rocker shaft bend

(TIR)* 0 - 0.10

(0 - 0.0039) less than 0.30

(0.0188)

Rocker arm

Inner diameter 20.014 - 20.035

(0.7880 - 0.7888) Ð

Clearance between

rocker arm and

rocker shaft 0.014 - 0.056

(0.0006 - 0.0022) less than 0.15

(0.0059)

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-147

http://vnx.su/

Page 241 of 1833

AVAILABLE THRUST WASHER

Unit: mm (in)

Thrust washer thickness

Standard 2.275 - 2.325 (0.0896 - 0.0915)

Oversize 0.20 (0.0079) 2.475 - 2.525 (0.0974 - 0.0994)

0.40 (0.0157) 2.675 - 2.725 (0.1053 - 0.1073)

MISCELLANEOUS COMPONENTS

Unit: mm (in)

Gear trainBacklash of each gear

Standard 0.07 - 0.11 (0.0028 - 0.0043)

Limit 0.20 (0.0079)

Flywheel Runout (Total indicator

reading) Less than 0.15 (0.0059)

Front plate Warpage limit 0.2 (0.008)

Cylinder head Head surface distorsion

Standard Less than 0.07 (0.0028)

Limit 0.2 (0.008)

Minimum height 89.7 (3.532)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-150

http://vnx.su/

Page 768 of 1833

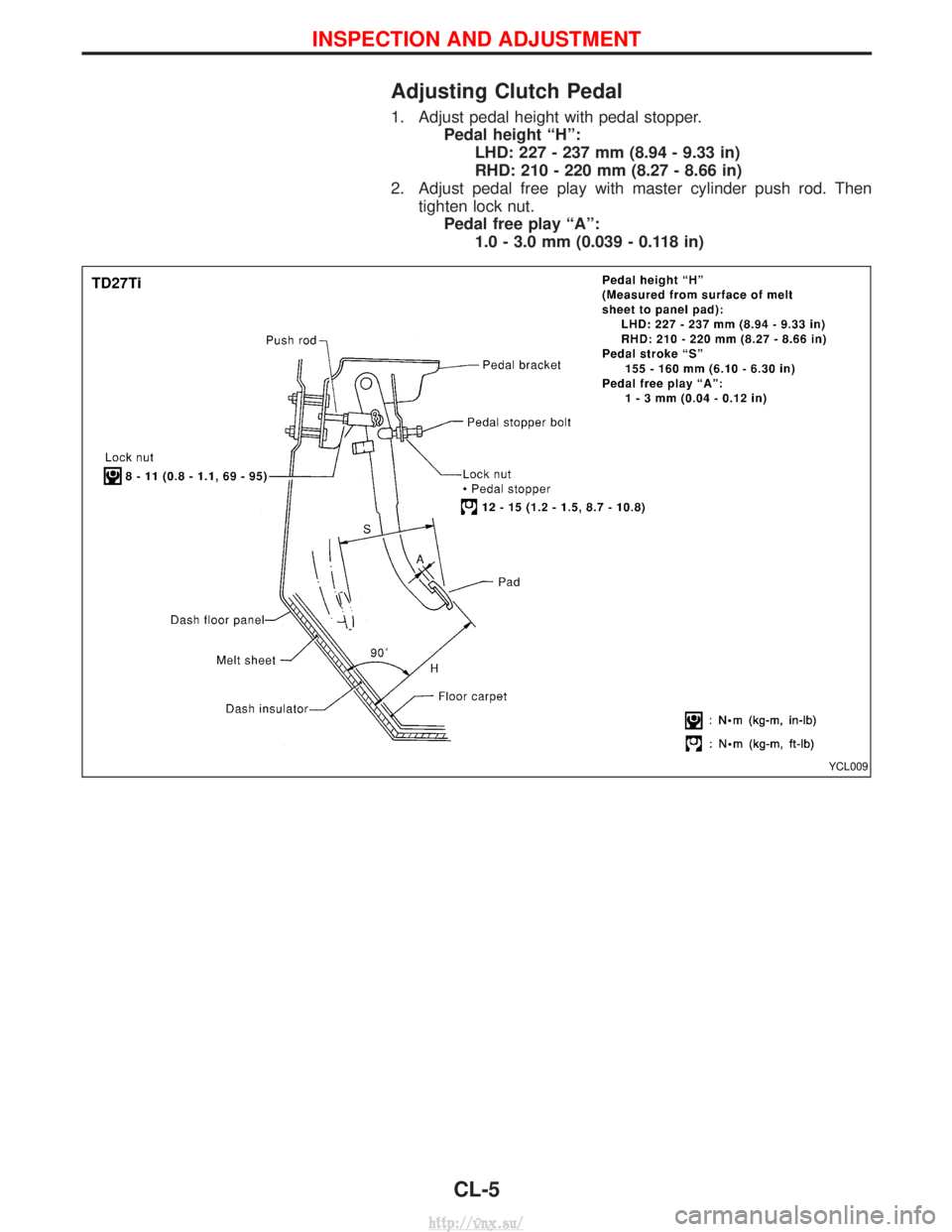

Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper.Pedal height ªHº:LHD: 227 - 237 mm (8.94 - 9.33 in)

RHD: 210 - 220 mm (8.27 - 8.66 in)

2. Adjust pedal free play with master cylinder push rod. Then tighten lock nut.Pedal free play ªAº: 1.0 - 3.0 mm (0.039 - 0.118 in)

YCL009

INSPECTION AND ADJUSTMENT

CL-5

http://vnx.su/

Page 775 of 1833

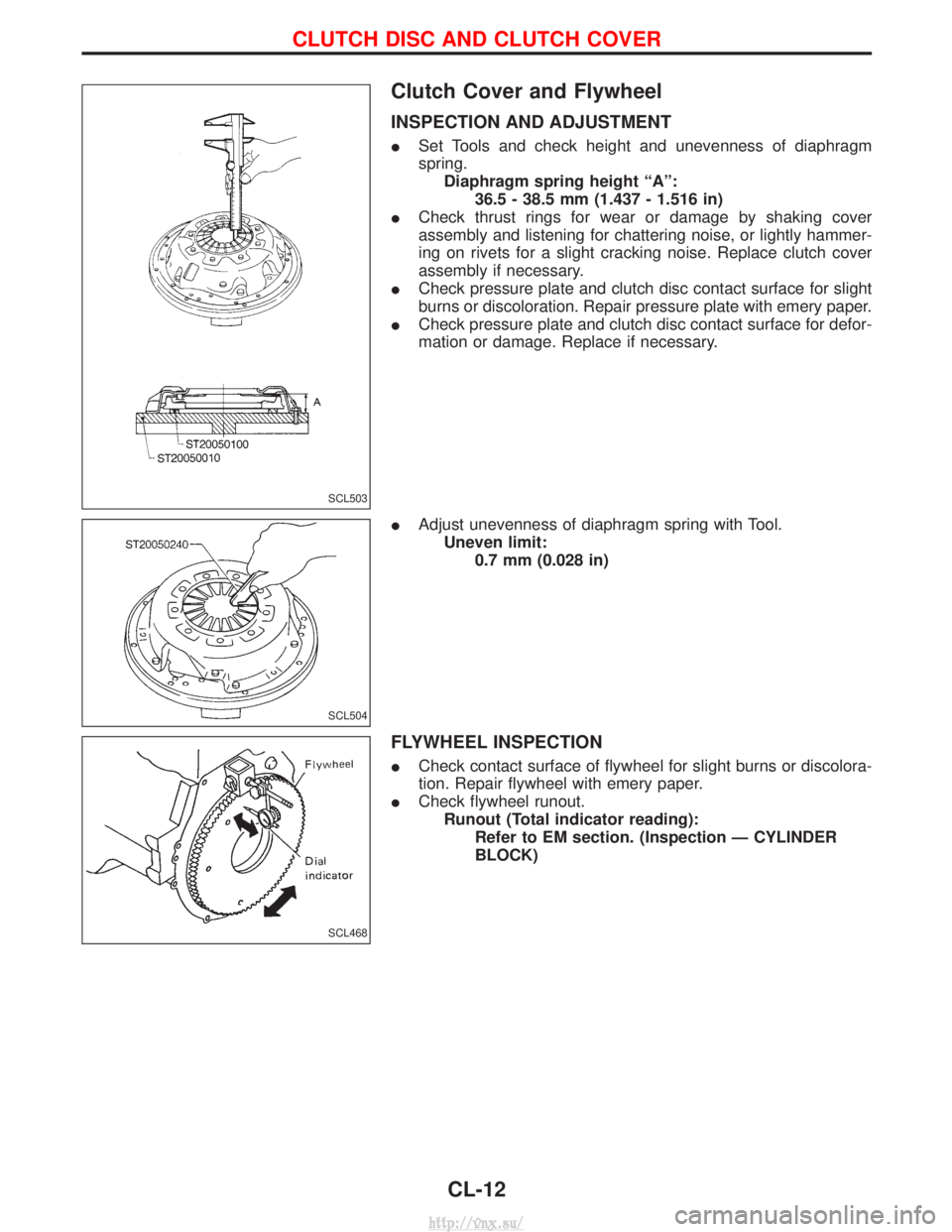

Clutch Cover and Flywheel

INSPECTION AND ADJUSTMENT

ISet Tools and check height and unevenness of diaphragm

spring.

Diaphragm spring height ªAº: 36.5 - 38.5 mm (1.437 - 1.516 in)

I Check thrust rings for wear or damage by shaking cover

assembly and listening for chattering noise, or lightly hammer-

ing on rivets for a slight cracking noise. Replace clutch cover

assembly if necessary.

I Check pressure plate and clutch disc contact surface for slight

burns or discoloration. Repair pressure plate with emery paper.

I Check pressure plate and clutch disc contact surface for defor-

mation or damage. Replace if necessary.

I Adjust unevenness of diaphragm spring with Tool.

Uneven limit: 0.7 mm (0.028 in)

FLYWHEEL INSPECTION

ICheck contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

I Check flywheel runout.

Runout (Total indicator reading): Refer to EM section. (Inspection Ð CYLINDER

BLOCK)

SCL503

SCL504

SCL468

CLUTCH DISC AND CLUTCH COVER

CL-12

http://vnx.su/

Page 777 of 1833

General Specifications

CLUTCH CONTROL SYSTEM

Type of clutch controlHydraulic

CLUTCH MASTER CYLINDER

Inner diametermm (in) 15.87 (5/8)

CLUTCH OPERATING CYLINDER

Inner diameter mm (in)

LHD 17.46 (11/16)

RHD 19.05 (3/4)

CLUTCH DISC

Unit: mm (in)

EngineTD27Ti ZD30DDTi

Model 250 260

Facing size

(Outer dia. x inner dia. x

thickness) 250 x 160 x 3.7

(9.84 x 6.30 x 0.1457)

Thickness of disc assembly

under load 7.0 - 7.4 (0.276 - 0.291)

Under a load of 5,884 N (600 kg, 1,323 lb)

CLUTCH COVER

Engine TD27TiZD30DDTi

Model 250 260

Full load N (kg, lb) 5,884 (600, 1,323) 6,760 (689, 1,520)

Inspection and Adjustment

CLUTCH PEDAL

Unit: mm (in)

Handle LHDRHD

Pedal height* 227 - 237

(8.94 - 9.33) 210 - 220

(8.27 - 8.66)

Pedal stroke 155 - 160 (6.10 - 6.30)

Pedal free play

(Backlash at clevis) 1.0 - 3.0 (0.039 - 0.118)

*: Measured from surface of melt sheet to surface of pedal

pad

CLUTCH DISC

Unit: mm (in)

Engine TD27TiZD30DDTi

Disc model 250 260

Rear limit of facing

surface to rivet head 0.3 (0.012)

Runout limit of facing 1 (0.04)

Distance of runout

check point (from the

hub center) 120 (4.72)

Maximum of spline

backlash of spline (at

outer edge of disc) 1.0 (0.039)

CLUTCH COVER

Unit: mm (in)

Engine

TD27TiZD30DDTi

Cover model 250 260

Diaphragm spring height 36.5 - 38.5 (1.437 - 1.516)

Uneven limit of dia-

phragm spring toe height

ªAº 0.7 (0.028)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-14

http://vnx.su/

Page 1052 of 1833

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION ................................................................2

PROPELLER SHAFT ......................................................5

On-Vehicle Service ......................................................6

Removal and Installation .............................................7

Inspection.....................................................................7

Disassembly.................................................................7

Assembly .....................................................................8

ON-VEHICLE SERVICE ................................................10

Front Oil Seal Replacement

(Front final drive: R180A) ..........................................10

Front Oil Seal Replacement

(Rear final drive: C200) .............................................10

REMOVAL AND INSTALLATION (Front final drive

- R180A) ........................................................................\

.12

Removal .....................................................................12

Installation ..................................................................12

REMOVAL AND INSTALLATION (Rear final drive

- C200) ........................................................................\

...13

Removal .....................................................................13

Installation ..................................................................13

FRONT FINAL DRIVE (R180A) ....................................14

DISASSEMBLY (R180A) ...............................................15

Pre-inspection ............................................................15

Final Drive Housing ...................................................15

Differential Case ........................................................18

Extension Tube and Differential Side Shaft ..............19

INSPECTION (R180A) ...................................................20

Ring Gear and Drive Pinion ......................................20

Differential Case Assembly........................................20

Bearing.......................................................................20

ADJUSTMENT (R180A) ................................................21 Drive Pinion Height ....................................................21

Side Bearing Preload.................................................24

Tooth Contact.............................................................27

ASSEMBLY (R180A) .....................................................28

Extension Tube and Differential Side Shaft ..............28

Differential Case ........................................................29

Final Drive Housing ...................................................30

REAR FINAL DRIVE (C200) .........................................35

Air Breather................................................................36

DISASSEMBLY (C200) ..................................................37

Pre-inspection ............................................................37

Differential Carrier......................................................38

Differential Case ........................................................40

INSPECTION (C200) .....................................................42

Ring Gear and Drive Pinion ......................................42

Differential Case Assembly........................................42

Bearing.......................................................................42

LIMITED SLIP DIFFERENTIAL (C200) .........................43

Preparation for Disassembly .....................................43

Disassembly...............................................................44

Inspection...................................................................44

Adjustment .................................................................45

Assembly ...................................................................47

ADJUSTMENT (C200) ...................................................49

Drive Pinion Height ....................................................49

Tooth Contact.............................................................52

ASSEMBLY (C200) ........................................................53

Differential Carrier......................................................53

SERVICE DATA AND SPECIFICATIONS (SDS) ..........57

Propeller Shaft ...........................................................57

Final Drive..................................................................58

http://vnx.su/

Page 1072 of 1833

To avoid confusion while calculating bearing shims, it is absolutely

necessary to stay with the metric system. If you measure anything

in inches, the results MUST be converted to the metric system.

Drive Pinion Height

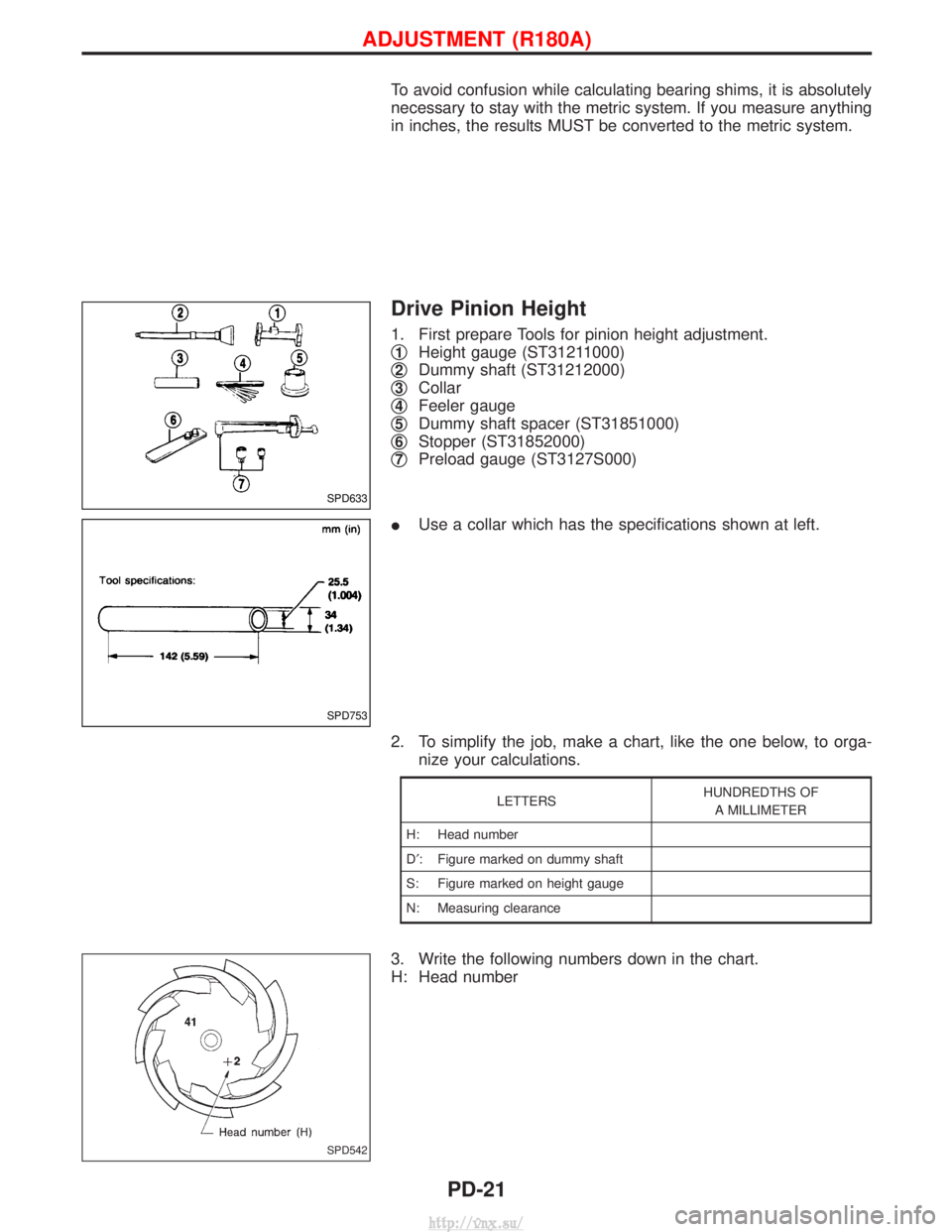

1. First prepare Tools for pinion height adjustment.

q

1Height gauge (ST31211000)

q

2Dummy shaft (ST31212000)

q

3Collar

q

4Feeler gauge

q

5Dummy shaft spacer (ST31851000)

q

6Stopper (ST31852000)

q

7Preload gauge (ST3127S000)

I Use a collar which has the specifications shown at left.

2. To simplify the job, make a chart, like the one below, to orga- nize your calculations.

LETTERS HUNDREDTHS OF

A MILLIMETER

H: Head number

D¢ : Figure marked on dummy shaft

S: Figure marked on height gauge

N: Measuring clearance

3. Write the following numbers down in the chart.

H: Head number

SPD633

SPD753

SPD542

ADJUSTMENT (R180A)

PD-21

http://vnx.su/